-

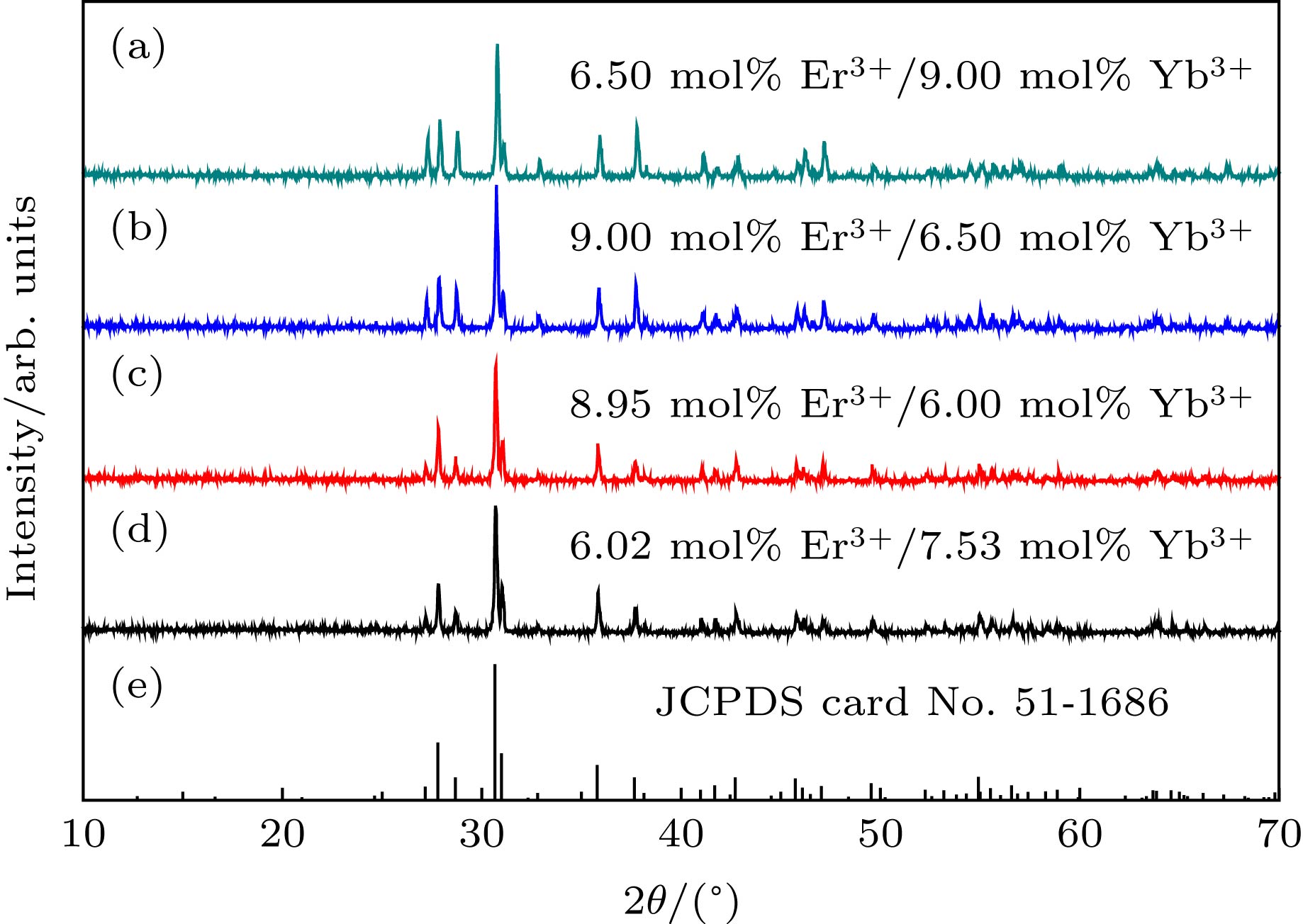

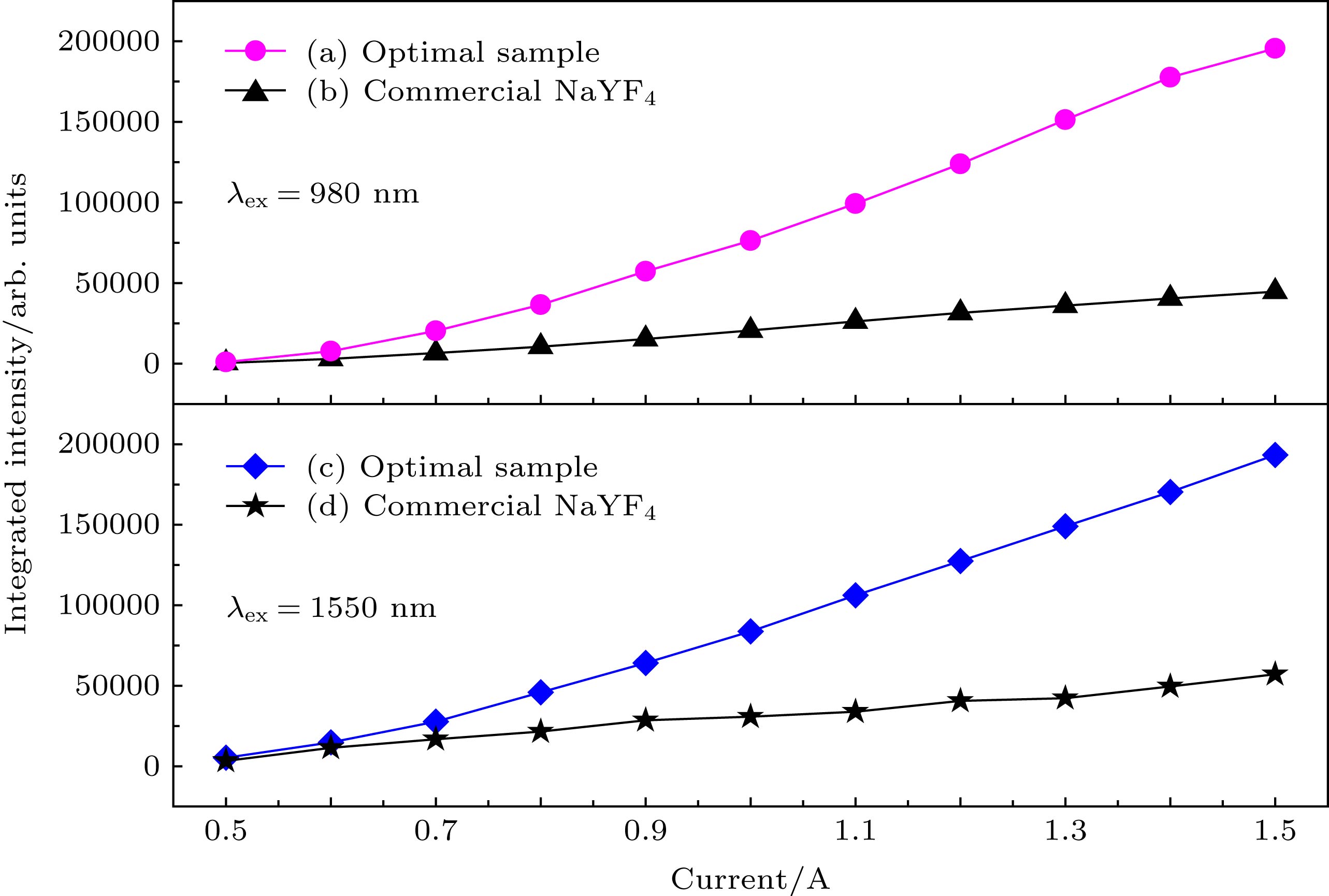

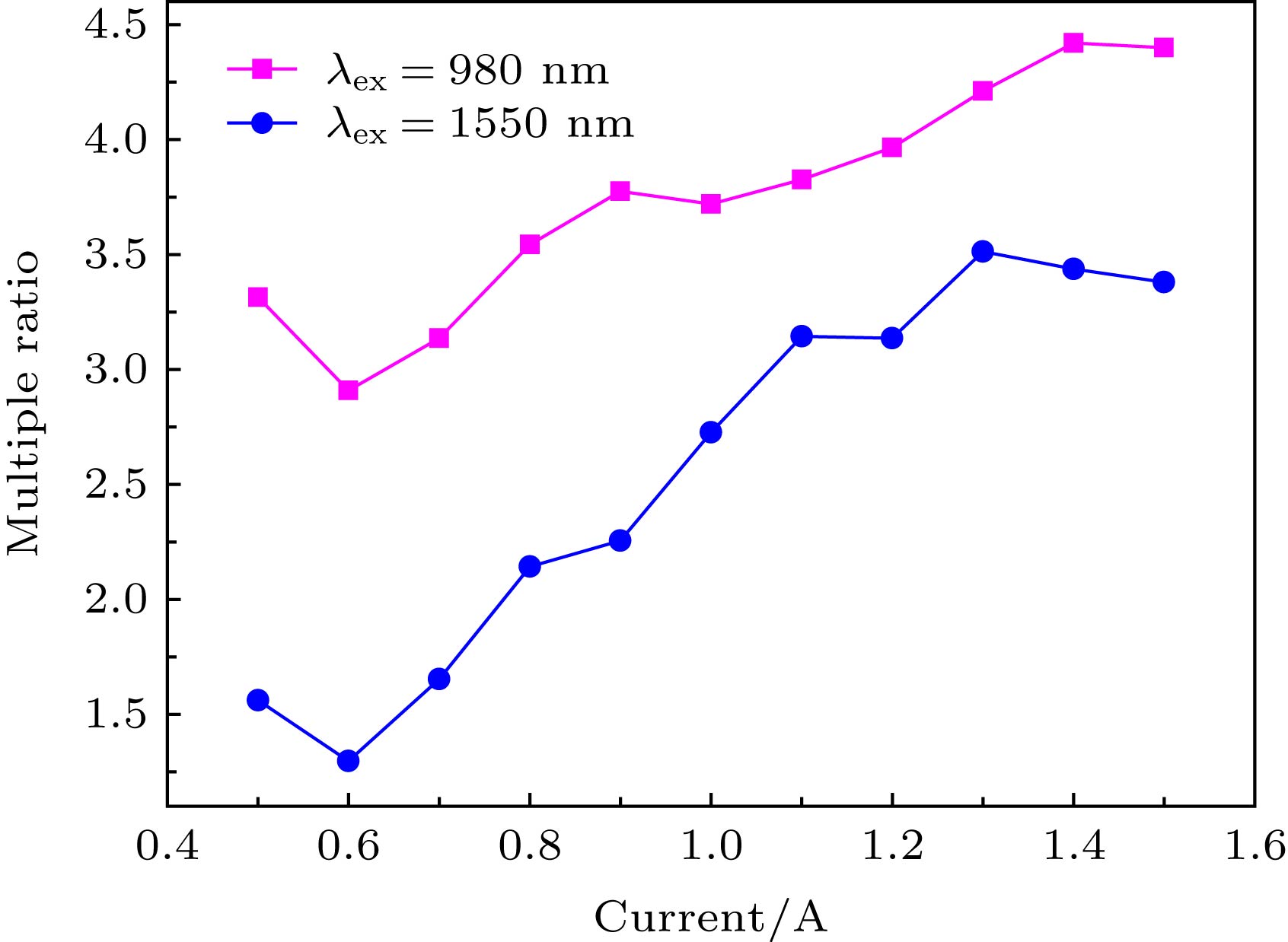

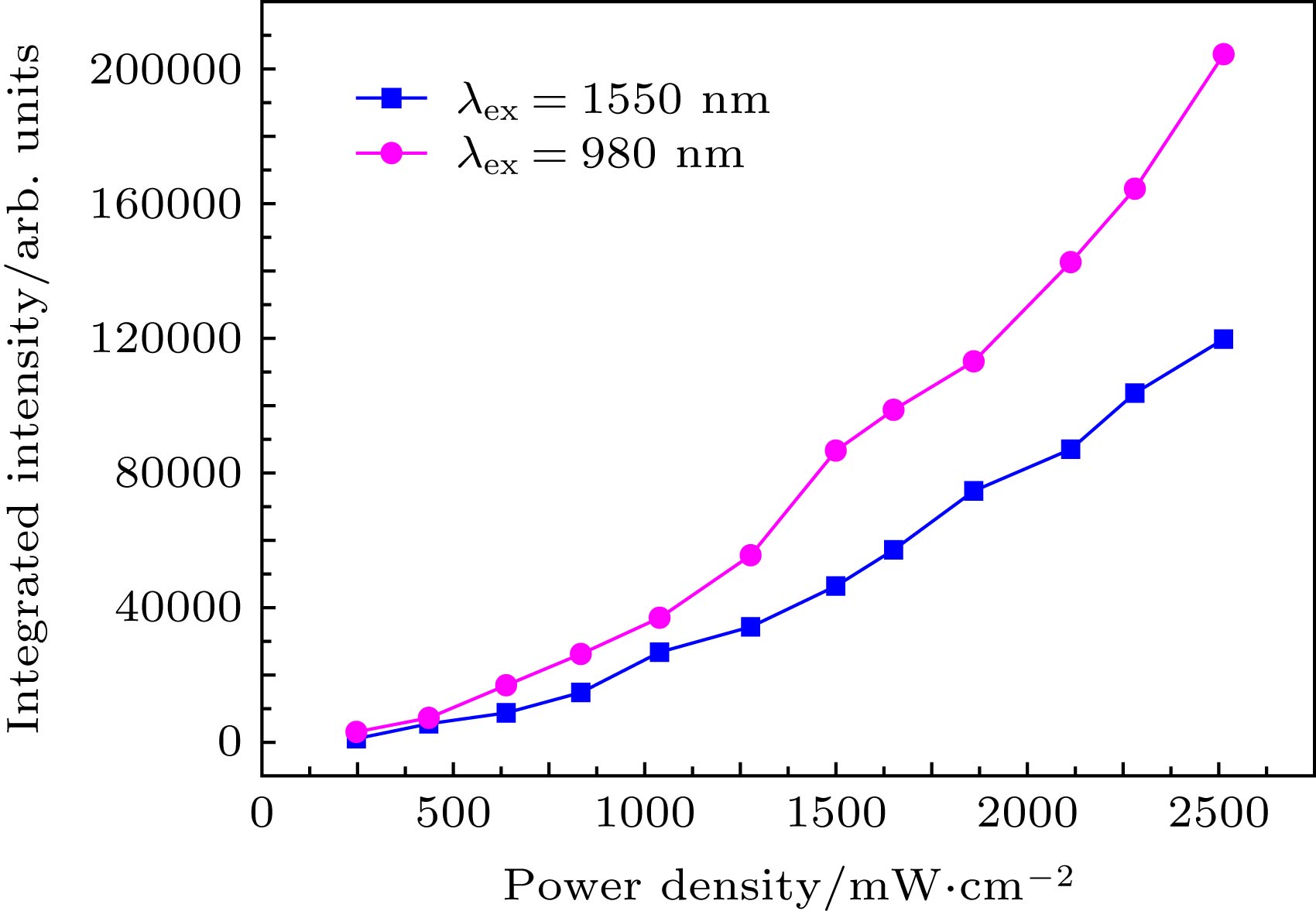

为得到最大发光强度的红光上转换Er3+/Yb3+共掺Ba5Gd8Zn4O21荧光粉, 采用均匀设计初步寻找Er3+/Yb3+共掺杂的浓度范围, 再通过二次通用旋转组合设计, 建立了Er3+/Yb3+掺杂浓度与荧光粉在980 nm与1550 nm激光激发下红色上转换发光强度的回归方程, 最后利用遗传算法解得回归方程的最优解, 即在980 nm与1550 nm激光激发下红光上转换最大发光强度对应的Er3+/Yb3+掺杂浓度, 用高温固相法分别制备出两种激发下的最优解荧光粉样品. 经X射线衍射仪分析, 证明所制备样品均为纯相Ba5Gd8Zn4O21. 在980 nm激光激发下, 最优样品的红光为双光子过程; 在1550 nm激光激发下, 最优样品的红光为三光子过程. 测量了最优样品关于温度的上转换发射光谱, 发现样品的红光上转换发光强度随着温度的升高而减弱. 所得最优样品与NaYF4∶Er3+/Yb3+红光商品粉进行比较, 在980 nm和1550 nm激光激发下, 最优样品红光上转换发光强度远强于NaYF4红光商品粉发光强度. 在相同功率密度激发下, 980 nm激光激发下的最优样品比1550 nm激光激发下的最优样品红光上转换发光强度更强.

-

关键词:

- 均匀试验设计 /

- 二次通用旋转组合设计 /

- 红光上转换 /

- Ba5Gd8Zn4O21∶Er3+/Yb3+

In order to obtain the Er3+/Yb3+ co-doped Ba5Gd8Zn4O21 up-conversion phosphor material with maximum red luminous intensity, three steps are adopted as follows. Firstly, the uniform design in the experimental optimal design is used to find the reasonable doping concentration of Er3+/Yb3+. Secondly, according to the quadratic general rotary unitized design, the regression equation of the red luminescence intensity of Er3+/Yb3+ co-doped Ba5Gd8Zn4O21 under 980 nm and 1550 nm excitations is established. Finally, the optimal solution of the regression equation is obtained by genetic algorithm. The Ba5Gd8Zn4O21:Er3+/Yb3+ phosphors are prepared by a high-temperature solid-phase method. The crystal structure for each of the prepared phosphors is analyzed by X-ray diffraction, and it is confirmed that the prepared phosphor samples of Ba5Gd8Zn4O21 are all in pure phase. Using the 980 nm laser as an excitation source, the relationship between the red up-conversion luminescence intensity of the optimal sample and the operating current of the laser is studied. It is found that the red luminescence is emitted through a double-photon process by the formula fitting analysis. Using the 1550 nm laser as the excitation source, it is found that red luminescence is emitted through a three-photon process. The up-conversion emission spectrum of the optimal sample with respect to temperature is measured and discussed, and it is found that the red up-conversion luminescence intensity of the sample is weakened as the temperature increases. The optimal samples are compared with the commercial phosphors of NaYF4:Er3+/Yb3+ under the 980 nm and 1550 nm excitation respectively, the luminescence intensity of the optimal sample is much stronger than that of the commercial phosphor of NaYF4:Er3+/Yb3+. Moreover, under the same power density excitation, the red up conversion luminescence intensity of the optimal sample at 980 nm is stronger than that at 1550 nm.-

Keywords:

- uniform experimental design /

- experiment scheme of quadratic general rotary unitized design /

- red up-conversion luminescence /

- Ba5Gd8Zn4O21:Er3+/Yb3+

[1] 孙佳石, 李树伟, 石琳琳, 周天民, 李香萍, 张金苏, 程丽红, 陈宝玖 2015 64 243301

Google Scholar

Google Scholar

Sun J S, Li S W, Shi L L, Zhou T M, Li X P, Zhang J S, Cheng L H, Chen B J 2015 Acta Phys. Sin. 64 243301

Google Scholar

Google Scholar

[2] Wang M, Mi C C, Wang W X, Liu C H, Wu Y F, Xu Z R, Mao C B, Xu S K 2009 ACS Nano 3 1580

Google Scholar

Google Scholar

[3] Gao G J, Busko D, Joseph R, Howard I A, Turshatov A, Richards B S 2018 ACS Appl. Mater. Interfaces 10 39851

Google Scholar

Google Scholar

[4] Homann C, Krukewitt L, Frenzel F, Grauel B, Wurth C, Resch-Genger U, Haase M 2018 Angew. Chem. Int. Ed. Engl. 57 8765

Google Scholar

Google Scholar

[5] Zhang Y Q, Xu S, Li X P, Zhang J S, Sun J S, Tong L L, Zhong H, Xia H P, Hua R N, Chen B J 2018 Sensor. Actuat. B: Chem. 257 829

Google Scholar

Google Scholar

[6] Kramer K W, Biner D, Frei G, Gudel H U, Hehlen M P, Luthi S R 2004 Chem. Mater. 16 1244

Google Scholar

Google Scholar

[7] Wang B, Cheng L H, Zhong H Y, Sun J S, Tian Y, Zhang X Q, Chen B J 2009 Opt. Mater. 31 1658

Google Scholar

Google Scholar

[8] Tian B N, Chen B J, Tian Y, Li X P, Zhang J S, Sun J S, Zhong H Y, Cheng L H, Fu S B, Zhong H, Wang Y Z, Zhang X Q, Xia H P, Hu R N 2013 J. Mater. Chem. C 1 2338

Google Scholar

Google Scholar

[9] Page R H, Schaffers K I, Waide P A, Tassano J B, Bischel W K 1998 J. Opt. Soc. Am. B 15 996

Google Scholar

Google Scholar

[10] 田碧凝 2013 硕士学位论文 (大连: 大连海事大学)

Tian B N 2013 M. S. Thesis (Dalian: Dalian Maritime University) (in Chinese)

[11] Li G Y, Zhou T M 2017 Nanosci. Nanotech. Lett. 9 1919

Google Scholar

Google Scholar

[12] Shi R, Li B Q, Liu C M, Liang H B 2016 J. Phys. Chem. C 120 19365

Google Scholar

Google Scholar

[13] Janani K, Ramasubramanian S, Thangavel R, Thiyagarajan P 2019 Solid State Sci. 91 119

Google Scholar

Google Scholar

[14] Liu Y X, Zhou W, Chen L, Lin Y, Chu X Y, Zheng T Q, Wan S L 2019 Fuel 253 1545

Google Scholar

Google Scholar

[15] Chen C, Li M, Wang C X, Fu S H, Yan W J, Chen C S 2018 Fiber. Polym. 19 1255

Google Scholar

Google Scholar

[16] 任露泉 2009 试验设计及其优化 (北京: 科学出版社) 第174—190页

Ren L Q 2009 Design of Experiment and Optimization (Beijing: Chemical Industry Press) pp174–190 (in Chinese)

[17] 孙佳石, 李香萍, 吴金磊, 李树伟, 石琳琳, 徐赛, 张金苏, 程丽红, 陈宝玖 2017 66 100201

Google Scholar

Google Scholar

Sun J S, Li X P, Wu J L, Li S W, Shi L L, Xu S, Zhang J S, Cheng L H, Chen B J 2017 Acta Phys. Sin. 66 100201

Google Scholar

Google Scholar

[18] Xiong W W, Yin C L, Zhang Y, Zhang J L 2009 Chin. J. Mech. Eng.-En. 22 862

Google Scholar

Google Scholar

[19] Tan G Z, Zhou D M, Jiang B, Dioubate M I 2008 J. Cent. South Univ. T. 15 845

Google Scholar

Google Scholar

[20] 杨志平, 刘玉峰, 王利伟, 余泉茂, 熊志军, 徐小岭 2007 56 546

Google Scholar

Google Scholar

Yang Z P, Liu Y F, Wang L W, Yu Q M, Xiong Z J, Xu X L 2007 Acta Phys. Sin. 56 546

Google Scholar

Google Scholar

[21] 王欣 2018 硕士学位论文 (大连: 大连海事大学)

Wang X 2018 M. S. Thesis (Dalian: Dalian Maritime University) (in Chinese)

[22] Suo H, Guo C F, Wang W B, Li T, Duan C K, Yin M 2016 Dalton T. 45 2629

Google Scholar

Google Scholar

[23] Li H Y, Noh H M, Moon B K, Choi B C, Jeong J H, Jang K, Lee H S, Yi S S 2013 Inorg. Chem. 52 11210

Google Scholar

Google Scholar

[24] Van U 1967 J. Electrochem. Soc. 114 1048

Google Scholar

Google Scholar

-

表 1 均匀试验设计

Table 1. Uniform experimental design.

因素试验

序号x1 (Er3+)/

mol%x2 (Yb3+)/

mol%y1550 nm y980 nm 1 1(1) 4(5.125) 3328.2 62033.4 2 2(2) 8(10.625) 11605.2 101937.9 3 3(3) 3(3.75) 32949.3 90471.5 4 4(4) 7(9.25) 38447.2 99822.8 5 5(5) 2(2.375) 79416.9 69237.5 6 6(6) 6(7.875) 145038.5 123959.0 7 7(7) 1(1) 132225.6 38588.2 8 8(8) 5(6.5) 155258.0 112564.1 9 9(9) 9(12) 105986.7 75933.5 表 2 自然因素水平编码表

Table 2. Natural factors level codes.

zj(xj) z1(Er3+)/mol% z2(Yb3+)/mol% z2j(2) 9 9 z0j + ${\varDelta _j} $(1) 8.2680 8.2680 z0j(0) 6.5 6.5 z0j – $ {\varDelta _j}$(–1) 4.7320 4.7320 z1j(–2) 4 4 ${\varDelta _j} = \dfrac{{{z_{2j}} - {z_{1j}}}}{{2r}}$ 1.7680 1.7680 ${x_j} = \dfrac{{{z_j} - {z_{0j}}}}{{{\varDelta _j}}}$ ${x_1} = \dfrac{{{z_1} - {\rm{6}}.{\rm{5}}}}{{{\rm{1}}.{\rm{7680}}}}$ ${x_2} = \dfrac{{{z_2} - {\rm{6}}.{\rm{5}}}}{{{\rm{1}}.{\rm{7680}}}}$ 表 3 二次通用旋转组合设计的试验方案及红光发光强度

Table 3. Red luminescence intensity and experiment scheme of quadratic general rotary unitized design.

序号 x0 x1 x2 x1x2 x12 x22 y1550 nm y980 nm 1 1 1 1 1 1 1 129443 76365 2 1 1 –1 –1 1 1 124201 54268 3 1 –1 1 –1 1 1 120440 89291 4 1 –1 –1 1 1 1 100410 65430 5 1 1.414 0 0 2 0 127744 67758 6 1 –1.414 0 0 2 0 101623 73300 7 1 0 1.414 0 0 2 112067 82410 8 1 0 –1.414 0 0 2 109503 53292 9 1 0 0 0 0 0 120229 86752 10 1 0 0 0 0 0 123993 80120 11 1 0 0 0 0 0 124176 82245 12 1 0 0 0 0 0 118780 96762 13 1 0 0 0 0 0 108829 86738 表 4 红光的T-检验及F-检验方差分析

Table 4. T-test and F-test with analysis of variance of red light

方差来源 偏差平方和1 偏差平方和2 自由度 t1统计量及F1比 t2 统计量及F2比 显著性水平α1 显著性水平α2 显著性1 显著性2 x0 — — 1 42.61 30.19 0.001 0.001 **** **** x1 — — 1 2.30 1.03 0.1 0.4 *** * x2 — — 1 0.95 2.80 0.4 0.02 * *** x1x2 — — 1 1.18 0.14 0.4 0.9 * 不显著 x12 — — 1 0.29 3.05 0.8 0.02 不显著 *** x22 — — 1 1.11 3.60 0.4 0.02 * *** 回归 991488682.6 1960893448 5 12.03 18.77 0.01 0.01 **** **** 剩余 115427203 146280989.8 7 — — — — — — 失拟 43457130.87 15074730.26 3 1.11 0.37 0.01 0.01 **** **** 误差 156531329.6 164236197.2 4 — — — — — — 总和 1106915886 2107174438 12 — — — — — — 注: ****极高显著水平(α ≤ 0.01); ***高显著性水平(α ≤ 0.1); **显著水平(α ≤ 0.25); *较显著水平(α ≤ 0.4). -

[1] 孙佳石, 李树伟, 石琳琳, 周天民, 李香萍, 张金苏, 程丽红, 陈宝玖 2015 64 243301

Google Scholar

Google Scholar

Sun J S, Li S W, Shi L L, Zhou T M, Li X P, Zhang J S, Cheng L H, Chen B J 2015 Acta Phys. Sin. 64 243301

Google Scholar

Google Scholar

[2] Wang M, Mi C C, Wang W X, Liu C H, Wu Y F, Xu Z R, Mao C B, Xu S K 2009 ACS Nano 3 1580

Google Scholar

Google Scholar

[3] Gao G J, Busko D, Joseph R, Howard I A, Turshatov A, Richards B S 2018 ACS Appl. Mater. Interfaces 10 39851

Google Scholar

Google Scholar

[4] Homann C, Krukewitt L, Frenzel F, Grauel B, Wurth C, Resch-Genger U, Haase M 2018 Angew. Chem. Int. Ed. Engl. 57 8765

Google Scholar

Google Scholar

[5] Zhang Y Q, Xu S, Li X P, Zhang J S, Sun J S, Tong L L, Zhong H, Xia H P, Hua R N, Chen B J 2018 Sensor. Actuat. B: Chem. 257 829

Google Scholar

Google Scholar

[6] Kramer K W, Biner D, Frei G, Gudel H U, Hehlen M P, Luthi S R 2004 Chem. Mater. 16 1244

Google Scholar

Google Scholar

[7] Wang B, Cheng L H, Zhong H Y, Sun J S, Tian Y, Zhang X Q, Chen B J 2009 Opt. Mater. 31 1658

Google Scholar

Google Scholar

[8] Tian B N, Chen B J, Tian Y, Li X P, Zhang J S, Sun J S, Zhong H Y, Cheng L H, Fu S B, Zhong H, Wang Y Z, Zhang X Q, Xia H P, Hu R N 2013 J. Mater. Chem. C 1 2338

Google Scholar

Google Scholar

[9] Page R H, Schaffers K I, Waide P A, Tassano J B, Bischel W K 1998 J. Opt. Soc. Am. B 15 996

Google Scholar

Google Scholar

[10] 田碧凝 2013 硕士学位论文 (大连: 大连海事大学)

Tian B N 2013 M. S. Thesis (Dalian: Dalian Maritime University) (in Chinese)

[11] Li G Y, Zhou T M 2017 Nanosci. Nanotech. Lett. 9 1919

Google Scholar

Google Scholar

[12] Shi R, Li B Q, Liu C M, Liang H B 2016 J. Phys. Chem. C 120 19365

Google Scholar

Google Scholar

[13] Janani K, Ramasubramanian S, Thangavel R, Thiyagarajan P 2019 Solid State Sci. 91 119

Google Scholar

Google Scholar

[14] Liu Y X, Zhou W, Chen L, Lin Y, Chu X Y, Zheng T Q, Wan S L 2019 Fuel 253 1545

Google Scholar

Google Scholar

[15] Chen C, Li M, Wang C X, Fu S H, Yan W J, Chen C S 2018 Fiber. Polym. 19 1255

Google Scholar

Google Scholar

[16] 任露泉 2009 试验设计及其优化 (北京: 科学出版社) 第174—190页

Ren L Q 2009 Design of Experiment and Optimization (Beijing: Chemical Industry Press) pp174–190 (in Chinese)

[17] 孙佳石, 李香萍, 吴金磊, 李树伟, 石琳琳, 徐赛, 张金苏, 程丽红, 陈宝玖 2017 66 100201

Google Scholar

Google Scholar

Sun J S, Li X P, Wu J L, Li S W, Shi L L, Xu S, Zhang J S, Cheng L H, Chen B J 2017 Acta Phys. Sin. 66 100201

Google Scholar

Google Scholar

[18] Xiong W W, Yin C L, Zhang Y, Zhang J L 2009 Chin. J. Mech. Eng.-En. 22 862

Google Scholar

Google Scholar

[19] Tan G Z, Zhou D M, Jiang B, Dioubate M I 2008 J. Cent. South Univ. T. 15 845

Google Scholar

Google Scholar

[20] 杨志平, 刘玉峰, 王利伟, 余泉茂, 熊志军, 徐小岭 2007 56 546

Google Scholar

Google Scholar

Yang Z P, Liu Y F, Wang L W, Yu Q M, Xiong Z J, Xu X L 2007 Acta Phys. Sin. 56 546

Google Scholar

Google Scholar

[21] 王欣 2018 硕士学位论文 (大连: 大连海事大学)

Wang X 2018 M. S. Thesis (Dalian: Dalian Maritime University) (in Chinese)

[22] Suo H, Guo C F, Wang W B, Li T, Duan C K, Yin M 2016 Dalton T. 45 2629

Google Scholar

Google Scholar

[23] Li H Y, Noh H M, Moon B K, Choi B C, Jeong J H, Jang K, Lee H S, Yi S S 2013 Inorg. Chem. 52 11210

Google Scholar

Google Scholar

[24] Van U 1967 J. Electrochem. Soc. 114 1048

Google Scholar

Google Scholar

计量

- 文章访问数: 10269

- PDF下载量: 78

- 被引次数: 0

下载:

下载: