-

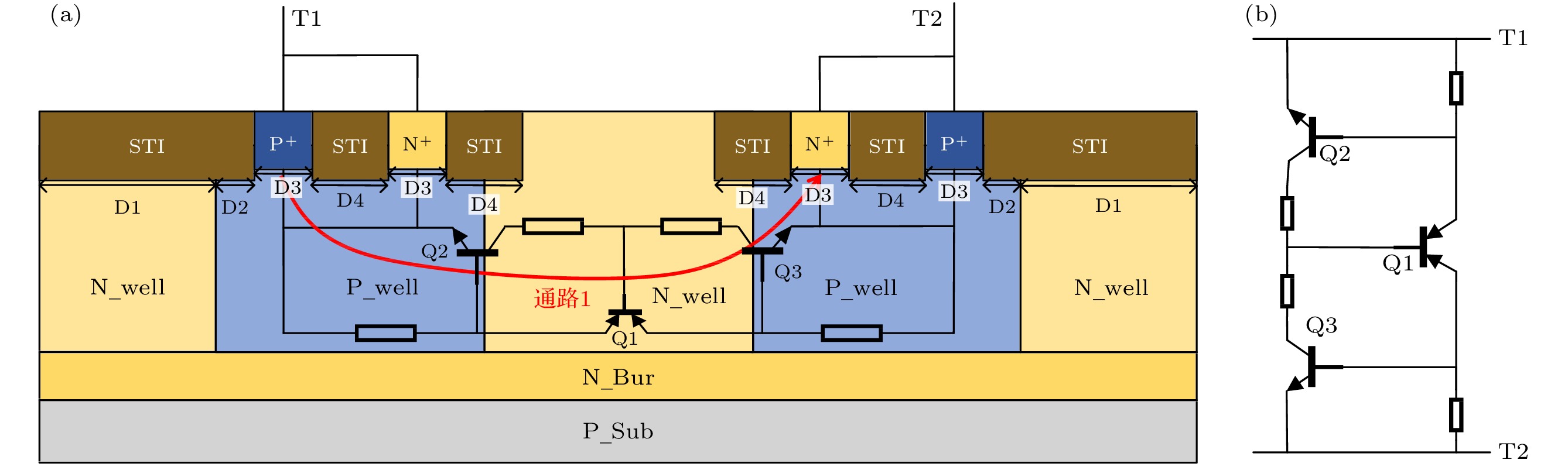

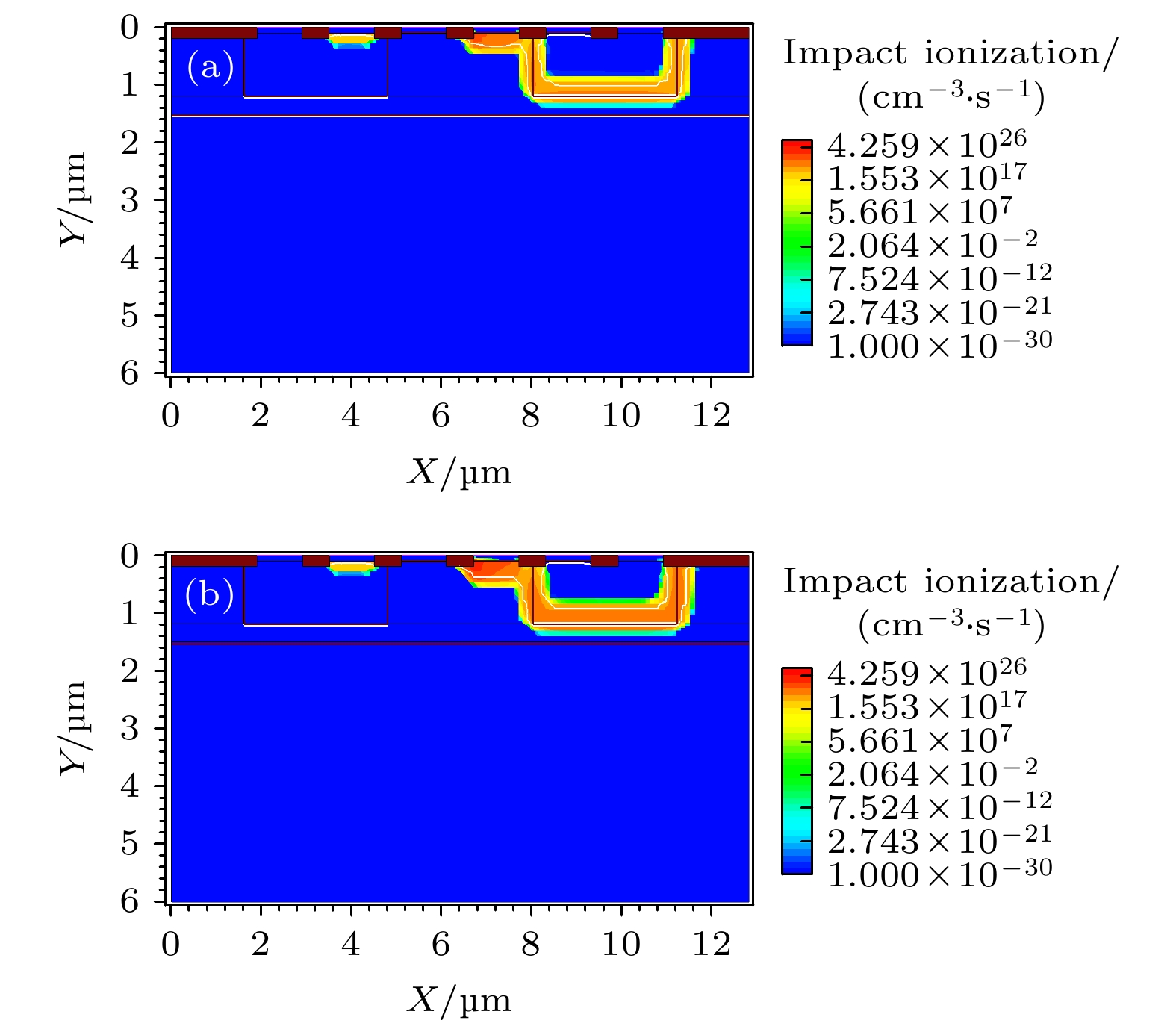

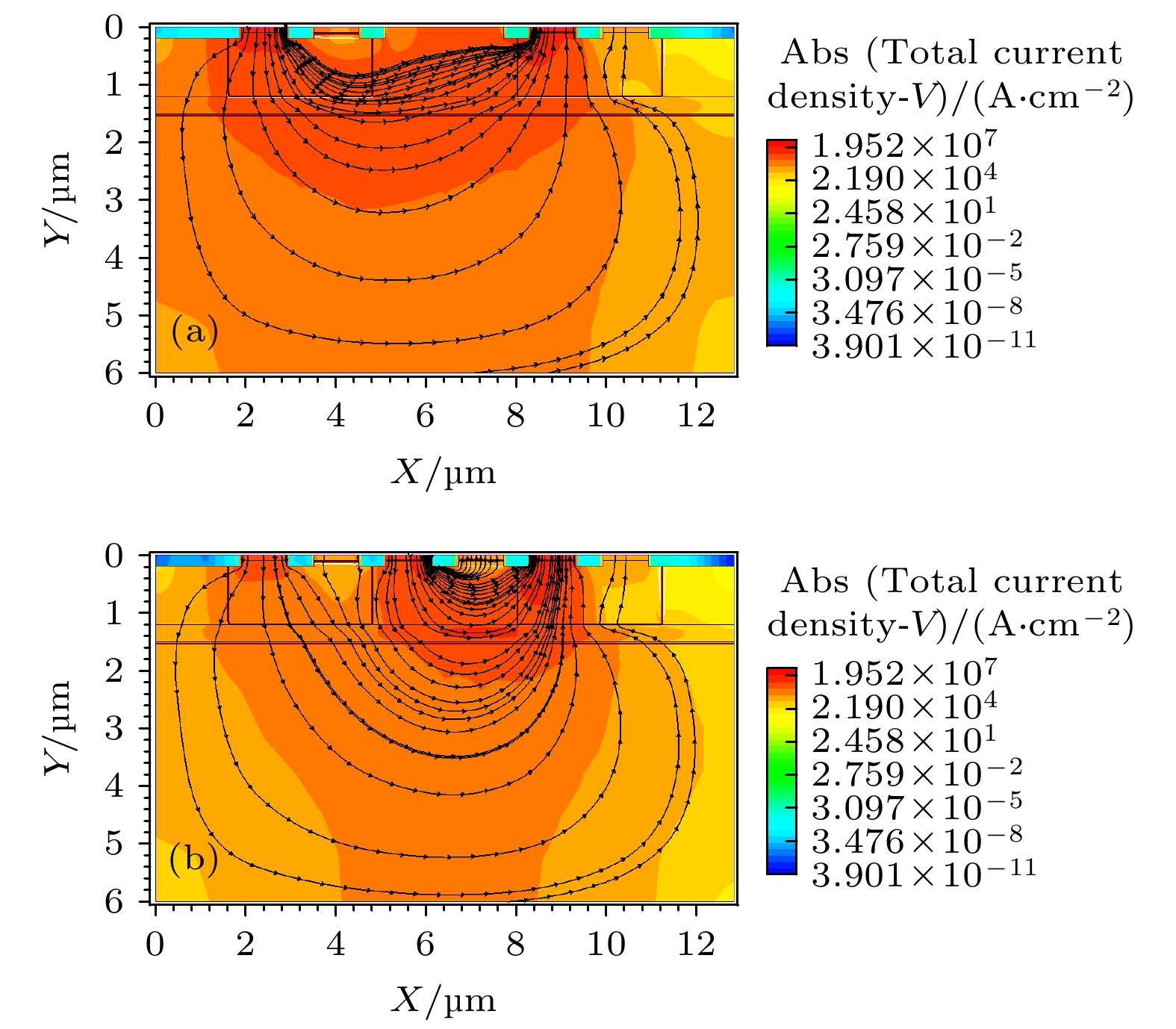

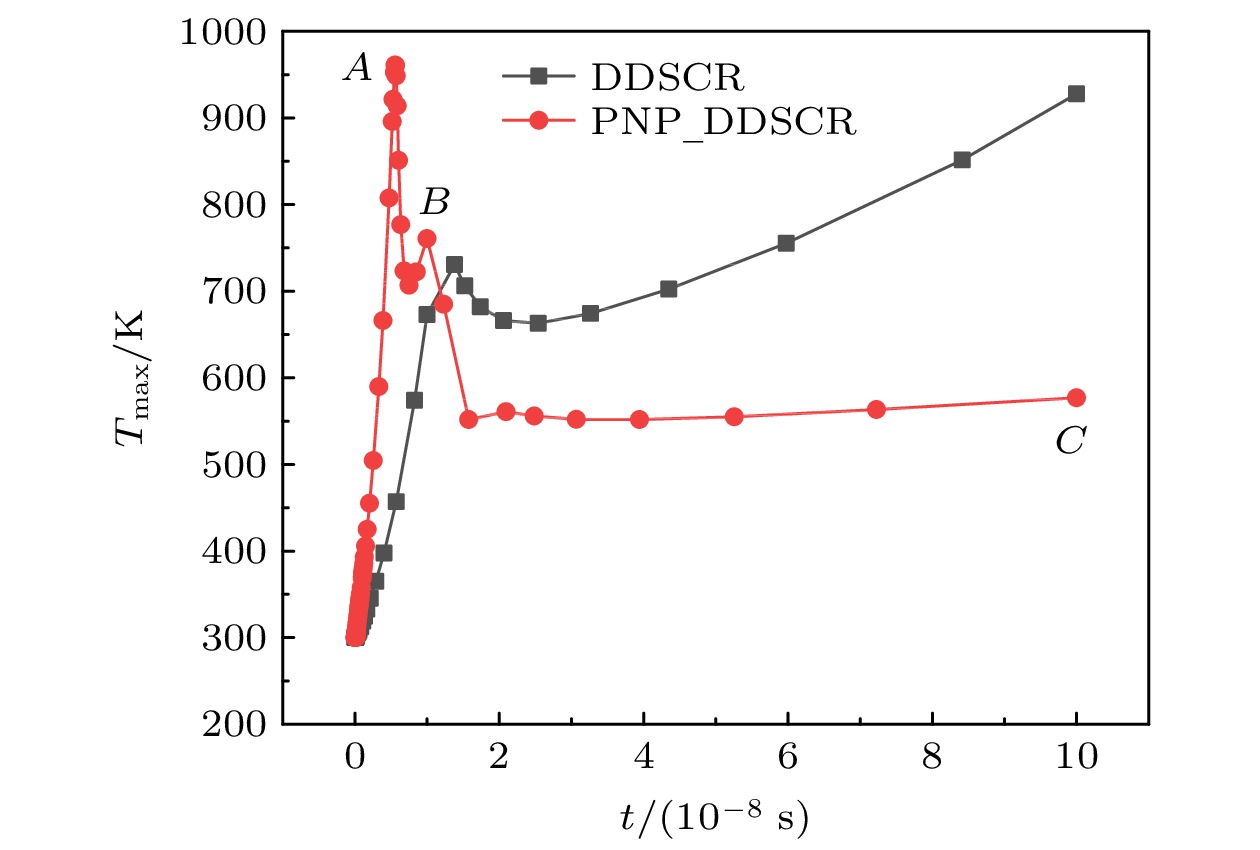

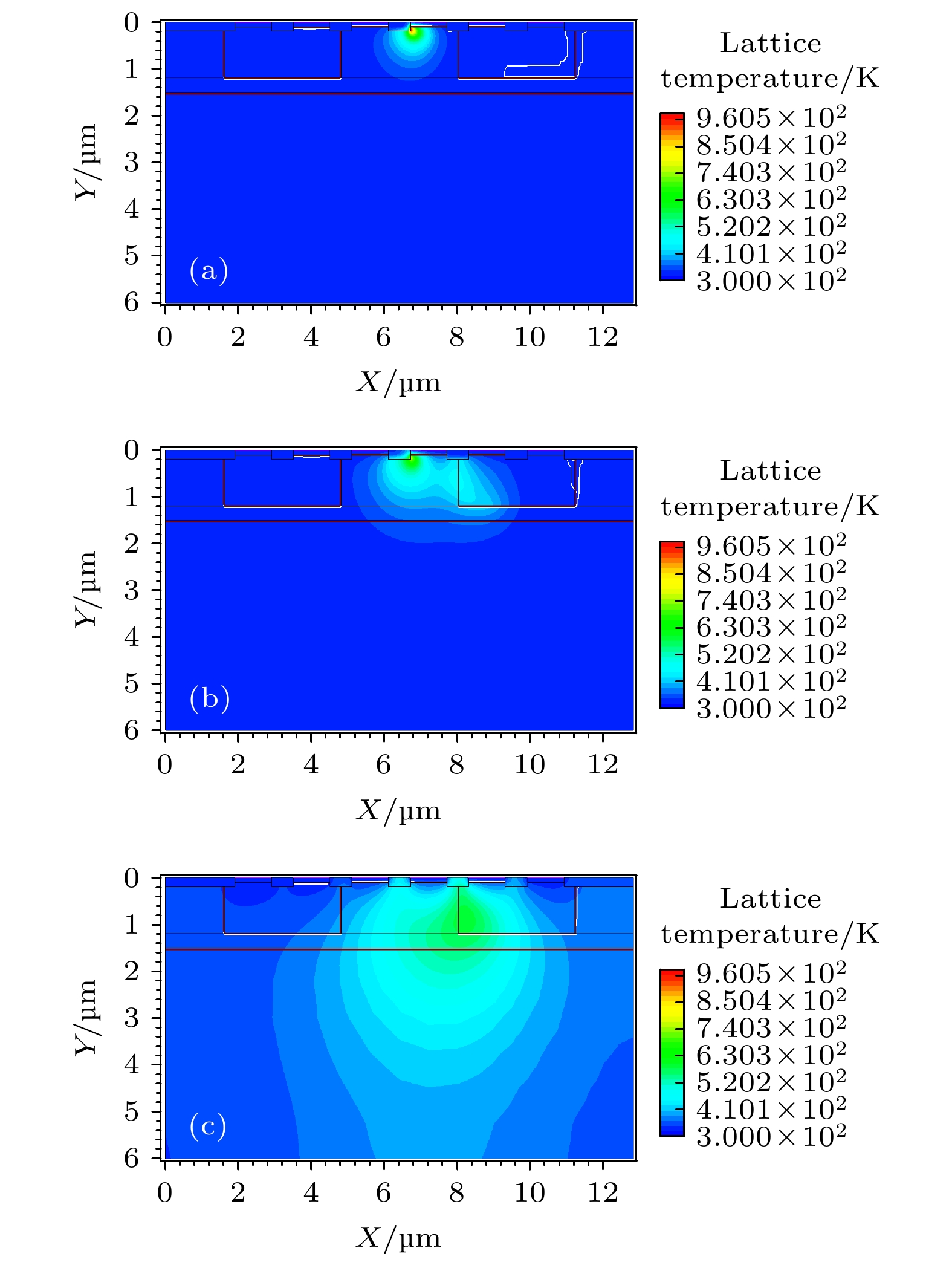

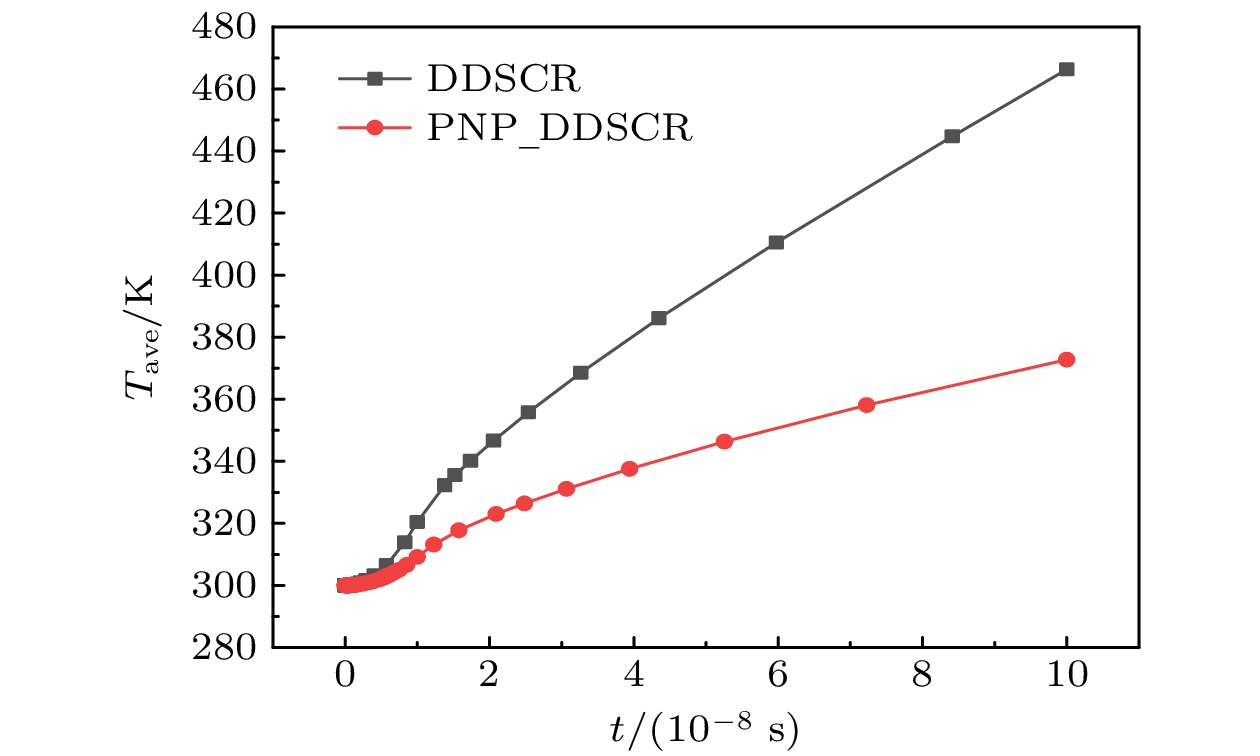

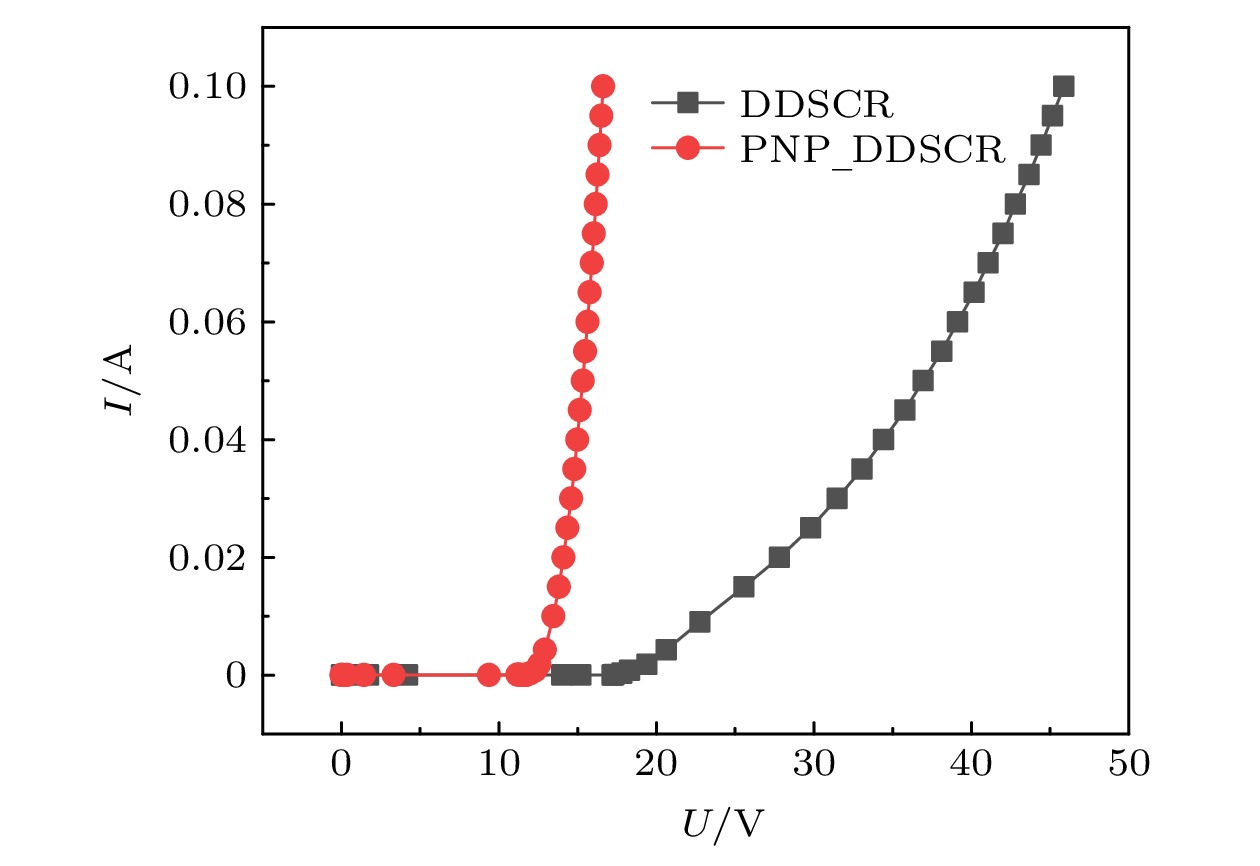

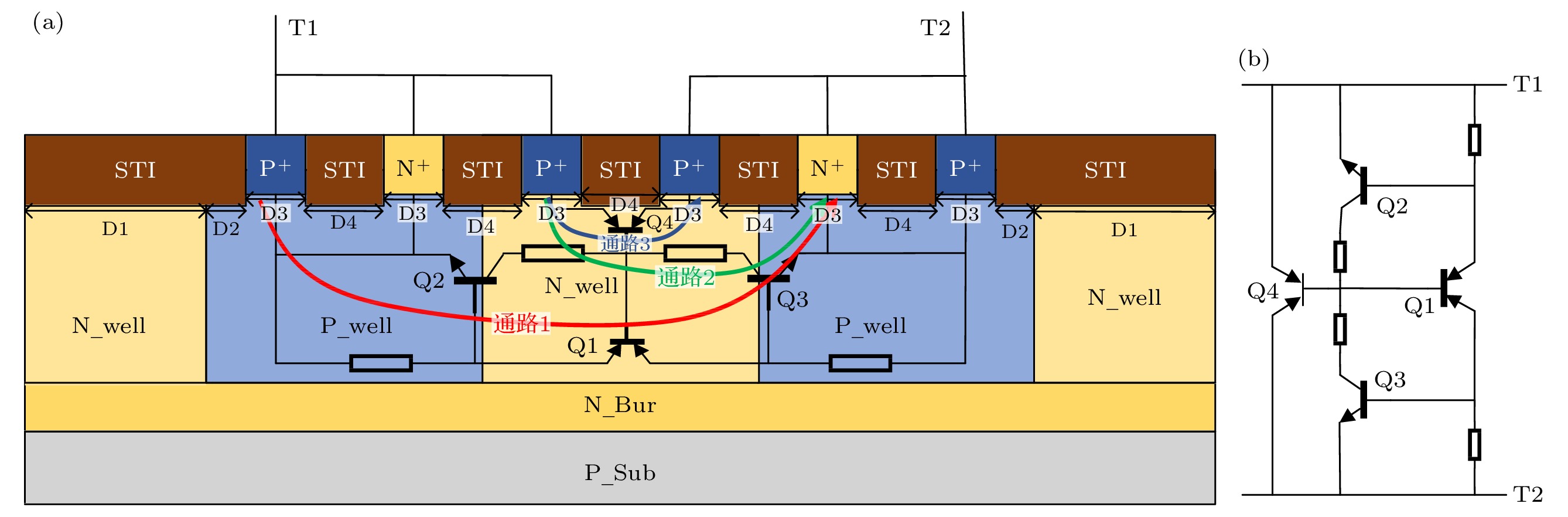

提出一种内嵌横向PNP晶体管的静电放电(ESD)双向防护器件(PNP_DDSCR). 对新结构器件在不同ESD应力模式下的响应过程以及电流输运机制进行研究, 内嵌横向PNP晶体管的引入, 提高了DDSCR系统内部寄生晶体管的注入效率, 促进正反馈系统建立, 同时引入两条新的电流泄放通路, 抑制电导调制效应, 提高了电流泄放能力. 结果表明, 与传统的DDSCR器件相比, PNP_DDSCR器件在传输线脉冲(TLP)测试仿真中触发电压下降了31%, 维持电压提高了16.8%, ESD设计窗口优化44.5%, 具有更低的导通电阻. 快速传输线脉冲(VF-TLP)测试仿真结果表明, 新结构器件对瞬态过冲电压有更好的钳位能力, 同时保持了较大的开启速度, 在VF-TLP应力0.1 A时, PNP_DDSCR器件的过冲电压仅为DDSCR器件的37%.With the shrinking of semiconductor technology and the increasing of integrated circuits, electrostatic discharge (ESD) as a common natural phenomenon has become one of the main reasons for the failure and reliability reduction of electronic products in integrated circuits. A novel dual-direction ESD device (PNP_DDSCR) with embedded lateral PNP transistor is proposed for diminishing ESD damage. The response process and current transportation of PNP_DDSCR under different ESD stress modes are investigated. Comparative analyses between conventional DDSCR and PNP_DDSCR are executed by TCAD simulation. On the stage of device triggering, the embedded lateral PNP transistor inner DDSCR system provides triggering current for device. The injection efficiency of parasitic transistor in the DDSCR system is improved, and the positive feedback system is promoted. Thus, the holding voltage of PNP_DDSCR is higher than that of conventional DDSCR. At the same time, an extra triggering path introduced by embedded lateral PNP transistor of PNP_DDSCR makes the total triggering path of device shorten. Therefore, the transient overshoot voltage of PNP_DDSCR is lower than that of DDSCR. For thermal performance, most of the heat first accumulates near the lateral PNP transistor , and then the peak point of heat turns to main SCR path with the conduction of PNP_DDSCR. The heat accumulation in PNP_DDSCR is shared by the path of embedded lateral PNP transistor. As a result, the average temperature in PNP_DDSCR is lower than that in DDSCR and the ability of PNP_DDSCR to dissipate heat is more perfect. Comparing with DDSCR, the conclusions are obtained. Under the condition of transmission line pulse (TLP) test simulation analyses, the triggering voltage is reduced by 31%, the holding voltage is increased by 16.8%, the ESD design window is optimized by 44.5%, and on-resistance is lower. When TLP stress is 2.67 A, the average temperature of PNP_DDSCR is much lower than that of traditional DDSCR in the whole conduction process. With the increase of pulse lasting time, average temperature difference between two devices becomes great further. According to the very fast TLP (VF-TLP) testing results, clamping capability of PNP_DDSCR under transient overshoot voltage is more stable under the condition of fast turn-on speed. When the VF-TLP stress is 0.1 A, the overshoot voltage of PNP_DDSCR device is the 37% of that of DDSCR device while the PNP_DDSCR maintains a relatively fast triggering speed. Thus, the ESD protection capability of PNP_DDSCR is superior.

-

Keywords:

- electrostatic protection /

- trigger voltage /

- holding voltage

[1] Zhou Z J, Jin X L 2017 IEEE Electrical Design of Advanced Packaging and Systems Symposium (EDAPS) Hangzhou, China, December 14–16, 2017 p1

[2] Do K I, Lee B S, Chae H G, Seo J J, Koo Y S 2018 2nd European Conference on Electrical Engineering and Computer Science (EECS) Bern, Switzerland, December 20–22, 2018 p524

[3] Zhou Z J, Jin X L, Wang Y, Dong P 2019 IEEE 13th International Conference on ASIC (ASICON) Chongqing, China, October 29th-November 1st, 2019 p1

[4] Du F B, Liu Z W, Liu J Z, Wang J, Liou J J 2019 IEEE Trans. Device Mater. Rel. 19 169

Google Scholar

Google Scholar

[5] Da W L, Gijs d R, Wei J T, Theo S, Albert J H 2018 IEEE Electron Device Lett. 39 331

Google Scholar

Google Scholar

[6] Do K I, Lee B S, Koo Y S 2019 IEEE J. Electron Devi. 7 601

Google Scholar

Google Scholar

[7] Do K I, Song B B, Koo Y S 2020 IEEE Trans. Electron Devi. 67 5020

Google Scholar

Google Scholar

[8] Zhu L, Liang H L, Gu X F, Xu J 2020 Chin. Phys. B 29 652

Google Scholar

Google Scholar

[9] Qi Z, Qiao M, He Y T, Zhang B 2017 Chin. Phys. B 26 350

Google Scholar

Google Scholar

[10] Huang C Y, Chen Q K, Chi J F, Huang T H 2021 IEEE Trans. Device Mater. Rel. 21 64

Google Scholar

Google Scholar

[11] Du F B, Hou F, Song W Q, Chen L, Nie Y L, Qing Y H, Xu Y C, Liu J Z, Liu Z W, Liou J J 2020 IEEE Trans. Electron Devi. 67 576

Google Scholar

Google Scholar

[12] Du F B, Chang K C, Lin X N, Hou F, Zhang Y X, Han A R, Luo X, Liu Z W 2022 IEEE Trans. Electron Devi. 69 3490

Google Scholar

Google Scholar

[13] Do K I, Koo Y S 2020 IEEE J. Electron Devi. 8 635

Google Scholar

Google Scholar

[14] Wu M, Chen Z J 2021 9th International Symposium on Next Generation Electronics (ISNE) Changsha, China, July 9–11, 2021 p1

[15] Zeng J, Dong S R, Liou J J, Han Y, Zhong L, Wang W H 2015 IEEE Trans. Electron Devi. 62 606

Google Scholar

Google Scholar

[16] Du F B, Jiang G J, Huang M C, Zou K P, Hou F, Song W Q, Liu J Z, Xiong X L, Hou L L, Liu Z W, Liou J J 2021 IEEE Trans. Electron Devi. 68 6338

Google Scholar

Google Scholar

[17] Liu J Z, Liu Y L, Han A R, Nie Y L, Huang Q P, Liu Z W 2022 IEEE Trans. Electron Devi. 69 2534

Google Scholar

Google Scholar

[18] Zhou Z J, Jin X L, Wang Y, Dong P 2021 Chin. Phys. B 30 610

Google Scholar

Google Scholar

[19] Wang Y, Jin X L, Peng Y, Luo J, Yang J, Zheng Z W, Jiang L Y, Zhong Z Y 2021 IEEE J. Emerg. Sel. Topics Power Electron. 9 994

Google Scholar

Google Scholar

[20] De R, Gijs 2018 IEEE J. Electron Devices Soc. 6 1097

Google Scholar

Google Scholar

[21] 施敏, 伍国珏 著 (耿莉, 张瑞智 译) 2008 半导体器件物理 (第3版) (西安: 西安交通大学出版社) 第187—201, 415—434页

Simon M, Kork K(translated by Geng L, Zhang R Z) 2008 Physics of Semiconductor Devices (3rd Ed.) (Xi’an: Xi’an Jiaotong University Press) pp187–201, 415–434(in Chinese)

[22] 约瑟夫 L, 海因里希 S, 乌维 S, 里克 D D著 (卞抗, 杨莹, 刘静, 蒋荣舟 译) 2019 功率半导体器件-原理、特性和可靠性 (第2版) (北京: 机械工业出版社) 第248—254页

Josef L, Heinrich S, Uwe S, Rik D D (translated by Bian K, Yang Y, Liu J, Jiang R Z) 2019 Semiconductor Power Devices: Physics, Characteristics, Reliability (2nd Ed.) (Beijing: China Machine Press) pp248–254 (in Chinese)

[23] Chen Q, Ma R, Zhang W, Lu F, Wang C K, Liang O, Zhang F L, Li C, Tang H, Xie Y H, Wang A 2016 IEEE Trans. Electron Devi. 63 3205

Google Scholar

Google Scholar

-

图 15 0.1 A VF-TLP脉冲强度不同时刻电势分布图 (a) 1×10–10 s时刻DDSCR电势分布图; (b) 1×10–10 s时刻PNP_DDSCR电势分布图; (c) 8×10–9 s时刻DDSCR电势分布图; (d) 8×10–9 s时刻PNP_DDSCR电势分布图

Fig. 15. Potential distribution diagram of 0.1 A VF-TLP pulse intensity at different times: (a) DDSCR potential distribution diagram at 1×10–10 s; (b) potential distribution diagram of PNP_DDSCR at 1×10–10 s; (c) DDSCR potential distribution diagram at 8×10–9 s; (d) potential distribution diagram of PNP_DDSCR at 8×10–9 s.

表 1 PNP_DDSCR的关键尺寸表

Table 1. Critical dimensions of PNP_ DDSCR.

名称 尺寸/μm DDSCR PNP_DDSCR D1 1.6 1.6 D2 0.3 0.3 D3 1.0 1.0 D4 0.6 0.6 表 2 掺杂浓度参数表

Table 2. Doping profile.

区域(Layer) 掺杂类型 掺杂浓度/cm–3 P_Sub Boron 1×1016 N_Bur Phosphorus 1×1019 P_Well Boron 1×1017 N_Well Phosphorus 1×1017 N+ Phosphorus 1×1020 P+ Boron 1×1020 -

[1] Zhou Z J, Jin X L 2017 IEEE Electrical Design of Advanced Packaging and Systems Symposium (EDAPS) Hangzhou, China, December 14–16, 2017 p1

[2] Do K I, Lee B S, Chae H G, Seo J J, Koo Y S 2018 2nd European Conference on Electrical Engineering and Computer Science (EECS) Bern, Switzerland, December 20–22, 2018 p524

[3] Zhou Z J, Jin X L, Wang Y, Dong P 2019 IEEE 13th International Conference on ASIC (ASICON) Chongqing, China, October 29th-November 1st, 2019 p1

[4] Du F B, Liu Z W, Liu J Z, Wang J, Liou J J 2019 IEEE Trans. Device Mater. Rel. 19 169

Google Scholar

Google Scholar

[5] Da W L, Gijs d R, Wei J T, Theo S, Albert J H 2018 IEEE Electron Device Lett. 39 331

Google Scholar

Google Scholar

[6] Do K I, Lee B S, Koo Y S 2019 IEEE J. Electron Devi. 7 601

Google Scholar

Google Scholar

[7] Do K I, Song B B, Koo Y S 2020 IEEE Trans. Electron Devi. 67 5020

Google Scholar

Google Scholar

[8] Zhu L, Liang H L, Gu X F, Xu J 2020 Chin. Phys. B 29 652

Google Scholar

Google Scholar

[9] Qi Z, Qiao M, He Y T, Zhang B 2017 Chin. Phys. B 26 350

Google Scholar

Google Scholar

[10] Huang C Y, Chen Q K, Chi J F, Huang T H 2021 IEEE Trans. Device Mater. Rel. 21 64

Google Scholar

Google Scholar

[11] Du F B, Hou F, Song W Q, Chen L, Nie Y L, Qing Y H, Xu Y C, Liu J Z, Liu Z W, Liou J J 2020 IEEE Trans. Electron Devi. 67 576

Google Scholar

Google Scholar

[12] Du F B, Chang K C, Lin X N, Hou F, Zhang Y X, Han A R, Luo X, Liu Z W 2022 IEEE Trans. Electron Devi. 69 3490

Google Scholar

Google Scholar

[13] Do K I, Koo Y S 2020 IEEE J. Electron Devi. 8 635

Google Scholar

Google Scholar

[14] Wu M, Chen Z J 2021 9th International Symposium on Next Generation Electronics (ISNE) Changsha, China, July 9–11, 2021 p1

[15] Zeng J, Dong S R, Liou J J, Han Y, Zhong L, Wang W H 2015 IEEE Trans. Electron Devi. 62 606

Google Scholar

Google Scholar

[16] Du F B, Jiang G J, Huang M C, Zou K P, Hou F, Song W Q, Liu J Z, Xiong X L, Hou L L, Liu Z W, Liou J J 2021 IEEE Trans. Electron Devi. 68 6338

Google Scholar

Google Scholar

[17] Liu J Z, Liu Y L, Han A R, Nie Y L, Huang Q P, Liu Z W 2022 IEEE Trans. Electron Devi. 69 2534

Google Scholar

Google Scholar

[18] Zhou Z J, Jin X L, Wang Y, Dong P 2021 Chin. Phys. B 30 610

Google Scholar

Google Scholar

[19] Wang Y, Jin X L, Peng Y, Luo J, Yang J, Zheng Z W, Jiang L Y, Zhong Z Y 2021 IEEE J. Emerg. Sel. Topics Power Electron. 9 994

Google Scholar

Google Scholar

[20] De R, Gijs 2018 IEEE J. Electron Devices Soc. 6 1097

Google Scholar

Google Scholar

[21] 施敏, 伍国珏 著 (耿莉, 张瑞智 译) 2008 半导体器件物理 (第3版) (西安: 西安交通大学出版社) 第187—201, 415—434页

Simon M, Kork K(translated by Geng L, Zhang R Z) 2008 Physics of Semiconductor Devices (3rd Ed.) (Xi’an: Xi’an Jiaotong University Press) pp187–201, 415–434(in Chinese)

[22] 约瑟夫 L, 海因里希 S, 乌维 S, 里克 D D著 (卞抗, 杨莹, 刘静, 蒋荣舟 译) 2019 功率半导体器件-原理、特性和可靠性 (第2版) (北京: 机械工业出版社) 第248—254页

Josef L, Heinrich S, Uwe S, Rik D D (translated by Bian K, Yang Y, Liu J, Jiang R Z) 2019 Semiconductor Power Devices: Physics, Characteristics, Reliability (2nd Ed.) (Beijing: China Machine Press) pp248–254 (in Chinese)

[23] Chen Q, Ma R, Zhang W, Lu F, Wang C K, Liang O, Zhang F L, Li C, Tang H, Xie Y H, Wang A 2016 IEEE Trans. Electron Devi. 63 3205

Google Scholar

Google Scholar

计量

- 文章访问数: 6089

- PDF下载量: 92

- 被引次数: 0

下载:

下载: