-

辐射制冷是一种通过光谱调控来实现降温的新型制冷技术, 相比于传统的主动制冷技术, 如吸收式制冷、压缩制冷等, 具有独特的优势, 在环境保护和能源利用方面具有重要意义. 本文首先从辐射制冷的基本原理出发, 介绍了自然界中生物所具有的辐射降温特性. 不同生物通过其材料、微观结构、行为等实现辐射制冷调控, 为人类探究新型辐射制冷材料和器件带来了启发. 本文也归纳了生物的辐射制冷机制, 总结了生物结构的优化方法, 并介绍了当前仿生辐射制冷的研究进展, 对仿生辐射制冷的研究方向、应用前景和材料制备方法进行了展望. 高功率、智能化的辐射制冷材料和器件是未来仿生辐射制冷的重要发展方向, 先进微纳加工技术的融入将使仿生辐射制冷在未来具有更广阔的市场和应用.As a new type of cooling technology, radiative cooling achieves temperature reduction through spectral regulation. Compared with the traditional active cooling technologies such as absorption-based cooling and compression-based cooling, the radiative cooling offers unique advantages, which are of great significance in environmental protection and energy utilization. First of all, the basic principle of radiative cooling and the radiative cooling within the natural biological systems are introduced in this review. The biological systems achieve their regulations of radiative cooling through controlling the materials, microstructures and behaviors in the systems, which also provide inspiration for us to explore new radiative cooling materials and devices. We also summarize the various mechanisms of radiative cooling in the biological systems and the optimization of such cooling structures. The recent research progress of bio-inspired radiative cooling is also presented. At the end, the outlook of the research directions, potential applications, and the material fabrication approaches for bio-inspired radiative cooling are discussed. The radiative cooling materials and devices with high power output and intelligent control should be an important development direction of bio-inspired radiative cooling in the future. With the integration of advanced micro/nano fabrication technology, bio-inspired radiative cooling will have a broader market and much room of applications in the future.

-

Keywords:

- radiative cooling /

- bio-inspired /

- micro/nano fabrication

[1] Raman A P, Anoma M A, Zhu L, Rephaeli E, Fan S 2014 Nature 515 540

Google Scholar

Google Scholar

[2] Chen Z, Zhu L, Raman AX, Fan S 2016 Nat. Commun. 7 13729

Google Scholar

Google Scholar

[3] Zhu L, Raman A P, Fan S 2015 P. Natl. Acad. Sci. USA. 112 12282

Google Scholar

Google Scholar

[4] Hossain M M, Jia B, Gu M 2015 Adv. Opt. Mater. 3 1047

Google Scholar

Google Scholar

[5] Mandal J, Fu Y, Overvig A C, Jia M, Sun K, Shi N N, Zhou H, Xiao X, Yu N, Yang Y 2018 Science 362 315

Google Scholar

Google Scholar

[6] Huang Z, Ruan X 2017 Int. J. Heat Mass Transfer 104 890

Google Scholar

Google Scholar

[7] Zhai Y, Ma Y, David S N, Zhao D, Lou R, Tan G, Yang R, Yin X 2017 Science 355 1062

Google Scholar

Google Scholar

[8] Gentle A R, Smith G B 2010 Nano Lett. 10 373

Google Scholar

Google Scholar

[9] Hsu P C, Song A Y, Catrysse P B, Liu C, Peng Y, Xie J, Fan S, Cui Y 2016 Science 353 1019

Google Scholar

Google Scholar

[10] Zeng S, Pian S, Su M, Wang Z, Wu M, Liu X, Chen M, Xiang Y, Wu J, Zhang M, Cen Q, Tang Y, Zhou X, Huang Z, Wang R, Tunuhe A, Sun X, Xia Z, Tian M, Chen M, Ma X, Yang L, Zhou J, Zhou H, Yang Q, Li X, Ma Y, Tao G 2021 Science 373 692

Google Scholar

Google Scholar

[11] Liu T, Takahara J 2017 Opt. Express 25 A612

Google Scholar

Google Scholar

[12] Zou C, Ren G, Hossain M M, Nirantar S, Withayachumnankul W, Ahmed T, Bhaskaran M, Sriram S, Gu M, Fumeaux C 2017 Adv. Opt. Mater. 5 1700460

Google Scholar

Google Scholar

[13] Yu H, Zhang H, Dai Z, Xia X 2019 ES Energy Environ. 6 69

Google Scholar

Google Scholar

[14] Yin X, Yang R, Tan G, Fan S 2020 Science 370 786

Google Scholar

Google Scholar

[15] Zhao B, Hu M, Ao X, Chen N, Pei G 2019 Appl. Energy 236 489

Google Scholar

Google Scholar

[16] Medina I, Newton E, Kearney M R, Mulder R A, Porter W P, Stuart-Fox D 2018 Nat. Commun. 9 3610

Google Scholar

Google Scholar

[17] Shi N N, Tsai C C, Carter M J, Mandal J, Overvig A C, Sfeir M Y, Lu M, Craig C L, Bernard G D, Yang Y, Yu N 2018 Light-Sci. Appl. 7 37

Google Scholar

Google Scholar

[18] Lou C, An S, Yang R, Zhu H, Shen Q, Jiang M, Fu B, Tao P, Song C, Deng T, Shang W 2021 APL Photonics 6 036101

Google Scholar

Google Scholar

[19] Jeong S Y, Tso C Y, Wong Y M, Chao C Y H, Huang B 2020 Sol. Energ. Mat. Sol. C. 206 110296

Google Scholar

Google Scholar

[20] Cheng Z, Han H, Wang F, Yan Y, Shi X, Liang H, Zhang X, Shuai Y 2021 Nano Energy 89 106377

Google Scholar

Google Scholar

[21] Li T, Zhai Y, He S, Gan W, Wei Z, Heidarinejad M, Dalgo D, Mi R, Zhao X, Song J, Dai J, Chen C, Aili A, Vellore A, Martini A, Yang R, Srebric J, Yin X, Hu L 2019 Science 364 760

Google Scholar

Google Scholar

[22] Zhao D, Aili A, Zhai Y, Xu S, Tan G, Yin X, Yang R 2019 Appl. Phys. Rev. 6 021306

Google Scholar

Google Scholar

[23] Chu S, Cui Y, Liu N 2017 Nat. Mater. 16 16

Google Scholar

Google Scholar

[24] Xie D, Yang Z, Liu X, Cui S, Zhou H, Fan T 2019 Soft Matter 15 4294

Google Scholar

Google Scholar

[25] Shi N N, Tsai C C, Camino F, Bernard G D, Yu N, Wehner R 2015 Science 349 298

Google Scholar

Google Scholar

[26] Zhang H, Ly K C S, Liu X, Chen Z, Yan M, Wu Z, Wang X, Zheng Y, Zhou H, Fan T 2020 P. Natl. Acad. Sci. USA. 117 14657

Google Scholar

Google Scholar

[27] Krishna A, Nie X, Warren A D, Llorente-Bousquets J E, Briscoe A D, Lee J 2020 P. Natl. Acad. Sci. USA. 117 1566

Google Scholar

Google Scholar

[28] Liu X, Wang D, Yang Z, Zhou H, Zhao Q, Fan T 2019 Adv. Opt. Mater. 7 1900687

Google Scholar

Google Scholar

[29] Tsai C C, Childers R A, Shi N N, Ren C, Pelaez J N, Bernard G D, Pierce N E, Yu N 2020 Nat. Commun. 11 551

Google Scholar

Google Scholar

[30] Stuart-Fox D, Newton E, Clusella-Trullas S 2017 Phil. Trans. R. Soc. B 372 20160345

Google Scholar

Google Scholar

[31] Krishna A, Lee J 2018 Nanosc. Microsc. Therm. Eng. 22 124

Google Scholar

Google Scholar

[32] Choi S H, Kim S W, Ku Z, Visbal-Onufrak M A, Kim S R, Choi K H, Ko H, Choi W, Urbas A M, Goo T W, Kim Y L 2018 Nat. Commun. 9 452

Google Scholar

Google Scholar

[33] Yang Z, Sun H, Xi Y, Qi Y, Mao Z, Wang P, Zhang J 2021 Sol. Energ. Mat. Sol. C. 227 111101

Google Scholar

Google Scholar

-

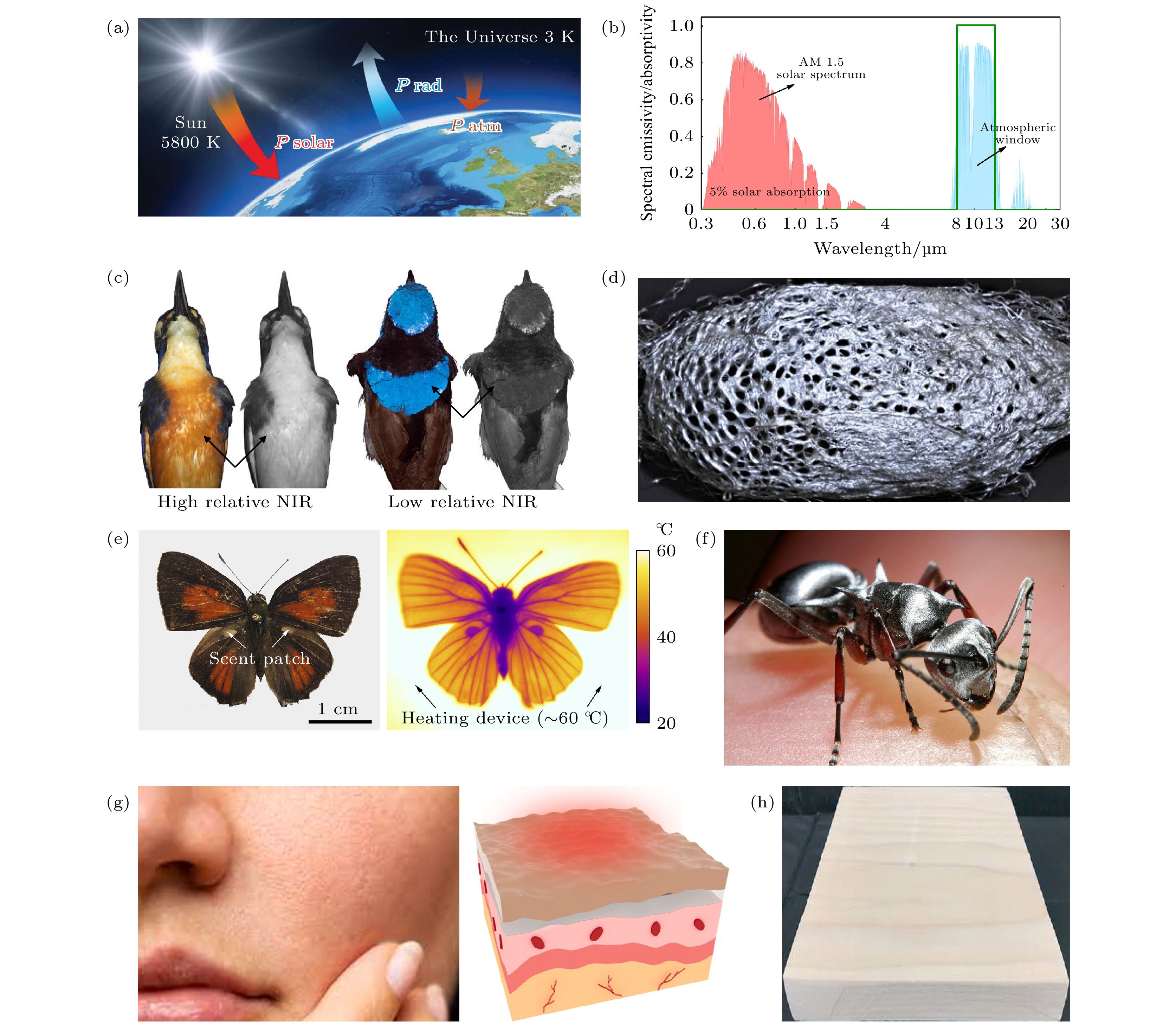

图 1 辐射制冷原理及自然界中对仿生辐射制冷具有启发性的生物和材料 (a) 发生在地球表面的辐射热流示意图[14]. Psolar, 地球表面对太阳辐射的吸收; Prad, 地球表面发射的热辐射; Patm, 地球表面对大气热辐射的吸收. (b) AM 1.5太阳光谱和典型的大气透明窗口[15]. (c)−(h) 典型的具有辐射制冷特性的生物体和生物材料, 依次为具有不同近红外发射特性的鸟类[16] (c), 彗星蛾蚕茧[17] (d), 滴燕灰蝶及其红外图像[18] (e), 撒哈拉沙漠银蚁[19] (f), 人类皮肤褶皱及其结构示意图[20] (g), 木材纤维[21] (h)

Fig. 1. Principles of radiative cooling and the nature organism that are inspirational for bio-inspired radiative cooling: (a) Schematic of radiative energy flows occurring at the terrestrial surfaces[14]. Psolar, solar radiation absorbed by the terrestrial surfaces; Prad, thermal radiation emitted by the terrestrial surfaces; Patm, atmospheric thermal radiation absorbed by the terrestrial surfaces. (b) AM 1.5 solar spectrum and typical atmospheric window[15]. (c)−(h) Typical organisms and biomaterials with radiative cooling properties: (c) Birds with different near-infrared (NIR) emissivity[16]; (d) comet moth cocoon[17]; (e) butterfly Rapala dioetas and its infrared image[18]; (f) Saharan silver ant[19]; (g) human skin and the structural schematic[20]; (h) wood fiber[21].

图 2 不同种类昆虫的热调节生物结构 (a) 白甲虫Goliathus goliatus的体温调节机制[24] (i)白甲虫的光学照片, (ii)鳞片的壳/空心圆筒结构的扫描电子显微镜图及横截面的透射电子显微镜图, (iii)壳/空心圆筒结构内部全反射示意图, 插图为不同入射角(θ1和θ2)下的薄膜干涉, (iv)中红外波段壳/空心圆筒结构、空心圆筒和实心圆筒的模拟反射光谱; (b) 撒哈拉沙漠银蚁Catagliphis bombycine[25] (i)银蚁的光学照片和其头部的扫描电子显微镜图, (ii)密排三角形毛发的扫描电子显微镜图; (c) 天牛neocerambyx gigas[26] (i) 天牛的光学照片, (ii)天牛绒毛的扫描电子显微镜图; (d) (i)四种不同蝶翅鳞片的“井字形”周期微结构模型及其(ii)在中红外波段的发射率[27]; (e) 尖翅银灰蝶[28] (i)光学照片, (ii)亮银色鳞片的扫描电子显微镜图, (iii)亮银色鳞片横截面的透射电子显微镜图

Fig. 2. Thermoregulatory biological structure of different insect species. (a) Thermoregulatory mechanism of Goliathus goliatus[24]: (i) Photograph of a male Goliathus goliatus; (ii) scanning electron microscopy (SEM) image of the shell / hollow cylinder structure and transmission electron microscopy (TEM) image of cross-section; (iii) schematic of total reflection in the shell / hollow cylinder structure, inset is the thin-film interference at different incident angles (θ1 and θ2); (iv) simulated reflectance spectra of shell/hollow cylinder structure, hollow cylinders and solid cylinders in the mid-infrared (MIR) band. (b) Catagliphis bombycine[25]: (i) Optical photograph and SEM frontal view of the head; (ii) SEM image of the dense triangular hair. (c) Neocerambyx gigas[26]: (i) Optical photograph; (ii) SEM image of the fluffs covering on the forewing. (d) (i) Periodic microstructure models of four different butterfly wing scales and (ii) their emission spectrum in the mid-infrared band[27]. (e) Butterfly Curetis acuta Moore[28]: (i) Optical photograph; (ii) SEM image of the central part of a silver scale, (iii) cross section TEM image of the silver scales.

图 3 仿生辐射制冷材料及其制备 (a) 天牛绒毛的仿生模型[26] (i)从绒毛到仿生辐射制冷薄膜材料的生物启发示意图; (ii)仿生辐射制冷薄膜的结构及其对可见光的反射和红外发射特性. (b) 用于辐射热管理的(i)微尺度树状结构及(ii)发射光谱[31]. (c) 彗星蛾蚕丝[17] (i)蚕丝的光学显微镜图; (ii)蚕丝横截面的扫描电子显微镜图; (iii)含有高密度孔隙的再生丝素蛋白纤维(上)和聚偏二氟乙烯纤维(下)的横截面及纵截面的扫描电子显微镜图. (d) 对木材进行脱木素和致密化处理得到的辐射制冷结构材料[21] (i)光学照片; (ii)对太阳光的散射和纤维素官能团分子振动导致的红外发射示意图. (e) 受天然纤维启发的辐射制冷材料[33] (i) 棉花的光学照片及微观结构示意图; (ii) 两种微孔聚丙烯片材的顶部和横截面视图的显微照片; (iii) 微孔聚丙烯片材的反射和发射特性

Fig. 3. Bio-inspired radiative cooling materials and the fabrication of such materials. (a) The bio-inspired model from neocerambyx gigas[26]: (i) Bio-inspired schematic diagram from fluff to radiative cooling film; (ii) structure of the radiative cooling film and its reflection characteristics for visible light and infrared emission. (b) (i) Micro-tree structures and (ii) their emissivity spectrum for radiation thermal management[31]. (c) Comet moth cocoon fibers[17]: (i) Optical microscopy image; (ii) SEM image of the transverse cross-section of a comet moth silk fiber; (iii) SEM images of the cross-section and longitudinal-section of regenerated silk fiber (upper) and polyvinylidene difluoride fiber (lower) containing high-density pores. (d) Wood for radiative cooling[21]: (i) Optical photograph; (ii) schematic of the wood structure in scattering solar irradiance and infrared emission caused by molecular vibration of cellulose functional groups. (e) Radiative cooling materials inspired by the natural fibers[33]: (i) Photograph of raw cotton and the schematic of its microstructure; (ii) micrographs showing top and cross-section views of the macroporous PP/SBS sheet and PP/SEPS sheet; (iii) reflection and emission characteristics of the macroporous PP sheets.

-

[1] Raman A P, Anoma M A, Zhu L, Rephaeli E, Fan S 2014 Nature 515 540

Google Scholar

Google Scholar

[2] Chen Z, Zhu L, Raman AX, Fan S 2016 Nat. Commun. 7 13729

Google Scholar

Google Scholar

[3] Zhu L, Raman A P, Fan S 2015 P. Natl. Acad. Sci. USA. 112 12282

Google Scholar

Google Scholar

[4] Hossain M M, Jia B, Gu M 2015 Adv. Opt. Mater. 3 1047

Google Scholar

Google Scholar

[5] Mandal J, Fu Y, Overvig A C, Jia M, Sun K, Shi N N, Zhou H, Xiao X, Yu N, Yang Y 2018 Science 362 315

Google Scholar

Google Scholar

[6] Huang Z, Ruan X 2017 Int. J. Heat Mass Transfer 104 890

Google Scholar

Google Scholar

[7] Zhai Y, Ma Y, David S N, Zhao D, Lou R, Tan G, Yang R, Yin X 2017 Science 355 1062

Google Scholar

Google Scholar

[8] Gentle A R, Smith G B 2010 Nano Lett. 10 373

Google Scholar

Google Scholar

[9] Hsu P C, Song A Y, Catrysse P B, Liu C, Peng Y, Xie J, Fan S, Cui Y 2016 Science 353 1019

Google Scholar

Google Scholar

[10] Zeng S, Pian S, Su M, Wang Z, Wu M, Liu X, Chen M, Xiang Y, Wu J, Zhang M, Cen Q, Tang Y, Zhou X, Huang Z, Wang R, Tunuhe A, Sun X, Xia Z, Tian M, Chen M, Ma X, Yang L, Zhou J, Zhou H, Yang Q, Li X, Ma Y, Tao G 2021 Science 373 692

Google Scholar

Google Scholar

[11] Liu T, Takahara J 2017 Opt. Express 25 A612

Google Scholar

Google Scholar

[12] Zou C, Ren G, Hossain M M, Nirantar S, Withayachumnankul W, Ahmed T, Bhaskaran M, Sriram S, Gu M, Fumeaux C 2017 Adv. Opt. Mater. 5 1700460

Google Scholar

Google Scholar

[13] Yu H, Zhang H, Dai Z, Xia X 2019 ES Energy Environ. 6 69

Google Scholar

Google Scholar

[14] Yin X, Yang R, Tan G, Fan S 2020 Science 370 786

Google Scholar

Google Scholar

[15] Zhao B, Hu M, Ao X, Chen N, Pei G 2019 Appl. Energy 236 489

Google Scholar

Google Scholar

[16] Medina I, Newton E, Kearney M R, Mulder R A, Porter W P, Stuart-Fox D 2018 Nat. Commun. 9 3610

Google Scholar

Google Scholar

[17] Shi N N, Tsai C C, Carter M J, Mandal J, Overvig A C, Sfeir M Y, Lu M, Craig C L, Bernard G D, Yang Y, Yu N 2018 Light-Sci. Appl. 7 37

Google Scholar

Google Scholar

[18] Lou C, An S, Yang R, Zhu H, Shen Q, Jiang M, Fu B, Tao P, Song C, Deng T, Shang W 2021 APL Photonics 6 036101

Google Scholar

Google Scholar

[19] Jeong S Y, Tso C Y, Wong Y M, Chao C Y H, Huang B 2020 Sol. Energ. Mat. Sol. C. 206 110296

Google Scholar

Google Scholar

[20] Cheng Z, Han H, Wang F, Yan Y, Shi X, Liang H, Zhang X, Shuai Y 2021 Nano Energy 89 106377

Google Scholar

Google Scholar

[21] Li T, Zhai Y, He S, Gan W, Wei Z, Heidarinejad M, Dalgo D, Mi R, Zhao X, Song J, Dai J, Chen C, Aili A, Vellore A, Martini A, Yang R, Srebric J, Yin X, Hu L 2019 Science 364 760

Google Scholar

Google Scholar

[22] Zhao D, Aili A, Zhai Y, Xu S, Tan G, Yin X, Yang R 2019 Appl. Phys. Rev. 6 021306

Google Scholar

Google Scholar

[23] Chu S, Cui Y, Liu N 2017 Nat. Mater. 16 16

Google Scholar

Google Scholar

[24] Xie D, Yang Z, Liu X, Cui S, Zhou H, Fan T 2019 Soft Matter 15 4294

Google Scholar

Google Scholar

[25] Shi N N, Tsai C C, Camino F, Bernard G D, Yu N, Wehner R 2015 Science 349 298

Google Scholar

Google Scholar

[26] Zhang H, Ly K C S, Liu X, Chen Z, Yan M, Wu Z, Wang X, Zheng Y, Zhou H, Fan T 2020 P. Natl. Acad. Sci. USA. 117 14657

Google Scholar

Google Scholar

[27] Krishna A, Nie X, Warren A D, Llorente-Bousquets J E, Briscoe A D, Lee J 2020 P. Natl. Acad. Sci. USA. 117 1566

Google Scholar

Google Scholar

[28] Liu X, Wang D, Yang Z, Zhou H, Zhao Q, Fan T 2019 Adv. Opt. Mater. 7 1900687

Google Scholar

Google Scholar

[29] Tsai C C, Childers R A, Shi N N, Ren C, Pelaez J N, Bernard G D, Pierce N E, Yu N 2020 Nat. Commun. 11 551

Google Scholar

Google Scholar

[30] Stuart-Fox D, Newton E, Clusella-Trullas S 2017 Phil. Trans. R. Soc. B 372 20160345

Google Scholar

Google Scholar

[31] Krishna A, Lee J 2018 Nanosc. Microsc. Therm. Eng. 22 124

Google Scholar

Google Scholar

[32] Choi S H, Kim S W, Ku Z, Visbal-Onufrak M A, Kim S R, Choi K H, Ko H, Choi W, Urbas A M, Goo T W, Kim Y L 2018 Nat. Commun. 9 452

Google Scholar

Google Scholar

[33] Yang Z, Sun H, Xi Y, Qi Y, Mao Z, Wang P, Zhang J 2021 Sol. Energ. Mat. Sol. C. 227 111101

Google Scholar

Google Scholar

计量

- 文章访问数: 16055

- PDF下载量: 839

- 被引次数: 0

下载:

下载: