-

磁制冷是一种节能环保的制冷技术, 具有广阔的应用前景. 目前, 基于主动磁回热循环的磁制冷系统被广泛研究并诞生了多个原型制冷机. 然而, 这些系统主要采用流体换热, 导致系统存在工作频率低、回热损失大、子部件设计复杂等问题, 使得制冷机成本升高和效率降低. 针对上述问题和难点, 引入固态传热增强机制和全固态磁制冷系统模型设计及优化已成为近年来研究的热点. 本文综述了全固态磁制冷系统的两类物理模型的研究进展, 即基于热二极管(电控热二极管和磁控热二极管)的全固态磁制冷模型和基于高热导率材料元件的全固态磁制冷模型. 与传统主动磁回热制冷模型进行比较分析, 表明全固态磁制冷具有更大的应用潜力. 最后, 对未来全固态磁制冷技术的研究进行了分析和展望.Magnetic refrigeration is a kind of energy-saving, environment-friendly and intrinsically-high-efficient refrigeration technology, which has a wide application prospect. At present, the magnetic refrigeration systems based on active magnetic regenerator cycle have been widely studied and many prototypes of refrigerators have been developed. However, fluids and gases are mainly applied to heat exchange in these systems, which brings some problems such as low operating frequency, large regenerative loss, and complicated sub-component design. These problems increase the cost and reduce the efficiency of magnetic refrigerators. In view of the above problems and challenges, researchers try to introduce the solid-state heat transfer enhancement mechanism, and to design and optimize the full-solid-state magnetic refrigeration system model. In this paper, the development process of magnetic refrigeration technology at room temperature is briefly introduced at first. And the reasons for the low operating frequency and efficiency of the magnetic refrigerator, caused by using fluids for heat exchange, are analyzed. Then, two types of solid-state heat exchange media are briefly described, which are thermal diodes (i.e., electric-field-controlled thermal diode and magnetic-field-controlled thermal diode) and high thermal-conductivity material elements. In this paper we review the research progress of the full-solid-state magnetic refrigeration model based on thermal diodes and high thermal-conductivity material elements. Some key items for these models are described in detail, such as the architectural design concept, physical mechanism and working principle, the main performance simulation results of these systems and their physical change rules. Then, the main performances (i.e. operating frequency, specific cooling power, temperature span, and coefficient of performance) of the full-solid-state magnetic refrigeration model and the AMR model are summarized and comparatively analyzed. It shows that the full-solid-state magnetic refrigeration system can work at high frequency and has greater specific-cooling-power. Meanwhile the design of full-solid-state magnetic refrigeration system is more compact and simpler. The characteristics and problems of the two types of solid heat exchange media are also analyzed. Due to the strong thermal transport capability, easy access and integration of thermoelectric elements, the full-solid-state magnetic refrigeration technology based on thermoelectric thermal diodes has greater application potential. Finally, the main research directions and key scientific problems for further studying the full-solid-state magnetic refrigeration field are discussed and analyzed.

-

Keywords:

- full solid state magnetic refrigeration /

- physical model /

- thermal diode /

- high thermal conductivity material element

[1] Franco V, Blázquez J S, Ipus J J, Law J Y, Moreno-Ramirez L M, Conde A 2018 Prog. Mater. Sci. 93 112

Google Scholar

Google Scholar

[2] Osmann S, Mohamed B 2014 Int. J. Refrig. 37 8

Google Scholar

Google Scholar

[3] Warburg E 1881 Ann. Phys. 13 141

[4] Giauque W F, MacDougall D P 1935 J. Am. Chem. Soc. 57 1175

Google Scholar

Google Scholar

[5] Brown G V 1976 J. Appl. Phys. 47 3673

[6] Steyert W A 1978 J. Appl. Phys. 49 1216

Google Scholar

Google Scholar

[7] Barclay J A 1982 J. Appl. Phys. 53 2887

Google Scholar

Google Scholar

[8] Barclay J A, Steyert W A 1982 U. S. Patent 4 332 135 [1982-06-01]

[9] Chen F C, Murphy R W, Mei V C 1992 J. Eng. Gas. Turb. Powe. 114 715

Google Scholar

Google Scholar

[10] Zimm C, Jastrab A, Sternberg A, Pecharsky V, Gschneidner Jr K, Osborne M, Anderson I 1998 Adv. Cryog. Eng. 43 1759

[11] Lawton Jr M L, Zimm C B, Jastrab A G 1999 U. S. Patent 5 934 078 [1999-08-10]

[12] Yu B F, Gao Q, Zhang B, Meng X Z, Chen Z 2003 Int. J. Refrig. 26 622

Google Scholar

Google Scholar

[13] Gschneidner K A J, Pecharsky V K 2008 Int. J. Refrig. 31 945

Google Scholar

Google Scholar

[14] Yu B F, Liu W, Egolf P W, Kitanovski A 2010 Int. J. Refrig. 33 1029

Google Scholar

Google Scholar

[15] Gomez J R, Garcia R F, Carril J C, Gomez M R 2013 Renew. Sust. Energ. Rev. 17 74

Google Scholar

Google Scholar

[16] Jacobs S, Auringer J, Boeder A, Chell J, Komorowski L, Leonard J, Russek S, Zimm C 2014 Int. J. Refrig. 37 84

Google Scholar

Google Scholar

[17] 李振兴, 李珂, 沈俊, 戴巍, 贾际琛, 郭小惠, 高新强, 公茂琼 2017 低温工程 1 13

Google Scholar

Google Scholar

Li Z X, Li K, Shen J, Dai W, Jia J C, Guo X H, Gao X Q, Gong M Q 2017 Cryogenics 1 13

Google Scholar

Google Scholar

[18] Teyber R, Holladay J, Meinhardt K, Polikarpov E, Thomsen E, Cuid J, Rowee A, Barclay J 2019 Appl. Energ. 236 426

Google Scholar

Google Scholar

[19] Kitanovski A, Egolf P W 2010 Int. J. Refrig. 33 449

Google Scholar

Google Scholar

[20] Aliev A M, Batdalov A B, Khanov L N, Koledov V V, Shavrov V G, Tereshina I S, Taskaev S V 2016 J. Alloy. Compd. 676 601

Google Scholar

Google Scholar

[21] Tomc U, Tušek J, Kitanovski A, Poredoš A 2013 Appl. Therm. Eng. 58 1

Google Scholar

Google Scholar

[22] Kitanovski A, Plaznik U, Tomc U, Poredoš A 2015 Int. J. Refrig. 57 288

Google Scholar

Google Scholar

[23] Monfared B 2017 Int. J. Refrig. 74 324

Google Scholar

Google Scholar

[24] Wu J H, Lu B W, Liu C P, He J 2018 Appl. Therm. Eng. 137 836

Google Scholar

Google Scholar

[25] Kitanovski A, Tušek J, Tomc U, Plaznik U, Ožbolt M, Poredoš A 2015 Magnetocaloric Energy Conversion (vol. preface) (Switzerland: Springer International Publishing Switzerland) pviii

[26] Tomc U, Tušek J, Kitanovski A, Poredoš A 2014 Int. J. Refrig. 37 185

Google Scholar

Google Scholar

[27] Egolf P W, Gravier L, Francfort T, Pawlowski A G, Courret G, Croci M 2014 Int. J. Refrig. 37 176

Google Scholar

Google Scholar

[28] de Vries W, van der Meer T H 2017 Appl. Therm. Eng. 111 377

Google Scholar

Google Scholar

[29] Tasaki Y, Takahashi H, Yasuda Y, Okamura T, Ito K 2012 Fifth ⅡF-ⅡR International Conference on Magnetic Refrigeration at Room Temperature, Thermag V Grenoble, France, September 17−20, 2012 p445

[30] Olsen U L, Bahl C R H, Engelbrecht K, Nielsen K K, Tasaki Y, Takahashi H 2014 Int. J. Refrig. 37 194

Google Scholar

Google Scholar

[31] Lu B W, Wu J H, He J, Huang J H 2019 Int. J. Refrig. 98 42

Google Scholar

Google Scholar

[32] Silva D J, BordaloB D, Pereira A M, Ventura J, Araújo J P 2012 Appl. Ener. 93 570

Google Scholar

Google Scholar

[33] Silva D J, VenturaJ, Araújo J P, Pereira A M 2014 Appl. Ener. 113 1149

Google Scholar

Google Scholar

[34] Silva D J, Bordalo B D, Pereira A M, Ventura J, Oliveira J C R E, Araújo J P 2016 Appl. Therm. Eng. 99 514

Google Scholar

Google Scholar

[35] Silva D J, Ventura J, Amaral J S, Amaral V S 2019 Int. J. Energy. Res. 43 742

Google Scholar

Google Scholar

[36] Zhang M, Momen A M, Abdelaziz O 2016 16th International Refrigeration and Air Conditioning Conference at Purdue West Lafayette, US, July 11−14 2016 p1758

[37] Utaka Y, Hua K, Chen Z H, Zhao Y J 2019 Appl. Therm. Eng. 155 196

Google Scholar

Google Scholar

[38] Wehmeyer G, Yabuki T, Monachon C, Wu J Q, Dames C 2017 Appl. Phys. Rev. 4 041304

Google Scholar

Google Scholar

[39] Salamon M B, Jaime M 2001 Rev. Mod. Phys. 73 583

Google Scholar

Google Scholar

[40] Jeong T, Moneck M T, Zhu J G 2012 IEEsran. Magn. 48 3031

Google Scholar

Google Scholar

[41] Kimling J, Nielsch K, Rott K, Reiss G 2013 Phys. Rev. B 87 134406

Google Scholar

Google Scholar

[42] Aprea C, Maiorino A 2010 Appl. Ener. 87 2690

Google Scholar

Google Scholar

[43] Liu M, Yu B F 2011 Int. J. Refrig. 34 617

Google Scholar

Google Scholar

[44] Vuarnoz A, Kawanami T 2012 Appl. Therm. Eng. 37 388

Google Scholar

Google Scholar

[45] Lozano J A, Engelbrecht K, Bahl C R H, Nielsen K K, Barbosa J R, Prata A T, Pryds N 2014 Int. J. Refrig. 37 92

Google Scholar

Google Scholar

[46] Eriksen D, Engelbrecht K, Bahl C R H 2015 Int. J. Refrig. 58 14

Google Scholar

Google Scholar

[47] Lionte S, Vasile C, Siroux M 2015 Appl. Therm. Eng. 75 871

Google Scholar

Google Scholar

[48] Lozano J A, Capovilla M S, Trevizoli P V, Engelbrecht K, Bahl C R H, Barbosa J R 2016 Int. J. Refrig. 68 187

Google Scholar

Google Scholar

[49] Lei T, Engelbrecht K, Nielsen K K, Christian T, Veje C T 2017 Appl. Therm. Eng. 111 1232

Google Scholar

Google Scholar

[50] Aprea C, Greco A, Maiorino A, Masselli C 2015 Appl. Therm. Eng. 91 767

Google Scholar

Google Scholar

[51] Govindappa P, Trevizoli P V, Campbel O, Niknia, I, Christiaanse T V, Teyber R, Misra S, Schwind M A, van Asten D, Zhang L 2017 J. Phys. D: Appl. Phys. 50 315001

Google Scholar

Google Scholar

[52] Navickaite K, Bez H N, Lei T, Barcza A, Vieyra H, Bahl C, Engelbrecht K 2018 Int. J. Refrig. 86 322

Google Scholar

Google Scholar

[53] Pecharsky V K, Gschneidner J K A 1997 Phys. Rev. Lett. 78 4494

Google Scholar

Google Scholar

[54] de Oliveira N A, von Ranke P J 2010 Phys. Rep. 489 89

Google Scholar

Google Scholar

[55] Shen B G, Sun J R, Hu F X, Zhang H W, Cheng Z H 2009 Adv. Mater. 21 4545

Google Scholar

Google Scholar

[56] Tusek J, Kitanovski A, Tomc U, Favero C, Poredoš A 2014 Int. J. Refrig. 37 117

Google Scholar

Google Scholar

[57] Wang Y X, Zhang H, Liu E K, Zhong X C, Tao K, Wu M L, Xing C F, Xiao Y N, Liu J, Long Y 2018 Adv. Electron. Mater. 4 1700636

Google Scholar

Google Scholar

[58] Balli M, Jandl S, Fournier P, Kedous-Lebouc A 2017 Appl. Phys. Rev. 4 021305

Google Scholar

Google Scholar

[59] Smith A, Bahl C R H, Bjørk R, Engelbrecht K, Nielsen K K, Pryds N 2012 Adv. Energy. Mater. 2 1288

Google Scholar

Google Scholar

[60] Zhao W Y, Liu Z Y, Sun Z G, Zhang Q J, Wei P, Mu X, Zhou H Y, Li C C, Ma S F, He D Q, Ji P X, Zhu W T, Nie X L, Su X L, Tang X F, Shen B G, Dong X L, Yang J H, Liu Y, Shi J 2017 Nature 549 247

Google Scholar

Google Scholar

[61] 李海波, 姜倩, 徐小农, 卢定伟 2016 低温工程 5 51

Google Scholar

Google Scholar

Li H B, Jiang Q, Xu X D, Lu D W 2016 Cryogenics 5 51

Google Scholar

Google Scholar

[62] Blumenthal P, Raatz A 2016 Europhys. Lett. 115 17004

Google Scholar

Google Scholar

[63] Hess T, Maier L M, Corhan P, Schäfer-Welsen O, Wöllenstein J, Bartholomé K 2019 Int. J. Refrig. 103 215

Google Scholar

Google Scholar

[64] Qiao K M, Hu F X, Liu Y, Li J, Kuang H, Zhang H R, Liang W H, Wang J, Sun J R, Shen B G 2019 Nano Energy 59 285

Google Scholar

Google Scholar

-

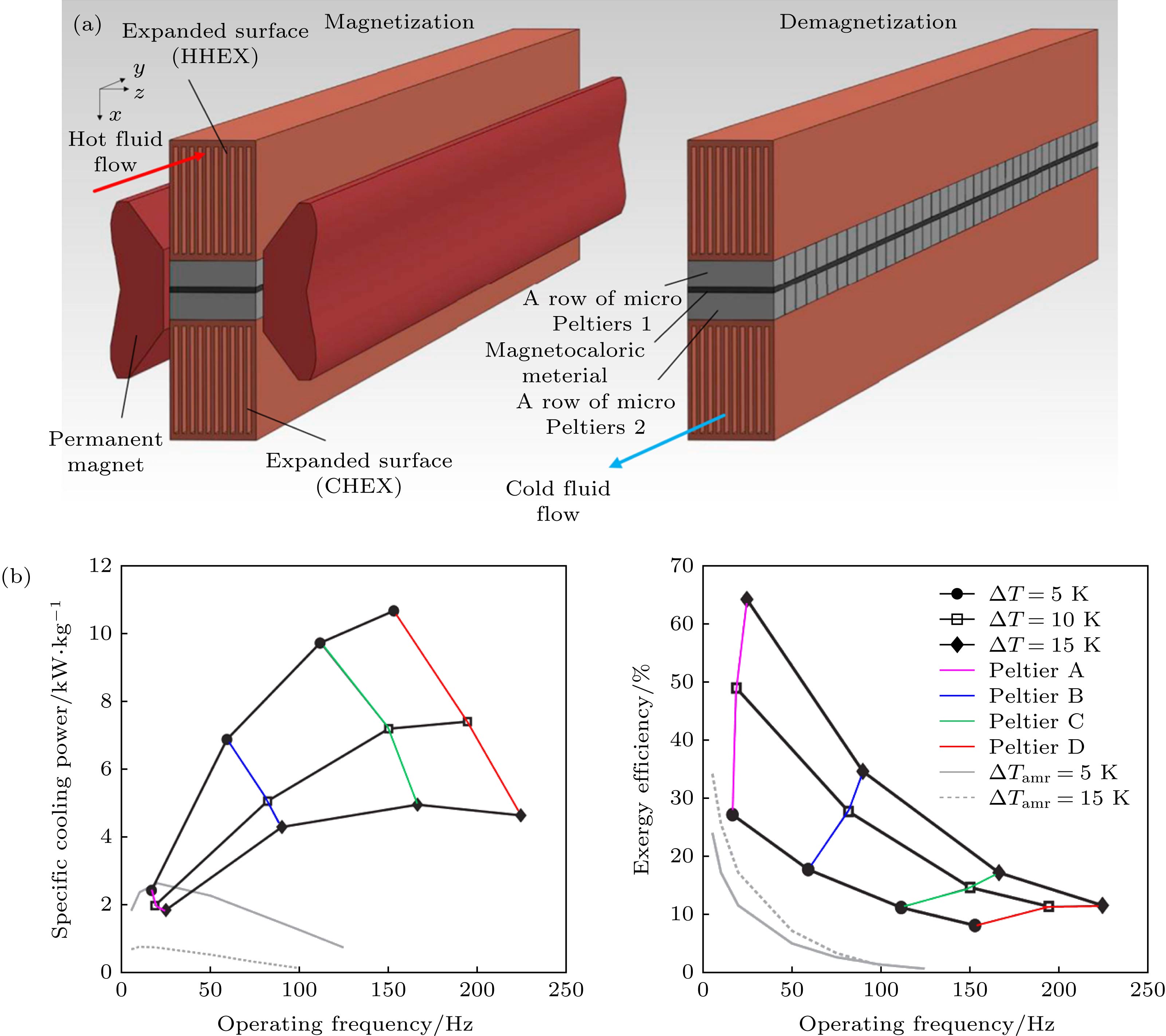

图 2 (a) 基于热二极管的全固态MR模型结构示意图[21]; (b) 带有热二极管的MR系统与平行板AMR在不同温跨和不同频率下最大SCP和㶲效率的比较[26]

Fig. 2. (a) Schematic diagram of the full solid state MR model based on a thermal diode[21]; (b) comparison of maximum SCP and exergy efficiency between MR system with thermal diode and parallel-plate AMR at different temperature spans and different frequencies[26].

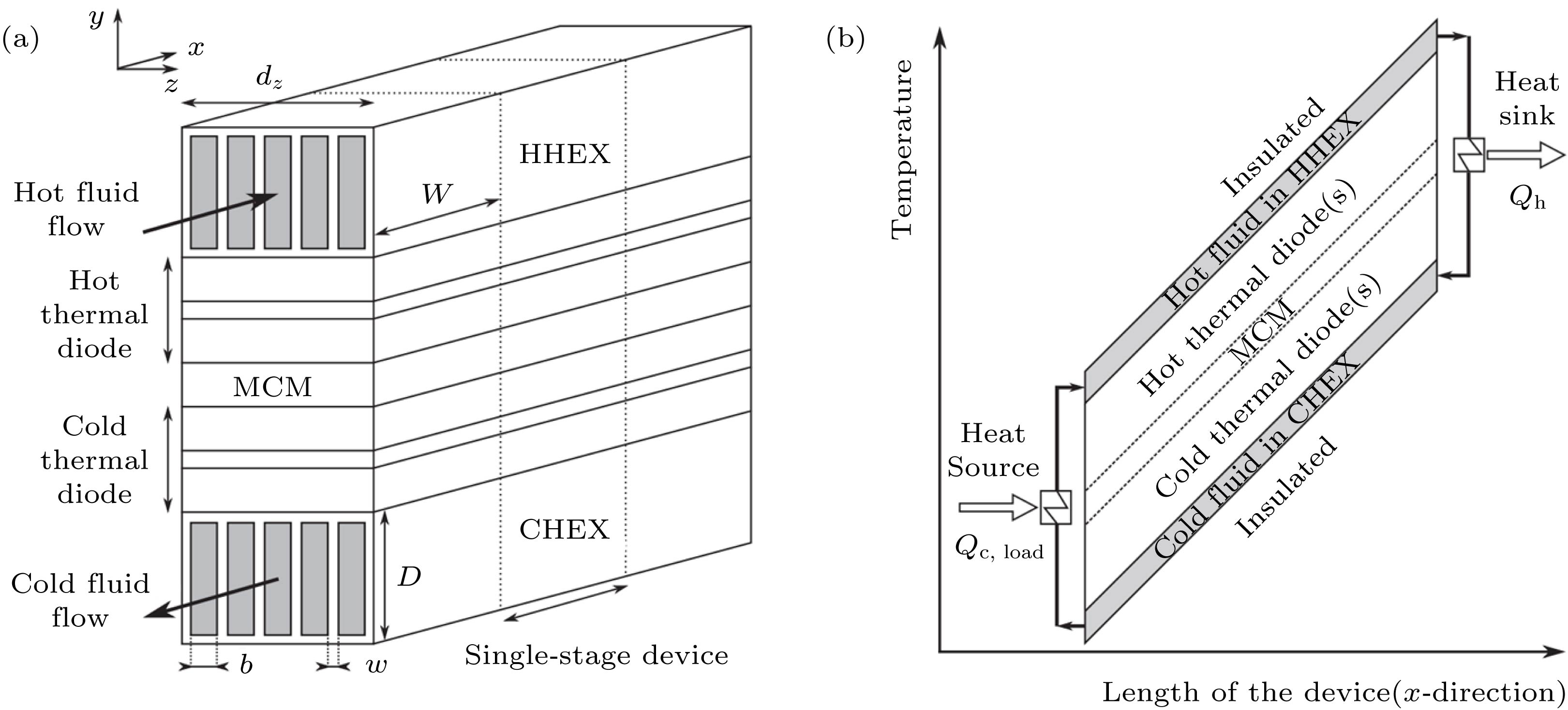

图 4 (a)基于热二极管的全固态MR模型示意图[30]; (b)工作原理[23]; (c)不同电流下COP和SCP的变化[23]; (d) Peltier元件不同长度下COP和SCP的变化[23]

Fig. 4. (a) Schematic diagram of a full solid state MR model based on thermal switch[30]; (b) operating principle[23]; (c) variation of COP and SCP with different current[23]; (d) variation of COP and SCP with the length of Peltier element [23].

图 5 (a) 全固态MR系统示意图[24]; (b) MUR循环原理[31]; (c) 仅Gd[31]; (d) 平行板[31]; (e) 拓扑优化结构[31]; (f) 实验设置[31]; (g)最大SCP随Peltier电源电压的变化[31]; (h) Peltier COP和温差随转速的变化[31]

Fig. 5. (a) Schematic diagram of the full solid state magnetic refrigeration system[24]; (b) MUR cycle principle[31]; (c) Gd-only[31]; (d) parallel sheets[31]; (e) topology optimization structure[31]; (f) experiment setup[31]; (g) variation of maximum SCP with different Peltier supply voltages[31]; (h) variation of Peltier COP and temperature difference with different rotating speeds[31].

图 6 (a) 基于kH元件和磁Brayton循环的全固态MR模型[32]; (b) 不同工作温度下SCP随工作频率的变化[32]; (c)最大SCP和COP随温度的变化[32]

Fig. 6. (a) A full solid state magnetic refrigeration model based on kH element and magnetic Brayton cycle[32]; (b) variation of SCP with operating frequency at different operating temperatures[32]; (c) maximum SCP and COP as a function of temperature[32].

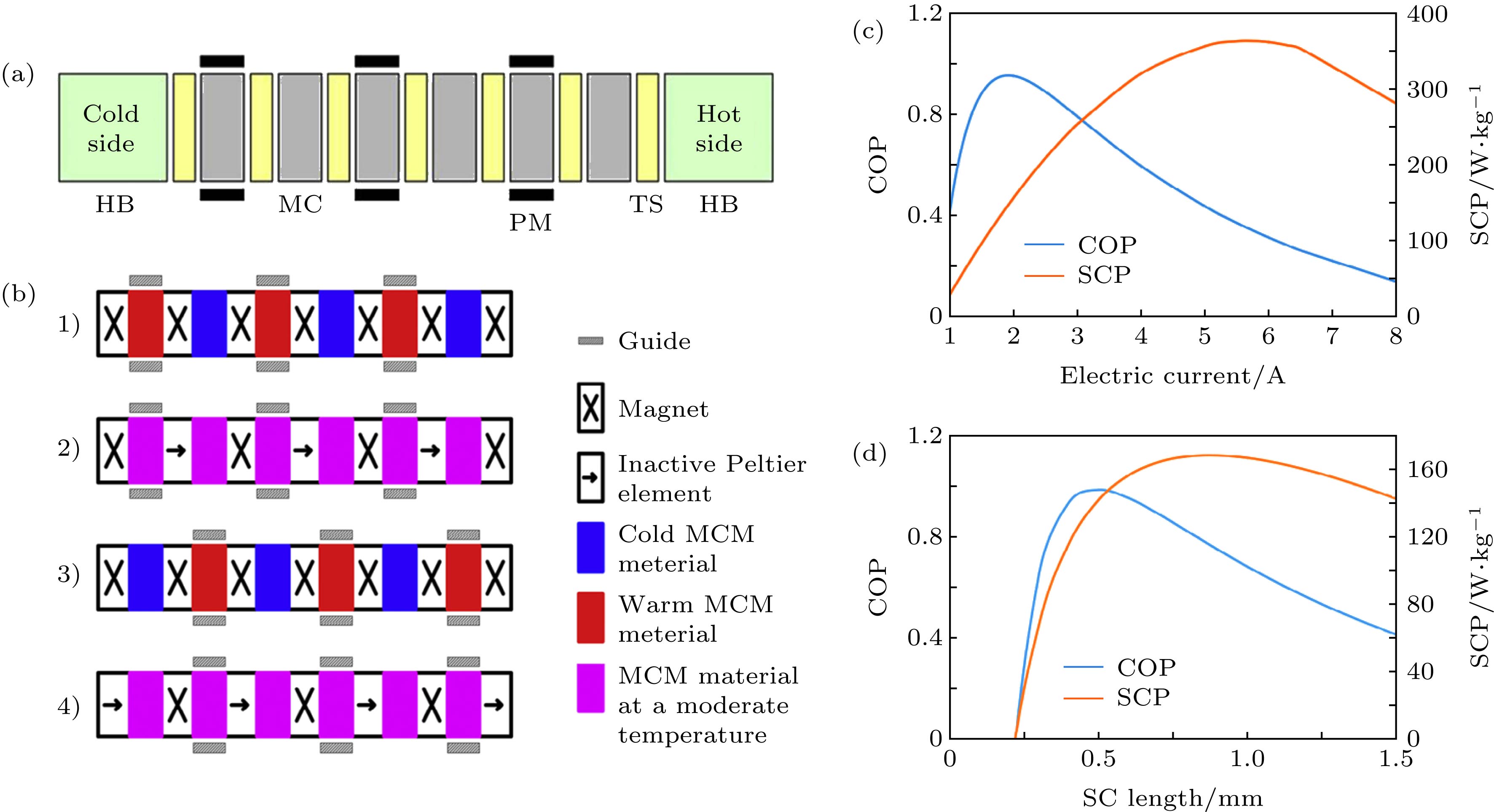

图 7 (a) 级联全固态MR系统的工作机制[33]; (b) 不同MCM元件数量下温跨随工作温度的变化[33]; (c) 不同热导率的MCM下温跨与工作频率的关系[34]

Fig. 7. (a) Working mechanism of the cascaded full solid state magnetic refrigeration system[33]; (b) variation of temperature span with operating temperature for different MCM components[33]; (c) dependence of the temperature span on the operating frequency for different thermal conductivities of the MCM[34].

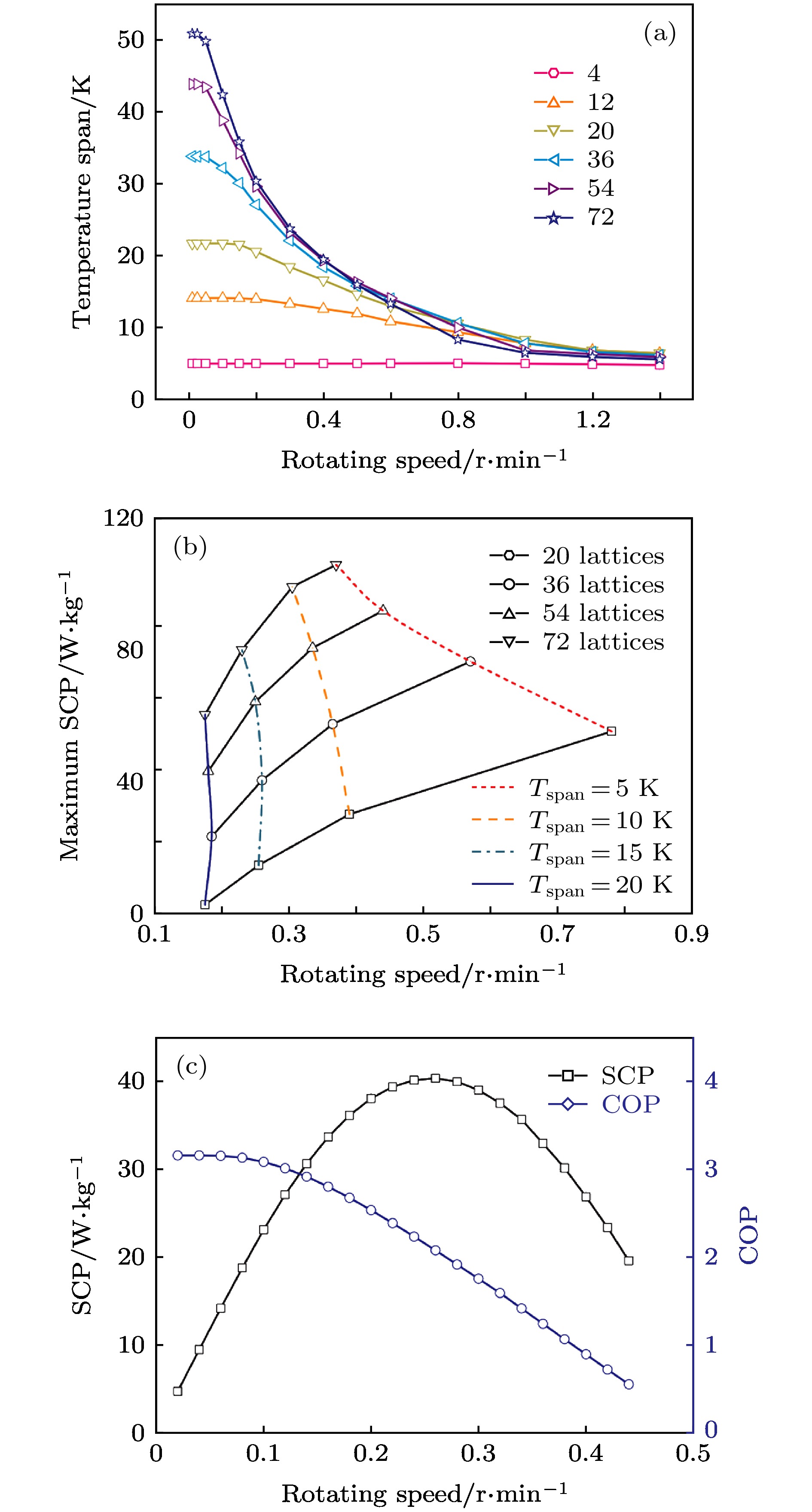

图 8 (a)不同网格数下温跨与转速的关系[24]; (b)不同温跨网格数下最大SCP与转速的关系[24]; (c) 32网格下最大SCP和COP与转速的关系[24]

Fig. 8. (a) Variation of temperature span with rotating speed at different lattice numbers[24]; (b) variation of maximum SCP with rotating speed at different temperature spans and lattice numbers[24]; (c) variation of maximum SCP and COP with different rotating speeds at 32 lattices[24].

表 1 3 V电压下, 带有铜块的MR和带有Peltier元件的MR的最大SCP比较[31]

Table 1. Maximum SCP comparison between MR with copper blocks and MR with Peltier elements under a 3 V supply voltage[31].

配置 温跨/K 最大SCP/W·kg–1 增加

百分比/%铜块 Peltier元件 平行板 5 67.6 133.8 98 10 26.1 64.9 149 拓扑优

化结构5 88.5 160.9 82 10 35.7 79.8 124 表 2 全固态MR模型与传统AMR模型的主要性能比较

Table 2. Comparison of main performances between full solid state MR model and traditional AMR model.

类型 磁工质 传热介质 工作频率/Hz 温跨/K SCP/W·kg–1 COP 参考文献 全固态MR 准2D全固态MR Gd Peltier元件 0—225 5—15 1 × 104 — [21] 全固态MR Gd Peltier元件 10 50 1.5 × 104 2.8 [27] 2D全固态MR Gd Peltier元件 20 — — 5.3—6.5 [28] 全固态MR Gd Peltier元件 20—200 60 — 4.0 [30] 1D全固态MR Gd Peltier元件 — 5 — 0.96—9.21 [23] 准2D全固态MR Gd Peltier元件 — 10 79.8 — [31] 1D全固态MR Gd kH元件 0—500 2.5 — 1.5 [32] 1D全固态MR Gd kH元件 — 11.5 — 4.0 [33] 准2D全固态MR Gd Cu块 — 5—50.9 2.6—105.8 1.5—4.2 [24] 传统AMR 1D AMR Gd 水 — 15 — 1.49—5.27 [42] 2D AMR Gd 水 — 3 — 5.4 [43] 1D AMR Gd 水 0.125 6 — 12.16 [44] AMR/旋转床 Gd 水+乙二醇 0~10 < 18.9 — — [45] 2D AMR Gd 水+乙二醇 0.75 10.2 60.59 3.1 [46] 2D AMR Gd 水 1.5 14.5 — ~2 [47] AMR/旋转床 Gd 水+乙二醇 0.8 7.1 — 0.54 [48] 1D AMR Gd 水+乙二醇 0.3—10 20 100 7.6—11.2 [49] 2D AMR ${\rm Gd_5(Si}_x{\rm Ge}_{1-x})_4 $ 水 1.25 ~10—16 — ~5 [50] AMR/平行板床 ${\rm MnFeP}_{1-x}{\rm As}_x $ 水+乙二醇 0.8 32 — — [51] 1D AMR LaFeSiMnHy 水+乙二醇 0.15 19.8 12.4 — [52] -

[1] Franco V, Blázquez J S, Ipus J J, Law J Y, Moreno-Ramirez L M, Conde A 2018 Prog. Mater. Sci. 93 112

Google Scholar

Google Scholar

[2] Osmann S, Mohamed B 2014 Int. J. Refrig. 37 8

Google Scholar

Google Scholar

[3] Warburg E 1881 Ann. Phys. 13 141

[4] Giauque W F, MacDougall D P 1935 J. Am. Chem. Soc. 57 1175

Google Scholar

Google Scholar

[5] Brown G V 1976 J. Appl. Phys. 47 3673

[6] Steyert W A 1978 J. Appl. Phys. 49 1216

Google Scholar

Google Scholar

[7] Barclay J A 1982 J. Appl. Phys. 53 2887

Google Scholar

Google Scholar

[8] Barclay J A, Steyert W A 1982 U. S. Patent 4 332 135 [1982-06-01]

[9] Chen F C, Murphy R W, Mei V C 1992 J. Eng. Gas. Turb. Powe. 114 715

Google Scholar

Google Scholar

[10] Zimm C, Jastrab A, Sternberg A, Pecharsky V, Gschneidner Jr K, Osborne M, Anderson I 1998 Adv. Cryog. Eng. 43 1759

[11] Lawton Jr M L, Zimm C B, Jastrab A G 1999 U. S. Patent 5 934 078 [1999-08-10]

[12] Yu B F, Gao Q, Zhang B, Meng X Z, Chen Z 2003 Int. J. Refrig. 26 622

Google Scholar

Google Scholar

[13] Gschneidner K A J, Pecharsky V K 2008 Int. J. Refrig. 31 945

Google Scholar

Google Scholar

[14] Yu B F, Liu W, Egolf P W, Kitanovski A 2010 Int. J. Refrig. 33 1029

Google Scholar

Google Scholar

[15] Gomez J R, Garcia R F, Carril J C, Gomez M R 2013 Renew. Sust. Energ. Rev. 17 74

Google Scholar

Google Scholar

[16] Jacobs S, Auringer J, Boeder A, Chell J, Komorowski L, Leonard J, Russek S, Zimm C 2014 Int. J. Refrig. 37 84

Google Scholar

Google Scholar

[17] 李振兴, 李珂, 沈俊, 戴巍, 贾际琛, 郭小惠, 高新强, 公茂琼 2017 低温工程 1 13

Google Scholar

Google Scholar

Li Z X, Li K, Shen J, Dai W, Jia J C, Guo X H, Gao X Q, Gong M Q 2017 Cryogenics 1 13

Google Scholar

Google Scholar

[18] Teyber R, Holladay J, Meinhardt K, Polikarpov E, Thomsen E, Cuid J, Rowee A, Barclay J 2019 Appl. Energ. 236 426

Google Scholar

Google Scholar

[19] Kitanovski A, Egolf P W 2010 Int. J. Refrig. 33 449

Google Scholar

Google Scholar

[20] Aliev A M, Batdalov A B, Khanov L N, Koledov V V, Shavrov V G, Tereshina I S, Taskaev S V 2016 J. Alloy. Compd. 676 601

Google Scholar

Google Scholar

[21] Tomc U, Tušek J, Kitanovski A, Poredoš A 2013 Appl. Therm. Eng. 58 1

Google Scholar

Google Scholar

[22] Kitanovski A, Plaznik U, Tomc U, Poredoš A 2015 Int. J. Refrig. 57 288

Google Scholar

Google Scholar

[23] Monfared B 2017 Int. J. Refrig. 74 324

Google Scholar

Google Scholar

[24] Wu J H, Lu B W, Liu C P, He J 2018 Appl. Therm. Eng. 137 836

Google Scholar

Google Scholar

[25] Kitanovski A, Tušek J, Tomc U, Plaznik U, Ožbolt M, Poredoš A 2015 Magnetocaloric Energy Conversion (vol. preface) (Switzerland: Springer International Publishing Switzerland) pviii

[26] Tomc U, Tušek J, Kitanovski A, Poredoš A 2014 Int. J. Refrig. 37 185

Google Scholar

Google Scholar

[27] Egolf P W, Gravier L, Francfort T, Pawlowski A G, Courret G, Croci M 2014 Int. J. Refrig. 37 176

Google Scholar

Google Scholar

[28] de Vries W, van der Meer T H 2017 Appl. Therm. Eng. 111 377

Google Scholar

Google Scholar

[29] Tasaki Y, Takahashi H, Yasuda Y, Okamura T, Ito K 2012 Fifth ⅡF-ⅡR International Conference on Magnetic Refrigeration at Room Temperature, Thermag V Grenoble, France, September 17−20, 2012 p445

[30] Olsen U L, Bahl C R H, Engelbrecht K, Nielsen K K, Tasaki Y, Takahashi H 2014 Int. J. Refrig. 37 194

Google Scholar

Google Scholar

[31] Lu B W, Wu J H, He J, Huang J H 2019 Int. J. Refrig. 98 42

Google Scholar

Google Scholar

[32] Silva D J, BordaloB D, Pereira A M, Ventura J, Araújo J P 2012 Appl. Ener. 93 570

Google Scholar

Google Scholar

[33] Silva D J, VenturaJ, Araújo J P, Pereira A M 2014 Appl. Ener. 113 1149

Google Scholar

Google Scholar

[34] Silva D J, Bordalo B D, Pereira A M, Ventura J, Oliveira J C R E, Araújo J P 2016 Appl. Therm. Eng. 99 514

Google Scholar

Google Scholar

[35] Silva D J, Ventura J, Amaral J S, Amaral V S 2019 Int. J. Energy. Res. 43 742

Google Scholar

Google Scholar

[36] Zhang M, Momen A M, Abdelaziz O 2016 16th International Refrigeration and Air Conditioning Conference at Purdue West Lafayette, US, July 11−14 2016 p1758

[37] Utaka Y, Hua K, Chen Z H, Zhao Y J 2019 Appl. Therm. Eng. 155 196

Google Scholar

Google Scholar

[38] Wehmeyer G, Yabuki T, Monachon C, Wu J Q, Dames C 2017 Appl. Phys. Rev. 4 041304

Google Scholar

Google Scholar

[39] Salamon M B, Jaime M 2001 Rev. Mod. Phys. 73 583

Google Scholar

Google Scholar

[40] Jeong T, Moneck M T, Zhu J G 2012 IEEsran. Magn. 48 3031

Google Scholar

Google Scholar

[41] Kimling J, Nielsch K, Rott K, Reiss G 2013 Phys. Rev. B 87 134406

Google Scholar

Google Scholar

[42] Aprea C, Maiorino A 2010 Appl. Ener. 87 2690

Google Scholar

Google Scholar

[43] Liu M, Yu B F 2011 Int. J. Refrig. 34 617

Google Scholar

Google Scholar

[44] Vuarnoz A, Kawanami T 2012 Appl. Therm. Eng. 37 388

Google Scholar

Google Scholar

[45] Lozano J A, Engelbrecht K, Bahl C R H, Nielsen K K, Barbosa J R, Prata A T, Pryds N 2014 Int. J. Refrig. 37 92

Google Scholar

Google Scholar

[46] Eriksen D, Engelbrecht K, Bahl C R H 2015 Int. J. Refrig. 58 14

Google Scholar

Google Scholar

[47] Lionte S, Vasile C, Siroux M 2015 Appl. Therm. Eng. 75 871

Google Scholar

Google Scholar

[48] Lozano J A, Capovilla M S, Trevizoli P V, Engelbrecht K, Bahl C R H, Barbosa J R 2016 Int. J. Refrig. 68 187

Google Scholar

Google Scholar

[49] Lei T, Engelbrecht K, Nielsen K K, Christian T, Veje C T 2017 Appl. Therm. Eng. 111 1232

Google Scholar

Google Scholar

[50] Aprea C, Greco A, Maiorino A, Masselli C 2015 Appl. Therm. Eng. 91 767

Google Scholar

Google Scholar

[51] Govindappa P, Trevizoli P V, Campbel O, Niknia, I, Christiaanse T V, Teyber R, Misra S, Schwind M A, van Asten D, Zhang L 2017 J. Phys. D: Appl. Phys. 50 315001

Google Scholar

Google Scholar

[52] Navickaite K, Bez H N, Lei T, Barcza A, Vieyra H, Bahl C, Engelbrecht K 2018 Int. J. Refrig. 86 322

Google Scholar

Google Scholar

[53] Pecharsky V K, Gschneidner J K A 1997 Phys. Rev. Lett. 78 4494

Google Scholar

Google Scholar

[54] de Oliveira N A, von Ranke P J 2010 Phys. Rep. 489 89

Google Scholar

Google Scholar

[55] Shen B G, Sun J R, Hu F X, Zhang H W, Cheng Z H 2009 Adv. Mater. 21 4545

Google Scholar

Google Scholar

[56] Tusek J, Kitanovski A, Tomc U, Favero C, Poredoš A 2014 Int. J. Refrig. 37 117

Google Scholar

Google Scholar

[57] Wang Y X, Zhang H, Liu E K, Zhong X C, Tao K, Wu M L, Xing C F, Xiao Y N, Liu J, Long Y 2018 Adv. Electron. Mater. 4 1700636

Google Scholar

Google Scholar

[58] Balli M, Jandl S, Fournier P, Kedous-Lebouc A 2017 Appl. Phys. Rev. 4 021305

Google Scholar

Google Scholar

[59] Smith A, Bahl C R H, Bjørk R, Engelbrecht K, Nielsen K K, Pryds N 2012 Adv. Energy. Mater. 2 1288

Google Scholar

Google Scholar

[60] Zhao W Y, Liu Z Y, Sun Z G, Zhang Q J, Wei P, Mu X, Zhou H Y, Li C C, Ma S F, He D Q, Ji P X, Zhu W T, Nie X L, Su X L, Tang X F, Shen B G, Dong X L, Yang J H, Liu Y, Shi J 2017 Nature 549 247

Google Scholar

Google Scholar

[61] 李海波, 姜倩, 徐小农, 卢定伟 2016 低温工程 5 51

Google Scholar

Google Scholar

Li H B, Jiang Q, Xu X D, Lu D W 2016 Cryogenics 5 51

Google Scholar

Google Scholar

[62] Blumenthal P, Raatz A 2016 Europhys. Lett. 115 17004

Google Scholar

Google Scholar

[63] Hess T, Maier L M, Corhan P, Schäfer-Welsen O, Wöllenstein J, Bartholomé K 2019 Int. J. Refrig. 103 215

Google Scholar

Google Scholar

[64] Qiao K M, Hu F X, Liu Y, Li J, Kuang H, Zhang H R, Liang W H, Wang J, Sun J R, Shen B G 2019 Nano Energy 59 285

Google Scholar

Google Scholar

计量

- 文章访问数: 13878

- PDF下载量: 192

- 被引次数: 0

下载:

下载: