-

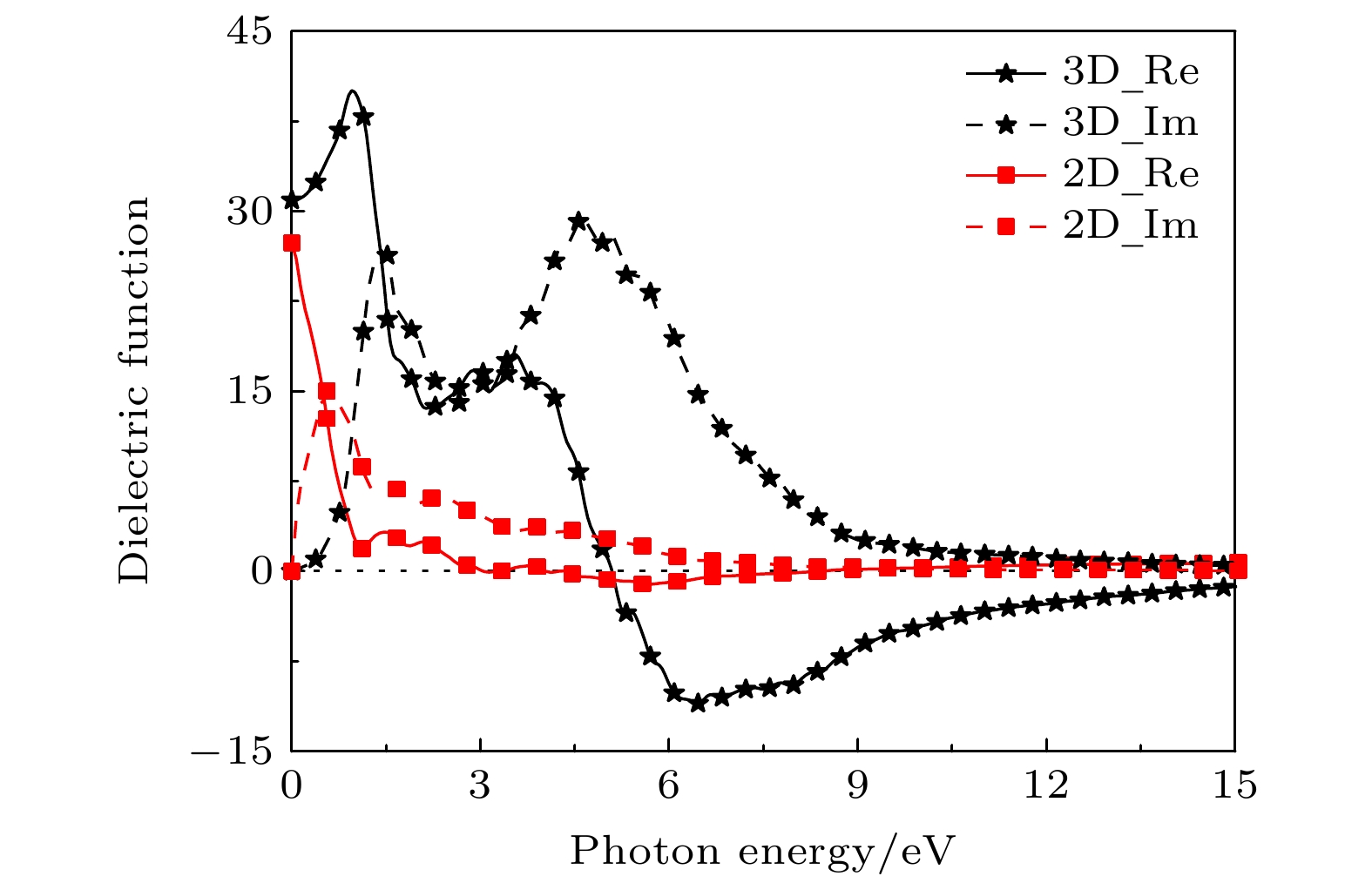

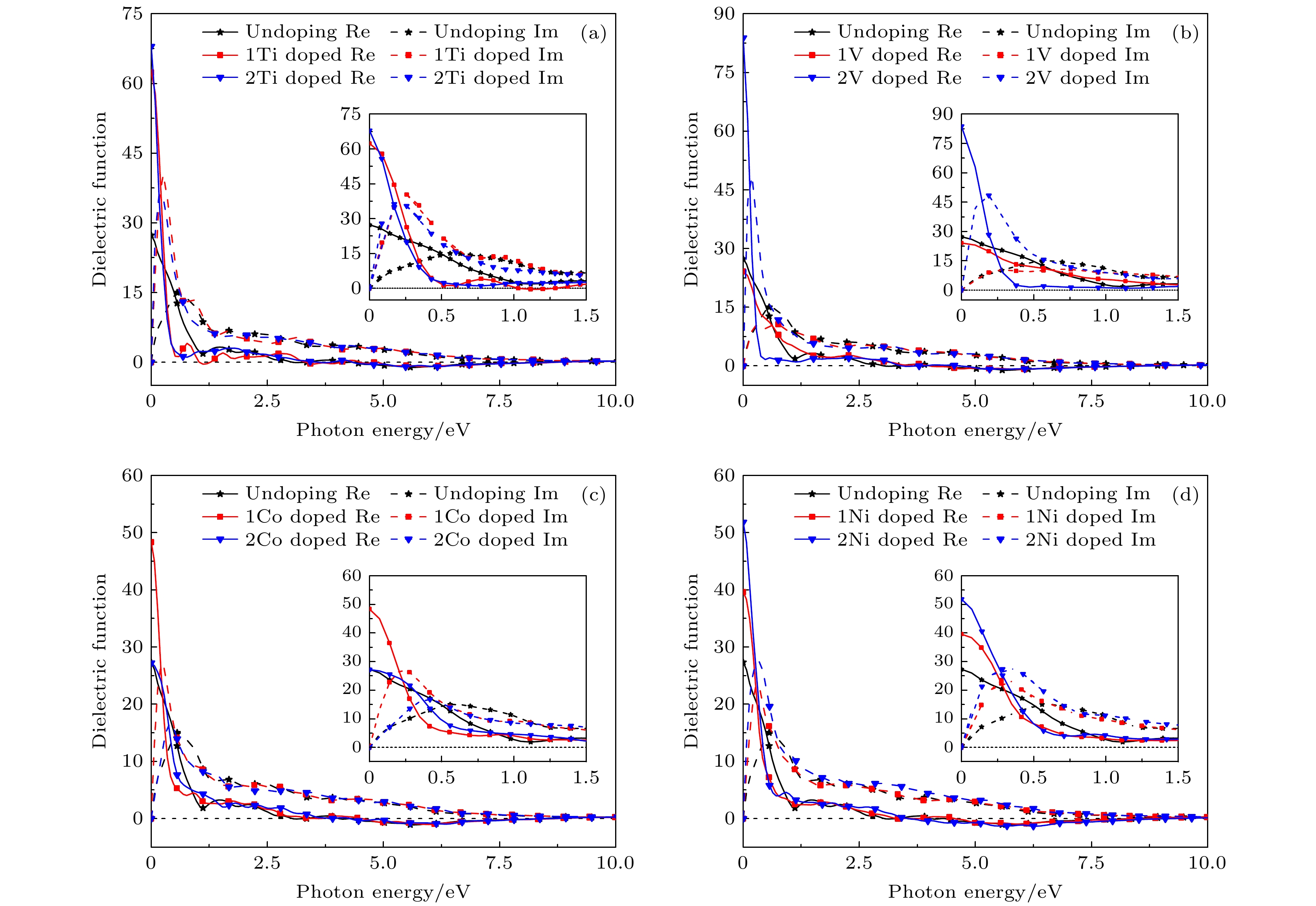

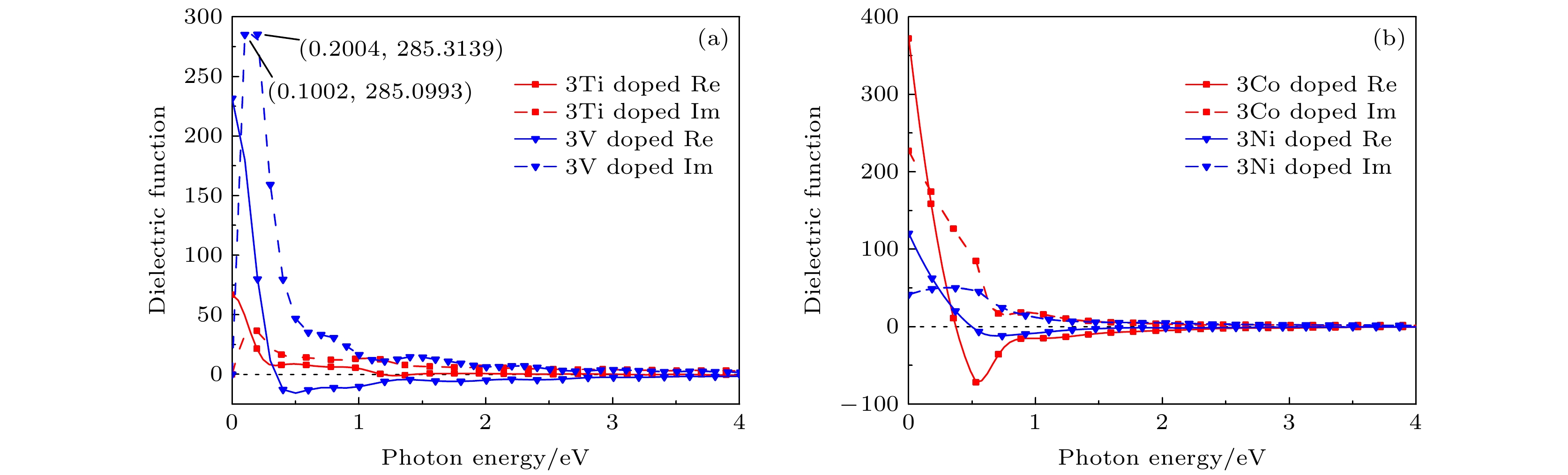

二维磁性材料的研究是一大热点, 其中单层CrSi2表现出优良的磁性, 有望应用于自旋电子学等领域, 但金属性限制了其部分层面的应用与发展. 采用基于密度泛函理论的第一性原理赝势平面波方法研究了不同元素(Ti, V, Co, Ni)、不同掺杂浓度(原子百分比为3.70%, 7.41%, 11.1%)对二维CrSi2电子结构、磁学及光学性质的影响, 期望改善二维CrSi2材料的相关性质, 也为开发基于二维CrSi2的电子器件提供有效的理论基础. 研究表明: 二维CrSi2在远红外以及紫外范围内的吸收系数与反射系数都很强, 表现出优异的光学性质. 在原子百分比为3.70%的浓度下掺杂Ti, V, Ni后, 成功打开了二维CrSi2的带隙, 导致其分别向间接半导体、稀磁半导体和半金属铁磁体转变, 同时, 掺杂能对单分子层CrSi2的磁性进行有效的调控. 掺杂后的二维CrSi2拥有良好的光学性质, 多数掺杂体系的光学性质峰值增大并发生蓝移, 但在原子百分比为11.1%的掺杂浓度下, 吸收峰红移. 二维CrSi2有望成为高稳定性的新型自旋电子器件的制备材料.

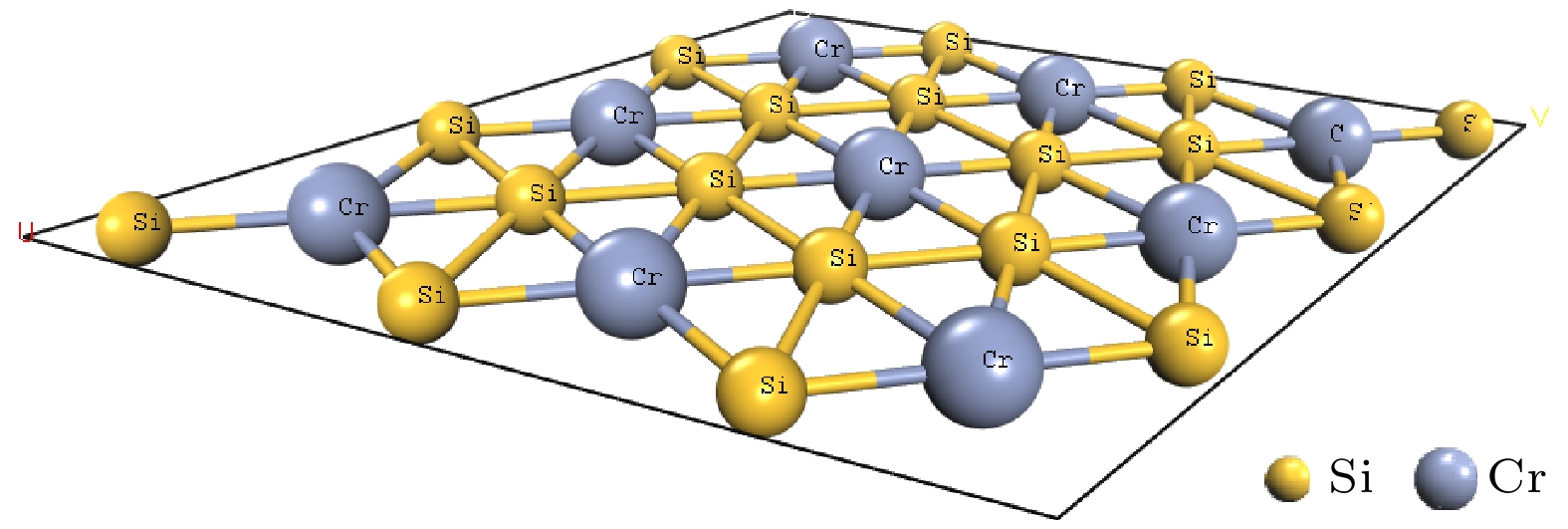

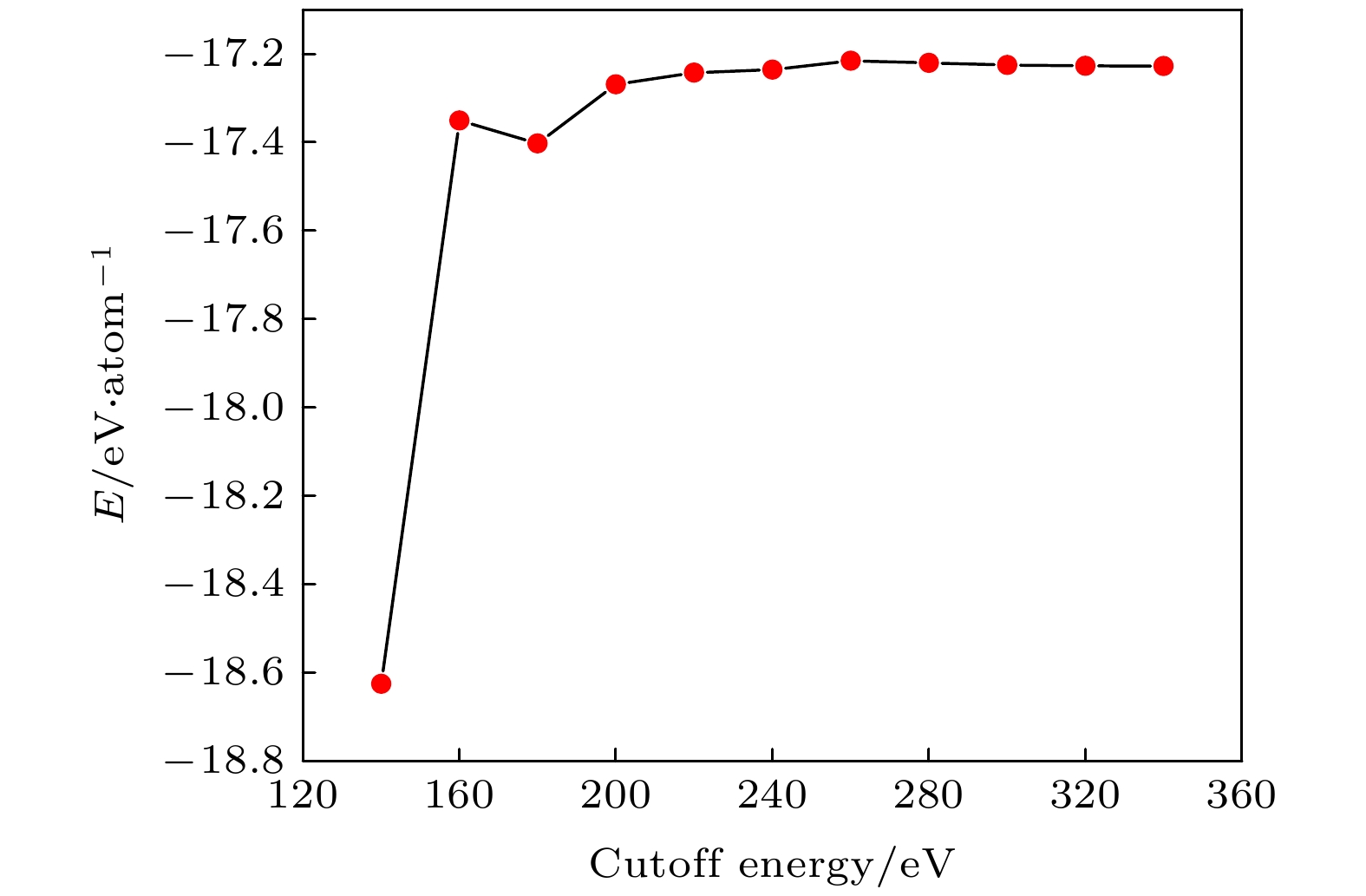

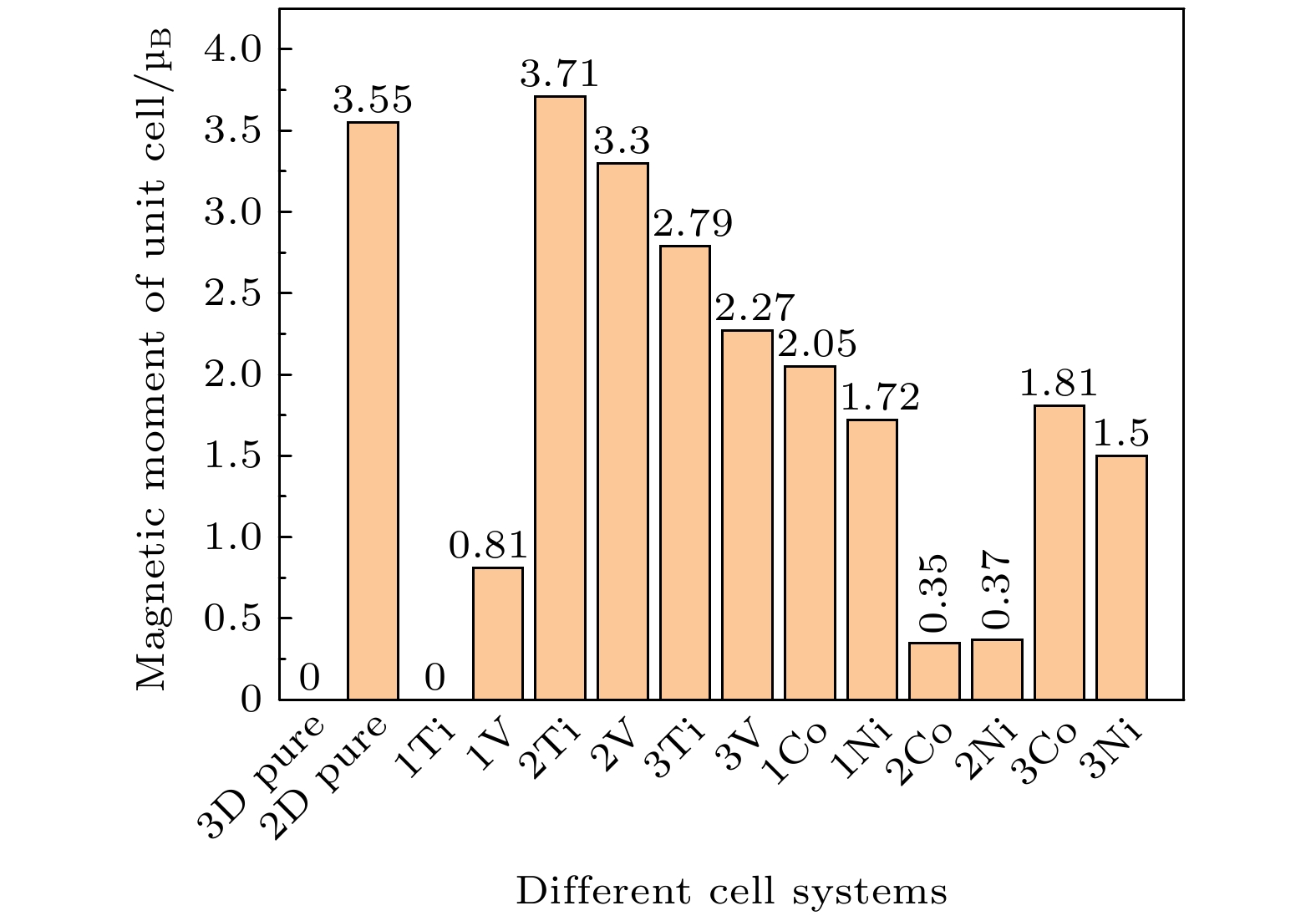

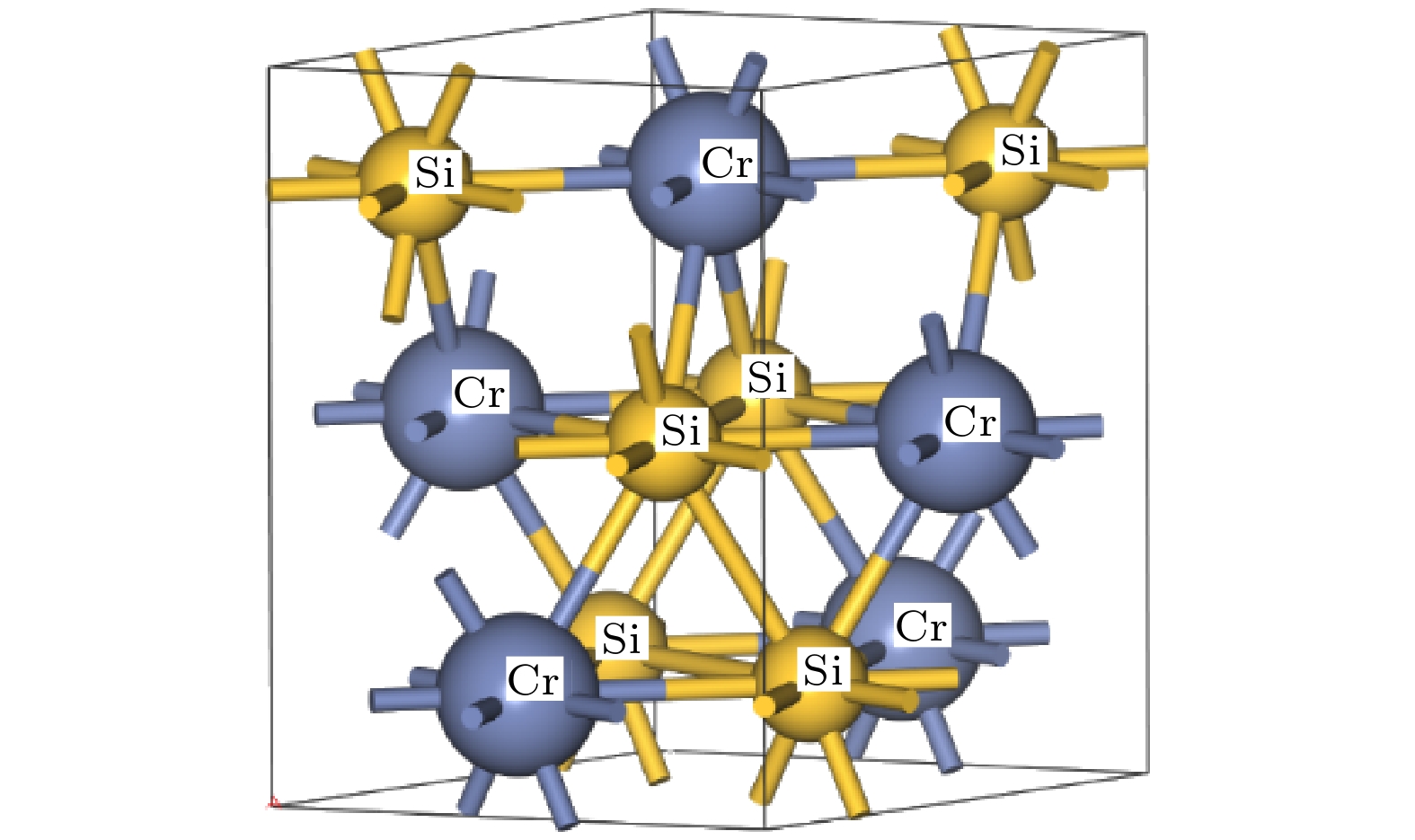

Two-dimensional materials have shown excellent optical, mechanical, thermal or magnetic properties, and have promising applications in the high performance electronic, optical, spintronic devices and energy transfer, energy storage, etc. Monolayer transition metal silicide CrSi2 has shown ferromagnetism and metal properties in previous studies, and it is expected to become a new two-dimensional material. The Ti, V, Co, Ni doped two-dimensional CrSi2 are studied with different doping concentrations by using the first-principal pseudopotential plane wave method based on density functional theory, and electronic structure, magnetic and optical properties are calculated and analyzed. The results show that the density of states in the two-dimensional CrSi2 system is asymmetric, and the crystal cells have obvious ferromagnetism with a magnetic moment of 3.55 μB. Two-dimensional CrSi2 has strong absorptivity and reflectivity in the far infrared and ultraviolet range, showing excellent optical properties. The electronic structures and magnetic properties of Ti, V, Co or Ni doped CrSi2 with different concentrations are calculated and analyzed, and the results show that the magnetic moment of the two-dimensional CrSi2 varies after doping different elements at a doping concentration of 3.70 at%. After doping Ti, the magnetic moment of the system changes to 0 μB at a doping concentration of 3.70 at%, showing that it is an indirect semiconductor. After doping V, the magnetic moment becomes smaller at a doping concentration of 3.70 at%, and the system has two degrees of freedom: electron charge and spin, showing the properties of diluted magnetic semiconductors. After doping Ni, the band gap Eg=0.09 eV appears in the spin-up band of the system at a doping concentration of 3.70 at%, while the spin-down band is metallic, and the system shows semi-metallic properties. The magnetic moment changes to 3.71 μB after doping Ti at a doping concentration of 7.41 at%. After doping Co and Ni, the magnetic moment of the system becomes smaller at the doping concentration of 7.41 at%, and the spin-down 3d orbital electrons of ferromagnetic elements take the dominant position. After doping Ni, the magnetic moment becomes 0.37 μB at the doping concentration of 7.41 at%. After doping Ti, the magnetic moment becomes 2.79 μB at a doping concentration of 33.3 at at%, after doping V, the magnetic moment becomes 2.27 μB, and the degree of spin becomes weaker at a doping concentration of 11.1 at%. After doping Co, the magnetic moment becomes 1.81 μB at the doping concentration of 11.1 at%. The magnetic moment becomes 1.5 μB after doping Ni at the doping concentration of 11.1 at%, which proves that the spin-up d orbital has less electronic contribution to the magnetic moment. The energy band range of each system is enlarged, and the interaction between atoms is enlarged, and the energy level splitting energy is enlarged at the doping concentration of 11.1 at%, which indicates that the effective mass of the system becomes smaller, the mobility of carriers turns stronger, and the metallization of materials grows stronger. The optical properties of Ti, V, Co or Ni doped CrSi2 with different concentrations are calculated and analyzed, and the results show that the two-dimensional CrSi2 after being doped has good optical properties. For most of systems, their optical properties are improved and blue-shifted at the doping concentrations of 3.70 at% and 7.41 at%, but the absorption peak is red-shifted at the doping concentration of 11.1 at%. By studying the properties of doped two-dimensional CrSi2, it is found that the two-dimensional CrSi2 has excellent electronic structure and optical properties, and the electronic structure, magnetic and optical properties of the two-dimensional CrSi2 can be effectively changed by doping. Two-dimensional CrSi2 is expected to be a promising material for preparing new high reliability and high stability spintronic devices, and the present research provides an effective theoretical basis for developing the two-dimensional CrSi2 based devices. -

Keywords:

- two-dimensional CrSi2 materials /

- electronic structure /

- magnetic properties /

- optical properties

[1] Novoselov K S, Geim A K, Morozov S V 2004 Science 306 666

Google Scholar

Google Scholar

[2] Lee C, Wei X, Kysar J W 2008 Science 321 385

Google Scholar

Google Scholar

[3] Zhang Y, Tan Y W, Stormer H L 2005 Nature 438 201

Google Scholar

Google Scholar

[4] Balandin A A, Ghosh S, Bao W 2008 Nano Lett 8 902

Google Scholar

Google Scholar

[5] Nair R R, Blake P, Grigorenko A N 2008 Science 320 1308

Google Scholar

Google Scholar

[6] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[7] Ribeiro-Palau R, Zhang C, Watanabe K, Taniguchi T, Hone J, Dean C R 2018 Science 361 690

Google Scholar

Google Scholar

[8] 王慧, 徐萌, 郑仁奎 2020 69 017301

Google Scholar

Google Scholar

Wang H, Xu M, Zheng R K 2020 Acta Phys. Sin. 69 017301

Google Scholar

Google Scholar

[9] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Google Scholar

Google Scholar

Wang S, Wang W H, Lv J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

Google Scholar

Google Scholar

[10] 黄申洋, 张国伟, 汪凡洁, 雷雨晨, 晏湖根 2021 70 027802

Google Scholar

Google Scholar

Huang S Y, Zhang G W, Wang F J, Lei Y C, Yan H G 2021 Acta Phys. Sin. 70 027802

Google Scholar

Google Scholar

[11] 王盼, 宗易昕, 文宏玉, 夏建白, 魏钟鸣 2021 70 026801

Google Scholar

Google Scholar

Wang P, Zong Y X, Wen H Y, Xia J B, Wei Z M 2021 Acta Phys. Sin. 70 026801

Google Scholar

Google Scholar

[12] Luo J C, Gao S J, Luo H, Wang L, Huang X W, Guo Z, Lai X J, Lin L W, Li R K Y, Gao J F 2021 Chem. Eng. J. 406 126898

Google Scholar

Google Scholar

[13] Li L K, Kim J, Jin C H, et al. 2017 Nat. Nanotechnol. 12 21

Google Scholar

Google Scholar

[14] Shen X, Zheng Q B, Kim J K 2021 Prog. Mater. Sci. 115 100708

Google Scholar

Google Scholar

[15] Faisal S, Mohamed A, Christine B H, Babak A, Soon M H, Chong M K, Yury G 2016 Science 353 1137

Google Scholar

Google Scholar

[16] Zhu X H, Zhang Y Y, Liu M L, Liu Y 2021 Biosens. Bioelectron. 171 112730

Google Scholar

Google Scholar

[17] Liu H, Neal A T, Zhu Z, Luo Z, Xu X, Tománek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[18] Li L, Yu Y, Ye G J, Ge Q Q, Ou X D, Wu H, Feng D L 2014 Nat. Nanotechnol. 9 372

Google Scholar

Google Scholar

[19] Feng B J, Zhang J, Zhong Q 2016 Nat. Chem. 8 564

Google Scholar

Google Scholar

[20] Mannix A J, Zhou X F, Kiraly B 2015 Science 350 1513

Google Scholar

Google Scholar

[21] Zhong H X, Quhe R G, Wang Y Y 2015 Chin.Phys.B 24 87

Google Scholar

Google Scholar

[22] Lin Y, Williams T V, Connell J W 2010 J. Phys. Chem. Lett. 1 277

Google Scholar

Google Scholar

[23] Wang X, Maeda K, Thomas A 2009 Nat. Mater. 8 76

Google Scholar

Google Scholar

[24] Naguib M, Mochalin V N, Barsoum M W 2014 Adv. Mater. 26 992

Google Scholar

Google Scholar

[25] Liu H, Du Y C, Deng Y X 2015 Chem. Soc. Rev. 44 2732

Google Scholar

Google Scholar

[26] Chhowalla M, Liu Z F, Zhang H 2015 Chem. Soc. Rev. 44 2584

Google Scholar

Google Scholar

[27] Chhowalla M, Shin H S, Eda G 2013 Nat. Chem. 5 263

Google Scholar

Google Scholar

[28] Xu M S, Liang T, Shi M M 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[29] Zhuang H L, Hennig R G 2013 Chem. Mater. 25 3232

Google Scholar

Google Scholar

[30] Wang Q, O’hare D 2012 Chem. Rev. 112 4124

Google Scholar

Google Scholar

[31] Dzade N, Obodo Y, Adjokatse K O 2010 J. Phys. Condens. Matter 22 375502

Google Scholar

Google Scholar

[32] Voon L C L Y, Guzman-Verri G G 2014 MRS Bull. 39 366

Google Scholar

Google Scholar

[33] Kara A, Enriquez H, Seitsonen A P, Lee Y V L C, Vizzini S, Aufray B, Oughaddou H 2012 Surf. Sci. Rep. 67 1

Google Scholar

Google Scholar

[34] Bisi O, Calandra C 1981 J. Phys. C 14 5479

Google Scholar

Google Scholar

[35] Abdul B, Hubby I, Bambang H, Toto S 2021 Int. J. Refract. Met. Hard Mater. 96 105497

Google Scholar

Google Scholar

[36] Fei L, He J L, Sheng Y G, Xi Y Y, Qian G F 2019 Surf. Coat. Technol. 374 966

Google Scholar

Google Scholar

[37] Wang X Q, Li H D, Wang J T 2012 Phys. Chem. Chem. Phys. 14 3031

Google Scholar

Google Scholar

[38] Zhang C W, Yan S S 2012 J. Phys. Chem. C 116 4163

Google Scholar

Google Scholar

[39] Kaloni T P, Gangopadhyay S, Singh N 2013 Phys. Rev. B 88 235418

Google Scholar

Google Scholar

[40] Dasgupta T, Etourneau J, Chevalier B, Matar S F, Umarji A M 2008 J. Appl. Phys. 103 113516

Google Scholar

Google Scholar

[41] Nagai H, Takamatsul T, Iijima Y, Hayashi K, Miyazaki Y 2018 JJAP 57 121801

Google Scholar

Google Scholar

[42] Naval K U, Kumaraswamidhas L A, Bhasker G, Sivaiah B, Saravanan M, Radhey S, Nagendra S C, Ruchi B, Ajay D 2018 J. Alloys Compd. 765 412

Google Scholar

Google Scholar

[43] 闫万珺, 周士芸, 谢泉, 郭本华, 张春红 2012 光学学报 32 171

Yan W J, Zhou S Y, Xie Q, Guo B H, Zhang C H 2012 Acta Opt. Sin. 32 171

[44] 闫万珺, 张忠政, 郭笑天, 桂放, 谢泉, 周士芸, 杨娇 2014 光学学报 34 193

Google Scholar

Google Scholar

Yan W J, Zhang Z Z, Guo X T, Gui F, Xie Q, Zhou S Y, Yang J 2014 Acta Opt. Sin. 34 193

Google Scholar

Google Scholar

[45] Han W, Kawakami R K, Gmitra M, Fabian J 2014 Nat. Nanotechnol. 59 794

Google Scholar

Google Scholar

[46] Maassen J, Ji W, Guo H 2011 Nano Lett. 11 151

Google Scholar

Google Scholar

[47] Parkin S, Yang S H 2015 Nat. Nanotechnol. 10 195

Google Scholar

Google Scholar

[48] Parkin S S, Hayashi M, Thomas L 2008 Science 320 190

Google Scholar

Google Scholar

[49] Eda G, Fujita T, Yamaguchi H, Voiry D 2012 ACS Nano 6 7311

Google Scholar

Google Scholar

[50] Ci L, Song L, Jin C, Jariwala D, Wu D, Li Y 2010 Nat. Mater. 9 430

Google Scholar

Google Scholar

[51] Zhang H, Liu L M, Lau W M 2013 J. Mater. Chem. A 1 10821

Google Scholar

Google Scholar

[52] Krijn M P, Eppenga R 1991 Phys. Rev. B 44 9042

Google Scholar

Google Scholar

[53] Mattheiss L F 1991 Phys. Rev. B 43 12549

Google Scholar

Google Scholar

[54] Viet Q B, Pham T T, Nguyen H, Le H M 2013 J. Phys. Chem. C 117 23364

Google Scholar

Google Scholar

[55] Chen S B, Yan W J 2019 J. Supercond. Novel Magn. 32 1341

Google Scholar

Google Scholar

[56] Chen S B, Chen Y, Yan W J, Zhou S Y, Xiong W, Yao X X, Qin X M 2018 J. Supercond. Novel Magn. 31 2759

Google Scholar

Google Scholar

[57] Chen S B, Zhou S Y, Yan W J, Chen Y, Qin X M, Xiong W 2019 Journal of Superconductivity and Novel Magnetism 32 1341

[58] Chen S B, Chen Y, Yan W J, Zeng Z Y, Chen X R, Qin X M 2021 J. Supercond. Novel Magn. 34 305

Google Scholar

Google Scholar

[59] Krijn E, Eppenga E 1991 Physics Review B 44 9042

[60] Borisenko V E 2000 Semiconducting Silicides (Berlin: Spinger) pp85–87

[61] Zeng Z Y, Yin Z. Y, Huang X, Li H, He Q Y, Lu G, Boey F, Zhang H 2011 Angew. Chem. Int. Ed. 50 11093

Google Scholar

Google Scholar

[62] Chen S B, Ying Chen, Yan W J, Zhou S Y, Qin X M, Xiong W, Liu L 2018 Appl. Sci. 8 1885

Google Scholar

Google Scholar

[63] Kronik L, Jain M, Chelikowsky J 2003 Phys. Rev. B 68 104411

Google Scholar

Google Scholar

[64] Park M S, Kwon S K, Min B I 2002 Phys. Rev. B 65 161201

Google Scholar

Google Scholar

[65] Donald K, Colin N 2005 Science 309 75

Google Scholar

Google Scholar

[66] 陈娜, 张盈祺, 姚可夫 2017 66 176113

Google Scholar

Google Scholar

Chen N, Zhang Y Q, Yao K F 2017 Acta Phys. Sin. 66 176113

Google Scholar

Google Scholar

[67] Sun F, Zhao G Q, Escanhoela C A, et al. 2017 Phys. Rev. B 95 094412

Google Scholar

Google Scholar

[68] Tu N T, Hai P N, Anh L D, Tanaka M 2016 Appl. Phys. Lett. 108 192401

Google Scholar

Google Scholar

[69] Coey M, Ackland K, Venkatesan M, Sen S 2016 Nat. Phys. 12 694

Google Scholar

Google Scholar

[70] 邓正, 赵国强, 靳常青 2019 68 167502

Google Scholar

Google Scholar

Deng Z, Zhao G Q, Jin C Q 2019 Acta Phys. Sin. 68 167502

Google Scholar

Google Scholar

[71] Yun S J, Duong D L, Ha D M, Singh K, Phan T L, Choi W, Kim Y M, Lee Y H 2020 Adv. Sci. 7 1906076

Google Scholar

Google Scholar

[72] 张浩杰, 张茹菲, 傅立承, 顾轶伦, 智国翔, 董金瓯, 赵雪芹, 宁凡龙 2021 70 107501

Google Scholar

Google Scholar

Zhang H J, Zhang R F, Fu L C, Gu Z L, Zhi G X, Dong J O, Zhao X Q, Ning F L 2021 Acta Phys. Sin. 70 107501

Google Scholar

Google Scholar

[73] Shi Q, Zhang X, Yang E, Yan J, Yu X Y, Sun C, Li S, Chen Z W 2018 Results Phys. 11 1004

Google Scholar

Google Scholar

[74] Wu C T, Halterman K 2018 Phys. Rev. B 98 054518

Google Scholar

Google Scholar

[75] Liu H X, Kawami T, Moges K, Uemura T, Yamamoto M, Shi F, Voyles P M 2015 J. Phys. D 48 164001

Google Scholar

Google Scholar

[76] Fujii S 2014 IEEE Trans. Magn. 50 1

Google Scholar

Google Scholar

[77] Liu Y, Ren L, Zheng Y, He S, Teo K L 2018 AIP Adv. 8 056328

Google Scholar

Google Scholar

-

图 10 不同浓度掺杂后二维CrSi2的态密度图 (a) Ti-3.70%; (b) V-3.70%; (c) Co-3.70%; (d) Ni-3.70%; (e) Ti-7.41%; (f) V-7.41%; (g) Co-7.41%; (h) Ni-7.41%

Fig. 10. Density of states of two-dimensional CrSi2 doped with different concentrations: (a) Ti-3.70%; (b) V-3.70%; (c) Co-3.70%; (d) Ni-3.70%; (e) Ti-7.41%; (f) V-7.41%; (g) Co-7.41%; (h) Ni-7.41%.

表 1 三维CrSi2的基本性质

Table 1. Basic properties of three-dimensional CrSi2

表 2 三维及二维CrSi2的结构优化结果

Table 2. Structural optimization results of three-dimensional and two-dimensional CrSi2.

Model a/nm b/nm c/nm Vo/nm3 3D-CrSi2 0.438 0.438 0.632 0.107 2D-CrSi2 0.441 0.441 1.5 2.274 表 3 过渡金属元素3d壳层的电子结构

Table 3. Electronic structure of 3d shell of transition metal elements.

原子序数 21 22 23 24 25 26 27 28 29 30 元素名 Sc Ti V Cr Mn Fe Co Ni Cu Zn 磁性 顺磁性 顺磁性 顺磁性 反铁磁性 反铁磁性 铁磁性 铁磁性 铁磁性 无磁性 无磁性 轨道结构 3d14s2 3d24s2 3d34s2 3d54s1 3d54s2 3d64s2 3d74s2 3d84s2 3d104s1 3d104s2 3d电子数及其自旋排布 ↑ ↑

↑↑

↑

↑↑

↑

↑

↑

↑↑

↑

↑

↑

↑↑↓

↑

↑

↑

↑↑↓

↑↓

↑

↑

↑↑↓

↑↓

↑↓

↑

↑↑↓

↑↓

↑↓

↑↓

↑↓↑↓

↑↓

↑↓

↑↓

↑↓4s轨道电子数 2 2 2 1 2 2 2 2 1 2 -

[1] Novoselov K S, Geim A K, Morozov S V 2004 Science 306 666

Google Scholar

Google Scholar

[2] Lee C, Wei X, Kysar J W 2008 Science 321 385

Google Scholar

Google Scholar

[3] Zhang Y, Tan Y W, Stormer H L 2005 Nature 438 201

Google Scholar

Google Scholar

[4] Balandin A A, Ghosh S, Bao W 2008 Nano Lett 8 902

Google Scholar

Google Scholar

[5] Nair R R, Blake P, Grigorenko A N 2008 Science 320 1308

Google Scholar

Google Scholar

[6] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[7] Ribeiro-Palau R, Zhang C, Watanabe K, Taniguchi T, Hone J, Dean C R 2018 Science 361 690

Google Scholar

Google Scholar

[8] 王慧, 徐萌, 郑仁奎 2020 69 017301

Google Scholar

Google Scholar

Wang H, Xu M, Zheng R K 2020 Acta Phys. Sin. 69 017301

Google Scholar

Google Scholar

[9] 王铄, 王文辉, 吕俊鹏, 倪振华 2021 70 026802

Google Scholar

Google Scholar

Wang S, Wang W H, Lv J P, Ni Z H 2021 Acta Phys. Sin. 70 026802

Google Scholar

Google Scholar

[10] 黄申洋, 张国伟, 汪凡洁, 雷雨晨, 晏湖根 2021 70 027802

Google Scholar

Google Scholar

Huang S Y, Zhang G W, Wang F J, Lei Y C, Yan H G 2021 Acta Phys. Sin. 70 027802

Google Scholar

Google Scholar

[11] 王盼, 宗易昕, 文宏玉, 夏建白, 魏钟鸣 2021 70 026801

Google Scholar

Google Scholar

Wang P, Zong Y X, Wen H Y, Xia J B, Wei Z M 2021 Acta Phys. Sin. 70 026801

Google Scholar

Google Scholar

[12] Luo J C, Gao S J, Luo H, Wang L, Huang X W, Guo Z, Lai X J, Lin L W, Li R K Y, Gao J F 2021 Chem. Eng. J. 406 126898

Google Scholar

Google Scholar

[13] Li L K, Kim J, Jin C H, et al. 2017 Nat. Nanotechnol. 12 21

Google Scholar

Google Scholar

[14] Shen X, Zheng Q B, Kim J K 2021 Prog. Mater. Sci. 115 100708

Google Scholar

Google Scholar

[15] Faisal S, Mohamed A, Christine B H, Babak A, Soon M H, Chong M K, Yury G 2016 Science 353 1137

Google Scholar

Google Scholar

[16] Zhu X H, Zhang Y Y, Liu M L, Liu Y 2021 Biosens. Bioelectron. 171 112730

Google Scholar

Google Scholar

[17] Liu H, Neal A T, Zhu Z, Luo Z, Xu X, Tománek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[18] Li L, Yu Y, Ye G J, Ge Q Q, Ou X D, Wu H, Feng D L 2014 Nat. Nanotechnol. 9 372

Google Scholar

Google Scholar

[19] Feng B J, Zhang J, Zhong Q 2016 Nat. Chem. 8 564

Google Scholar

Google Scholar

[20] Mannix A J, Zhou X F, Kiraly B 2015 Science 350 1513

Google Scholar

Google Scholar

[21] Zhong H X, Quhe R G, Wang Y Y 2015 Chin.Phys.B 24 87

Google Scholar

Google Scholar

[22] Lin Y, Williams T V, Connell J W 2010 J. Phys. Chem. Lett. 1 277

Google Scholar

Google Scholar

[23] Wang X, Maeda K, Thomas A 2009 Nat. Mater. 8 76

Google Scholar

Google Scholar

[24] Naguib M, Mochalin V N, Barsoum M W 2014 Adv. Mater. 26 992

Google Scholar

Google Scholar

[25] Liu H, Du Y C, Deng Y X 2015 Chem. Soc. Rev. 44 2732

Google Scholar

Google Scholar

[26] Chhowalla M, Liu Z F, Zhang H 2015 Chem. Soc. Rev. 44 2584

Google Scholar

Google Scholar

[27] Chhowalla M, Shin H S, Eda G 2013 Nat. Chem. 5 263

Google Scholar

Google Scholar

[28] Xu M S, Liang T, Shi M M 2013 Chem. Rev. 113 3766

Google Scholar

Google Scholar

[29] Zhuang H L, Hennig R G 2013 Chem. Mater. 25 3232

Google Scholar

Google Scholar

[30] Wang Q, O’hare D 2012 Chem. Rev. 112 4124

Google Scholar

Google Scholar

[31] Dzade N, Obodo Y, Adjokatse K O 2010 J. Phys. Condens. Matter 22 375502

Google Scholar

Google Scholar

[32] Voon L C L Y, Guzman-Verri G G 2014 MRS Bull. 39 366

Google Scholar

Google Scholar

[33] Kara A, Enriquez H, Seitsonen A P, Lee Y V L C, Vizzini S, Aufray B, Oughaddou H 2012 Surf. Sci. Rep. 67 1

Google Scholar

Google Scholar

[34] Bisi O, Calandra C 1981 J. Phys. C 14 5479

Google Scholar

Google Scholar

[35] Abdul B, Hubby I, Bambang H, Toto S 2021 Int. J. Refract. Met. Hard Mater. 96 105497

Google Scholar

Google Scholar

[36] Fei L, He J L, Sheng Y G, Xi Y Y, Qian G F 2019 Surf. Coat. Technol. 374 966

Google Scholar

Google Scholar

[37] Wang X Q, Li H D, Wang J T 2012 Phys. Chem. Chem. Phys. 14 3031

Google Scholar

Google Scholar

[38] Zhang C W, Yan S S 2012 J. Phys. Chem. C 116 4163

Google Scholar

Google Scholar

[39] Kaloni T P, Gangopadhyay S, Singh N 2013 Phys. Rev. B 88 235418

Google Scholar

Google Scholar

[40] Dasgupta T, Etourneau J, Chevalier B, Matar S F, Umarji A M 2008 J. Appl. Phys. 103 113516

Google Scholar

Google Scholar

[41] Nagai H, Takamatsul T, Iijima Y, Hayashi K, Miyazaki Y 2018 JJAP 57 121801

Google Scholar

Google Scholar

[42] Naval K U, Kumaraswamidhas L A, Bhasker G, Sivaiah B, Saravanan M, Radhey S, Nagendra S C, Ruchi B, Ajay D 2018 J. Alloys Compd. 765 412

Google Scholar

Google Scholar

[43] 闫万珺, 周士芸, 谢泉, 郭本华, 张春红 2012 光学学报 32 171

Yan W J, Zhou S Y, Xie Q, Guo B H, Zhang C H 2012 Acta Opt. Sin. 32 171

[44] 闫万珺, 张忠政, 郭笑天, 桂放, 谢泉, 周士芸, 杨娇 2014 光学学报 34 193

Google Scholar

Google Scholar

Yan W J, Zhang Z Z, Guo X T, Gui F, Xie Q, Zhou S Y, Yang J 2014 Acta Opt. Sin. 34 193

Google Scholar

Google Scholar

[45] Han W, Kawakami R K, Gmitra M, Fabian J 2014 Nat. Nanotechnol. 59 794

Google Scholar

Google Scholar

[46] Maassen J, Ji W, Guo H 2011 Nano Lett. 11 151

Google Scholar

Google Scholar

[47] Parkin S, Yang S H 2015 Nat. Nanotechnol. 10 195

Google Scholar

Google Scholar

[48] Parkin S S, Hayashi M, Thomas L 2008 Science 320 190

Google Scholar

Google Scholar

[49] Eda G, Fujita T, Yamaguchi H, Voiry D 2012 ACS Nano 6 7311

Google Scholar

Google Scholar

[50] Ci L, Song L, Jin C, Jariwala D, Wu D, Li Y 2010 Nat. Mater. 9 430

Google Scholar

Google Scholar

[51] Zhang H, Liu L M, Lau W M 2013 J. Mater. Chem. A 1 10821

Google Scholar

Google Scholar

[52] Krijn M P, Eppenga R 1991 Phys. Rev. B 44 9042

Google Scholar

Google Scholar

[53] Mattheiss L F 1991 Phys. Rev. B 43 12549

Google Scholar

Google Scholar

[54] Viet Q B, Pham T T, Nguyen H, Le H M 2013 J. Phys. Chem. C 117 23364

Google Scholar

Google Scholar

[55] Chen S B, Yan W J 2019 J. Supercond. Novel Magn. 32 1341

Google Scholar

Google Scholar

[56] Chen S B, Chen Y, Yan W J, Zhou S Y, Xiong W, Yao X X, Qin X M 2018 J. Supercond. Novel Magn. 31 2759

Google Scholar

Google Scholar

[57] Chen S B, Zhou S Y, Yan W J, Chen Y, Qin X M, Xiong W 2019 Journal of Superconductivity and Novel Magnetism 32 1341

[58] Chen S B, Chen Y, Yan W J, Zeng Z Y, Chen X R, Qin X M 2021 J. Supercond. Novel Magn. 34 305

Google Scholar

Google Scholar

[59] Krijn E, Eppenga E 1991 Physics Review B 44 9042

[60] Borisenko V E 2000 Semiconducting Silicides (Berlin: Spinger) pp85–87

[61] Zeng Z Y, Yin Z. Y, Huang X, Li H, He Q Y, Lu G, Boey F, Zhang H 2011 Angew. Chem. Int. Ed. 50 11093

Google Scholar

Google Scholar

[62] Chen S B, Ying Chen, Yan W J, Zhou S Y, Qin X M, Xiong W, Liu L 2018 Appl. Sci. 8 1885

Google Scholar

Google Scholar

[63] Kronik L, Jain M, Chelikowsky J 2003 Phys. Rev. B 68 104411

Google Scholar

Google Scholar

[64] Park M S, Kwon S K, Min B I 2002 Phys. Rev. B 65 161201

Google Scholar

Google Scholar

[65] Donald K, Colin N 2005 Science 309 75

Google Scholar

Google Scholar

[66] 陈娜, 张盈祺, 姚可夫 2017 66 176113

Google Scholar

Google Scholar

Chen N, Zhang Y Q, Yao K F 2017 Acta Phys. Sin. 66 176113

Google Scholar

Google Scholar

[67] Sun F, Zhao G Q, Escanhoela C A, et al. 2017 Phys. Rev. B 95 094412

Google Scholar

Google Scholar

[68] Tu N T, Hai P N, Anh L D, Tanaka M 2016 Appl. Phys. Lett. 108 192401

Google Scholar

Google Scholar

[69] Coey M, Ackland K, Venkatesan M, Sen S 2016 Nat. Phys. 12 694

Google Scholar

Google Scholar

[70] 邓正, 赵国强, 靳常青 2019 68 167502

Google Scholar

Google Scholar

Deng Z, Zhao G Q, Jin C Q 2019 Acta Phys. Sin. 68 167502

Google Scholar

Google Scholar

[71] Yun S J, Duong D L, Ha D M, Singh K, Phan T L, Choi W, Kim Y M, Lee Y H 2020 Adv. Sci. 7 1906076

Google Scholar

Google Scholar

[72] 张浩杰, 张茹菲, 傅立承, 顾轶伦, 智国翔, 董金瓯, 赵雪芹, 宁凡龙 2021 70 107501

Google Scholar

Google Scholar

Zhang H J, Zhang R F, Fu L C, Gu Z L, Zhi G X, Dong J O, Zhao X Q, Ning F L 2021 Acta Phys. Sin. 70 107501

Google Scholar

Google Scholar

[73] Shi Q, Zhang X, Yang E, Yan J, Yu X Y, Sun C, Li S, Chen Z W 2018 Results Phys. 11 1004

Google Scholar

Google Scholar

[74] Wu C T, Halterman K 2018 Phys. Rev. B 98 054518

Google Scholar

Google Scholar

[75] Liu H X, Kawami T, Moges K, Uemura T, Yamamoto M, Shi F, Voyles P M 2015 J. Phys. D 48 164001

Google Scholar

Google Scholar

[76] Fujii S 2014 IEEE Trans. Magn. 50 1

Google Scholar

Google Scholar

[77] Liu Y, Ren L, Zheng Y, He S, Teo K L 2018 AIP Adv. 8 056328

Google Scholar

Google Scholar

计量

- 文章访问数: 7936

- PDF下载量: 236

- 被引次数: 0

下载:

下载: