-

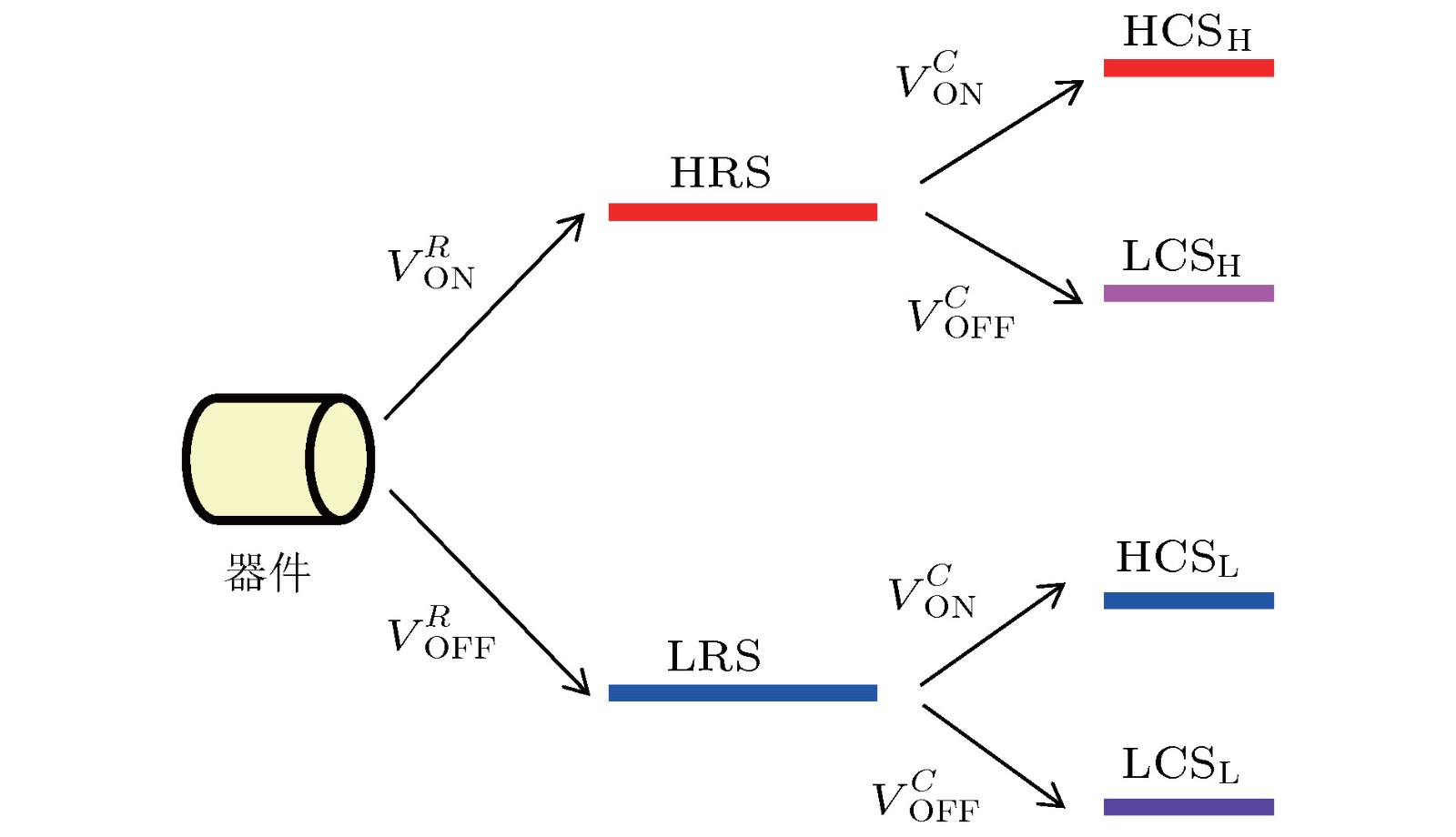

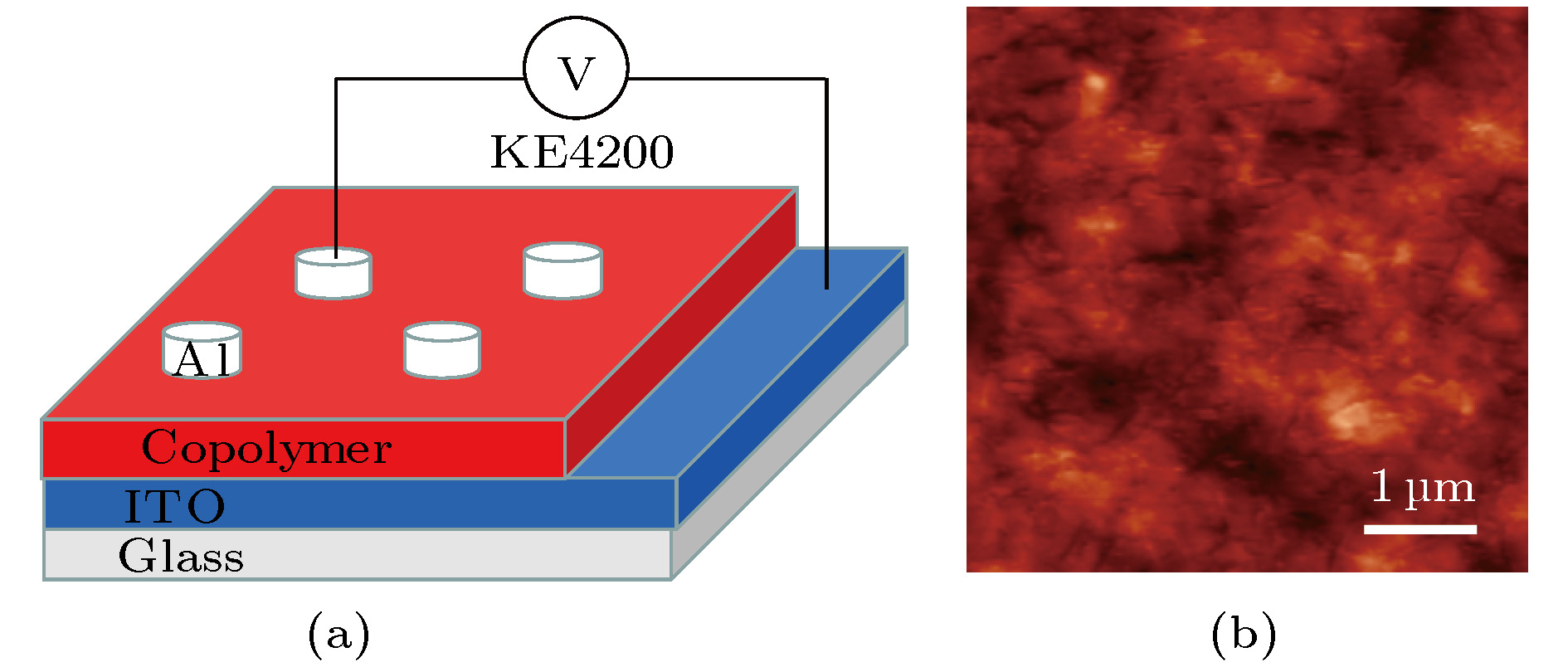

With the advent of the information age, big data put forward higher requirements for capacity of storage devices. Compared with the method of reducing the size of the device to enhance the integration level, the high density storage of increasing the memory state of the single device will be very beneficial to solving the problem. In this work, we propose an idea of two-parameter and multi-state memory device involved in both resistance and capacitance operation levels. At first, a new donor-acceptor (D-A)-type copolymer is designed and synthesized. Then, the memory device of Al/copolymer/ITO structure is fabricated, and the current-voltage (I-V) and capacitance-voltage (C-V) curves are measured by a KEITHLEY 4200 semiconductor characterization system. The device not only displays the obvious memory resistance characteristics, but also has the memory capacitance behavior in single resistance state, which results in two resistance states and four capacitance states, so that the device has the capability of two-parameter and multi-state memory. In addition, the device shows more capacitance states after the switching behavior has been modulated by the voltage amplitude, which provides an effective method to control the memory states. In order to study the conductive mechanism of the device, we test the relationship between resistance and temperature. It is found that the resistance decreases with the increase of temperature, indicating that the device has the obvious semiconductor properties. Furthermore, the fitting results of I-V data show that the mechanism of resistance switching is in good consistence with the classical trap-controlled space charge limited current theory. The capacitance switching in single resistance state is closely related to the polarization characteristic of D-A structure in the copolymer film. The polarization force microscopy phase image shows that the copolymer film has obvious polarization and depolarization characteristics under the external electric field. Based on the polarization characteristics of copolymer, the correlation between memory resistance and memory capacitance is established by introducing a polarization operator of molecules, and the matrix model describing the two-parameter and multi-state memory characteristics is given. The above results show that the multi-state memory characteristics will store more information than 2-bits mode in a single cell, which will provide a reference for improving the storage density of information.

-

Keywords:

- memory resistance /

- memory capacitance /

- multi-state characteristic

[1] Chua L O 1971 IEEE Trans. Circuit Theory 18 507

Google Scholar

Google Scholar

[2] Strukov D B, Snider G S, Stewart D R, Williams R S 2008 Nature 453 80

Google Scholar

Google Scholar

[3] 王媛, 董瑞新, 闫循领 2015 64 048402

Google Scholar

Google Scholar

Wang Y, Dong R X, Yan X L 2015 Acta Phys. Sin. 64 048402

Google Scholar

Google Scholar

[4] Wang M, Cai S H, Pan C, Wang C Y, Lian X J, Zhuo Y, Xu K, Cao T J, Pan X Q, Wang B G, Liang S J, Yang J J, Wang P, Miao F 2018 Nat. Electron. 1 130

Google Scholar

Google Scholar

[5] 余志强, 刘敏丽, 郎建勋, 钱楷, 张昌华 2018 67 157302

Google Scholar

Google Scholar

Yu Z Q, Liu M L, Lang J X, Qian K, Zhang C H 2018 Acta Phys. Sin. 67 157302

Google Scholar

Google Scholar

[6] Banerjee W, Liu Q, Lv H, Long S, Liu M 2017 Nanoscale 9 14442

Google Scholar

Google Scholar

[7] Yan X, Wang J, Zhao M, Li X, Wang H, Zhang L, Lu C, Ren D 2018 Appl. Phys. Lett. 113 013503

Google Scholar

Google Scholar

[8] Wang L Y, Wang Z Y, Zhao W, Hu B, Xie L H, Yi M D, Ling H F, Zhang C X, Chen Y, Lin J Y, Zhu J L, Huang W 2017 Adv. Electron. Mater. 3 1600244

Google Scholar

Google Scholar

[9] Ventra M D, Pershin Y V, Chua L O 2009 Proc. IEEE 97 1717

Google Scholar

Google Scholar

[10] Pershin Y V, Di Ventra M 2011 Adv. Phys. 60 145

Google Scholar

Google Scholar

[11] Bessonov A A, Kirikova M N, Petukhov D I, Allen M, Ryhänen T, Bailey M J A 2015 Nat. Mater. 14 199

Google Scholar

Google Scholar

[12] Haik M Y, Ayesh A I, Abdulrehman T, Haik Y 2014 Mater. Lett. 124 67

Google Scholar

Google Scholar

[13] Albamartin M, Firmager T, Atherton J, Rosamond M C, Ashall D, Ghaferi A A, Ayesh A, Gallant A J, Mabrook M F, Petty M C, Zeze D A 2012 J. Phys. D: Appl. Phys. 45 295401

Google Scholar

Google Scholar

[14] Yan Z B, Liu J M 2013 Sci. Rep. 3 2482

Google Scholar

Google Scholar

[15] Salaoru I, Khiat A, Li Q, Berdan R, Prodromakis T 2013 Appl. Phys. Lett. 103 233513

Google Scholar

Google Scholar

[16] Park M, Park S, Yoo K H 2016 ACS Appl. Mater. Interfaces 8 14046

Google Scholar

Google Scholar

[17] Pan R B, Li J, Zhuge F, Zhu L Q, Liang L Y, Zhang H L, Gao J H, Cao H T, Fu B, Li K 2016 Appl. Phys. Lett. 108 013504

Google Scholar

Google Scholar

[18] Hu L X, Fu S, Chen Y H, Cao H T, Liang L Y, Zhang H L, Gao J H, Wang J R, Zhuge F 2017 Adv. Mater. 29 1606927

Google Scholar

Google Scholar

[19] Menzel S, Bottger U, Waser R 2012 J. Appl. Phys. 111 014501

Google Scholar

Google Scholar

[20] Fujii T, Kawasaki M, Sawa A, Akoh H, Kawazoe Y, Tokura Y 2005 Appl. Phys. Lett. 86 012107

Google Scholar

Google Scholar

[21] Ko Y, Kim Y, Baek H, Cho J 2011 ACS Nano 5 9918

Google Scholar

Google Scholar

[22] Sun Y, Ai C, Lu J, Li L, Wen D, Bai X 2016 Thin Solid Films 598 293

Google Scholar

Google Scholar

[23] Wang H, Meng F B, Cai Y R, Zheng L Y, Li Y G , Liu Y J , Jiang Y Y, Wang X T, Chen X D 2013 Adv. Mater. 25 5498

Google Scholar

Google Scholar

[24] Mohanta K, Majee S K, Batabyal S K, Pal A J 2006 J. Phys. Chem. B 110 18231

Google Scholar

Google Scholar

[25] Zhang Y, Kong L, Ju X, Zhao J 2017 Polymers 10 23

Google Scholar

Google Scholar

[26] Irgashev R A, Teslenko A Y, Zhilina E F, Schepochkin A V, El'Tsov O S, Rusinov G L, Charushin V N 2014 Tetrahedron 70 4685

Google Scholar

Google Scholar

-

图 2 (a)器件Al/共聚物/ITO与Al/ITO(内插图)的I-V特性曲线, 红色和蓝色分别代表器件处在HRS和LRS; (b)器件Al/共聚物/ITO的C-V曲线, 红色和蓝色分别对应HRS和LRS下的C-V曲线; 扫描方向如图中箭头所示; 器件电阻(c)和电容(d)的时间保持特性

Fig. 2. (a) The I-V curves of Al/copolymer/ITO device. Inset is the Al/ ITO device. Red and blue curves represent HRS and LRS, respectively. (b) C-V curves of Al/copolymer/ITO device. Red and blue curves correspond to the C-V characteristics in HRS and LRS, respectively. The arrows show direction of voltage sweep. The retention time characteristics of resistance (c) and capacitance (d)

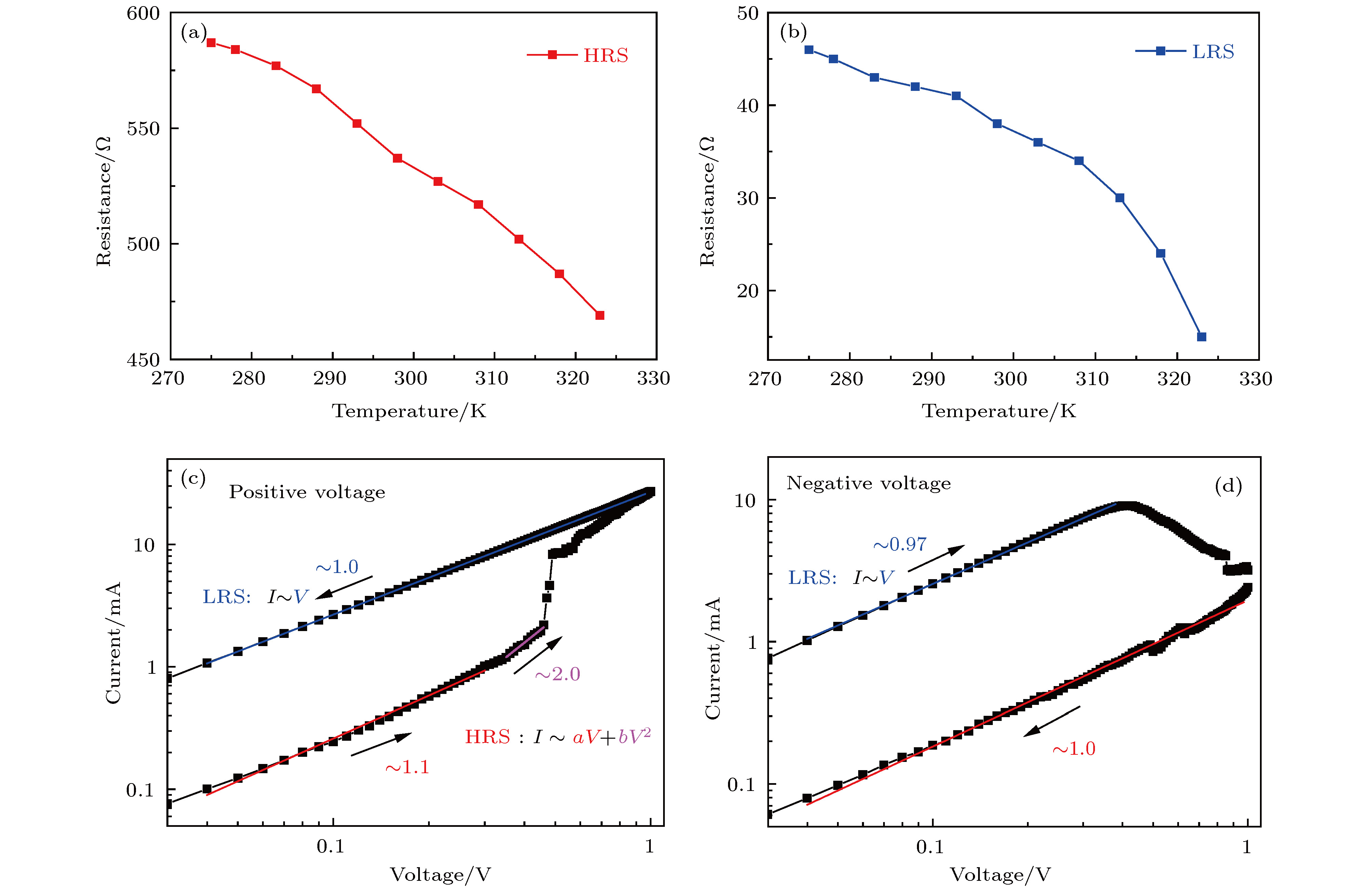

图 4 在高(a)、低(b)阻态下器件的电阻随温度的变化; (c)正电压区域和(d)负电压区域器件的双对数I-V曲线, 图中已标出了每段的斜率

Fig. 4. Resistance versus temperature plots for the device in HRS (a) and LRS (b). Double-logarithmic I-V curves of the device: exerted (c) positive voltage or (d) negative voltage, and the value of the slope is marked in the figure

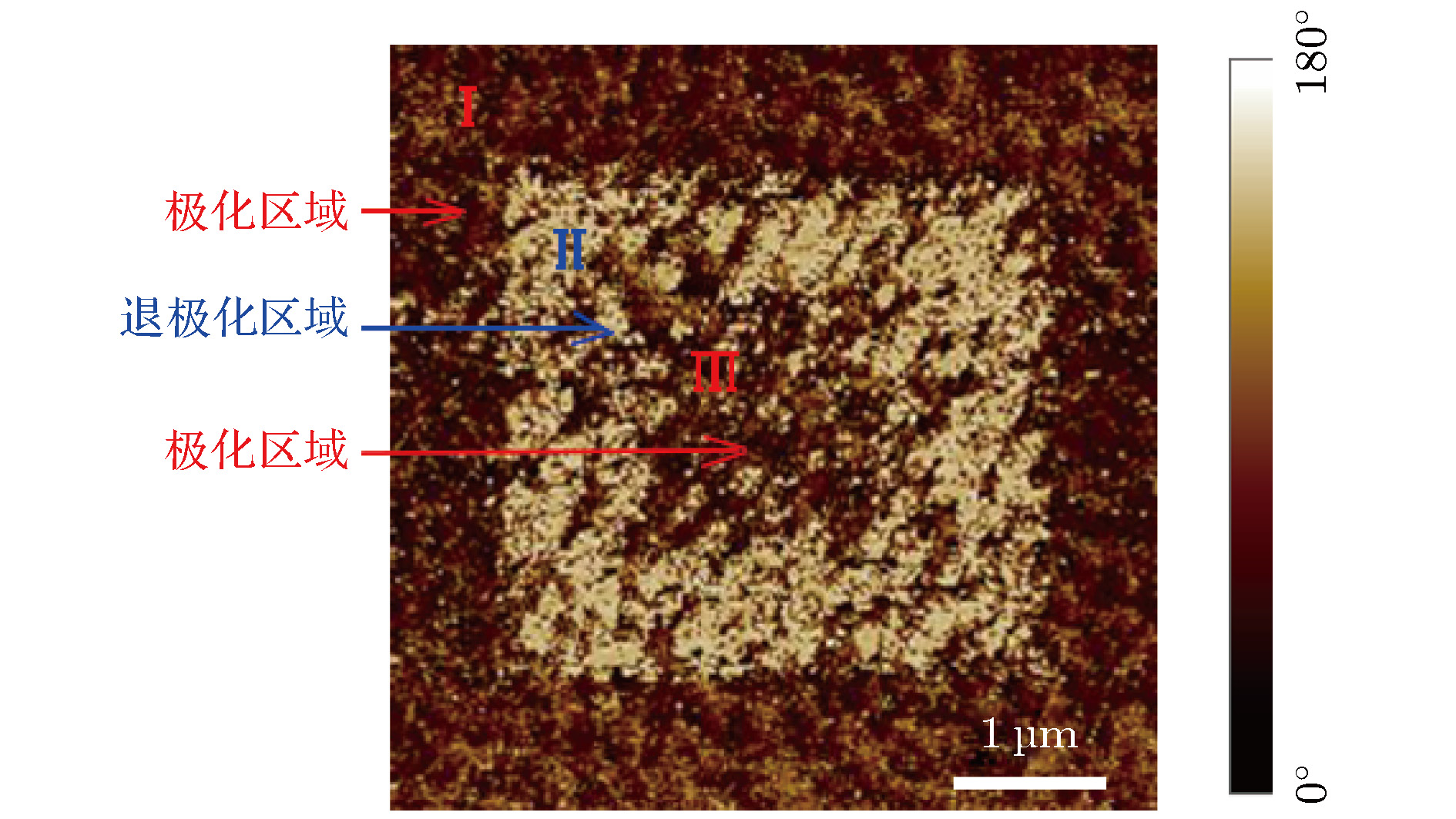

图 5 共聚物薄膜的PFM相位图, 其中首先对5

${\text{μ}} {\rm{m}}$ × 5${\text{μ}} {\rm{m}}$ 区域的薄膜施加–10 V的偏压, 然后对内部的3.5${\text{μ}} {\rm{m}}$ × 3.5${\text{μ}} {\rm{m}}$ 区域施加+10 V的偏压, 再对中心的1.5${\text{μ}} {\rm{m}}$ × 1.5${\text{μ}} {\rm{m}}$ 区域施加–10 V的偏压, 最后通过15 mV的交变信号对5${\text{μ}} {\rm{m}}$ × 5${\text{μ}} {\rm{m}}$ 薄膜的极化程度进行测量Fig. 5. The PFM phase image of the copolymer film. First, an external voltage of –10 V was applied to a square of 5

${\text{μ}} {\rm{m}}$ × 5${\text{μ}} {\rm{m}}$ . Secondly, +10 V was applied to a square of 3.5${\text{μ}} {\rm{m}}$ × 3.5${\text{μ}} {\rm{m}}$ , and then –10 V was applied to a square of 1.5${\text{μ}} {\rm{m}}$ × 1.5${\text{μ}} {\rm{m}}$ . Finally, the polarization degree of 5${\text{μ}} {\rm{m}}$ × 5${\text{μ}} {\rm{m}}$ film was measured by 15 mV alternating signal. -

[1] Chua L O 1971 IEEE Trans. Circuit Theory 18 507

Google Scholar

Google Scholar

[2] Strukov D B, Snider G S, Stewart D R, Williams R S 2008 Nature 453 80

Google Scholar

Google Scholar

[3] 王媛, 董瑞新, 闫循领 2015 64 048402

Google Scholar

Google Scholar

Wang Y, Dong R X, Yan X L 2015 Acta Phys. Sin. 64 048402

Google Scholar

Google Scholar

[4] Wang M, Cai S H, Pan C, Wang C Y, Lian X J, Zhuo Y, Xu K, Cao T J, Pan X Q, Wang B G, Liang S J, Yang J J, Wang P, Miao F 2018 Nat. Electron. 1 130

Google Scholar

Google Scholar

[5] 余志强, 刘敏丽, 郎建勋, 钱楷, 张昌华 2018 67 157302

Google Scholar

Google Scholar

Yu Z Q, Liu M L, Lang J X, Qian K, Zhang C H 2018 Acta Phys. Sin. 67 157302

Google Scholar

Google Scholar

[6] Banerjee W, Liu Q, Lv H, Long S, Liu M 2017 Nanoscale 9 14442

Google Scholar

Google Scholar

[7] Yan X, Wang J, Zhao M, Li X, Wang H, Zhang L, Lu C, Ren D 2018 Appl. Phys. Lett. 113 013503

Google Scholar

Google Scholar

[8] Wang L Y, Wang Z Y, Zhao W, Hu B, Xie L H, Yi M D, Ling H F, Zhang C X, Chen Y, Lin J Y, Zhu J L, Huang W 2017 Adv. Electron. Mater. 3 1600244

Google Scholar

Google Scholar

[9] Ventra M D, Pershin Y V, Chua L O 2009 Proc. IEEE 97 1717

Google Scholar

Google Scholar

[10] Pershin Y V, Di Ventra M 2011 Adv. Phys. 60 145

Google Scholar

Google Scholar

[11] Bessonov A A, Kirikova M N, Petukhov D I, Allen M, Ryhänen T, Bailey M J A 2015 Nat. Mater. 14 199

Google Scholar

Google Scholar

[12] Haik M Y, Ayesh A I, Abdulrehman T, Haik Y 2014 Mater. Lett. 124 67

Google Scholar

Google Scholar

[13] Albamartin M, Firmager T, Atherton J, Rosamond M C, Ashall D, Ghaferi A A, Ayesh A, Gallant A J, Mabrook M F, Petty M C, Zeze D A 2012 J. Phys. D: Appl. Phys. 45 295401

Google Scholar

Google Scholar

[14] Yan Z B, Liu J M 2013 Sci. Rep. 3 2482

Google Scholar

Google Scholar

[15] Salaoru I, Khiat A, Li Q, Berdan R, Prodromakis T 2013 Appl. Phys. Lett. 103 233513

Google Scholar

Google Scholar

[16] Park M, Park S, Yoo K H 2016 ACS Appl. Mater. Interfaces 8 14046

Google Scholar

Google Scholar

[17] Pan R B, Li J, Zhuge F, Zhu L Q, Liang L Y, Zhang H L, Gao J H, Cao H T, Fu B, Li K 2016 Appl. Phys. Lett. 108 013504

Google Scholar

Google Scholar

[18] Hu L X, Fu S, Chen Y H, Cao H T, Liang L Y, Zhang H L, Gao J H, Wang J R, Zhuge F 2017 Adv. Mater. 29 1606927

Google Scholar

Google Scholar

[19] Menzel S, Bottger U, Waser R 2012 J. Appl. Phys. 111 014501

Google Scholar

Google Scholar

[20] Fujii T, Kawasaki M, Sawa A, Akoh H, Kawazoe Y, Tokura Y 2005 Appl. Phys. Lett. 86 012107

Google Scholar

Google Scholar

[21] Ko Y, Kim Y, Baek H, Cho J 2011 ACS Nano 5 9918

Google Scholar

Google Scholar

[22] Sun Y, Ai C, Lu J, Li L, Wen D, Bai X 2016 Thin Solid Films 598 293

Google Scholar

Google Scholar

[23] Wang H, Meng F B, Cai Y R, Zheng L Y, Li Y G , Liu Y J , Jiang Y Y, Wang X T, Chen X D 2013 Adv. Mater. 25 5498

Google Scholar

Google Scholar

[24] Mohanta K, Majee S K, Batabyal S K, Pal A J 2006 J. Phys. Chem. B 110 18231

Google Scholar

Google Scholar

[25] Zhang Y, Kong L, Ju X, Zhao J 2017 Polymers 10 23

Google Scholar

Google Scholar

[26] Irgashev R A, Teslenko A Y, Zhilina E F, Schepochkin A V, El'Tsov O S, Rusinov G L, Charushin V N 2014 Tetrahedron 70 4685

Google Scholar

Google Scholar

计量

- 文章访问数: 10496

- PDF下载量: 157

- 被引次数: 0

下载:

下载: