-

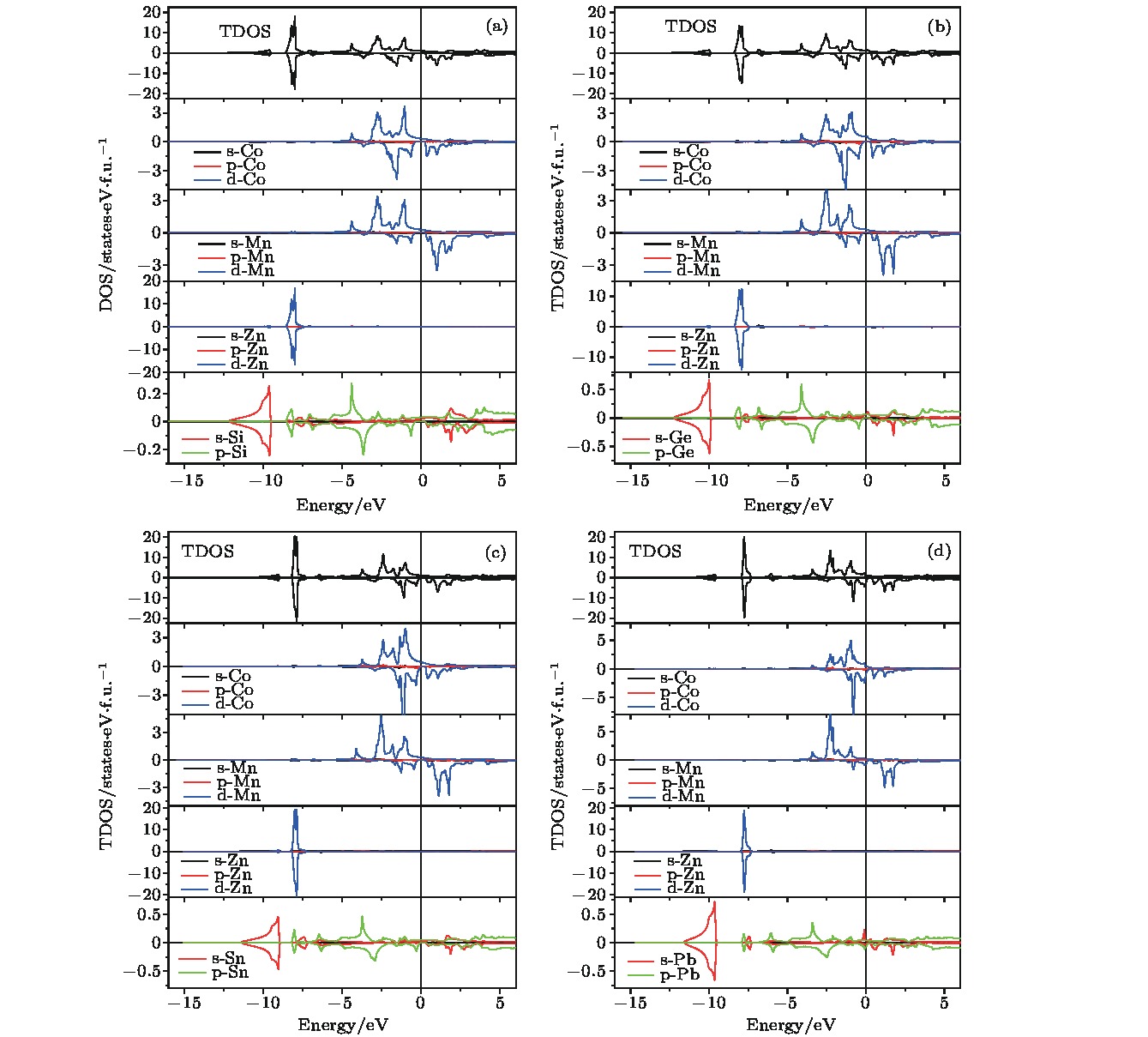

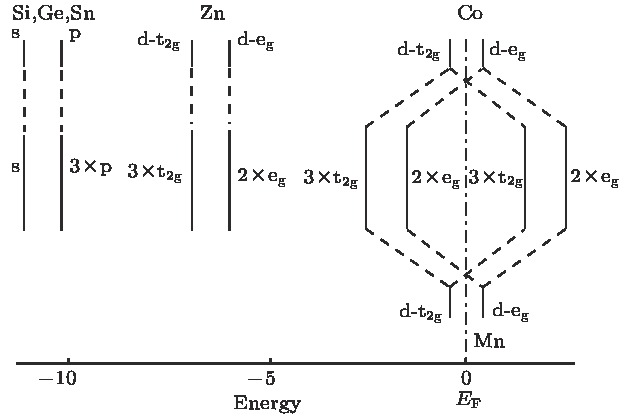

通过第一原理计算理论预测了CoMnZnZ (Z = Si, Ge, Sn, Pb)系列Heusler合金的弹性常数、电子结构和磁性, 并根据弹性常数计算得到弹性模量等参量, 计算了该系列化合物声速和德拜温度. 计算采用全势线性缀加平面波方法, 交换相关函数采用基于Perdew-Burke-Ernzerhof的广义梯度近似泛函. 弹性模量结果表明晶体呈现韧性特征; 承受剪切的性能弱于承受单轴压缩的性能; 结构组成具有较低的各向异性性能. 电子结构的计算显示CoMnZnZ (Z = Si, Ge, Sn)三个化合物属于半金属铁磁体, 但是CoMnZnPb化合物并不显示半金属特性. CoMnZnZ (Z = Si, Ge, Sn)三个化合物的磁矩通过Slater-Pauling法则进行计算得到的量值与第一原理计算得到的完全一致, 遵从总的价电子数减去28的 Slater-Pauling法则, 三个化合物磁矩为整数且自旋极化率为100%. 利用轨道杂化理论解释了此系列化合物半金属性的根源.

-

关键词:

- Heusler化合物 /

- 半金属 /

- 第一性原理 /

- 电子结构

Using the first principle full-potential linearized augmented wave method we study the electronic structure and elastic and magnetic properties of CoMnZnZ (Z = Si, Ge, Sn, Pb) LiMgPdSn-type Heusler alloys. These compounds have the composition CoMnZnZ with 1︰1︰1︰1 stoichiometry, where Z denotes the main group element Si, or Ge, or Sn, or Pb. The exchange-correlations are treated within the generalized gradient approximation of Perdewe-Burke-Ernzerhof. For each of all studied Heusler alloys, the ferromagnetic state is considered to be more stable than the paramagnetic state, judged by the energy. The total energy of the magnetic calculation is lower than that of the nonmagnetic state for each of all three serise compounds at the equilibrium lattice constant, indicating that the magnetic state is more stable than the nonmagnetic state. We determine the elastic constants C11, C12 and C44, which have not been established previously in experiment nor in theory. The elastic constant indicates the weakened resistance to sheardeformation compared with the resistance to unidirectional compression. We derive other mechanical parameters, i.e., the shear modulus G, Young’s modulus E, Poisson’s ratio ν, and shear anisotropic factor A, which are the important elastic moduli for applications. These compounds each have a lower anisotropy and possess a low probability to develop micro-crack or structural defect in its growing process. The sound velocity and Debye temperature for each of the CoMnZnZ (Z = Si, Ge, Sn, Pb) compounds in their stable structure are calculated. The CoMnZnPb exhibits the lowest Debye temperature, and the highest value is observed for CoMnZnGe. The electronic structure calculations show that CoMnZnZ (Z = Si, Ge, Sn) each exhibit a gap in the band of minority states, and they are clearly half-metallic ferromagnets, except for the CoMnZnPb. The CoMnZnZ (Z = Si, Ge, Sn) compounds and their magnetic moments are in reasonable agreement with the Slater-Pauling rule, and they comply with a Slater-Pauling rule of Mt = Zt – 28, which indicates the half metallicity and high spin polarization for these compounds. The CoMnZnSi compound has the largest half-metallic gap value and the gap is about 0.66 eV. The magnetic properties are primarily determined by the Mn atoms, which contribute the highest magnetic moments. The localmoment of the Z element atom is negligibly small. The hybridization of the d orbitals between Co and Mn can explain the origin of the Slater-Pauling rule in half-metallic quaternary Heusler alloys. The half-metallic gap comes mainly from the interaction between the Co and Mn atoms.-

Keywords:

- Heusler compounds /

- half metallic materials /

- first principle /

- electronic structure

[1] Bernevig B A, Hughes T L, Zhang S C 2006 Science 314 1757

Google Scholar

Google Scholar

[2] Galanakis I, Dederichs P H, Papanikolaou N 2002 Phys. Rev. B 66 174429

Google Scholar

Google Scholar

[3] Skaftouros S, Ozdogan K, Sasioglu E, Galanakis I 2013 Phys. Rev. B 87 024420

Google Scholar

Google Scholar

[4] Luo H, Meng F, Liu H, Li J, Liu E, Wu G, Zhu X, Jiang C 2012 J. Magn. Magn. Mater. 324 2127

Google Scholar

Google Scholar

[5] Luo H, Liu G, Meng F, Wang L, Liu E, Wu G, Zhu X, Jiang C 2011 Computat. Mater. Sci. 50 3119

Google Scholar

Google Scholar

[6] Gao Q, Li L, Lei G, Deng J B, Hun X R 2015 J. Magn. Magn. Mater. 379 288

Google Scholar

Google Scholar

[7] Bainsla L, Mallick A I, Coelho A A, Nigam A K, Varaprasad B, Takahashi Y K, Alam A, Suresh K G, Hono K 2015 J. Magn. Magn. Mater. 394 82

Google Scholar

Google Scholar

[8] Berri S, Maouche D, Ibrir M, Zerarga F 2014 J. Magn. Magn. Mater. 354 65

Google Scholar

Google Scholar

[9] Ozdogan K, Sasioglu E, Galanakis I 2013 J. Appl. Phys. 113 193903 5

[10] Halder M, Mukadam M D, Suresh K G, Yusuf S M 2015 J. Magn. Magn. Mater. 377 220

Google Scholar

Google Scholar

[11] Venkateswara E Y, Gupta S, Varma M R, Singh P, Suresh K G, Alam A 2015 Phys. Rev. B 92 224413

[12] Bainsla L, Yadav A K, Venkateswara Y, Jha S N, Bhattacharyya D, Suresh K G 2015 J. Alloys Compounds 651 509

Google Scholar

Google Scholar

[13] Al-zyadi J M K, Gao G Y, Yao K L 2015 J. Magn. Magn. Mater. 378 1

Google Scholar

Google Scholar

[14] 姚仲瑜, 孙丽, 潘孟美, 孙书娟, 刘汉军 2018 67 217501

Google Scholar

Google Scholar

Yao Z Y, Sun L, Pan M M, Sun S J, Liu H J 2018 Acta Phys. Sin. 67 217501

Google Scholar

Google Scholar

[15] 黄海深, 孙剑, 吴波, 杨秀德, 李平 2018 材料导报 32 2124

Google Scholar

Google Scholar

Huang H S, Sun J, Wu B, Yang X D, Li P 2018 Mater. Reports 32 2124

Google Scholar

Google Scholar

[16] Alijani V, Ouardi S, Fecher G H, Winterlik J, Naghavi S S, Kozina X, Stryganyuk G, Felser C, Ikenaga E, Yamashita Y, Ueda S, Kobayashi K 2011 Phys. Rev. B 84 224416

Google Scholar

Google Scholar

[17] Klaer P, Balke B, Alijani V, Winterlik J, Fecher G H, Felser C, Elmers H J 2011 Phys. Rev. B 84 144413

Google Scholar

Google Scholar

[18] Vajiheh A, Juergen W, Gerhard H F, Naghavi S S, Stanislav C, Thomas G, Claudia F 2012 J. Phys.: Condens. Matter 24 046001

Google Scholar

Google Scholar

[19] Benkabou M, Rached H, Abdellaoui A, Rached D, Khenata R, Elahmar M H, Abidri B, Benkhettou N, Bin-Omran S 2015 J. Alloys Compd. 647 276

Google Scholar

Google Scholar

[20] Jia L Y, Xu J L, Zhao R B, Pan H, Shen J L, Yuan L Y, Li G K, Ma L, Zhen C M, Hou D L 2018 J. Supercond. Nov. Magn. 31 1067

Google Scholar

Google Scholar

[21] 辛月朋, 马悦兴, 郝红月, 孟凡斌, 刘何燕, 罗鸿志 2016 65 147102

Google Scholar

Google Scholar

Xin Y P, Ma Y X, Hao H Y, Meng F B, Liu H Y, Luo H Z 2016 Acta Phys. Sin. 65 147102

Google Scholar

Google Scholar

[22] Murnaghan F 1944 Proc. Nat. Acad. Sci. USA 50 697

[23] Rached H, Rached D, Khenata R, Reshak A H, Rabah M 2009 Phys. Status Solidi (b)

246 1580  Google Scholar

Google Scholar

[24] Rached H, Rached D, Rabah M, Khenata R, Reshak A H 2010 Physica B: Condens. Matter 405 3515

Google Scholar

Google Scholar

[25] Pettifor D G 1992 Mater. Sci. Technol. 8 345

Google Scholar

Google Scholar

[26] Kanchana V, Vaitheeswaran G, Ma Y, Xie Y, Svane A, Eriksson O 2009 Phys. Rev. B 80 125108

Google Scholar

Google Scholar

[27] Pugh S F 1954 The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science 45 823

Google Scholar

Google Scholar

[28] Haines J, Leger J, Bocquillon G 2001 Ann. Rev. Mater. Res. 31 1

Google Scholar

Google Scholar

[29] Biskri Z E, Rached H, Bouchear M, Rached D 2014 J. Mech. Behav. Biomed. Mater. 32 345

Google Scholar

Google Scholar

[30] Anderson O L 1963 J. Phys. Chem. Solids 24 909

Google Scholar

Google Scholar

-

表 1 CoMnZnSi, CoMnZnGe, CoMnZnSn, CoMnZnPb四种化合物对应的平衡晶格常数a0、体积弹性模量B、压力导数B'和平衡能量E0

Table 1. Calculated equilibrium lattice parameters a0, bulk modulus B, its pressure derivative B' and equilibrium energy E0 for CoMnZnZ (Z = Si, Ge, Sn, Pb) compounds.

Material a0/Å B/GPa B' E0/Ryd CoMnZnSi 5.81 163.57 4.56 -9276.59 CoMnZnGe 5.93 154.83 3.78 -12894.68 CoMnZnSn 6.18 122.29 5.20 -21054.64 CoMnZnPb 6.35 67.80 10.15 -50552.93 表 2 计算得到的各化合物的单晶弹性常数Cij、多晶剪切模量G、杨氏模量E、泊松比ν和剪切各向异性常数A

Table 2. Calculated single crystal elastic constants Cij and polycrystalline elastic modulus (shear modulus G, Young’s modulus E, Poisson’s ratio ν) shear anisotropic factor A for compounds.

Material C11 C12 C44 G E ν A CoMnZnSi 106.37 175.86 73.27 0.76 2.27 0.50 –2.11 CoMnZnGe 94.93 150.45 60.36 0.97 2.90 0.50 –2.17 CoMnZnSn 94.17 130.42 60.59 4.87 14.41 0.48 –3.34 CoMnZnPb 58.98 97.61 30.17 –1.69 –5.12 0.51 –1.56 表 3 计算得到的温度压力均为0状态下的纵向(vl)、横向(vt)、平均声速 (vm)和德拜温度(θD)

Table 3. Calculated longitudinal (vl), transverse (vt), and average (vm) sound velocity and Debye temperature (θD) for compounds.

Material vt/ m·s–1 vl/ m·s–1 vm/ m·s–1 θD/K CoMnZnSi 3732.6 3178.9 2341 208.63 CoMnZnGe 1366 1001.9 6397.9 284.78 CoMnZnSn 3030 8999.9 2901.3 172.36 CoMnZnPb 1147 4121.8 7588.8 81.813 表 4 每分子式总自旋磁矩Mt、间隙区磁矩Mi和各原子磁矩(MX, M'X, MY, MZ)、自旋极化率

Table 4. Total, interstitial and local magnetic moments, calculated spin-polarization.

Material Mt/μB Mi/μB MX/μB M'X/μB MY/μB MZ/μB Spin polarization ratio/% CoMnZnSi 4.00 0.0872 0.91 3.01 0.01 –0.02 100 CoMnZnGe 4.00 0.0005 0.81 3.20 0.02 –0.03 100 CoMnZnSn 4.00 –0.0321 0.74 3.34 –0.01 –0.04 100 CoMnZnPb 4.34 –0.0181 0.87 3.49 –0.02 –0.01 47 -

[1] Bernevig B A, Hughes T L, Zhang S C 2006 Science 314 1757

Google Scholar

Google Scholar

[2] Galanakis I, Dederichs P H, Papanikolaou N 2002 Phys. Rev. B 66 174429

Google Scholar

Google Scholar

[3] Skaftouros S, Ozdogan K, Sasioglu E, Galanakis I 2013 Phys. Rev. B 87 024420

Google Scholar

Google Scholar

[4] Luo H, Meng F, Liu H, Li J, Liu E, Wu G, Zhu X, Jiang C 2012 J. Magn. Magn. Mater. 324 2127

Google Scholar

Google Scholar

[5] Luo H, Liu G, Meng F, Wang L, Liu E, Wu G, Zhu X, Jiang C 2011 Computat. Mater. Sci. 50 3119

Google Scholar

Google Scholar

[6] Gao Q, Li L, Lei G, Deng J B, Hun X R 2015 J. Magn. Magn. Mater. 379 288

Google Scholar

Google Scholar

[7] Bainsla L, Mallick A I, Coelho A A, Nigam A K, Varaprasad B, Takahashi Y K, Alam A, Suresh K G, Hono K 2015 J. Magn. Magn. Mater. 394 82

Google Scholar

Google Scholar

[8] Berri S, Maouche D, Ibrir M, Zerarga F 2014 J. Magn. Magn. Mater. 354 65

Google Scholar

Google Scholar

[9] Ozdogan K, Sasioglu E, Galanakis I 2013 J. Appl. Phys. 113 193903 5

[10] Halder M, Mukadam M D, Suresh K G, Yusuf S M 2015 J. Magn. Magn. Mater. 377 220

Google Scholar

Google Scholar

[11] Venkateswara E Y, Gupta S, Varma M R, Singh P, Suresh K G, Alam A 2015 Phys. Rev. B 92 224413

[12] Bainsla L, Yadav A K, Venkateswara Y, Jha S N, Bhattacharyya D, Suresh K G 2015 J. Alloys Compounds 651 509

Google Scholar

Google Scholar

[13] Al-zyadi J M K, Gao G Y, Yao K L 2015 J. Magn. Magn. Mater. 378 1

Google Scholar

Google Scholar

[14] 姚仲瑜, 孙丽, 潘孟美, 孙书娟, 刘汉军 2018 67 217501

Google Scholar

Google Scholar

Yao Z Y, Sun L, Pan M M, Sun S J, Liu H J 2018 Acta Phys. Sin. 67 217501

Google Scholar

Google Scholar

[15] 黄海深, 孙剑, 吴波, 杨秀德, 李平 2018 材料导报 32 2124

Google Scholar

Google Scholar

Huang H S, Sun J, Wu B, Yang X D, Li P 2018 Mater. Reports 32 2124

Google Scholar

Google Scholar

[16] Alijani V, Ouardi S, Fecher G H, Winterlik J, Naghavi S S, Kozina X, Stryganyuk G, Felser C, Ikenaga E, Yamashita Y, Ueda S, Kobayashi K 2011 Phys. Rev. B 84 224416

Google Scholar

Google Scholar

[17] Klaer P, Balke B, Alijani V, Winterlik J, Fecher G H, Felser C, Elmers H J 2011 Phys. Rev. B 84 144413

Google Scholar

Google Scholar

[18] Vajiheh A, Juergen W, Gerhard H F, Naghavi S S, Stanislav C, Thomas G, Claudia F 2012 J. Phys.: Condens. Matter 24 046001

Google Scholar

Google Scholar

[19] Benkabou M, Rached H, Abdellaoui A, Rached D, Khenata R, Elahmar M H, Abidri B, Benkhettou N, Bin-Omran S 2015 J. Alloys Compd. 647 276

Google Scholar

Google Scholar

[20] Jia L Y, Xu J L, Zhao R B, Pan H, Shen J L, Yuan L Y, Li G K, Ma L, Zhen C M, Hou D L 2018 J. Supercond. Nov. Magn. 31 1067

Google Scholar

Google Scholar

[21] 辛月朋, 马悦兴, 郝红月, 孟凡斌, 刘何燕, 罗鸿志 2016 65 147102

Google Scholar

Google Scholar

Xin Y P, Ma Y X, Hao H Y, Meng F B, Liu H Y, Luo H Z 2016 Acta Phys. Sin. 65 147102

Google Scholar

Google Scholar

[22] Murnaghan F 1944 Proc. Nat. Acad. Sci. USA 50 697

[23] Rached H, Rached D, Khenata R, Reshak A H, Rabah M 2009 Phys. Status Solidi (b)

246 1580  Google Scholar

Google Scholar

[24] Rached H, Rached D, Rabah M, Khenata R, Reshak A H 2010 Physica B: Condens. Matter 405 3515

Google Scholar

Google Scholar

[25] Pettifor D G 1992 Mater. Sci. Technol. 8 345

Google Scholar

Google Scholar

[26] Kanchana V, Vaitheeswaran G, Ma Y, Xie Y, Svane A, Eriksson O 2009 Phys. Rev. B 80 125108

Google Scholar

Google Scholar

[27] Pugh S F 1954 The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science 45 823

Google Scholar

Google Scholar

[28] Haines J, Leger J, Bocquillon G 2001 Ann. Rev. Mater. Res. 31 1

Google Scholar

Google Scholar

[29] Biskri Z E, Rached H, Bouchear M, Rached D 2014 J. Mech. Behav. Biomed. Mater. 32 345

Google Scholar

Google Scholar

[30] Anderson O L 1963 J. Phys. Chem. Solids 24 909

Google Scholar

Google Scholar

计量

- 文章访问数: 11225

- PDF下载量: 96

- 被引次数: 0

下载:

下载: