-

采用第一性原理的方法系统研究了碱(土)金属原子、过渡金属原子和非金属原子吸附的二维CrI3单层的电学和磁学性质. 结果表明, 金属原子倾向于吸附在6个I原子形成的环中心并且与Cr原子处于同一高度, 非金属原子吸附在I原子形成的环内, 但位置则依赖于原子种类. 除Ti和Mn原子之外的其他原子的吸附并未改变CrI3单层的本征铁磁半导体属性, 而Ti和Mn原子的吸附则使CrI3单层转变为反铁磁构型. 金属原子的吸附导致Cr原子局域磁矩增加, 但不超过4μB; 而非金属原子的吸附则使Cr原子的局域磁矩呈现多样化. 结合分波态密度我们对Cr局域磁矩的变化机制进行了细致分析, 发现Cr磁矩的增加与电荷转移直接相关. 我们的研究结果为铁磁半导体CrI3的性能调控提供了新的思路, 在未来自旋电子学中有着潜在的应用前景.Recent experimental discovery of intrinsic ferromagnetism (FM) in chromium triiodide (CrI3) monolayer opens a new way to low-dimensional spintronics. Two-dimensional (2D) CrI3 monolayer is of great significance for its magnetic and electronic properties. Generally, surface atomic adsorption is an effective way to modify the physical properties of layered magnetic materials. Here in this work, we use the first-principles method based on density functional theory (DFT) to systematically study the electronic structure and magnetic properties of 2D CrI3 monolayers that have adsorbed other metal atoms (specifically, alkali (alkaline earth) metal (Li, K and Mg), transition metal (Ti, V, Mn, Fe, Co and Ni) and non-metal (N, P, O and S) atoms). Our results show that the metal atoms tend to be adsorbed in the center of the ring formed by the six I atoms and stay at the same height as Cr atoms, while the positions of the optimized non-metal atoms are in the ring formed by the six I atoms and depend on the type of the atoms. The adsorption of atoms (except for Ti and Mn atoms) does not change the intrinsic ferromagnetic semiconducting properties of CrI3 monolayer. The CrI3 monolayers with Ti or Mn adsorption are antiferromagnetic semiconductors. Moreover, we find that the adsorption of different atoms regulates the local magnetic moments of Cr atoms. The adsorption of metal atoms increases the local magnetic moments of Cr atoms, but not exceeding 4μB. However, the adsorption of non-metallic atoms makes the local magnetic moments of Cr atoms diversified. The adsorption of O and N atoms retain the local magnetic moment of Cr atoms, while the adsorption of P and S atoms increase the local magnetic moment. By combining the projected density of states, we analyze in detail the local magnetic moments of Cr atoms. The increase of the local magnetic moments of Cr atoms is directly related to the charges transferring. Our results provide new ideas for regulating the performance of the magnetism of 2D intrinsic ferromagnetic semiconductor CrI3, which will have potential applications in the spintronics in the future.

-

Keywords:

- atomic adsorption /

- first principles /

- two-dimensional CrI3 monolayer /

- electronic structures and magnetic properties

[1] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[2] Ferrari A C, Meyer J C, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov K S, Roth S, Geim A K 2006 Phys. Rev. Lett. 97 187401

Google Scholar

Google Scholar

[3] Castro Neto A H, Guinea F, Peres N M R, Novoselov K S, Geim A K 2009 Rev. Mod. Phys. 81 109

Google Scholar

Google Scholar

[4] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[5] Chen Q, Ouyang Y, Yuan S, Li R, Wang J 2014 ACS Appl. Mater. Inter. 6 16835

Google Scholar

Google Scholar

[6] Dong L, Kumar H, Anasori B, Gogotsi Y, Shenoy V B 2017 J. Phys. Chem. Lett. 8 422

Google Scholar

Google Scholar

[7] Ma X C, Wu X, Wang H D, Wang Y C 2018 J. Mater. Chem. A 6 2295

Google Scholar

Google Scholar

[8] Kadantsev E S, Hawrylak P 2012 Solid State Commun. 152 909

Google Scholar

Google Scholar

[9] Li F, Wei W, Zhao P, Huang B, Dai Y 2017 J. Phys. Chem. Lett. 8 5959

Google Scholar

Google Scholar

[10] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[11] Dean C R, Young A F, Meric I, Lee C, Wang L, Sorgenfrei S, Watanabe K, Taniguchi T, Kim P, Shepard K L, Hone J 2010 Nat. Nanotechnol. 5 722

Google Scholar

Google Scholar

[12] Qiao J, Kong X, Hu Z X, Yang F, Ji W 2014 Nat. Commun. 5 4475

Google Scholar

Google Scholar

[13] Li L, Yu Y, Ye G J, Ge Q, Ou X, Wu H, Feng D, Chen X H, Zhang Y 2014 Nat. Nanotechnol. 9 372

Google Scholar

Google Scholar

[14] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol. 7 699

Google Scholar

Google Scholar

[15] Ghorbani-Asl M, Kuc A, Miro P, Heine T 2016 Adv. Mater. 28 853

Google Scholar

Google Scholar

[16] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol. 6 147

Google Scholar

Google Scholar

[17] Tao L, Cinquanta E, Chiappe D, Grazianetti C, Fanciulli M, Dubey M, Molle A, Akinwande D 2015 Nat. Nanotechnol. 10 227

Google Scholar

Google Scholar

[18] Ma L, Dai J, Zeng X C 2017 Adv. Energy Mater. 7

Google Scholar

Google Scholar

[19] Jing Y, Zhou Z, Cabrera C R, Chen Z 2014 J. Mater. Chem. A 2

Google Scholar

Google Scholar

[20] Bonaccorso F, Colombo L, Yu G, Stoller M, Tozzini V, Ferrari A C, Ruoff R S, Pellegrini V 2015 Science 347 1246501

Google Scholar

Google Scholar

[21] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X 2017 Nature 546 270

Google Scholar

Google Scholar

[22] Zhang W B, Qu Q, Zhu P, Lam C H 2015 J. Mater. Chem. C 3 12457

Google Scholar

Google Scholar

[23] Fu Y K, Sun Y, Luo X 2019 J. Appl. Phys. 125 053901

Google Scholar

Google Scholar

[24] Wang H B, Fan F R, Zhu S S, Wu H 2016 Europhys. Lett. 114 47001

Google Scholar

Google Scholar

[25] McGuire M A, Dixit H, Cooper V R, Sales B C 2015 Chem. Mater. 27 612

Google Scholar

Google Scholar

[26] Webster L, Liang L, Yan J A 2018 Phys. Chem. Chem. Phys. 20 23546

Google Scholar

Google Scholar

[27] Larson D T, Kaxiras E 2018 Phys. Rev. B 98 085406

Google Scholar

Google Scholar

[28] Shcherbakov D, Stepanov P, Weber D, Wang Y, Hu J, Zhu Y, Watanabe K, Taniguchi T, Mao Z, Windl W, Goldberger J, Bockrath M, Lau C N 2018 Nano Lett. 18 4214

Google Scholar

Google Scholar

[29] Chen L B, Chung J H, Gao B, Chen T, Stone M B, Kolesnikov A I, Huang Q Z, Dai P C 2018 Phys. Rev. X 8 041028

Google Scholar

Google Scholar

[30] Zeng Y, Wang L, Li S, He C, Zhong D, Yao D X 2019 J. Phys. Codens. Mat. 31 395502

Google Scholar

Google Scholar

[31] Zhou Y G, Wang Z G, Yang P, Zu X T, Yang L, Sun X, Gao F 2012 ACS Nano 6 9727

Google Scholar

Google Scholar

[32] Zhu S Z, Li T 2016 Phys. Rev. B 93 115401

Google Scholar

Google Scholar

[33] 吴木生, 徐波, 刘刚, 欧阳楚英 2012 61 227102

Google Scholar

Google Scholar

Wu M S, Xu B, Liu G, Ouyang C Y 2012 Acta Phys. Sin. 61 227102

Google Scholar

Google Scholar

[34] Rai H M, Saxena S K, Mishra V, Late R, Kumar R, Sagdeo P R, Jaiswal N K, Srivastava P 2016 RSC Adv. 6 11014

Google Scholar

Google Scholar

[35] Osada M, Yoguchi S, Itose M, Li B W, Ebina Y, Fukuda K, Kotani Y, Ono K, Ueda S, Sasaki T 2014 Nanoscale 6 14227

Google Scholar

Google Scholar

[36] Guan J, Yu G, Ding X, Chen W, Shi Z, Huang X, Sun C 2013 Chemphyschem. 14 2841

Google Scholar

Google Scholar

[37] Du A J, Chen Y, Zhu Z H, Amal R, Lu G Q, Smith S C 2009 J. Am. Chem. Soc. 131 17354

Google Scholar

Google Scholar

[38] 黄炳铨, 周铁戈, 吴道雄, 张召富, 李百奎 2019 68 246301

Google Scholar

Google Scholar

Huang B Q, Zhou T G, Wu D X, Zhang Z F, Li B K 2019 Acta Phys. Sin. 68 246301

Google Scholar

Google Scholar

[39] Kan E, Li M, Hu S, Xiao C, Xiang H, Deng K 2013 J. Phys. Chem. Lett. 4 1120

Google Scholar

Google Scholar

[40] Barone V, Peralta J E 2008 Nano Lett. 8 2210

Google Scholar

Google Scholar

[41] Allen M J, Tung V C, Kaner R B 2010 J. Am. Chem. Soc. 110 132

Google Scholar

Google Scholar

[42] Lee K W, Lee C E 2012 Adv. Mater. 24 2019

Google Scholar

Google Scholar

[43] 栾晓玮, 孙建平, 王凡嵩, 韦慧兰, 胡艺凡 2019 68 026802

Google Scholar

Google Scholar

Luan X W, Sun J P, Wang F S, Wei H L, Hu Y F 2019 Acta Phys. Sin. 68 026802

Google Scholar

Google Scholar

[44] 杨光敏, 梁志聪, 黄海华 2017 66 057301

Google Scholar

Google Scholar

Yang G M, Liang Z C, Huang H H 2017 Acta Phys. Sin. 66 057301

Google Scholar

Google Scholar

[45] Zheng F W, Zhao J Z, Liu Z, Li M L, Zhou M, Zhang S B, Zhang P 2018 Nanoscale 10 14298

Google Scholar

Google Scholar

[46] Gao Y, Wang J, Li Z P, Yang J J, Xia M R, Hao X F, Xu Y H, Gao F M 2019 Phys. Status. Solidi-R. 13 1800410

Google Scholar

Google Scholar

[47] Qin W J, Xu B, Liao S S, Liu G, Sun B Z, Wu M S 2020 Solid State Commun. 321 114037

Google Scholar

Google Scholar

[48] Liu J, Shi M C, Lu J W, Anantram M P 2018 Phys. Rev. B 97 054416

Google Scholar

Google Scholar

[49] Guo Y L, Yuan S J, Wang B, Shi L, Wang J L 2018 J. Mater. Chem. C 6 5716

Google Scholar

Google Scholar

[50] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[51] Kresse G, Hafner J 1994 Phys. Rev. B: Condens. Matter 49 14251

Google Scholar

Google Scholar

[52] Kresse G, Furthmiiller J 1996 Science 6 15

[53] Blochl P E 1994 Phys. Rev. B: Condens. Matter 50 17953

Google Scholar

Google Scholar

[54] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[55] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[56] Perdew J P, Ernzerhof M, Burke K 1996 J. Chem. Phys. 105 9982

Google Scholar

Google Scholar

[57] Liechtenstein A I, Anisimov V V, Zaanen J 1995 Phys. Rev. B: Condens. Matter 52 R5467

Google Scholar

Google Scholar

[58] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[59] Goodenough J B 1958 J. Phys. Chem. Solids 6 287

Google Scholar

Google Scholar

[60] Anderson P W 1959 Phys. Rev. 115 2

Google Scholar

Google Scholar

-

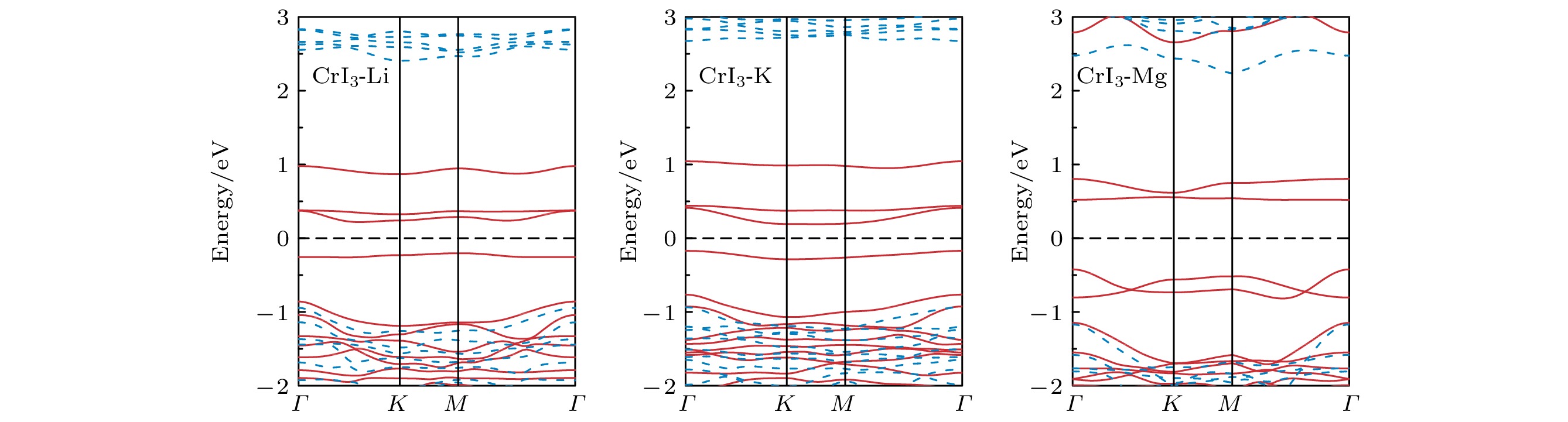

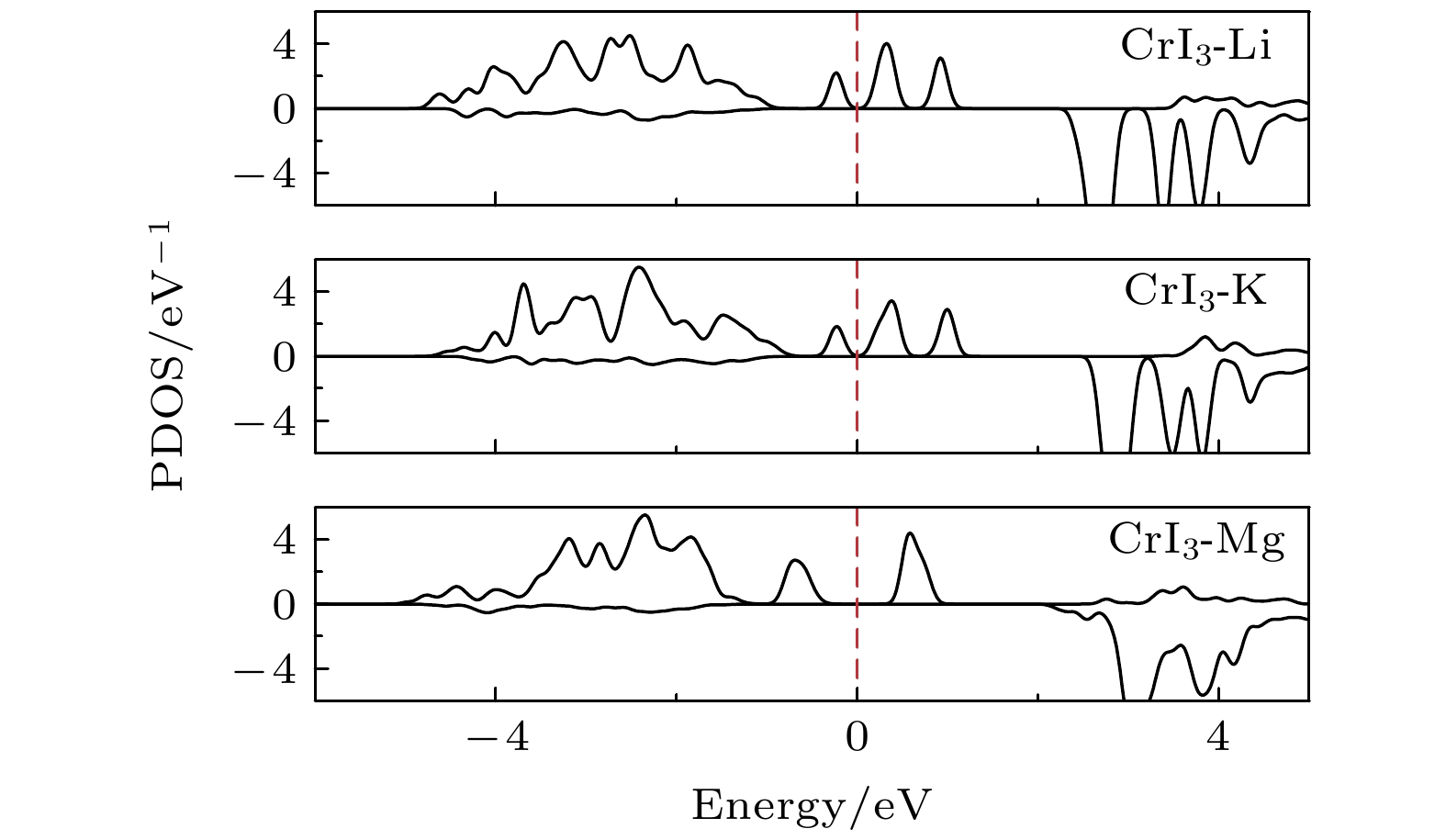

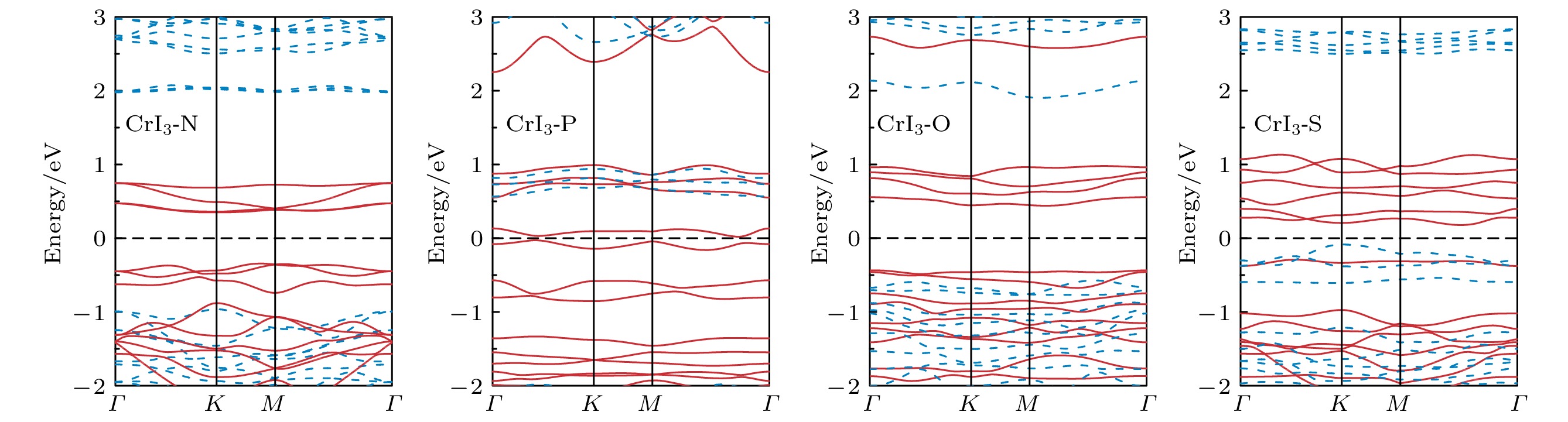

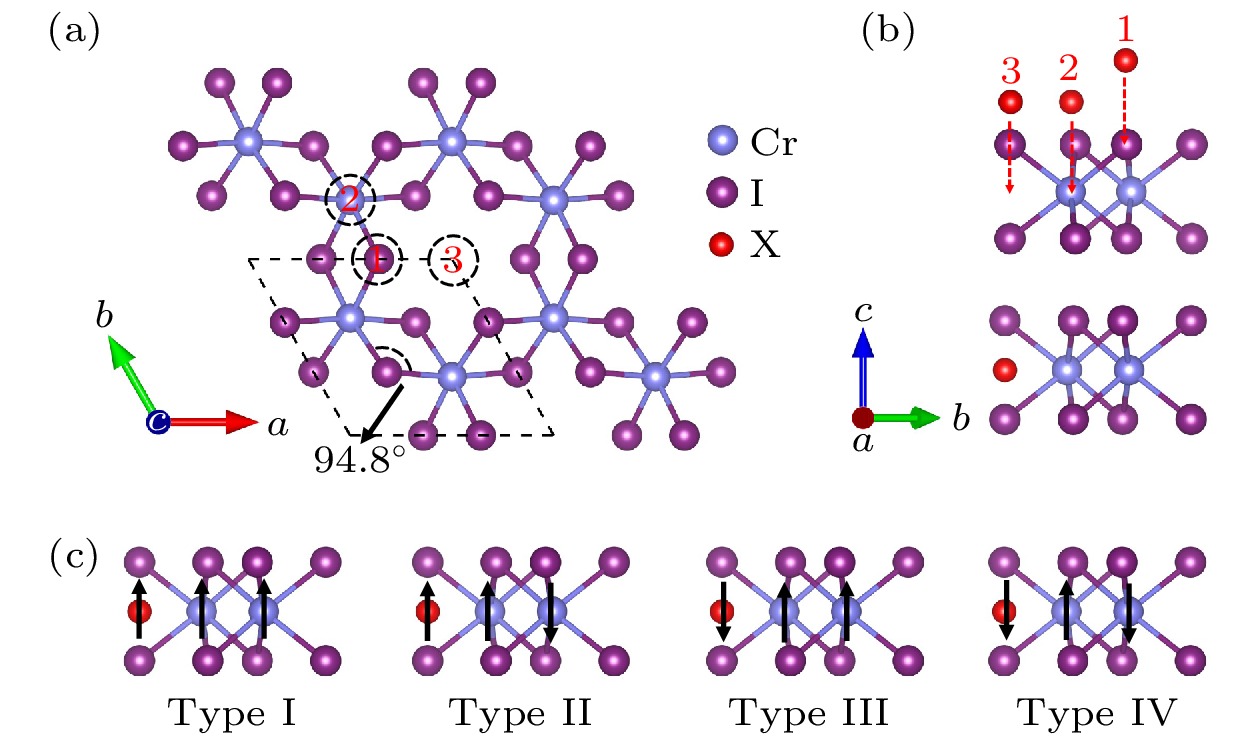

图 1 (a) CrI3单层的原子结构俯视图(3个不同的吸附位用黑色的虚线圆圈表示); (b) CrI3单层的原子结构侧视图(上图中红色球为3个不同的吸附位, 下图中红色球为原子在吸附位3处吸附后的原子优化位置); (c) 四种不同的磁构型结构

Fig. 1. (a) Top view of atomic structure diagram of CrI3 monolayer (three different adsorption sites are represented by black dashed circle); (b) side view of atomic structure diagram of CrI3 monolayer (three different adsorption sites are shown with red balls in the top picture, and the optimized site of adsorption atom is shown with red ball in the bottom picture); (c) four different magnetic configurations.

图 2 完美CrI3单层的 (a) 能态密度(红色实线表示Cr-d轨道的分波态密度, 蓝色实线表示I-p轨道的分波态密度)和 (b) 能带结构(红色实线表示上自旋电子的能带, 蓝色虚线表示下自旋电子的能带)

Fig. 2. (a) Energy density of states (red solid line for Cr-d projected density of states, blue solid line for I-p projected density of states) and (b) band structure (red solid line for spin up, blue dashed line for spin down) of perfect CrI3 monolayer.

表 1 各种原子位于不同吸附位的CrI3单层优化后的体系能量(E )

Table 1. Energies (E ) of the optimized CrI3 monolayer with various atoms adsorbed at different sites.

原子 E位置1/eV E位置2/eV E位置3/eV Li –32.147 –31.308 –32.152 K –31.411 –30.634 –31.430 Mg –32.156 –31.267 –32.173 Ti — –35.245 –35.472 V –35.293 –34.067 –36.513 Mn –36.923 –35.369 –36.937 Fe –31.450 –33.560 –34.959 Co –30.225 –31.895 –33.242 Ni –29.182 –30.606 –31.603 N –31.274 –32.801 –33.337 P –31.362 –31.664 –31.798 O –32.233 –33.183 –33.240 S –30.657 –30.155 –30.887 表 2 碱(土)金属原子吸附后的CrI3单层的能量(E )和Cr原子的局域磁矩(MCr)

Table 2. Energy (E ) and local magnetic moments (MCr) of CrI3 monolayer adsorbed by alkali (alkaline earth) metal atoms.

原子 E/meV MCr/μB 铁磁 反铁磁 Li 0 59 (4, 3) K 0 52 (4, 3) Mg 0 6 (4, 4) 表 3 过渡金属原子吸附后的CrI3单层的能量(E )和Cr原子的局域磁矩(MCr)

Table 3. Energy (E ) and local magnetic moments (MCr) of CrI3 monolayer adsorbed by transition metal atoms.

原子 E/meV MCr/μB Type Ⅰ Type Ⅱ Type Ⅲ Type Ⅳ Ti 570 0 12 0 (4, –4) V 0 22 30 22 (4, 4) Mn 37 0 38 0 (4, –4) Fe 40 14 0 14 (4, 4) Co 41 40 0 35 (4, 4) Ni 67 38 0 38 (4, 4) 表 4 非金属原子吸附后的CrI3单层的能量(E )和Cr原子的局域磁矩(MCr)

Table 4. Energy (E ) and local magnetic moments (MCr) of CrI3 monolayer adsorbed by non-metal atoms.

原子 E/meV MCr/μB Type Ⅰ Type Ⅱ Type Ⅲ Type Ⅳ N 0 63 37 63 (3, 3) P 0 29 — — (4.5, 4.5) O 0 89 — — (3, 3) S 210 71 0 71 (4, 4) -

[1] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[2] Ferrari A C, Meyer J C, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov K S, Roth S, Geim A K 2006 Phys. Rev. Lett. 97 187401

Google Scholar

Google Scholar

[3] Castro Neto A H, Guinea F, Peres N M R, Novoselov K S, Geim A K 2009 Rev. Mod. Phys. 81 109

Google Scholar

Google Scholar

[4] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[5] Chen Q, Ouyang Y, Yuan S, Li R, Wang J 2014 ACS Appl. Mater. Inter. 6 16835

Google Scholar

Google Scholar

[6] Dong L, Kumar H, Anasori B, Gogotsi Y, Shenoy V B 2017 J. Phys. Chem. Lett. 8 422

Google Scholar

Google Scholar

[7] Ma X C, Wu X, Wang H D, Wang Y C 2018 J. Mater. Chem. A 6 2295

Google Scholar

Google Scholar

[8] Kadantsev E S, Hawrylak P 2012 Solid State Commun. 152 909

Google Scholar

Google Scholar

[9] Li F, Wei W, Zhao P, Huang B, Dai Y 2017 J. Phys. Chem. Lett. 8 5959

Google Scholar

Google Scholar

[10] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[11] Dean C R, Young A F, Meric I, Lee C, Wang L, Sorgenfrei S, Watanabe K, Taniguchi T, Kim P, Shepard K L, Hone J 2010 Nat. Nanotechnol. 5 722

Google Scholar

Google Scholar

[12] Qiao J, Kong X, Hu Z X, Yang F, Ji W 2014 Nat. Commun. 5 4475

Google Scholar

Google Scholar

[13] Li L, Yu Y, Ye G J, Ge Q, Ou X, Wu H, Feng D, Chen X H, Zhang Y 2014 Nat. Nanotechnol. 9 372

Google Scholar

Google Scholar

[14] Wang Q H, Kalantar-Zadeh K, Kis A, Coleman J N, Strano M S 2012 Nat. Nanotechnol. 7 699

Google Scholar

Google Scholar

[15] Ghorbani-Asl M, Kuc A, Miro P, Heine T 2016 Adv. Mater. 28 853

Google Scholar

Google Scholar

[16] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol. 6 147

Google Scholar

Google Scholar

[17] Tao L, Cinquanta E, Chiappe D, Grazianetti C, Fanciulli M, Dubey M, Molle A, Akinwande D 2015 Nat. Nanotechnol. 10 227

Google Scholar

Google Scholar

[18] Ma L, Dai J, Zeng X C 2017 Adv. Energy Mater. 7

Google Scholar

Google Scholar

[19] Jing Y, Zhou Z, Cabrera C R, Chen Z 2014 J. Mater. Chem. A 2

Google Scholar

Google Scholar

[20] Bonaccorso F, Colombo L, Yu G, Stoller M, Tozzini V, Ferrari A C, Ruoff R S, Pellegrini V 2015 Science 347 1246501

Google Scholar

Google Scholar

[21] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X 2017 Nature 546 270

Google Scholar

Google Scholar

[22] Zhang W B, Qu Q, Zhu P, Lam C H 2015 J. Mater. Chem. C 3 12457

Google Scholar

Google Scholar

[23] Fu Y K, Sun Y, Luo X 2019 J. Appl. Phys. 125 053901

Google Scholar

Google Scholar

[24] Wang H B, Fan F R, Zhu S S, Wu H 2016 Europhys. Lett. 114 47001

Google Scholar

Google Scholar

[25] McGuire M A, Dixit H, Cooper V R, Sales B C 2015 Chem. Mater. 27 612

Google Scholar

Google Scholar

[26] Webster L, Liang L, Yan J A 2018 Phys. Chem. Chem. Phys. 20 23546

Google Scholar

Google Scholar

[27] Larson D T, Kaxiras E 2018 Phys. Rev. B 98 085406

Google Scholar

Google Scholar

[28] Shcherbakov D, Stepanov P, Weber D, Wang Y, Hu J, Zhu Y, Watanabe K, Taniguchi T, Mao Z, Windl W, Goldberger J, Bockrath M, Lau C N 2018 Nano Lett. 18 4214

Google Scholar

Google Scholar

[29] Chen L B, Chung J H, Gao B, Chen T, Stone M B, Kolesnikov A I, Huang Q Z, Dai P C 2018 Phys. Rev. X 8 041028

Google Scholar

Google Scholar

[30] Zeng Y, Wang L, Li S, He C, Zhong D, Yao D X 2019 J. Phys. Codens. Mat. 31 395502

Google Scholar

Google Scholar

[31] Zhou Y G, Wang Z G, Yang P, Zu X T, Yang L, Sun X, Gao F 2012 ACS Nano 6 9727

Google Scholar

Google Scholar

[32] Zhu S Z, Li T 2016 Phys. Rev. B 93 115401

Google Scholar

Google Scholar

[33] 吴木生, 徐波, 刘刚, 欧阳楚英 2012 61 227102

Google Scholar

Google Scholar

Wu M S, Xu B, Liu G, Ouyang C Y 2012 Acta Phys. Sin. 61 227102

Google Scholar

Google Scholar

[34] Rai H M, Saxena S K, Mishra V, Late R, Kumar R, Sagdeo P R, Jaiswal N K, Srivastava P 2016 RSC Adv. 6 11014

Google Scholar

Google Scholar

[35] Osada M, Yoguchi S, Itose M, Li B W, Ebina Y, Fukuda K, Kotani Y, Ono K, Ueda S, Sasaki T 2014 Nanoscale 6 14227

Google Scholar

Google Scholar

[36] Guan J, Yu G, Ding X, Chen W, Shi Z, Huang X, Sun C 2013 Chemphyschem. 14 2841

Google Scholar

Google Scholar

[37] Du A J, Chen Y, Zhu Z H, Amal R, Lu G Q, Smith S C 2009 J. Am. Chem. Soc. 131 17354

Google Scholar

Google Scholar

[38] 黄炳铨, 周铁戈, 吴道雄, 张召富, 李百奎 2019 68 246301

Google Scholar

Google Scholar

Huang B Q, Zhou T G, Wu D X, Zhang Z F, Li B K 2019 Acta Phys. Sin. 68 246301

Google Scholar

Google Scholar

[39] Kan E, Li M, Hu S, Xiao C, Xiang H, Deng K 2013 J. Phys. Chem. Lett. 4 1120

Google Scholar

Google Scholar

[40] Barone V, Peralta J E 2008 Nano Lett. 8 2210

Google Scholar

Google Scholar

[41] Allen M J, Tung V C, Kaner R B 2010 J. Am. Chem. Soc. 110 132

Google Scholar

Google Scholar

[42] Lee K W, Lee C E 2012 Adv. Mater. 24 2019

Google Scholar

Google Scholar

[43] 栾晓玮, 孙建平, 王凡嵩, 韦慧兰, 胡艺凡 2019 68 026802

Google Scholar

Google Scholar

Luan X W, Sun J P, Wang F S, Wei H L, Hu Y F 2019 Acta Phys. Sin. 68 026802

Google Scholar

Google Scholar

[44] 杨光敏, 梁志聪, 黄海华 2017 66 057301

Google Scholar

Google Scholar

Yang G M, Liang Z C, Huang H H 2017 Acta Phys. Sin. 66 057301

Google Scholar

Google Scholar

[45] Zheng F W, Zhao J Z, Liu Z, Li M L, Zhou M, Zhang S B, Zhang P 2018 Nanoscale 10 14298

Google Scholar

Google Scholar

[46] Gao Y, Wang J, Li Z P, Yang J J, Xia M R, Hao X F, Xu Y H, Gao F M 2019 Phys. Status. Solidi-R. 13 1800410

Google Scholar

Google Scholar

[47] Qin W J, Xu B, Liao S S, Liu G, Sun B Z, Wu M S 2020 Solid State Commun. 321 114037

Google Scholar

Google Scholar

[48] Liu J, Shi M C, Lu J W, Anantram M P 2018 Phys. Rev. B 97 054416

Google Scholar

Google Scholar

[49] Guo Y L, Yuan S J, Wang B, Shi L, Wang J L 2018 J. Mater. Chem. C 6 5716

Google Scholar

Google Scholar

[50] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[51] Kresse G, Hafner J 1994 Phys. Rev. B: Condens. Matter 49 14251

Google Scholar

Google Scholar

[52] Kresse G, Furthmiiller J 1996 Science 6 15

[53] Blochl P E 1994 Phys. Rev. B: Condens. Matter 50 17953

Google Scholar

Google Scholar

[54] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[55] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[56] Perdew J P, Ernzerhof M, Burke K 1996 J. Chem. Phys. 105 9982

Google Scholar

Google Scholar

[57] Liechtenstein A I, Anisimov V V, Zaanen J 1995 Phys. Rev. B: Condens. Matter 52 R5467

Google Scholar

Google Scholar

[58] Monkhorst H J, Pack J D 1976 Phys. Rev. B 13 5188

Google Scholar

Google Scholar

[59] Goodenough J B 1958 J. Phys. Chem. Solids 6 287

Google Scholar

Google Scholar

[60] Anderson P W 1959 Phys. Rev. 115 2

Google Scholar

Google Scholar

计量

- 文章访问数: 9200

- PDF下载量: 206

- 被引次数: 0

下载:

下载: