-

当前, 尽管集成电路制造工艺水平不断提高, 但受到量子效应的限制, 器件尺寸的缩小使业界遇到了可靠性低、功耗大等瓶颈, 微电子行业延续了近50年的“摩尔定律”将难以持续. 2004年二维材料—石墨烯的问世, 为突破集成电路的功耗瓶颈带来了新的机遇. 由于低维特性, 二维材料在一层或者几层原子厚度中表现出丰富多样的电学、磁学、力学和光学等物理特性. 其中, 铁磁性在信息处理、存储等技术上有着广泛的应用价值. 然而, 目前在实验上合成的具有铁磁性的二维材料屈指可数. 同时, 在二维系统中长程有序磁态会因为热涨落的因素在有限温度内受到强烈的抑制, 无法在室温下保持铁磁性, 这为后续工作带来了不可忽视的限制与挑战. 因此实现二维磁性材料室温下的铁磁有序及其调控是现阶段需要解决的重大问题. 本综述详细地介绍了二维磁性材料的发展过程、制备方法及其优越性能, 并着重阐述了调控二维磁性材料居里温度的方法. 最后, 扼要地分析并展望了二维磁性材料在未来的应用前景.

-

关键词:

- 二维磁性材料 /

- 居里温度 /

- 新型二维自旋电子器件

To date, despite the continuous improvement of integrated circuit manufacturing technology, it has been limited by quantum effects and the shrinking of device size has caused the industry to encounter bottlenecks such as low reliability and high power consumption. The “Moore’s Law” that has lasted for nearly 50 years in the microelectronics industry will not be sustainable. In 2004, the advent of graphene, a two-dimensional (2D) material, brought new opportunities to break through the power consumption bottleneck of integrated circuits. Due to the low dimensionality, 2D materials exhibit a variety of fasinatingly electrical, ferromagnetic, mechanical, and optical properties at an atomic level. Among them, ferromagnetism has a wide range of applications in information processing, magnetic memory and other technologies. However, only a few 2D ferromagnetic materials are successfully synthesized. Meanwhile, the magnetic long-range order will be strongly suppressed within a limited temperature range due to thermal fluctuations, and thus bringing non-ignorable limitations and challenges to subsequent work. Therefore, the realization and control of room-temperature ferromagnetism in 2D magnetic materials is the major concern at this stage. In light of the above, this review first introduces the development process, preparation methods and superior properties of 2D magnetic materials in detail, and then focuses on the methods of manipulating the Curie temperature of 2D magnetic material. Finally, we briefly give an outlook of the application prospects in the future.-

Keywords:

- two-dimensional magnetic materials /

- Curie temperature /

- new two-dimensional spintronic devices

[1] Sato N, Xue F, White R M, Bi C, Wang S X 2018 Nat. Electron. 1 508

Google Scholar

Google Scholar

[2] Chappert C, Fert A, Van Dau F N 2007 Nat. Mater. 6 813

Google Scholar

Google Scholar

[3] Zhang D, Hou Y, Zeng L, Zhao W S 2019 IEEE Trans. Nanotechnol. 18 518

Google Scholar

Google Scholar

[4] Mennel L, Symonowicz J, Wachter S, Polyushkin D K, Molina-Mendoza A J, Mueller T 2020 Nature 579 62

Google Scholar

Google Scholar

[5] Zhu J 2008 Proc. IEEE 96 1786

Google Scholar

Google Scholar

[6] Liu L, Moriyama T, Ralph D C, Buhrman R A 2011 Phys. Rev. Lett. 106 036601

[7] Sun J Z, Brown S L, Chen W, Delenia E A, Gaidis M C, Harms J, Hu G, Jiang X, Kilaru R, Kula W, Lauer G, Liu L Q, Murthy S, Nowak J, O’Sullivan E J, Parkin S S P, Robertazzi R P, Rice P M, Sandhu G, Topuria T, Worledge D C 2013 Phys. Rev. B 88 104426

Google Scholar

Google Scholar

[8] Parkin S S P, Kaiser C, Panchula A, Rice P M, Hughes B, Samant M, Yang S H 2004 Nat. Mater. 3 862

Google Scholar

Google Scholar

[9] Wolf S A, Lu J, Stan M R, Chen E, Treger D M 2010 Proc. IEEE 98 2155

Google Scholar

Google Scholar

[10] Van Den Brink A, Vermijs G, Solignac A, Koo J, Kohlhepp J T, Swagten H J M, Koopmans B 2016 Nat. Commun. 7 1

[11] Novoselov K S, Geim A K, Morozov S V, Jiang D, Katsnelson M I, Grigorieva I V, Dubonos S V, Firsov A A 2005 Nature 438 197

Google Scholar

Google Scholar

[12] Hashimoto A, Suenaga K, Gloter A, Urita K, Iijima S 2004 Nature 430 870

Google Scholar

Google Scholar

[13] Schedin F, Geim A K, Morozov S V, Hill E W, Blake P, Katsnelson M I, Novoselov K S 2007 Nat. Mater. 6 652

Google Scholar

Google Scholar

[14] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[15] Mas-Ballesté R, Gómez-Navarro C, Gómez-Herrero J, Zamora F 2011 Nanoscale 3 20

Google Scholar

Google Scholar

[16] Dirac P A M, Fowler R H 1926 Proc. R. Soc. London, Ser. A 112 661

Google Scholar

Google Scholar

[17] Gong C, Zhang X 2019 Science 363 6428

[18] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[19] Novoselov K S, Jiang D, Schedin F, Booth T J, Khotkevich V V, Morozov S V, Geim A K 2005 Proc. Natl. Acad. Sci. U.S.A. 102 10451

Google Scholar

Google Scholar

[20] Mermin N D, Wagner H 1966 Phys. Rev. Lett. 17 1133

Google Scholar

Google Scholar

[21] Mounet N, Gibertini M, Schwaller P, Campi D, Merkys A, Marrazzo A, Sohier T, Castelli I E, Cepellotti A, Pizzi G, Marzari N 2018 Nat. Nanotechnol. 13 246

Google Scholar

Google Scholar

[22] Alghamdi M, Lohmann M, Li J, Jothi P R, Shao Q, Aldosary M, Su T, Fokwa B P T, Shi J 2019 Nano Lett. 19 4400

Google Scholar

Google Scholar

[23] Wang X, Tang J, Xia X, He C, Zhang J, Liu Y, Wan C, Fang C, Guo C, Yang W, Guang Y, Zhang X, Xu H, Wei J, Liao M, Lu X, Feng J, Li X, Peng Y, Wei H, Yang R, Shi D, Zhang X, Han Z, Zhang Z, Zhang G, Yu G, Han X 2019 Sci. Adv. 5 eaaw8904

Google Scholar

Google Scholar

[24] Novoselov K S, Mishchenko A, Carvalho A, Castro Neto A H 2016 Science 353 6298

[25] Gong C, Li L, Li Z, Ji H, Stern A, Xia Y, Cao T, Bao W, Wang C, Wang Y, Qiu Z Q, Cava R J, Louie S G, Xia J, Zhang X 2017 Nature 546 265

Google Scholar

Google Scholar

[26] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X D 2017 Nature 546 270

Google Scholar

Google Scholar

[27] Si C, Zhou J, Sun Z 2015 ACS Appl. Mater. Interfaces 7 17510

Google Scholar

Google Scholar

[28] Zhu Y, Kong X, Rhone T D, Guo H 2018 Phys. Rev. Mater. 2 81001

Google Scholar

Google Scholar

[29] Du J, Xia C, Xiong W, Wang T, Jia Y, Li J 2017 Nanoscale 9 17585

Google Scholar

Google Scholar

[30] He J, Li X, Lyu P, Nachtigall P 2017 Nanoscale 9 2246

Google Scholar

Google Scholar

[31] Wang H, Liu Y, Wu P, Hou W, Jiang Y, Li X, Pandey C, Chen D, Yang Q, Wang H, Wei D, Lei N, Kang W, Wen L, Nie T X, Zhao W S, Wang K L 2020 ACS Nano 14 10045

Google Scholar

Google Scholar

[32] Dong X J, You J Y, Gu B, Su G 2019 Phys. Rev. Appl. 12 14020

Google Scholar

Google Scholar

[33] Deng Y, Yu Y, Song Y, Zhang J, Wang N Z, Sun Z, Yi Y, Wu Y Z, Wu S, Zhu J, Wang J, Chen X H, Zhang Y B 2018 Nature 563 94

Google Scholar

Google Scholar

[34] Wen Y, Liu Z, Zhang Y, Xia C, Zhai B, Zhang X, Zhai G, Shen C, He P, Cheng R, Yin L, Yao Y, Getaye Sendeku M, Wang Z, Ye X, Liu C, Jiang C, Shan C, Long Y, He J 2020 Nano Lett. 20 3130

Google Scholar

Google Scholar

[35] Cai X, Luo Y, Liu B, Cheng H M 2018 Chem. Soc. Rev. 47 6224

Google Scholar

Google Scholar

[36] Yi M, Shen Z 2015 J. Mater. Chem. A 3 11700

Google Scholar

Google Scholar

[37] Zhang Y, Zhang L, Zhou C 2013 Acc. Chem. Res. 46 2329

Google Scholar

Google Scholar

[38] Ji Q, Zhang Y, Zhang Y, Liu Z 2015 Chem. Soc. Rev. 44 2587

Google Scholar

Google Scholar

[39] Mattevi C, Kim H, Chhowalla M 2011 J. Mater. Chem. 21 3324

Google Scholar

Google Scholar

[40] Ago H, Ito Y, Mizuta N, Yoshida K, Hu B, Orofeo C M, Tsuji M, Ikeda K, Mizuno S 2010 ACS Nano 4 7407

Google Scholar

Google Scholar

[41] Vo-Van C, Kimouche A, Reserbat-Plantey A, Fruchart O, Bayle-Guillemaud P, Bendiab N, Coraux J 2011 Appl. Phys. Lett. 98 181903

Google Scholar

Google Scholar

[42] Coleman J N 2009 Adv. Funct. Mater. 19 3680

Google Scholar

Google Scholar

[43] Coleman J N 2013 Acc. Chem. Res. 46 14

Google Scholar

Google Scholar

[44] Cui X, Zhang C, Hao R, Hou Y 2011 Nanoscale 3 2118

Google Scholar

Google Scholar

[45] Ojrzynska M, Wroblewska A, Judek J, Malolepszy A, Duzynska A, Zdrojek M 2020 Opt. Express 28 7274

Google Scholar

Google Scholar

[46] Ciesielski A, Samorì P 2014 Chem. Soc. Rev. 43 381

Google Scholar

Google Scholar

[47] Neave J H, Dobson P J, Joyce B A, Zhang J 1985 Appl. Phys. Lett. 47 100

Google Scholar

Google Scholar

[48] May A F, Ovchinnikov D, Zheng Q, Hermann R, Calder S, Huang B, Fei Z, Liu Y, Xu X, McGuire M A 2019 ACS Nano 13 4436

Google Scholar

Google Scholar

[49] Dalitz R H, Peierls R E 1997 Selected Scientific Papers of Sir Rudolf Peierls (Vol. 1) (Singapore: World Scientific Publishing Co. Pte. Ltd) pp 9–225

[50] Joyce G S 1969 J. Phys. C: Solid State Phys. 2 1531

Google Scholar

Google Scholar

[51] Hohenberg P C 1967 Phys. Rev. 158 383

Google Scholar

Google Scholar

[52] Ising E 1925 Z. Phys. 31 253

Google Scholar

Google Scholar

[53] Kosterlitz J M, Thouless D J 1973 J. Phys. C: Solid State Phys. 6 1181

Google Scholar

Google Scholar

[54] Berezinsky V L 1971 Sov. Phys. JETP 32 493

[55] Liu S, Yuan X, Zou Y, Sheng Y, Huang C, Zhang E, Ling J, Liu Y, Wang W, Zhang C, Zou J, Wang K, Xiu F X 2017 npj 2D Mater. Appl. 1 30

Google Scholar

Google Scholar

[56] Tan C, Lee J, Jung S G, Park T, Albarakati S, Partridge J, Field M R, McCulloch D G, Wang L, Lee C 2018 Nat. Commun. 9 1554

[57] Fei Z, Huang B, Malinowski P, Wang W, Song T, Sanchez J, Yao W, Xiao D, Zhu X, May A F, Wu W, Cobden D H, Chu J H, Xu X D 2018 Nat. Mater. 17 778

Google Scholar

Google Scholar

[58] Kim D, Park S, Lee J, Yoon J, Joo S, Kim T, Min K, Park S Y, Kim C, Moon K W, Lee C, Hong J, Hwang C 2019 Nanotechnology 30 245701

Google Scholar

Google Scholar

[59] Xu J, Phelan W A, Chien C L 2019 Nano Lett. 19 8250

Google Scholar

Google Scholar

[60] Park S Y, Kim D S, Liu Y, Hwang J, Kim Y, Kim W, Kim J Y, Petrovic C, Hwang C, Mo S K, Kim H, Min B C, Koo H C, Chang J, Jang C, Choi J W, Ryu H 2020 Nano Lett. 20 95

Google Scholar

Google Scholar

[61] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[62] Gibertini M, Koperski M, Morpurgo A F, Novoselov K S 2019 Nat. Nanotechnol. 14 408

Google Scholar

Google Scholar

[63] Huang B, Clark G, Klein D R, MacNeill D, Navarro-Moratalla E, Seyler K L, Wilson N, McGuire M A, Cobden D H, Xiao D, Yao W, Jarillo-Herrero P, Xu X D 2018 Nat. Nanotechnol. 13 544

Google Scholar

Google Scholar

[64] Jiang S, Li L, Wang Z, Mak K F, Shan J 2018 Nat. Nanotechnol. 13 549

Google Scholar

Google Scholar

[65] Lin X, Yang W, Wang K L, Zhao W 2019 Nat. Electron. 2 274

Google Scholar

Google Scholar

[66] Bonilla M, Kolekar S, Ma Y, Diaz H C, Kalappattil V, Das R, Eggers T, Gutierrez H R, Phan M H, Batzill M 2018 Nat. Nanotechnol. 13 289

Google Scholar

Google Scholar

[67] O’Hara D J, Zhu T, Trout A H, Ahmed A S, Luo Y K, Lee C H, Brenner M R, Rajan S, Gupta J A, McComb D W, Kawakami R K 2018 Nano Lett. 18 3125

Google Scholar

Google Scholar

[68] Wang Z, Zhang T, Ding M, Dong B, Li Y, Chen M, Li X, Huang J, Wang H, Zhao X, Li Y, Li D, Jia C, Sun L, Guo H, Ye Y, Sun D, Chen Y, Yang T, Zhang J, Ono S, Han Z, Zhang Z D 2018 Nat. Nanotechnol. 13 554

Google Scholar

Google Scholar

[69] Verzhbitskiy I A, Kurebayashi H, Cheng H, Zhou J, Khan S, Feng Y P, Eda G 2020 Nat. Electron. 3 460

Google Scholar

Google Scholar

[70] Seo J, Kim D Y, An E S, Kim K, Kim G Y, Hwang S Y, Kim D W, Jang B G, Kim H, Eom G, Seo S Y, Stania R, Muntwiler M, Lee J, Watanabe K, Taniguchi T, Jo Y J, Lee J, Min B Il, Jo M H, Yeom H W, Choi S Y, Shim J H, Kim J S 2020 Sci. Adv. 6 eaay8912

Google Scholar

Google Scholar

[71] Yang M, Li Q, Chopdekar R V, Stan C, Cabrini S, Choi J W, Wang S, Wang T, Gao N, Scholl A, Tamura N, Hwang C, Wang F, Qiu Z Q 2020 Adv. Quantum Technol. 3 2000017

Google Scholar

Google Scholar

[72] Li Q, Yang M, Gong C, Chopdekar R V, N’Diaye A T, Turner J, Chen G, Scholl A, Shafer P, Arenholz E, Schmid A K, Wang S, Liu K, Gao N, Admasu A S, Cheong S W, Hwang C, Li J, Wang F, Zhang X, Qiu Z Q 2018 Nano Lett. 18 5974

Google Scholar

Google Scholar

[73] Liu S, Yang K, Liu W, Zhang E, Li Z, Zhang X, Liao Z, Zhang W, Sun J, Yang Y, Gao H, Huang C, Ai L, Wong P K J, Wee A T S, N’Diaye A T, Morton S A, Kou X, Zou J, Xu Y, Wu H, Xiu F X 2019 Natl. Sci. Rev. 7 745

[74] Dong X J, You J Y, Zhang Z, Gu B, Su G 2020 Phys. Rev. B 102 144443

Google Scholar

Google Scholar

[75] Kou X, Fan Y, Wang K L 2019 J. Phys. Chem. Solids 128 2

Google Scholar

Google Scholar

[76] Yu J, Wu W, Wang Y, Zhu K, Zeng X, Chen Y, Liu Y, Yin C, Cheng S, Lai Y, He K, Xue Q 2020 Appl. Phys. Lett. 116 141603

Google Scholar

Google Scholar

[77] Katmis F, Lauter V, Nogueira F S, Assaf B A, Jamer M E, Wei P, Satpati B, Freeland J W, Eremin I, Heiman D, Jarillo-Herrero P, Moodera J S 2016 Nature 533 513

Google Scholar

Google Scholar

[78] Wang Z, Sapkota D, Taniguchi T, Watanabe K, Mandrus D, Morpurgo A F 2018 Nano Lett. 18 4303

Google Scholar

Google Scholar

[79] Albarakati S, Tan C, Chen Z J, Partridge J G, Zheng G, Farrar L, Mayes E L H, Field M R, Lee C, Wang Y, Xiong Y, Tian M, Xiang F, Hamilton A R, Tretiakov O A, Culcer D, Zhao Y J, Wang L 2019 Sci. Adv. 5 eaaw0409

Google Scholar

Google Scholar

-

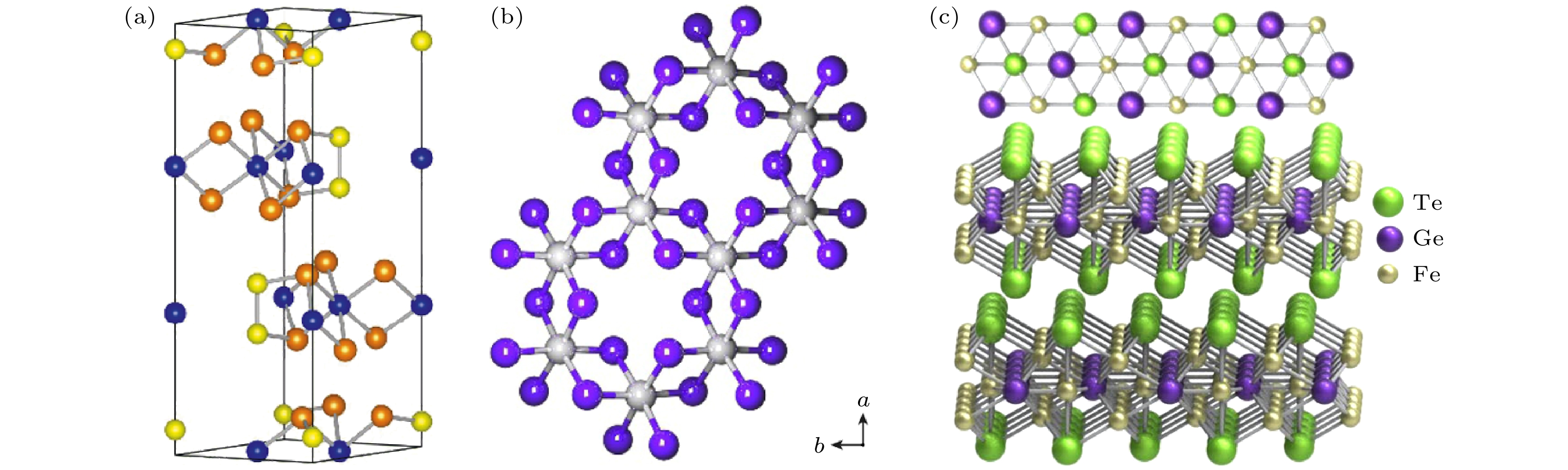

图 3 (a) Cr2Ge2Te6的原子结构视图[25], 其中蓝色、黄色和橘色的球分别代表Cr, Ge和 Te原子. (b) 单层CrI3的平面内原子结构视图, 其中灰色和紫色的球分别代表Cr和I原子[26]. (c) Fe3GeTe2的面内和面外原子结构视图, 其中黄色、紫色和绿色的球分别代表Fe, Ge和 Te原子[55]

Fig. 3. (a) Atomic structure view of Cr2Ge2Te6. The blue, yellow, and orange balls represent Cr, Ge, and Te atoms, respectively[25]. (b) In-plane atomic structure view of a single layer of CrI3. The gray and purple balls represent Cr and I atoms, respectively[26]. (c) In-plane and out-of-plane atomic structure views of Fe3GeTe2. The yellow, purple and green balls represent Fe, Ge and Te atoms, respectively[55].

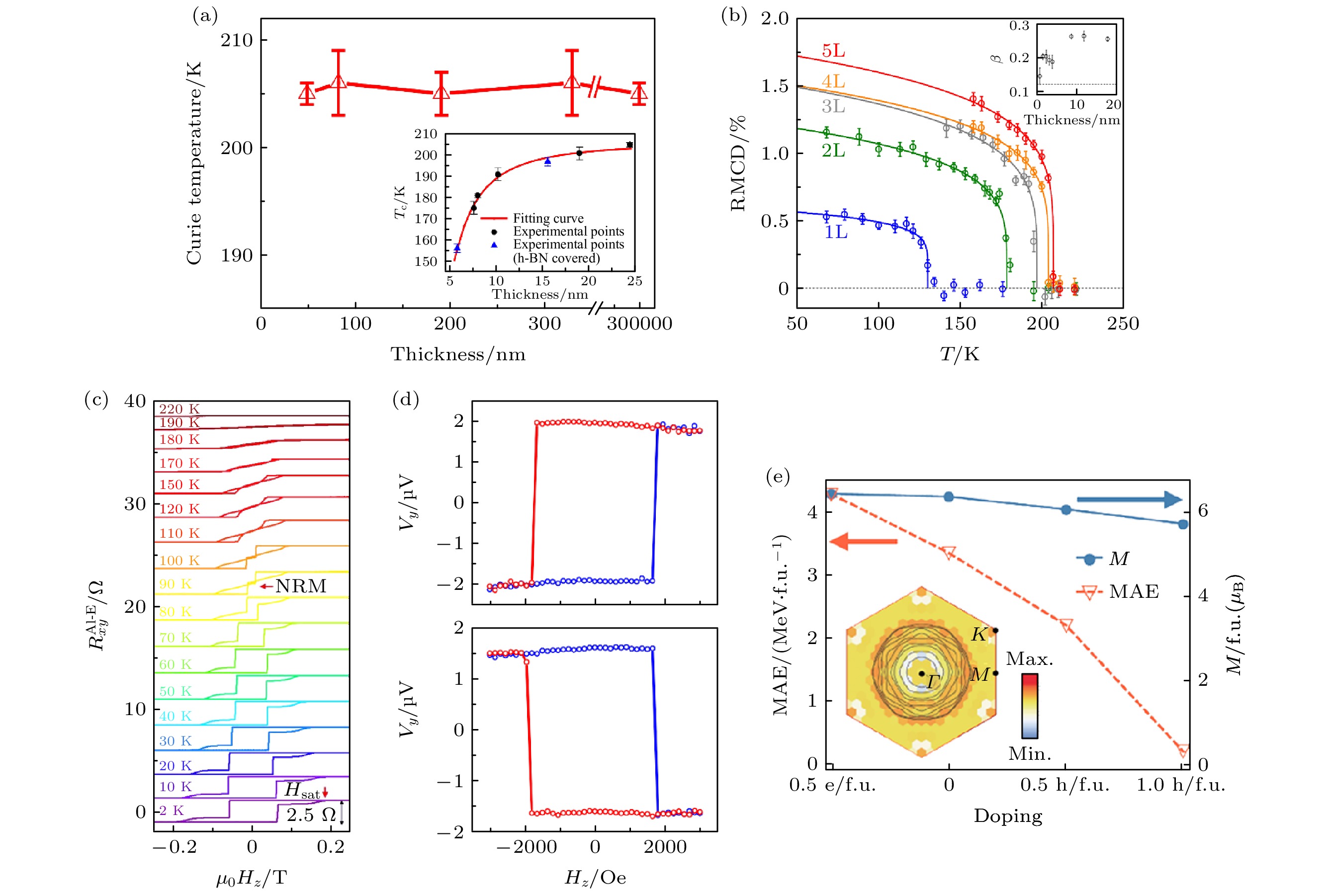

图 4 (a), (b) FGT薄膜的居里温度随厚度的依赖关系[56,57]; (c)不同温度下30 nm FGT/O-FGT薄膜器件的反常霍尔电阻与垂直磁场的关系, 其中在90 K温度下出现负的剩磁[58]; (d) FGT薄膜的能斯特信号横向电压与垂直磁场的关系, 温度梯度分别为

$\nabla {T_x} = 1.3\;{\rm{K}} \cdot {{\text{μ} }}{{\rm{m}}^{ - 1}}$ 和$\nabla {T_x} = - 1.1\;{\rm{K}} \cdot {\text{μ} }{{\rm{m}}^{ - 1}}$ [59]; (e) Fe3–xGeTe2薄膜的磁晶各向异性能与磁化强度随掺杂浓度变化的关系[60]Fig. 4. (a), (b) Thickness-dependent Curie temperature of FGT films for critical analysis[56,57]; (c) relationship between the anomalous Hall resistance of 30 nm thick FGT/O-FGT device and the perpendicular magnetic field under different temperatures, where the negative remanence magnetization appears at 90 K[58]; (d) relationship between the transverse voltage of the Nernst signal of FGT film and the perpendicular magnetic field with temperature gradient of

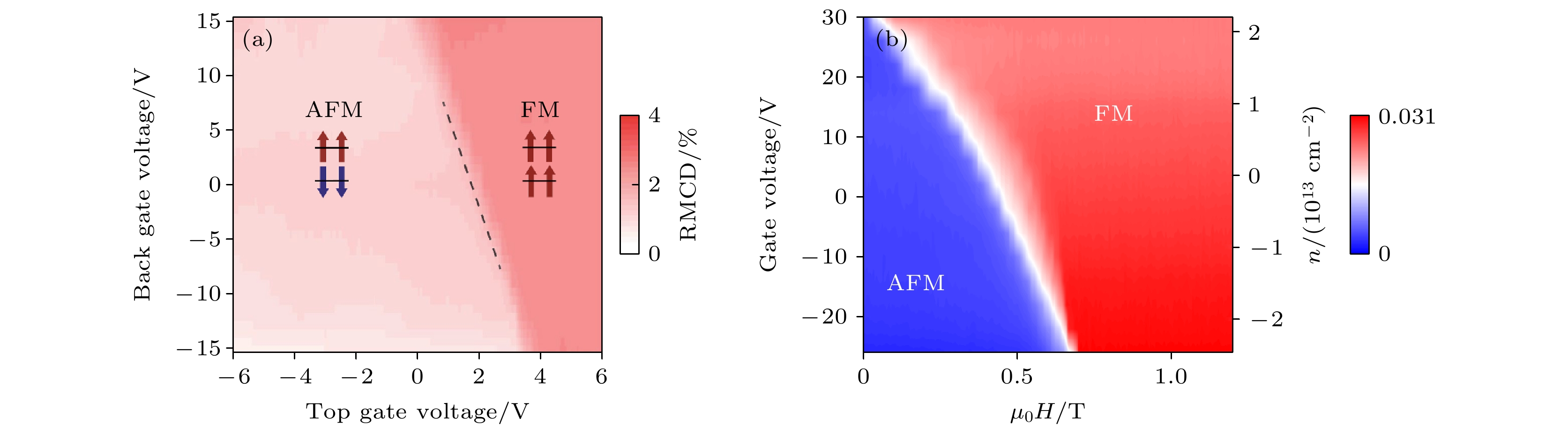

$\nabla {T_x} = 1.3\;{\rm{K}} \cdot {\text{μ} }{{\rm{m}}^{ - 1}}$ and$\nabla {T_x} = - 1.1\;{\rm{K}} \cdot {\text{μ} }{{\rm{m}}^{ - 1}}$ , respectively[59]; (e) change of the magnetocrystalline anisotropy of Fe3–xGeTe2 film and the magnetization with doping concentration[60]图 5 (a) 在μ0H = 0.78 T时, RMCD强度与顶栅电压和背栅电压的关系, 可以看出在双层CrI3中利用静电门控制的磁性转变[63]; (b) 4 K时双层CrI3中栅极电压-掺杂密度-磁场相位图, 可以看出双层CrI3中利用电子掺杂控制的磁性转变[64]

Fig. 5. (a) RMCD signals under the top gate and back gate voltage at μ0H = 0.78 T. Magnetic transition can be controlled by electrostatic gate in double-layer CrI3[63]. (b) Gate voltage-electron doping density-magnetic field phase diagram in double layer CrI3 at 4 K. Magnetic transition can be controlled by electron doping in double-layer CrI3[64].

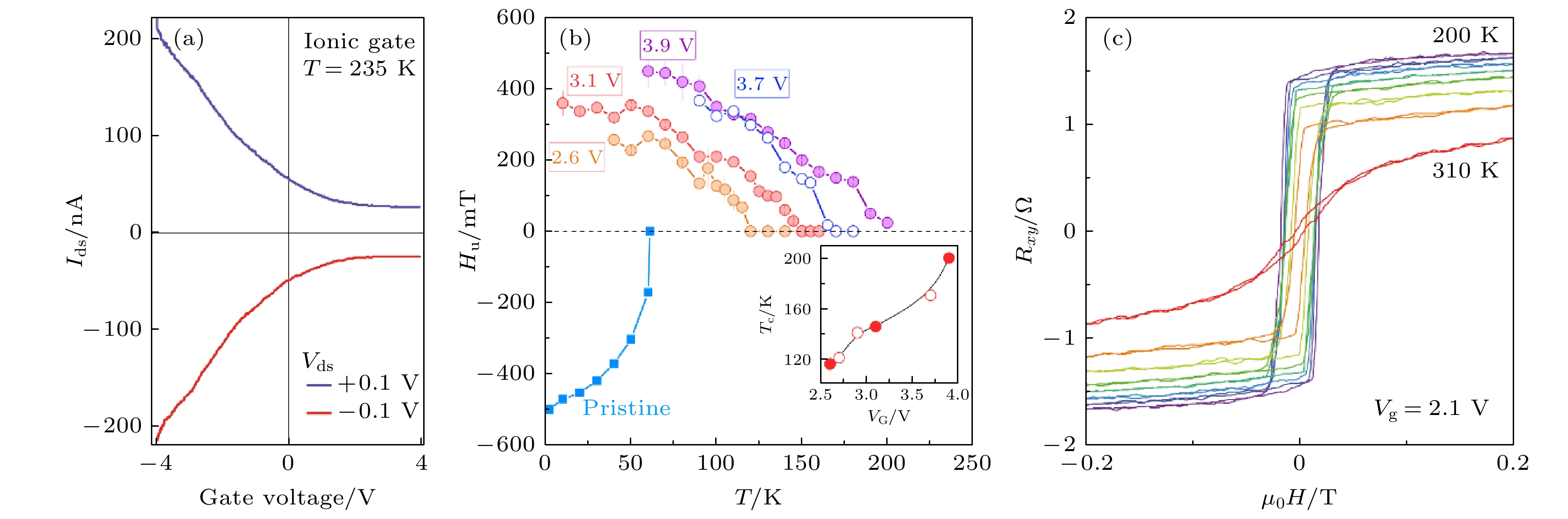

图 7 (a) CGT薄膜在不同栅电压下的场效应曲线[68]; (b)静电掺杂的CGT薄膜器件在不同栅电压下居里温度的变化[69]; (c)栅电压调控的四层FGT薄膜的霍尔曲线[33]

Fig. 7. (a) Field-effect Ids curves of CGT film[68]; (b) variation of Curie temperature of CGT device with electron doping under different voltages[69]; (c) gate-voltage controlled Hall curves of four-layer FGT flake[33].

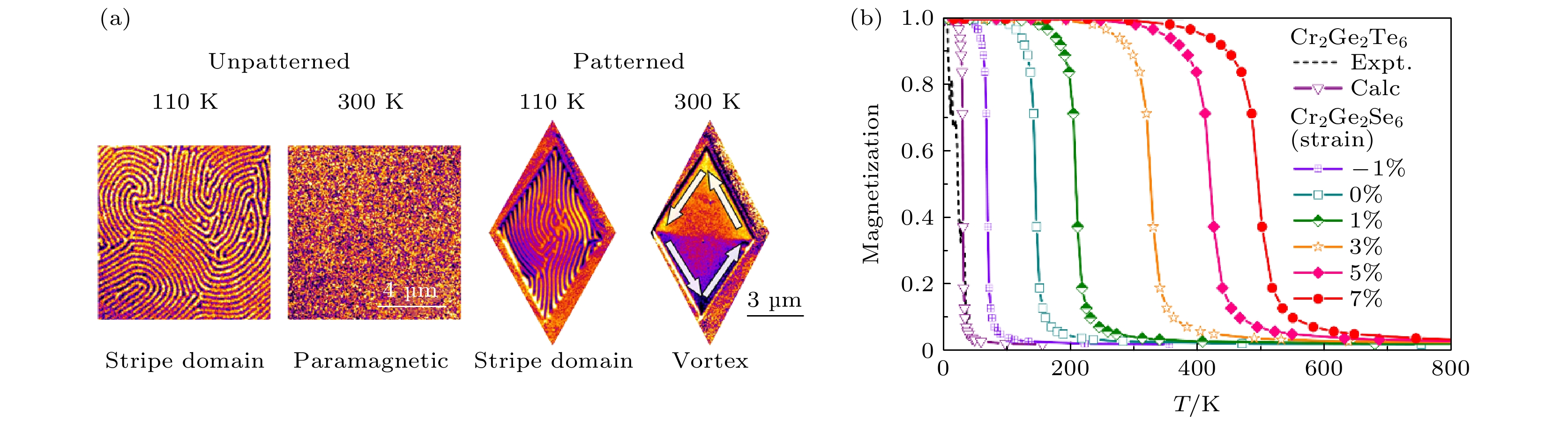

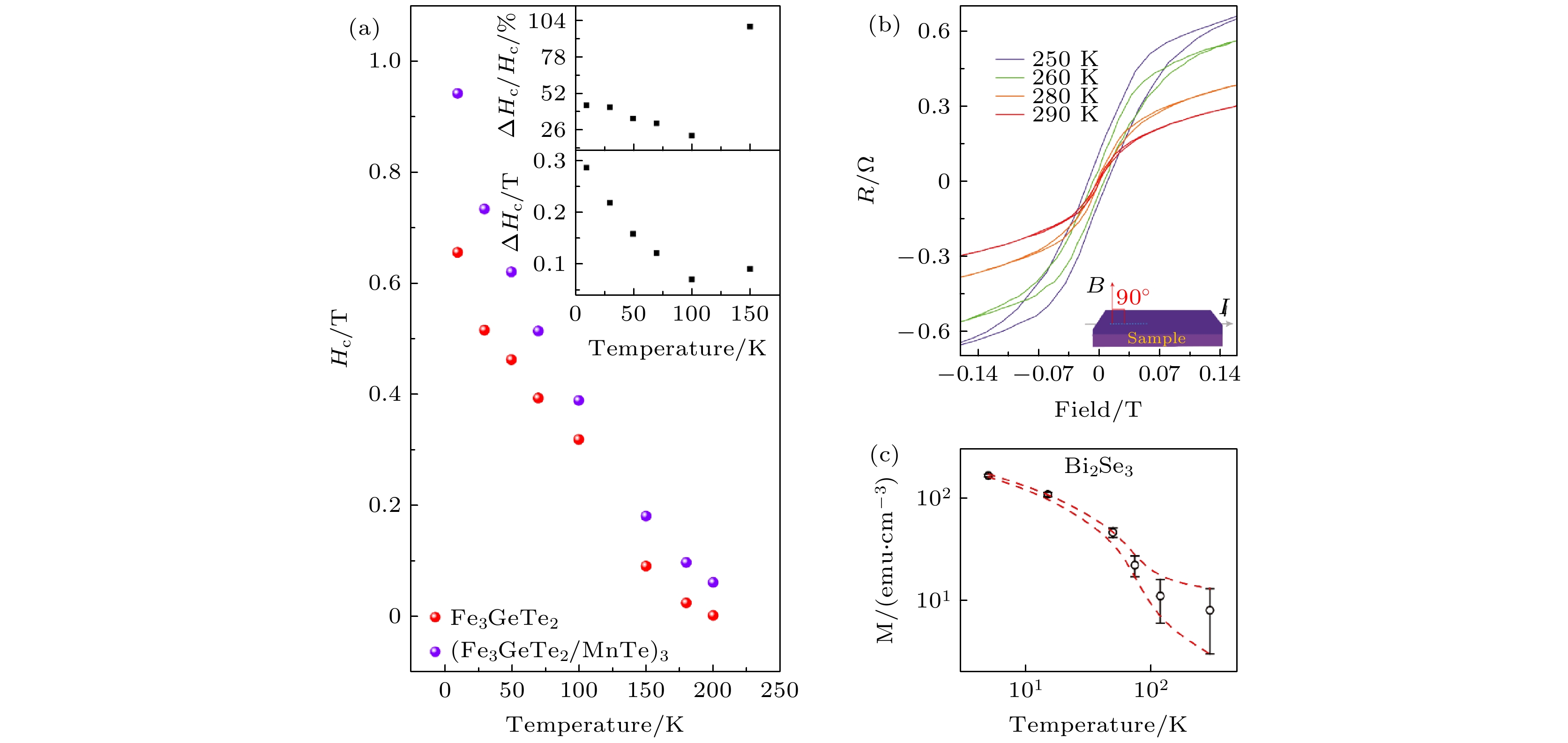

图 10 (a) 反铁磁MnTe增强Fe3GeTe2铁磁性[55]; (b) 反铁磁CrSb近邻效应诱导居里温度的变化[73]; (c) EuS/Bi2Se3界面增强居里温度[77]

Fig. 10. (a) Antiferromagnetic MnTe induced Fe3GeTe2 ferromagnetism enhancement[55]; (b) antiferromagnetic CrSb proximity-induced Curie temperature increase[73]; (c) EuS/Bi2Se3 interfacial-enhanced Curie temperature[77].

图 11 (a) Bi2Te3(8)/FGT(5)异质结构随温度变化的电阻率; (b), (c) 不同温度下的面外反常霍尔曲线; (d) 不同温度下的面内反常霍尔曲线; (e) 阿罗特图来精准表征居里温度; (f) 300 K下异质结构的磁光克尔信号; (g), (h), (i) 不同厚度下异质结构的居里温度表征[31]

Fig. 11. (a) Resistivity of Bi2Te3(8)/FGT(5) heterostructure with the variation of temperature; (b), (c) out-of-plane anomalous Hall curves under different temperatures; (d) in-plane anomalous Hall curves under different temperatures; (e) Arrott plot for characterizing the Curie temperature; (f) magneto-optical Kerr signal of the heterostructure at 300 K; (g), (h), (i) thickness-dependent Curie temperature[31].

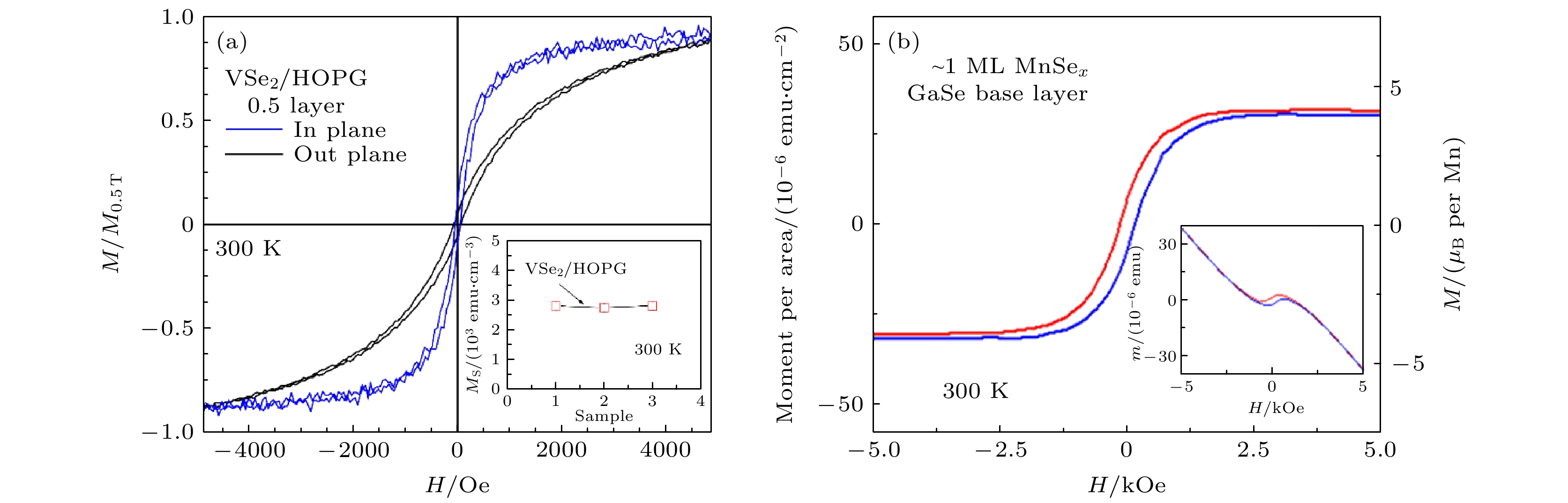

2D材料/异质结构 $ {T_{\rm{c}}}/K $ 计算/制造方法 VSe2/MoS2和VSe2/HOPE

vdW heterostructure> 300 MBE VS2/WS2 vdW heterostructure 487 DFT VS2/MoS2 vdW heterostructure 485 DFT VTe2 128 DFT MnSe2/GaSe和MnSe2/SnSe2

vdW heterostructure> 300 MBE MnSe2 286 DFT MnS2 253 DFT MnI2 15 DFT NiI2 63 DFT CrSCI 150 DFT CrSBr 160 DFT CrSI 170 DFT CrI3 45 机械剥离法 CrI3 161 DFT CrI3 95 DFT CrCl3 49 DFT CrBr3 73 DFT CrF3 41 DFT CrTe3 71 DFT NiCl3 400 DFT CrGeTe3 30 机械剥离法 CrGeTe3 314 DFT CrGeTe3 130 DFT CrSiTe3 214 DFT CrSiTe3 90 DFT CrSiTe3 170 DFT Cr3Te4 2057 DFT Fe3GeTe2 20—300 机械剥离法 Fe3GeTe2 270—300 机械剥离法 Cr3C > 300 DFT 表 2 FGT和Bi2Te3/FGT磁性相互交换作用

Table 2. Magnetic interaction of FGT and Bi2Te3/FGT.

E0 EFM

/eVEAFM-In

/eVEAFM-L

/eVJ1

/meVJ2

/meVJ3

/meVPure FGT 0 –11.441 –10.703 –11.272 3.675 –1.817 0.663 Bi2Te3/FGT 0 –16.400 –15.196 –15.742 5.906 –2.923 1.064 -

[1] Sato N, Xue F, White R M, Bi C, Wang S X 2018 Nat. Electron. 1 508

Google Scholar

Google Scholar

[2] Chappert C, Fert A, Van Dau F N 2007 Nat. Mater. 6 813

Google Scholar

Google Scholar

[3] Zhang D, Hou Y, Zeng L, Zhao W S 2019 IEEE Trans. Nanotechnol. 18 518

Google Scholar

Google Scholar

[4] Mennel L, Symonowicz J, Wachter S, Polyushkin D K, Molina-Mendoza A J, Mueller T 2020 Nature 579 62

Google Scholar

Google Scholar

[5] Zhu J 2008 Proc. IEEE 96 1786

Google Scholar

Google Scholar

[6] Liu L, Moriyama T, Ralph D C, Buhrman R A 2011 Phys. Rev. Lett. 106 036601

[7] Sun J Z, Brown S L, Chen W, Delenia E A, Gaidis M C, Harms J, Hu G, Jiang X, Kilaru R, Kula W, Lauer G, Liu L Q, Murthy S, Nowak J, O’Sullivan E J, Parkin S S P, Robertazzi R P, Rice P M, Sandhu G, Topuria T, Worledge D C 2013 Phys. Rev. B 88 104426

Google Scholar

Google Scholar

[8] Parkin S S P, Kaiser C, Panchula A, Rice P M, Hughes B, Samant M, Yang S H 2004 Nat. Mater. 3 862

Google Scholar

Google Scholar

[9] Wolf S A, Lu J, Stan M R, Chen E, Treger D M 2010 Proc. IEEE 98 2155

Google Scholar

Google Scholar

[10] Van Den Brink A, Vermijs G, Solignac A, Koo J, Kohlhepp J T, Swagten H J M, Koopmans B 2016 Nat. Commun. 7 1

[11] Novoselov K S, Geim A K, Morozov S V, Jiang D, Katsnelson M I, Grigorieva I V, Dubonos S V, Firsov A A 2005 Nature 438 197

Google Scholar

Google Scholar

[12] Hashimoto A, Suenaga K, Gloter A, Urita K, Iijima S 2004 Nature 430 870

Google Scholar

Google Scholar

[13] Schedin F, Geim A K, Morozov S V, Hill E W, Blake P, Katsnelson M I, Novoselov K S 2007 Nat. Mater. 6 652

Google Scholar

Google Scholar

[14] Geim A K, Novoselov K S 2007 Nat. Mater. 6 183

Google Scholar

Google Scholar

[15] Mas-Ballesté R, Gómez-Navarro C, Gómez-Herrero J, Zamora F 2011 Nanoscale 3 20

Google Scholar

Google Scholar

[16] Dirac P A M, Fowler R H 1926 Proc. R. Soc. London, Ser. A 112 661

Google Scholar

Google Scholar

[17] Gong C, Zhang X 2019 Science 363 6428

[18] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[19] Novoselov K S, Jiang D, Schedin F, Booth T J, Khotkevich V V, Morozov S V, Geim A K 2005 Proc. Natl. Acad. Sci. U.S.A. 102 10451

Google Scholar

Google Scholar

[20] Mermin N D, Wagner H 1966 Phys. Rev. Lett. 17 1133

Google Scholar

Google Scholar

[21] Mounet N, Gibertini M, Schwaller P, Campi D, Merkys A, Marrazzo A, Sohier T, Castelli I E, Cepellotti A, Pizzi G, Marzari N 2018 Nat. Nanotechnol. 13 246

Google Scholar

Google Scholar

[22] Alghamdi M, Lohmann M, Li J, Jothi P R, Shao Q, Aldosary M, Su T, Fokwa B P T, Shi J 2019 Nano Lett. 19 4400

Google Scholar

Google Scholar

[23] Wang X, Tang J, Xia X, He C, Zhang J, Liu Y, Wan C, Fang C, Guo C, Yang W, Guang Y, Zhang X, Xu H, Wei J, Liao M, Lu X, Feng J, Li X, Peng Y, Wei H, Yang R, Shi D, Zhang X, Han Z, Zhang Z, Zhang G, Yu G, Han X 2019 Sci. Adv. 5 eaaw8904

Google Scholar

Google Scholar

[24] Novoselov K S, Mishchenko A, Carvalho A, Castro Neto A H 2016 Science 353 6298

[25] Gong C, Li L, Li Z, Ji H, Stern A, Xia Y, Cao T, Bao W, Wang C, Wang Y, Qiu Z Q, Cava R J, Louie S G, Xia J, Zhang X 2017 Nature 546 265

Google Scholar

Google Scholar

[26] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X D 2017 Nature 546 270

Google Scholar

Google Scholar

[27] Si C, Zhou J, Sun Z 2015 ACS Appl. Mater. Interfaces 7 17510

Google Scholar

Google Scholar

[28] Zhu Y, Kong X, Rhone T D, Guo H 2018 Phys. Rev. Mater. 2 81001

Google Scholar

Google Scholar

[29] Du J, Xia C, Xiong W, Wang T, Jia Y, Li J 2017 Nanoscale 9 17585

Google Scholar

Google Scholar

[30] He J, Li X, Lyu P, Nachtigall P 2017 Nanoscale 9 2246

Google Scholar

Google Scholar

[31] Wang H, Liu Y, Wu P, Hou W, Jiang Y, Li X, Pandey C, Chen D, Yang Q, Wang H, Wei D, Lei N, Kang W, Wen L, Nie T X, Zhao W S, Wang K L 2020 ACS Nano 14 10045

Google Scholar

Google Scholar

[32] Dong X J, You J Y, Gu B, Su G 2019 Phys. Rev. Appl. 12 14020

Google Scholar

Google Scholar

[33] Deng Y, Yu Y, Song Y, Zhang J, Wang N Z, Sun Z, Yi Y, Wu Y Z, Wu S, Zhu J, Wang J, Chen X H, Zhang Y B 2018 Nature 563 94

Google Scholar

Google Scholar

[34] Wen Y, Liu Z, Zhang Y, Xia C, Zhai B, Zhang X, Zhai G, Shen C, He P, Cheng R, Yin L, Yao Y, Getaye Sendeku M, Wang Z, Ye X, Liu C, Jiang C, Shan C, Long Y, He J 2020 Nano Lett. 20 3130

Google Scholar

Google Scholar

[35] Cai X, Luo Y, Liu B, Cheng H M 2018 Chem. Soc. Rev. 47 6224

Google Scholar

Google Scholar

[36] Yi M, Shen Z 2015 J. Mater. Chem. A 3 11700

Google Scholar

Google Scholar

[37] Zhang Y, Zhang L, Zhou C 2013 Acc. Chem. Res. 46 2329

Google Scholar

Google Scholar

[38] Ji Q, Zhang Y, Zhang Y, Liu Z 2015 Chem. Soc. Rev. 44 2587

Google Scholar

Google Scholar

[39] Mattevi C, Kim H, Chhowalla M 2011 J. Mater. Chem. 21 3324

Google Scholar

Google Scholar

[40] Ago H, Ito Y, Mizuta N, Yoshida K, Hu B, Orofeo C M, Tsuji M, Ikeda K, Mizuno S 2010 ACS Nano 4 7407

Google Scholar

Google Scholar

[41] Vo-Van C, Kimouche A, Reserbat-Plantey A, Fruchart O, Bayle-Guillemaud P, Bendiab N, Coraux J 2011 Appl. Phys. Lett. 98 181903

Google Scholar

Google Scholar

[42] Coleman J N 2009 Adv. Funct. Mater. 19 3680

Google Scholar

Google Scholar

[43] Coleman J N 2013 Acc. Chem. Res. 46 14

Google Scholar

Google Scholar

[44] Cui X, Zhang C, Hao R, Hou Y 2011 Nanoscale 3 2118

Google Scholar

Google Scholar

[45] Ojrzynska M, Wroblewska A, Judek J, Malolepszy A, Duzynska A, Zdrojek M 2020 Opt. Express 28 7274

Google Scholar

Google Scholar

[46] Ciesielski A, Samorì P 2014 Chem. Soc. Rev. 43 381

Google Scholar

Google Scholar

[47] Neave J H, Dobson P J, Joyce B A, Zhang J 1985 Appl. Phys. Lett. 47 100

Google Scholar

Google Scholar

[48] May A F, Ovchinnikov D, Zheng Q, Hermann R, Calder S, Huang B, Fei Z, Liu Y, Xu X, McGuire M A 2019 ACS Nano 13 4436

Google Scholar

Google Scholar

[49] Dalitz R H, Peierls R E 1997 Selected Scientific Papers of Sir Rudolf Peierls (Vol. 1) (Singapore: World Scientific Publishing Co. Pte. Ltd) pp 9–225

[50] Joyce G S 1969 J. Phys. C: Solid State Phys. 2 1531

Google Scholar

Google Scholar

[51] Hohenberg P C 1967 Phys. Rev. 158 383

Google Scholar

Google Scholar

[52] Ising E 1925 Z. Phys. 31 253

Google Scholar

Google Scholar

[53] Kosterlitz J M, Thouless D J 1973 J. Phys. C: Solid State Phys. 6 1181

Google Scholar

Google Scholar

[54] Berezinsky V L 1971 Sov. Phys. JETP 32 493

[55] Liu S, Yuan X, Zou Y, Sheng Y, Huang C, Zhang E, Ling J, Liu Y, Wang W, Zhang C, Zou J, Wang K, Xiu F X 2017 npj 2D Mater. Appl. 1 30

Google Scholar

Google Scholar

[56] Tan C, Lee J, Jung S G, Park T, Albarakati S, Partridge J, Field M R, McCulloch D G, Wang L, Lee C 2018 Nat. Commun. 9 1554

[57] Fei Z, Huang B, Malinowski P, Wang W, Song T, Sanchez J, Yao W, Xiao D, Zhu X, May A F, Wu W, Cobden D H, Chu J H, Xu X D 2018 Nat. Mater. 17 778

Google Scholar

Google Scholar

[58] Kim D, Park S, Lee J, Yoon J, Joo S, Kim T, Min K, Park S Y, Kim C, Moon K W, Lee C, Hong J, Hwang C 2019 Nanotechnology 30 245701

Google Scholar

Google Scholar

[59] Xu J, Phelan W A, Chien C L 2019 Nano Lett. 19 8250

Google Scholar

Google Scholar

[60] Park S Y, Kim D S, Liu Y, Hwang J, Kim Y, Kim W, Kim J Y, Petrovic C, Hwang C, Mo S K, Kim H, Min B C, Koo H C, Chang J, Jang C, Choi J W, Ryu H 2020 Nano Lett. 20 95

Google Scholar

Google Scholar

[61] Cao Y, Fatemi V, Fang S, Watanabe K, Taniguchi T, Kaxiras E, Jarillo-Herrero P 2018 Nature 556 43

Google Scholar

Google Scholar

[62] Gibertini M, Koperski M, Morpurgo A F, Novoselov K S 2019 Nat. Nanotechnol. 14 408

Google Scholar

Google Scholar

[63] Huang B, Clark G, Klein D R, MacNeill D, Navarro-Moratalla E, Seyler K L, Wilson N, McGuire M A, Cobden D H, Xiao D, Yao W, Jarillo-Herrero P, Xu X D 2018 Nat. Nanotechnol. 13 544

Google Scholar

Google Scholar

[64] Jiang S, Li L, Wang Z, Mak K F, Shan J 2018 Nat. Nanotechnol. 13 549

Google Scholar

Google Scholar

[65] Lin X, Yang W, Wang K L, Zhao W 2019 Nat. Electron. 2 274

Google Scholar

Google Scholar

[66] Bonilla M, Kolekar S, Ma Y, Diaz H C, Kalappattil V, Das R, Eggers T, Gutierrez H R, Phan M H, Batzill M 2018 Nat. Nanotechnol. 13 289

Google Scholar

Google Scholar

[67] O’Hara D J, Zhu T, Trout A H, Ahmed A S, Luo Y K, Lee C H, Brenner M R, Rajan S, Gupta J A, McComb D W, Kawakami R K 2018 Nano Lett. 18 3125

Google Scholar

Google Scholar

[68] Wang Z, Zhang T, Ding M, Dong B, Li Y, Chen M, Li X, Huang J, Wang H, Zhao X, Li Y, Li D, Jia C, Sun L, Guo H, Ye Y, Sun D, Chen Y, Yang T, Zhang J, Ono S, Han Z, Zhang Z D 2018 Nat. Nanotechnol. 13 554

Google Scholar

Google Scholar

[69] Verzhbitskiy I A, Kurebayashi H, Cheng H, Zhou J, Khan S, Feng Y P, Eda G 2020 Nat. Electron. 3 460

Google Scholar

Google Scholar

[70] Seo J, Kim D Y, An E S, Kim K, Kim G Y, Hwang S Y, Kim D W, Jang B G, Kim H, Eom G, Seo S Y, Stania R, Muntwiler M, Lee J, Watanabe K, Taniguchi T, Jo Y J, Lee J, Min B Il, Jo M H, Yeom H W, Choi S Y, Shim J H, Kim J S 2020 Sci. Adv. 6 eaay8912

Google Scholar

Google Scholar

[71] Yang M, Li Q, Chopdekar R V, Stan C, Cabrini S, Choi J W, Wang S, Wang T, Gao N, Scholl A, Tamura N, Hwang C, Wang F, Qiu Z Q 2020 Adv. Quantum Technol. 3 2000017

Google Scholar

Google Scholar

[72] Li Q, Yang M, Gong C, Chopdekar R V, N’Diaye A T, Turner J, Chen G, Scholl A, Shafer P, Arenholz E, Schmid A K, Wang S, Liu K, Gao N, Admasu A S, Cheong S W, Hwang C, Li J, Wang F, Zhang X, Qiu Z Q 2018 Nano Lett. 18 5974

Google Scholar

Google Scholar

[73] Liu S, Yang K, Liu W, Zhang E, Li Z, Zhang X, Liao Z, Zhang W, Sun J, Yang Y, Gao H, Huang C, Ai L, Wong P K J, Wee A T S, N’Diaye A T, Morton S A, Kou X, Zou J, Xu Y, Wu H, Xiu F X 2019 Natl. Sci. Rev. 7 745

[74] Dong X J, You J Y, Zhang Z, Gu B, Su G 2020 Phys. Rev. B 102 144443

Google Scholar

Google Scholar

[75] Kou X, Fan Y, Wang K L 2019 J. Phys. Chem. Solids 128 2

Google Scholar

Google Scholar

[76] Yu J, Wu W, Wang Y, Zhu K, Zeng X, Chen Y, Liu Y, Yin C, Cheng S, Lai Y, He K, Xue Q 2020 Appl. Phys. Lett. 116 141603

Google Scholar

Google Scholar

[77] Katmis F, Lauter V, Nogueira F S, Assaf B A, Jamer M E, Wei P, Satpati B, Freeland J W, Eremin I, Heiman D, Jarillo-Herrero P, Moodera J S 2016 Nature 533 513

Google Scholar

Google Scholar

[78] Wang Z, Sapkota D, Taniguchi T, Watanabe K, Mandrus D, Morpurgo A F 2018 Nano Lett. 18 4303

Google Scholar

Google Scholar

[79] Albarakati S, Tan C, Chen Z J, Partridge J G, Zheng G, Farrar L, Mayes E L H, Field M R, Lee C, Wang Y, Xiong Y, Tian M, Xiang F, Hamilton A R, Tretiakov O A, Culcer D, Zhao Y J, Wang L 2019 Sci. Adv. 5 eaaw0409

Google Scholar

Google Scholar

计量

- 文章访问数: 19902

- PDF下载量: 1467

- 被引次数: 0

下载:

下载: