-

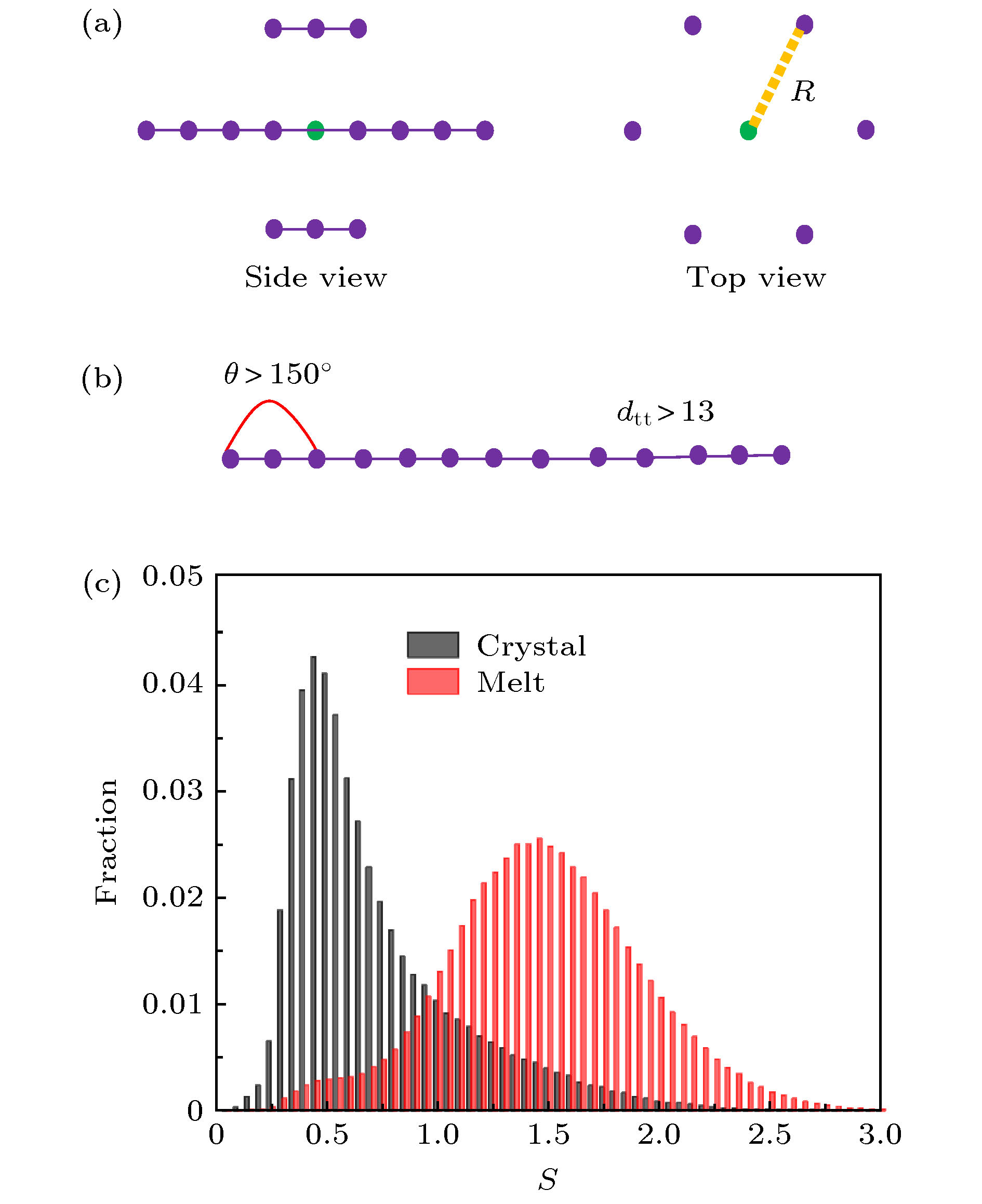

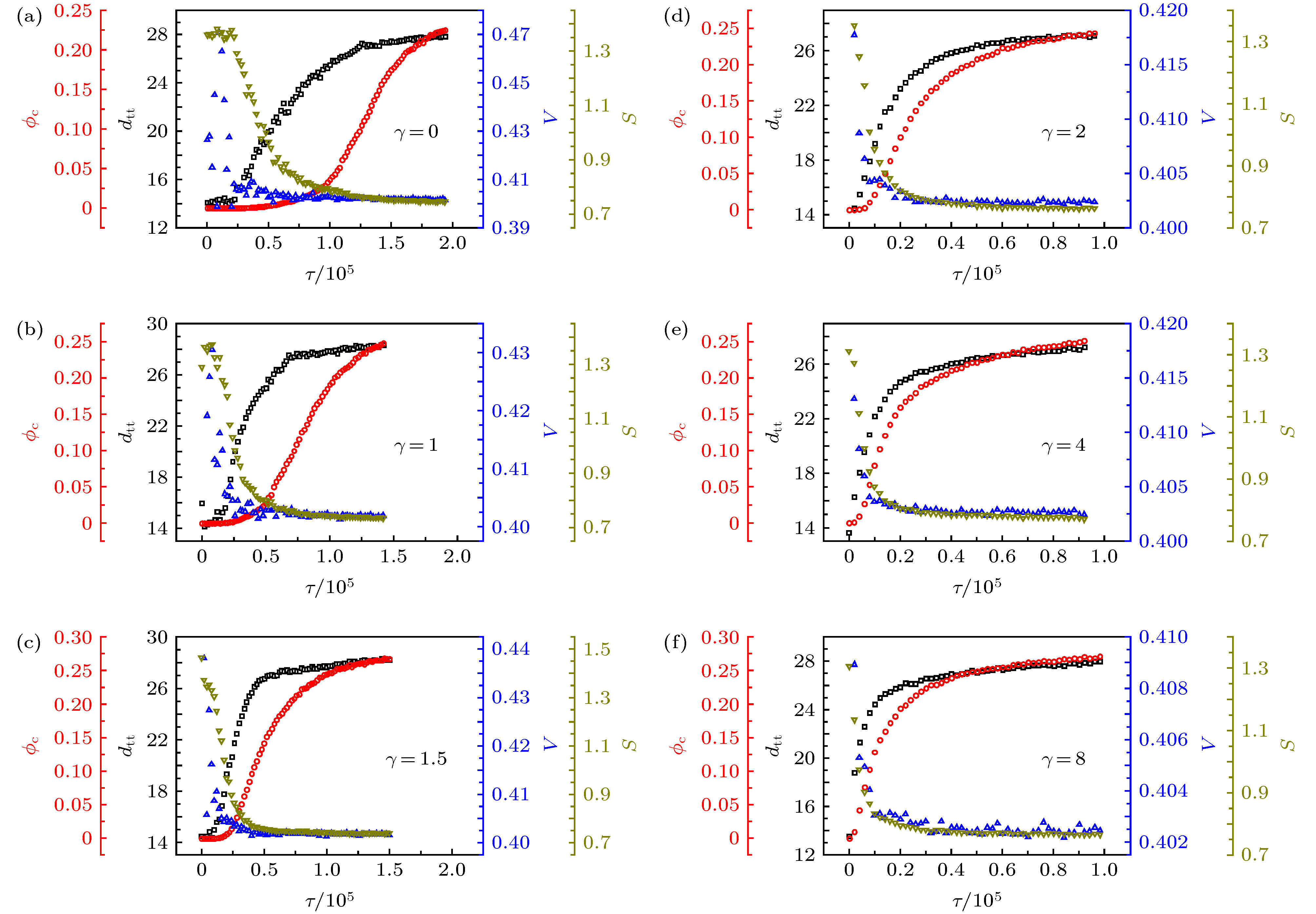

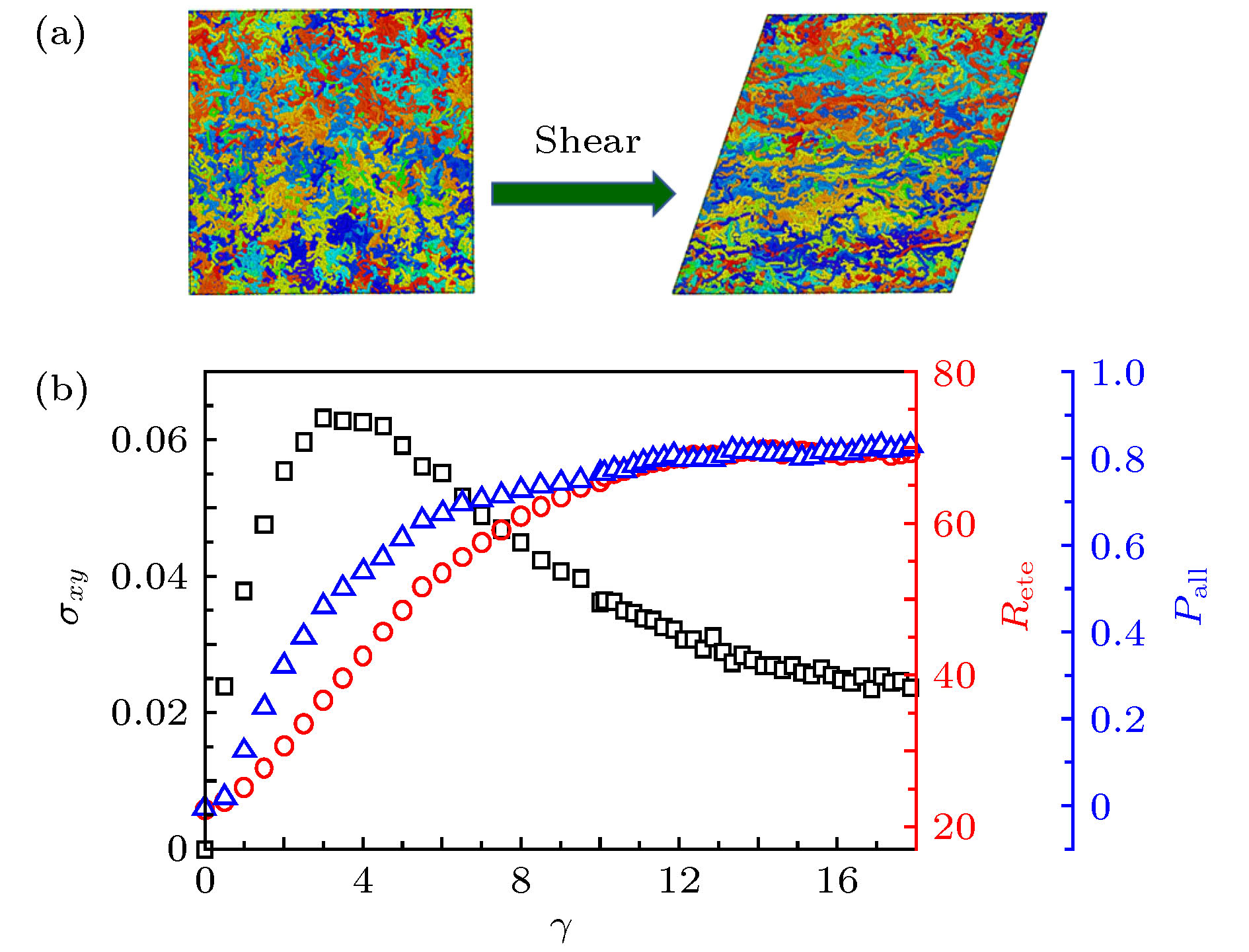

通过分子动力学模拟方法对不同预取向聚乙烯醇熔体(polyvinyl alcohol, PVA)形成的半晶态高分子熔体形成核结晶及拉伸过程中的应力-应变响应特性进行了系统地研究. 模拟结果显示预取向度高的PVA熔体对应更快的成核动力学. 通过追踪全trans伸直链长度(d tt)、成核原子维诺体积(V )和中心对称参数(S)等序参量在不同取向度熔体下的等温成核与结晶演化过程, 给出了PVA熔体成核路径及形成半晶态的分子构象; 通过对形成的半晶态高分子结构进一步分析, 发现随着熔体取向度的增加, 晶体和无定型对应的取向度也会增加, 但是当应变剪切大于5时, 其对应的结晶度、晶体和无定型取向度不再发生变化; 通过对无定型区链结构的定义与分析, 可知取向度越高的熔体对应越高的Tie链数目, 随着熔体取向度的增加, Loop链的数目也会减小; 通过恒速拉伸应力测试可知, 所形成半晶态高分子结构力学响应会随着取向度及Tie链数增加而增加, 当取向及Tie链数目相同时, 应力-应变曲线形状大小也基本保持一致.Molecular dynamics simulations have been used to study the effect of the pre-orientation on the microstructure of lamella crystal and the stress response of polyvinyl alcohol (PVA) semicrystalline polymer under stretching. For the different pre-oriented systems, nucleation is demonstrated to be a two-step process, however, in a different intermediate order. For the isotropic PVA polymer melt, the segment needs more time to adjust its inter-chain structure, therefore, the nucleation is assisted by local order structures, while the nucleation of the oriented PVA melt is promoted by density fluctuation. The nucleation process is the result of coupling effect of conformational and orientational ordering. The transformation from flexible chains into conformational ordered segments circumvents the entropic penalty under the shear flow, which is the most peculiar and rate-limited step in polymer crystallization. Therefore, the current work suggests that the acceleration of the nucleation rate by shear deformation is mainly attributed to the different kinetic pathway via conformational/orientational ordering-density fluctuation-nucleation. From the different pre-oriented PVA semicrystalline polymers, we know that the higher oriented degree corresponds to a higher number of Tie chains and lower Loop chains, and the higher number of Tie chains corresponds to a stronger stress-strain response. And the detailed molecular structural evolution of semicrystalline polymer under stretching is also given in this work.

-

Keywords:

- pre-oriented /

- crystallization /

- polyvinyl alcohol melts /

- amorphous /

- stress-strain

[1] Li L, de Jeu W 2005 Adv. Polym. Sci. 181 75

[2] Liu D, Cui K, Huang N, Wang Z, Li L 2015 Sci. China Chem. 58 1570

Google Scholar

Google Scholar

[3] Stephanou P S, Tsimouri I C, Mavrantzas V G 2016 Macromolecules 49 3161

Google Scholar

Google Scholar

[4] Luo C, Kröger M, Sommer J U 2016 Macromolecules 49 9017

Google Scholar

Google Scholar

[5] Luo C, Kröger M, Sommer J U 2017 Polymer 109 71

Google Scholar

Google Scholar

[6] Tang X, Yang J, Xu T, Tian F, Xie C, Li L 2017 Phys. Rev. Mate. 1 073401

[7] Yang J, Tang X, Wang Z, Xu T, Tian F, Ji Y, Li L 2017 J. Chem. Phys. 146 014901

Google Scholar

Google Scholar

[8] Tang X, Yang J, Tian F, Xu T, Xie C, Chen W, Li L 2018 J. Chem. Phys. 149 224901

Google Scholar

Google Scholar

[9] Yamamoto T 2014 Macromolecules 47 3192

Google Scholar

Google Scholar

[10] Baig C, Edwards B J 2010 Europhys. Lett. 89 36003

Google Scholar

Google Scholar

[11] Yang J S, Yang C, Wang M, Chen B, Ma X 2011 Phys. Chem. Chem. Phys. 13 15476

Google Scholar

Google Scholar

[12] Yang J S, Huang D H, Cao Q, Li Q, Wang L, Wang F 2013 Chin. Phys. B 22 098101

Google Scholar

Google Scholar

[13] 杨俊升, 黄多辉 2019 68 138301

Google Scholar

Google Scholar

Yang J S, Huang D H 2019 Acta Phys. Sin. 68 138301

Google Scholar

Google Scholar

[14] 杨文龙, 韩浚生, 王宇, 林家齐, 何国强, 孙洪国 2017 66 227101

Google Scholar

Google Scholar

Yang W L, Han J S, Wang Y, Lin J Q, He G Q, Sun H G 2017 Acta Phys. Sin. 66 227101

Google Scholar

Google Scholar

[15] 潘登, 刘长鑫, 张泽洋, 高玉金, 郝秀红 2019 68 176801

Google Scholar

Google Scholar

Pan D, Liu C X, Zhang Z Y, Gao Y J, Hao X H 2019 Acta Phys. Sin. 68 176801

Google Scholar

Google Scholar

[16] Cui K, Ma Z, Wang Z, Ji Y, Liu D, Huang N, Chen L, Zhang W, Li L 2015 Macromolecules 48 5276

Google Scholar

Google Scholar

[17] Cui K, Meng L, Ji Y, Li J, Zhu S, Li X, Tian N, Liu D, Li L 2014 Macromolecules 47 677

Google Scholar

Google Scholar

[18] Luo C, Sommer J 2016 ACS Macro Lett. 5 30

Google Scholar

Google Scholar

[19] Tang X, Chen W, Li L 2019 Macromolecules 52 3575

Google Scholar

Google Scholar

[20] Meyer H, Müller-Plathe F 2001 J. Chem. Phys. 115 7807

Google Scholar

Google Scholar

[21] Luo C, Sommer J 2009 Comp. Phys. Comm. 180 1382

Google Scholar

Google Scholar

[22] Wang S, Wang Y, Cheng S, Li X, Zhu X, Sun H 2013 Macromolecules 46 3147

Google Scholar

Google Scholar

[23] Kelchner C L, Plimpton S, Hamilton J 1998 Phys. Rev. B 58 11085

Google Scholar

Google Scholar

[24] Wang Z, Ju J, Yang J, Ma Z, Liu D, Cui K, Yang H, Chang J, Huang N, Li L 2016 Sci. Rep. 6 32968

Google Scholar

Google Scholar

[25] Wang Y, Jiang Z, Wu Z, Men Y 2013 Macromolecules 45 518

Google Scholar

Google Scholar

[26] Siviour C R, Jordan J L 2016 J. Dyn. Behav. Mater. 2 15

Google Scholar

Google Scholar

[27] Lin Y, Li X, Meng L, Chen X, Li L 2018 Macromolecules 51 2690

Google Scholar

Google Scholar

[28] Lin Y, Li X, Meng L, Chen X, Lü F, Zhang Q, Li L 2018 Polymer 148 79

Google Scholar

Google Scholar

-

图 5 (a)不同剪切应下PVA半晶态高分子对应的

${\phi _{\rm{c}}}$ 、晶体取向参数Pc和无定型结构取向参数Pa; (b)不同剪切应变下PVA半晶态高分子无定型链结构数目的演化Fig. 5. (a)

${\phi _{\rm{c}}}$ , crystalline order parameter Pc, and amorphous order parameter Pa for PVA semicrystalline polymers with different shear strains; (b) the evolution of the numbers of amorphous chains for PVA semicrystalline polymers with different shear strains. -

[1] Li L, de Jeu W 2005 Adv. Polym. Sci. 181 75

[2] Liu D, Cui K, Huang N, Wang Z, Li L 2015 Sci. China Chem. 58 1570

Google Scholar

Google Scholar

[3] Stephanou P S, Tsimouri I C, Mavrantzas V G 2016 Macromolecules 49 3161

Google Scholar

Google Scholar

[4] Luo C, Kröger M, Sommer J U 2016 Macromolecules 49 9017

Google Scholar

Google Scholar

[5] Luo C, Kröger M, Sommer J U 2017 Polymer 109 71

Google Scholar

Google Scholar

[6] Tang X, Yang J, Xu T, Tian F, Xie C, Li L 2017 Phys. Rev. Mate. 1 073401

[7] Yang J, Tang X, Wang Z, Xu T, Tian F, Ji Y, Li L 2017 J. Chem. Phys. 146 014901

Google Scholar

Google Scholar

[8] Tang X, Yang J, Tian F, Xu T, Xie C, Chen W, Li L 2018 J. Chem. Phys. 149 224901

Google Scholar

Google Scholar

[9] Yamamoto T 2014 Macromolecules 47 3192

Google Scholar

Google Scholar

[10] Baig C, Edwards B J 2010 Europhys. Lett. 89 36003

Google Scholar

Google Scholar

[11] Yang J S, Yang C, Wang M, Chen B, Ma X 2011 Phys. Chem. Chem. Phys. 13 15476

Google Scholar

Google Scholar

[12] Yang J S, Huang D H, Cao Q, Li Q, Wang L, Wang F 2013 Chin. Phys. B 22 098101

Google Scholar

Google Scholar

[13] 杨俊升, 黄多辉 2019 68 138301

Google Scholar

Google Scholar

Yang J S, Huang D H 2019 Acta Phys. Sin. 68 138301

Google Scholar

Google Scholar

[14] 杨文龙, 韩浚生, 王宇, 林家齐, 何国强, 孙洪国 2017 66 227101

Google Scholar

Google Scholar

Yang W L, Han J S, Wang Y, Lin J Q, He G Q, Sun H G 2017 Acta Phys. Sin. 66 227101

Google Scholar

Google Scholar

[15] 潘登, 刘长鑫, 张泽洋, 高玉金, 郝秀红 2019 68 176801

Google Scholar

Google Scholar

Pan D, Liu C X, Zhang Z Y, Gao Y J, Hao X H 2019 Acta Phys. Sin. 68 176801

Google Scholar

Google Scholar

[16] Cui K, Ma Z, Wang Z, Ji Y, Liu D, Huang N, Chen L, Zhang W, Li L 2015 Macromolecules 48 5276

Google Scholar

Google Scholar

[17] Cui K, Meng L, Ji Y, Li J, Zhu S, Li X, Tian N, Liu D, Li L 2014 Macromolecules 47 677

Google Scholar

Google Scholar

[18] Luo C, Sommer J 2016 ACS Macro Lett. 5 30

Google Scholar

Google Scholar

[19] Tang X, Chen W, Li L 2019 Macromolecules 52 3575

Google Scholar

Google Scholar

[20] Meyer H, Müller-Plathe F 2001 J. Chem. Phys. 115 7807

Google Scholar

Google Scholar

[21] Luo C, Sommer J 2009 Comp. Phys. Comm. 180 1382

Google Scholar

Google Scholar

[22] Wang S, Wang Y, Cheng S, Li X, Zhu X, Sun H 2013 Macromolecules 46 3147

Google Scholar

Google Scholar

[23] Kelchner C L, Plimpton S, Hamilton J 1998 Phys. Rev. B 58 11085

Google Scholar

Google Scholar

[24] Wang Z, Ju J, Yang J, Ma Z, Liu D, Cui K, Yang H, Chang J, Huang N, Li L 2016 Sci. Rep. 6 32968

Google Scholar

Google Scholar

[25] Wang Y, Jiang Z, Wu Z, Men Y 2013 Macromolecules 45 518

Google Scholar

Google Scholar

[26] Siviour C R, Jordan J L 2016 J. Dyn. Behav. Mater. 2 15

Google Scholar

Google Scholar

[27] Lin Y, Li X, Meng L, Chen X, Li L 2018 Macromolecules 51 2690

Google Scholar

Google Scholar

[28] Lin Y, Li X, Meng L, Chen X, Lü F, Zhang Q, Li L 2018 Polymer 148 79

Google Scholar

Google Scholar

计量

- 文章访问数: 11975

- PDF下载量: 152

- 被引次数: 0

下载:

下载: