-

Magnetic semiconductors (MSs) that can manipulate both spin degree of freedom and charge degree of freedom have become an important research field in semiconductor spintronics. In recent years, a new series of bulk form MSs, which are iso-structure to the iron-based superconductors were reported. In these new materials, spins and carriers are separately introduced, and can be precisely manipulated. Li(Zn, Mn)As with TC ~50 K is the first bulk MS with spins and charges separated. The Li(Zn, Mn)As has p-type carriers, which is in contradiction with the theoretical calculation results by Mašek et al., who claimed that doping extra Li will induce n-type carriers. So, it is necessary to study the formation reason of hole carriers in Li(Zn, Mn)As and their effect on ferromagnetic ordering. In this work, a series of Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1) new materials are successfully synthesized by introducing n-type carriers into the p-type bulk MS Li1.05(Zn0.925, Mn0.075)As through (Zn2+, In3+) substitution. Magnetization measurements reveal that all the samples still maintain a ferromagnetic transition signal similar to MS Li1.05(Zn0.925, Mn0.075)As, and the Curie temperature TC is obviously suppressed with the increase of In-doping concentration. Clear hysteresis loops demonstrate the ferromagnetic ordering state. The resistivity increases gradually with the increase of In-doping concentration. Our results show that the (Zn2+, In3+) substitution successfully introduces n-type carriers into Li1.05(Zn0.925, Mn0.075)As, and the original p-type carriers in Li1.05(Zn0.925, Mn0.075)As, which are partial neutralized, resulting in the decrease of p-type carrier concentrations, which obviously suppresses the ferromagnetic ordering of Li(Zn, Mn)As. It reflects the important roles played by carriers in forming ferromagnetic ordering in MS materials. The fabrication of Li1.05(Zn0.925–y, Mn0.075, Iny)As material gives us a better understanding of the mechanism of ferromagnetic ordering in Li(Zn, Mn)As, and these results will be helpful in searching for more novel magnetic semiconductor materials.

-

Keywords:

- magnetic semiconductor /

- Curie temperature /

- ferromagnetic ordering

[1] Žutić I, Fabian J, Sarma S D 2004 Rev. Mod. Phys. 76 323

Google Scholar

Google Scholar

[2] Dietl T, Ohno H 2014 Rev. Mod. Phys. 86 187

Google Scholar

Google Scholar

[3] Ohno H, Shen N A, Matsukura F, Oiwa A, Endo A, Katsumoto S, Iye Y 1996 Appl. Phys. Lett. 69 363

Google Scholar

Google Scholar

[4] Dietl T 2010 Nat. Mater. 9 965

Google Scholar

Google Scholar

[5] Chen L, Yang X, Yang F, Zhao J, Misuraca J, Xiong P, von Molnár S 2011 Nano Lett. 11 2584

Google Scholar

Google Scholar

[6] Ding C, Qin C, Man H, Imai T, Ning F 2013 Phys. Rev. B 88 041108

Google Scholar

Google Scholar

[7] Gu Y, Guo S L, Ning F L 2019 J. Semicond. 40 081506

Google Scholar

Google Scholar

[8] Guo S L, Ning F L 2018 Chin. Phys. B 27 097502

Google Scholar

Google Scholar

[9] Dietl T, Bonanni A, Ohno H 2019 J. Semicond. 40 080301

Google Scholar

Google Scholar

[10] 邓正, 赵国强, 靳常青 2019 68 167502

Google Scholar

Google Scholar

Deng Z, Zhao G Q, Jin C Q 2019 Acta Phys. Sin. 68 167502

Google Scholar

Google Scholar

[11] Zhao G Q, Deng Z, Jin C Q 2019 J. Semicond. 40 081505

Google Scholar

Google Scholar

[12] Deng Z, Jin C Q, Liu Q, Wang X, Zhu J, Feng S, Chen L, Yu R, Arguello C, Goko T, Ning F, Zhang J, Wang Y, Aczel A, Munsie T, Williams T, Luke G, Kakeshita T, Uchida S, Higemoto W, Ito T, Gu Bo, Maekawa S, Morris G, Uemura Y 2011 Nat. Commun. 2 422

Google Scholar

Google Scholar

[13] Ding C, Man H, Qin C, Lu J, Sun Y, Wang Q, Yu B, Feng C, Goko T, Arguello C, Ning F 2013 Phys. Rev. B 88 041102

Google Scholar

Google Scholar

[14] Zhao K, Deng Z, Wang X, et al. 2013 Nat. Commun. 4 1442

Google Scholar

Google Scholar

[15] Zhao K, Chen B, Zhao G Q, Yuan Z, Liu Q, Deng Z, Zhu J, Jin C Q 2014 Chin. Sci. Bull. 59 2524

Google Scholar

Google Scholar

[16] Wang X, Liu Q, Lv Y, Gao W, Yang L, Yu R, Li F, Jin C Q 2008 Solid State Commun. 148 538

Google Scholar

Google Scholar

[17] Kamihara Y, Watanabe T, Hirano M, Hosono H 2008 J. Am. Chem. Soc. 130 3296

Google Scholar

Google Scholar

[18] Rotter M, Tegel M, Johrendt D 2008 Phys. Rev. Lett. 101 107006

Google Scholar

Google Scholar

[19] Zhao X, Dong J, Fu L, Gu Y, Zhang R, Yang Q, Xie L, Tang Y, Ning F 2022 J. Semicond. 43 112501

Google Scholar

Google Scholar

[20] Dong J, Zhao X, Fu L, Gu Y, Zhang R, Yang Q, Xie L, Ning F 2022 J. Semicond. 43 072501

Google Scholar

Google Scholar

[21] Yu S, Peng Y, Zhao G Q, Zhao J F, Wang X C, Zhang J, Deng Z, Jin C Q 2023 J. Semicond. 44 032501

Google Scholar

Google Scholar

[22] Kuriyama K, Nakamura F 1987 Phys. Rev. B 36 4439

Google Scholar

Google Scholar

[23] Kuriyama K, Kato T, Kawada K 1994 Phys. Rev. B 49 11452

Google Scholar

Google Scholar

[24] Wei S, Zunger A 1986 Phys. Rev. Lett. 56 528

Google Scholar

Google Scholar

[25] Mašek J, Kudrnovský J, Máca F, et al. 2007 Phys. Rev. Lett. 98 067202

Google Scholar

Google Scholar

[26] Toby B H, Von Dreele R B 2013 J. Appl. Crystallogr. 46 544

Google Scholar

Google Scholar

[27] Ding C, Gong X, Man H, Zhi G, Guo S, Zhao Y, Wang H, Chen B, Ning F 2014 Europhys. Lett. 107 17004

Google Scholar

Google Scholar

-

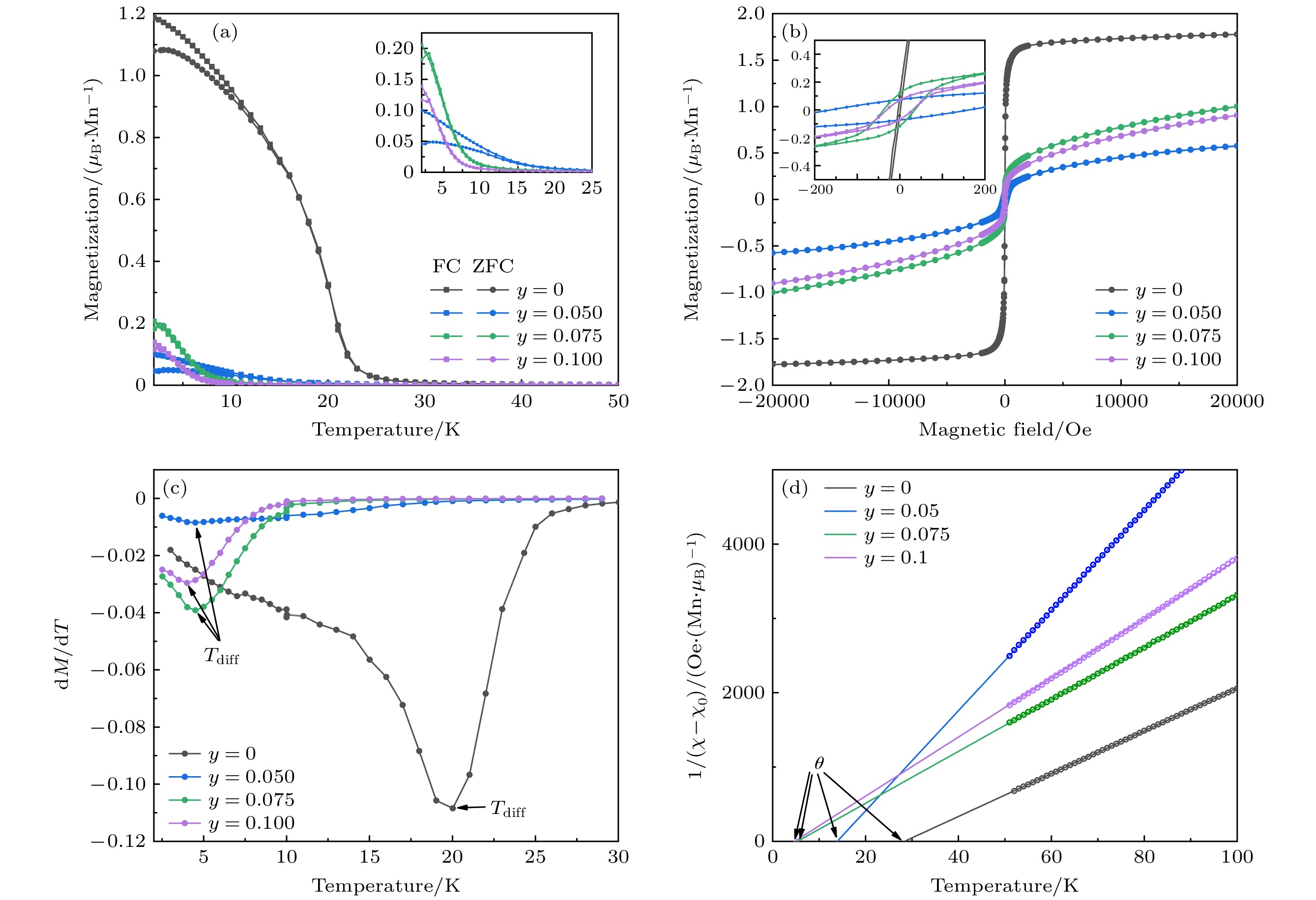

图 1 (a) Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)的X射线衍射图; (b) Li1.05(Zn0.875, Mn0.075, In0.05)As的Rietveld 精修结果; (c) Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)的晶格常数a

Figure 1. (a) The X-ray diffraction patterns for Li1.05(Zn0.925, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1); (b) the Rietveld refinement of Li1.05(Zn0.87, Mn0.075, In0.05)As; (c) the lattice parameter of Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1).

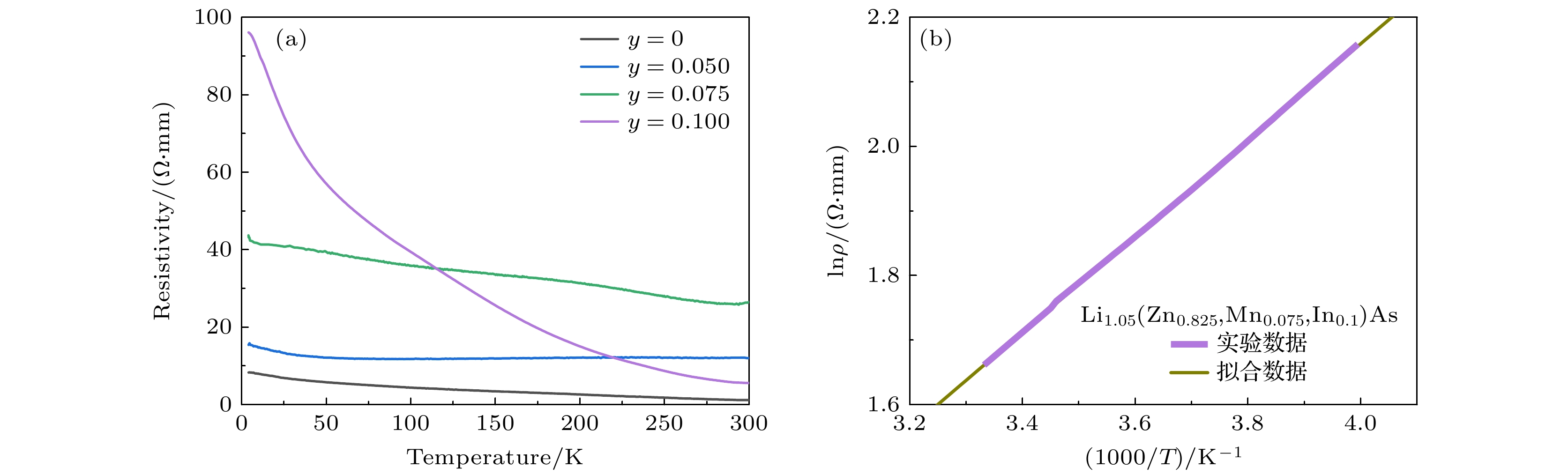

图 2 (a) Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)在100 Oe外场下的场冷及零场冷磁化强度曲线, 插图为y = 0.05, 0.075, 0.1的样品在2—25 K的磁化强度曲线; (b) Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)在温度为2 K下的等温磁化强度曲线, 插图为–200—200 Oe的局部放大图; (c) Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)的磁化强度对温度的一阶导数与温度的关系 (dM/dT-T), 箭头标注为 Tdiff; (d) Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)的1/(χ–χ0)线性拟合结果, 箭头标注为外斯温度θ

Figure 2. (a) The temperature dependence magnetization for Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1) in zero-field cooling (ZFC) and field cooling (FC) conditions with an applied external field of 100 Oe, inset shows the temperature dependence magnetization for y = 0.05, 0.075, 0.1 samples from 2 K to 25 K; (b) the iso-thermal magnetization for Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1) at 2 K, inset shows the partial enlarged curves with temperature from –200 Oe to 200 Oe; (c) the dM/dT versus T curves for Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1), the arrow marked Tdiff; (d) the linear fitting results of 1/(χ–χ0) versus T for Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1), the arrow marked the weiss temperature θ.

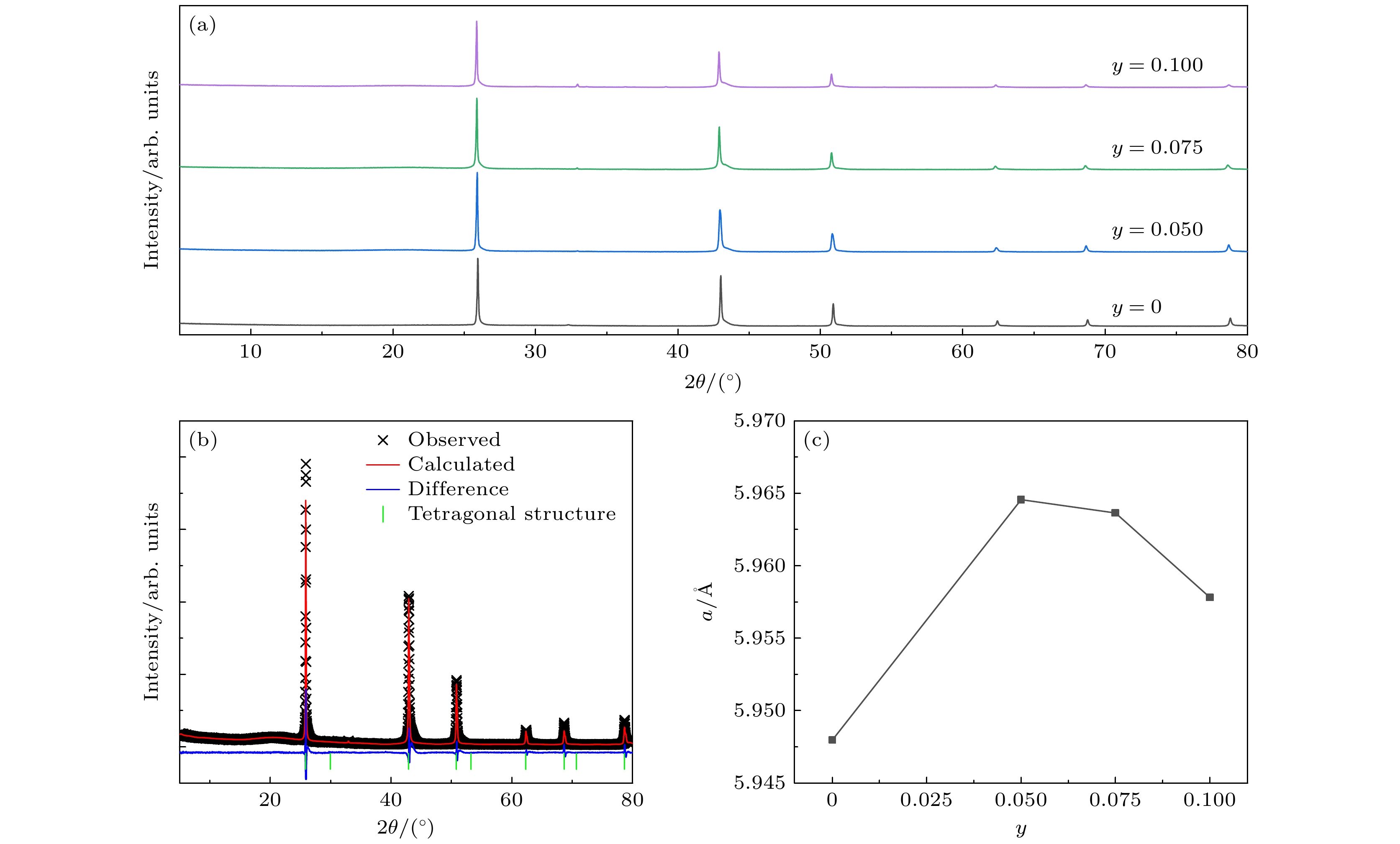

图 3 (a) Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)电阻率随温度变化的关系; (b) Li1.05(Zn0.825, Mn0.075, In0.1)As在室温附近的lnρ - 1000/T的实验数据和激发能拟合曲线

Figure 3. (a) Temperature dependence of Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1) resistance; (b) experimental data and activation energy fitting curves of lnρ - 1000/T for Li1.05(Zn0.925–y, Mn0.075, Iny)As near room temperature.

表 1 Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1)的外斯温度θ、Tdiff、有效磁矩µeff、矫顽力HC

Table 1. The Weiss temperature θ, Tdiff, the effective moment µeff and the coercive field HC of Li1.05(Zn0.925–y, Mn0.075, Iny)As (y = 0, 0.05, 0.075, 0.1).

y θ/K Tdiff/K µeff /(μB/Mn) HC/Oe 0 28.4 20 3.9 5 0.05 13.9 4.5 2.6 150 0.075 5.3 4.5 3.6 35 0.1 4.9 4 3.4 30 -

[1] Žutić I, Fabian J, Sarma S D 2004 Rev. Mod. Phys. 76 323

Google Scholar

Google Scholar

[2] Dietl T, Ohno H 2014 Rev. Mod. Phys. 86 187

Google Scholar

Google Scholar

[3] Ohno H, Shen N A, Matsukura F, Oiwa A, Endo A, Katsumoto S, Iye Y 1996 Appl. Phys. Lett. 69 363

Google Scholar

Google Scholar

[4] Dietl T 2010 Nat. Mater. 9 965

Google Scholar

Google Scholar

[5] Chen L, Yang X, Yang F, Zhao J, Misuraca J, Xiong P, von Molnár S 2011 Nano Lett. 11 2584

Google Scholar

Google Scholar

[6] Ding C, Qin C, Man H, Imai T, Ning F 2013 Phys. Rev. B 88 041108

Google Scholar

Google Scholar

[7] Gu Y, Guo S L, Ning F L 2019 J. Semicond. 40 081506

Google Scholar

Google Scholar

[8] Guo S L, Ning F L 2018 Chin. Phys. B 27 097502

Google Scholar

Google Scholar

[9] Dietl T, Bonanni A, Ohno H 2019 J. Semicond. 40 080301

Google Scholar

Google Scholar

[10] 邓正, 赵国强, 靳常青 2019 68 167502

Google Scholar

Google Scholar

Deng Z, Zhao G Q, Jin C Q 2019 Acta Phys. Sin. 68 167502

Google Scholar

Google Scholar

[11] Zhao G Q, Deng Z, Jin C Q 2019 J. Semicond. 40 081505

Google Scholar

Google Scholar

[12] Deng Z, Jin C Q, Liu Q, Wang X, Zhu J, Feng S, Chen L, Yu R, Arguello C, Goko T, Ning F, Zhang J, Wang Y, Aczel A, Munsie T, Williams T, Luke G, Kakeshita T, Uchida S, Higemoto W, Ito T, Gu Bo, Maekawa S, Morris G, Uemura Y 2011 Nat. Commun. 2 422

Google Scholar

Google Scholar

[13] Ding C, Man H, Qin C, Lu J, Sun Y, Wang Q, Yu B, Feng C, Goko T, Arguello C, Ning F 2013 Phys. Rev. B 88 041102

Google Scholar

Google Scholar

[14] Zhao K, Deng Z, Wang X, et al. 2013 Nat. Commun. 4 1442

Google Scholar

Google Scholar

[15] Zhao K, Chen B, Zhao G Q, Yuan Z, Liu Q, Deng Z, Zhu J, Jin C Q 2014 Chin. Sci. Bull. 59 2524

Google Scholar

Google Scholar

[16] Wang X, Liu Q, Lv Y, Gao W, Yang L, Yu R, Li F, Jin C Q 2008 Solid State Commun. 148 538

Google Scholar

Google Scholar

[17] Kamihara Y, Watanabe T, Hirano M, Hosono H 2008 J. Am. Chem. Soc. 130 3296

Google Scholar

Google Scholar

[18] Rotter M, Tegel M, Johrendt D 2008 Phys. Rev. Lett. 101 107006

Google Scholar

Google Scholar

[19] Zhao X, Dong J, Fu L, Gu Y, Zhang R, Yang Q, Xie L, Tang Y, Ning F 2022 J. Semicond. 43 112501

Google Scholar

Google Scholar

[20] Dong J, Zhao X, Fu L, Gu Y, Zhang R, Yang Q, Xie L, Ning F 2022 J. Semicond. 43 072501

Google Scholar

Google Scholar

[21] Yu S, Peng Y, Zhao G Q, Zhao J F, Wang X C, Zhang J, Deng Z, Jin C Q 2023 J. Semicond. 44 032501

Google Scholar

Google Scholar

[22] Kuriyama K, Nakamura F 1987 Phys. Rev. B 36 4439

Google Scholar

Google Scholar

[23] Kuriyama K, Kato T, Kawada K 1994 Phys. Rev. B 49 11452

Google Scholar

Google Scholar

[24] Wei S, Zunger A 1986 Phys. Rev. Lett. 56 528

Google Scholar

Google Scholar

[25] Mašek J, Kudrnovský J, Máca F, et al. 2007 Phys. Rev. Lett. 98 067202

Google Scholar

Google Scholar

[26] Toby B H, Von Dreele R B 2013 J. Appl. Crystallogr. 46 544

Google Scholar

Google Scholar

[27] Ding C, Gong X, Man H, Zhi G, Guo S, Zhao Y, Wang H, Chen B, Ning F 2014 Europhys. Lett. 107 17004

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 3848

- PDF Downloads: 57

- Cited By: 0

DownLoad:

DownLoad: