-

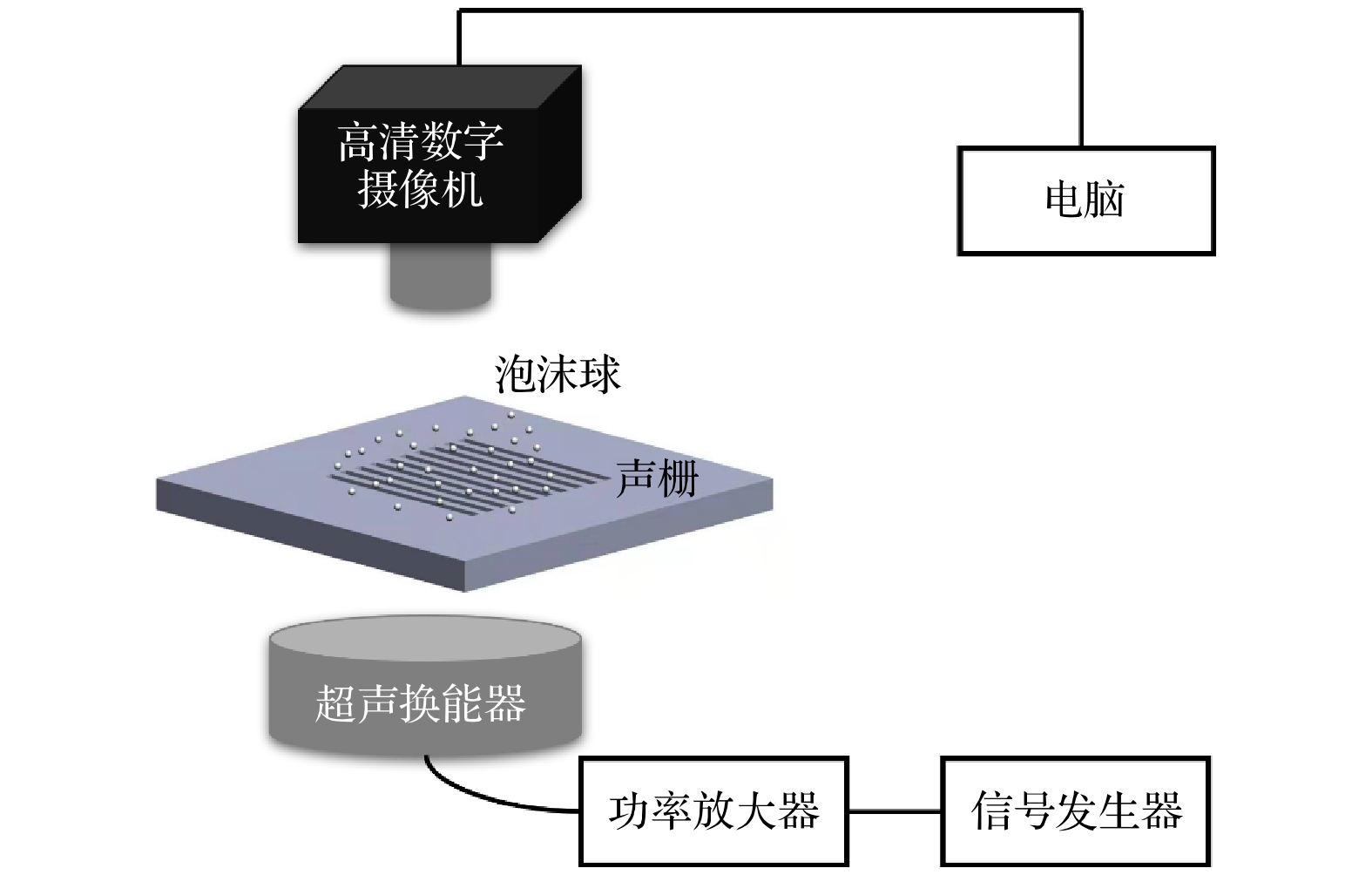

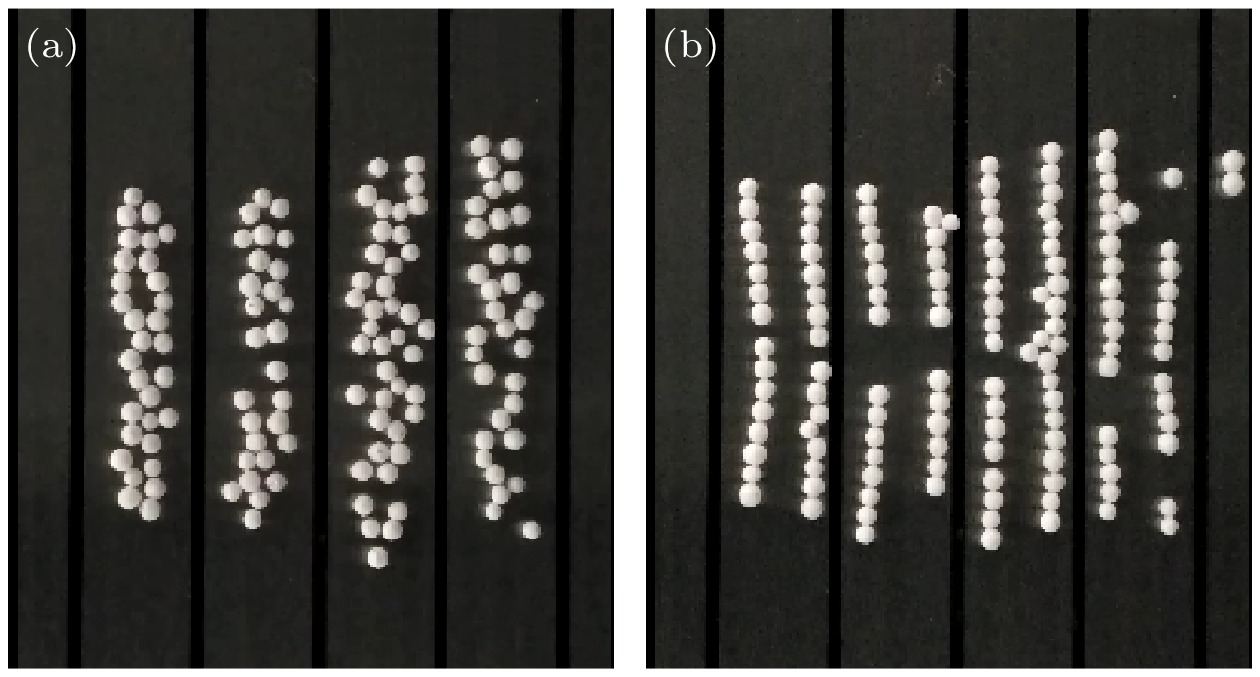

声操控微粒技术可以非接触无损伤地控制声场中的物体运动, 其在精密制造、材料工程、体外诊断等领域具有广阔的应用前景. 传统声操控微粒技术一般采用自由声场, 如利用单个换能器或阵列换能器产生的聚焦声场、行波场或驻波场等. 然而, 一般单个换能器产生的声场仅能操控单个微粒; 而阵列换能器的驱动系统复杂, 导致操控器件成本高昂且难以微型化; 因此, 亟需研究新的声场形态实现多样性微粒操控. 本工作中, 采用单个换能器产生的平面波激发一维声栅的共振声场, 实验实现了大规模泡沫微球的周期排列操控. 其操控机制是由于声栅狭缝中法布里-珀罗谐振声场与声栅表面周期衍射场共振耦合, 在声栅表面形成周期分布的局域梯度声场, 导致微粒在平行于声栅表面受到声捕获力, 在垂直于声栅表面受到指向表面的声吸引力, 实现了微粒周期排列在声栅表面上. 该工作为利用超声在空气中大规模排列微粒提供了理论基础和技术支持.Manipulation of particles by ultrasonic waves is a primary technique in the fields of precision manufacturing, materials engineering, and in vitro diagnosis, since it can control the motion of objects in the sound field in a contactless and noninvasive manner. In general, the free sound field, such as the focused field and the plane wave generated by a single transducer can only manipulate a single particle. While the complex field generated by a transducer array should be actuated by a complex electric control system, which makes the manipulation device expensive and cumbersome. Thus, modulated acoustic field for particle manipulation is still needed. Here, we experimental realize a one-dimensional acoustic grating to tune sound fields for the parallel pattern of multiple particles. The physical mechanism is that due to the resonance coupling between the periodic diffraction wave on the surface of the acoustic grating and the Fabry-Perot resonant sound field in the acoustic grating slit, a periodical gradient sound field on the surface of the acoustic grating is induced. Then, particles in the periodical gradient sound field can be trapped in two stable positions in one period of the grating. These concepts and realizations of particle patterns in the acoustic grating pave the way for implementing the parallel manipulation of particles in acoustic manipulation technologies.

-

Keywords:

- acoustic tweezers /

- acoustic radiation force /

- sound grating /

- particle pattern

[1] Borgnis F E 1953 Rev. Mod. Phys. 25 653

Google Scholar

Google Scholar

[2] Takahi H, Yasutaka H, Akio A, Hideki N, Masahiko K, Naoki I 1993 J. Acoust. Soc. Am. 93 154

Google Scholar

Google Scholar

[3] Tatsuki F, Asier M, Bruce W, Thomas L H 2019 Appl. Phys. Lett. 115 064101

Google Scholar

Google Scholar

[4] Hirayama R, Martinez P D, Masuda N, Subramanian S 2019 Nature 575 320

Google Scholar

Google Scholar

[5] Smalley D E, Nygaard E, Squire K, Van W J, Rasmussen J, Gneiting S, Qaderi K, Goodsell J, Roger W, Lindsey M 2018 Nature 553 486

Google Scholar

Google Scholar

[6] Wiklund M, Radel S, Hawkes J J 2013 Lab Chip 13 25

Google Scholar

Google Scholar

[7] Gao Y, Harder R, Southworth S H, Guest J R, Huang X J, Yan Z J, Ocola L E, Yifat Y, Sule N, Ho P J 2019 Proc. Natl. Acad. Sci. U. S. A. 116 4018

Google Scholar

Google Scholar

[8] Ozcelik A, Rufo J, Guo F, Gu Y Y, Li P, Lata J, Huang T J 2018 Nat. Methods 15 1021

Google Scholar

Google Scholar

[9] Li F, Cai F Y, Zhang L K, Liu Z Y, Li F, Meng L, Wu J R, Li J Y, Zhang X F, Zheng H R 2020 Phys. Rev. A 13 044077

Google Scholar

Google Scholar

[10] Li F, Cai F Y, Liu Z Y, Meng L, Qian M, Wang C, Cheng Q, Qian M L, Liu X, Wu J R, Li J Y, Zheng H R 2014 Phys. Rev. A 1 051001

Google Scholar

Google Scholar

[11] Melde K, Mark A G, Qiu T, Fischer P 2016 Nature 537 518

Google Scholar

Google Scholar

[12] Memoli G, Caleap M, Asakawa M, Sahoo D R, Drinkwater B W, Subramanian S 2017 Nat. Commun. 8 14608

Google Scholar

Google Scholar

[13] 黄先玉, 蔡飞燕, 李文成, 郑海荣, 何兆剑, 邓科, 赵鹤平 2017 66 044301

Google Scholar

Google Scholar

Huang X Y, Cai F Y, Li W C, Zheng H R, He Z J, Deng K, Zhao H P 2017 Acta Phys. Sin. 66 044301

Google Scholar

Google Scholar

[14] 冯若, 姚锦钟, 关立勋 1999 超声手册 (南京: 南京大学出版社) 128

Feng R, Yao J Z, Guan L X 1999 Ultrasonics Handbook (Nanjing: Nanjin University Press) 128 (in Chinese)

[15] Sweden S https://cn.comsol.com/ [2022-9-1]

[16] Lu M H, Liu X K, Feng L, Li J, Huang C P, Chen Y F, ZhuY Y, Zhu S, Ming N 2007 Phys. Rev. Lett. 99 174301

Google Scholar

Google Scholar

[17] Zhu X F, Liang B, Kan W W, Peng Y G, Cheng J C 2016 Phys. Rev. A 5 054015

Google Scholar

Google Scholar

[18] Gor'kov L P 1962 Sov. Phys. Dokl. 6 773

[19] Bruus H 2012 Lab Chip 12 1014

Google Scholar

Google Scholar

[20] Xu D, Cai F Y, Chen M, Li F, Wang C, Meng L, Xu D H, Wang W, Wu J R, Zheng H R 2019 Ultrasonics 93 18

Google Scholar

Google Scholar

[21] He Z J, Jia H, Qiu C Y, Ye Y T, Hao R, Ke M Z, Liu Z Y 2011 Phys. Rev. B 83 132101

Google Scholar

Google Scholar

-

图 1 声栅样品示意图与归一化透射谱, 以及一维声栅归一化声压分布图 (a) 声栅样品示意图; (b) 平面波透过声栅样品的透射谱; (c) 共振频率为39.6 kHz时声场分布图; (d) 非共振频率为38 kHz时声场分布图

Fig. 1. Schematic diagram of the grating sample with normalized transmission spectrum, and normalized sound pressure distribution of the 1D grating: (a) Schematic diagram of the grating sample; (b) transmission spectrum of the plane wave through the grating sample; (c) the pressure field at resonant frequency of 39.6 kHz; (d) the pressure field at off resonant frequency of 38 kHz.

图 2 泡沫球位置变化在X方向上从–1.5d到1.5d, 在Z方向上从0.24d到1.2d, 半径约为

$ r = 0.5\; {\text{mm}} $ 的泡沫球在一维声栅上所受归一化声辐射力空间分布图 (a) 黑色三角形箭头表示声辐射力所指方向, 颜色深浅表示声辐射力的大小, 灰色矩形表示一维声栅; (b) X方向上泡沫球位置变化从–0.5d到0.5d的归一化声辐射力Fx (蓝色实线)与Fz (红色实线)曲线图Fig. 2. Spatial distribution of the normalized acoustic radiation force on a one-dimensional sound grid for a foam sphere with a radius of about r = 0.5 mm varying from –1.5d to 1.5d in the X-direction and from 0.24d to 1.2d in the Z-direction: (a) The black triangle arrow indicates the direction of the acoustic radiation force, the color shade indicates the size of the acoustic radiation force, and the gray rectangle indicates the one-dimensional acoustic grid; (b) plot of normalized acoustic radiation force Fx (blue solid line) versus Fz (red solid line) for the change in position of the foam sphere from –0.5d to 0.5d in the X-direction.

表 1 材料声学参数

Table 1. Material acoustic parameters.

密度/(kg·m–3) 纵波波速/(m·s–1) 横波波速/(m·s–1) 空气 1.29 340 — 泡沫球 100 820 550 钢 7760 6010 3320 -

[1] Borgnis F E 1953 Rev. Mod. Phys. 25 653

Google Scholar

Google Scholar

[2] Takahi H, Yasutaka H, Akio A, Hideki N, Masahiko K, Naoki I 1993 J. Acoust. Soc. Am. 93 154

Google Scholar

Google Scholar

[3] Tatsuki F, Asier M, Bruce W, Thomas L H 2019 Appl. Phys. Lett. 115 064101

Google Scholar

Google Scholar

[4] Hirayama R, Martinez P D, Masuda N, Subramanian S 2019 Nature 575 320

Google Scholar

Google Scholar

[5] Smalley D E, Nygaard E, Squire K, Van W J, Rasmussen J, Gneiting S, Qaderi K, Goodsell J, Roger W, Lindsey M 2018 Nature 553 486

Google Scholar

Google Scholar

[6] Wiklund M, Radel S, Hawkes J J 2013 Lab Chip 13 25

Google Scholar

Google Scholar

[7] Gao Y, Harder R, Southworth S H, Guest J R, Huang X J, Yan Z J, Ocola L E, Yifat Y, Sule N, Ho P J 2019 Proc. Natl. Acad. Sci. U. S. A. 116 4018

Google Scholar

Google Scholar

[8] Ozcelik A, Rufo J, Guo F, Gu Y Y, Li P, Lata J, Huang T J 2018 Nat. Methods 15 1021

Google Scholar

Google Scholar

[9] Li F, Cai F Y, Zhang L K, Liu Z Y, Li F, Meng L, Wu J R, Li J Y, Zhang X F, Zheng H R 2020 Phys. Rev. A 13 044077

Google Scholar

Google Scholar

[10] Li F, Cai F Y, Liu Z Y, Meng L, Qian M, Wang C, Cheng Q, Qian M L, Liu X, Wu J R, Li J Y, Zheng H R 2014 Phys. Rev. A 1 051001

Google Scholar

Google Scholar

[11] Melde K, Mark A G, Qiu T, Fischer P 2016 Nature 537 518

Google Scholar

Google Scholar

[12] Memoli G, Caleap M, Asakawa M, Sahoo D R, Drinkwater B W, Subramanian S 2017 Nat. Commun. 8 14608

Google Scholar

Google Scholar

[13] 黄先玉, 蔡飞燕, 李文成, 郑海荣, 何兆剑, 邓科, 赵鹤平 2017 66 044301

Google Scholar

Google Scholar

Huang X Y, Cai F Y, Li W C, Zheng H R, He Z J, Deng K, Zhao H P 2017 Acta Phys. Sin. 66 044301

Google Scholar

Google Scholar

[14] 冯若, 姚锦钟, 关立勋 1999 超声手册 (南京: 南京大学出版社) 128

Feng R, Yao J Z, Guan L X 1999 Ultrasonics Handbook (Nanjing: Nanjin University Press) 128 (in Chinese)

[15] Sweden S https://cn.comsol.com/ [2022-9-1]

[16] Lu M H, Liu X K, Feng L, Li J, Huang C P, Chen Y F, ZhuY Y, Zhu S, Ming N 2007 Phys. Rev. Lett. 99 174301

Google Scholar

Google Scholar

[17] Zhu X F, Liang B, Kan W W, Peng Y G, Cheng J C 2016 Phys. Rev. A 5 054015

Google Scholar

Google Scholar

[18] Gor'kov L P 1962 Sov. Phys. Dokl. 6 773

[19] Bruus H 2012 Lab Chip 12 1014

Google Scholar

Google Scholar

[20] Xu D, Cai F Y, Chen M, Li F, Wang C, Meng L, Xu D H, Wang W, Wu J R, Zheng H R 2019 Ultrasonics 93 18

Google Scholar

Google Scholar

[21] He Z J, Jia H, Qiu C Y, Ye Y T, Hao R, Ke M Z, Liu Z Y 2011 Phys. Rev. B 83 132101

Google Scholar

Google Scholar

计量

- 文章访问数: 4666

- PDF下载量: 99

- 被引次数: 0

下载:

下载: