-

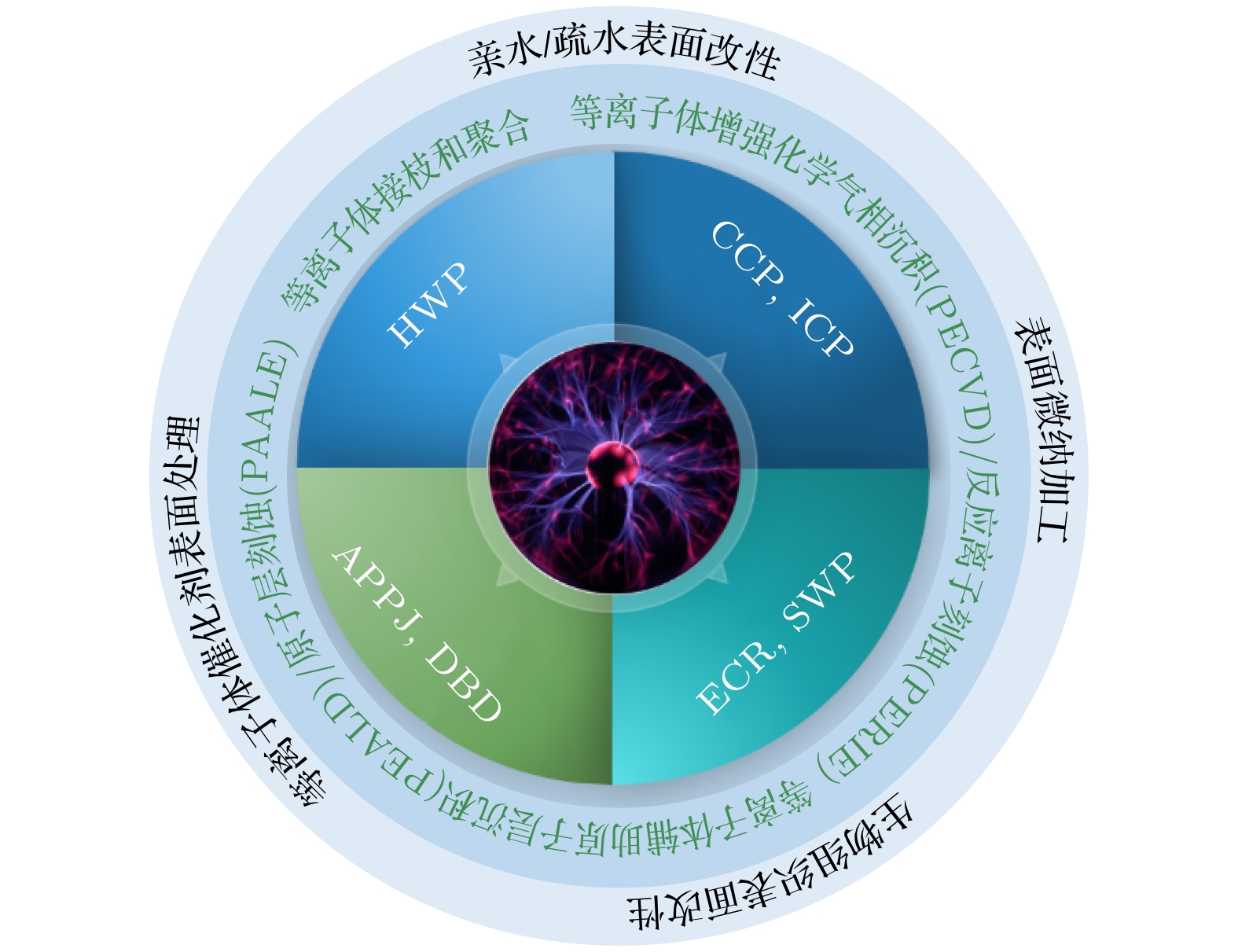

等离子体技术在现代材料制备和表面处理过程中起着重要的作用. 本文聚焦于非热等离子体(NTP)材料表面处理及功能化应用, 重点综述NTP在材料表面处理及功能化过程中的最新研究进展, 包括激励产生等离子体的等离子体源、NTP材料表面处理及功能化工艺以及具体应用. 其中, 激励产生等离子体的等离子体源包括感应耦合等离子体/容性耦合等离子体、电子回旋共振/表面波等离子体、螺旋波等离子体、大气压射流等离子体和介质阻挡放电等; NTP材料表面处理及功能化工艺包括等离子体表面接枝和聚合、等离子体增强化学气相沉积和等离子体辅助原子层沉积、等离子体增强反应刻蚀和等离子体辅助原子层刻蚀工艺等; 等离子体表面处理及功能化的具体应用领域包括亲水/疏水表面改性、表面微纳加工、生物组织表面处理、催化剂表面处理等. 最后提出了NTP技术材料表面处理及功能化的应用前景与发展趋势.Plasma technology plays an important role in preparing and processing materials nowadays. This review focuses on the applications of non-thermal plasma (NTP) in the surface treatment and functionalization of materials, including the plasma sources for generating plasmas, NTP techniques and specific application fields. The plasma sources include inductively coupled plasma, capacitively coupled plasma, electron cyclotron resonance plasma, surface wave plasma, helicon wave plasma, atmospheric pressure plasma jet, and dielectric barrier discharge plasma. The NTP techniques for material surface treatment and functionalization include plasma surface grafting and polymerization, plasma enhanced chemical vapor deposition, plasma assisted atomic layer deposition, plasma enhanced reactive ion etching, and plasma assisted atomic layer etching. Specific applications of plasma surface treatment and functionalization cover hydrophilic/hydrophobic surface modification, surface micro-nano processing, biological tissue surface treatment, and catalyst surfaces treatment. Finally, the application prospects and development trends of NTP technology for material surface treatment and functionalization are proposed.

-

Keywords:

- plasma /

- surface treatment /

- grafting /

- polymerization /

- deposition /

- etching

[1] Zhang H B, Sang L J, Wang Z D, Liu Z W, Yang L Z, Chen Q 2018 Plasma Sci. Technol. 20 063001

Google Scholar

Google Scholar

[2] Langmuir I 1928 Proc. Natl Acad. Sci. 14 627

Google Scholar

Google Scholar

[3] Desmet T, Morent R, De Geyter N, Leys C, Schacht E, Dubruel P 2009 Biomacromolecules 10 2351

Google Scholar

Google Scholar

[4] Li Y P, Zhang Z C, Shi W, Lei M K 2014 Surf. Coat. Technol. 259 77

Google Scholar

Google Scholar

[5] Kim H, Jung S J, Han Y H, Lee H Y, Kim J N, Jang D S, Lee J J 2008 Thin Solid Films 516 3530

Google Scholar

Google Scholar

[6] Han D C, Choi Y C, Shin H J, Kwak G, Ahn K S, Kim J H, Lee D K 2011 Mol. Cryst. Liq. Cryst. 539 210

Google Scholar

Google Scholar

[7] Kim M C, Masuoka T 2009 Appl. Surf. Sci. 255 4684

Google Scholar

Google Scholar

[8] Juarez-Moreno J A, Chacon-Argaez U, Barron-Zambrano J, Carrera-Figueiras C, Quintana-Owen P, Talavera-Pech W, Perez-Padilla Y, Avila-Ortega A 2018 Plasma Sci. Technol. 20 065506

Google Scholar

Google Scholar

[9] Yang L, Wang Z D, Zhang S Y, Yang L Z, Chen Q 2009 Chin. Phys. B 18 5401

Google Scholar

Google Scholar

[10] Liston E M, Martinu L, Wertheimer M R 1993 J. Adhes. Sci. Technol. 7 1091

Google Scholar

Google Scholar

[11] 赵化侨 1993 等离子体化学与工艺 (合肥: 中国科学技术大学出版社) 第186页

Zhao H Q 1993 Plasma Chemistry and Technology (Hefei: China Science and Technology Press) p186 (in Chinese)

[12] Samukawa S, Furuoya S 1993 Appl. Phys. Lett. 63 2044

Google Scholar

Google Scholar

[13] Anton R, Wiegner T, Naumann W, Liebmann M, Klein C, Bradley C 2000 Rev. Sci. Instrum. 71 1177

Google Scholar

Google Scholar

[14] Guruvenket S, Rao G M, Komath M, Raichur A M 2004 Appl. Surf. Sci. 236 278

Google Scholar

Google Scholar

[15] Guruvenket S, Komath M, Vijayalakshmi S P, Raichur A M, Rao G M 2003 J. Appl. Polym. Sci. 90 1618

Google Scholar

Google Scholar

[16] Conrads H, Schmidt M 2000 Plasma Sources Sci. Technol. 9 441

Google Scholar

Google Scholar

[17] Shenton M, Lovell-Hoare M, Stevens G C 2001 J. Phys. D: Appl. Phys. 34 2754

Google Scholar

Google Scholar

[18] Takagi S, Yamazaki O, Yamauchi K, Shinmura T 2013 Jpn. J. Appl. Phys. 52 086502

Google Scholar

Google Scholar

[19] 蓝朝晖, 胡希伟, 江中和, 刘明海 2010 59 4093

Google Scholar

Google Scholar

Lan C H, Hu X W, Jiang Z H, Liu M H 2010 Acta Phys. Sin. 59 4093

Google Scholar

Google Scholar

[20] Bogdanov T, Tsonev I, Marinova P, Benova E, Rusanov K, Rusanova M, Atanassov I, Kozakova Z, Krcma F 2018 Appl. Sci. 8 1870

Google Scholar

Google Scholar

[21] Sasai K, Suzuki H, Toyoda H 2016 Jpn. J. Appl. Phys. 55 016203

Google Scholar

Google Scholar

[22] Boswell R W 1970 Phys. Lett. A 33 457

Google Scholar

Google Scholar

[23] Tynan G R, Bailey III A D, Campbell G A, Charatan R, de Chambrier A, Gibson G, Hemker D J, Jones K, Kuthi A, Lee C, Shoji T, Wilcoxson M 1997 J. Vac. Sci. Technol. A 15 2885

Google Scholar

Google Scholar

[24] Chen F F, Evans J D, Tynan G R 2001 Plasma Sources Sci. Technol. 10 236

Google Scholar

Google Scholar

[25] Chen F F, Torreblanca H 2007 Plasma Phys. Controlled Fusion 49 A81

Google Scholar

Google Scholar

[26] Chen F F 2008 IEEE Trans. Plasma Sci. 36 2095

Google Scholar

Google Scholar

[27] Chen F F, Torreblanca H 2009 Phys. Plasmas 16 057102

Google Scholar

Google Scholar

[28] Zhang G L, Huang T Y, Jin C G, Wu X M, Zhuge L J, Ji H T 2018 Plasma Sci. Technol. 20 085603

Google Scholar

Google Scholar

[29] Huang T Y, Jin C G, Yu Y W, Hu J S, Yang J H, Ding F, Chen X H, Ji P Y, Qian J W, Huang J J, Yu B, Wu X M 2020 IEEE Trans. Plasma Sci. 48 2878

Google Scholar

Google Scholar

[30] Akishev Y, Goossens O, Callebaut T, Leys C, Napartovich A, Trushkin N 2001 J. Phys. D: Appl. Phys. 34 2875

Google Scholar

Google Scholar

[31] Moon S Y, Choe W, Kang B K 2004 Appl. Phys. Lett. 84 188

Google Scholar

Google Scholar

[32] Moon S Y, Choe W, Uhm H S, Hwang Y S, Choi J J 2002 Phys. Plasmas 9 4045

Google Scholar

Google Scholar

[33] 梅丹华, 方志, 邵涛 2020 中国电机工程学报 40 1339

Google Scholar

Google Scholar

Mei D, Fang Z, Shao T 2020 Proc. CSEE 40 1339

Google Scholar

Google Scholar

[34] Massines F, Gherardi N, Naudé N, Ségur P 2005 Plasma Phys. Controlled Fusion 47 B577

Google Scholar

Google Scholar

[35] Lu X, Keidar M, Laroussi M, Choi E, Szili E J, Ostrikov K 2019 Mater. Sci. Eng., R. 138 36

Google Scholar

Google Scholar

[36] 吴淑群, 聂兰兰, 卢新培 2015 高电压技术 41 2602

Google Scholar

Google Scholar

Wu S Q, Nie L L, Lu X P 2015 High Volt. Eng. 41 2602

Google Scholar

Google Scholar

[37] Kong F, Zhang P H, Yu W X, Zhang C, Liu J B, Ren C Y, Shao T 2020 Appl. Surf. Sci. 527 146826

Google Scholar

Google Scholar

[38] 胡多, 任成燕, 章程, 邱锦涛, 孔飞, 邵涛, 严萍 2019 中国电机工程学报 39 4633

Google Scholar

Google Scholar

Hu D, Ren C Y, Zhang C, Qiu J T, Kong F, Shao T, Yan P 2019 Proc. CSEE 39 4633

Google Scholar

Google Scholar

[39] 王新新 2009 高电压技术 34 1

Google Scholar

Google Scholar

Wang X X 2009 High Volt. Eng. 34 1

Google Scholar

Google Scholar

[40] Fridman A, Chirokov A, Gutsol A 2005 J. Phys. D: Appl. Phys. 38 R1

Google Scholar

Google Scholar

[41] Foest R, Schmidt M, Becker K 2006 Int. J. Mass Spectrom. 248 87

Google Scholar

Google Scholar

[42] 牛铮, 邵涛, 章程, 于洋, 姜慧, 严萍 2011 高电压技术 37 1536

Google Scholar

Google Scholar

Niu Z, Shao T, Zhang C, Yu Y, Jiang H, Yan P 2011 High Volt. Eng. 37 1536

Google Scholar

Google Scholar

[43] Kim D Y, Kim S J, Joh H M, Chung T H 2018 Phys. Plasmas 25 073505

Google Scholar

Google Scholar

[44] Zhang H B, Li H, Fang M, Wang Z D, Sang L J, Yang L Z, Chen Q 2016 Appl. Surf. Sci. 388 539

Google Scholar

Google Scholar

[45] 力伯曼 M A, 里登伯格 A J 著 (蒲以康 译) 2007 等离子体放电原理与材料处理 (北京: 科学出版社) 第12−18页

Lieberman M A, Lichtenberg A J (translated by Pu Y K) 2007 Principles of Plasma Discharges and Materials Processing (Beijing: Science Press) pp12−18 (in Chinese)

[46] 戴忠玲, 毛明, 王友年 2006 物理 35 693

Google Scholar

Google Scholar

Dai Z L, Mao M, Wang Y N 2006 Physics 35 693

Google Scholar

Google Scholar

[47] Weng Y, Kushne M J 1992 J. Appl. Phys. 72 33

Google Scholar

Google Scholar

[48] Moisan M, Zakrzewski Z 1991 J. Phys. D: Appl. Phys. 24 1025

Google Scholar

Google Scholar

[49] Boivin R F, Kline J L, Scime E E 2001 Phys. Plasmas 8 5303

Google Scholar

Google Scholar

[50] Wolf R, Sparavigna A C 2010 Engineering 02 397

Google Scholar

Google Scholar

[51] Hansen R H, Schonhorn H 1966 J. Polym. Sci. C 4 203

Google Scholar

Google Scholar

[52] Wang R X, Zhang C, Liu X, Xie Q, Yan P, Shao T 2015 Appl. Surf. Sci. 328 509

Google Scholar

Google Scholar

[53] Mirabedini S M, Arabi H, Salem A, Asiaban S 2007 Prog. Org. Coat. 60 105

Google Scholar

Google Scholar

[54] Tatoulian M, Arefi-Khonsari F, Borra J P 2007 Plasma Processes Polym. 4 360

Google Scholar

Google Scholar

[55] Olivier A, Meyer F, Raquez J M, Damman P, Dubois P 2012 Prog. Polym. Sci. 37 157

Google Scholar

Google Scholar

[56] Sheridan R J, Orski S V, Muramoto S, Stafford C M, Beers K L 2016 Langmuir 32 8071

Google Scholar

Google Scholar

[57] Pandiyaraj K N, Ram Kumar M C, Arun Kumar A, Padmanabhan P V A, Deshmukh R R, Bah M, Ismat S S, Su P G, Halleluyah M, Halim A S 2016 Appl. Surf. Sci. 370 545

Google Scholar

Google Scholar

[58] Wang C, Chen J R 2007 Appl. Surf. Sci. 253 4599

Google Scholar

Google Scholar

[59] Wang C, Chen J R, Li R 2008 Appl. Surf. Sci. 254 2882

Google Scholar

Google Scholar

[60] Vasilets V N, Hermel G, Konig U, Werner C, Muller M, Simon F, Grundke K, Ikada Y, Jacobasch H J 1997 Biomaterials 18 1139

Google Scholar

Google Scholar

[61] Wu T, Efimenko K, Genzer J 2002 J. Am. Chem. Soc. 124 9394

Google Scholar

Google Scholar

[62] Xue Y H, Quan W, Liu X L, Han C, Li H, Liu H 2017 Macromolecules 50 6482

Google Scholar

Google Scholar

[63] Kuzuya M, Yamashiro T, Kondo S I, Tsuiki M 1997 Plasmas Polym. 2 113

Google Scholar

Google Scholar

[64] Sasai Y, Oikawa M, Kondo S-i, Kuzuya M 2007 J. Photopolym. Sci. Technol. 20 197

Google Scholar

Google Scholar

[65] Sasai Y, Kondo S I, Yamauchi Y, Kuzuya M 2006 J. Photopolym. Sci. Technol. 19 265

Google Scholar

Google Scholar

[66] Kuzuya M, Sawa T, Mouri M, Kondo S I, Takai O 2003 Surf. Coat. Technol. 169-170 587

Google Scholar

Google Scholar

[67] Kuzuya M, Sawa T, Yamashiro T, Kondo S I, Takai O 2001 J. Photopolym. Sci. Technol. 14 87

Google Scholar

Google Scholar

[68] Biederman H 1987 Vacuum 37 367

Google Scholar

Google Scholar

[69] Goodman I, Nesbitt B F 1960 Polymer 1 384

Google Scholar

Google Scholar

[70] Goodman J 1960 J. Polym. Sci. Part A: Polym. Chem. 44 551

Google Scholar

Google Scholar

[71] Pandiyaraj K N, Ferraria A M, do Rego A M B, Deshmukh R R, Su P G, Halleluyah M, Halim A S 2015 Appl. Surf. Sci. 328 1

Google Scholar

Google Scholar

[72] Friedrich J 2011 Plasma Processes Polym. 8 783

Google Scholar

Google Scholar

[73] Ligot S, Bousser E, Cossement D, Klemberg-Sapieha J, Viville P, Dubois P, Snyders R 2015 Plasma Processes Polym. 12 508

Google Scholar

Google Scholar

[74] Xu L, Guo Y, Liu L, Bai G, Shi J, Zhang L, Chang X, Zhang R, Zhang J, Yu J 2020 Prog. Org. Coat. 146 105727

Google Scholar

Google Scholar

[75] Bélard L, Poncin-Epaillard F, Dole P, Avérous L 2013 Eur. Polym. J. 49 882

Google Scholar

Google Scholar

[76] Tkavc T, Petrinič I, Luxbacher T, Vesel A, Ristić T, Zemljič L F 2014 Int. J. Adhes. Adhes. 48 168

Google Scholar

Google Scholar

[77] Han D C, Choi Y C, Shin H J, Son S, Kim J H, Sohn S H, Lee D K 2010 Mol. Cryst. Liq. Cryst. 532 148

Google Scholar

Google Scholar

[78] Dayss E, Leps G, Meinhardt J 1999 Surf. Coat. Technol. 116-119 986

Google Scholar

Google Scholar

[79] Fang Z, Liu Y, Liu K, Shao T, Zhang C 2012 Vacuum 86 1305

Google Scholar

Google Scholar

[80] Polonskyi O, Kylian O, Petr M, Choukourov A, Hanus J, Biederman H 2013 Thin Solid Films 540 65

Google Scholar

Google Scholar

[81] Wang H, Yang L Z, Chen Q 2014 Plasma Sci. Technol. 16 37

Google Scholar

Google Scholar

[82] Park M, Oh S, Kim H, Jung D, Choi D, Park J S 2013 Thin Solid Films 546 153

Google Scholar

Google Scholar

[83] Starostin S A, Creatore M, Bouwstra J B, van de Sanden M C M, de Vries H W 2015 Plasma Processes Polym. 12 545

Google Scholar

Google Scholar

[84] Scopece P, Viaro A, Sulcis R, Kulyk I, Patelli A, Guglielmi M 2009 Plasma Processes Polym. 6 S705

Google Scholar

Google Scholar

[85] Durocher-Jean A, Durán I R, Asadollahi S, Laroche G, Stafford L 2020 Plasma Processes Polym. 17 1900229

Google Scholar

Google Scholar

[86] Fei F, Chen Q, Liu Z, Liu F, Solodovnyk A 2012 Plasma Chem. Plasma Process. 32 755

Google Scholar

Google Scholar

[87] Fei F, Wang Z, Chen Q, Liu Z, Sang L 2013 Surf. Coat. Technol. 228 S61

Google Scholar

Google Scholar

[88] Seman M T, Richards D N, Rowlette P C, Kubala N G, Wolden C A 2008 J. Vac. Sci. Technol. A 26 1213

Google Scholar

Google Scholar

[89] Ozeki K, Nagashima I, Ohgoe Y, Hirakuri K K, Mukaibayashi H, Masuzawa T 2009 Appl. Surf. Sci. 255 7286

Google Scholar

Google Scholar

[90] Abbas G A, Roy S S, Papakonstantinou P, McLaughlin J A 2005 Carbon 43 303

Google Scholar

Google Scholar

[91] George S M 2010 Chem. Rev. 110 111

Google Scholar

Google Scholar

[92] Guo Z, Li H, Chen Q, Sang L J, Yang L Z, Liu Z W, Wang X W 2015 Chem. Mater. 27 5988

Google Scholar

Google Scholar

[93] Meng X B, Wang X W, Geng D S, Ozgit-Akgun C, Schneider N, Elam J W 2017 Mater. Horiz. 4 133

Google Scholar

Google Scholar

[94] Lee J G, Kim H G, Kim S S 2013 Thin Solid Films 534 515

Google Scholar

Google Scholar

[95] Langereis E, Creatore M, Heil S B S, van de Sanden M C M, Kessels W M M 2006 Appl. Phys. Lett. 89 081915

Google Scholar

Google Scholar

[96] Kim L H, Kim K, Park S, Jeong Y J, Kim H, Chung D S, Kim S H, Park C E 2014 ACS Appl. Mater. Interfaces 6 6731

Google Scholar

Google Scholar

[97] Donnelly V M, Kornblit A 2013 J. Vac. Sci. Technol. A 31 050825

Google Scholar

Google Scholar

[98] Paetzelt H, Böhm G, Arnold T 2015 Plasma Sources Sci. Technol. 24 025002

Google Scholar

Google Scholar

[99] Osipov A A, Iankevich G A, Speshilova A B, Osipov A A, Endiiarova E V, Berezenko V I, Tyurikova I A, Tyurikov K S, Alexandrov S E 2020 Sci. Rep. 10 19977

Google Scholar

Google Scholar

[100] Petit-Etienne C, Darnon M, Vallier L, Pargon E, Cunge G, Fouchier M, Bodart P, Haass M, Brihoum M, Joubert O, Banna S, Lill T 2011 J. Vac. Sci. Technol. B 29 051202

Google Scholar

Google Scholar

[101] Harrison S E, Voss L F, Torres A M, Frye C D, Shao Q H, Nikolic R J 2017 J. Vac. Sci. Technol. A 35 061303

Google Scholar

Google Scholar

[102] 罗童, 陈强 2019 真空与低温 25 19

Google Scholar

Google Scholar

Luo T, Chen Q 2019 Vac. Cryog. 25 19

Google Scholar

Google Scholar

[103] Kanarik K J, Lill T, Hudson E A, Sriraman S, Tan S, Marks J, Vahedi V, Gottscho R A 2015 J. Vac. Sci. Technol. A 33 020802

Google Scholar

Google Scholar

[104] Athavale S D, Economou D J 1995 J. Vac. Sci. Technol. A 13 966

Google Scholar

Google Scholar

[105] Metzler D, Bruce R L, Engelmann S, Joseph E A, Oehrlein G S 2014 J. Vac. Sci. Technol. A 32 020603

Google Scholar

Google Scholar

[106] Honda M, Katsunuma T, Tabata M, Tsuji A, Oishi T, Hisamatsu T, Ogawa S, Kihara Y 2017 J. Phys. D: Appl. Phys. 50 234002

Google Scholar

Google Scholar

[107] Ohba T, Yang W B, Tan S, Kanarik K J, Nojiri K 2017 Jpn. J. Appl. Phys. 56 06HB06

Google Scholar

Google Scholar

[108] Kauppinen C, Khan S A, Sundqvist J, Suyatin D B, Suihkonen S, Kauppinen E I, Sopanen M 2017 J. Vac. Sci. Technol. A 35 060603

Google Scholar

Google Scholar

[109] Benjamin N M P, Chapman B N, Boswell R W 1991 Proc. SPIE 1392 95

Google Scholar

Google Scholar

[110] Mameli A, Verheijen M A, Mackus A J M, Kessels W M M, Roozeboom F 2018 ACS Appl. Mater. Interfaces 10 38588

Google Scholar

Google Scholar

[111] Antoun G, Lefaucheux P, Tillocher T, Dussart R, Yamazaki K, Yatsuda K, Faguet J, Maekawa K 2019 Appl. Phys. Lett. 115 153109

Google Scholar

Google Scholar

[112] Bodas D S, Khan-Malek C 2007 Sens. Actuators, B 120 719

Google Scholar

Google Scholar

[113] Godeau G, Amigoni S, Darmanin T, Guittard F 2016 Appl. Surf. Sci. 387 28

Google Scholar

Google Scholar

[114] Son J, Lee J Y, Han N, Cha J, Choi J, Kwon J, Nam S, Yoo K H, Lee G H, Hong J 2020 Nano Lett. 20 5625

Google Scholar

Google Scholar

[115] Peng Q, Qu L, Dai L, Park K, Vaia R A 2008 ACS Nano 2 1833

Google Scholar

Google Scholar

[116] Graff G L, Williford R E, Burrows P E 2004 J. Appl. Phys. 96 1840

Google Scholar

Google Scholar

[117] Majee S, Cerqueira M F, Tondelier D, Geffroy B, Bonnassieux Y, Alpuim P, Bourée J E 2015 Prog. Org. Coat. 80 27

Google Scholar

Google Scholar

[118] Tashiro H, Nakaya M, Hotta A 2013 Diamond Relat. Mater. 35 7

Google Scholar

Google Scholar

[119] Hwang K H, Seo S W, Jung E, Chae H, Cho S 2014 Korean J. Chem. Eng. 31 528

Google Scholar

Google Scholar

[120] Lim S H, Seo S W, Lee H, Chae H, Cho S M 2016 Korean J. Chem. Eng. 33 1971

Google Scholar

Google Scholar

[121] Popelka A, Abdulkareem A, Mahmoud A A, Nassr M G, Al-Ruweidi M K A A, Mohamoud K J, Hussein M K, Lehocky M, Vesela D, Humpolicek P, Kasak P 2020 Surf. Coat. Technol. 400 126216

Google Scholar

Google Scholar

[122] 周鑫才, 梁徳凤, 陈伟建, 张文浩, 曹颖光, 卢新培 2018 临床口腔医学杂志 34 341

Google Scholar

Google Scholar

Zhou X C, Liang D F, Chen W J, Zhang W H, Cao Y G, Lu X P 2018 J. Clin. Stomatol. 34 341

Google Scholar

Google Scholar

[123] Chang Y C, Lee W F, Feng S W, Huang H M, Lin C T, Teng N C, Chang W J 2016 PLoS One 11 e0146219

Google Scholar

Google Scholar

[124] Yamamoto H, Shibata Y, Miyazaki T 2005 J. Dent. Res. 84 668

Google Scholar

Google Scholar

[125] Pan Y H, Lin J C Y, Chen M K, Salamanca E, Choy C S, Tsai P Y, Leu S J, Yang K C, Huang H M, Yao W L, Chang W J 2020 Materials 13 3771

Google Scholar

Google Scholar

[126] 谢超, 周波, 周灵, 吴雨洁, 王双印 2020 化学进展 32 1172

Google Scholar

Google Scholar

Xie C, Zhou B, Zhou L, Wu Y J, Wang S Y 2020 Prog. Chem. 32 1172

Google Scholar

Google Scholar

[127] Xu L, Jiang Q, Xiao Z, Li X, Huo J, Wang S Y, Dai L 2016 Angew. Chem. Int. Ed. 55 5277

Google Scholar

Google Scholar

[128] Yan D F, Chen R, Xiao Z H, Wang S Y 2019 Electrochim. Acta 303 316

Google Scholar

Google Scholar

[129] Guo Y, Gao X, Zhang C, Wu Y, Chang X, Wang T, Zheng X, Du A, Wang B, Zheng J, Ostrikov K, Li X G 2019 J. Mater. Chem. A 7 8129

Google Scholar

Google Scholar

-

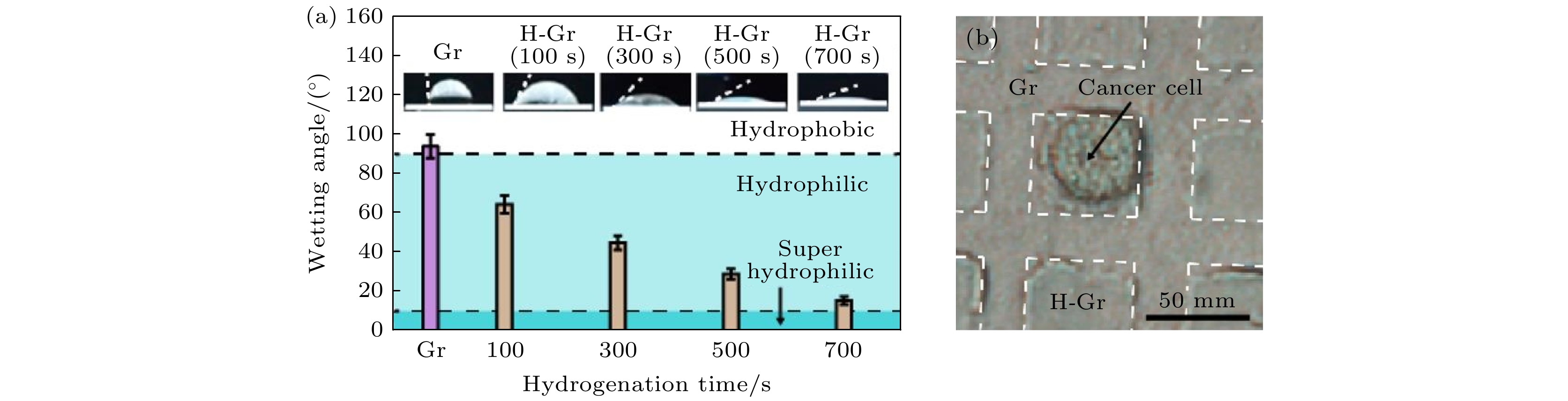

图 5 H2等离子体表面处理石墨烯 (a)处理700 s时石墨烯的水接触角从原始样品的93°下降至16°; (b)改性石墨烯表面亲水性区域对癌细胞的吸附定位[114]

Fig. 5. Modification of graphene by H2 plasma: (a) Control of the graphene wettability via hydrogenation. The as-grown graphene is hydrophobic, with a large wetting angle of 93°. As hydrogenation proceeds, leading to a very small wetting angle of 16° at 700 s. (b) Optical microscopic image of cancer cells positioned on the hydrophilic surface of patterned graphene[114].

表 1 几种非热等离子体源放电参数

Table 1. Discharge parameters of several NTP sources.

NTP源 频率/MHz 气压/Pa 电子温度/eV 电子密度/cm–3 磁场强度/G 参考文献 CCP 0.05—13.56 1—102 1—5 109—1011 0 蒲以康等[45] ICP 1—100 (常用13.56) 10–1—1 1—10 1011—1012 0 戴忠玲等[46] ECR 300—2450 (常用2450, 915) 10–2—10–1 2—20 1011—1013 0—1000 (与频率有关) Weng等[47] SWP 1—10000 (常用2450) 10–1—102 1—10 1011—1012 0 Moisan等[48] HWP 1—50 (常用13.56) 10–2—10 2—20 1011—1014 100—2000 Boivin等[49] APPJ 0—10000 105 1—5 1011—1014 0 吴淑群等[36] DBD 0.05—10 105 1—10 1014—1015 0 Wang等[39] 表 2 非热等离子体聚合物基材表面接枝和聚合

Table 2. Polymer substrate surface grafting and polymerization by NTP.

NTP源 改性气氛 改性基材 主要结论 参考文献 RF-CCP (13.56 MHz) Ar 棉、麻织物 超疏水性(↑)、穿着舒适度(↑) Xu等[74] RF-CCP (13.56 MHz, 20 W) C2H2 聚乳酸、聚已酸内酯 涂层附着性(↑)、氧气阻隔性(↑) Bélard等[75] RF-ICP (27.12 MHz, 200 W) O2, CO2 PET 亲水性(↑)、含氧基团数量(↑) Tkavc等[76] RF-ICP (13.56 MHz, 400 W) O2 PET 表面粗糙度(↑)、水接触角(↓)、

含氧基团数量(↑)Han等[77] MW-ECR (2.45 GHz, 300 W) Ar, AAc PP 表面张力(↑)、Cu涂层附着性(↑) Dayss等[78] MW-SWP (2.45 GHz, 250 W) CO2 聚四氟乙烯(PTFE) 水接触角(↓)、含氧基团数量(↑) Vasilets等[60] MW-SWP (2.45 GHz, 1600 W) Ar 氟基三聚物(THV) 含氧基团数量(↑) Sasai等[21] APPJ (50 kHz, 0—20 kV) TEOS/O2/Ar 聚全氟乙丙烯(FEP) 含硅基团数量(↑)、沿面闪络电压(↑) 胡多等[38] DBD (1 kHz, 25 kV) 空气 PET 表面粗糙度(↑)、水接触角(↓)、

含氧基团数量(↑)Fang等[79] DBD (RTR, 40 kHz) AAc, C2H6O, C3H7N PE 水接触角(↓)、Al 涂层附着性(↑) Zhang等[44] 表 3 非热等离子体沉积无机功能涂层

Table 3. Inorganic functional coatings deposited by NTP.

无机薄膜 NTP源 工作气氛 衬底 主要结论 参考文献 SiOx PECVD (DBD, 200 kHz, 3 kV) TEOS/O2/N2 PEN 附着性能(↑)、阻隔性能(↑) Starostin等[83] SiOx PECVD (CPP, 40 kHz, 50 W) HMDSO/O2 PVC 抗迁移性能(↑) Fei等[86,87] AlOx PECVD (1 Hz, 30 W) TMA/O2 硅片 沉积速率(↑)、薄膜纯度(↑) Seman等[88] DLC PECVD (RF, 13.56 MHz, 250 W) CH4 PTFE 薄膜质量(↑)、阻隔性能(↑) Ozeki等[89] a-C:H PECVD (RF, 13.56 MHz) C2H2/Ar PC, PET 薄膜硬度(↓)、阻隔性能(↑) Abbas等[90] a-C:H PECVD (RF, 13.56 MHz, 0-90 W) n-C6H14/Ar PET, 硅片 致密性(↑)、阻隔性能(↑) Polonsky等[80] SiOxCyHz PECVD (APPJ, 20 kHz, 350 V) 空气/HMDSO PP 阻隔性能(↑) Scopece等[84] SiOxCyH PECVD (MW-APPJ, 2.45 GHz, 2000 W) Ar/HMDSO 玻璃 抗雾性能(↑) Durocher-Jean等[85] AlxOy PAALD (CCP, 60 Hz, 500 W) TMA/O2 PEN WVTR: 8.85 × 10–4 g·m–2·d–1 Lee等[94] Al2O3 PAALD (RF-ICP) TMA/O2 PEN WVTR: 5.0 × 10–3 g·m–2·d–1 Langereis等[95] Al2O3/TiO2 PAALD (APPJ, 20 kHz, 350 V) TMA/TDMAT OTFT 防腐性能(↑)、阻隔性能(↑) Kim等[96] 表 4 非热等离子体辅助材料表面刻蚀

Table 4. Material surface etching assisted by NTP.

衬底 NTP源 刻蚀气体 主要结果 参考文献 Si PERIE (RF-APPJ, 13.56 MHz) He/N2/CF4 刻蚀速率: 0.068 mm3·min–1; RRMS: 0.2—2.44 nm Paetzelt等[98] SiC PERIE (RF-ICP, 6.78 MHz, 1000 W) SF6/O2 刻蚀速率: 1.28 µm·min–1; RRMS: 0.7 nm Osipov等[99] SiO2 PERIE (RF-ICP, 13.56 MHz, 500 W) Cl2 刻蚀速率: 2.2 nm·min-1 Petit-Etienne等[100] GaN PERIE (MW-ECR, 2.45 GHz, 850 W) Cl2 刻蚀速率: 0.28 μm·min–1; 刻蚀选择性: 39∶1 Harrison等[101] HfO2 PERIE (MW-ECR, 2.45 GHz, 600 W) CF4/Ar/O2 刻蚀速率: 0.36 nm·min–1; RRMS: 0.17 nm 罗童等[102] SiO2 PAALE (RF-ICP, 13.56 MHz) Ar/C4F8 刻蚀速率: 0.2—0.3 Å·s–1 Metzler等[105] GaN PAALE (RF-ICP) Cl2/Ar EPC: 0.4 nm·cycle–1; RRMS: 0.6 nm Ohba等[107] GaN PAALE (RF-ICP, 50 W) Cl2/Ar 刻蚀速率: 2.87 Å·cycle–1 Kauppinen等[108] ZnO PAALE (RF-ICP, 13.56 MHz, 200 W) Hacac/O2 EPC: 0.5—1.3 Å·cycle–1; 刻蚀选择性: 80∶1 Mameli等[110] SiO2 PAALE (RF-ICP, 13.56 MHz) Ar/C4F8 EPC: 0.4 nm·cycle–1; RRMS: 1.2 nm Antoun等[111] -

[1] Zhang H B, Sang L J, Wang Z D, Liu Z W, Yang L Z, Chen Q 2018 Plasma Sci. Technol. 20 063001

Google Scholar

Google Scholar

[2] Langmuir I 1928 Proc. Natl Acad. Sci. 14 627

Google Scholar

Google Scholar

[3] Desmet T, Morent R, De Geyter N, Leys C, Schacht E, Dubruel P 2009 Biomacromolecules 10 2351

Google Scholar

Google Scholar

[4] Li Y P, Zhang Z C, Shi W, Lei M K 2014 Surf. Coat. Technol. 259 77

Google Scholar

Google Scholar

[5] Kim H, Jung S J, Han Y H, Lee H Y, Kim J N, Jang D S, Lee J J 2008 Thin Solid Films 516 3530

Google Scholar

Google Scholar

[6] Han D C, Choi Y C, Shin H J, Kwak G, Ahn K S, Kim J H, Lee D K 2011 Mol. Cryst. Liq. Cryst. 539 210

Google Scholar

Google Scholar

[7] Kim M C, Masuoka T 2009 Appl. Surf. Sci. 255 4684

Google Scholar

Google Scholar

[8] Juarez-Moreno J A, Chacon-Argaez U, Barron-Zambrano J, Carrera-Figueiras C, Quintana-Owen P, Talavera-Pech W, Perez-Padilla Y, Avila-Ortega A 2018 Plasma Sci. Technol. 20 065506

Google Scholar

Google Scholar

[9] Yang L, Wang Z D, Zhang S Y, Yang L Z, Chen Q 2009 Chin. Phys. B 18 5401

Google Scholar

Google Scholar

[10] Liston E M, Martinu L, Wertheimer M R 1993 J. Adhes. Sci. Technol. 7 1091

Google Scholar

Google Scholar

[11] 赵化侨 1993 等离子体化学与工艺 (合肥: 中国科学技术大学出版社) 第186页

Zhao H Q 1993 Plasma Chemistry and Technology (Hefei: China Science and Technology Press) p186 (in Chinese)

[12] Samukawa S, Furuoya S 1993 Appl. Phys. Lett. 63 2044

Google Scholar

Google Scholar

[13] Anton R, Wiegner T, Naumann W, Liebmann M, Klein C, Bradley C 2000 Rev. Sci. Instrum. 71 1177

Google Scholar

Google Scholar

[14] Guruvenket S, Rao G M, Komath M, Raichur A M 2004 Appl. Surf. Sci. 236 278

Google Scholar

Google Scholar

[15] Guruvenket S, Komath M, Vijayalakshmi S P, Raichur A M, Rao G M 2003 J. Appl. Polym. Sci. 90 1618

Google Scholar

Google Scholar

[16] Conrads H, Schmidt M 2000 Plasma Sources Sci. Technol. 9 441

Google Scholar

Google Scholar

[17] Shenton M, Lovell-Hoare M, Stevens G C 2001 J. Phys. D: Appl. Phys. 34 2754

Google Scholar

Google Scholar

[18] Takagi S, Yamazaki O, Yamauchi K, Shinmura T 2013 Jpn. J. Appl. Phys. 52 086502

Google Scholar

Google Scholar

[19] 蓝朝晖, 胡希伟, 江中和, 刘明海 2010 59 4093

Google Scholar

Google Scholar

Lan C H, Hu X W, Jiang Z H, Liu M H 2010 Acta Phys. Sin. 59 4093

Google Scholar

Google Scholar

[20] Bogdanov T, Tsonev I, Marinova P, Benova E, Rusanov K, Rusanova M, Atanassov I, Kozakova Z, Krcma F 2018 Appl. Sci. 8 1870

Google Scholar

Google Scholar

[21] Sasai K, Suzuki H, Toyoda H 2016 Jpn. J. Appl. Phys. 55 016203

Google Scholar

Google Scholar

[22] Boswell R W 1970 Phys. Lett. A 33 457

Google Scholar

Google Scholar

[23] Tynan G R, Bailey III A D, Campbell G A, Charatan R, de Chambrier A, Gibson G, Hemker D J, Jones K, Kuthi A, Lee C, Shoji T, Wilcoxson M 1997 J. Vac. Sci. Technol. A 15 2885

Google Scholar

Google Scholar

[24] Chen F F, Evans J D, Tynan G R 2001 Plasma Sources Sci. Technol. 10 236

Google Scholar

Google Scholar

[25] Chen F F, Torreblanca H 2007 Plasma Phys. Controlled Fusion 49 A81

Google Scholar

Google Scholar

[26] Chen F F 2008 IEEE Trans. Plasma Sci. 36 2095

Google Scholar

Google Scholar

[27] Chen F F, Torreblanca H 2009 Phys. Plasmas 16 057102

Google Scholar

Google Scholar

[28] Zhang G L, Huang T Y, Jin C G, Wu X M, Zhuge L J, Ji H T 2018 Plasma Sci. Technol. 20 085603

Google Scholar

Google Scholar

[29] Huang T Y, Jin C G, Yu Y W, Hu J S, Yang J H, Ding F, Chen X H, Ji P Y, Qian J W, Huang J J, Yu B, Wu X M 2020 IEEE Trans. Plasma Sci. 48 2878

Google Scholar

Google Scholar

[30] Akishev Y, Goossens O, Callebaut T, Leys C, Napartovich A, Trushkin N 2001 J. Phys. D: Appl. Phys. 34 2875

Google Scholar

Google Scholar

[31] Moon S Y, Choe W, Kang B K 2004 Appl. Phys. Lett. 84 188

Google Scholar

Google Scholar

[32] Moon S Y, Choe W, Uhm H S, Hwang Y S, Choi J J 2002 Phys. Plasmas 9 4045

Google Scholar

Google Scholar

[33] 梅丹华, 方志, 邵涛 2020 中国电机工程学报 40 1339

Google Scholar

Google Scholar

Mei D, Fang Z, Shao T 2020 Proc. CSEE 40 1339

Google Scholar

Google Scholar

[34] Massines F, Gherardi N, Naudé N, Ségur P 2005 Plasma Phys. Controlled Fusion 47 B577

Google Scholar

Google Scholar

[35] Lu X, Keidar M, Laroussi M, Choi E, Szili E J, Ostrikov K 2019 Mater. Sci. Eng., R. 138 36

Google Scholar

Google Scholar

[36] 吴淑群, 聂兰兰, 卢新培 2015 高电压技术 41 2602

Google Scholar

Google Scholar

Wu S Q, Nie L L, Lu X P 2015 High Volt. Eng. 41 2602

Google Scholar

Google Scholar

[37] Kong F, Zhang P H, Yu W X, Zhang C, Liu J B, Ren C Y, Shao T 2020 Appl. Surf. Sci. 527 146826

Google Scholar

Google Scholar

[38] 胡多, 任成燕, 章程, 邱锦涛, 孔飞, 邵涛, 严萍 2019 中国电机工程学报 39 4633

Google Scholar

Google Scholar

Hu D, Ren C Y, Zhang C, Qiu J T, Kong F, Shao T, Yan P 2019 Proc. CSEE 39 4633

Google Scholar

Google Scholar

[39] 王新新 2009 高电压技术 34 1

Google Scholar

Google Scholar

Wang X X 2009 High Volt. Eng. 34 1

Google Scholar

Google Scholar

[40] Fridman A, Chirokov A, Gutsol A 2005 J. Phys. D: Appl. Phys. 38 R1

Google Scholar

Google Scholar

[41] Foest R, Schmidt M, Becker K 2006 Int. J. Mass Spectrom. 248 87

Google Scholar

Google Scholar

[42] 牛铮, 邵涛, 章程, 于洋, 姜慧, 严萍 2011 高电压技术 37 1536

Google Scholar

Google Scholar

Niu Z, Shao T, Zhang C, Yu Y, Jiang H, Yan P 2011 High Volt. Eng. 37 1536

Google Scholar

Google Scholar

[43] Kim D Y, Kim S J, Joh H M, Chung T H 2018 Phys. Plasmas 25 073505

Google Scholar

Google Scholar

[44] Zhang H B, Li H, Fang M, Wang Z D, Sang L J, Yang L Z, Chen Q 2016 Appl. Surf. Sci. 388 539

Google Scholar

Google Scholar

[45] 力伯曼 M A, 里登伯格 A J 著 (蒲以康 译) 2007 等离子体放电原理与材料处理 (北京: 科学出版社) 第12−18页

Lieberman M A, Lichtenberg A J (translated by Pu Y K) 2007 Principles of Plasma Discharges and Materials Processing (Beijing: Science Press) pp12−18 (in Chinese)

[46] 戴忠玲, 毛明, 王友年 2006 物理 35 693

Google Scholar

Google Scholar

Dai Z L, Mao M, Wang Y N 2006 Physics 35 693

Google Scholar

Google Scholar

[47] Weng Y, Kushne M J 1992 J. Appl. Phys. 72 33

Google Scholar

Google Scholar

[48] Moisan M, Zakrzewski Z 1991 J. Phys. D: Appl. Phys. 24 1025

Google Scholar

Google Scholar

[49] Boivin R F, Kline J L, Scime E E 2001 Phys. Plasmas 8 5303

Google Scholar

Google Scholar

[50] Wolf R, Sparavigna A C 2010 Engineering 02 397

Google Scholar

Google Scholar

[51] Hansen R H, Schonhorn H 1966 J. Polym. Sci. C 4 203

Google Scholar

Google Scholar

[52] Wang R X, Zhang C, Liu X, Xie Q, Yan P, Shao T 2015 Appl. Surf. Sci. 328 509

Google Scholar

Google Scholar

[53] Mirabedini S M, Arabi H, Salem A, Asiaban S 2007 Prog. Org. Coat. 60 105

Google Scholar

Google Scholar

[54] Tatoulian M, Arefi-Khonsari F, Borra J P 2007 Plasma Processes Polym. 4 360

Google Scholar

Google Scholar

[55] Olivier A, Meyer F, Raquez J M, Damman P, Dubois P 2012 Prog. Polym. Sci. 37 157

Google Scholar

Google Scholar

[56] Sheridan R J, Orski S V, Muramoto S, Stafford C M, Beers K L 2016 Langmuir 32 8071

Google Scholar

Google Scholar

[57] Pandiyaraj K N, Ram Kumar M C, Arun Kumar A, Padmanabhan P V A, Deshmukh R R, Bah M, Ismat S S, Su P G, Halleluyah M, Halim A S 2016 Appl. Surf. Sci. 370 545

Google Scholar

Google Scholar

[58] Wang C, Chen J R 2007 Appl. Surf. Sci. 253 4599

Google Scholar

Google Scholar

[59] Wang C, Chen J R, Li R 2008 Appl. Surf. Sci. 254 2882

Google Scholar

Google Scholar

[60] Vasilets V N, Hermel G, Konig U, Werner C, Muller M, Simon F, Grundke K, Ikada Y, Jacobasch H J 1997 Biomaterials 18 1139

Google Scholar

Google Scholar

[61] Wu T, Efimenko K, Genzer J 2002 J. Am. Chem. Soc. 124 9394

Google Scholar

Google Scholar

[62] Xue Y H, Quan W, Liu X L, Han C, Li H, Liu H 2017 Macromolecules 50 6482

Google Scholar

Google Scholar

[63] Kuzuya M, Yamashiro T, Kondo S I, Tsuiki M 1997 Plasmas Polym. 2 113

Google Scholar

Google Scholar

[64] Sasai Y, Oikawa M, Kondo S-i, Kuzuya M 2007 J. Photopolym. Sci. Technol. 20 197

Google Scholar

Google Scholar

[65] Sasai Y, Kondo S I, Yamauchi Y, Kuzuya M 2006 J. Photopolym. Sci. Technol. 19 265

Google Scholar

Google Scholar

[66] Kuzuya M, Sawa T, Mouri M, Kondo S I, Takai O 2003 Surf. Coat. Technol. 169-170 587

Google Scholar

Google Scholar

[67] Kuzuya M, Sawa T, Yamashiro T, Kondo S I, Takai O 2001 J. Photopolym. Sci. Technol. 14 87

Google Scholar

Google Scholar

[68] Biederman H 1987 Vacuum 37 367

Google Scholar

Google Scholar

[69] Goodman I, Nesbitt B F 1960 Polymer 1 384

Google Scholar

Google Scholar

[70] Goodman J 1960 J. Polym. Sci. Part A: Polym. Chem. 44 551

Google Scholar

Google Scholar

[71] Pandiyaraj K N, Ferraria A M, do Rego A M B, Deshmukh R R, Su P G, Halleluyah M, Halim A S 2015 Appl. Surf. Sci. 328 1

Google Scholar

Google Scholar

[72] Friedrich J 2011 Plasma Processes Polym. 8 783

Google Scholar

Google Scholar

[73] Ligot S, Bousser E, Cossement D, Klemberg-Sapieha J, Viville P, Dubois P, Snyders R 2015 Plasma Processes Polym. 12 508

Google Scholar

Google Scholar

[74] Xu L, Guo Y, Liu L, Bai G, Shi J, Zhang L, Chang X, Zhang R, Zhang J, Yu J 2020 Prog. Org. Coat. 146 105727

Google Scholar

Google Scholar

[75] Bélard L, Poncin-Epaillard F, Dole P, Avérous L 2013 Eur. Polym. J. 49 882

Google Scholar

Google Scholar

[76] Tkavc T, Petrinič I, Luxbacher T, Vesel A, Ristić T, Zemljič L F 2014 Int. J. Adhes. Adhes. 48 168

Google Scholar

Google Scholar

[77] Han D C, Choi Y C, Shin H J, Son S, Kim J H, Sohn S H, Lee D K 2010 Mol. Cryst. Liq. Cryst. 532 148

Google Scholar

Google Scholar

[78] Dayss E, Leps G, Meinhardt J 1999 Surf. Coat. Technol. 116-119 986

Google Scholar

Google Scholar

[79] Fang Z, Liu Y, Liu K, Shao T, Zhang C 2012 Vacuum 86 1305

Google Scholar

Google Scholar

[80] Polonskyi O, Kylian O, Petr M, Choukourov A, Hanus J, Biederman H 2013 Thin Solid Films 540 65

Google Scholar

Google Scholar

[81] Wang H, Yang L Z, Chen Q 2014 Plasma Sci. Technol. 16 37

Google Scholar

Google Scholar

[82] Park M, Oh S, Kim H, Jung D, Choi D, Park J S 2013 Thin Solid Films 546 153

Google Scholar

Google Scholar

[83] Starostin S A, Creatore M, Bouwstra J B, van de Sanden M C M, de Vries H W 2015 Plasma Processes Polym. 12 545

Google Scholar

Google Scholar

[84] Scopece P, Viaro A, Sulcis R, Kulyk I, Patelli A, Guglielmi M 2009 Plasma Processes Polym. 6 S705

Google Scholar

Google Scholar

[85] Durocher-Jean A, Durán I R, Asadollahi S, Laroche G, Stafford L 2020 Plasma Processes Polym. 17 1900229

Google Scholar

Google Scholar

[86] Fei F, Chen Q, Liu Z, Liu F, Solodovnyk A 2012 Plasma Chem. Plasma Process. 32 755

Google Scholar

Google Scholar

[87] Fei F, Wang Z, Chen Q, Liu Z, Sang L 2013 Surf. Coat. Technol. 228 S61

Google Scholar

Google Scholar

[88] Seman M T, Richards D N, Rowlette P C, Kubala N G, Wolden C A 2008 J. Vac. Sci. Technol. A 26 1213

Google Scholar

Google Scholar

[89] Ozeki K, Nagashima I, Ohgoe Y, Hirakuri K K, Mukaibayashi H, Masuzawa T 2009 Appl. Surf. Sci. 255 7286

Google Scholar

Google Scholar

[90] Abbas G A, Roy S S, Papakonstantinou P, McLaughlin J A 2005 Carbon 43 303

Google Scholar

Google Scholar

[91] George S M 2010 Chem. Rev. 110 111

Google Scholar

Google Scholar

[92] Guo Z, Li H, Chen Q, Sang L J, Yang L Z, Liu Z W, Wang X W 2015 Chem. Mater. 27 5988

Google Scholar

Google Scholar

[93] Meng X B, Wang X W, Geng D S, Ozgit-Akgun C, Schneider N, Elam J W 2017 Mater. Horiz. 4 133

Google Scholar

Google Scholar

[94] Lee J G, Kim H G, Kim S S 2013 Thin Solid Films 534 515

Google Scholar

Google Scholar

[95] Langereis E, Creatore M, Heil S B S, van de Sanden M C M, Kessels W M M 2006 Appl. Phys. Lett. 89 081915

Google Scholar

Google Scholar

[96] Kim L H, Kim K, Park S, Jeong Y J, Kim H, Chung D S, Kim S H, Park C E 2014 ACS Appl. Mater. Interfaces 6 6731

Google Scholar

Google Scholar

[97] Donnelly V M, Kornblit A 2013 J. Vac. Sci. Technol. A 31 050825

Google Scholar

Google Scholar

[98] Paetzelt H, Böhm G, Arnold T 2015 Plasma Sources Sci. Technol. 24 025002

Google Scholar

Google Scholar

[99] Osipov A A, Iankevich G A, Speshilova A B, Osipov A A, Endiiarova E V, Berezenko V I, Tyurikova I A, Tyurikov K S, Alexandrov S E 2020 Sci. Rep. 10 19977

Google Scholar

Google Scholar

[100] Petit-Etienne C, Darnon M, Vallier L, Pargon E, Cunge G, Fouchier M, Bodart P, Haass M, Brihoum M, Joubert O, Banna S, Lill T 2011 J. Vac. Sci. Technol. B 29 051202

Google Scholar

Google Scholar

[101] Harrison S E, Voss L F, Torres A M, Frye C D, Shao Q H, Nikolic R J 2017 J. Vac. Sci. Technol. A 35 061303

Google Scholar

Google Scholar

[102] 罗童, 陈强 2019 真空与低温 25 19

Google Scholar

Google Scholar

Luo T, Chen Q 2019 Vac. Cryog. 25 19

Google Scholar

Google Scholar

[103] Kanarik K J, Lill T, Hudson E A, Sriraman S, Tan S, Marks J, Vahedi V, Gottscho R A 2015 J. Vac. Sci. Technol. A 33 020802

Google Scholar

Google Scholar

[104] Athavale S D, Economou D J 1995 J. Vac. Sci. Technol. A 13 966

Google Scholar

Google Scholar

[105] Metzler D, Bruce R L, Engelmann S, Joseph E A, Oehrlein G S 2014 J. Vac. Sci. Technol. A 32 020603

Google Scholar

Google Scholar

[106] Honda M, Katsunuma T, Tabata M, Tsuji A, Oishi T, Hisamatsu T, Ogawa S, Kihara Y 2017 J. Phys. D: Appl. Phys. 50 234002

Google Scholar

Google Scholar

[107] Ohba T, Yang W B, Tan S, Kanarik K J, Nojiri K 2017 Jpn. J. Appl. Phys. 56 06HB06

Google Scholar

Google Scholar

[108] Kauppinen C, Khan S A, Sundqvist J, Suyatin D B, Suihkonen S, Kauppinen E I, Sopanen M 2017 J. Vac. Sci. Technol. A 35 060603

Google Scholar

Google Scholar

[109] Benjamin N M P, Chapman B N, Boswell R W 1991 Proc. SPIE 1392 95

Google Scholar

Google Scholar

[110] Mameli A, Verheijen M A, Mackus A J M, Kessels W M M, Roozeboom F 2018 ACS Appl. Mater. Interfaces 10 38588

Google Scholar

Google Scholar

[111] Antoun G, Lefaucheux P, Tillocher T, Dussart R, Yamazaki K, Yatsuda K, Faguet J, Maekawa K 2019 Appl. Phys. Lett. 115 153109

Google Scholar

Google Scholar

[112] Bodas D S, Khan-Malek C 2007 Sens. Actuators, B 120 719

Google Scholar

Google Scholar

[113] Godeau G, Amigoni S, Darmanin T, Guittard F 2016 Appl. Surf. Sci. 387 28

Google Scholar

Google Scholar

[114] Son J, Lee J Y, Han N, Cha J, Choi J, Kwon J, Nam S, Yoo K H, Lee G H, Hong J 2020 Nano Lett. 20 5625

Google Scholar

Google Scholar

[115] Peng Q, Qu L, Dai L, Park K, Vaia R A 2008 ACS Nano 2 1833

Google Scholar

Google Scholar

[116] Graff G L, Williford R E, Burrows P E 2004 J. Appl. Phys. 96 1840

Google Scholar

Google Scholar

[117] Majee S, Cerqueira M F, Tondelier D, Geffroy B, Bonnassieux Y, Alpuim P, Bourée J E 2015 Prog. Org. Coat. 80 27

Google Scholar

Google Scholar

[118] Tashiro H, Nakaya M, Hotta A 2013 Diamond Relat. Mater. 35 7

Google Scholar

Google Scholar

[119] Hwang K H, Seo S W, Jung E, Chae H, Cho S 2014 Korean J. Chem. Eng. 31 528

Google Scholar

Google Scholar

[120] Lim S H, Seo S W, Lee H, Chae H, Cho S M 2016 Korean J. Chem. Eng. 33 1971

Google Scholar

Google Scholar

[121] Popelka A, Abdulkareem A, Mahmoud A A, Nassr M G, Al-Ruweidi M K A A, Mohamoud K J, Hussein M K, Lehocky M, Vesela D, Humpolicek P, Kasak P 2020 Surf. Coat. Technol. 400 126216

Google Scholar

Google Scholar

[122] 周鑫才, 梁徳凤, 陈伟建, 张文浩, 曹颖光, 卢新培 2018 临床口腔医学杂志 34 341

Google Scholar

Google Scholar

Zhou X C, Liang D F, Chen W J, Zhang W H, Cao Y G, Lu X P 2018 J. Clin. Stomatol. 34 341

Google Scholar

Google Scholar

[123] Chang Y C, Lee W F, Feng S W, Huang H M, Lin C T, Teng N C, Chang W J 2016 PLoS One 11 e0146219

Google Scholar

Google Scholar

[124] Yamamoto H, Shibata Y, Miyazaki T 2005 J. Dent. Res. 84 668

Google Scholar

Google Scholar

[125] Pan Y H, Lin J C Y, Chen M K, Salamanca E, Choy C S, Tsai P Y, Leu S J, Yang K C, Huang H M, Yao W L, Chang W J 2020 Materials 13 3771

Google Scholar

Google Scholar

[126] 谢超, 周波, 周灵, 吴雨洁, 王双印 2020 化学进展 32 1172

Google Scholar

Google Scholar

Xie C, Zhou B, Zhou L, Wu Y J, Wang S Y 2020 Prog. Chem. 32 1172

Google Scholar

Google Scholar

[127] Xu L, Jiang Q, Xiao Z, Li X, Huo J, Wang S Y, Dai L 2016 Angew. Chem. Int. Ed. 55 5277

Google Scholar

Google Scholar

[128] Yan D F, Chen R, Xiao Z H, Wang S Y 2019 Electrochim. Acta 303 316

Google Scholar

Google Scholar

[129] Guo Y, Gao X, Zhang C, Wu Y, Chang X, Wang T, Zheng X, Du A, Wang B, Zheng J, Ostrikov K, Li X G 2019 J. Mater. Chem. A 7 8129

Google Scholar

Google Scholar

计量

- 文章访问数: 24216

- PDF下载量: 713

- 被引次数: 0

下载:

下载: