-

静电放电 (electro-static discharge, ESD) 防护结构的维持电压是决定器件抗闩锁性能的关键参数, 但ESD器件参数的热致变化使得防护器件在高温环境中有闩锁风险. 本文研究了ESD防护结构N沟道金属-氧化物-半导体(N-channel metal oxide semiconductor, NMOS)在30—195 ℃的工作温度下的维持特性. 研究基于0.18 μm部分耗尽绝缘体上硅工艺下制备的NMOS器件展开. 在不同的工作温度下, 使用传输线脉冲测试系统测试器件的ESD特性. 实验结果表明, 随着温度的升高, 器件的维持电压降低. 通过半导体工艺及器件模拟工具进行二维建模及仿真, 提取并分析不同温度下器件的电势、电流密度、静电场、载流子注入浓度等物理参数的分布差异. 通过研究以上影响维持电压的关键参数随温度的变化规律, 对维持电压温度特性的内在作用机制进行了详细讨论, 并提出了改善维持电压温度特性的方法.

-

关键词:

- 静电放电 /

- 金属-氧化物-半导体场效应晶体管 /

- 维持电压 /

- 高温

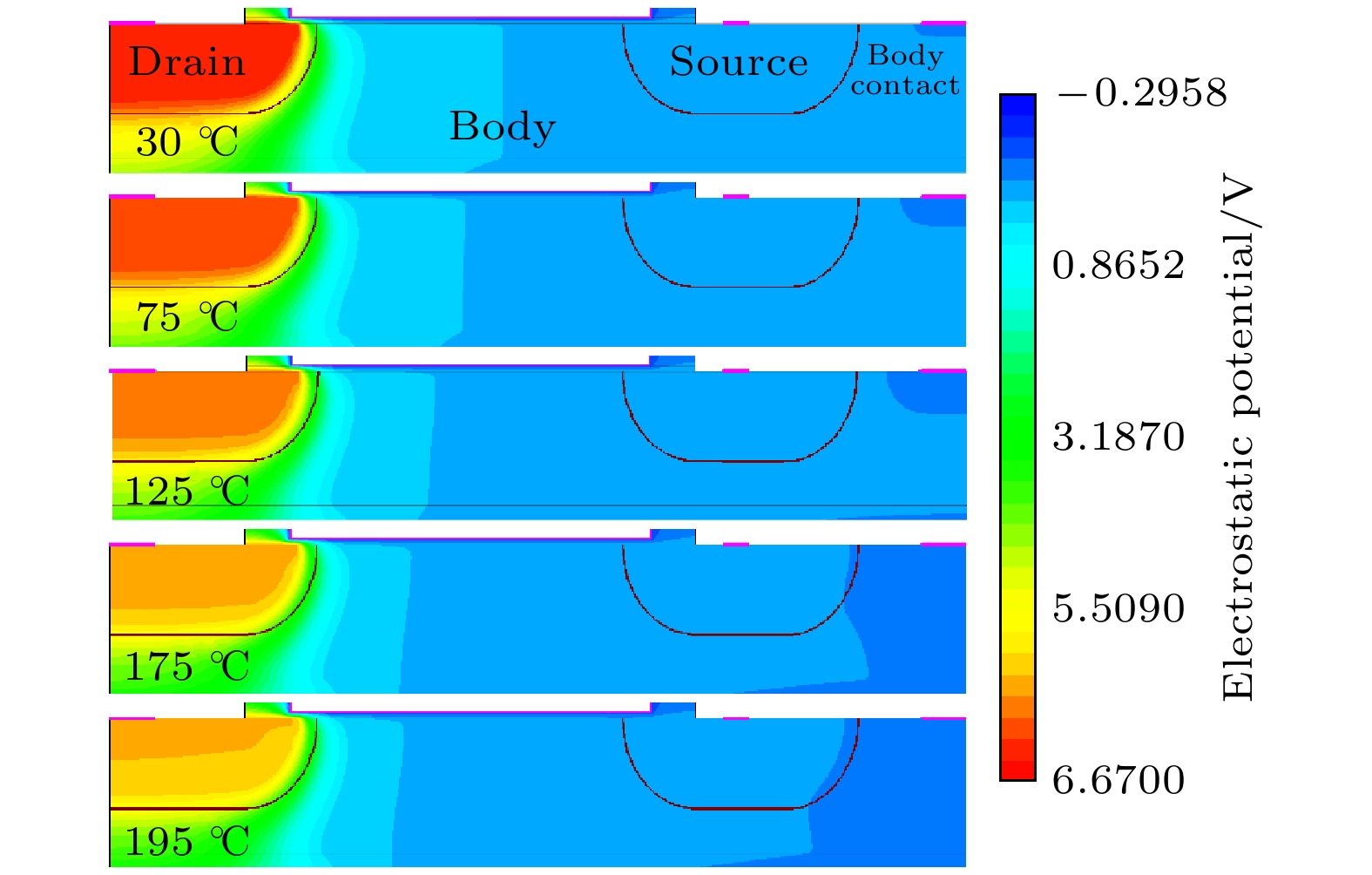

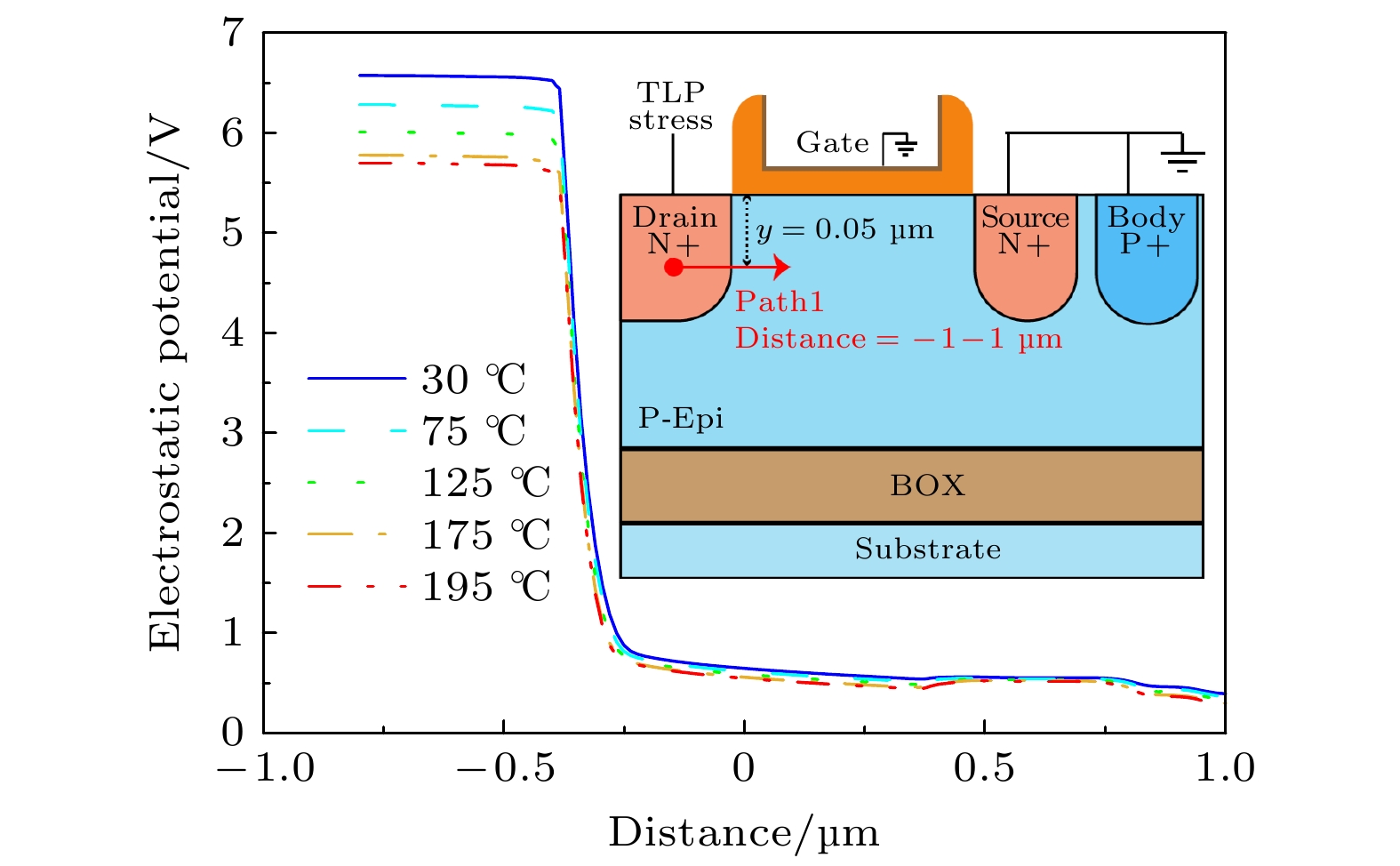

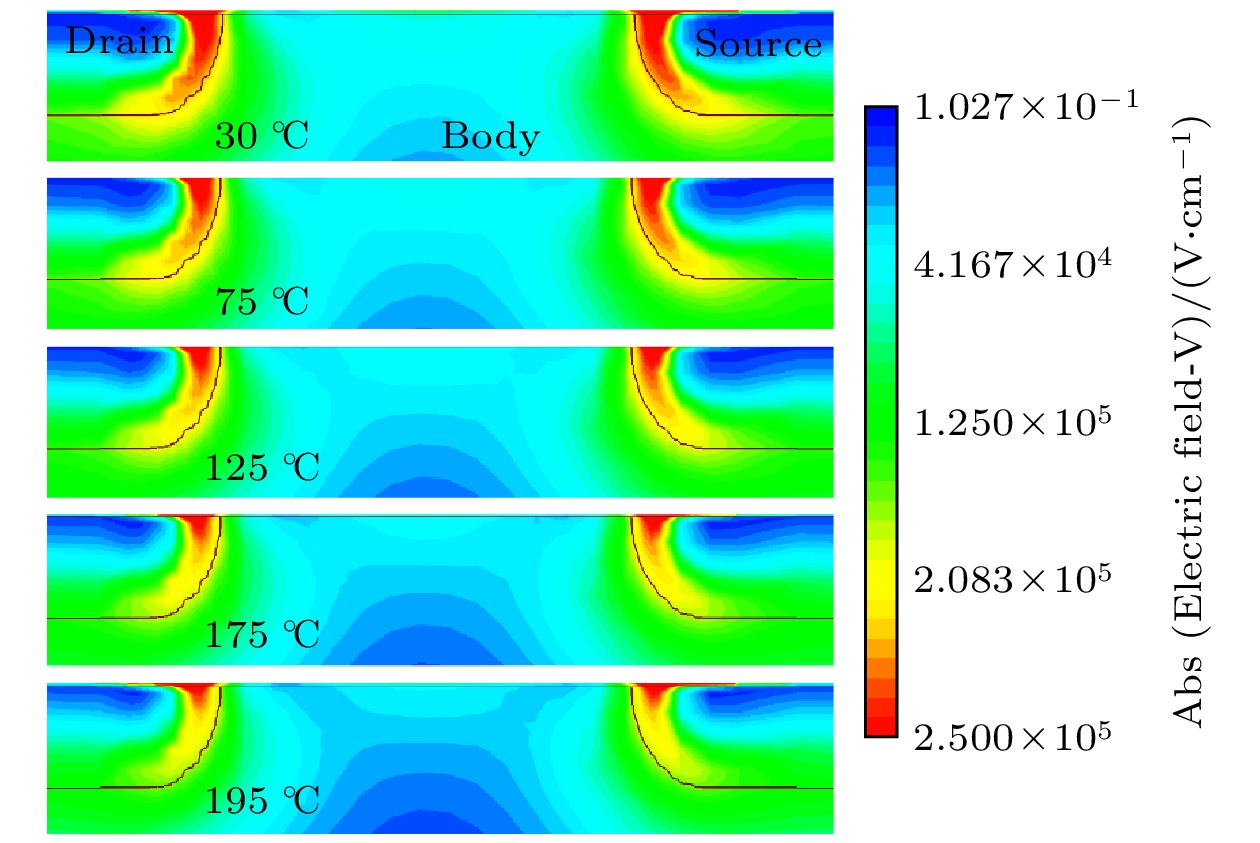

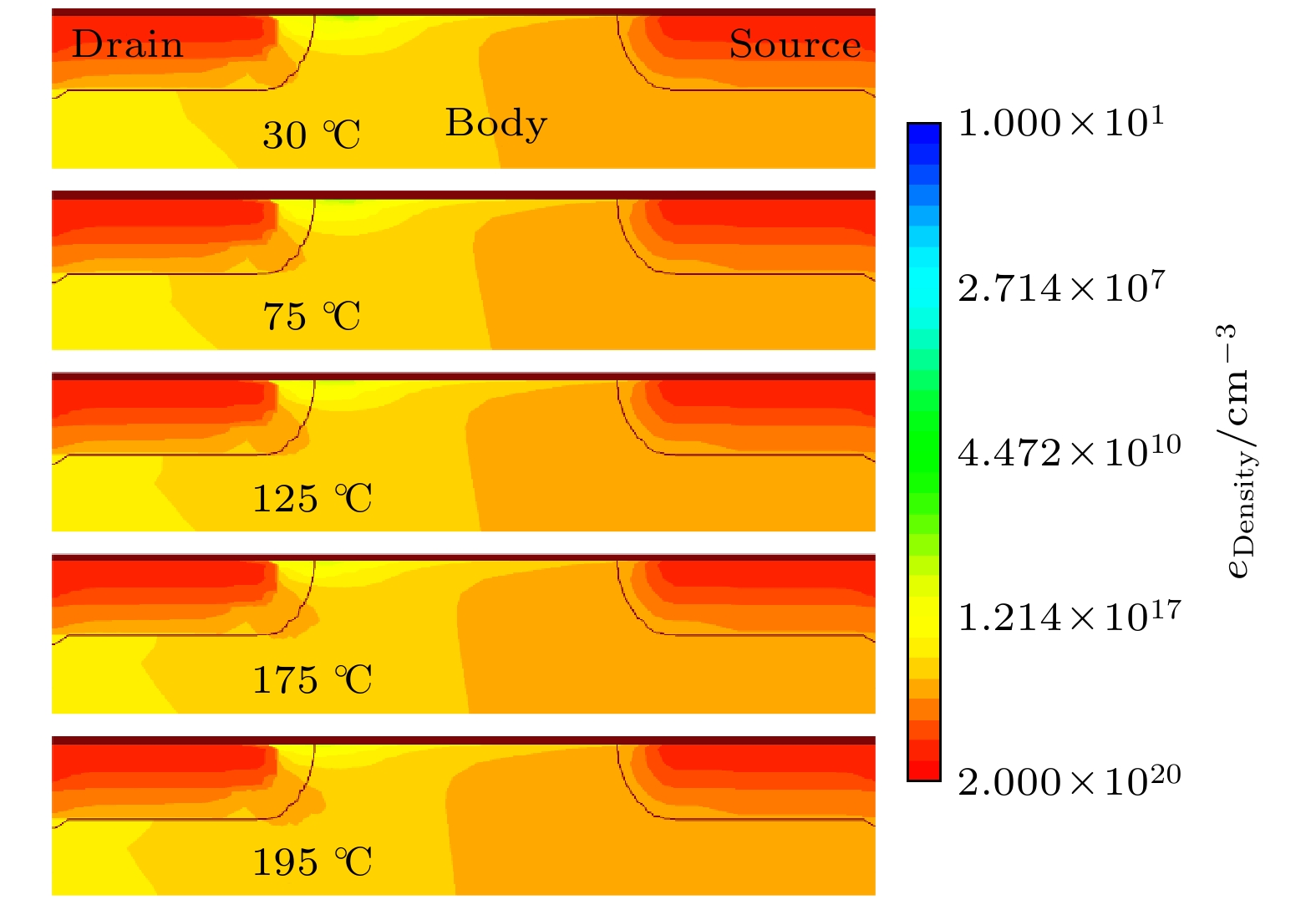

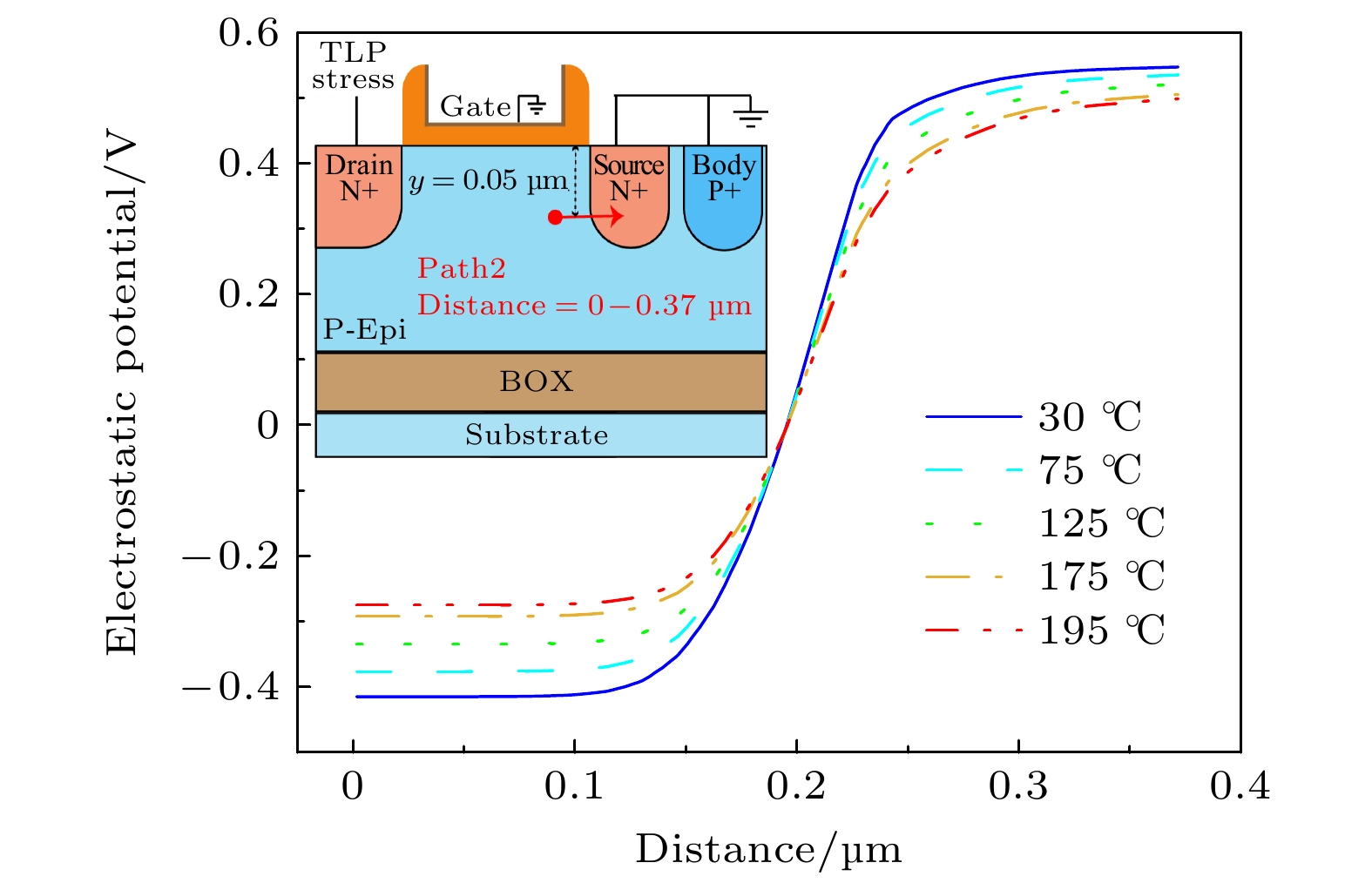

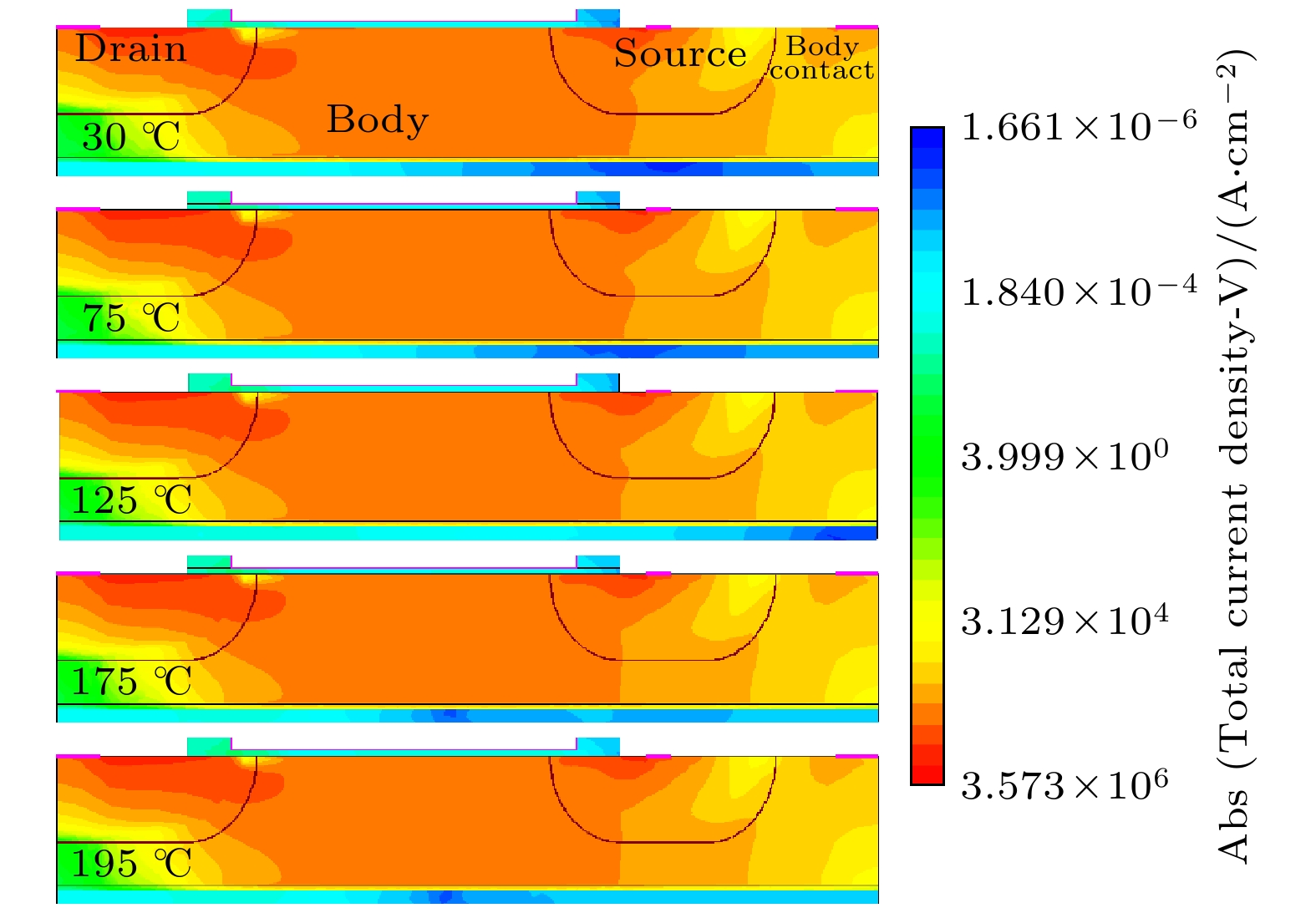

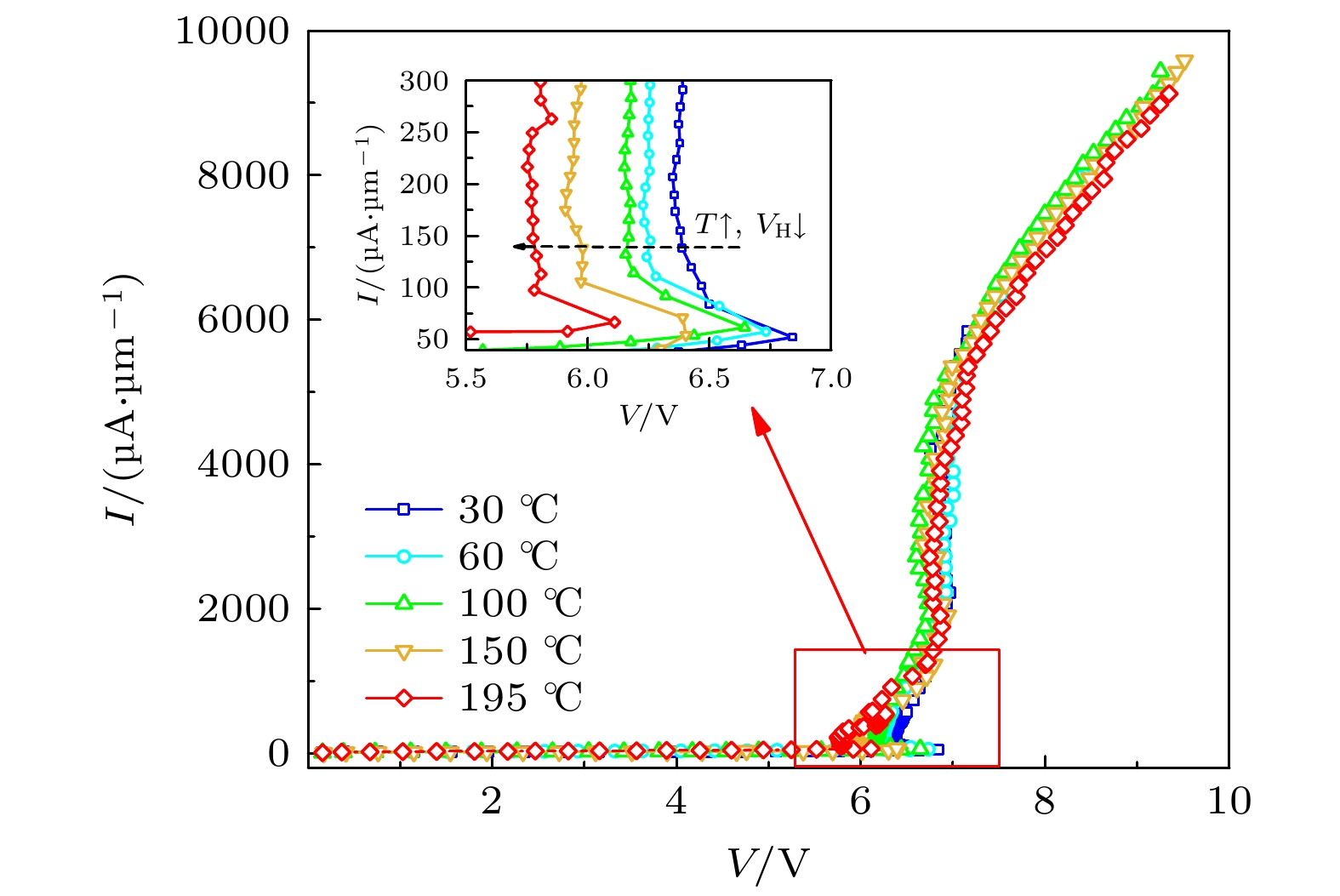

The holding voltage of electrostatic discharge (ESD) protecting structure is the critical parameter to determine the latch-up performance of the protecting device, but the thermal change of ESD device parameters lead the protecting device to suffer latch-up risk at high ambient temperature. In this paper, the holding characteristics of the ESD protecting device at various ambient temperatures ranging from 30 ℃ to 195 ℃ are studied. The investigated ESD structure is the N-channel metal oxide semiconductor (NMOS) transistors fabricated with the 0.18 μm partially depleted silicon-on-insulator process. The ESD characteristics of the device are measured by the transmission line pulse test system at different ambient temperatures. The test results show that the holding voltage (VH) decreases with temperature increasing. The TCAD simulation is carried out to support and analyze the experimental results, and the same trend of VH versus temperature is obtained. Through the analysis of simulation results and theoretical derivation, the underlying physical mechanisms related to the effects of temperature on VH and holding current (IH) are discussed in detail. When the drain is subjected to the same current pulsing and the Source and Body are both grounded, the distributions of current density, electric potential, and injected electron density of NMOS at various temperatures are extracted and analyzed. When the Drain, Source, and Body are all grounded, the distributions of the electrostatic field at various temperatures are extracted and analyzed. The distribution of electric potential in NMOS indicates that the voltage drop on the Drain-Body junction (VDB) is affected by ambient temperature significantly, and the variation of VDB dominates the variation trend of VH with temperature increasing. The reducing electrostatic field and increasing injected electron density with temperature decreasing contribute to the decreasing of VDB. The trend of IH and parasitic Body resistance (RBody) weakens the temperature dependence of the VH. The current gain of parasitic bipolar transistor (β) decreases with ambient temperature rising, which is the main contributor to the decreasing of IH. Therefore, increasing IH and RBody is helpful in reducing the temperature dependence of the latch-immune ESD protection structure.-

Keywords:

- electrostatic discharge /

- metal-oxide-semiconductor field-effect transistor /

- holding voltage /

- high temperature

[1] Bafleur M, Caignet F, Nolhier N, 2017 ESD Protection Methodologies (Amsterdam, Holland: Elsevier) xvii

[2] Vinson J E, Liou J J 1998 Proc. IEEE 86 399

Google Scholar

Google Scholar

[3] Duvvury C, Amerasekera A 1993 Proc. IEEE 81 690

Google Scholar

Google Scholar

[4] Ker M D 1999 IEEE Trans. Electron. Devices 46 173

Google Scholar

Google Scholar

[5] Ker M D, Hsu C K 2005 IEEE Trans. Device Mater. Reliab. 5 235

Google Scholar

Google Scholar

[6] Voldman S H 2008 LATCHUP (Hoboken, New Jersey: John Wiley & Sons) p1

[7] Boselli G, Duvvury C 2005 Microelectron. Reliab. 45 1406

Google Scholar

Google Scholar

[8] Voldman S H 2005 Microelectron. Reliab. 45 437

Google Scholar

Google Scholar

[9] Wang A 2002 On-chip ESD Protection for Integrated Circuits: An IC Design Perspective (Boston, MA: Springer) p1

[10] Ker M, Wu C Y, Chang H H 1996 IEEE Trans. Electron. Devices 43 588

Google Scholar

Google Scholar

[11] Li C, Zhang F, Wang C K, Chen Q, Lu F, Wang H, Di M F, Cheng Y H, Zhao H J, Wang A 2018 14th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT) Qingdao, China 2018 p743

[12] Wang J X, Li X J, Zhao F Z, Zeng C B, Li D L, Li L C, Li J J, Li B, Han Z S, Luo J J 2021 Chin. Phys. B 30 078501

Google Scholar

Google Scholar

[13] Wang J X, Zhao F Z, Ni T, Li D L, G L C, Wang J J, Li X J, Zeng C B, Luo J J, Han Z S 2021 Microelectron. Reliab. 126 114239

Google Scholar

Google Scholar

[14] Tazzoli A, Marino F A, Cordoni M, Benvenuti A, Colombo P, Zanoni E, Meneghesso G 2007 Microelectron. Reliab. 47 1444

Google Scholar

Google Scholar

[15] Won J I, Lee H D, Lee K Y, Kim K D, Koo Y S 2009 IEEE Region 10 Conference 2009 Singapore, 2009 p2553

[16] Jang S L, Lin S L 2000 Solid-State Electron. 44 2139

Google Scholar

Google Scholar

[17] Liang W, Dong A, Li H, Miao M, Kuo C C, Klebanov M, Liou J J 2016 Microelectron. Reliab. 66 46

Google Scholar

Google Scholar

[18] Meneghesso G, Tazzoli A, Marino F A, Cordoni M, Colombo P 2008 46 th Annual IEEE International Reliability Physics Symposium Phoenix 2008 p3

[19] Hou F, Liu J Z, Liu Z W, Huang W, Gong T X, Liou J J 2019 IEEE Trans. Electron Devices 66 2044

Google Scholar

Google Scholar

[20] Do K I, Jin H S, Lee B S, Koo Y S 2021 IEEE J. Electron Devices Soc. 9 1017

Google Scholar

Google Scholar

[21] Wu M, Lu W Z, Zhang C C, Peng W, Zeng Y, Jin H, Xu J, Chen Z J 2020 Semicond. Sci. Technol. 35 045016

Google Scholar

Google Scholar

[22] Li S S 1978 Solid-State Electron. 21 1109

Google Scholar

Google Scholar

[23] Khanna V K 2017 Extreme-Temperature and Harsh-Environment Electronics: Physics, Technology and Applications (Boca Raton: CRC Press)

-

-

[1] Bafleur M, Caignet F, Nolhier N, 2017 ESD Protection Methodologies (Amsterdam, Holland: Elsevier) xvii

[2] Vinson J E, Liou J J 1998 Proc. IEEE 86 399

Google Scholar

Google Scholar

[3] Duvvury C, Amerasekera A 1993 Proc. IEEE 81 690

Google Scholar

Google Scholar

[4] Ker M D 1999 IEEE Trans. Electron. Devices 46 173

Google Scholar

Google Scholar

[5] Ker M D, Hsu C K 2005 IEEE Trans. Device Mater. Reliab. 5 235

Google Scholar

Google Scholar

[6] Voldman S H 2008 LATCHUP (Hoboken, New Jersey: John Wiley & Sons) p1

[7] Boselli G, Duvvury C 2005 Microelectron. Reliab. 45 1406

Google Scholar

Google Scholar

[8] Voldman S H 2005 Microelectron. Reliab. 45 437

Google Scholar

Google Scholar

[9] Wang A 2002 On-chip ESD Protection for Integrated Circuits: An IC Design Perspective (Boston, MA: Springer) p1

[10] Ker M, Wu C Y, Chang H H 1996 IEEE Trans. Electron. Devices 43 588

Google Scholar

Google Scholar

[11] Li C, Zhang F, Wang C K, Chen Q, Lu F, Wang H, Di M F, Cheng Y H, Zhao H J, Wang A 2018 14th IEEE International Conference on Solid-State and Integrated Circuit Technology (ICSICT) Qingdao, China 2018 p743

[12] Wang J X, Li X J, Zhao F Z, Zeng C B, Li D L, Li L C, Li J J, Li B, Han Z S, Luo J J 2021 Chin. Phys. B 30 078501

Google Scholar

Google Scholar

[13] Wang J X, Zhao F Z, Ni T, Li D L, G L C, Wang J J, Li X J, Zeng C B, Luo J J, Han Z S 2021 Microelectron. Reliab. 126 114239

Google Scholar

Google Scholar

[14] Tazzoli A, Marino F A, Cordoni M, Benvenuti A, Colombo P, Zanoni E, Meneghesso G 2007 Microelectron. Reliab. 47 1444

Google Scholar

Google Scholar

[15] Won J I, Lee H D, Lee K Y, Kim K D, Koo Y S 2009 IEEE Region 10 Conference 2009 Singapore, 2009 p2553

[16] Jang S L, Lin S L 2000 Solid-State Electron. 44 2139

Google Scholar

Google Scholar

[17] Liang W, Dong A, Li H, Miao M, Kuo C C, Klebanov M, Liou J J 2016 Microelectron. Reliab. 66 46

Google Scholar

Google Scholar

[18] Meneghesso G, Tazzoli A, Marino F A, Cordoni M, Colombo P 2008 46 th Annual IEEE International Reliability Physics Symposium Phoenix 2008 p3

[19] Hou F, Liu J Z, Liu Z W, Huang W, Gong T X, Liou J J 2019 IEEE Trans. Electron Devices 66 2044

Google Scholar

Google Scholar

[20] Do K I, Jin H S, Lee B S, Koo Y S 2021 IEEE J. Electron Devices Soc. 9 1017

Google Scholar

Google Scholar

[21] Wu M, Lu W Z, Zhang C C, Peng W, Zeng Y, Jin H, Xu J, Chen Z J 2020 Semicond. Sci. Technol. 35 045016

Google Scholar

Google Scholar

[22] Li S S 1978 Solid-State Electron. 21 1109

Google Scholar

Google Scholar

[23] Khanna V K 2017 Extreme-Temperature and Harsh-Environment Electronics: Physics, Technology and Applications (Boca Raton: CRC Press)

计量

- 文章访问数: 9041

- PDF下载量: 122

- 被引次数: 0

下载:

下载: