-

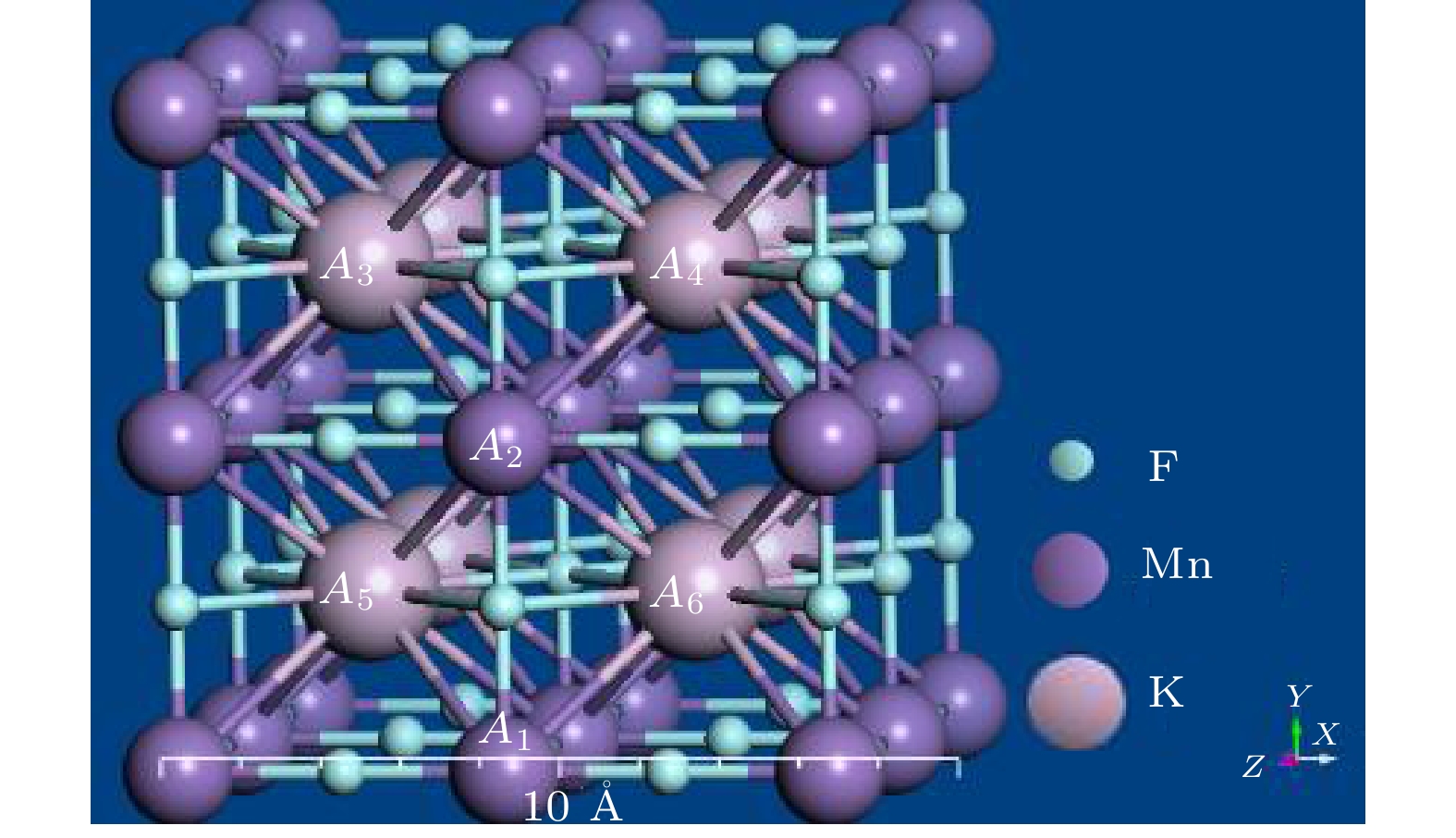

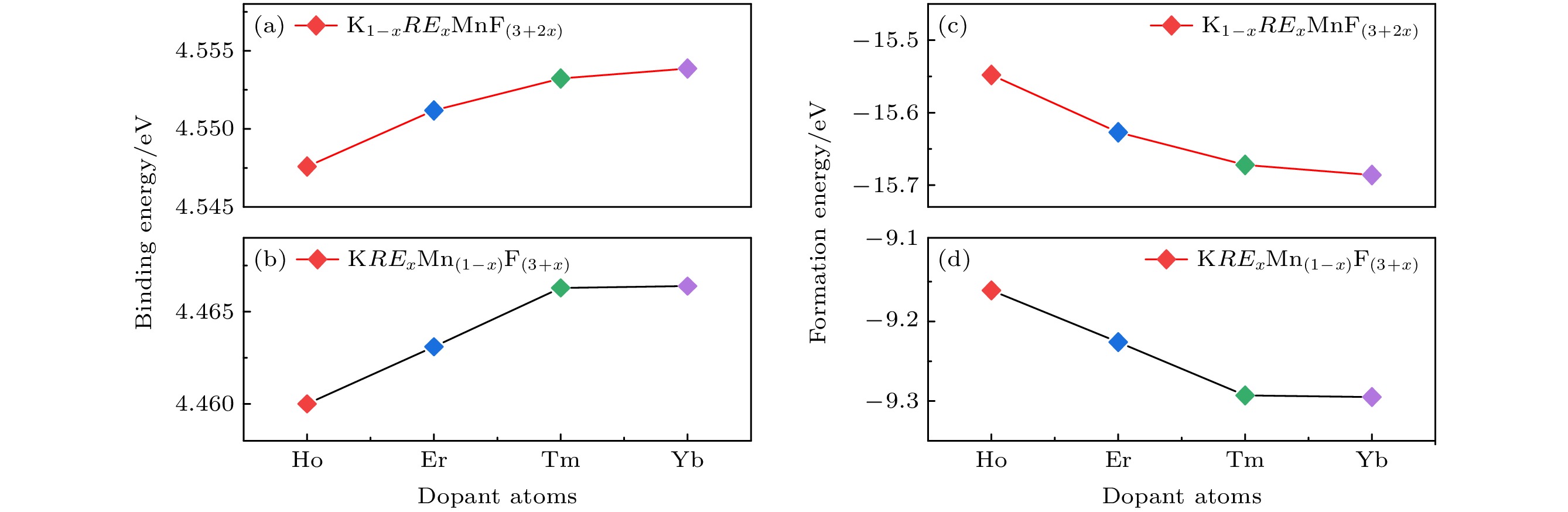

具有单(纯)色上转换荧光发射特性的发光材料, 有望在三维显示、照明、生物成像、促进植物生长以及提高太阳能电池光电转换效率等领域得到应用, 受到研究人员的广泛关注. 本研究通过玻璃热处理析晶的方法, 在稀土离子Yb3+/Er3+共掺的氟硅酸盐玻璃中原位生长出了钙钛矿型的KMnF3氟化物纳米晶体, 并观测到了显著增强的高单色性上转换红色发光. 采用具有高分辨率的透射电子显微测试分析技术和第一性原理计算相结合, 研究了稀土离子在KMnF3纳米晶复合微晶玻璃中的掺杂机制, 并讨论了稀土离子微观分布和能量传递效应对其上转换发光性能的影响. 实验结果表明: 稀土离子将通过优先取代KMnF3晶体中K+格位的方式选择性富集在具有低声子能量的氟化物纳米晶体中, 并由此获得显著增强的上转换发光强度.Luminescent materials with an efficient single-(pure) color up-conversion luminescence (UCL) are expected to be applied to three-dimensional (3D) display, lighting, biological imaging, promoting plant growth and improving the photoelectric conversion efficiency of solar cells. In this work, perovskite-type KMnF3 fluoride nanocrystals (NCs) are grown in situ in a fluorosilicate glass co-doped with rare earth (RE) ions Yb3+/Er3+ by a controlled thermal treatment. Compared with precursor glass (PG), the nano-glass composites (also referred to as glass ceramics, or GC in short) thus obtained exhibit a significantly enhanced (by 6 times) red UCL emission. Although a weak green UCL emission can be also observed in the GC, the intensity ratio of the red UCL emission to green UCL emission is as high as 30, implying a good color purity. It is suggested that the dramatic enhancement of UCL emissions in the GCs is due to the doping of RE ions into the KMnF3 NCs with a much lower phonon energy (330 cm–1) than that of the silica glass matrix about 1100 cm–1. However, the doping mechanisms of RE ions into KMnF3 nano-glass composites are not yet conclusive, mainly because of the charge and ionic radius mismatch between RE ion dopants and cations of KMnF3. This work combines the high-resolution transmission electron microscopy (HR-TEM) analysis technology and the first principles calculation, to unravel the doping mechanism of RE ions in KMnF3 nano-glass composites. First, the HR-TEM study provides straightforward evidence that RE ions are preferentially accumulated in KMnF3 NCs embedded in the glass matrix. Then, through the first-principles calculation considering the charge balance, it is found that the formation energy of RE ions substituting for K+ is lower than for Mn2+ lattice sites in KMnF3, which is most likely related to the fact that the ionic radius of the eight-fold coordinated K+ is larger than that of the six-fold coordinated Mn2+ and thus is more conductive to accommodating the large size RE ions. The electronic densities of states at the top of the valence band and the bottom of the conduction band of KMnF3 increase after doping the RE ions. It is inferred from the profile of partial density of state that RE ions have a strong bonding tendency with F– in the crystal. Benefiting from the efficient energy transfer between RE ions and Mn2+ in KMnF3, the green UCL emission is dramatically quenched, and consequently, the GC is endowed with a highly pure red UCL emission. The present study is expected to deepen the understanding of RE ions doping mechanisms in NCs and facilitate the design of highly efficient UCL materials based on nano-glass composites.

-

Keywords:

- glass ceramics /

- up conversion luminescence /

- rare earth doping /

- first principles calculation

[1] Zeng S J, Yi Z G, Lu W, Qian C, Wang H B, Rao L, Zeng T M., Liu H R, Liu H J, Fei B, Hao J H 2014 Adv. Funct. Mater. 24 4051

Google Scholar

Google Scholar

[2] Wu M, Jiang X F, Song E H, Su J, Chen Z T, Dai W B, Ye S, Zhang Q Y 2016 J. Mater. Chem. C 4 9598

Google Scholar

Google Scholar

[3] Song E H, Ye S, Liu T H, Du P P, Si R, Jing X P, Ding S, Peng M Y, Zhang Q Y, Wondraczek L 2015 Adv. Sci. 2 1500089

Google Scholar

Google Scholar

[4] Shi S, Sun L D, Xue Y X, Dong H, Wu K, Guo S C, Wu B, Yan C H 2018 Nano. Lett. 18 2964

Google Scholar

Google Scholar

[5] Wang J, Wang F, Wang C, Liu Z, Liu X G 2011 Angew. Chem. 123 10553

Google Scholar

Google Scholar

[6] Tian G, Gu Z J, Zhou L J, Yin W Y, Liu X X, Yan L, Jin S, Ren W L, Xing G M, Li S J, Zhao Y L 2012 Adv. Mater. 24 1226

Google Scholar

Google Scholar

[7] Zhang Y L, Wang F, Lang Y B, Yin J, Zhang M L, Liu X H, Zhang D M, Zhao D, Qin G S, Qin W P 2015 J. Mater. Chem. C 3 9827

Google Scholar

Google Scholar

[8] 任晶, 卢小送, 王鹏飞 2019 光子学报 48 1148007

Google Scholar

Google Scholar

Ren J, Lu X S, Wang P F 2019 Acta Photonica Sin. 48 1148007

Google Scholar

Google Scholar

[9] 高志刚, 肖静, 任晶 2021 激光与光电子学进展 58 1516001

Google Scholar

Google Scholar

Gao Z G, Xiao J, Ren J 2021 Laser Optoelectron. Prog. 58 1516001

Google Scholar

Google Scholar

[10] Chen J K, Peng Y Z, Li X Y, Chen W, Huang H, Lin L, Chen D Q 2019 J. Mater. Chem. C 7 4109

Google Scholar

Google Scholar

[11] Li X Y, Chen D Q, Huang F, Chang G C, Zhao J J, Qiao X S, Xu X H, Du J C, Yin M 2018 Laser Photonics Rev. 12 1800030

Google Scholar

Google Scholar

[12] Zhong J S, Chen D Q, Peng Y Z, Lu Y D, Chen X, Li X Y, Ji Z G 2018 J. Alloys Compd. 763 34

Google Scholar

Google Scholar

[13] Chen S Y Z, Song W H, Cao J K, Hu F F, Guo H 2020 J. Alloys Compd. 825 154011

Google Scholar

Google Scholar

[14] Yang Q H, Zhao L, Fang Z H, Yang Z, Cao J Y, Cai Y Y, Zhou D C, Yu X, Qiu J B, Xu X H 2021 J. Rare Earths 39 712

Google Scholar

Google Scholar

[15] Teng L M, Zhang W N, Chen W P, Gao J K, Sun X Y, Guo H 2020 Ceram. Int. 46 10718

Google Scholar

Google Scholar

[16] Chen S Y Z, Zhang W N, Teng L M, Chen J, Sun X Y, Guo H, Qiao X S 2021 J. Eur. Ceram. Soc. 41 6722

Google Scholar

Google Scholar

[17] 陈宇暄, 黄立辉, 赵静涛, 赵士龙, 徐时清 2021 发光学报 42 804

Google Scholar

Google Scholar

Chen Y X, Huang L H, Zhao L H, Zhao J T, Zhao S L, Xu S Q 2021 Chin. J. Lumin. 42 804

Google Scholar

Google Scholar

[18] Lin C G, Bocker C, Rüssel C 2015 Nano Lett. 15 6764

Google Scholar

Google Scholar

[19] Lin C G, Liu C, Zhao Z Y, Li L G, Bocker C, Rüssel C 2015 Opt. Lett. 40 5263

Google Scholar

Google Scholar

[20] Cao J K, Guo H, Hu F F, Li L Y, Xu S H, Peng M Y 2018 J. Am. Ceram. Soc. 101 3890

Google Scholar

Google Scholar

[21] Gao Z G, Guo S, Lu X S, Orava J, Wagner T, Zheng L R, Liu Y Y, Sun S Y, He F, Yang P P, Ren J, Yang J 2018 Adv. Opt. Mater. 6 1701407

Google Scholar

Google Scholar

[22] Kresse G, Furthmuller J 1996 Comp. Mater. Sci. 6 15

Google Scholar

Google Scholar

[23] Kohn W, Sham L J 1965 Phys. Rev. A 140 1133

Google Scholar

Google Scholar

[24] Perdew J P, Wang Y 1992 Phys. Rev. B 45 13244

Google Scholar

Google Scholar

[25] Hu Q L, Gao Z G, Lu X S, Ren J, He F, Fang Z J, Liu Y Y, Sun S Y, Yang P P, Wang P F 2017 J. Mater. Chem. C 5 11806

Google Scholar

Google Scholar

[26] Gao Z G, Lai Z Q, Lu K L, Guo S, Liu L, He F, Yang P P, Ren J, Zhang J Z, Yang J 2019 Opt. Lett. 44 4674

Google Scholar

Google Scholar

[27] Kapusta J, Daniel P, Ratuszna A 1999 Phys. Rev. B 59 14235

Google Scholar

Google Scholar

[28] Gao Z G, Lu X S, Zhang Y D, Guo S, Liu Y Y, Sun S Y, He F, Yang P P, Ren J, Yang J 2018 J. Am. Ceram. Soc. 101 2868

Google Scholar

Google Scholar

[29] Sun B C, Xie Y Q, Zhao Y L, Li X, Chen J F, Song Y S, Zhao L, Li Z G, Zhao H T, Ren J, Zhang J Z 2021 J. Mater. Chem. C 9 17504

Google Scholar

Google Scholar

[30] Buscaglia M T, Buscaglia V, Viviani M 2001 J. Am. Ceram. Soc 84 376

[31] Zhang C, Wang C L, Li J C, Yang K, Zhang Y F, Wu Q Z 2008 Mater. Chem. Phys. 107 215

Google Scholar

Google Scholar

[32] Shannon R D 1976 Acta Crystallogr. A 32 751

Google Scholar

Google Scholar

-

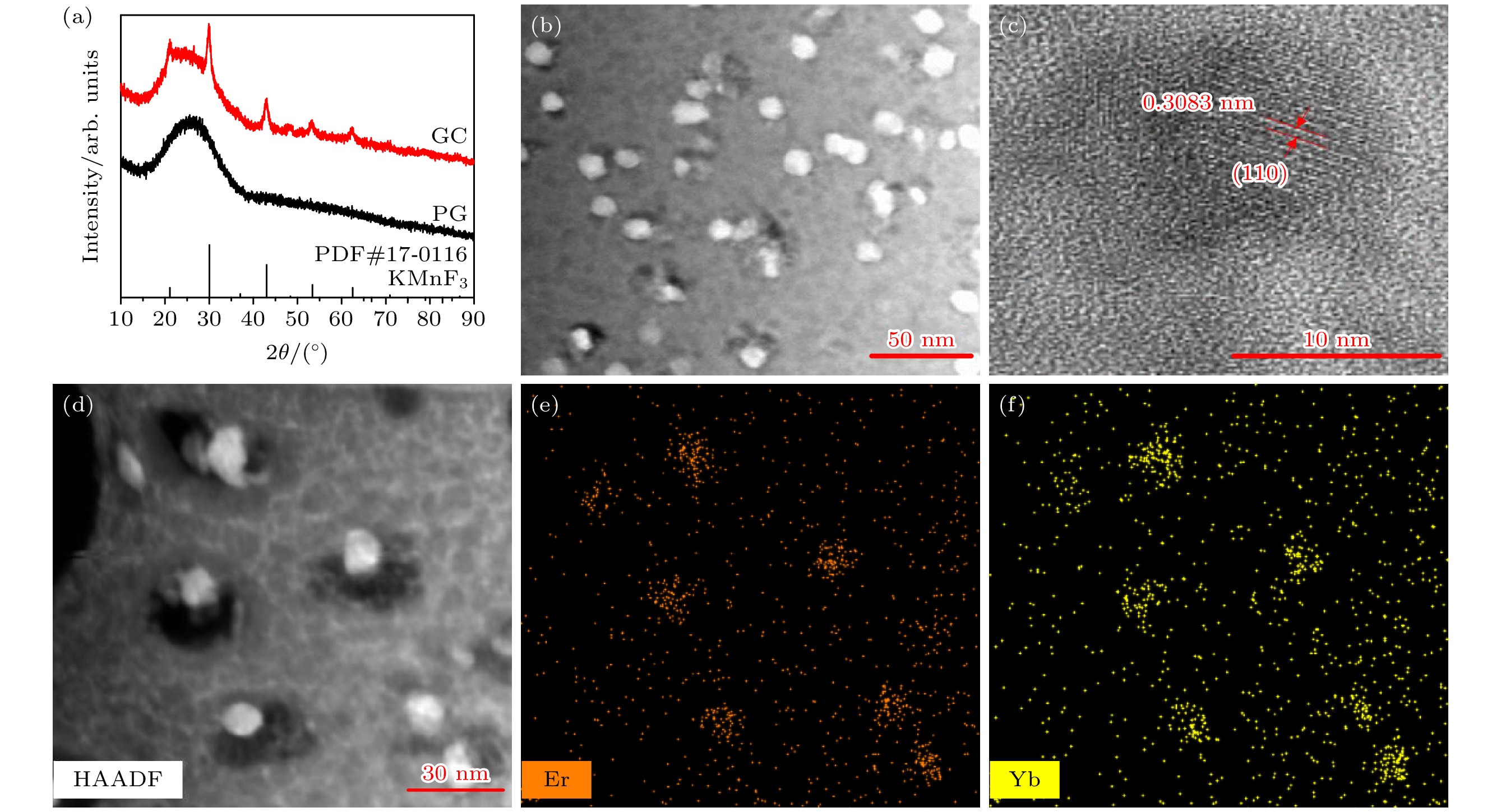

图 1 (a) 前驱体玻璃PG和微晶玻璃GC样品以及KMnF3晶体(PDF#17-0116)的X射线衍射图; 微晶玻璃样品的 (b) 暗场和 (c) 高分辨TEM图像; (d) 高角环形暗场电镜图像; 能量仪测试GC样品中稀土离子 (e) Er和 (f) Yb分布. 不同颜色的深度与元素的浓度正相关

Fig. 1. (a) X-ray diffraction (XRD) patterns of the precursor glass (PG) and the glass ceramic (GC) samples. Also shown is the standard XRD pattern of the KMnF3 crystal (PDF#17-0116); (b) dark field and (c) high resolution TEM images of the GC sample; (d) high-angle-annular-dark-field (HAADF) TEM image of the GC sample, and the corresponding elemental mappings of (e) Er and (f) Yb, with their concentrations reflected by the brightness in colors.

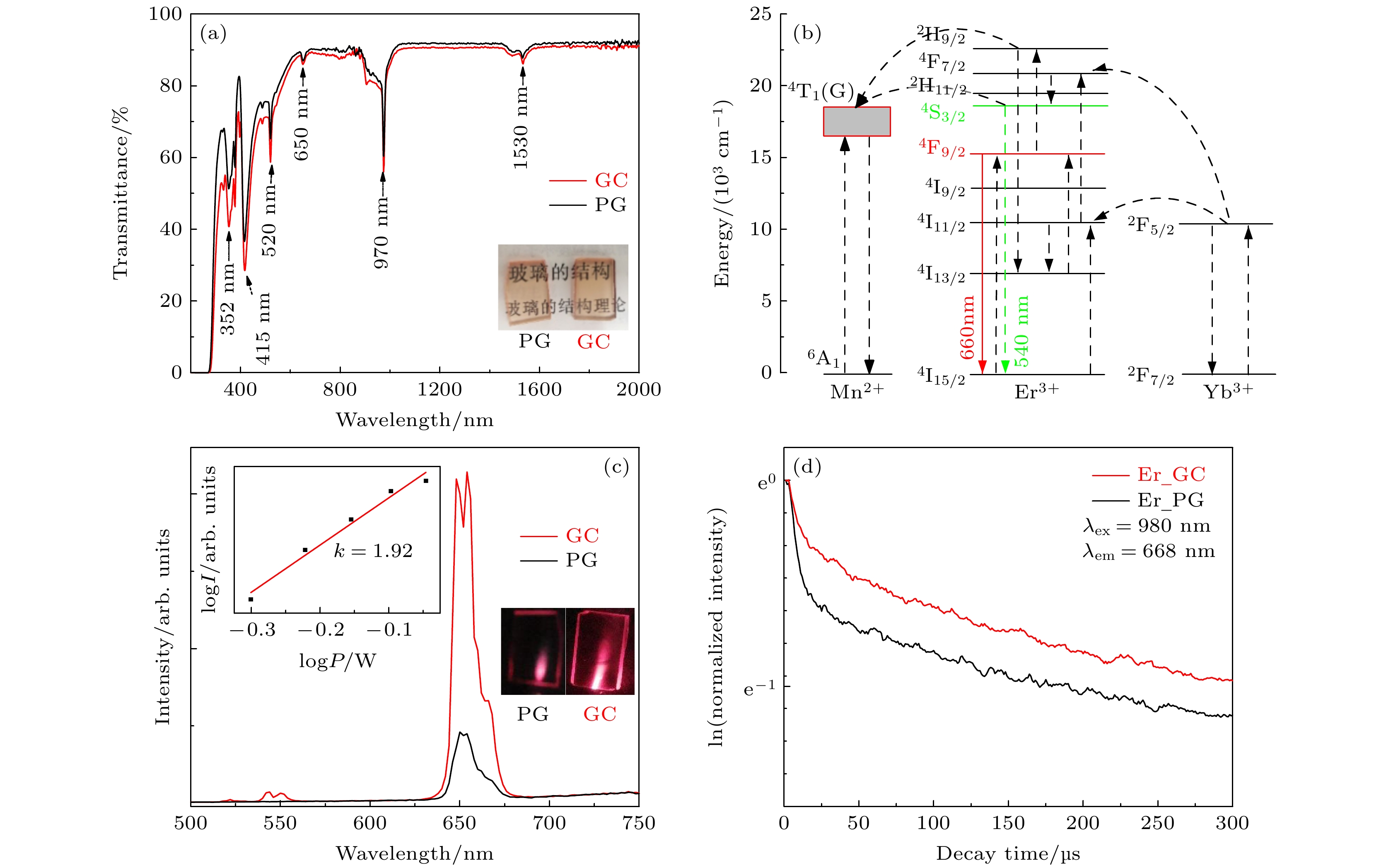

图 2 (a) 前驱体玻璃PG和微晶玻璃GC的透过光谱; (b) Mn2+调制 Yb3+/Er3+上转化发光示意图; (c) 样品的上转换荧光发射光谱; (d) 样品的668 nm荧光的衰减曲线. 激发光源为功率密度为1 W/cm2的976 nm半导体激光器. (c)中插图为样品上转换发光照片以及上转换发光强度随泵浦激光功率变化, 红线为对数据进行线性拟合

Fig. 2. (a) Transmission spectra of the PG and GC samples; (b) schematic energy-level diagram illustrating the energy transfer processes between Mn2+, Yb3+ and Er3+; (c) up-conversion luminescence (UCL) spectra of the samples. The excitation source is a 976 nm laser diode (LD) with a power density of 1 W∕cm2. Inset images: photos of the samples taken under the irradiation of a 976 nm LD and the log-log plot of UCL intensity vs. the excitation light intensity; (d) decay curves of the 658 nm red UCL emission of the samples.

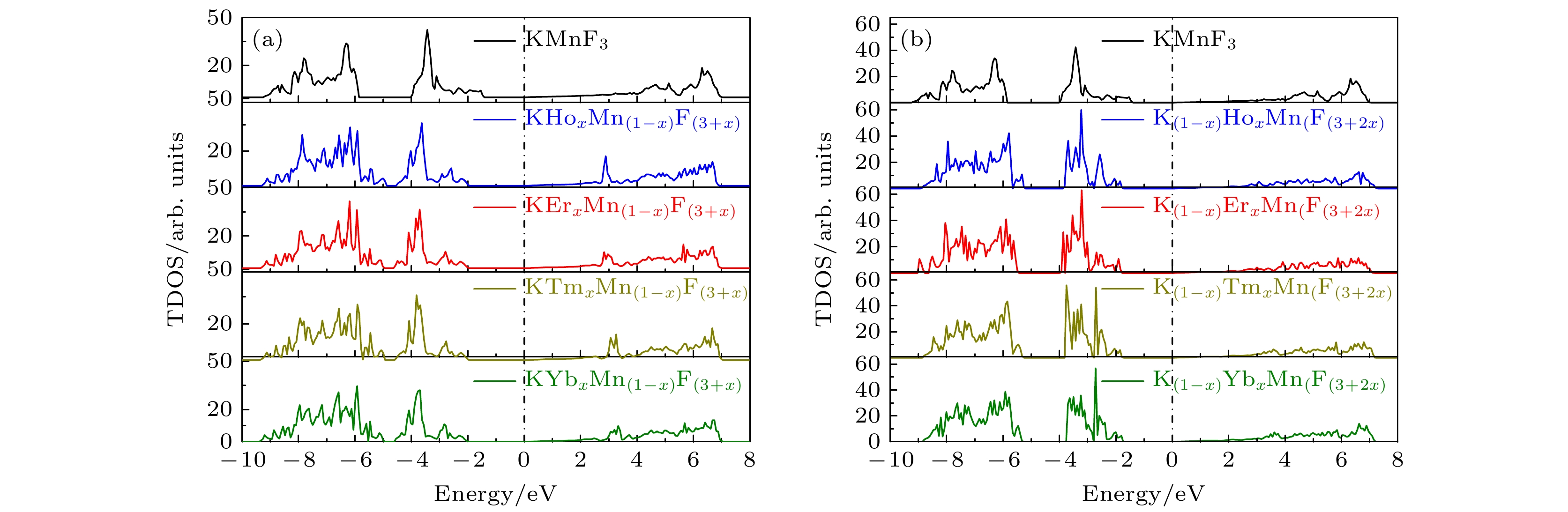

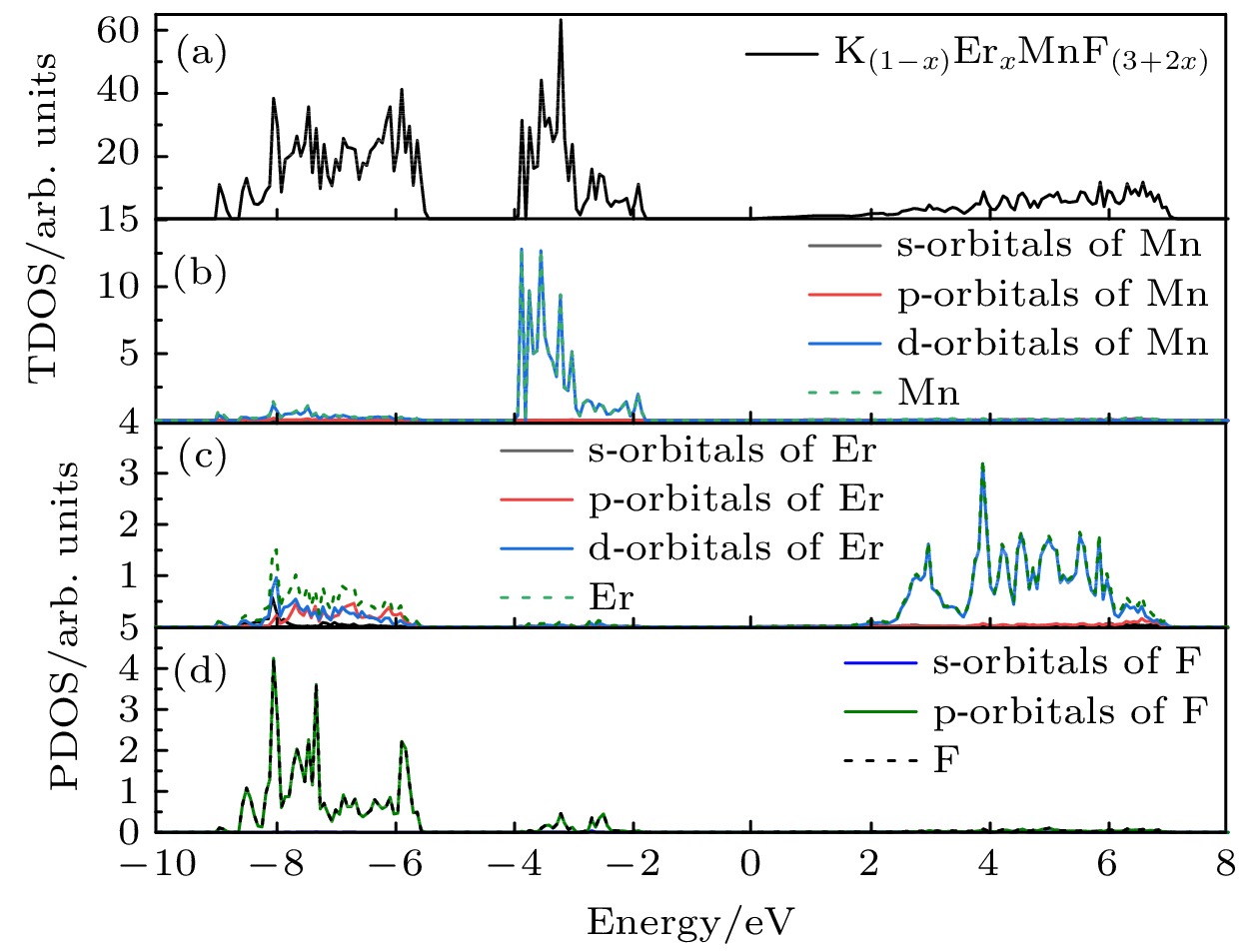

图 6 (a) Er 3+取代KMnF3中K+晶体格位后晶体的总电子态密度(TDOS); (b) Mn电子态密度图与Mn的3d, 3p和4s轨道的分波态密度(PDOS); (c) Er态密度图与Er的4d, 5p和6s轨道的分波态密度; (d) F态密度图与F的2p和2s轨道的分波态密度

Fig. 6. (a) Total density of electronic states (TDOS) of Er 3+ substituting for K+ in the KMnF3 crystal; (b) DOS of Mn (green dotted line) and partial density of states (PDOS) of the Mn 3d, 3p, 4s orbitals; (c) DOS of Er DOS and PDOS of the Er 4d, 5p, 6s orbitals; (d) DOS of F and PDOS of the F 2p and 2s orbitals.

-

[1] Zeng S J, Yi Z G, Lu W, Qian C, Wang H B, Rao L, Zeng T M., Liu H R, Liu H J, Fei B, Hao J H 2014 Adv. Funct. Mater. 24 4051

Google Scholar

Google Scholar

[2] Wu M, Jiang X F, Song E H, Su J, Chen Z T, Dai W B, Ye S, Zhang Q Y 2016 J. Mater. Chem. C 4 9598

Google Scholar

Google Scholar

[3] Song E H, Ye S, Liu T H, Du P P, Si R, Jing X P, Ding S, Peng M Y, Zhang Q Y, Wondraczek L 2015 Adv. Sci. 2 1500089

Google Scholar

Google Scholar

[4] Shi S, Sun L D, Xue Y X, Dong H, Wu K, Guo S C, Wu B, Yan C H 2018 Nano. Lett. 18 2964

Google Scholar

Google Scholar

[5] Wang J, Wang F, Wang C, Liu Z, Liu X G 2011 Angew. Chem. 123 10553

Google Scholar

Google Scholar

[6] Tian G, Gu Z J, Zhou L J, Yin W Y, Liu X X, Yan L, Jin S, Ren W L, Xing G M, Li S J, Zhao Y L 2012 Adv. Mater. 24 1226

Google Scholar

Google Scholar

[7] Zhang Y L, Wang F, Lang Y B, Yin J, Zhang M L, Liu X H, Zhang D M, Zhao D, Qin G S, Qin W P 2015 J. Mater. Chem. C 3 9827

Google Scholar

Google Scholar

[8] 任晶, 卢小送, 王鹏飞 2019 光子学报 48 1148007

Google Scholar

Google Scholar

Ren J, Lu X S, Wang P F 2019 Acta Photonica Sin. 48 1148007

Google Scholar

Google Scholar

[9] 高志刚, 肖静, 任晶 2021 激光与光电子学进展 58 1516001

Google Scholar

Google Scholar

Gao Z G, Xiao J, Ren J 2021 Laser Optoelectron. Prog. 58 1516001

Google Scholar

Google Scholar

[10] Chen J K, Peng Y Z, Li X Y, Chen W, Huang H, Lin L, Chen D Q 2019 J. Mater. Chem. C 7 4109

Google Scholar

Google Scholar

[11] Li X Y, Chen D Q, Huang F, Chang G C, Zhao J J, Qiao X S, Xu X H, Du J C, Yin M 2018 Laser Photonics Rev. 12 1800030

Google Scholar

Google Scholar

[12] Zhong J S, Chen D Q, Peng Y Z, Lu Y D, Chen X, Li X Y, Ji Z G 2018 J. Alloys Compd. 763 34

Google Scholar

Google Scholar

[13] Chen S Y Z, Song W H, Cao J K, Hu F F, Guo H 2020 J. Alloys Compd. 825 154011

Google Scholar

Google Scholar

[14] Yang Q H, Zhao L, Fang Z H, Yang Z, Cao J Y, Cai Y Y, Zhou D C, Yu X, Qiu J B, Xu X H 2021 J. Rare Earths 39 712

Google Scholar

Google Scholar

[15] Teng L M, Zhang W N, Chen W P, Gao J K, Sun X Y, Guo H 2020 Ceram. Int. 46 10718

Google Scholar

Google Scholar

[16] Chen S Y Z, Zhang W N, Teng L M, Chen J, Sun X Y, Guo H, Qiao X S 2021 J. Eur. Ceram. Soc. 41 6722

Google Scholar

Google Scholar

[17] 陈宇暄, 黄立辉, 赵静涛, 赵士龙, 徐时清 2021 发光学报 42 804

Google Scholar

Google Scholar

Chen Y X, Huang L H, Zhao L H, Zhao J T, Zhao S L, Xu S Q 2021 Chin. J. Lumin. 42 804

Google Scholar

Google Scholar

[18] Lin C G, Bocker C, Rüssel C 2015 Nano Lett. 15 6764

Google Scholar

Google Scholar

[19] Lin C G, Liu C, Zhao Z Y, Li L G, Bocker C, Rüssel C 2015 Opt. Lett. 40 5263

Google Scholar

Google Scholar

[20] Cao J K, Guo H, Hu F F, Li L Y, Xu S H, Peng M Y 2018 J. Am. Ceram. Soc. 101 3890

Google Scholar

Google Scholar

[21] Gao Z G, Guo S, Lu X S, Orava J, Wagner T, Zheng L R, Liu Y Y, Sun S Y, He F, Yang P P, Ren J, Yang J 2018 Adv. Opt. Mater. 6 1701407

Google Scholar

Google Scholar

[22] Kresse G, Furthmuller J 1996 Comp. Mater. Sci. 6 15

Google Scholar

Google Scholar

[23] Kohn W, Sham L J 1965 Phys. Rev. A 140 1133

Google Scholar

Google Scholar

[24] Perdew J P, Wang Y 1992 Phys. Rev. B 45 13244

Google Scholar

Google Scholar

[25] Hu Q L, Gao Z G, Lu X S, Ren J, He F, Fang Z J, Liu Y Y, Sun S Y, Yang P P, Wang P F 2017 J. Mater. Chem. C 5 11806

Google Scholar

Google Scholar

[26] Gao Z G, Lai Z Q, Lu K L, Guo S, Liu L, He F, Yang P P, Ren J, Zhang J Z, Yang J 2019 Opt. Lett. 44 4674

Google Scholar

Google Scholar

[27] Kapusta J, Daniel P, Ratuszna A 1999 Phys. Rev. B 59 14235

Google Scholar

Google Scholar

[28] Gao Z G, Lu X S, Zhang Y D, Guo S, Liu Y Y, Sun S Y, He F, Yang P P, Ren J, Yang J 2018 J. Am. Ceram. Soc. 101 2868

Google Scholar

Google Scholar

[29] Sun B C, Xie Y Q, Zhao Y L, Li X, Chen J F, Song Y S, Zhao L, Li Z G, Zhao H T, Ren J, Zhang J Z 2021 J. Mater. Chem. C 9 17504

Google Scholar

Google Scholar

[30] Buscaglia M T, Buscaglia V, Viviani M 2001 J. Am. Ceram. Soc 84 376

[31] Zhang C, Wang C L, Li J C, Yang K, Zhang Y F, Wu Q Z 2008 Mater. Chem. Phys. 107 215

Google Scholar

Google Scholar

[32] Shannon R D 1976 Acta Crystallogr. A 32 751

Google Scholar

Google Scholar

计量

- 文章访问数: 8514

- PDF下载量: 119

- 被引次数: 0

下载:

下载: