-

碳纳米管晶体管作为新一代纳米器件, 由于缺乏成熟的阈值电压调控机制, 仍难以运用到实际逻辑电路中. 本文提出了一种简单易实现且能够大规模处理的表面掺杂方法, 通过AuCl3的p型掺杂作用来实现对晶体管阈值电压的有效调控, 研究了不同掺杂浓度对碳纳米管电学性能的影响. 实验结果表明, 在低掺杂浓度条件下, 不仅实现了晶体管阈值电压稳定调控, 器件导电性能也大幅提高, 迁移率提升2—3倍. 更进一步地, 研究了退火对掺杂后器件的电学性能影响, 发现在同等掺杂条件下, 退火温度达到50 ℃时, p型掺杂效果最佳. 最后采用第一性原理计算方法, 验证了金离子对碳纳米管的掺杂调控机制. 这项研究为未来实现大面积低功耗逻辑电路以及高性能电子器件提供了重要指导.Carbon nanotube-based field-effect transistors (CNFETs), as a new generation of nanodevices, are still difficult to apply to actual logic circuits due to the lack of a mature threshold voltage control mechanism. Here in this work, a feasible and large-scale processing surface doping method is demonstrated to effectively modulate the threshold voltage of CNFETs through the p-type doping effect of gold chloride (AuCl3). A comprehensive mapping from electrical parameters (Ion/Ioff, Vth and mobility) to doping concentration is carefully investigated, demonstrating a p-doping effect induced by surface charge transfer between Au3+ and carbon nanotube networks (CNTs). Threshold voltage of CNFETs can be effectively adjusted by varying the doping concentration. More importantly, the devices doped with low concentration AuCl3 exhibit good electrical properties including greatly improved electrical conductivity, 2–3 times higher in mobility than intrinsic carbon nanotubes. Furthermore, the effects of annealing on the electrical properties of the AuCl3-doping CNFETs are studied, demonstrating that the p-type doping effect reaches the optimized state at a temperature of 50 °C. Finally, first-principles calculation method is used to verify the doping control mechanism of Au3+ to carbon nanotubes. This research provides important guidance for realizing large-area low-power logic circuits and high-performance electronic devices in the future.

-

Keywords:

- carbon nanotube networks /

- surface doping /

- threshold voltage modulation /

- density functional theory

[1] Waldrop M 2016 Nature 530 144

Google Scholar

Google Scholar

[2] Markov I 2014 Nature 512 147

Google Scholar

Google Scholar

[3] Wang H M, He M S, Zhang Y Y 2019 Acta Phys. Chim. Sin. 35 1207

Google Scholar

Google Scholar

[4] Feng P, Xu W W, Yang Y, Wan X, Shi Y, Wan Q, Zhao J W, Cui Z 2017 Adv. Funct. Mater. 27 1604447

Google Scholar

Google Scholar

[5] Esqueda I, Yan X D, Rutherglen C, Kane A, Cain T, Marsh P, Liu Q Z, Galatsis K, Wang H, Zhou C W 2018 ACS Nano 12 7352

Google Scholar

Google Scholar

[6] Dai S L, Zhao Y W, Wang Y, Zhang J Y, Fang L, Jin S, Shao Y L, Huang J 2019 Adv. Funct. Mater. 29 1903700

Google Scholar

Google Scholar

[7] Zhong D L, Zhao C Y, Liu L J, Zhang Z Y, Peng L 2018 Appl. Phys. Lett. 112 153109

Google Scholar

Google Scholar

[8] Kawanago T, Oda S 2017 Appl. Phys. Lett. 110 133507

Google Scholar

Google Scholar

[9] Lee H, Kim J, Lee C 2016 Appl. Phys. Lett. 109 222105

Google Scholar

Google Scholar

[10] Lee H, Shin J, Jeon P, Lee J, Kim J, Hwang H, Park E, Yoon W, Ju S, Im S 2015 Small 11 2132

Google Scholar

Google Scholar

[11] Zschieschang U, Holzmann T, Kuhn A, Aghamohammadi M, Lotsch B V, Klauk H 2015 J. Appl. Phys. 117 104509

Google Scholar

Google Scholar

[12] Choi H C, Shim M, Bangsaruntip S, Dai H 2002 J. Am. Chem. Soc. 124 9057

Google Scholar

Google Scholar

[13] Shin N, Zessin J, Lee M H, Hambsch M, Mannsfeld S C B 2018 Adv. Funct. Mater. 28 1802265

Google Scholar

Google Scholar

[14] Kharlamova M V, Kramberger C, Saito T, Sato Y, Suenaga K, Pichler T, Shiozawa H 2017 Nanoscale 9 7998

Google Scholar

Google Scholar

[15] 张华林, 何鑫, 张振华 2021 70 056101

Google Scholar

Google Scholar

Zhang H L, He X, Zhang Z H 2021 Acta Phys. Sin. 70 056101

Google Scholar

Google Scholar

[16] Shin D H, Kim J M, Jang C W, Kim J H, Kim S, Choi S H 2013 J. Appl. Phys. 113 064305

Google Scholar

Google Scholar

[17] Choi D C, Kim M, Song Y J, Hussain S, Song W S, An K S, Jung J 2018 Appl. Surf. Sci. 427 48

Google Scholar

Google Scholar

[18] Kim K K, Reina A, Shi Y, Park H, Li L J, Lee Y H, Kong J 2010 Nanotechnology 21 285205

Google Scholar

Google Scholar

[19] 王苏杰, 李树强, 吴小明, 陈芳, 江风益 2020 69 048103

Google Scholar

Google Scholar

Wang S J, Li S Q, Wu X M, Chen F, Jiang F Y 2020 Acta Phys. Sin. 69 048103

Google Scholar

Google Scholar

[20] Kim S M, Kim K K, Jo Y W, Park M H, Chae S J, Duong D L, Yang C W, Kong J, Lee Y H 2011 ACS Nano 5 1236

Google Scholar

Google Scholar

[21] Xu J L, Dai R X, Xin Y, Sun Y L, Li X, Yu Y X, Xiang L, Xie D, Wang S D, Ren T L 2017 Sci. Rep. 76 751

Google Scholar

Google Scholar

[22] Yoon S M, Kim U J, Benayad A, Lee I H, Son H, Shin H J, Choi W M, LeeY H, Jin Y W, Lee E H, Lee S Y, Choi J Y, Kim J M 2011 ACS Nano 5 1352

Google Scholar

Google Scholar

[23] 张辉, 蔡晓明, 郝振亮, 阮子林, 卢建臣, 蔡金明 2017 66 218103

Google Scholar

Google Scholar

Zhang H, Cai X M, Hao Z L, Ruan Z L, Lu J C, Cai J M 2017 Acta Phys. Sin. 66 218103

Google Scholar

Google Scholar

[24] Perdew J P, Burke K, Ernzerhof M 1998 Phys. Rev. Lett. 80 891

Google Scholar

Google Scholar

[25] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[26] Kresse G, Joubert D 1999 Phys. Lett. B 59 1758

Google Scholar

Google Scholar

[27] Blöchl P E 1994 Phys. Lett. B 50 17953

Google Scholar

Google Scholar

[28] Monkhorst H J, Pack J D 1976 Phys. Lett. B 13 5188

Google Scholar

Google Scholar

-

图 4 (a) 不同掺杂浓度下碳纳米管的拉曼光谱; (b) 不同掺杂浓度下碳纳米管晶体管的转移特性曲线, 漏源电压Vds被固定在–1 V; (c) 阈值电压随AuCl3浓度的变化曲线, 插图为从转移特性曲线中提取阈值电压的计算方式; (d) 开关比以及迁移率随AuCl3浓度的变化曲线

Fig. 4. Modulation of the AuCl3 concentration on the electrical performance of CNFET: (a) Raman Spectra of the CNT under different doping concentrations; (b) the transfer curves (Ids-Vg) of a CNFET device with different doping concentrations, with the drain-source voltage fixed at –1 V; (c) threshold voltage value of the doped CNFET device as a function of AuCl3 concentration. The inset illustrates the calculation method of threshold voltage extracted from transfer curves; (d) ON/OFF current ratio (Ion/Ioff) and the field-effect mobility ratio (μratio = μdoped/μpristine) as a function of the doping concentrations.

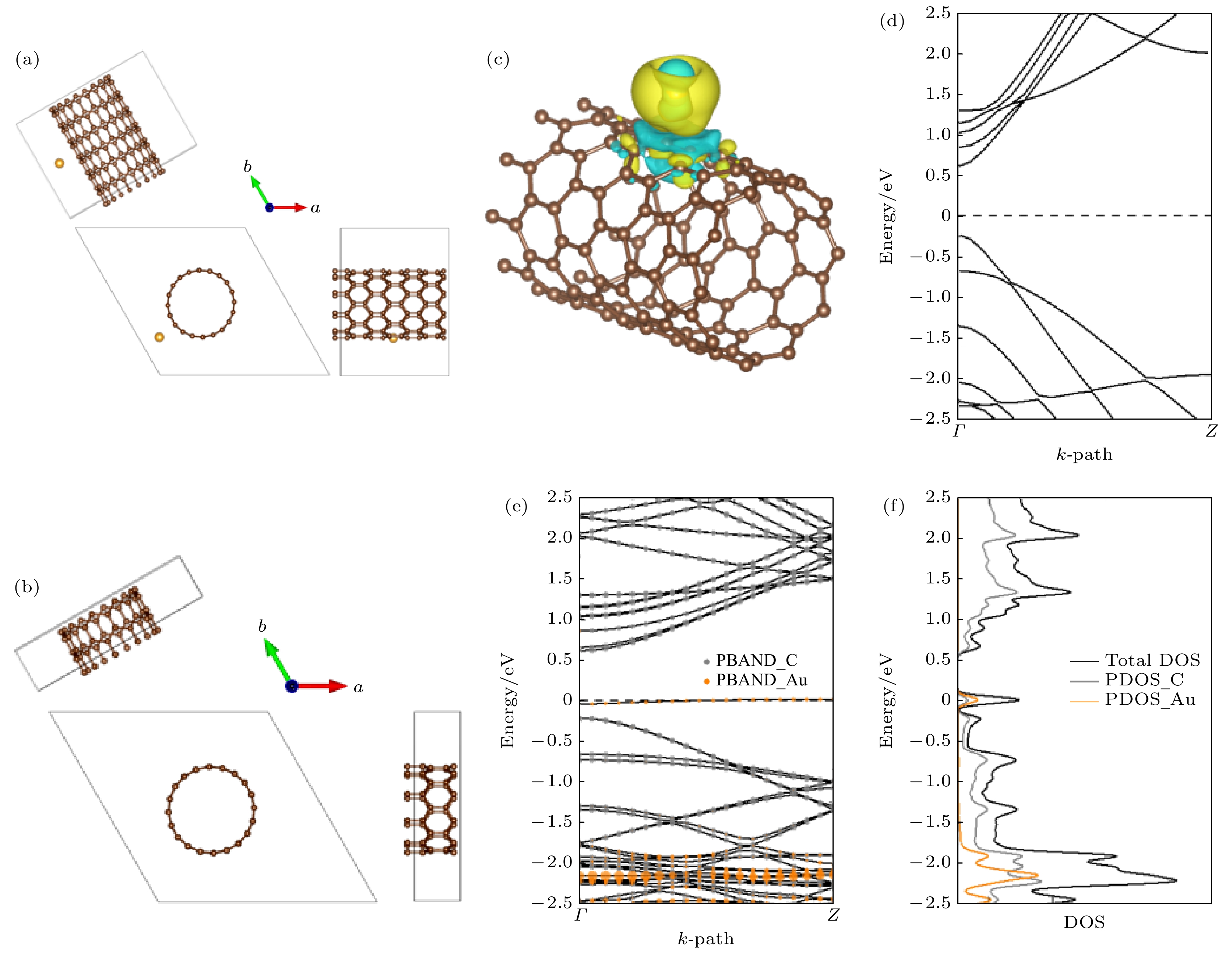

图 6 (a), (b) 碳纳米管与金/碳纳米管的晶胞结构; (c) 金/碳纳米管的二次差分密度图; (d) (10, 0)碳纳米管的能带结构图, 虚线为费米能级; (e) 金/碳纳米管系统的能带结构和投影能带, 灰色气泡为每个k点处碳元素的权重, 橙色气泡则为金元素对应的权重; (f) 金/碳纳米管系统的态密度和投影态密度, 黑色实线为总态密度, 灰色实线为投影到碳元素的态密度, 橙色实线为投影到金元素的态密度

Fig. 6. (a) (b) Crystal structures of CNT and Au/CNT are presented in; (c) Au/CNT difference charge density plot; (d) band structure of (10, 0) CNT, with dash line the Fermi energy; (e) band structure and projected band structure of each element, with solid line the total bands, gray bubble the projected weights of C, orange bubble the projected weights of Au; (f) total DOS and projected DOS, with black solid line the total DOS, gray solid line PDOS of C, orange solid line PDOS of Au.

-

[1] Waldrop M 2016 Nature 530 144

Google Scholar

Google Scholar

[2] Markov I 2014 Nature 512 147

Google Scholar

Google Scholar

[3] Wang H M, He M S, Zhang Y Y 2019 Acta Phys. Chim. Sin. 35 1207

Google Scholar

Google Scholar

[4] Feng P, Xu W W, Yang Y, Wan X, Shi Y, Wan Q, Zhao J W, Cui Z 2017 Adv. Funct. Mater. 27 1604447

Google Scholar

Google Scholar

[5] Esqueda I, Yan X D, Rutherglen C, Kane A, Cain T, Marsh P, Liu Q Z, Galatsis K, Wang H, Zhou C W 2018 ACS Nano 12 7352

Google Scholar

Google Scholar

[6] Dai S L, Zhao Y W, Wang Y, Zhang J Y, Fang L, Jin S, Shao Y L, Huang J 2019 Adv. Funct. Mater. 29 1903700

Google Scholar

Google Scholar

[7] Zhong D L, Zhao C Y, Liu L J, Zhang Z Y, Peng L 2018 Appl. Phys. Lett. 112 153109

Google Scholar

Google Scholar

[8] Kawanago T, Oda S 2017 Appl. Phys. Lett. 110 133507

Google Scholar

Google Scholar

[9] Lee H, Kim J, Lee C 2016 Appl. Phys. Lett. 109 222105

Google Scholar

Google Scholar

[10] Lee H, Shin J, Jeon P, Lee J, Kim J, Hwang H, Park E, Yoon W, Ju S, Im S 2015 Small 11 2132

Google Scholar

Google Scholar

[11] Zschieschang U, Holzmann T, Kuhn A, Aghamohammadi M, Lotsch B V, Klauk H 2015 J. Appl. Phys. 117 104509

Google Scholar

Google Scholar

[12] Choi H C, Shim M, Bangsaruntip S, Dai H 2002 J. Am. Chem. Soc. 124 9057

Google Scholar

Google Scholar

[13] Shin N, Zessin J, Lee M H, Hambsch M, Mannsfeld S C B 2018 Adv. Funct. Mater. 28 1802265

Google Scholar

Google Scholar

[14] Kharlamova M V, Kramberger C, Saito T, Sato Y, Suenaga K, Pichler T, Shiozawa H 2017 Nanoscale 9 7998

Google Scholar

Google Scholar

[15] 张华林, 何鑫, 张振华 2021 70 056101

Google Scholar

Google Scholar

Zhang H L, He X, Zhang Z H 2021 Acta Phys. Sin. 70 056101

Google Scholar

Google Scholar

[16] Shin D H, Kim J M, Jang C W, Kim J H, Kim S, Choi S H 2013 J. Appl. Phys. 113 064305

Google Scholar

Google Scholar

[17] Choi D C, Kim M, Song Y J, Hussain S, Song W S, An K S, Jung J 2018 Appl. Surf. Sci. 427 48

Google Scholar

Google Scholar

[18] Kim K K, Reina A, Shi Y, Park H, Li L J, Lee Y H, Kong J 2010 Nanotechnology 21 285205

Google Scholar

Google Scholar

[19] 王苏杰, 李树强, 吴小明, 陈芳, 江风益 2020 69 048103

Google Scholar

Google Scholar

Wang S J, Li S Q, Wu X M, Chen F, Jiang F Y 2020 Acta Phys. Sin. 69 048103

Google Scholar

Google Scholar

[20] Kim S M, Kim K K, Jo Y W, Park M H, Chae S J, Duong D L, Yang C W, Kong J, Lee Y H 2011 ACS Nano 5 1236

Google Scholar

Google Scholar

[21] Xu J L, Dai R X, Xin Y, Sun Y L, Li X, Yu Y X, Xiang L, Xie D, Wang S D, Ren T L 2017 Sci. Rep. 76 751

Google Scholar

Google Scholar

[22] Yoon S M, Kim U J, Benayad A, Lee I H, Son H, Shin H J, Choi W M, LeeY H, Jin Y W, Lee E H, Lee S Y, Choi J Y, Kim J M 2011 ACS Nano 5 1352

Google Scholar

Google Scholar

[23] 张辉, 蔡晓明, 郝振亮, 阮子林, 卢建臣, 蔡金明 2017 66 218103

Google Scholar

Google Scholar

Zhang H, Cai X M, Hao Z L, Ruan Z L, Lu J C, Cai J M 2017 Acta Phys. Sin. 66 218103

Google Scholar

Google Scholar

[24] Perdew J P, Burke K, Ernzerhof M 1998 Phys. Rev. Lett. 80 891

Google Scholar

Google Scholar

[25] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[26] Kresse G, Joubert D 1999 Phys. Lett. B 59 1758

Google Scholar

Google Scholar

[27] Blöchl P E 1994 Phys. Lett. B 50 17953

Google Scholar

Google Scholar

[28] Monkhorst H J, Pack J D 1976 Phys. Lett. B 13 5188

Google Scholar

Google Scholar

计量

- 文章访问数: 8298

- PDF下载量: 114

- 被引次数: 0

下载:

下载: