-

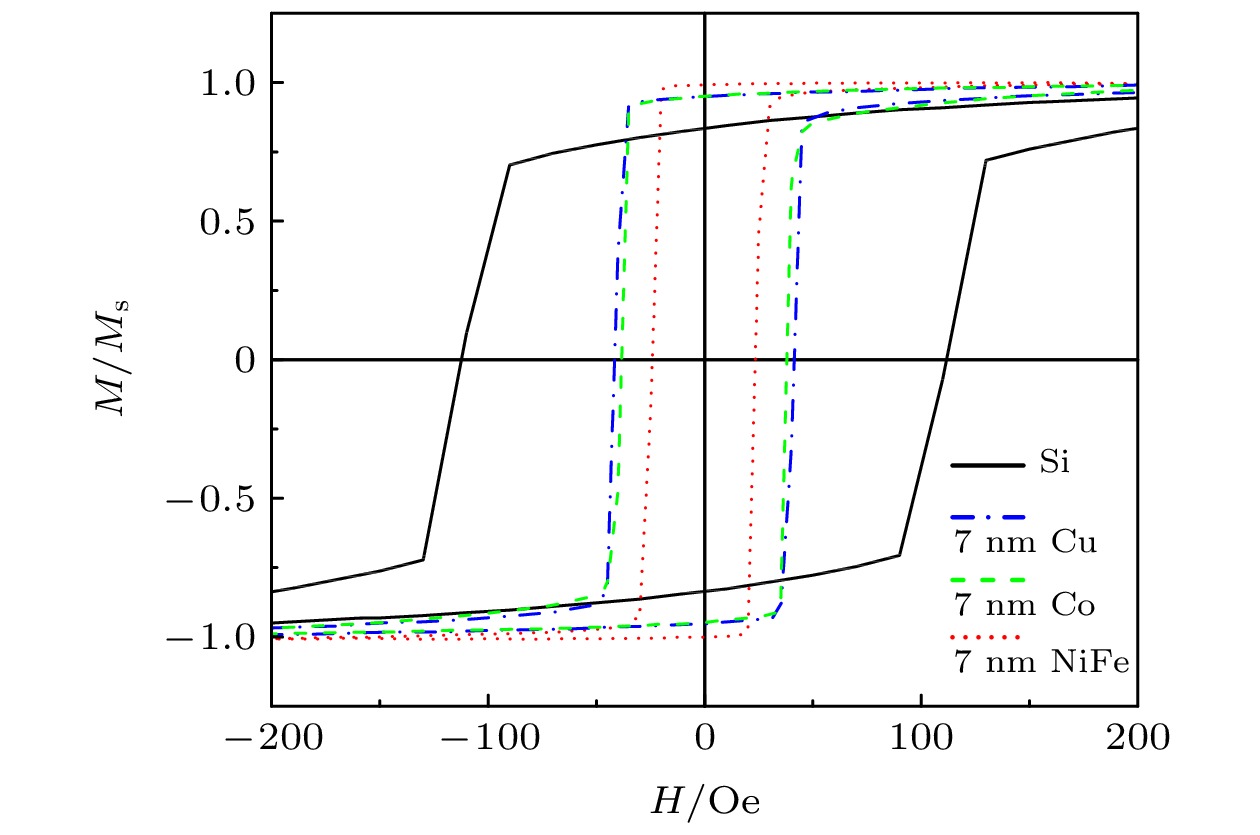

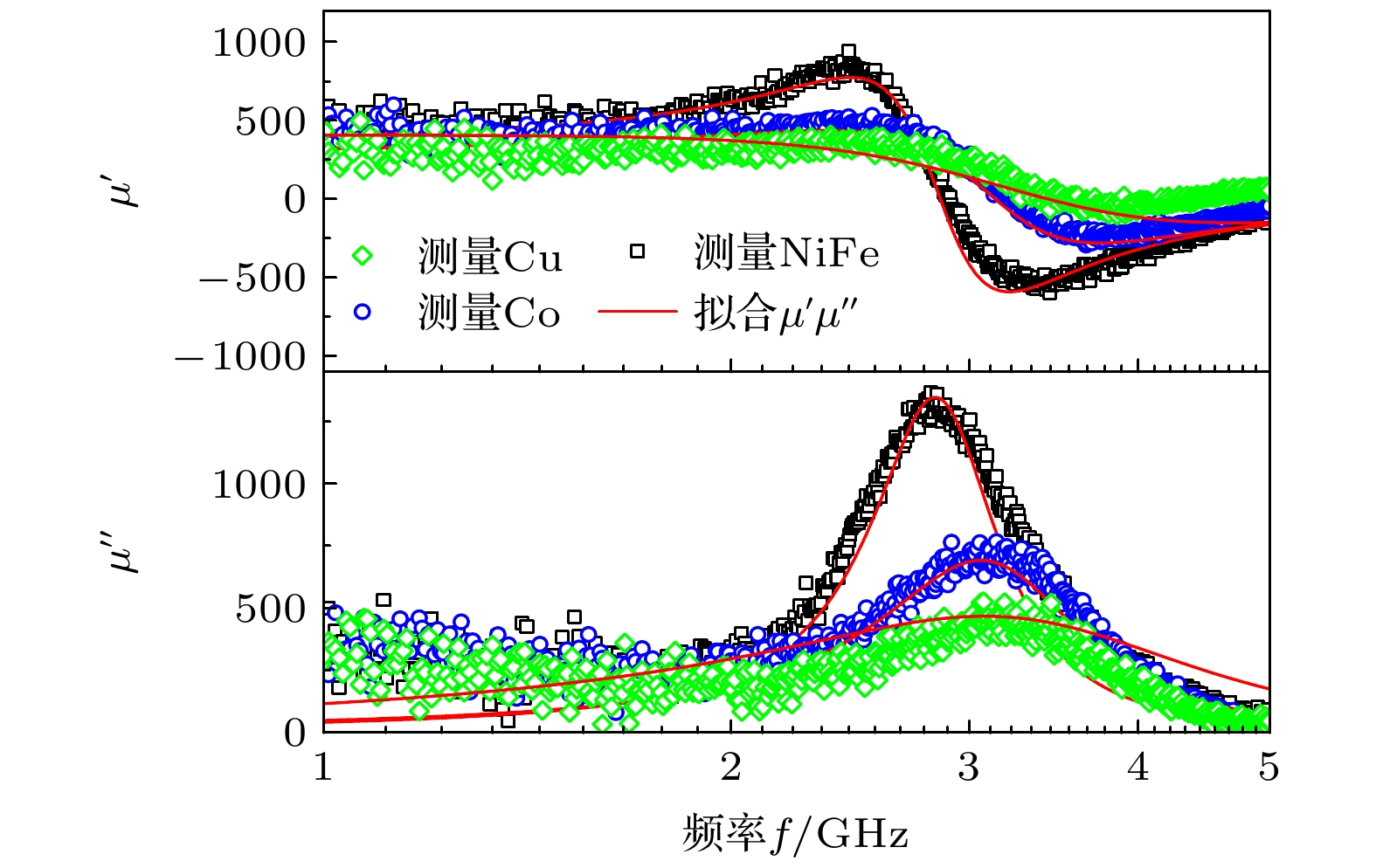

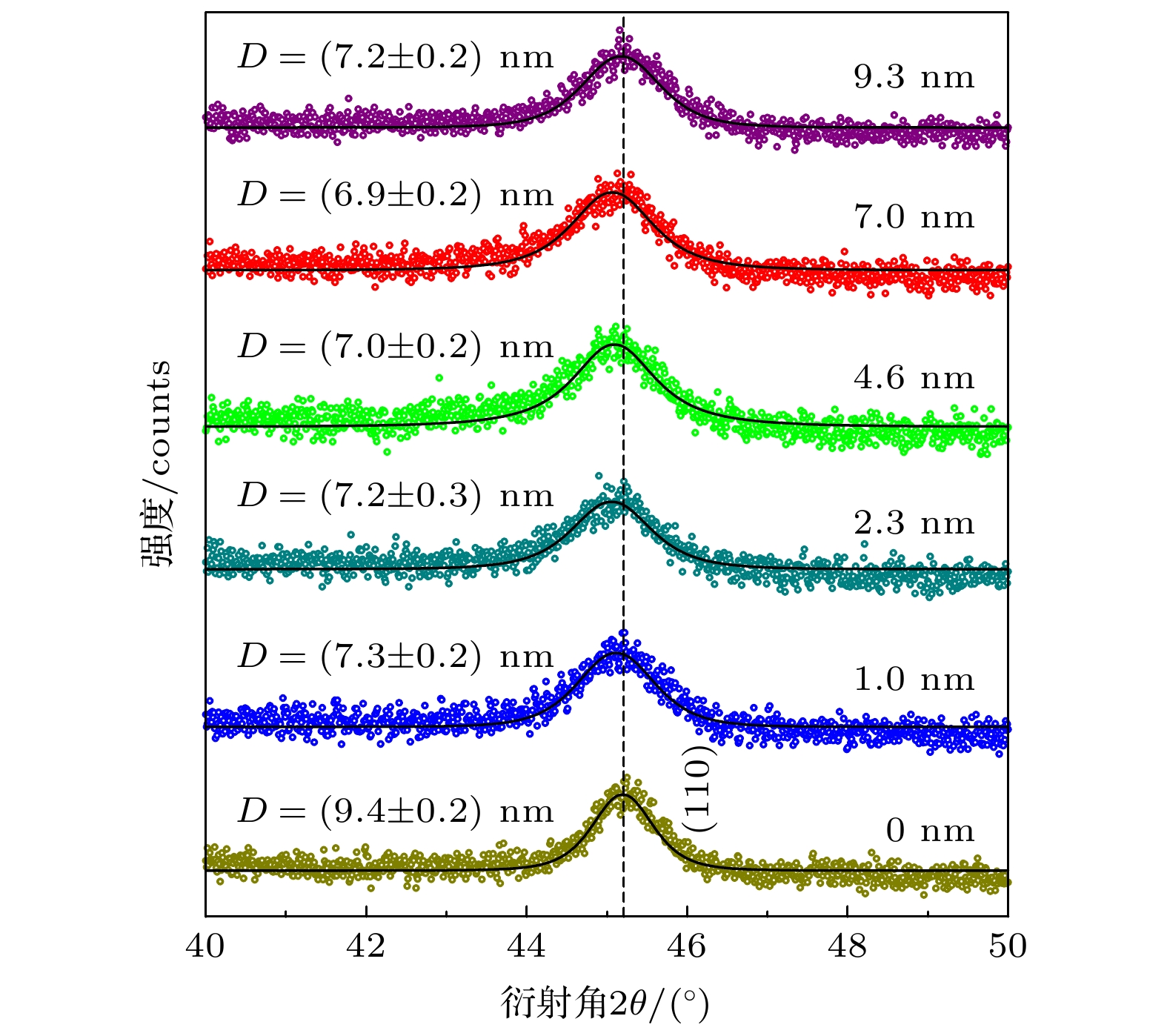

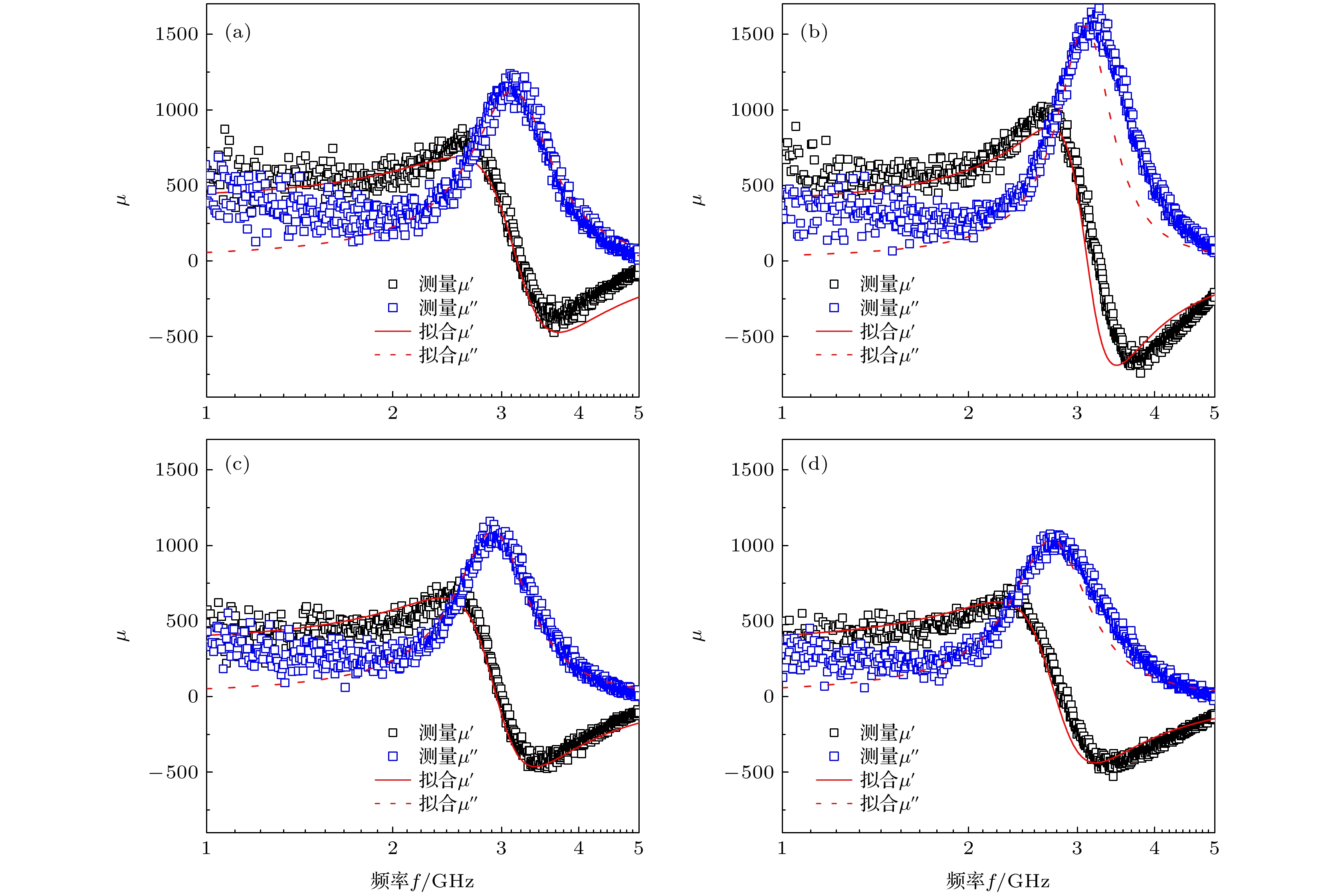

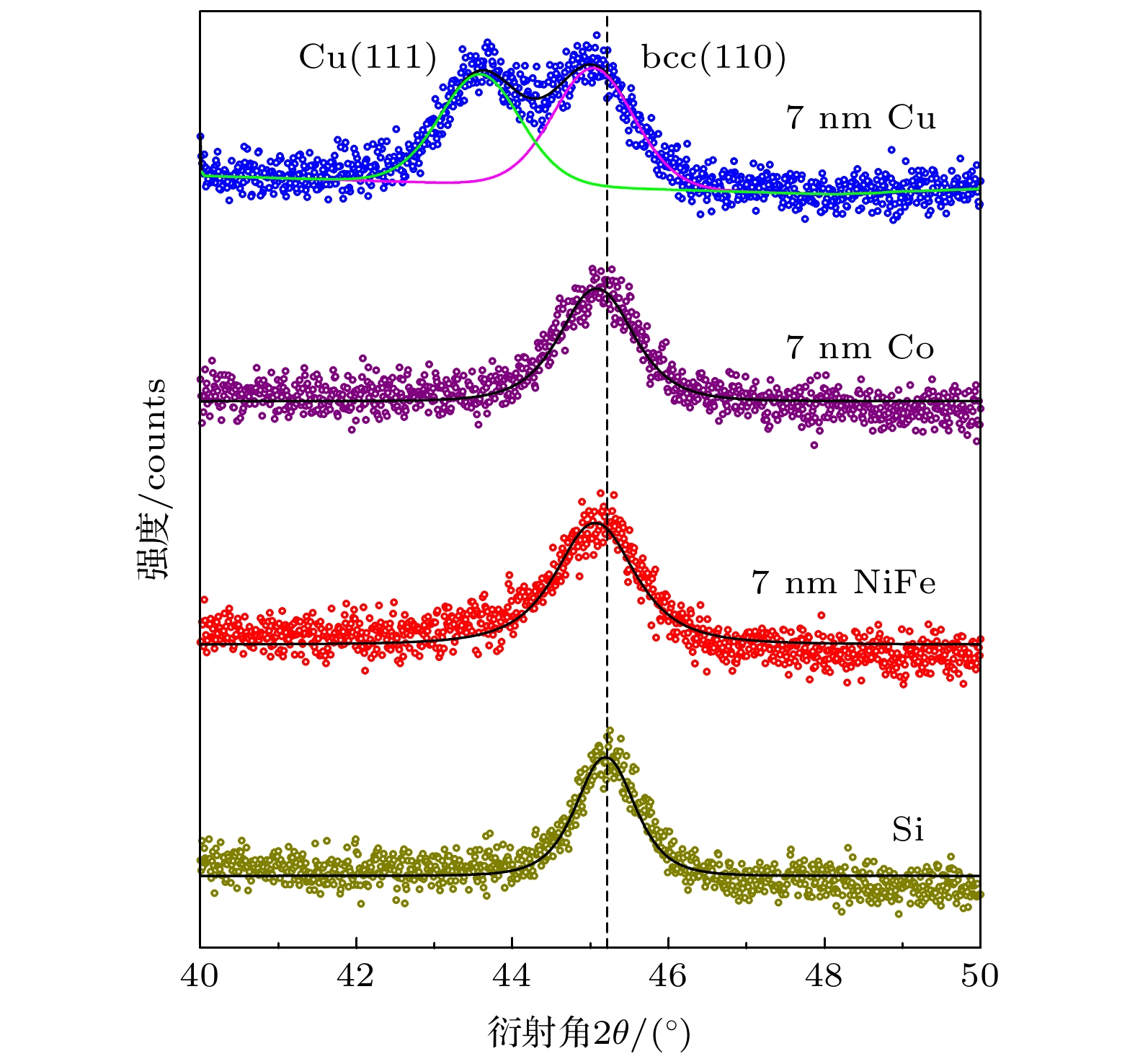

Fe100-xCox (x = 30–40) alloys have the highest saturation magnetizations, 4πMs ≥ 24 kG (1 G = 10–4 T). Therefore, FeCo thin flms have been widely used in microwave magnetic devices. However, the as-deposited FeCo film has a large coercivity, which is attributed to the large saturation magnetostriction and high magneto-crystalline anisotropy. On the basis of maintaining high saturation magnetization, adding an appropriate underlayer is a simple and effective method to reduce the coercivity of the film and facilitate the magnetic field-induced in-plane uniaxial magnetic anisotropy. Since these kinds of films are used in a high-frequency environment, the eddy current loss in GHz band must be considered. For a certain film material, the thinner the film, the lower the eddy current loss is. However, at present, the thickness of ferromagnetic layer is generally tens of nanometers or even hundreds of nanometers, which will not help to suppress the eddy current loss at high frequency. In the present study, to obtain FeCo films with good soft magnetic properties and excellent high-frequency characteristics, Fe65Co35 alloy films with a thickness of 13 nm and different underlayers (Cu, Co and Ni80Fe20) are prepared by magnetron sputtering. The effects of different underlayer materials and different NiFe underlayer thickness values on the structures and magnetic properties of FeCo films are studied. The results show that the introduction of underlayers can increase the in-plane uniaxial magnetic anisotropies of films, and the soft magnetic properties of films are significantly improved. The reason why the good soft magnetic properties can be achieved is attributed to the grain refinement, the dipolar interaction between layers, and the reduction of surface roughness. For different underlayer materials with the same thickness, NiFe underlayer can obviously improve the soft magnetic properties of FeCo films: the covercivity of easy axis is 23 Oe. By changing the thickness of NiFe underlayer, the dynamic magnetic properties of films can be adjusted. The resonance frequency changes from 3.13 GHz for NiFe(1 nm)/FeCo(13 nm) film to 2.78 GHz for NiFe(9.3 nm)/ FeCo(13 nm) film. For all NiFe/FeCo bilayer films, the real part of the permeability μ′ at low frequency has a large value of 350–450, and the damping coefficient α shows a small value of 0.01–0.02. In addition, the smaller film thickness can reduce eddy current loss, which contributes to its application in high-frequency microwave magnetic devices.

-

Keywords:

- FeCo alloy films /

- underlayers /

- soft magnetic properties /

- high-frequency characteristics

[1] Li T Y, Liu X Y, Li J W, Pan L N, He A N, Dong Y Q 2022 J. Magn. Magn. Mater. 547 168777

Google Scholar

Google Scholar

[2] Cronin D, Lordan D, Wei G, McCloskey P, Mathúna C O, Masood A 2020 J. Appl. Phys. 127 243903

Google Scholar

Google Scholar

[3] Tang X L, Yu Y, Su H, Zhang H W, Zhong Z Y, Jing Y L 2018 J. Mater. Sci. 53 3573

Google Scholar

Google Scholar

[4] Chai G, Phuoc N N, Ong C K 2012 Sci. Rep. 2 832

Google Scholar

Google Scholar

[5] Masood A, McCloskey P, Mathúna C Ó, Kulkarni S 2017 J. Phys. Conf. Ser. 903 012050

Google Scholar

Google Scholar

[6] Kurlyandskaya G V, Shcherbinin S V, Volchkov S O, Bhagat S M, Calle E, Pérez R, Vazquez M 2018 J. Magn. Magn. Mater. 459 154

Google Scholar

Google Scholar

[7] Zheng F, Ma Z, Gao H, Pan F C, Li S T, Cao J W, Bai J M, Wei F L 2017 J. Mater. Sci. Mater. Electron. 28 17448

Google Scholar

Google Scholar

[8] Yang F J, Min J J, Hui J H, Chen H B, Degao L, Li W J, Chen X Q, Yang C P 2017 J. Mater. Sci. Mater. Electron. 28 11733

Google Scholar

Google Scholar

[9] Baco S, Abbas Q A, Hayward T J, Morley N A 2021 J. Alloy. Compd. 881 160549

Google Scholar

Google Scholar

[10] Cabral L, Aragon F H, Villegas-Lelovsky L, Lima M P, Macedo W A A, Da Silva J L F 2019 ACS Appl. Mater. Inter. 11 1529

Google Scholar

Google Scholar

[11] Vopsaroiu M, Georgieva M, Grundy P J, Fernandez G V, Manzoor S, Thwaites M J, O’Grady K 2005 J. Appl. Phys. 97 10N303

Google Scholar

Google Scholar

[12] Vas’ko V A, Rantschler J O, Kief M T 2004 IEEE Trans. Magn. 40 2335

Google Scholar

Google Scholar

[13] Xi L, Du J H, Zhou J J, Ma J H, Li X Y, Wang Z, Zuo Y L, Xue D S 2012 Thin Solid Films 520 5421

Google Scholar

Google Scholar

[14] 王璇, 郑富, 卢佳, 白建民, 王颖, 魏福林 2011 60 017505

Google Scholar

Google Scholar

Wang X, Zheng F, Lu J, Bai J M, Wang Y, Wei F L 2011 Acta. Phys. Sin. 60 017505

Google Scholar

Google Scholar

[15] Wang X, Zheng F, Liu Z Y, Liu X X, Wei D, Wei F L 2009 J. Appl. Phys. 105 07B714

Google Scholar

Google Scholar

[16] Wu Y P, Yang Y, Yang Z H, Ma F S, Zong B Y, Ding J 2014 J. Appl. Phys. 116 093905

Google Scholar

Google Scholar

[17] Xu F, Liao Z Q, Huang Q J, Ong C K, Li S D 2011 IEEE Trans. Magn. 47 3921

Google Scholar

Google Scholar

[18] Acosta A, Fitzell K, Schneider J D, Dong C Z, Yao Z, Wang Y E, Carman G P, Sun N X, Chang J P 2020 Appl. Phys. Lett. 116 222404

Google Scholar

Google Scholar

[19] Acosta A, Fitzell K, Schneider J D, Dong C Z, Yao Z, Sheil R, Wang Y E, Carman G P, Sun N X, Chang J P 2020 J. Appl. Phys. 128 013903

Google Scholar

Google Scholar

[20] Fu Y, Miyao T, Cao J W, Yang Z, Matsumoto M, Liu X X, Morisako A 2007 J. Magn. Magn. Mater. 308 165

Google Scholar

Google Scholar

[21] Li Y B, Li Z H, Liu X, Fu Y, Wei F L, Kamzin A S, Wei D 2010 J. Appl. Phys. 107 09A325

Google Scholar

Google Scholar

[22] Sun N X, Wang S X 2002 J. Appl. Phys. 92 1477

Google Scholar

Google Scholar

[23] Shimatsu T, Katada H, Watanabe I, Muraoka H, Nakamura Y 2003 IEEE Trans. Magn. 39 2365

Google Scholar

Google Scholar

[24] Langford J I, Wilson A J C 1978 J. Appl. Cryst. 11 102

Google Scholar

Google Scholar

[25] Scherrer P 1918 Nachr. Ges. Wiss. Göttingen 26 98

[26] Herzer G 1990 IEEE Trans. Magn. 26 1397

Google Scholar

Google Scholar

[27] Jiang H, Chen Y J, Chen L F, Huai Y M 2002 J. Appl. Phys. 91 6821

Google Scholar

Google Scholar

[28] Inturi V R, Barnard J A 1996 J. Appl. Phys. 79 5904

Google Scholar

Google Scholar

[29] Liu X X, Kanda H, Morisako A 2011 J. Phys. Conf. Ser. 266 012037

Google Scholar

Google Scholar

[30] Jung H S, Doyle W D, Wittig J E, Al-Sharab J F, Bentley J 2002 Appl. Phys. Lett. 81 2415

Google Scholar

Google Scholar

[31] O'Grady K, Laidler H 1999 J. Magn. Magn. Mater. 200 616

Google Scholar

Google Scholar

[32] Wohlfarth E P 1958 J. Appl. Phys. 29 595

Google Scholar

Google Scholar

[33] Henkel O 1964 Phys. Stat. Sol. 7 919

Google Scholar

Google Scholar

[34] Gilbert T L 2004 IEEE Trans. Magn. 40 3443

Google Scholar

Google Scholar

[35] Ge S H, Yao D S, Yamaguchi M, Yang X L, Zuo H P, Ishii T, Zhou D, Li F 2007 J. Phys. D Appl. Phys. 40 3660

Google Scholar

Google Scholar

[36] Kuanr B K, Camley R E, Celinski Z 2005 J. Magn. Magn. Mater. 286 276

Google Scholar

Google Scholar

[37] Ben Youssef J, Vukadinovic N, Billet D, Labrune M 2004 Phys. Rev. B 69 174402

Google Scholar

Google Scholar

[38] Wu Y P, Han G C, Kong L B 2010 J. Magn. Magn. Mater. 322 3223

Google Scholar

Google Scholar

[39] Zhong X X, Soh W T, Phuoc N N, Liu Y, Ong C K 2015 J. Appl. Phys. 117 013906

Google Scholar

Google Scholar

[40] Fu Y, Cheng X F, Yang Z 2006 Phys. Stat. Sol. (a) 203 963

Google Scholar

Google Scholar

[41] Phuoca N N, Hungb L T, Ongb C K 2011 J. Alloy. Compd. 509 4010

Google Scholar

Google Scholar

-

图 10 (a) NiFe/FeCo薄膜的各向异性场和共振频率与NiFe衬底层厚度的关系; (b) NiFe/FeCo薄膜的阻尼系数和频率线宽与NiFe衬底层厚度的关系

Figure 10. (a) Dependence of anisotropic field and resonance frequency of NiFe/FeCo films on thickness of NiFe underlayers; (b) dependence of damping coefficient and frequency linewidth of NiFe/FeCo films on thickness of NiFe underlayers.

表 1 Si基底和不同衬底上沉积的FeCo薄膜的易轴矫顽力、剩磁比、应变、晶粒尺寸以及阻尼系数

Table 1. Coercivity of easy axis, remanent magnetization ratio, strain, grain size, and damping coefficient of FeCo films deposited on Si substrate and different underlayers.

衬底层

材料易轴矫顽力

Hc/Oe剩磁比

Mr/Ms应变

∆ε/%晶粒尺寸

D/nm阻尼

αSi 112 0.834 — 9.4±0.2 — Cu 41 0.949 0.59 7.5±0.6 0.045 Co 38 0.951 0.27 7.5±0.2 0.025 NiFe 23 0.991 0.29 6.9±0.2 0.015 表 2 不同衬底上沉积的FeCo薄膜的磁性总结

Table 2. Summary of magnetic properties of FeCo films deposited on different underlayers.

-

[1] Li T Y, Liu X Y, Li J W, Pan L N, He A N, Dong Y Q 2022 J. Magn. Magn. Mater. 547 168777

Google Scholar

Google Scholar

[2] Cronin D, Lordan D, Wei G, McCloskey P, Mathúna C O, Masood A 2020 J. Appl. Phys. 127 243903

Google Scholar

Google Scholar

[3] Tang X L, Yu Y, Su H, Zhang H W, Zhong Z Y, Jing Y L 2018 J. Mater. Sci. 53 3573

Google Scholar

Google Scholar

[4] Chai G, Phuoc N N, Ong C K 2012 Sci. Rep. 2 832

Google Scholar

Google Scholar

[5] Masood A, McCloskey P, Mathúna C Ó, Kulkarni S 2017 J. Phys. Conf. Ser. 903 012050

Google Scholar

Google Scholar

[6] Kurlyandskaya G V, Shcherbinin S V, Volchkov S O, Bhagat S M, Calle E, Pérez R, Vazquez M 2018 J. Magn. Magn. Mater. 459 154

Google Scholar

Google Scholar

[7] Zheng F, Ma Z, Gao H, Pan F C, Li S T, Cao J W, Bai J M, Wei F L 2017 J. Mater. Sci. Mater. Electron. 28 17448

Google Scholar

Google Scholar

[8] Yang F J, Min J J, Hui J H, Chen H B, Degao L, Li W J, Chen X Q, Yang C P 2017 J. Mater. Sci. Mater. Electron. 28 11733

Google Scholar

Google Scholar

[9] Baco S, Abbas Q A, Hayward T J, Morley N A 2021 J. Alloy. Compd. 881 160549

Google Scholar

Google Scholar

[10] Cabral L, Aragon F H, Villegas-Lelovsky L, Lima M P, Macedo W A A, Da Silva J L F 2019 ACS Appl. Mater. Inter. 11 1529

Google Scholar

Google Scholar

[11] Vopsaroiu M, Georgieva M, Grundy P J, Fernandez G V, Manzoor S, Thwaites M J, O’Grady K 2005 J. Appl. Phys. 97 10N303

Google Scholar

Google Scholar

[12] Vas’ko V A, Rantschler J O, Kief M T 2004 IEEE Trans. Magn. 40 2335

Google Scholar

Google Scholar

[13] Xi L, Du J H, Zhou J J, Ma J H, Li X Y, Wang Z, Zuo Y L, Xue D S 2012 Thin Solid Films 520 5421

Google Scholar

Google Scholar

[14] 王璇, 郑富, 卢佳, 白建民, 王颖, 魏福林 2011 60 017505

Google Scholar

Google Scholar

Wang X, Zheng F, Lu J, Bai J M, Wang Y, Wei F L 2011 Acta. Phys. Sin. 60 017505

Google Scholar

Google Scholar

[15] Wang X, Zheng F, Liu Z Y, Liu X X, Wei D, Wei F L 2009 J. Appl. Phys. 105 07B714

Google Scholar

Google Scholar

[16] Wu Y P, Yang Y, Yang Z H, Ma F S, Zong B Y, Ding J 2014 J. Appl. Phys. 116 093905

Google Scholar

Google Scholar

[17] Xu F, Liao Z Q, Huang Q J, Ong C K, Li S D 2011 IEEE Trans. Magn. 47 3921

Google Scholar

Google Scholar

[18] Acosta A, Fitzell K, Schneider J D, Dong C Z, Yao Z, Wang Y E, Carman G P, Sun N X, Chang J P 2020 Appl. Phys. Lett. 116 222404

Google Scholar

Google Scholar

[19] Acosta A, Fitzell K, Schneider J D, Dong C Z, Yao Z, Sheil R, Wang Y E, Carman G P, Sun N X, Chang J P 2020 J. Appl. Phys. 128 013903

Google Scholar

Google Scholar

[20] Fu Y, Miyao T, Cao J W, Yang Z, Matsumoto M, Liu X X, Morisako A 2007 J. Magn. Magn. Mater. 308 165

Google Scholar

Google Scholar

[21] Li Y B, Li Z H, Liu X, Fu Y, Wei F L, Kamzin A S, Wei D 2010 J. Appl. Phys. 107 09A325

Google Scholar

Google Scholar

[22] Sun N X, Wang S X 2002 J. Appl. Phys. 92 1477

Google Scholar

Google Scholar

[23] Shimatsu T, Katada H, Watanabe I, Muraoka H, Nakamura Y 2003 IEEE Trans. Magn. 39 2365

Google Scholar

Google Scholar

[24] Langford J I, Wilson A J C 1978 J. Appl. Cryst. 11 102

Google Scholar

Google Scholar

[25] Scherrer P 1918 Nachr. Ges. Wiss. Göttingen 26 98

[26] Herzer G 1990 IEEE Trans. Magn. 26 1397

Google Scholar

Google Scholar

[27] Jiang H, Chen Y J, Chen L F, Huai Y M 2002 J. Appl. Phys. 91 6821

Google Scholar

Google Scholar

[28] Inturi V R, Barnard J A 1996 J. Appl. Phys. 79 5904

Google Scholar

Google Scholar

[29] Liu X X, Kanda H, Morisako A 2011 J. Phys. Conf. Ser. 266 012037

Google Scholar

Google Scholar

[30] Jung H S, Doyle W D, Wittig J E, Al-Sharab J F, Bentley J 2002 Appl. Phys. Lett. 81 2415

Google Scholar

Google Scholar

[31] O'Grady K, Laidler H 1999 J. Magn. Magn. Mater. 200 616

Google Scholar

Google Scholar

[32] Wohlfarth E P 1958 J. Appl. Phys. 29 595

Google Scholar

Google Scholar

[33] Henkel O 1964 Phys. Stat. Sol. 7 919

Google Scholar

Google Scholar

[34] Gilbert T L 2004 IEEE Trans. Magn. 40 3443

Google Scholar

Google Scholar

[35] Ge S H, Yao D S, Yamaguchi M, Yang X L, Zuo H P, Ishii T, Zhou D, Li F 2007 J. Phys. D Appl. Phys. 40 3660

Google Scholar

Google Scholar

[36] Kuanr B K, Camley R E, Celinski Z 2005 J. Magn. Magn. Mater. 286 276

Google Scholar

Google Scholar

[37] Ben Youssef J, Vukadinovic N, Billet D, Labrune M 2004 Phys. Rev. B 69 174402

Google Scholar

Google Scholar

[38] Wu Y P, Han G C, Kong L B 2010 J. Magn. Magn. Mater. 322 3223

Google Scholar

Google Scholar

[39] Zhong X X, Soh W T, Phuoc N N, Liu Y, Ong C K 2015 J. Appl. Phys. 117 013906

Google Scholar

Google Scholar

[40] Fu Y, Cheng X F, Yang Z 2006 Phys. Stat. Sol. (a) 203 963

Google Scholar

Google Scholar

[41] Phuoca N N, Hungb L T, Ongb C K 2011 J. Alloy. Compd. 509 4010

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 6361

- PDF Downloads: 112

- Cited By: 0

DownLoad:

DownLoad: