-

TiB2材料由于高熔点和低原子序数成为新一代核反应堆等离子体壁材料的候选者之一. 然而, 单一TiB2材料难以制备和加工, 因此在TiB2中加入助烧剂来优化其性能具有重要的应用价值. 本论文利用放电等离子体烧结得到Ti质量分数分别为3%和6%的两种TiB2-SiC-Ti材料. 材料在室温条件下进行能量60 keV, 离子注量为2 × 1017 ions/cm2的He+辐照, 辐照前后材料都进行1500 ℃热处理. 利用能量色散光谱、拉曼光谱、掠角X射线衍射光谱、维氏硬度、划痕深度和宽度分布、扫描电子显微镜等手段表征材料在制备态、辐照后和退火下的微观结构及宏观性能. 结果显示, TiB2-SiC-Ti(Ti的质量分数为3%)材料本身致密性低、耐磨性差、硬度低且抗氧化性弱. 但与TiB2-SiC-Ti(Ti的质量分数为6%)材料相比, TiB2-SiC-Ti(Ti的质量分数为3%)材料更抗辐照; 论文对该实验结果进行讨论, 认为在3%—6%质量分数范围内, 增加Ti含量有助于提升TiB2-SiC-Ti材料致密性和力学性能.

-

关键词:

- TiB2-SiC-Ti材料 /

- 离子辐照 /

- 高温氧化 /

- 力学性能

Since the 21st century, low atomic number material coating has been considered as one of methods for treating the first wall of controllable thermonuclear fusion device . The TiB2 material with high melting point, high hardness, low coefficient of thermal expansion, excellent wear resistance and low atomic number has entered into people’s field of vision. Single TiB2 is difficult to sinter and process into other products. Therefore, adding ceramic and metal additives to TiB2 matrix material to effectively improve the mechanical properties and processability of the material has become a research hotspot. On the basis of the existing researches of TiB2-SiC, in the present work the metal Ti powder is added as the second additive to improve the properties of TiB2 composite. The TiB2 and SiC are mixed at a mass ratio of 2 to 3, then two kinds of TiB2-SiC-Ti materials with different amounts of Ti content are prepared by spark plasma sintering (SPS) technology. The materials are irradiated by a He+ beam with energy of 60 keV and ion fluence of 2 × 1017 ions/cm2 at room temperature. The material is heat-treated at 1500 ℃ before and also after irradiation. The performances of prepared samples, the effect of irradiation on materials and the results of high temperature heat treatment are characterized by energy dispersive spectroscopy, Raman spectrum, grazing angle x-ray diffraction spectrum, Vickers hardness, wear resistance test, and scanning electron microscope. The results show that the surface morphology and toughness of TiB2-SiC-Ti material with 3% Ti mass fraction are poor as shown in SEM images. The wear resistance test indicates that the material surface is seriously worn and the wear resistance is poor. The X-ray diffraction spectrum and Raman spectra show that the material is oxidized seriously at 1500 ℃, which is likely to be the cause of the poor compactness of materials. Raman spectra, Grazing angle X-ray diffraction spectrum and some Vickers hardness data before and after irradiation indicate that the material with low Ti content possess better crystal structure and weaker irradiation hardening. In conclusion, the TiB2-SiC-Ti material with 3% Ti mass fraction exhibits lower density, poorer wear resistance and lower hardness, while the material with lower Ti mass fraction is more resistant to irradiation than the material with 6% Ti mass fraction at room temperature.-

Keywords:

- TiB2-SiC-Ti materials /

- ion irradiation /

- high-temperature oxidation /

- mechanical character

[1] Stacey Jr W M, Abdou M A, Bertoncini P J, Bolta C C, Brooks J N, Evans K, Fasolo J A, Jung J C, Kustom R L, Maroni A, Mattas R F, Monich J S, Moretti A, Mills F E, Misra B, Norem J H, Patten J S, Praeg W F, Smelser P, Smith D L, Stevens H C, Turner L, Wang S T, Youngdahl C K 1976 Proceedings of the Second Topical Meeting on “The Technology of Controlled Nuclear Fusion” Richland, 1976 p21

[2] Kaminsky M 1976 Proceedings of the Second Topical Meeting on “The Technology of Controlled Nuclear Fusion” Richland, 1976 p169

[3] Rossing T D, Das S K, Kaminsky M 1977 J. Vac. Sci. Technol. 14 550

Google Scholar

Google Scholar

[4] Mattox D M 1978 First Wall Coating Workshop Report Sandia Laboratories, Albuquerque, 1978 p1

[5] Boutard J L, Alamo A, Lindau R, Rieth M 2008 CR. Phys. 9 287

Google Scholar

Google Scholar

[6] Zhao G L, Huang C Z, Liu H L, Zou B, Zhu H T, Wang J 2014 Mater. Sci. Eng. A 606 108

Google Scholar

Google Scholar

[7] Bhattacharya A, Parish C M, Koyanagi T, Petrie C M, King D, Hilmas G, Fahrenholtz W G, Zinkle S J, Katoh Y 2019 Acta Mater. 165 26

Google Scholar

Google Scholar

[8] Istgaldi H, Nayebi B, Ahmadi Z, Shahi P, Asl M S 2020 Ceram. Int. 46 23155

Google Scholar

Google Scholar

[9] Konigshofer R, Furnsinn S, Steinkellner P 2005 Int. J. Refract. Met. H. 23 350

Google Scholar

Google Scholar

[10] Murthy T S R C, Balasubramaniam R, Basu B, Suri A K, Mungole M N 2006 J. Eur. Ceram. Soc. 26 187

Google Scholar

Google Scholar

[11] Asl M S, Kakroudi M G, Kondolaji R A, Nasiri H 2015 Ceram. Int. 41 5843

Google Scholar

Google Scholar

[12] Germi M D, Mahaseni Z H, Ahmadi Z, Asl M S 2018 Mater. Charact. 145 225

Google Scholar

Google Scholar

[13] Namini A S, Motallebzadeh A, Nayebi B, Asl M S, Azadbeh M 2019 Mater. Chem. Phys. 223 789

Google Scholar

Google Scholar

[14] Mahaseni Z H, Germi M D, Ahmadi Z, Asl M S 2018 Ceram. Int. 44 13367

Google Scholar

Google Scholar

[15] Nguyen V H, Asl M S, Mahaseni Z H, Germi M D, Delbari S A, Le Q V, Ahmadi Z, Shokouhimehr M, Namini A S, Mohammadi M 2020 Ceram. Int. 46 25341

Google Scholar

Google Scholar

[16] Ahmadi Z, Nayebi B, Asl M S, Farahbakhsh I, Balak Z 2018 Ceram. Int. 44 11431

Google Scholar

Google Scholar

[17] Zou B, Huang C Z, Song J P, Liu Z Y, Liu L, Zhao Y 2012 Mater. Sci. Eng. A 540 235

Google Scholar

Google Scholar

[18] Song J P, Huang C Z, Lv M, Zou B, Wang S Y, Wang J, An J 2014 Mater. Sci. Eng. A 605 137

Google Scholar

Google Scholar

[19] Chlup Z, Baca L, Halasova M, Neubauer E, Hadraba H, Stelzer N, Roupcova P 2015 J. Eur. Ceram. Soc. 35 2745

Google Scholar

Google Scholar

[20] Zhang Z H, Shen X B, Wang F C, Lee S K, Fan Q B, Cao M S 2012 Scripta Mater. 66 167

Google Scholar

Google Scholar

[21] Mukhopadhyay A, Raju G B, Basu B, Suri A K 2009 J. Eur. Ceram. Soc. 29 505

Google Scholar

Google Scholar

[22] Asl M S, Namini A S, Kakroudi M G 2016 Ceram. Int. 42 5375

Google Scholar

Google Scholar

[23] Murthy T S R C, Subramanian C, Fotedar R K, Gonal M R, Sengupta P, Kumar S, Suri A K 2009 Int. J. Refract. Met. H. 27 629

Google Scholar

Google Scholar

[24] Li M, Zhou X B, Yang H, Du S Y, Huang Q 2018 Scripta Mater. 143 149

Google Scholar

Google Scholar

[25] He Q L, Tian S, Xie J J, Xiang C L, Wang H, Wang W M, Fu Z Y 2020 J. Eur. Ceram. Soc. 40 2862

Google Scholar

Google Scholar

[26] Kovalcikova A, Tatarko P, Sedlak R, Medved D, Chlup Z, Mudra E, Dusza J 2020 J. Eur. Ceram. Soc. 40 4860

Google Scholar

Google Scholar

[27] Singlard M, Tessier-Doyen N, Chevallier G, Oriol S, Fiore G, Vieille B, Estournes C, Vardelle M, Rossignol S 2018 Ceram. Int. 44 22357

Google Scholar

Google Scholar

[28] Zou B, Ji W B, Huang C Z, Xu K T, Li S S 2014 Int. J. Refract. Met. H. 47 1

Google Scholar

Google Scholar

[29] Cai X Q, Wang D P, Wang Y, Yang Z W 2021 J. Manuf. Processes 64 1349

Google Scholar

Google Scholar

[30] Wang Y, Liu Q, Zhang B, Zhang H Q, Jin Y C, Zhong Z X, Ye J, Ren Y H, Ye F, Wang W 2021 Ceram. Int. 47 10665

Google Scholar

Google Scholar

[31] Song B, Yang W, Liu X M, Chen H Y, Akhlaghi M 2021 Ceram. Int. 47 29174

Google Scholar

Google Scholar

[32] Zhao B, Zhao Y Q, Hou Z M, Luo Y Y, Zhang W, Zhang P X, Wu J P 2018 Fusion Eng. Des. 137 405

Google Scholar

Google Scholar

[33] Vajdi M, Moghanlou F S, Ahmadi Z, Motallebzadeh A, Asl M S 2019 Ceram. Int. 45 8333

Google Scholar

Google Scholar

[34] Tatarko P, Grasso S, Kovalcikova A, Medved D, Dlouhy I, Reece M J 2020 J. Eur. Ceram. Soc. 40 1111

Google Scholar

Google Scholar

[35] Iltis X, Lefebvre F, Lemaignan C 1995 J. Nucl. Mater. 224 109

Google Scholar

Google Scholar

[36] Garner A, Baxter F, Frankel P, Topping M, Harte A, Slater T, Tejland P, Romero J, Darby E, Cole-Baker A, Gass M, Preuss M 2018 Zirconium in the Nuclear Industry: 18 th International Symposium West Conshohocken, 2018 p491

[37] Wang J, Ren D L, Chen L L, Man G A, Zhang H Y, Zhang H P, Luo L H, Li W P, Pan Y B, Gao P F, Zhu Y B, Wang Z G 2020 J. Nucl. Mater. 539 152275

Google Scholar

Google Scholar

[38] Bhattacharya A, Parish C M, Koyanagi T, Petrie C M, King D, Hilmas G, Fahrenholtz W G, Zinkle S J, Katoh Y 2019 Acta Materialia 165 26

[39] Golanski G, Purzynska H 2022 Int. J. Pres. Ves. Pip. 195 104574

Google Scholar

Google Scholar

[40] Paul B, Kishor J, Karthik A, Murthy T S R C, Sunil S 2022 Int. J. Refract. Met. H. 103 105752

Google Scholar

Google Scholar

[41] Guo W C, He Q L, Wang A Y, Tian T, Liu C, Hu L X, Wang H, Wang W M, Fu Z Y 2021 J. Mater. Res. Technol. 15 6700

Google Scholar

Google Scholar

[42] Rafaja D, Valvoda V, Perry A J, Treglio J R 1997 Surf. Coat. Tech. 92 135

Google Scholar

Google Scholar

[43] Lu X R, Shu X Y, Wang L, Shao D D, Zhang H B, Zhang K B, Xie Y 2019 J. Alloys Compd. 771 973

Google Scholar

Google Scholar

[44] Agarwal S, Chen Q, Koyanagi T, Zhao Y, Zinkle S J, Weber W J 2019 J. Nucl. Mater. 526 151778

Google Scholar

Google Scholar

[45] Lopez-Honorato E, Meadows P J, Shatwell R A, Xiao P 2010 Carbon 48 881

[46] Baca L, Stelzer N 2008 J. Eur. Ceram. Soc. 28 907

Google Scholar

Google Scholar

[47] Buixaderas E, Anghel E M, Atkinson I, Simon P, Bratan V, Petrescu S 2015 Ceram. Int. 41 2680

Google Scholar

Google Scholar

[48] Ohsaka T, Izumi F, Fujiki Y 1978 J. Raman Spectrosc. 7 321

Google Scholar

Google Scholar

[49] Bezrodna T, Gavrilko T, Puchkovska G, Shimanovska V, Baran J, Marchewka M 2002 J. Mol. Struct. 614 315

Google Scholar

Google Scholar

[50] Santara B, Giri P K, Imakita K, Fujii M 2014 J. Phys. D Appl. Phys. 47 215302

Google Scholar

Google Scholar

[51] Hernandez A, Barrios M L, Sanchez M L 2019 Mater. Today 13 446

[52] Zheng G M, Zhao J, Zhou Y H 2012 Wear 290 41

[53] Wang R D, Li P, Li B S, Hu L J, Huang F, Huang Q 2022 Corros. Sci. 201 110301

Google Scholar

Google Scholar

[54] Wang H, Ren F, Tang J, Qin W J, Hu L L, Dong L, Yang B, Cai G X, Jiang C Z 2018 Acta Mater. 144 691

Google Scholar

Google Scholar

[55] Zhang W, Chen L, Xu C G, Lu W Y, Wang Y J, Ouyang J H, Zhou Y 2021 J. Mater. Sci. Technol. 72 23

Google Scholar

Google Scholar

[56] Wang Y, Liu Q, Zhang B, Zhang H Q, Jin Y C, Zhong Z X, Ye J, Ren Y H, Ye F, Wang W 2021 Ceramics International 47 10665

-

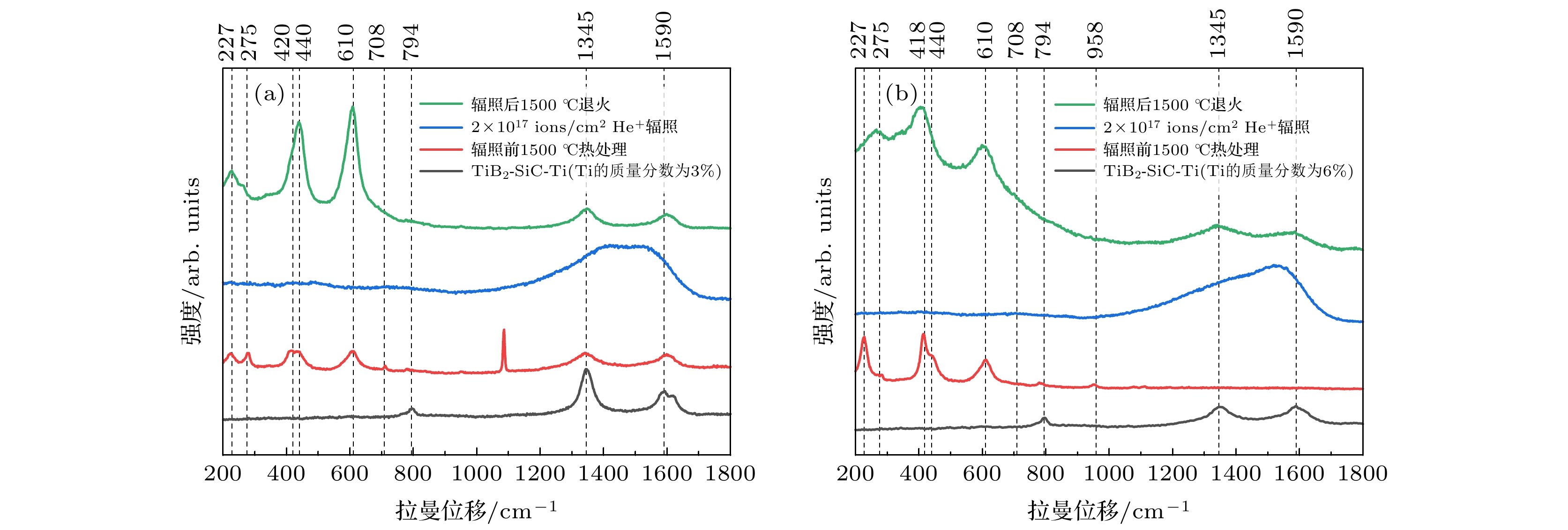

图 3 制备态、辐照前1500 ℃热处理、室温下氦离子辐照和辐照后1500 ℃退火4种条件下TiB2-SiC-Ti(Ti的质量分数为3%)样品(a)和TiB2-SiC-Ti(Ti的质量分数为6%)样品(b)的拉曼光谱

Fig. 3. Raman spectra of TiB2-SiC-Ti (the mass fraction of Ti is 3%) (a) and TiB2-SiC-Ti (the mass fraction of Ti is 6%) (b) under four conditions: Original state, heat treatment at 1500 ℃ before irradiation, irradiation with 60 keV to a fluence of 2 × 1017 ions/cm2 at room temperature followed by annealing at 1500 ℃.

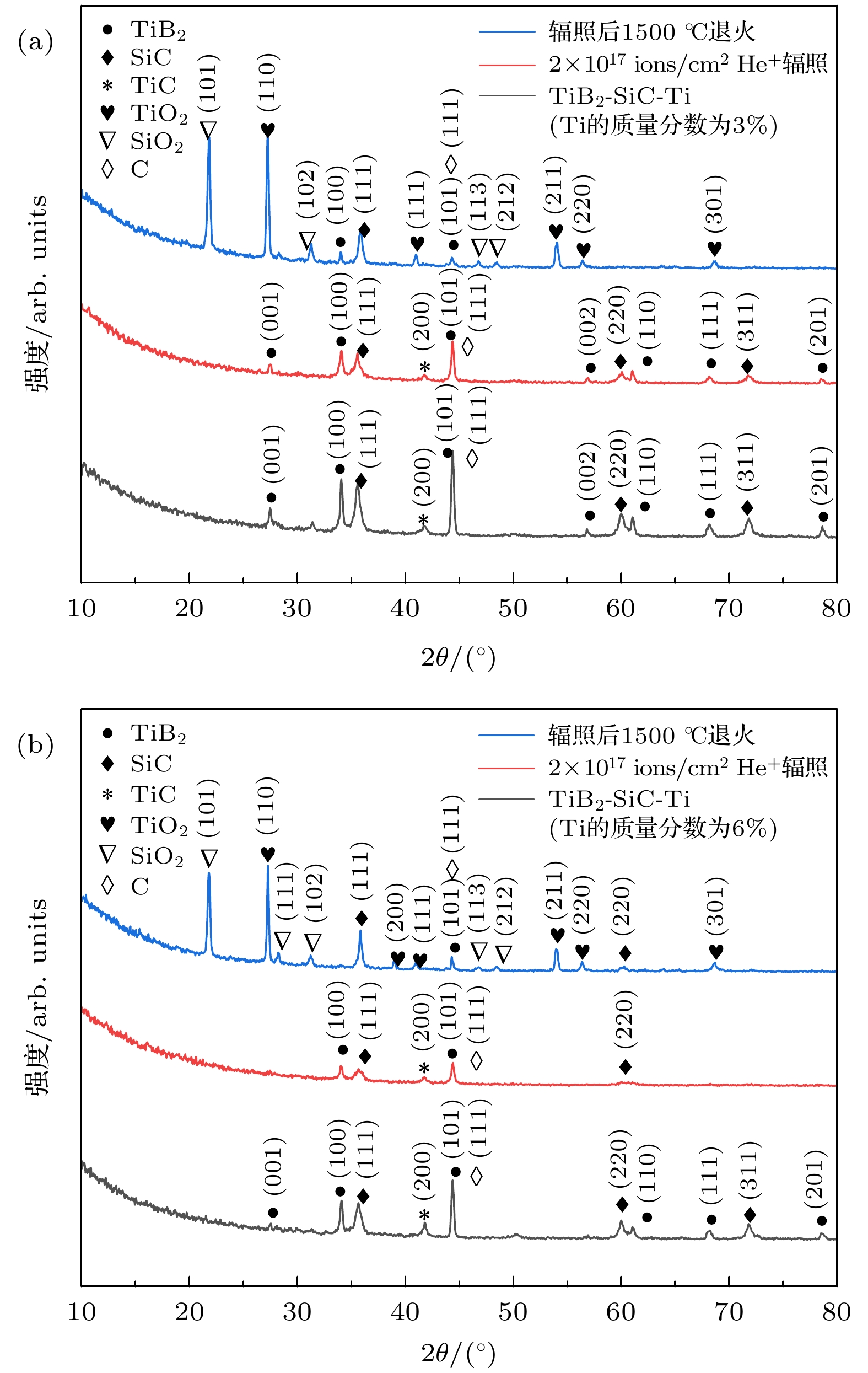

图 5 0.5°入射角下TiB2-SiC-Ti(Ti的质量分数为3%) (a) 和TiB2-SiC-Ti(Ti的质量分数为6%) (b) 样品的X射线衍射图谱, 包括原始状态、室温下60 keV, 2 × 1017 ions/cm2 He+ 辐照以及辐照后1500 ℃退火3种条件

Fig. 5. Grazing angle X-ray diffraction patterns of TiB2-SiC-Ti (the mass fraction of Ti is 3%) (a) and TiB2-SiC-Ti (the mass fraction of Ti is 6%) (b) at 0.5° incident angle, including the as-grown, 60 keV, 2 × 1017 ions/cm2 irradiation at room temperature followed by annealing at 1500 ℃

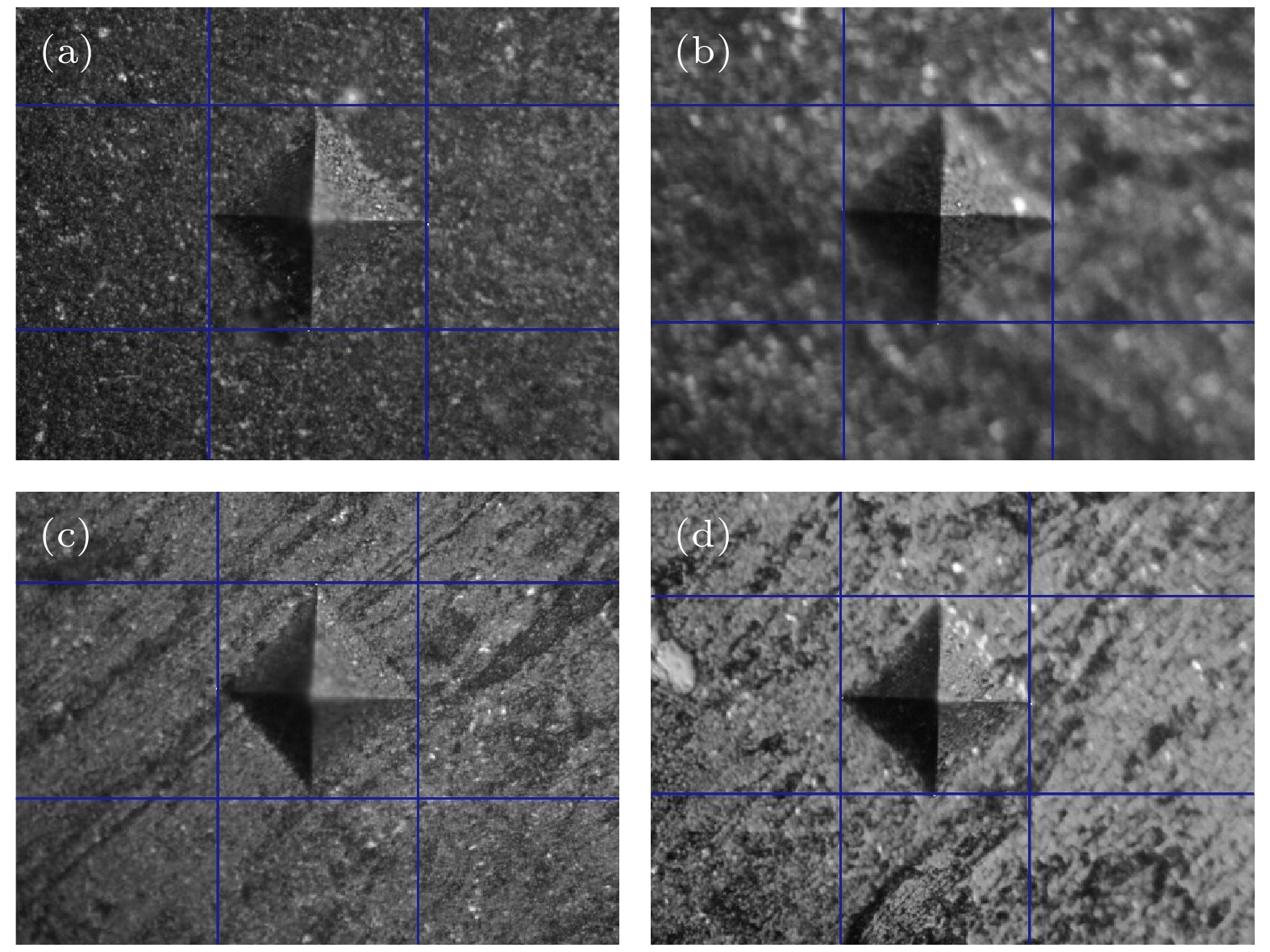

图 6 维氏硬度测试的实测硬度图 (a) TiB2-SiC-Ti(Ti的质量分数为3%); (b) 2 × 1017 ions/cm2 He+室温辐照的TiB2-SiC-Ti(Ti的质量分数为3%); (c) TiB2-SiC-Ti(Ti的质量分数为6%); (d) 2 × 1017 ions/cm2 He+ 室温辐照的TiB2-SiC-Ti(Ti的质量分数为6%)

Fig. 6. Measured hardness diagram of Vickers hardness test: (a) TiB2-SiC-Ti(the mass fraction of Ti is 3%); (b) TiB2-SiC-Ti(the mass fraction of Ti is 3%) irradiated with He+ to a fluence of 2 × 1017 ions/cm2 at room temperature; (c) TiB2-SiC-Ti (the mass fraction of Ti is 6%); (d) TiB2-SiC-Ti (the mass fraction of Ti is 6%) irradiated with He+ to a fluence of 2 × 1017 ions/cm2 at room temperature.

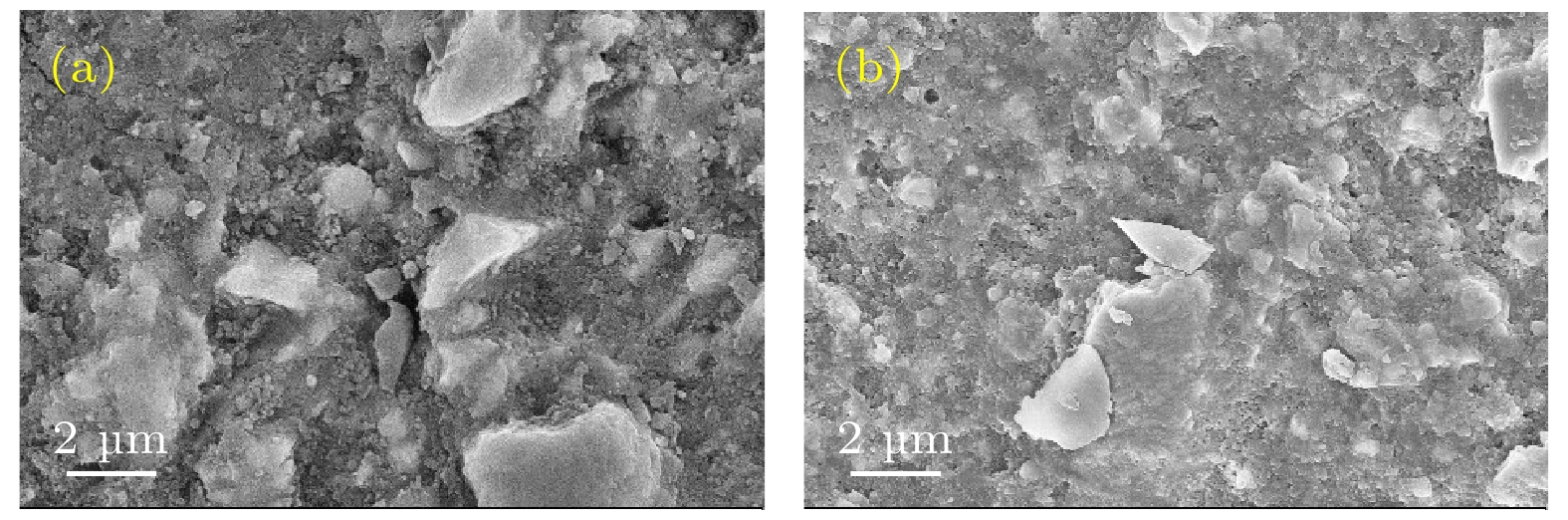

图 8 维氏硬度测试后压痕处的SEM图像 (a), (c), (e) TiB2-SiC-Ti(Ti的质量分数为3%); (b), (d), (f) TiB2-SiC-Ti(Ti的质量分数为6%)

Fig. 8. Scanning electron microscope image of indentation after Vickers hardness test: (a), (c), (e) TiB2-SiC-Ti (the mass fraction of Ti is 3%); (b), (d), (f) TiB2-SiC-Ti (the mass fraction of Ti is 6%).

表 1 TiB2-SiC-Ti复合材料中各物质的拉曼峰

Table 1. Raman peaks of various substances in TiB2-SiC-Ti composites.

物质 峰的位置/cm–1 振动模式 TiB2 275, 418 声子振动 TiO2 227 二阶散射峰 446 平面外振动 610 Ti-O拉伸振动 SiO2 708 Si-O拉伸振动 SiC 794, 958 Si-C伸缩振动 C 1345, 1590 面内伸缩振动 表 2 TiO2位于610 cm–1处的峰的有效面积

Table 2. The effective area of TiO2 peak at 610 cm–1.

材料 条件 有效

面积面积增

加率/%TiB2-SiC-Ti

(Ti的质量分数为3%)1500 ℃热处理 35209 442 辐照后1500 ℃退火 190919 TiB2-SiC-Ti

(Ti的质量分数为6%)1500 ℃热处理 48570 131 辐照后1500 ℃退火 112214 表 3 两种Ti含量、相同TiB2晶面指数处的峰强和半高宽

Table 3. Peak intensity and FWHM of samples at the same TiB2 crystal plane index.

晶面指数 (001) (100) (101) (002) (201) (112) TiB2-SiC-Ti

(Ti的质量分数为3%)峰高 696 1624 2708 244 280 240 半高宽 0.163 0.244 0.211 0.287 0.332 0.342 TiB2-SiC-Ti

(Ti的质量分数为6%)峰高 715 1623 2870 295 290 266 半高宽 0.159 0.210 0.211 0.251 0.315 0.334 表 4 1 kgf载荷下的维氏硬度值

Table 4. Vickers hardness value under 1 kgf load.

样品 HV 误差 硬度变化/% TiB2-SiC-Ti

(Ti的质量分数为3%)290.104 ± 0.03 6.9 TiB2-SiC-Ti

(Ti的质量分数为3%) (辐照)311.489 ± 1.22 TiB2-SiC-Ti

(Ti的质量分数为6%)344.824 ± 17.80 9.2 TiB2-SiC-Ti

(Ti的质量分数为6%) (辐照)379.775 ± 0.62 -

[1] Stacey Jr W M, Abdou M A, Bertoncini P J, Bolta C C, Brooks J N, Evans K, Fasolo J A, Jung J C, Kustom R L, Maroni A, Mattas R F, Monich J S, Moretti A, Mills F E, Misra B, Norem J H, Patten J S, Praeg W F, Smelser P, Smith D L, Stevens H C, Turner L, Wang S T, Youngdahl C K 1976 Proceedings of the Second Topical Meeting on “The Technology of Controlled Nuclear Fusion” Richland, 1976 p21

[2] Kaminsky M 1976 Proceedings of the Second Topical Meeting on “The Technology of Controlled Nuclear Fusion” Richland, 1976 p169

[3] Rossing T D, Das S K, Kaminsky M 1977 J. Vac. Sci. Technol. 14 550

Google Scholar

Google Scholar

[4] Mattox D M 1978 First Wall Coating Workshop Report Sandia Laboratories, Albuquerque, 1978 p1

[5] Boutard J L, Alamo A, Lindau R, Rieth M 2008 CR. Phys. 9 287

Google Scholar

Google Scholar

[6] Zhao G L, Huang C Z, Liu H L, Zou B, Zhu H T, Wang J 2014 Mater. Sci. Eng. A 606 108

Google Scholar

Google Scholar

[7] Bhattacharya A, Parish C M, Koyanagi T, Petrie C M, King D, Hilmas G, Fahrenholtz W G, Zinkle S J, Katoh Y 2019 Acta Mater. 165 26

Google Scholar

Google Scholar

[8] Istgaldi H, Nayebi B, Ahmadi Z, Shahi P, Asl M S 2020 Ceram. Int. 46 23155

Google Scholar

Google Scholar

[9] Konigshofer R, Furnsinn S, Steinkellner P 2005 Int. J. Refract. Met. H. 23 350

Google Scholar

Google Scholar

[10] Murthy T S R C, Balasubramaniam R, Basu B, Suri A K, Mungole M N 2006 J. Eur. Ceram. Soc. 26 187

Google Scholar

Google Scholar

[11] Asl M S, Kakroudi M G, Kondolaji R A, Nasiri H 2015 Ceram. Int. 41 5843

Google Scholar

Google Scholar

[12] Germi M D, Mahaseni Z H, Ahmadi Z, Asl M S 2018 Mater. Charact. 145 225

Google Scholar

Google Scholar

[13] Namini A S, Motallebzadeh A, Nayebi B, Asl M S, Azadbeh M 2019 Mater. Chem. Phys. 223 789

Google Scholar

Google Scholar

[14] Mahaseni Z H, Germi M D, Ahmadi Z, Asl M S 2018 Ceram. Int. 44 13367

Google Scholar

Google Scholar

[15] Nguyen V H, Asl M S, Mahaseni Z H, Germi M D, Delbari S A, Le Q V, Ahmadi Z, Shokouhimehr M, Namini A S, Mohammadi M 2020 Ceram. Int. 46 25341

Google Scholar

Google Scholar

[16] Ahmadi Z, Nayebi B, Asl M S, Farahbakhsh I, Balak Z 2018 Ceram. Int. 44 11431

Google Scholar

Google Scholar

[17] Zou B, Huang C Z, Song J P, Liu Z Y, Liu L, Zhao Y 2012 Mater. Sci. Eng. A 540 235

Google Scholar

Google Scholar

[18] Song J P, Huang C Z, Lv M, Zou B, Wang S Y, Wang J, An J 2014 Mater. Sci. Eng. A 605 137

Google Scholar

Google Scholar

[19] Chlup Z, Baca L, Halasova M, Neubauer E, Hadraba H, Stelzer N, Roupcova P 2015 J. Eur. Ceram. Soc. 35 2745

Google Scholar

Google Scholar

[20] Zhang Z H, Shen X B, Wang F C, Lee S K, Fan Q B, Cao M S 2012 Scripta Mater. 66 167

Google Scholar

Google Scholar

[21] Mukhopadhyay A, Raju G B, Basu B, Suri A K 2009 J. Eur. Ceram. Soc. 29 505

Google Scholar

Google Scholar

[22] Asl M S, Namini A S, Kakroudi M G 2016 Ceram. Int. 42 5375

Google Scholar

Google Scholar

[23] Murthy T S R C, Subramanian C, Fotedar R K, Gonal M R, Sengupta P, Kumar S, Suri A K 2009 Int. J. Refract. Met. H. 27 629

Google Scholar

Google Scholar

[24] Li M, Zhou X B, Yang H, Du S Y, Huang Q 2018 Scripta Mater. 143 149

Google Scholar

Google Scholar

[25] He Q L, Tian S, Xie J J, Xiang C L, Wang H, Wang W M, Fu Z Y 2020 J. Eur. Ceram. Soc. 40 2862

Google Scholar

Google Scholar

[26] Kovalcikova A, Tatarko P, Sedlak R, Medved D, Chlup Z, Mudra E, Dusza J 2020 J. Eur. Ceram. Soc. 40 4860

Google Scholar

Google Scholar

[27] Singlard M, Tessier-Doyen N, Chevallier G, Oriol S, Fiore G, Vieille B, Estournes C, Vardelle M, Rossignol S 2018 Ceram. Int. 44 22357

Google Scholar

Google Scholar

[28] Zou B, Ji W B, Huang C Z, Xu K T, Li S S 2014 Int. J. Refract. Met. H. 47 1

Google Scholar

Google Scholar

[29] Cai X Q, Wang D P, Wang Y, Yang Z W 2021 J. Manuf. Processes 64 1349

Google Scholar

Google Scholar

[30] Wang Y, Liu Q, Zhang B, Zhang H Q, Jin Y C, Zhong Z X, Ye J, Ren Y H, Ye F, Wang W 2021 Ceram. Int. 47 10665

Google Scholar

Google Scholar

[31] Song B, Yang W, Liu X M, Chen H Y, Akhlaghi M 2021 Ceram. Int. 47 29174

Google Scholar

Google Scholar

[32] Zhao B, Zhao Y Q, Hou Z M, Luo Y Y, Zhang W, Zhang P X, Wu J P 2018 Fusion Eng. Des. 137 405

Google Scholar

Google Scholar

[33] Vajdi M, Moghanlou F S, Ahmadi Z, Motallebzadeh A, Asl M S 2019 Ceram. Int. 45 8333

Google Scholar

Google Scholar

[34] Tatarko P, Grasso S, Kovalcikova A, Medved D, Dlouhy I, Reece M J 2020 J. Eur. Ceram. Soc. 40 1111

Google Scholar

Google Scholar

[35] Iltis X, Lefebvre F, Lemaignan C 1995 J. Nucl. Mater. 224 109

Google Scholar

Google Scholar

[36] Garner A, Baxter F, Frankel P, Topping M, Harte A, Slater T, Tejland P, Romero J, Darby E, Cole-Baker A, Gass M, Preuss M 2018 Zirconium in the Nuclear Industry: 18 th International Symposium West Conshohocken, 2018 p491

[37] Wang J, Ren D L, Chen L L, Man G A, Zhang H Y, Zhang H P, Luo L H, Li W P, Pan Y B, Gao P F, Zhu Y B, Wang Z G 2020 J. Nucl. Mater. 539 152275

Google Scholar

Google Scholar

[38] Bhattacharya A, Parish C M, Koyanagi T, Petrie C M, King D, Hilmas G, Fahrenholtz W G, Zinkle S J, Katoh Y 2019 Acta Materialia 165 26

[39] Golanski G, Purzynska H 2022 Int. J. Pres. Ves. Pip. 195 104574

Google Scholar

Google Scholar

[40] Paul B, Kishor J, Karthik A, Murthy T S R C, Sunil S 2022 Int. J. Refract. Met. H. 103 105752

Google Scholar

Google Scholar

[41] Guo W C, He Q L, Wang A Y, Tian T, Liu C, Hu L X, Wang H, Wang W M, Fu Z Y 2021 J. Mater. Res. Technol. 15 6700

Google Scholar

Google Scholar

[42] Rafaja D, Valvoda V, Perry A J, Treglio J R 1997 Surf. Coat. Tech. 92 135

Google Scholar

Google Scholar

[43] Lu X R, Shu X Y, Wang L, Shao D D, Zhang H B, Zhang K B, Xie Y 2019 J. Alloys Compd. 771 973

Google Scholar

Google Scholar

[44] Agarwal S, Chen Q, Koyanagi T, Zhao Y, Zinkle S J, Weber W J 2019 J. Nucl. Mater. 526 151778

Google Scholar

Google Scholar

[45] Lopez-Honorato E, Meadows P J, Shatwell R A, Xiao P 2010 Carbon 48 881

[46] Baca L, Stelzer N 2008 J. Eur. Ceram. Soc. 28 907

Google Scholar

Google Scholar

[47] Buixaderas E, Anghel E M, Atkinson I, Simon P, Bratan V, Petrescu S 2015 Ceram. Int. 41 2680

Google Scholar

Google Scholar

[48] Ohsaka T, Izumi F, Fujiki Y 1978 J. Raman Spectrosc. 7 321

Google Scholar

Google Scholar

[49] Bezrodna T, Gavrilko T, Puchkovska G, Shimanovska V, Baran J, Marchewka M 2002 J. Mol. Struct. 614 315

Google Scholar

Google Scholar

[50] Santara B, Giri P K, Imakita K, Fujii M 2014 J. Phys. D Appl. Phys. 47 215302

Google Scholar

Google Scholar

[51] Hernandez A, Barrios M L, Sanchez M L 2019 Mater. Today 13 446

[52] Zheng G M, Zhao J, Zhou Y H 2012 Wear 290 41

[53] Wang R D, Li P, Li B S, Hu L J, Huang F, Huang Q 2022 Corros. Sci. 201 110301

Google Scholar

Google Scholar

[54] Wang H, Ren F, Tang J, Qin W J, Hu L L, Dong L, Yang B, Cai G X, Jiang C Z 2018 Acta Mater. 144 691

Google Scholar

Google Scholar

[55] Zhang W, Chen L, Xu C G, Lu W Y, Wang Y J, Ouyang J H, Zhou Y 2021 J. Mater. Sci. Technol. 72 23

Google Scholar

Google Scholar

[56] Wang Y, Liu Q, Zhang B, Zhang H Q, Jin Y C, Zhong Z X, Ye J, Ren Y H, Ye F, Wang W 2021 Ceramics International 47 10665

计量

- 文章访问数: 5801

- PDF下载量: 72

- 被引次数: 0

下载:

下载: