-

先进的振动控制技术在航空航天及船舶领域具有广泛需求. 当前, 大多数系统的吸振与隔振设计分离, 且现有隔振设计难以有效增强低频线谱隔离. 因此, 本文针对典型欧拉梁, 提出了一种吸隔振一体化设计方法. 基于声学超材料的带隙波阻原理, 研究了振动在横向和纵向的传播特性及其协同调节规律. 结果表明, 通过使用波阻隔振器实现多种模态的吸振和隔振, 无需额外结构即可高效控制低频和宽带振动. 在横向通路中, 引入局域共振带隙显著提高了低频隔振效果; 在纵向通路中, 除了近零及Bragg带隙外, 波阻隔振器还能产生多种带隙, 实现了低频宽带吸振. 研究显示, 通过叠加纵向与横向带隙可达成100 Hz内87.3%的带隙占比. 采用有限元法验证了解析结果的准确性. 研究结果为复杂梁、板、管路、框架等结构的吸隔振一体化设计提供了可行思路.Advanced vibration control technology is widely needed in the fields of aerospace and shipbuilding. Currently, separate vibration absorption and isolation design of most systems are separated, and existing isolation designs cannot effectively enhance the isolation of low-frequency line spectra. There is an urgent need to develop integrated vibration absorption and isolation designs and strengthen low-frequency line spectrum control. In response to this need, this paper focuses on a typical Euler beam and the investigation of the propagation characteristics of vibrations in transverse direction and longitudinal direction, the principles of integrated vibration absorption and isolation design, and the synergistic regulation of bandgaps, based on acoustic metamaterial bandgap wave-insulating vibration control configurations and analytical methods. Ultimately, without adding additional structures, the wave-insulating vibration control device is used to generate multiple modes of vibration absorption and isolation simultaneously, achieving an integrated low-frequency, broadband, and high-efficiency vibration absorption and isolation design. This method achieves broadband vibration isolation in the transverse vibration isolation path while also introducing local resonance bandgaps that significantly improve low-frequency vibration isolation. In the longitudinal (forward propagation) path, in addition to near-zero and Bragg bandgaps, multilayer isolators generate multimodal local resonant bandgaps, achieving low-frequency broadband vibration absorption and effective control in the entire frequency range. This paper elucidates the synergistic modulation of longitudinal and transverse bandgaps, showing that by superimposing these bandgaps, an impressive bandgap ratio of 87.3% below 100 Hz across the entire frequency range can be achieved. Furthermore, an entity structure is designed, and the accuracy of the analytical results is verified by using the finite element method. The findings provide feasible design ideas for realizing the integrated vibration absorption and isolation of complex structures such as beams, plates, pipelines, and frames.

-

Keywords:

- metamaterial /

- bandgap /

- vibration absorption /

- vibration isolation

[1] 苏常伟, 梁冉, 王雪仁, 周涛, 李海超 2023 舰船科学技术 45 1

Google Scholar

Google Scholar

Su C W, Liang R, Wang X R, Zhou T, Li H C 2023 Ship Sci. Technol. 45 1

Google Scholar

Google Scholar

[2] 杜德锋, 何江贤, 孟凡凯 2023 声学技术 42 552

Google Scholar

Google Scholar

Du D F, He J X, Meng F K 2023 Tech. Acoust. 42 552

Google Scholar

Google Scholar

[3] Jiang S D, Bi K M, Ma R S, Xu K 2024 J. Sound Vib. 586 118510

Google Scholar

Google Scholar

[4] Djedoui N, Ounis A 2022 Pract. Period. Struct. Des. Constr. 27 3

Google Scholar

Google Scholar

[5] Nigdeli S M, Bekdas G 2017 KSCE J. Civ. Eng. 912 21

Google Scholar

Google Scholar

[6] Lu Z, Wang Z X, Zhou Y, Lu X L 2018 J. Sound Vib. 423 18

Google Scholar

Google Scholar

[7] 熊怀, 孔宪仁, 刘源 2015 振动工程学报 28 785

Google Scholar

Google Scholar

Xiong H, Kong X R, Liu Y 2015 J. Vib. Eng. 28 785

Google Scholar

Google Scholar

[8] Rong K J, Yang M, Lu Z, Zhang J W, Tian L, Wu S Y 2024 J. Build. Eng. 89 109253

Google Scholar

Google Scholar

[9] Wei C 2024 J. Braz. Soc. Mech. Sci. Eng. 46 120

Google Scholar

Google Scholar

[10] Zhou J H, Zhou J X, Pan H B, Wang K, Cai C Q, Wen G L 2024 Appl. Math. Mech. 45 1189

Google Scholar

Google Scholar

[11] Liu T, Li A Q, Zhang H Y 2024 Mech. Syst. Signal Proc. 206 110852

Google Scholar

Google Scholar

[12] Zhao F, Ji J C, Cao S Q, Ye K, Luo Q T 2024 Nonlinear Dyn. 112 1815

Google Scholar

Google Scholar

[13] Yan G, Lu J J, Qi W H, Liu F R, Yan H, Zhao L C, Wu Z Y, Zhang W M 2024 Nonlinear Dyn. 112 5955

Google Scholar

Google Scholar

[14] Xing X D, Chen Z B, Feng Z Q 2023 J. Vib. Eng. Technol. 11 1595

Google Scholar

Google Scholar

[15] Ma H Y, Wang K, Zhao H F, Zhao C, Xue J, Liang C, Yan B 2023 J. Sound Vib. 565 117905

Google Scholar

Google Scholar

[16] Wang Q, Chen Z X, Wang Y H, Gong N, Yang J, Li W H, Sun S S 2024 Mech. Syst. Signal Proc. 208 111029

Google Scholar

Google Scholar

[17] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[18] Montero De Espinosa F R, Jiménez E, Torres M 1998 Phys. Rev. Lett. 80 1208

Google Scholar

Google Scholar

[19] Hu G B, Austin A C M, Sorokin V, Tang L H 2021 Mech. Syst. Signal Proc. 146 106982

Google Scholar

Google Scholar

[20] Liu Z Y, Zhang X X, Mao Y M, Zhu Y Y, Yang Z Y, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[21] 尹剑飞, 蔡力, 方鑫, 肖勇, 杨海滨, 张弘佳, 钟杰, 赵宏刚, 郁殿龙, 温激鸿 2022 力学进展 52 508

Google Scholar

Google Scholar

Yin J F, Cai L, Fang X, Xiao Y, Yang H B, Zhang H J, Zhong J, Zhao H G, Yu D L, Wen J H 2022 Adv. Mech. 52 508

Google Scholar

Google Scholar

[22] Redondo J, Godinho L, Staliunas K, Sánchez-Pérez J V 2023 Appl. Acoust. 211 109555

Google Scholar

Google Scholar

[23] Wei W, Guan F, Fang X 2024 Appl. Math. Mech. 45 1171

Google Scholar

Google Scholar

[24] Sheng P, Fang X, Wen J H, Yu D L 2021 J. Sound Vib. 492 115739

Google Scholar

Google Scholar

[25] 杜春阳, 郁殿龙, 刘江伟, 温激鸿 2017 66 140701

Google Scholar

Google Scholar

Du C Y, Yu D L, Liu J W, Wen J H 2017 Acta Phys. Sin. 66 140701

Google Scholar

Google Scholar

[26] Cai C Q, Zhou J X, Wang K, Pan H B, Tan D G, Xu D L, Wen G L 2022 Mech. Syst. Signal Proc. 174 109119

Google Scholar

Google Scholar

[27] Wang G, Wan S K, Hong J, Liu S, Li X H 2023 Mech. Syst. Signal Proc. 188 110036

Google Scholar

Google Scholar

[28] Fan X L, Li J Q, Zhang X Y, Li F M 2022 Int. J. Mech. Sci. 236 107742

Google Scholar

Google Scholar

[29] Yao D H, Xiong M K, Luo J Y, Yao L Y 2022 Mech. Syst. Signal Proc. 168 108721

Google Scholar

Google Scholar

[30] Liu Y, Cheng L, Du J T 2022 J. Acoust. Soc. Am. 152 3471

Google Scholar

Google Scholar

[31] Wang S, Wang M Q, Guo Z W 2021 Phys. Lett. A 417 127671

Google Scholar

Google Scholar

[32] Zhou W, Li Y, Yan G, Zhou J 2024 Eur. J. Mech. Solid. 103 105143

Google Scholar

Google Scholar

[33] Zhuang D, Dimitrios C, Jian Y 2021 Appl. Acoust. 178 108013

Google Scholar

Google Scholar

[34] 吴健, 白晓春, 肖勇, 耿明昕, 郁殿龙, 温激鸿 2016 65 064602

Google Scholar

Google Scholar

Wu J, Bai X C, Xiao Y, Geng M X, Yu D L, Wen J H 2016 Acta Phys. Sin. 65 064602

Google Scholar

Google Scholar

[35] 张鑫浩, 赵才友, 郑钧元, 牛亚文, 未娜超 2023 机械科学与技术 42 338

Google Scholar

Google Scholar

Zhang X H, Zhao C Y, Zheng J Y, Niu Y W, Wei N C 2023 Mechanical Science and Technology for Aerospace Engineering 42 338

Google Scholar

Google Scholar

[36] 肖勇 2012 博士学位论文 (长沙: 国防科学技术大学

Xiao Y 2012 Ph. D. Dissertation (Changsha: National University of Defense Technology

[37] Gao Y Q, Wang L F, Sun W, Wu K, Hu H Y 2022 Acta Mech. 233 477

Google Scholar

Google Scholar

[38] 温激鸿, 蔡力, 郁殿龙, 肖勇, 赵宏刚, 尹剑飞, 杨海滨 2018 声学超材料基础理论与应用 (北京: 科学出版社) 第313页

Wen J H, Cai L, Yu D L, Xiao Y, Zhao H G, Yin J F, Yang H B 2018 Basic Theory and Application of Acoustic Metamaterials (Beijing: Science Press) p313

[39] Xiao L, Bursi O S, Li H, Wang M, Du X L 2023 Int. J. Mech. Sci. 237 107770

Google Scholar

Google Scholar

[40] Mu D, Wang K, Shu H S, Lu J H 2022 Int. J. Mech. Sci. 236 107761

Google Scholar

Google Scholar

[41] 郁殿龙 2006 博士学位论文 (长沙: 国防科学技术大学)

Yu D L 2006 Ph. D. Dissertation (Changsha: National University of Defense Technology

[42] Xiao Y, Wang S, Li Y, Wen J H 2021 Mech. Syst. Signal Proc. 159 107777

Google Scholar

Google Scholar

-

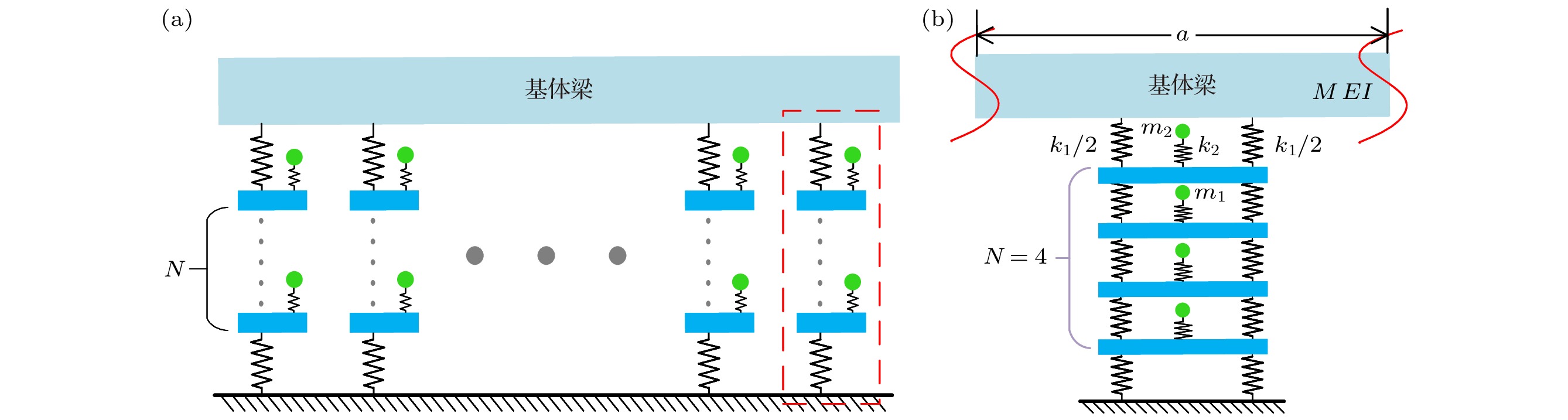

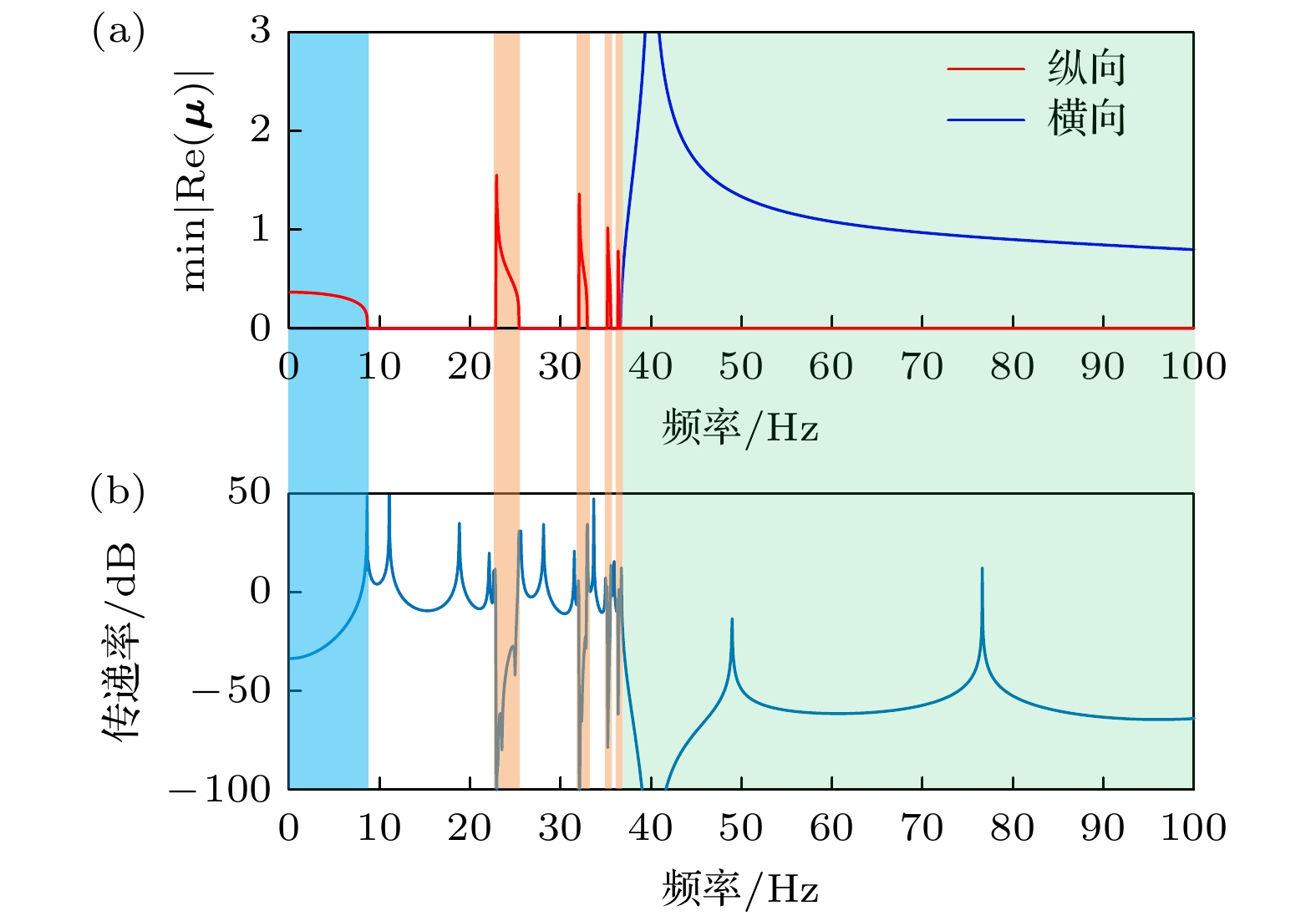

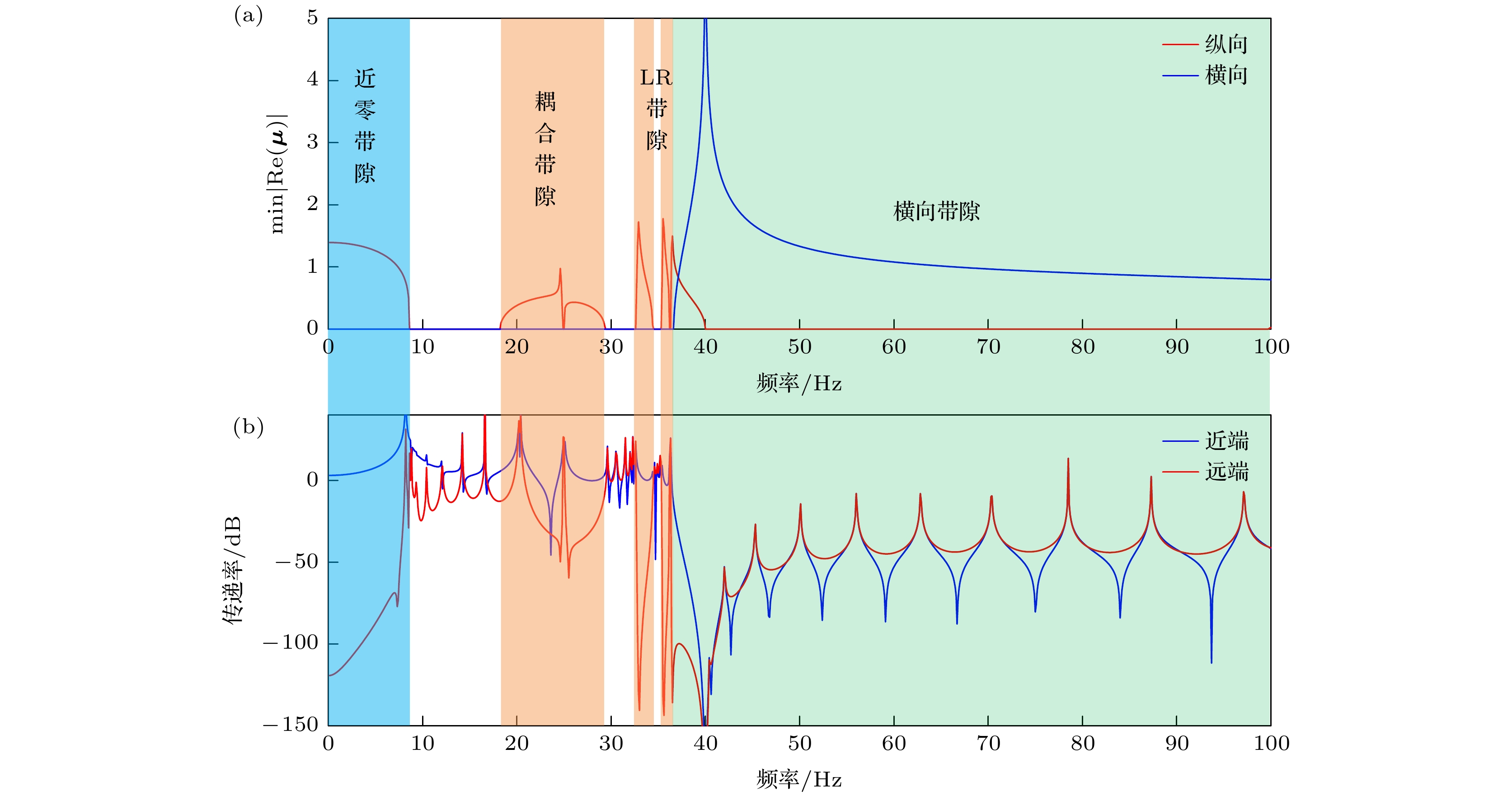

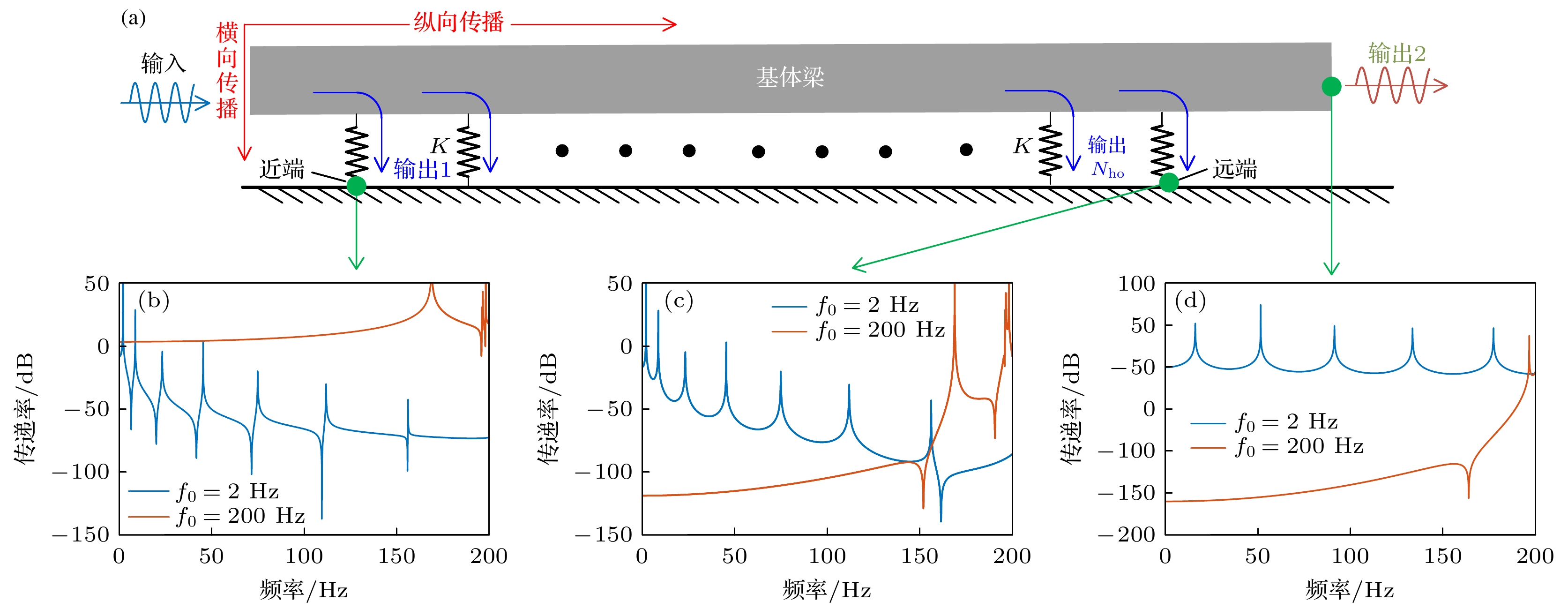

图 1 传统周期支撑梁的振动传递特性分析 (a) 振动传播路径示意图; (b)不同f0下的近端支撑的横向振动传递率; (c) 不同f0下的远端支撑的横向振动传递率; (d)右端截面的纵向振动传递率

Fig. 1. Analysis of vibration propagation in a traditional periodic support structure of a beam: (a) Schematic diagram of the vibration propagation path; (b) transverse vibration transmission ratio of the proximal support at different f0; (c) transverse vibration transmission ratio of the distal support at different f0; (d) longitudinal vibration transmission ratio of the right-end section.

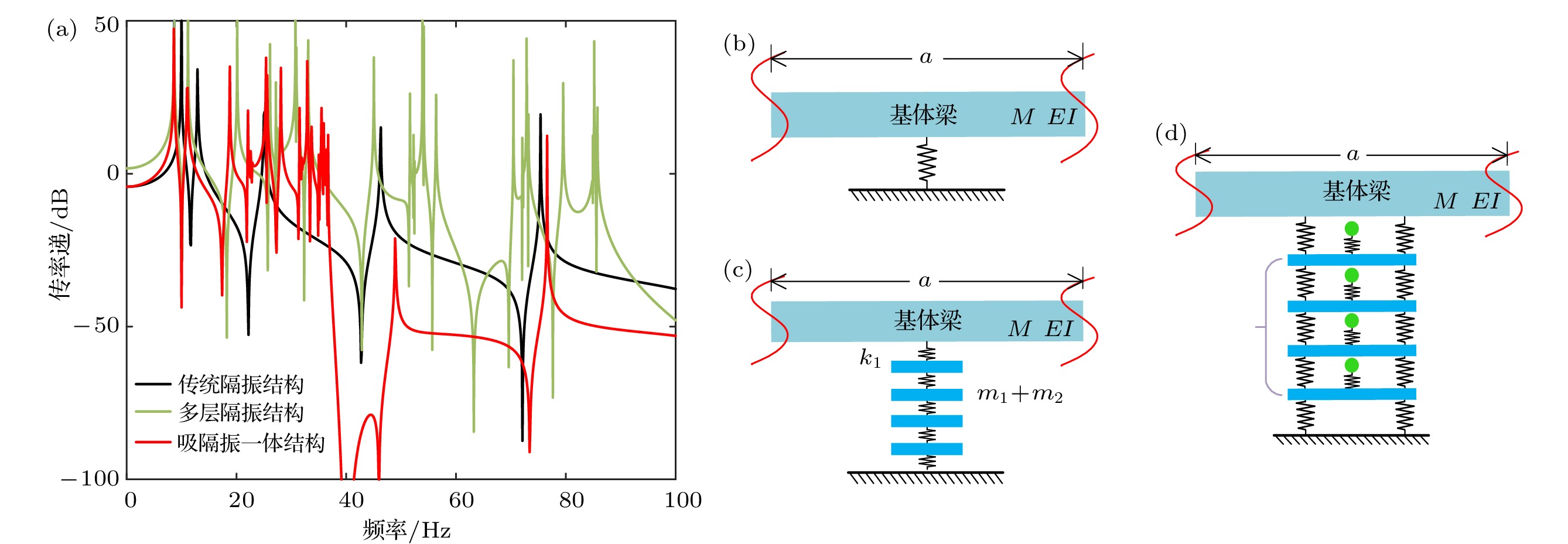

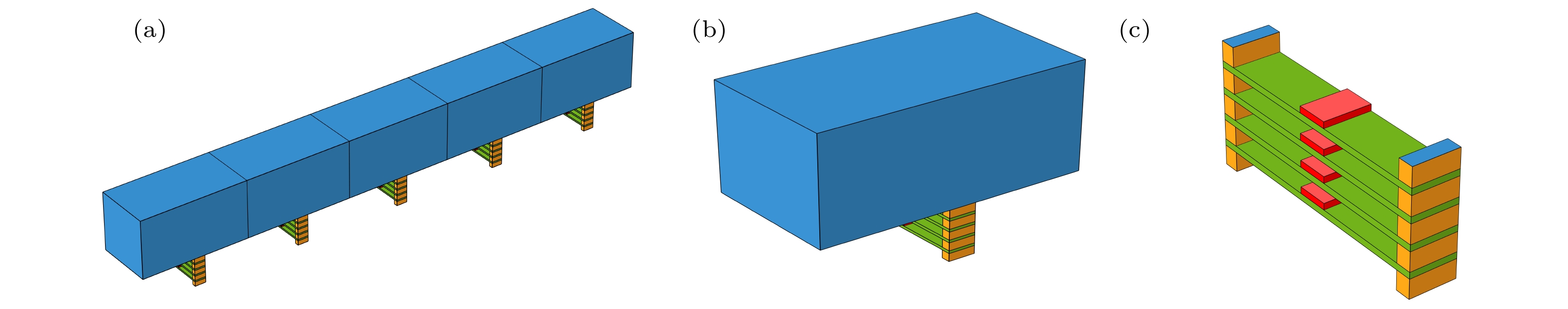

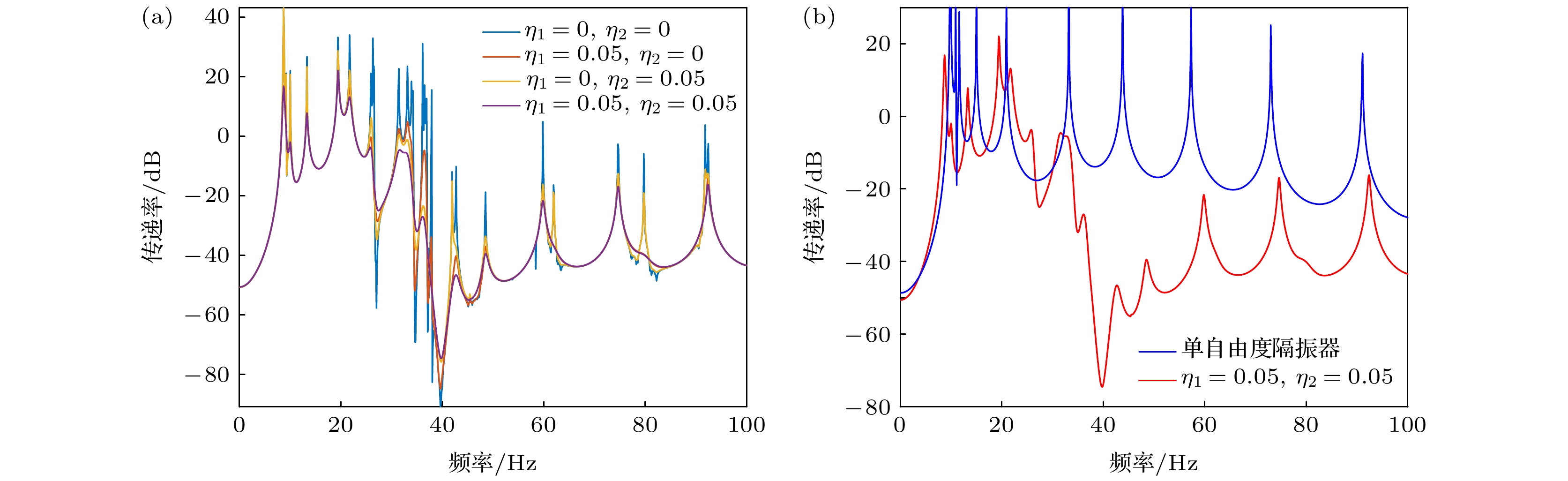

图 3 传统结构和吸隔振一体结构在近端的支撑结构的振动传动率 (a)传递率曲线; (b)传统隔振结构; (c)多层隔振结构; (d)吸隔振一体结构

Fig. 3. Vibration transmission ratio of the traditional structure and the integrated vibration isolation and absorption structure at proximal support structure: (a) Transmission ratio curve; (b) traditional vibration isolation structure; (c) multi-layer vibration isolation structure; (d) integrated vibration isolation and absorption structure.

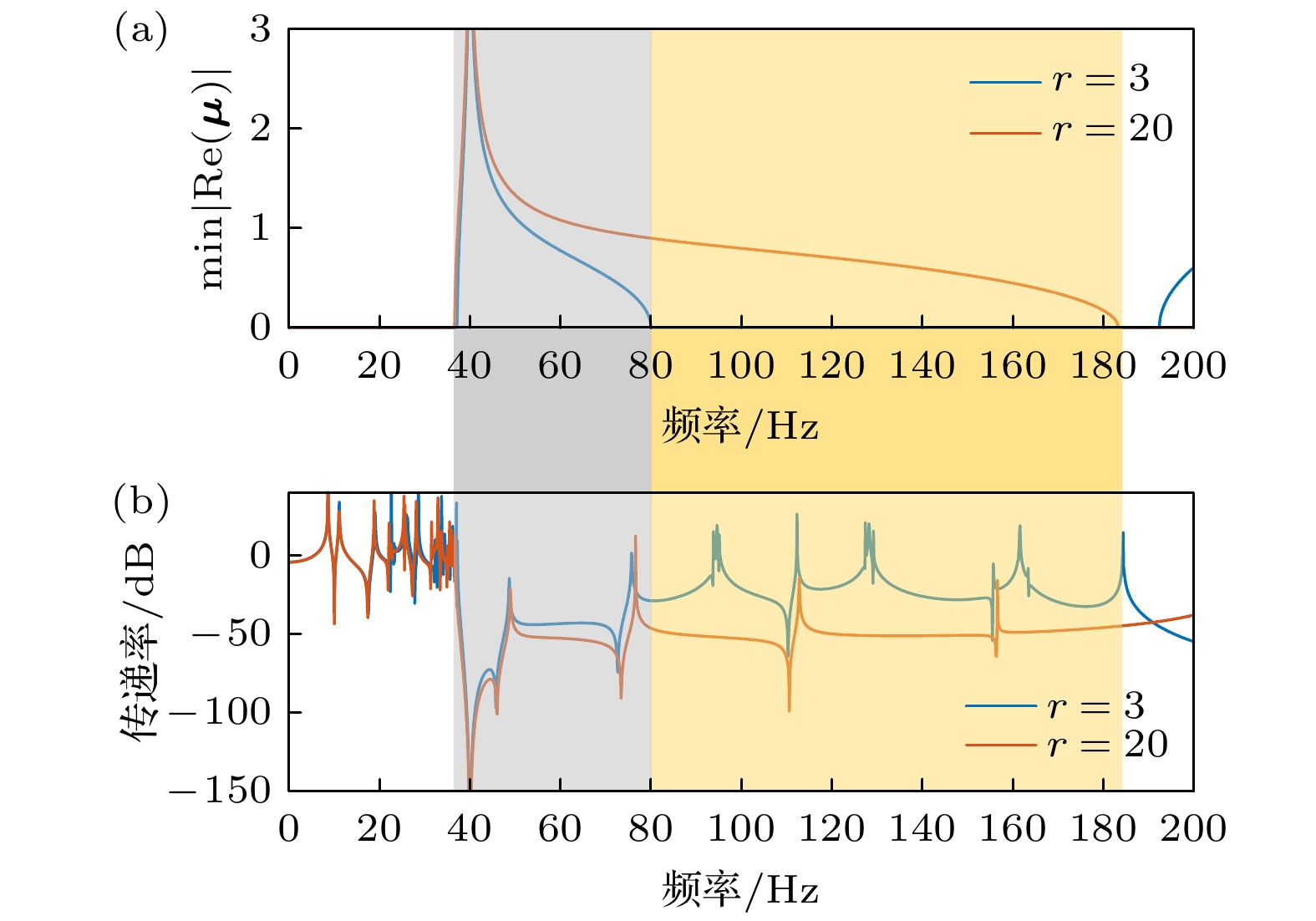

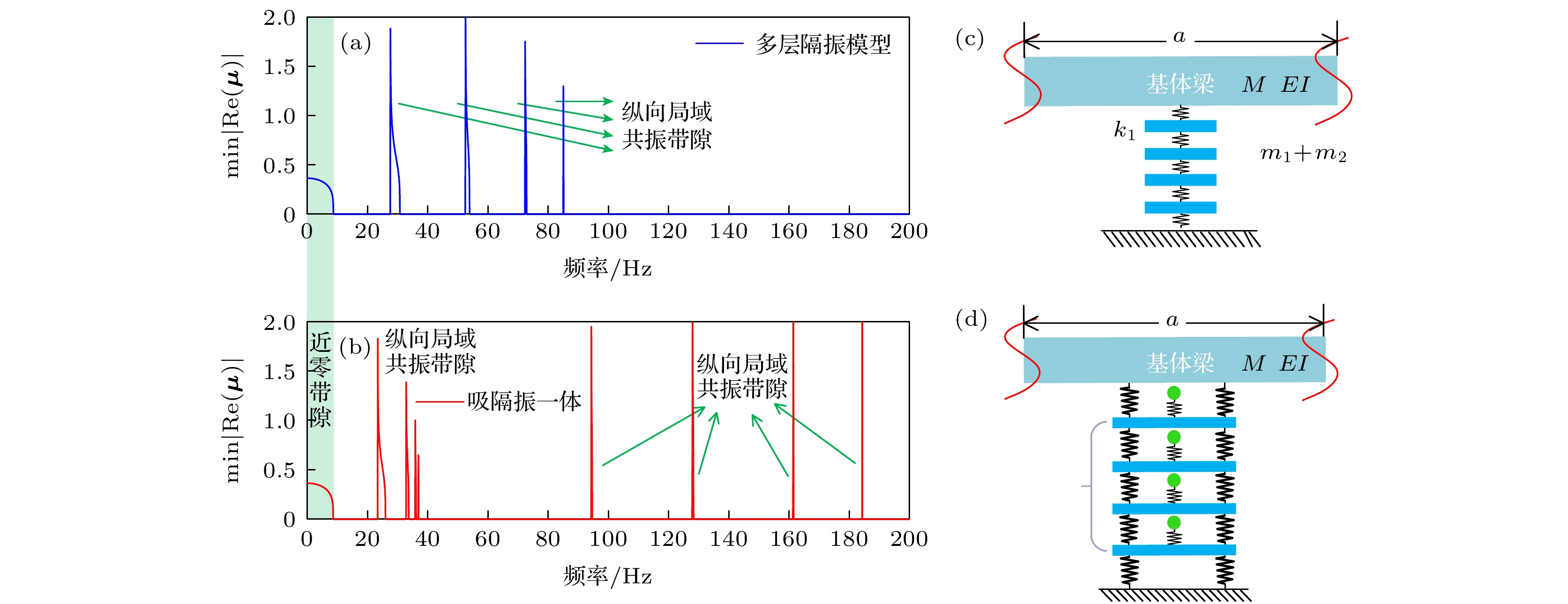

图 5 不同形式支撑梁的元胞模型和对应纵向衰减系数 (a)多层隔振模型纵向衰减系数; (b)吸隔振一体模型纵向衰减系数; (c) 多层隔振模型示意图; (d) 吸隔振一体模型示意图

Fig. 5. Metacell models and corresponding longitudinal attenuation coefficients of support beams in different configurations: (a) Longitudinal attenuation coefficient of the multi-layer vibration isolation model; (b) longitudinal attenuation coefficient of the integrated vibration isolation and absorption model; (c) schematic diagram of multi-layer vibration isolation model; (d) schematic diagram of integrated vibration isolation and absorption model.

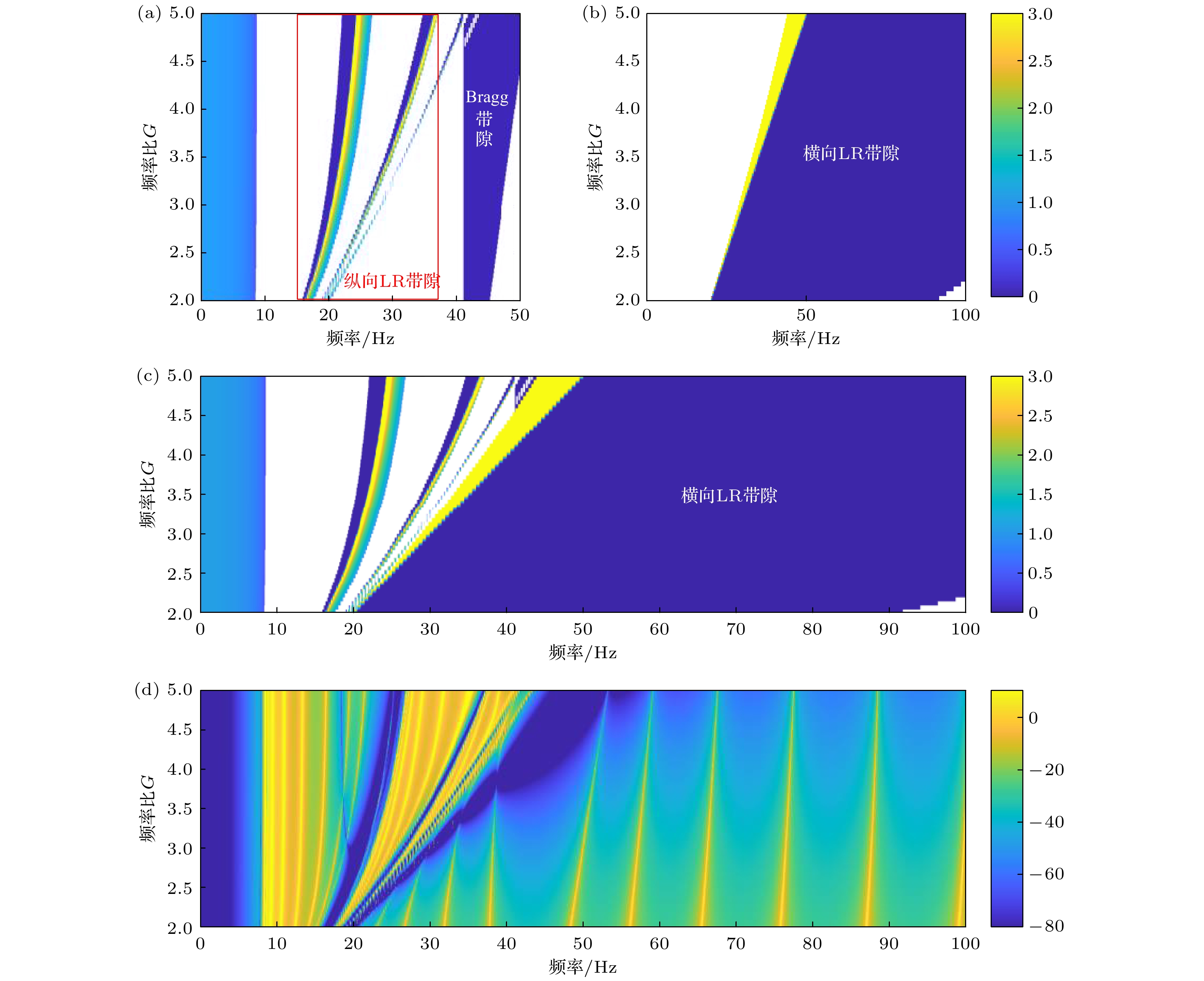

图 7 频率比G的调制规律 (a) G对于纵向带隙的调制规律; (b) G对于横向带隙的调制规律; (c) G对于叠加带隙的影响; (d) G对于传递率的影响

Fig. 7. Modulation rules of frequency ratio G: (a) Modulation rules of G for longitudinal bandgaps; (b) modulation rules of G for transverse bandgaps; (c) the effect of G on superimposed band gaps; (d) the effect of G on transmission ratio.

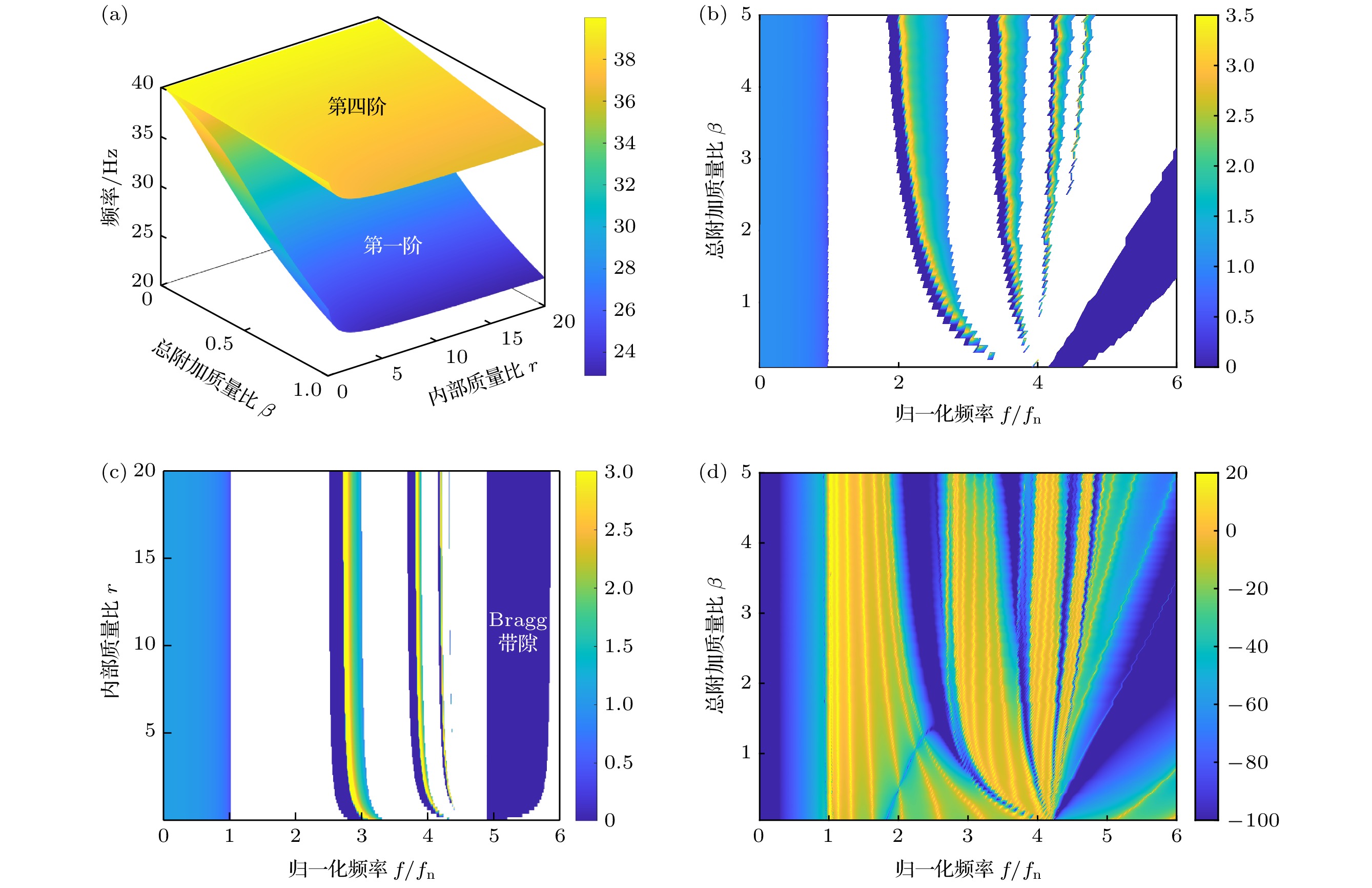

图 8 质量比r和附加质量比$\beta $的调制规律 (a)横向LR带隙起始频率的调制; (b) $\beta $对于横向LR带隙的宽度影响; (c) r对于横向LR带隙的宽度影响; (d)附加质量比$\beta $的归一化传递率

Fig. 8. Modulation law of the mass ratio r and the additional mass ratio $\beta $: (a) Modulation of the starting frequency of the transverse LR bandgap; (b) the effect of the additional mass ratio $\beta $ on the width of the transverse LR bandgap; (c) the effect of r on the width of the transverse LR bandgap; (d) the normalized transfer rate of the additional mass ratio $\beta $.

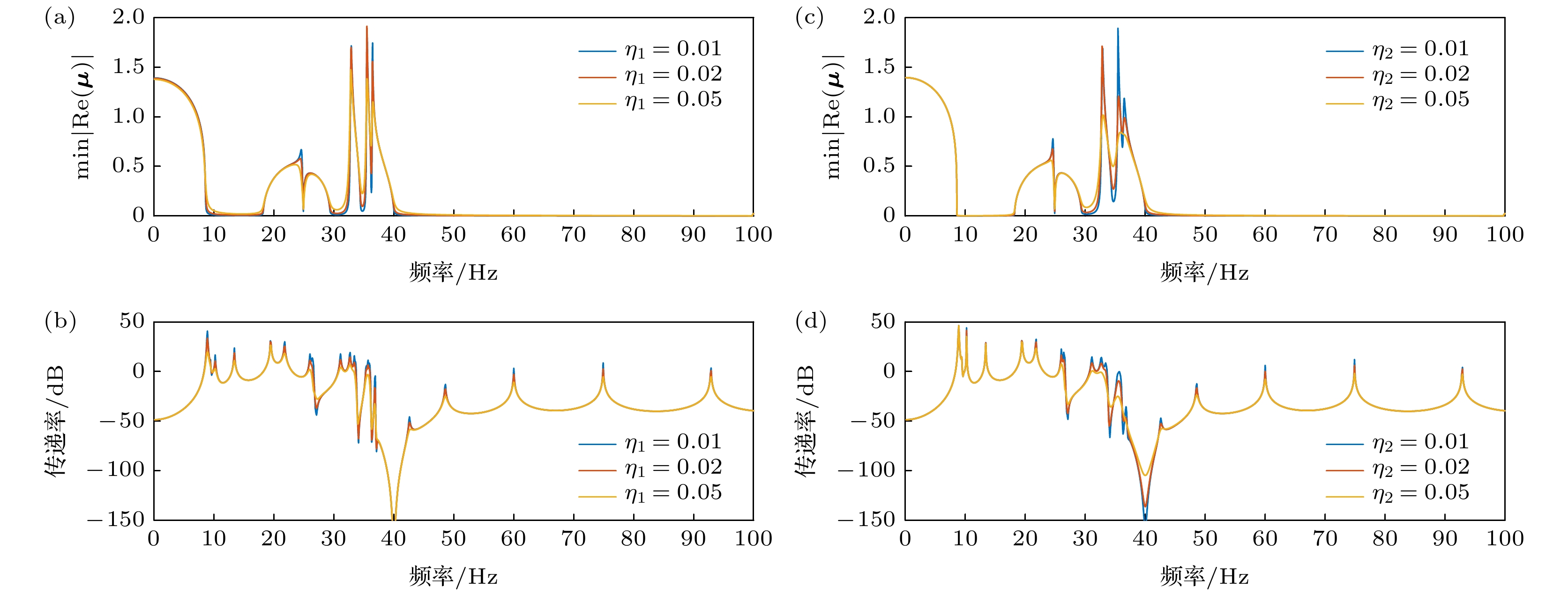

图 11 损耗因子${\eta _1}$和${\eta _2}$对于衰减系数和传递率曲线的影响 (a) 不同损耗因子${\eta _1}$对应的衰减系数; (b) 不同损耗因子${\eta _1}$对应的传递率曲线; (c) 不同损耗因子${\eta _2}$对应的衰减系数; (d) 不同损耗因子${\eta _2}$对应的传递率曲线

Fig. 11. Effects of attenuation factor ${\eta _1}$ and ${\eta _2}$ on attenuation coefficient and transmission ratio curves: (a) Attenuation coefficient corresponding to different ${\eta _1}$; (b) transmission ratio curves corresponding to different ${\eta _1}$; (c) attenuation coefficient corresponding to different ${\eta _2}$; (d) transmission ratio curves corresponding to different ${\eta _2}$.

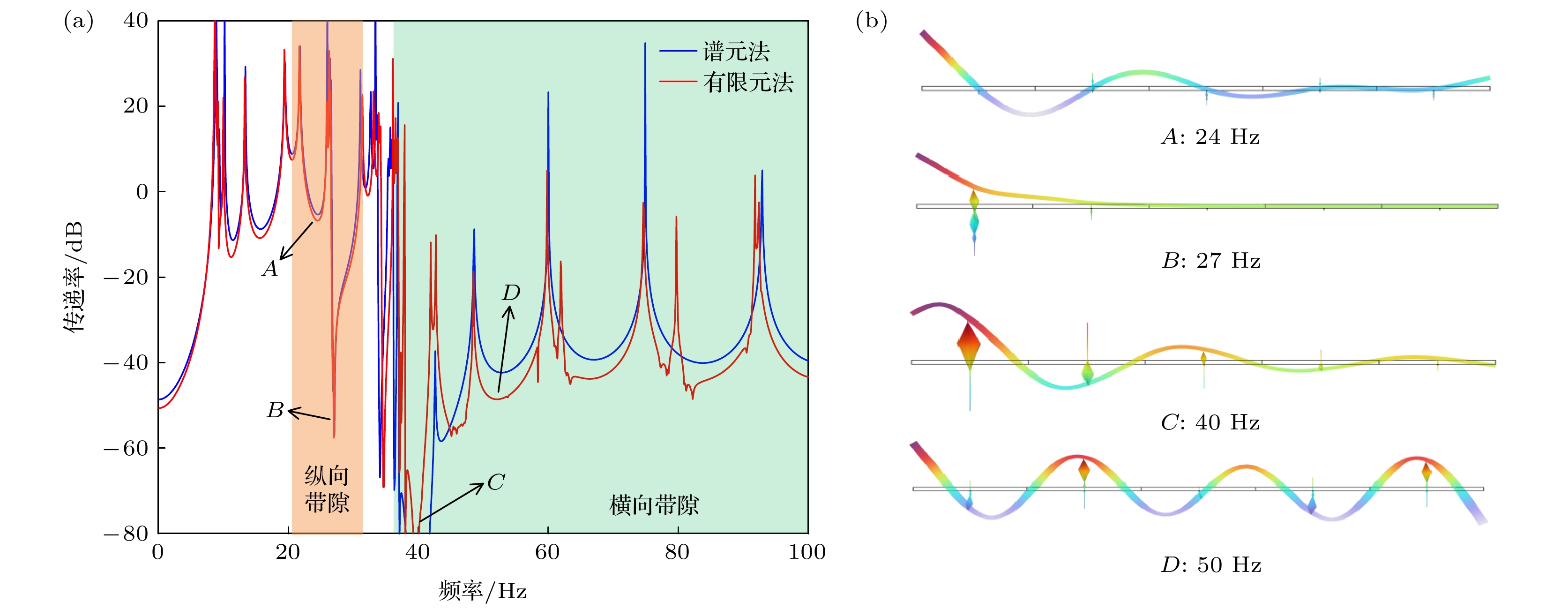

图 13 5周期的吸隔振一体超材料梁的振动特性 (a)谱元法和有限元法计算得到的振动传递率对比; (b)特定频率下的吸隔振一体超材料的振动响应

Fig. 13. Vibration characteristics of the 5-period vibration isolation and absorption integrated metamaterial beam: (a) Comparison of vibration transmission ratios obtained by the spectral element method and the finite element method; (b) vibration response of the integrated vibration isolation and absorption metamaterial at specific frequencies.

表 1 三种耦合方式的带隙宽度和总宽度

Table 1. Bandgap width and total width of the three coupling modes.

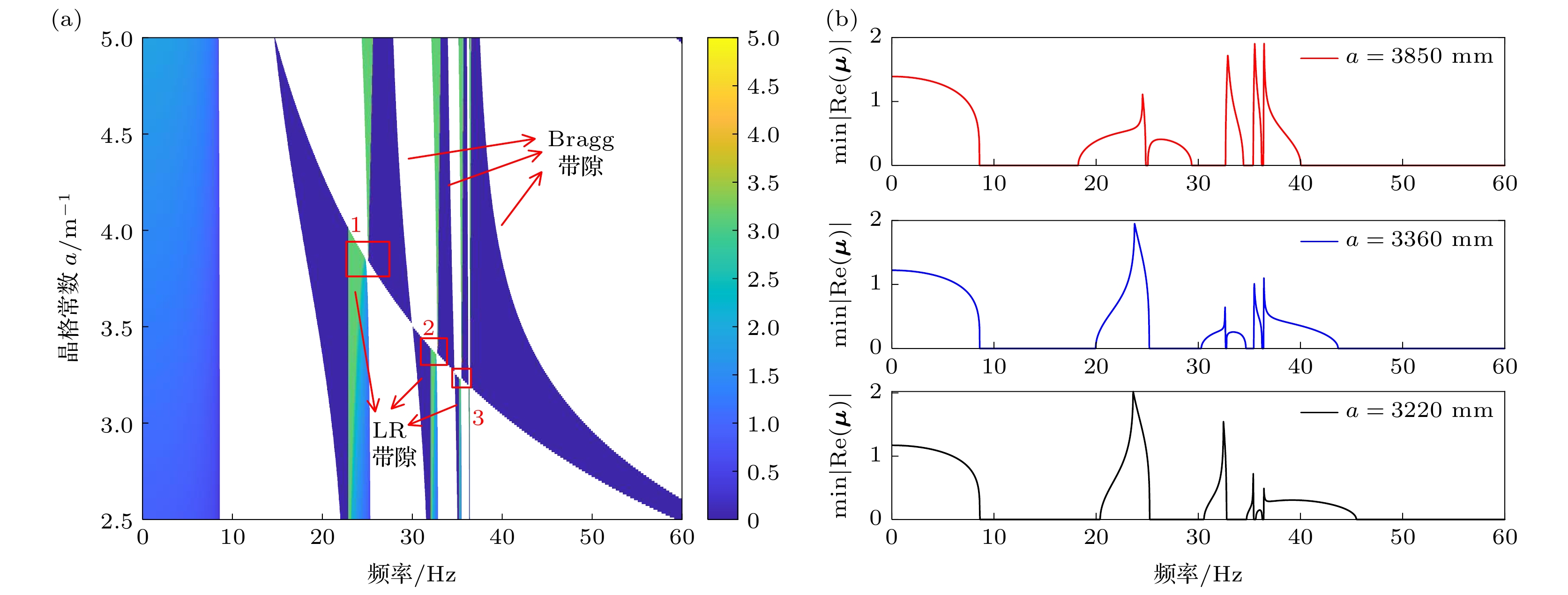

晶格常数 a/mm 3000 3850 3360 3220 1st 起始频率/Hz 21.4—26.0 18.2—29.4 19.9—25.2 20.3—25.2 宽度/Hz 4.4 11.2 5.3 4.9 2nd 起始频率/Hz 31.7—33.8 32.6—34.5 30.2—34.7 30.6—32.8 宽度/Hz 2.1 1.9 4.5 2.2 3rd 起始频率/Hz 35.5—36.1 35.3—36.2 35.4—36.3 34.7—36.3 宽度/Hz 0.6 0.9 0.9 1.6 4th 起始频率/Hz 36.8—37.0 36.3—40 36.4—43.7 36.4—45.5 宽度/Hz 0.2 4.7 7.3 9.1 总宽度/Hz 7.3 18.7 18.0 17.8 -

[1] 苏常伟, 梁冉, 王雪仁, 周涛, 李海超 2023 舰船科学技术 45 1

Google Scholar

Google Scholar

Su C W, Liang R, Wang X R, Zhou T, Li H C 2023 Ship Sci. Technol. 45 1

Google Scholar

Google Scholar

[2] 杜德锋, 何江贤, 孟凡凯 2023 声学技术 42 552

Google Scholar

Google Scholar

Du D F, He J X, Meng F K 2023 Tech. Acoust. 42 552

Google Scholar

Google Scholar

[3] Jiang S D, Bi K M, Ma R S, Xu K 2024 J. Sound Vib. 586 118510

Google Scholar

Google Scholar

[4] Djedoui N, Ounis A 2022 Pract. Period. Struct. Des. Constr. 27 3

Google Scholar

Google Scholar

[5] Nigdeli S M, Bekdas G 2017 KSCE J. Civ. Eng. 912 21

Google Scholar

Google Scholar

[6] Lu Z, Wang Z X, Zhou Y, Lu X L 2018 J. Sound Vib. 423 18

Google Scholar

Google Scholar

[7] 熊怀, 孔宪仁, 刘源 2015 振动工程学报 28 785

Google Scholar

Google Scholar

Xiong H, Kong X R, Liu Y 2015 J. Vib. Eng. 28 785

Google Scholar

Google Scholar

[8] Rong K J, Yang M, Lu Z, Zhang J W, Tian L, Wu S Y 2024 J. Build. Eng. 89 109253

Google Scholar

Google Scholar

[9] Wei C 2024 J. Braz. Soc. Mech. Sci. Eng. 46 120

Google Scholar

Google Scholar

[10] Zhou J H, Zhou J X, Pan H B, Wang K, Cai C Q, Wen G L 2024 Appl. Math. Mech. 45 1189

Google Scholar

Google Scholar

[11] Liu T, Li A Q, Zhang H Y 2024 Mech. Syst. Signal Proc. 206 110852

Google Scholar

Google Scholar

[12] Zhao F, Ji J C, Cao S Q, Ye K, Luo Q T 2024 Nonlinear Dyn. 112 1815

Google Scholar

Google Scholar

[13] Yan G, Lu J J, Qi W H, Liu F R, Yan H, Zhao L C, Wu Z Y, Zhang W M 2024 Nonlinear Dyn. 112 5955

Google Scholar

Google Scholar

[14] Xing X D, Chen Z B, Feng Z Q 2023 J. Vib. Eng. Technol. 11 1595

Google Scholar

Google Scholar

[15] Ma H Y, Wang K, Zhao H F, Zhao C, Xue J, Liang C, Yan B 2023 J. Sound Vib. 565 117905

Google Scholar

Google Scholar

[16] Wang Q, Chen Z X, Wang Y H, Gong N, Yang J, Li W H, Sun S S 2024 Mech. Syst. Signal Proc. 208 111029

Google Scholar

Google Scholar

[17] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[18] Montero De Espinosa F R, Jiménez E, Torres M 1998 Phys. Rev. Lett. 80 1208

Google Scholar

Google Scholar

[19] Hu G B, Austin A C M, Sorokin V, Tang L H 2021 Mech. Syst. Signal Proc. 146 106982

Google Scholar

Google Scholar

[20] Liu Z Y, Zhang X X, Mao Y M, Zhu Y Y, Yang Z Y, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[21] 尹剑飞, 蔡力, 方鑫, 肖勇, 杨海滨, 张弘佳, 钟杰, 赵宏刚, 郁殿龙, 温激鸿 2022 力学进展 52 508

Google Scholar

Google Scholar

Yin J F, Cai L, Fang X, Xiao Y, Yang H B, Zhang H J, Zhong J, Zhao H G, Yu D L, Wen J H 2022 Adv. Mech. 52 508

Google Scholar

Google Scholar

[22] Redondo J, Godinho L, Staliunas K, Sánchez-Pérez J V 2023 Appl. Acoust. 211 109555

Google Scholar

Google Scholar

[23] Wei W, Guan F, Fang X 2024 Appl. Math. Mech. 45 1171

Google Scholar

Google Scholar

[24] Sheng P, Fang X, Wen J H, Yu D L 2021 J. Sound Vib. 492 115739

Google Scholar

Google Scholar

[25] 杜春阳, 郁殿龙, 刘江伟, 温激鸿 2017 66 140701

Google Scholar

Google Scholar

Du C Y, Yu D L, Liu J W, Wen J H 2017 Acta Phys. Sin. 66 140701

Google Scholar

Google Scholar

[26] Cai C Q, Zhou J X, Wang K, Pan H B, Tan D G, Xu D L, Wen G L 2022 Mech. Syst. Signal Proc. 174 109119

Google Scholar

Google Scholar

[27] Wang G, Wan S K, Hong J, Liu S, Li X H 2023 Mech. Syst. Signal Proc. 188 110036

Google Scholar

Google Scholar

[28] Fan X L, Li J Q, Zhang X Y, Li F M 2022 Int. J. Mech. Sci. 236 107742

Google Scholar

Google Scholar

[29] Yao D H, Xiong M K, Luo J Y, Yao L Y 2022 Mech. Syst. Signal Proc. 168 108721

Google Scholar

Google Scholar

[30] Liu Y, Cheng L, Du J T 2022 J. Acoust. Soc. Am. 152 3471

Google Scholar

Google Scholar

[31] Wang S, Wang M Q, Guo Z W 2021 Phys. Lett. A 417 127671

Google Scholar

Google Scholar

[32] Zhou W, Li Y, Yan G, Zhou J 2024 Eur. J. Mech. Solid. 103 105143

Google Scholar

Google Scholar

[33] Zhuang D, Dimitrios C, Jian Y 2021 Appl. Acoust. 178 108013

Google Scholar

Google Scholar

[34] 吴健, 白晓春, 肖勇, 耿明昕, 郁殿龙, 温激鸿 2016 65 064602

Google Scholar

Google Scholar

Wu J, Bai X C, Xiao Y, Geng M X, Yu D L, Wen J H 2016 Acta Phys. Sin. 65 064602

Google Scholar

Google Scholar

[35] 张鑫浩, 赵才友, 郑钧元, 牛亚文, 未娜超 2023 机械科学与技术 42 338

Google Scholar

Google Scholar

Zhang X H, Zhao C Y, Zheng J Y, Niu Y W, Wei N C 2023 Mechanical Science and Technology for Aerospace Engineering 42 338

Google Scholar

Google Scholar

[36] 肖勇 2012 博士学位论文 (长沙: 国防科学技术大学

Xiao Y 2012 Ph. D. Dissertation (Changsha: National University of Defense Technology

[37] Gao Y Q, Wang L F, Sun W, Wu K, Hu H Y 2022 Acta Mech. 233 477

Google Scholar

Google Scholar

[38] 温激鸿, 蔡力, 郁殿龙, 肖勇, 赵宏刚, 尹剑飞, 杨海滨 2018 声学超材料基础理论与应用 (北京: 科学出版社) 第313页

Wen J H, Cai L, Yu D L, Xiao Y, Zhao H G, Yin J F, Yang H B 2018 Basic Theory and Application of Acoustic Metamaterials (Beijing: Science Press) p313

[39] Xiao L, Bursi O S, Li H, Wang M, Du X L 2023 Int. J. Mech. Sci. 237 107770

Google Scholar

Google Scholar

[40] Mu D, Wang K, Shu H S, Lu J H 2022 Int. J. Mech. Sci. 236 107761

Google Scholar

Google Scholar

[41] 郁殿龙 2006 博士学位论文 (长沙: 国防科学技术大学)

Yu D L 2006 Ph. D. Dissertation (Changsha: National University of Defense Technology

[42] Xiao Y, Wang S, Li Y, Wen J H 2021 Mech. Syst. Signal Proc. 159 107777

Google Scholar

Google Scholar

计量

- 文章访问数: 4878

- PDF下载量: 222

- 被引次数: 0

下载:

下载: