-

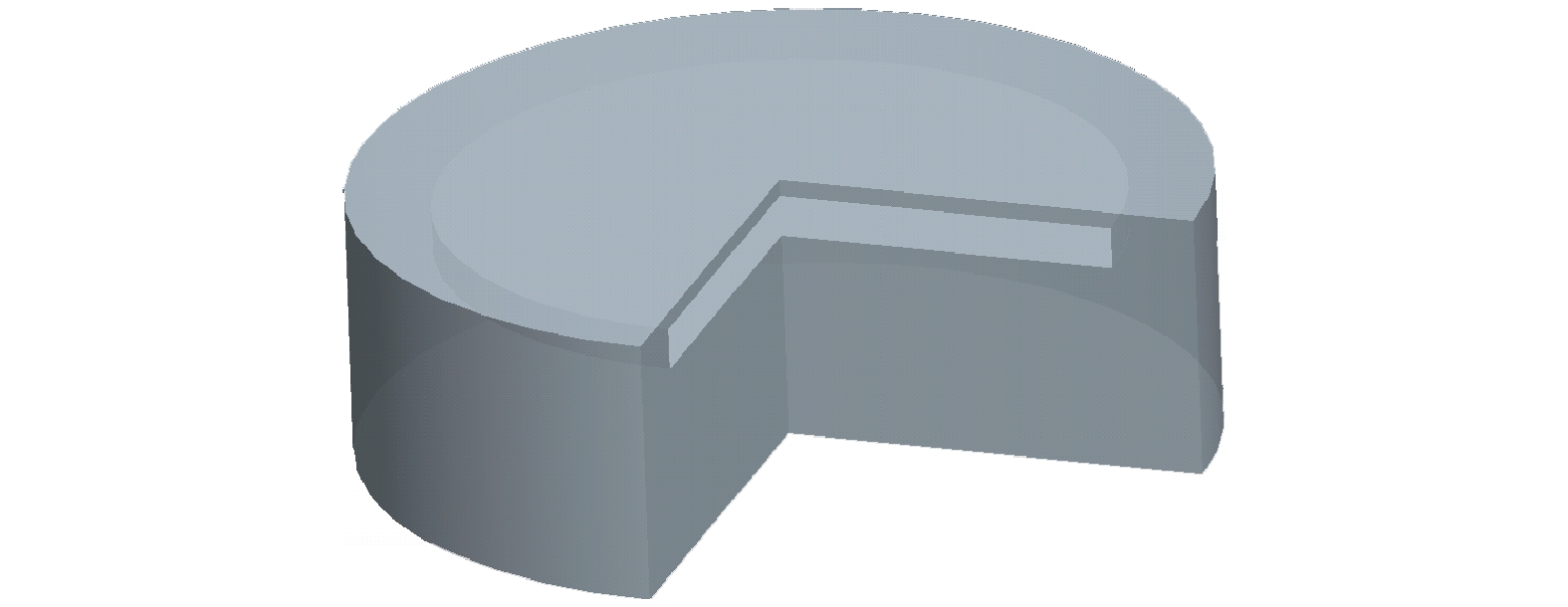

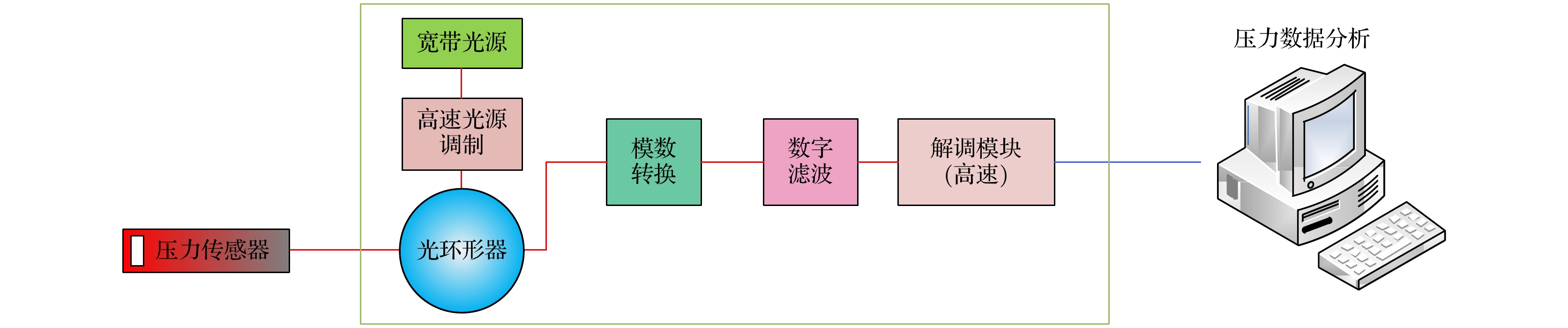

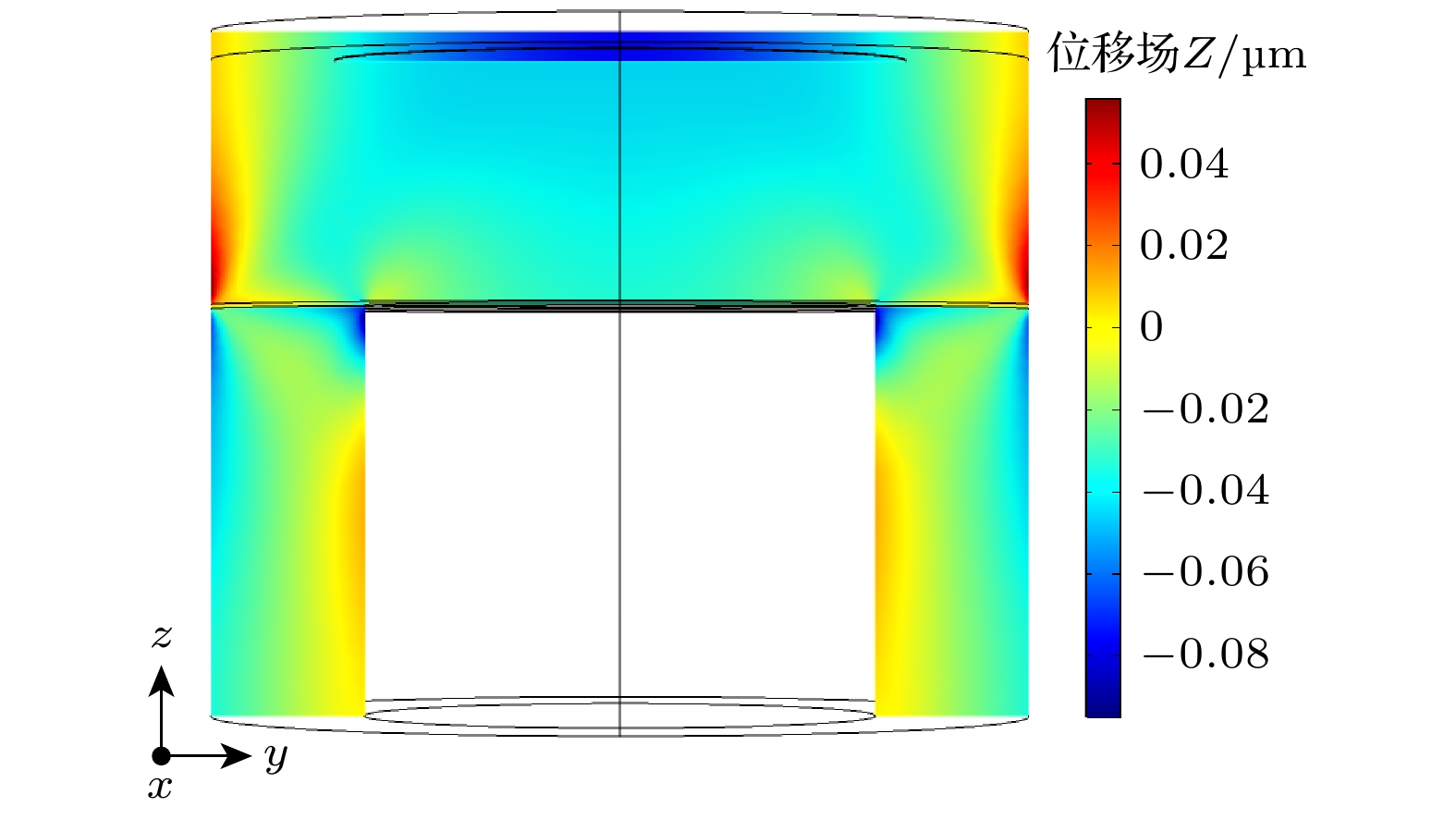

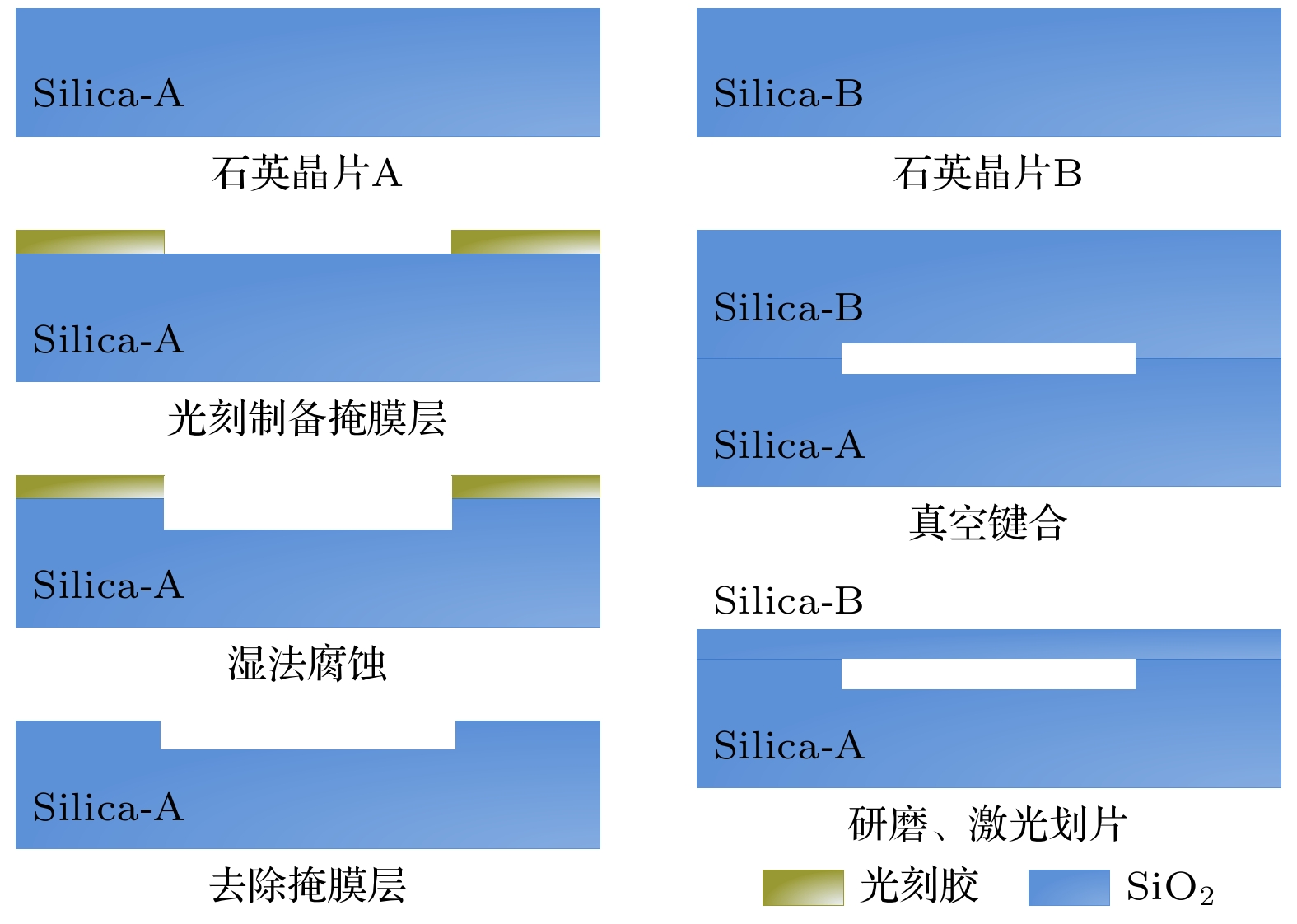

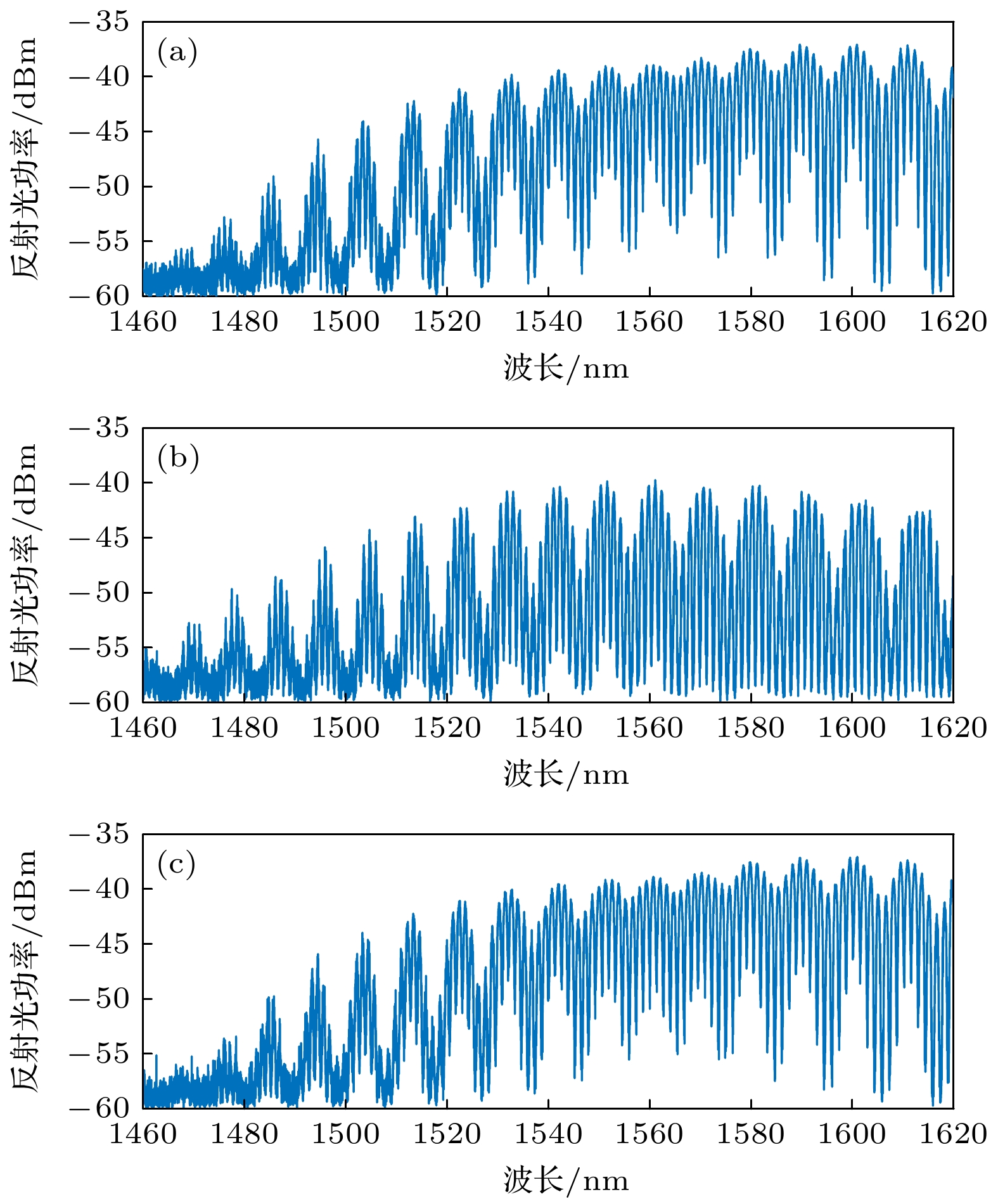

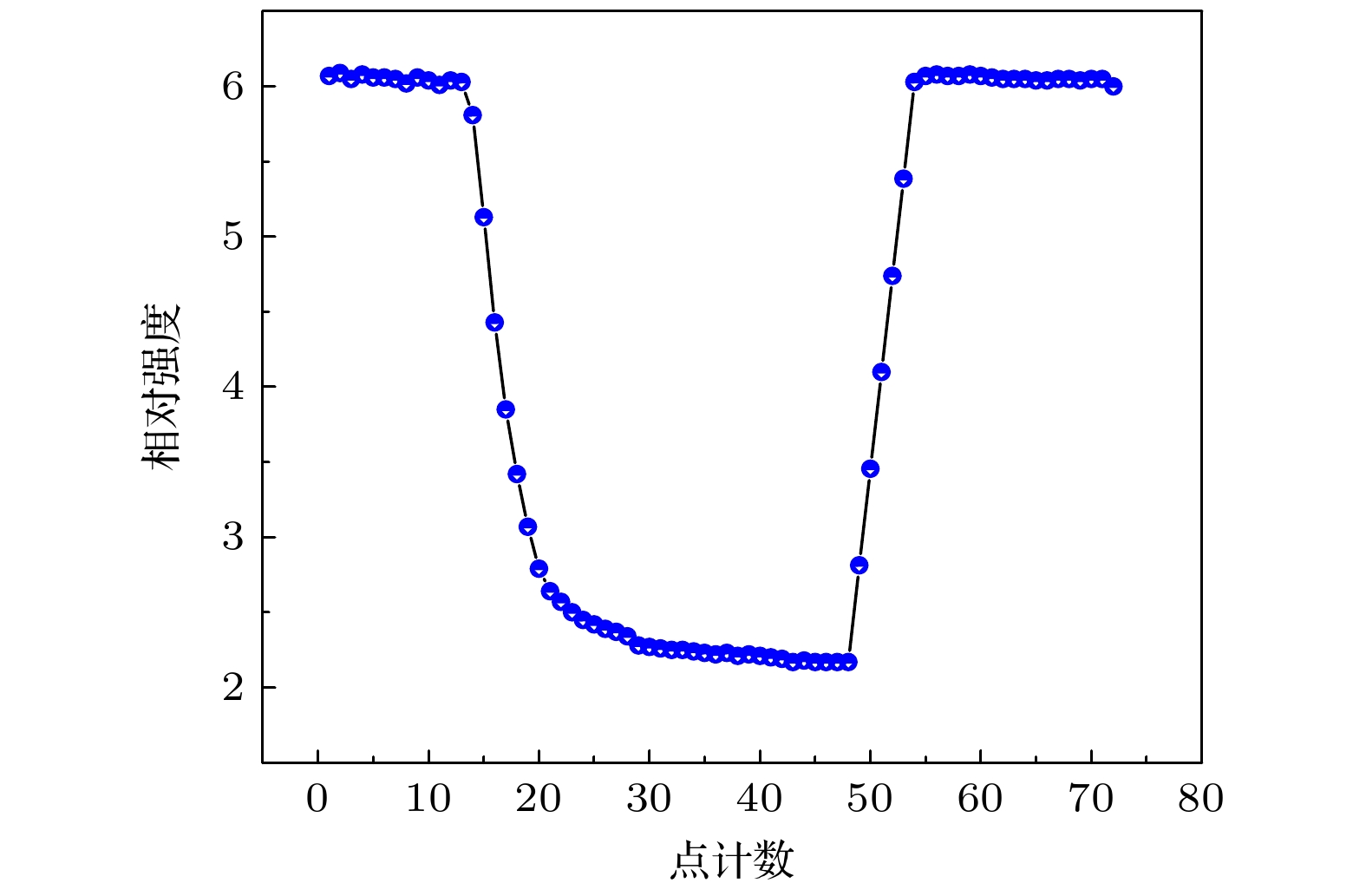

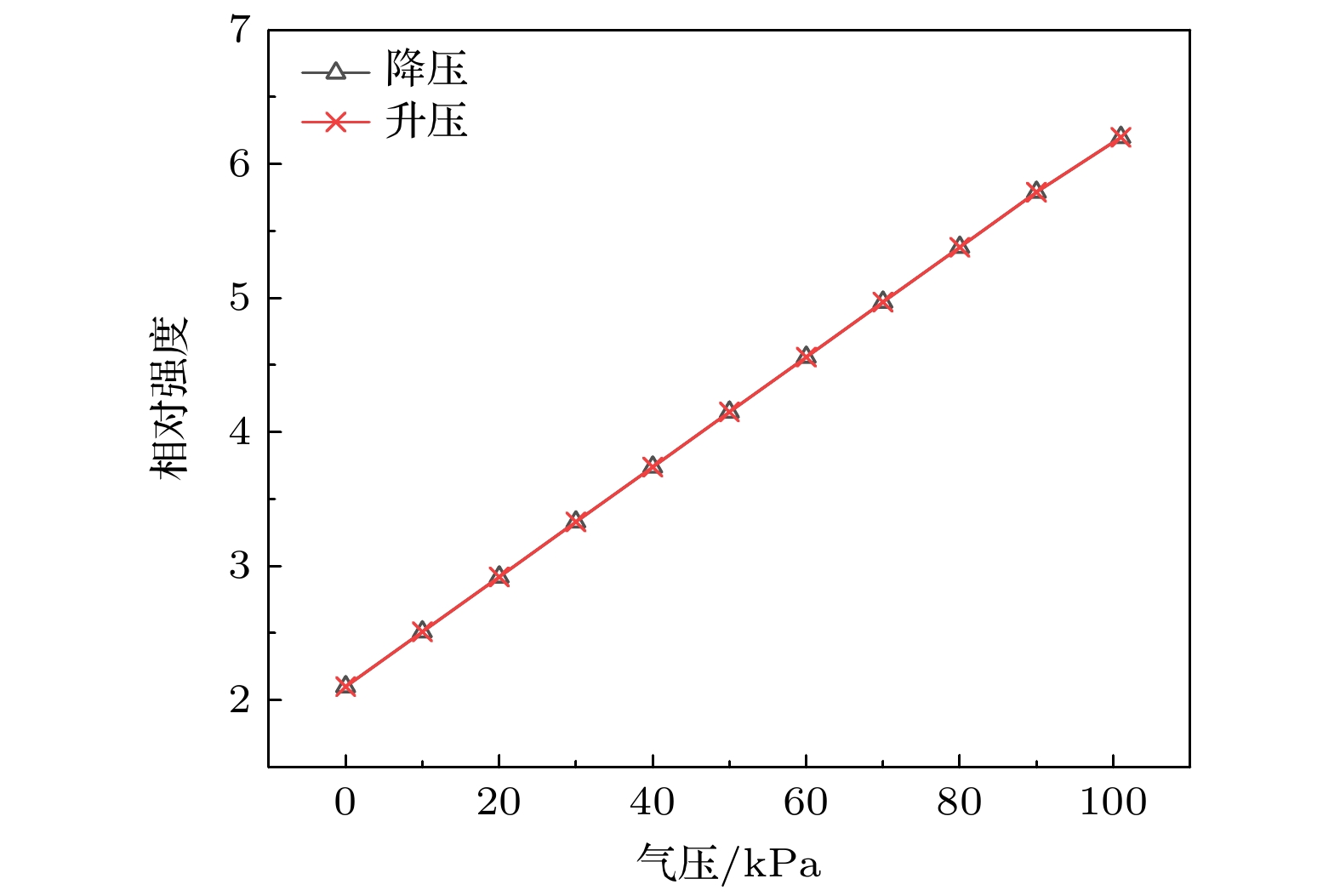

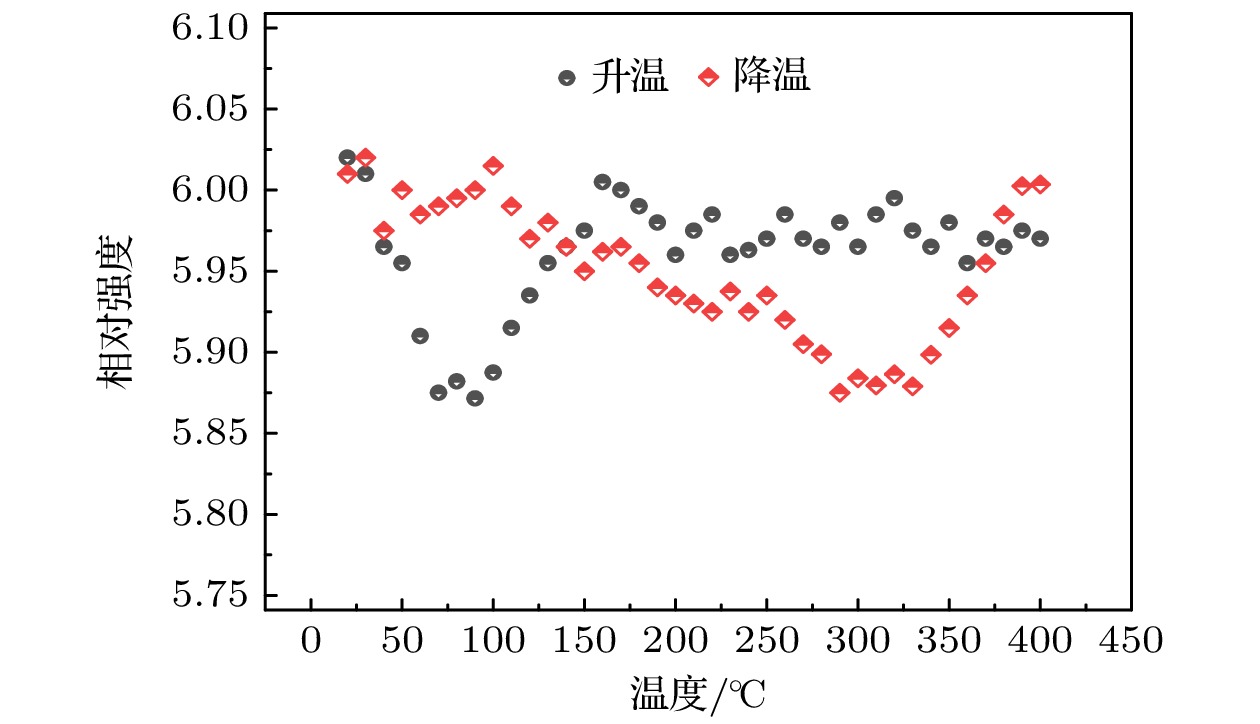

In aerospace, petrochemical, gas turbines and other high-temperature environments, pressure measurement of equipment has always been a challenge to be solved. The electrical high temperature pressure sensor has the problem of component failure in high temperature environment, and it is difficult to use in the high temperature environment for a long time. The detection device of the optical fiber sensor does not include electrical components, so it has the advantages of high working temperature, high measurement accuracy, anti-electromagnetic interference and so on. In order to use a sensor to measure pressure in high temperature environment, a temperature-weakly sensitive optical fiber micro-electro-mechanical system (MEMS) pressure sensing technology is proposed. The technique uses extrisic Fabry-Pérot interference (EFPI) model. It uses the MEMS pressure chip to passively modulate the optical signal of the interference, and then realizes the pressure signal measurement. Among them, MEMS pressure sensitive chip is the core component of the sensor. The MEMS pressure sensitive chip adopts the design method of all solid state vacuum absolute pressure. Change in environmental pressure will deform the membrane. This phenomenon can cause change in the cavity of the EFPI cavity. Therefore, stress information can be obtained by measuring changes in EFPI cavity. The thermal stress and temperature parasitical response introduced by thermal expansion of the material are calculated by simulation. The influence of temperature signal on chip displacement is analyzed by the above results. On this basis, a prototype of high temperature pressure sensor is developed by combining the sub-micron white light interference response technology and low thermal stress packaging technology. In order to test the ability of the sensor to implement actual measurement, this paper carry out the pressure test and high temperature test respectively. When the pressure changes from 0 kPa to 100 kPa, the spectral intensity of the sensor output has a linear relationship with the pressure. During the temperature changing from 20–400 ℃, the spectral intensity of the sensor output does not change significantly. The experimental test results show that the pressure measurement of 0–100 kPa can be satisfied in the range of 20–400 ℃, and the measurement error introduced by temperature change is less than 4%. Therefore, the fiber pressure sensor can be used to measure the pressure in high temperature environment.

-

Keywords:

- high temperature /

- fiber pressure sensor /

- extrisic Fabry-Pérot interference /

- micro-electro-mechanical system chip

[1] Wang Z, Chen J, Wei H, Liu H, Ma Z, Chen N, Wang T, Pang F 2020 Appl. Opt. 59 5189

Google Scholar

Google Scholar

[2] Li W W, Liang T, Jia P G, Lei C, Hong Y P, Li Y W, Yao Z, Liu W Y, Xiong J J 2019 Appl. Opt. 58 1662

Google Scholar

Google Scholar

[3] Ma W Y, Jiang Y, Gao H C 2019 Meas. Sci. Technol. 30 025104

Google Scholar

Google Scholar

[4] 何文涛, 李艳华, 邹江波, 张世名, 赵和平, 金小锋, 杨龙 2016 遥测遥控 37 61

Google Scholar

Google Scholar

He W T, Li Y H, Zou J B, Zhang S M, Zhao H P, Jin X F, Yang L 2016 J. Telem. Track. Command. 37 61

Google Scholar

Google Scholar

[5] Guo S W, Eriksen H, Childress K, Fink A, Hoffman M 2009 Sens. Actuator A Phys. 154 255

Google Scholar

Google Scholar

[6] 李达, 白雪平, 王文祥, 易丛, 李刚, 贾鲁生, 李书兆 2018 中国海上油气 30 196

Li D, Bai X P, Wang W X, Yi C, Li G, Jia L S, Li S Z 2018 China Offshore Oil Gas 30 196

[7] Fraga M A, Furlan H, Pessoa R S, Massi M 2014 Microsyst. Technol. 20 9

Google Scholar

Google Scholar

[8] 施兴华, 路瑞, 杭岑, 稽春艳 2016 中国海洋平台 45 135

Shi X H, Lu R, Hang C, Ji C Y 2016 China Offshore Platf. 45 135

[9] 刘铁根, 王双, 江俊峰, 刘琨, 尹金德 2014 仪器仪表学报 35 1681

Liu T G, Wang S, Jiang J F, Liu K, Yin J D 2014 Chin. J. Sci. Instrum. 35 1681

[10] Ma Z B, Cheng S L, Kou W Y, Chen H B, Wang W, Zhang X X, Guo T X 2019 Sensors 19 4097

Google Scholar

Google Scholar

[11] Dai L H, Wang M, Cai D Y, Rong H, Zhu J L, Jia S, You J J 2013 IEEE Photon. Technol. Lett. 25 2505

Google Scholar

Google Scholar

[12] Yu Q X, Zhou X L 2011 Photonic Sens. 1 72

Google Scholar

Google Scholar

[13] Chen X Z, Tong X L, Zhang C, Deng C W, Mao Y, Chen S M 2022 Opt. Commun. 506 127580

Google Scholar

Google Scholar

[14] 毛国培, 李金洋, 史青 2020 遥测遥控 41 12

Mao G P, Li J Y, Shi Q 2020 J. Telem. Track. Command. 41 12

[15] Harpin A 2009 Sensor and Test Conference Nuremberg, Germany, May 26–28, 2009 p89

[16] Pechstedt R D 2013 Fifth European Workshop on Optical Fibre Sensors Krakow, Poland, May 19–22, 2013 p879405

[17] Sposito A, Pechstedt R D 2016 Metrology for Aerospace. IEEE Florence, Italy, June 22–23, 2016 p97

[18] Yi J H, Lally E, Wang A B, Xu Y 2011 IEEE Photon. Technol. Lett. 23 9

Google Scholar

Google Scholar

[19] Mills D A, Alexander D, Subhash G, Sheplak M 2014 SPIE Sensing Technology + Applications Baltimore, MD, United States, June 5–6, 2014 p9113

[20] Zhou H C, Mills D A, Vera A, Garraud A, Oates W, Sheplak M 2019 AIAA Scitech 2019 Forum San Diego, California, January 7–11, 2019 p2044

[21] Tomboza W, Cotillard R, Roussel N, Huy M C P, Bouwmans G, Laffont G 2022 Optica Advanced Photonics Congress Maastricht, Limburg Netherlands, July 24–28, 2022 pBTh2A. 3

[22] 饶云江 2009 电子科技大学学报 38 487

Rao Y J 2009 J. Univ. Electron. Sci. Technol. China 38 487

[23] 张硕, 江毅 2018 仪表技术与传感器 1 10

Zhang S, Jiang Y 2018 Instrum. Tech. Sens. 1 10

[24] Zhang Y T, Jiang Y, Cui Y, Feng X X, Hu J 2022 Meas. Sci. Technol. 33 055117

Google Scholar

Google Scholar

[25] 盛天宇, 李建, 李鸿昌, 蒋永刚 2022 中国机械工程 33 1803

Google Scholar

Google Scholar

Sheng T Y, Li J, Li H C, Jiang Y G 2022 Chin. J. Mech. Eng. En. 33 1803

Google Scholar

Google Scholar

[26] 郭雪涛 2019 硕士学位论文 (西安: 西北工业大学)

Guo X T 2019 M. S. Thesis (Xi’an: Northwestern Polytechnical University

[27] 陈青青, 唐瑛, 王可宁, 陈海滨, 马志波 2018 激光与光电子学进展 55 110603

Google Scholar

Google Scholar

Chen Q Q, Tang Y, Wang K N, Chen H B, Ma Z B 2018 Laser Optoelectron. Prog. 55 110603

Google Scholar

Google Scholar

[28] 李奇思 2019 硕士学位论文 (太原: 中北大学)

Li Q S 2019 M. S. Thesis (Taiyuan: North University of China

[29] 颜维海 2022 硕士学位论文 (西安: 西安工业大学)

Yan W H 2022 M. S. Thesis (Xi’an: Xi’an Technological University

[30] Li J S, Jia P G, Fang G C, Wang J, Qian J, Ren Q Y, Xiong J J 2022 Sens. Actuator A Phys. 334 113363

Google Scholar

Google Scholar

[31] 何文涛, 赵光再, 宁佳晨, 李金洋, 史青 2019 遥测遥控 40 17

He W T, Zhao G Z, Ning J C, Li J Y, Shi Q 2019 J. Telem. Track. Command. 40 17

[32] 徐鹏柏 2018 博士学位论文 (哈尔滨: 哈尔滨工业大学)

Xu P B 2018 Ph. D. Dissertation (Harbin: Harbin Institute of Technology

[33] 张伟航 2016 硕士学位论文 (天津: 天津大学)

Zhang W H 2016 M. S. Thesis (Tianjin: Tianjin University

-

表 1 敏感芯片的结构参数

Table 1. Structural parameters of the chip.

结构 芯片

直径芯片

厚度感压腔

直径感压

膜厚腔体

长度尺寸/mm 2 0.7 1.4 0.08 0.002 -

[1] Wang Z, Chen J, Wei H, Liu H, Ma Z, Chen N, Wang T, Pang F 2020 Appl. Opt. 59 5189

Google Scholar

Google Scholar

[2] Li W W, Liang T, Jia P G, Lei C, Hong Y P, Li Y W, Yao Z, Liu W Y, Xiong J J 2019 Appl. Opt. 58 1662

Google Scholar

Google Scholar

[3] Ma W Y, Jiang Y, Gao H C 2019 Meas. Sci. Technol. 30 025104

Google Scholar

Google Scholar

[4] 何文涛, 李艳华, 邹江波, 张世名, 赵和平, 金小锋, 杨龙 2016 遥测遥控 37 61

Google Scholar

Google Scholar

He W T, Li Y H, Zou J B, Zhang S M, Zhao H P, Jin X F, Yang L 2016 J. Telem. Track. Command. 37 61

Google Scholar

Google Scholar

[5] Guo S W, Eriksen H, Childress K, Fink A, Hoffman M 2009 Sens. Actuator A Phys. 154 255

Google Scholar

Google Scholar

[6] 李达, 白雪平, 王文祥, 易丛, 李刚, 贾鲁生, 李书兆 2018 中国海上油气 30 196

Li D, Bai X P, Wang W X, Yi C, Li G, Jia L S, Li S Z 2018 China Offshore Oil Gas 30 196

[7] Fraga M A, Furlan H, Pessoa R S, Massi M 2014 Microsyst. Technol. 20 9

Google Scholar

Google Scholar

[8] 施兴华, 路瑞, 杭岑, 稽春艳 2016 中国海洋平台 45 135

Shi X H, Lu R, Hang C, Ji C Y 2016 China Offshore Platf. 45 135

[9] 刘铁根, 王双, 江俊峰, 刘琨, 尹金德 2014 仪器仪表学报 35 1681

Liu T G, Wang S, Jiang J F, Liu K, Yin J D 2014 Chin. J. Sci. Instrum. 35 1681

[10] Ma Z B, Cheng S L, Kou W Y, Chen H B, Wang W, Zhang X X, Guo T X 2019 Sensors 19 4097

Google Scholar

Google Scholar

[11] Dai L H, Wang M, Cai D Y, Rong H, Zhu J L, Jia S, You J J 2013 IEEE Photon. Technol. Lett. 25 2505

Google Scholar

Google Scholar

[12] Yu Q X, Zhou X L 2011 Photonic Sens. 1 72

Google Scholar

Google Scholar

[13] Chen X Z, Tong X L, Zhang C, Deng C W, Mao Y, Chen S M 2022 Opt. Commun. 506 127580

Google Scholar

Google Scholar

[14] 毛国培, 李金洋, 史青 2020 遥测遥控 41 12

Mao G P, Li J Y, Shi Q 2020 J. Telem. Track. Command. 41 12

[15] Harpin A 2009 Sensor and Test Conference Nuremberg, Germany, May 26–28, 2009 p89

[16] Pechstedt R D 2013 Fifth European Workshop on Optical Fibre Sensors Krakow, Poland, May 19–22, 2013 p879405

[17] Sposito A, Pechstedt R D 2016 Metrology for Aerospace. IEEE Florence, Italy, June 22–23, 2016 p97

[18] Yi J H, Lally E, Wang A B, Xu Y 2011 IEEE Photon. Technol. Lett. 23 9

Google Scholar

Google Scholar

[19] Mills D A, Alexander D, Subhash G, Sheplak M 2014 SPIE Sensing Technology + Applications Baltimore, MD, United States, June 5–6, 2014 p9113

[20] Zhou H C, Mills D A, Vera A, Garraud A, Oates W, Sheplak M 2019 AIAA Scitech 2019 Forum San Diego, California, January 7–11, 2019 p2044

[21] Tomboza W, Cotillard R, Roussel N, Huy M C P, Bouwmans G, Laffont G 2022 Optica Advanced Photonics Congress Maastricht, Limburg Netherlands, July 24–28, 2022 pBTh2A. 3

[22] 饶云江 2009 电子科技大学学报 38 487

Rao Y J 2009 J. Univ. Electron. Sci. Technol. China 38 487

[23] 张硕, 江毅 2018 仪表技术与传感器 1 10

Zhang S, Jiang Y 2018 Instrum. Tech. Sens. 1 10

[24] Zhang Y T, Jiang Y, Cui Y, Feng X X, Hu J 2022 Meas. Sci. Technol. 33 055117

Google Scholar

Google Scholar

[25] 盛天宇, 李建, 李鸿昌, 蒋永刚 2022 中国机械工程 33 1803

Google Scholar

Google Scholar

Sheng T Y, Li J, Li H C, Jiang Y G 2022 Chin. J. Mech. Eng. En. 33 1803

Google Scholar

Google Scholar

[26] 郭雪涛 2019 硕士学位论文 (西安: 西北工业大学)

Guo X T 2019 M. S. Thesis (Xi’an: Northwestern Polytechnical University

[27] 陈青青, 唐瑛, 王可宁, 陈海滨, 马志波 2018 激光与光电子学进展 55 110603

Google Scholar

Google Scholar

Chen Q Q, Tang Y, Wang K N, Chen H B, Ma Z B 2018 Laser Optoelectron. Prog. 55 110603

Google Scholar

Google Scholar

[28] 李奇思 2019 硕士学位论文 (太原: 中北大学)

Li Q S 2019 M. S. Thesis (Taiyuan: North University of China

[29] 颜维海 2022 硕士学位论文 (西安: 西安工业大学)

Yan W H 2022 M. S. Thesis (Xi’an: Xi’an Technological University

[30] Li J S, Jia P G, Fang G C, Wang J, Qian J, Ren Q Y, Xiong J J 2022 Sens. Actuator A Phys. 334 113363

Google Scholar

Google Scholar

[31] 何文涛, 赵光再, 宁佳晨, 李金洋, 史青 2019 遥测遥控 40 17

He W T, Zhao G Z, Ning J C, Li J Y, Shi Q 2019 J. Telem. Track. Command. 40 17

[32] 徐鹏柏 2018 博士学位论文 (哈尔滨: 哈尔滨工业大学)

Xu P B 2018 Ph. D. Dissertation (Harbin: Harbin Institute of Technology

[33] 张伟航 2016 硕士学位论文 (天津: 天津大学)

Zhang W H 2016 M. S. Thesis (Tianjin: Tianjin University

计量

- 文章访问数: 4408

- PDF下载量: 120

- 被引次数: 0

下载:

下载: