-

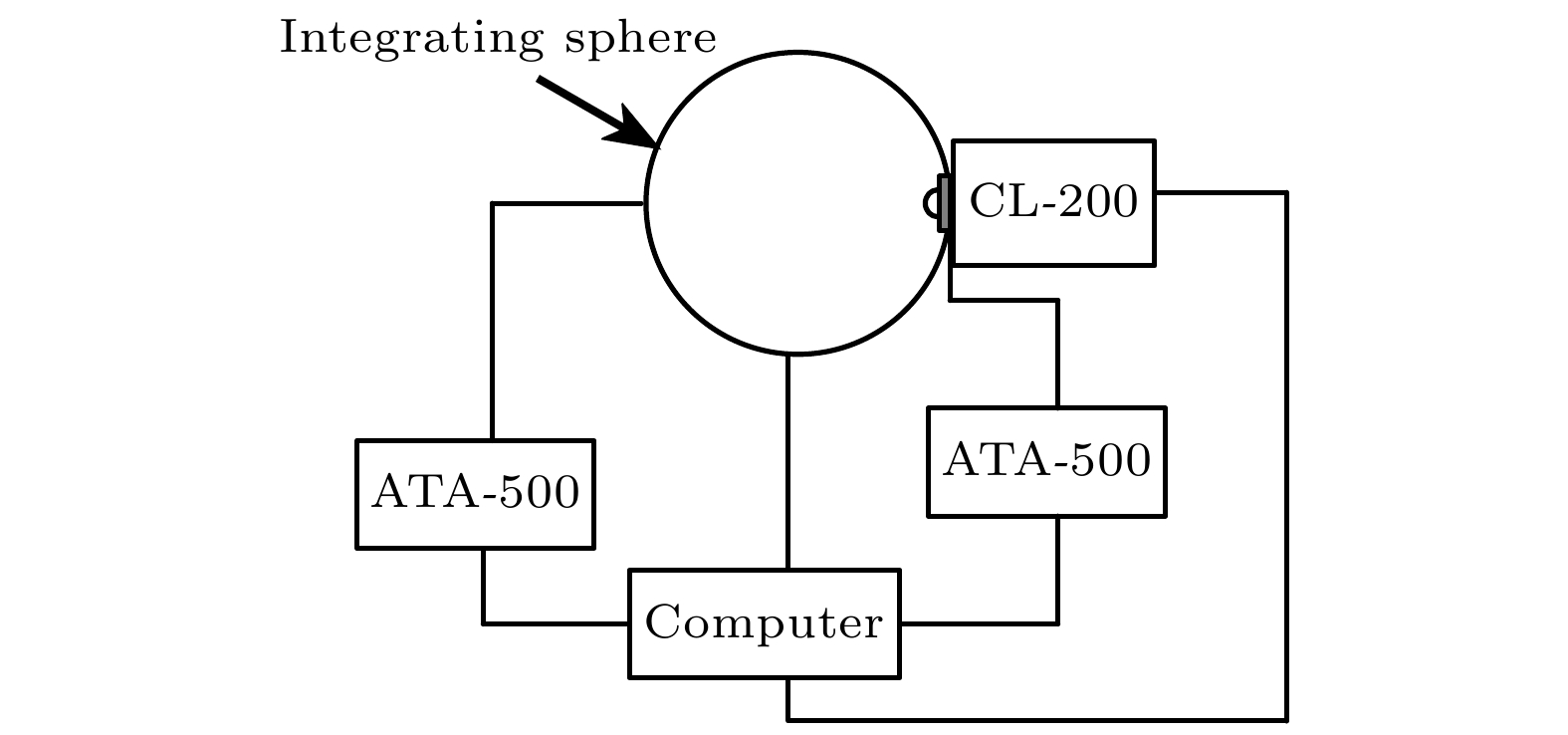

根据白光发光二极管(LED)发光光谱特点, 通过分析蓝光光谱和由蓝光激发黄色荧光粉产生的黄光光谱的交点(即整个光谱的波谷点)特性, 利用常规可见光光谱仪设计了一套基于光谱法的LED稳态热阻测量系统, 采用正常的驱动电流通过一定的函数算法进行拟合, 得到整体光谱波谷处归一化光谱强度与结温间敏感系数K和定标函数, 再根据温升曲线可计算出任意工作状态下LED结温相对于基底的温升, 并结合LED的热耗散功率从而得到LED的稳态热阻. 本方法避免了类似正向压降法采用极小电流定标而需要高速数据采集模块和高速取样转换等模块导致的设备昂贵的缺点, 从而降低了成本. 最后采用本文设计的系统和美国Mentor Graphics公司的T3Ster仪器分别对多种LED进行测量并对结果进行了比较, 发现稳态热阻最大偏离度仅为3.64%. 表明本文设计的系统和方法在不需要昂贵设备的情况下便可以达到与Mentor Graphics公司的T3Ster仪器相仿的精度. 本方法采用非传统式光谱法测量, 具有可远程实时在线检测LED结温和低成本的特点, 对LED封装结构没有任何限制, 因此比Mentor Graphics公司T3Ster设备采用的电压法有更广的应用范围, 具有一定的实用价值.According to the luminous spectrum characteristics of white light emission diode (WLED) light emission spectrum, through the analysis of the intersection (the trough point of the whole spectrum) of blue light spectrum and yellow light spectrum generated by blue light excited yellow phosphor, in this paper we design an LED steady-state thermal resistance measurement system based on the spectroscopic method by using the conventional spectrometer, and we also use the normal driving current to fit the whole spectrum trough through a certain function algorithm. According to the temperature rise curve, we can calculate the temperature rise of the LED junction temperature relative to the substrate under any working condition, and combine the heat dissipation power of the LED to get the steady-state thermal resistance of the LED. This method avoids the limitation of a similar forward voltage drop method which uses the minimum current calibration and requires the modules of high-speed data acquisition and high-speed sampling conversion, thus making the equipment expensive. Therefore it is necessary to reduce its cost. Finally, the system designed in this paper and the T3Ster instrument of Mentor Graphics Corporation in the United States are both used to measure various LEDs and their results are compared with each other. The results show that the maximum deviation of steady-state thermal resistance is only 3.64%. It indicates that the system and method designed in this paper can achieve the same precision as T3Ster instrument of Mentor Graphics Corporation, demonstrating that the system and method designed in this paper can achieve the same precision as the T3Ster instrument of Mentor Graphics, under the condition without needing expensive equipment, Moreover, this method uses non-traditional spectral method to measure the junction temperature of LED, which has the characteristics of remote real-time online detection of LED junction temperature, low cost, and no restrictions on the LED packaging structure. Therefore, this method has a wider application range than the voltage method adopted by Mentor Graphics T3Ster equipment, and has a certain practical value.

[1] 陈依新, 沈光地, 高志远, 郭伟玲, 张光沉, 韩军, 朱彦旭 2011 60 087206

Google Scholar

Google Scholar

Chen Y X, Shen G D, Gao Z Y, Guo W L, Zhang G C, Han J, Zhu Y X 2011 Acta Phys. Sin. 60 087206

Google Scholar

Google Scholar

[2] 郭春生, 张燕峰, 万宁, 李睿, 朱慧, 冯士维 2013 62 218503

Google Scholar

Google Scholar

Guo C S, Zhang Y F, Wan N, Li R, Zhu H, Feng S W 2013 Acta Phys. Sin. 62 218503

Google Scholar

Google Scholar

[3] 赵华龙, 梁志毅, 石兴春, 杨小君 2007 光子学报 36 244

Zhao H L, Liang Z Y, Shi X C, Yang X J 2007 Acta Photon. Sin. 36 244

[4] 杨新, 郭伟玲, 王嘉露, 邓杰, 邰建鹏, 孙捷 2020 光谱学与光谱分析 40 368

Google Scholar

Google Scholar

Yang X, GuoW L, Wang J L, Deng J, Tai J P, Sun J 2020 Spectroscopy and Spectral Analysis 40 368

Google Scholar

Google Scholar

[5] 王健, 黄先, 刘丽, 吴庆, 褚明辉, 张立功, 侯凤勤, 刘学彦, 赵成久, 范翊, 罗劲松, 蒋大鹏 2008 发光学报 29 358

Wang J, Huang X, Liu L, Wu Q, Chu M H, Zhang L G, Hou F Q, Liu X Y, Zhao C J, Fang Y, Luo J S, Jiang D P 2008 Chin. J. Lumin. 29 358

[6] 余彬海, 王垚浩 2005 发光学报 26 761

Google Scholar

Google Scholar

Yu B H, Wang Y H 2005 Chin. J. Lumin. 26 761

Google Scholar

Google Scholar

[7] 招瑜, 魏爱香, 刘俊 2015 64 118501

Google Scholar

Google Scholar

Zhao Y, Wei A X, Liu J 2015 Acta Phys. Sin. 64 118501

Google Scholar

Google Scholar

[8] Chen K, Narendran N 2013 Microelectron. Reliabililty 53 701

Google Scholar

Google Scholar

[9] 程星福, 刘显明, 陈伟民, 赖伟 2014 光电子·激光 25 1949

Cheng X F, Liu X M, Chen W M, Lai W 2014 J. Optoelectron. Laser 25 1949

[10] Gu Y M, Narendran N 2004 Third International Conference on Solid State Lighting, Proceedings of SPIE 5187 San Diego, California, United States, January 26, 2004 p93

[11] 刘康, 孙华锐 2020 69 028501

Google Scholar

Google Scholar

Liu K, Sun H R 2020 Acta Phys. Sin. 69 028501

Google Scholar

Google Scholar

[12] 蒋福春, 何思宇, 刘远海, 刘文, 柴广跃, 赵志刚, 李百奎 2020 光子学报 49 0330003

Google Scholar

Google Scholar

Jiang F C, He S Y, Liu Y H, Liu W, Chai G Y, Zhao Z G, Li B K 2020 Acta Photon. Sin. 49 0330003

Google Scholar

Google Scholar

[13] Hong E, Narendran N 2004 Third International Conference on Solid State Lighting, Proceedings of SPIE 5187 San Diego, California, United States, January 26, 2004 p93

[14] 邱西振, 张方辉 2013 光谱学与光谱分析 33 36

Google Scholar

Google Scholar

Qiu X Z, Zhang F H 2013 Spectroscopy and Spectral Analysis 33 36

Google Scholar

Google Scholar

[15] 陈贵锋, 谭小动, 万尾甜, 沈俊, 郝秋艳, 唐成春, 朱建军, 刘宗顺, 赵德刚, 张书明 2011 60 076104

Google Scholar

Google Scholar

Chen G F, Tian X D, Wan W T, Shen J, Hao Q Y, Tang C C, Zhu J J, Liu X S, Zhao D G, Zhang S M 2011 Acta Phys. Sin. 60 076104

Google Scholar

Google Scholar

[16] 饶丰, 方涛, 王紫凌, 陈晨 2020 光子学报 49 0912002

Google Scholar

Google Scholar

Rao F, Fang T, Wang Z L, Chen C 2020 Acta Photon. Sin. 49 0912002

Google Scholar

Google Scholar

[17] 蒋福春, 何思宇, 刘远海, 刘文, 柴广跃, 李百奎, 彭冬生 2020 光谱学与光谱分析 40 2087

Google Scholar

Google Scholar

Jiang F C, He S Y, Liu Y H, Liu W, Chai G Y, Li B K, Peng D S 2020 Spectroscopy and Spectral Analysis 40 2087

Google Scholar

Google Scholar

[18] 秦贤满 1996 半导体技术 3 32

Qin X M 1996 Semiconductor Technology 3 32

[19] 赵晓霞, 王晓君, 陈宝玖, 孟庆, 裕颜斌, 狄卫华 2007 光谱学与光谱分析 27 629

Zhao X X, Wang X J, Chen B J, Meng Q Y, Yan B, Di W H 2007 Spectroscopy and Spectral Analysis 27 629

[20] 殷录桥, 翁菲, 宋朋, 张金龙, 杨卫桥, 张建华 2014 光学学报 34 0323002

Google Scholar

Google Scholar

Yin L Q, Weng F, Song P, Zhang J L, Yang W Q, Zhang J H 2014 Acta Opt. Sin. 34 0323002

Google Scholar

Google Scholar

-

表 1 不同温度下高色温白光LED光谱波谷相对强度

Table 1. Relative strength of spectral trough of white LED with high color temperature at different temperatures.

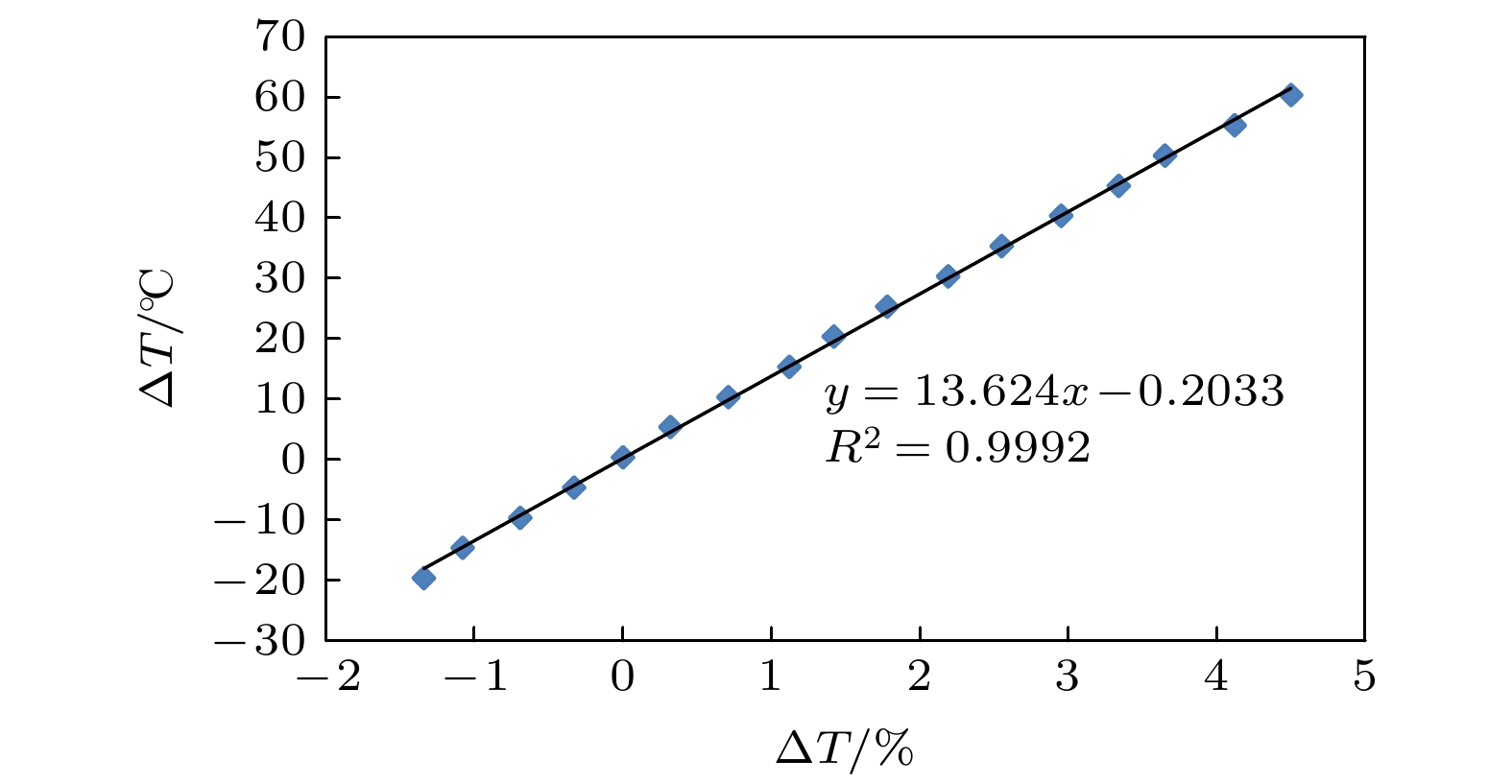

温度 ∆T/℃ 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 波谷相对强度∆I/% 9.98 10.24 10.63 10.99 11.32 11.64 12.03 12.44 12.74 13.10 13.51 13.87 14.27 14.66 14.97 15.44 15.82 表 2 相对于基准状态下, 不同温度下高色温白光LED光谱波谷相对强度

Table 2. Relative strength of spectral trough of white LED with high color temperature at different temperatures to reference state.

温度差 T/℃ –20 –15 –10 –5 0 5 10 15 20 25 30 35 40 45 50 55 60 波谷归一化强度差I/% –1.34 –1.08 –0.69 –0.33 0 0.32 0.71 1.12 1.42 1.78 2.19 2.55 2.95 3.34 3.65 4.12 4.50 表 3 不同温度下低色温白光LED光谱波谷相对强度

Table 3. Relative strength of spectral trough of white LED with high color temperature at different temperatures.

温度差∆Tj/℃ –20 –15 –10 –5 0 5 10 15 20 25 30 35 40 波谷处归一化强度差∆I /% –1.20 –0.83 –0.54 –0.15 0 0.33 0.70 0.97 1.36 1.68 1.94 2.41 2.71 表 4 四种大功率白光LED稳态热阻测试结果

Table 4. Steady state thermal resistance test results of four kinds of high power white LED.

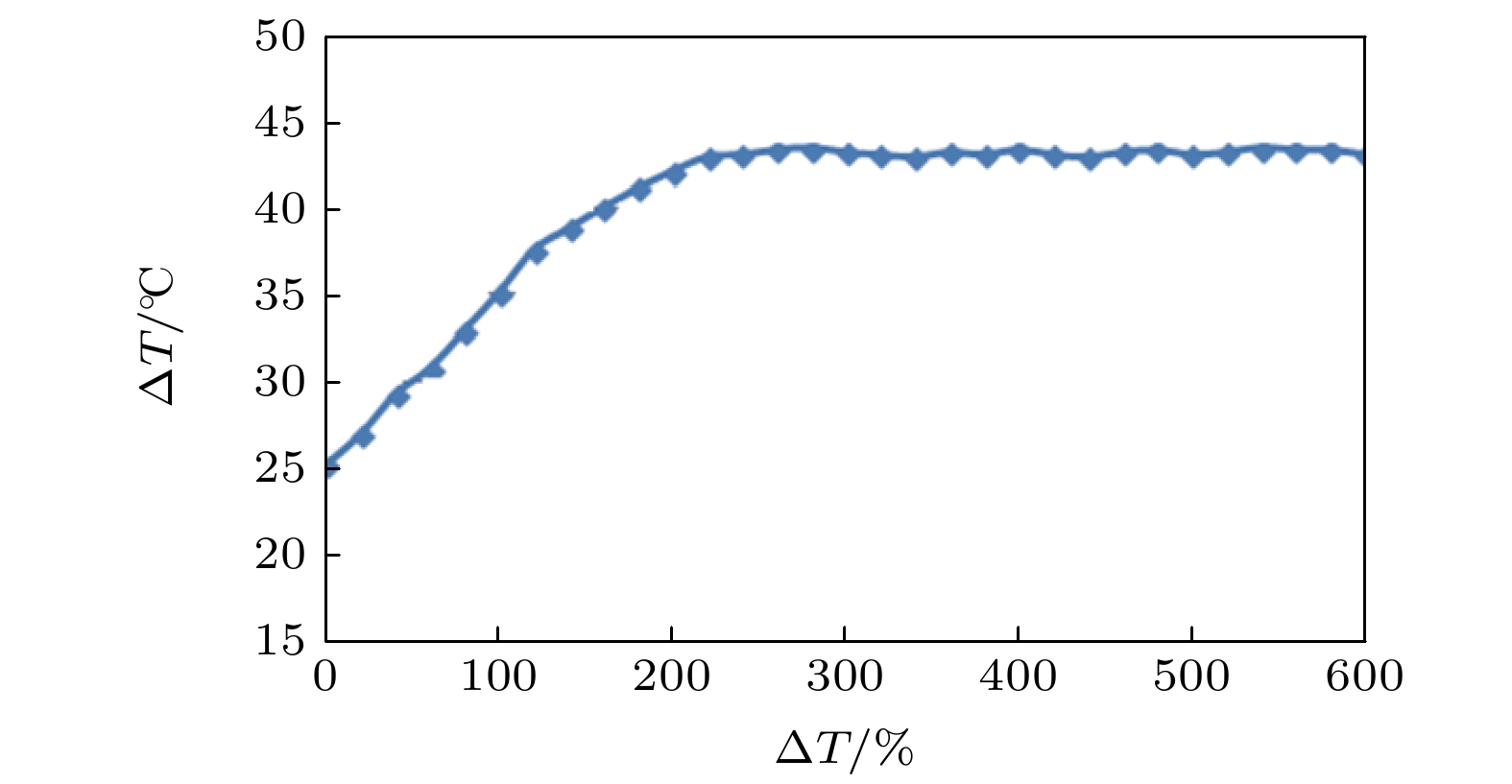

LED种类 高色温LED(A) 高色温LED(B) 低色温LED(C) 低色温LED(D) 热耗散功率/W 0.909 0.891 0.862 0.875 稳定时结温/℃ 43.1 38.6 40.3 44.6 基板温度/℃ 25.0 25.1 25.0 25.0 本文方法所得稳态热阻/(℃·W–1) 19.9 15.2 17.7 22.3 采用T3Ster电压法测得稳态热阻/(℃·W–1) 19.2 14.9 18.1 21.9 偏离度/% 3.64 2.01 –2.21 1.83 -

[1] 陈依新, 沈光地, 高志远, 郭伟玲, 张光沉, 韩军, 朱彦旭 2011 60 087206

Google Scholar

Google Scholar

Chen Y X, Shen G D, Gao Z Y, Guo W L, Zhang G C, Han J, Zhu Y X 2011 Acta Phys. Sin. 60 087206

Google Scholar

Google Scholar

[2] 郭春生, 张燕峰, 万宁, 李睿, 朱慧, 冯士维 2013 62 218503

Google Scholar

Google Scholar

Guo C S, Zhang Y F, Wan N, Li R, Zhu H, Feng S W 2013 Acta Phys. Sin. 62 218503

Google Scholar

Google Scholar

[3] 赵华龙, 梁志毅, 石兴春, 杨小君 2007 光子学报 36 244

Zhao H L, Liang Z Y, Shi X C, Yang X J 2007 Acta Photon. Sin. 36 244

[4] 杨新, 郭伟玲, 王嘉露, 邓杰, 邰建鹏, 孙捷 2020 光谱学与光谱分析 40 368

Google Scholar

Google Scholar

Yang X, GuoW L, Wang J L, Deng J, Tai J P, Sun J 2020 Spectroscopy and Spectral Analysis 40 368

Google Scholar

Google Scholar

[5] 王健, 黄先, 刘丽, 吴庆, 褚明辉, 张立功, 侯凤勤, 刘学彦, 赵成久, 范翊, 罗劲松, 蒋大鹏 2008 发光学报 29 358

Wang J, Huang X, Liu L, Wu Q, Chu M H, Zhang L G, Hou F Q, Liu X Y, Zhao C J, Fang Y, Luo J S, Jiang D P 2008 Chin. J. Lumin. 29 358

[6] 余彬海, 王垚浩 2005 发光学报 26 761

Google Scholar

Google Scholar

Yu B H, Wang Y H 2005 Chin. J. Lumin. 26 761

Google Scholar

Google Scholar

[7] 招瑜, 魏爱香, 刘俊 2015 64 118501

Google Scholar

Google Scholar

Zhao Y, Wei A X, Liu J 2015 Acta Phys. Sin. 64 118501

Google Scholar

Google Scholar

[8] Chen K, Narendran N 2013 Microelectron. Reliabililty 53 701

Google Scholar

Google Scholar

[9] 程星福, 刘显明, 陈伟民, 赖伟 2014 光电子·激光 25 1949

Cheng X F, Liu X M, Chen W M, Lai W 2014 J. Optoelectron. Laser 25 1949

[10] Gu Y M, Narendran N 2004 Third International Conference on Solid State Lighting, Proceedings of SPIE 5187 San Diego, California, United States, January 26, 2004 p93

[11] 刘康, 孙华锐 2020 69 028501

Google Scholar

Google Scholar

Liu K, Sun H R 2020 Acta Phys. Sin. 69 028501

Google Scholar

Google Scholar

[12] 蒋福春, 何思宇, 刘远海, 刘文, 柴广跃, 赵志刚, 李百奎 2020 光子学报 49 0330003

Google Scholar

Google Scholar

Jiang F C, He S Y, Liu Y H, Liu W, Chai G Y, Zhao Z G, Li B K 2020 Acta Photon. Sin. 49 0330003

Google Scholar

Google Scholar

[13] Hong E, Narendran N 2004 Third International Conference on Solid State Lighting, Proceedings of SPIE 5187 San Diego, California, United States, January 26, 2004 p93

[14] 邱西振, 张方辉 2013 光谱学与光谱分析 33 36

Google Scholar

Google Scholar

Qiu X Z, Zhang F H 2013 Spectroscopy and Spectral Analysis 33 36

Google Scholar

Google Scholar

[15] 陈贵锋, 谭小动, 万尾甜, 沈俊, 郝秋艳, 唐成春, 朱建军, 刘宗顺, 赵德刚, 张书明 2011 60 076104

Google Scholar

Google Scholar

Chen G F, Tian X D, Wan W T, Shen J, Hao Q Y, Tang C C, Zhu J J, Liu X S, Zhao D G, Zhang S M 2011 Acta Phys. Sin. 60 076104

Google Scholar

Google Scholar

[16] 饶丰, 方涛, 王紫凌, 陈晨 2020 光子学报 49 0912002

Google Scholar

Google Scholar

Rao F, Fang T, Wang Z L, Chen C 2020 Acta Photon. Sin. 49 0912002

Google Scholar

Google Scholar

[17] 蒋福春, 何思宇, 刘远海, 刘文, 柴广跃, 李百奎, 彭冬生 2020 光谱学与光谱分析 40 2087

Google Scholar

Google Scholar

Jiang F C, He S Y, Liu Y H, Liu W, Chai G Y, Li B K, Peng D S 2020 Spectroscopy and Spectral Analysis 40 2087

Google Scholar

Google Scholar

[18] 秦贤满 1996 半导体技术 3 32

Qin X M 1996 Semiconductor Technology 3 32

[19] 赵晓霞, 王晓君, 陈宝玖, 孟庆, 裕颜斌, 狄卫华 2007 光谱学与光谱分析 27 629

Zhao X X, Wang X J, Chen B J, Meng Q Y, Yan B, Di W H 2007 Spectroscopy and Spectral Analysis 27 629

[20] 殷录桥, 翁菲, 宋朋, 张金龙, 杨卫桥, 张建华 2014 光学学报 34 0323002

Google Scholar

Google Scholar

Yin L Q, Weng F, Song P, Zhang J L, Yang W Q, Zhang J H 2014 Acta Opt. Sin. 34 0323002

Google Scholar

Google Scholar

计量

- 文章访问数: 6603

- PDF下载量: 62

- 被引次数: 0

下载:

下载: