-

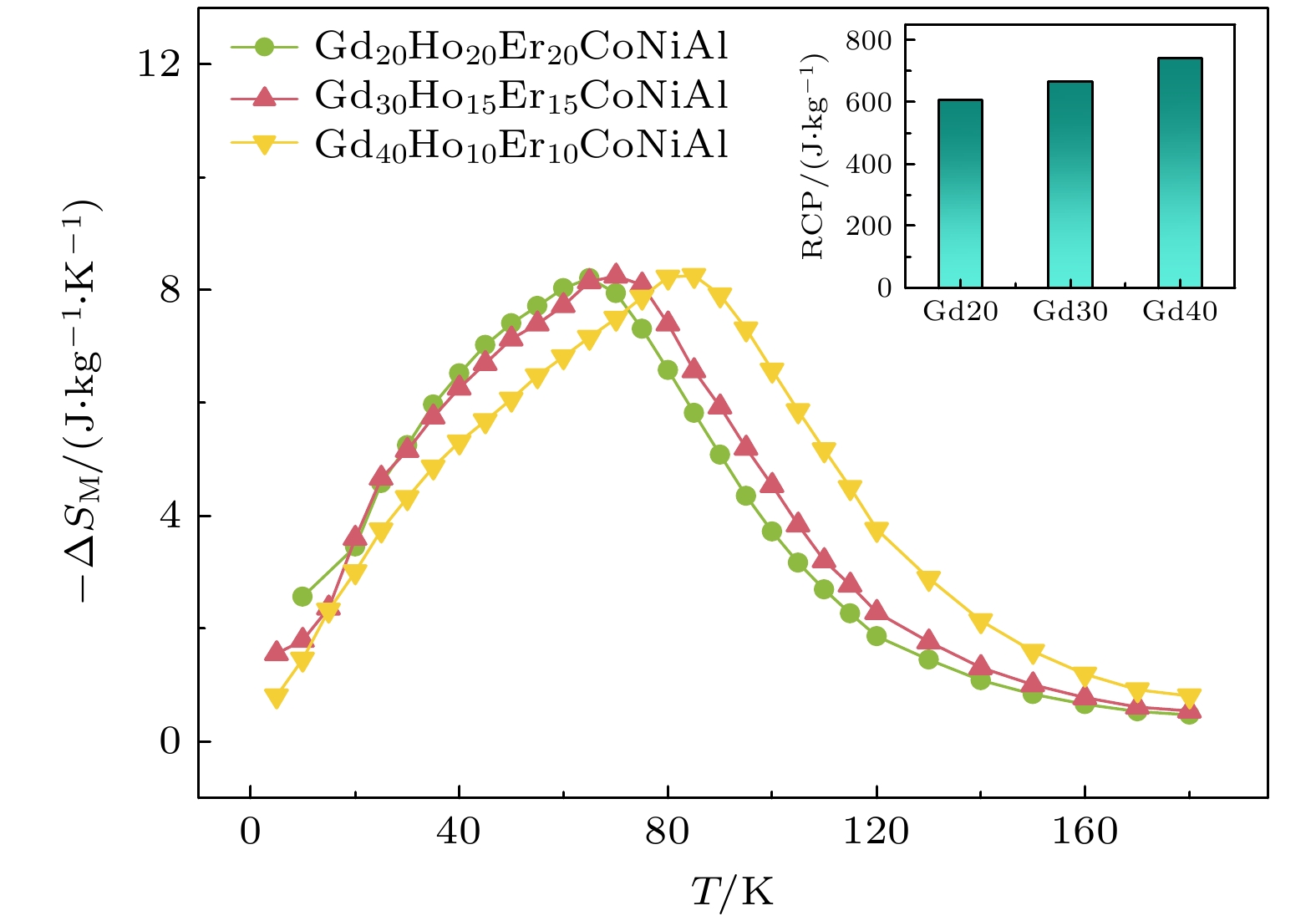

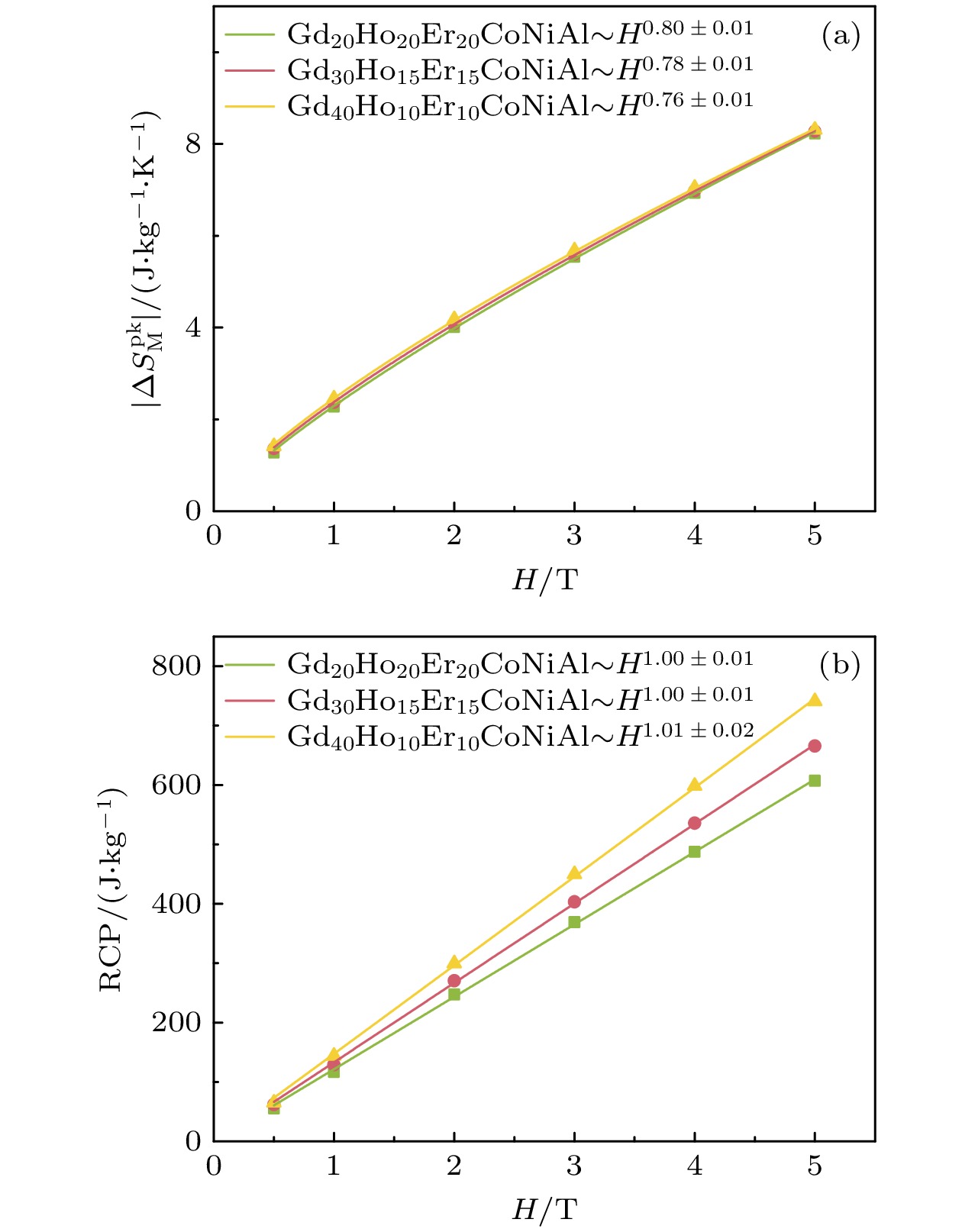

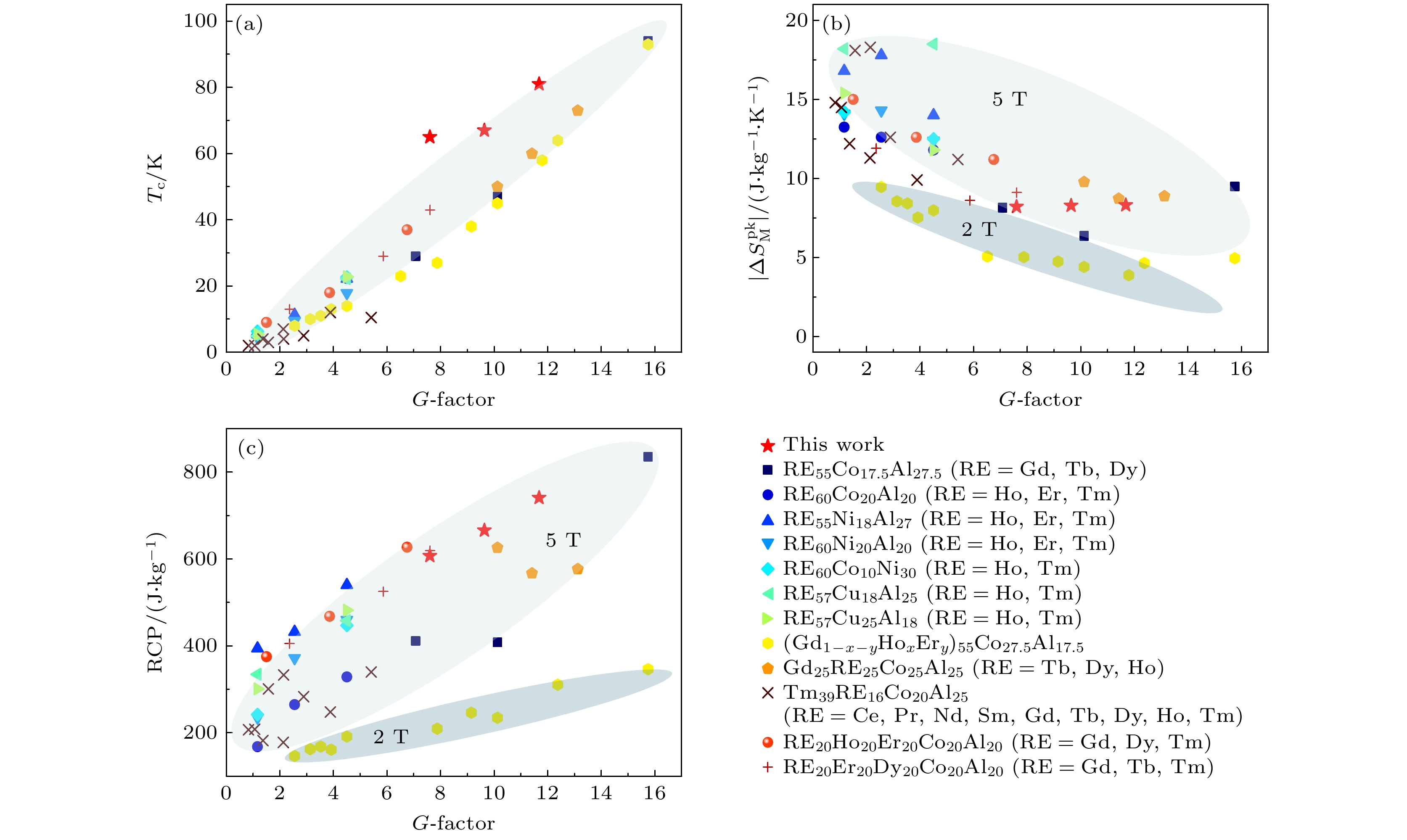

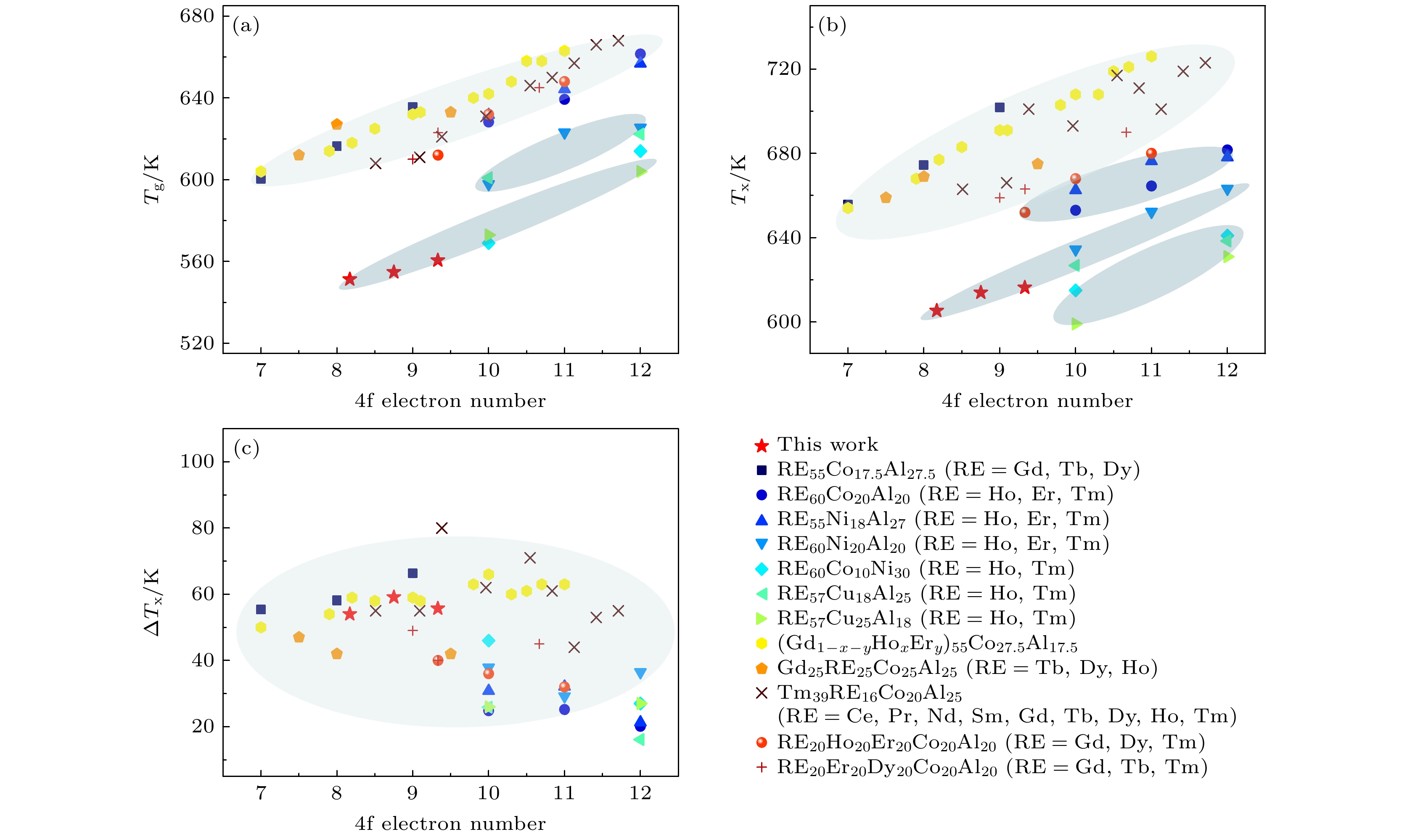

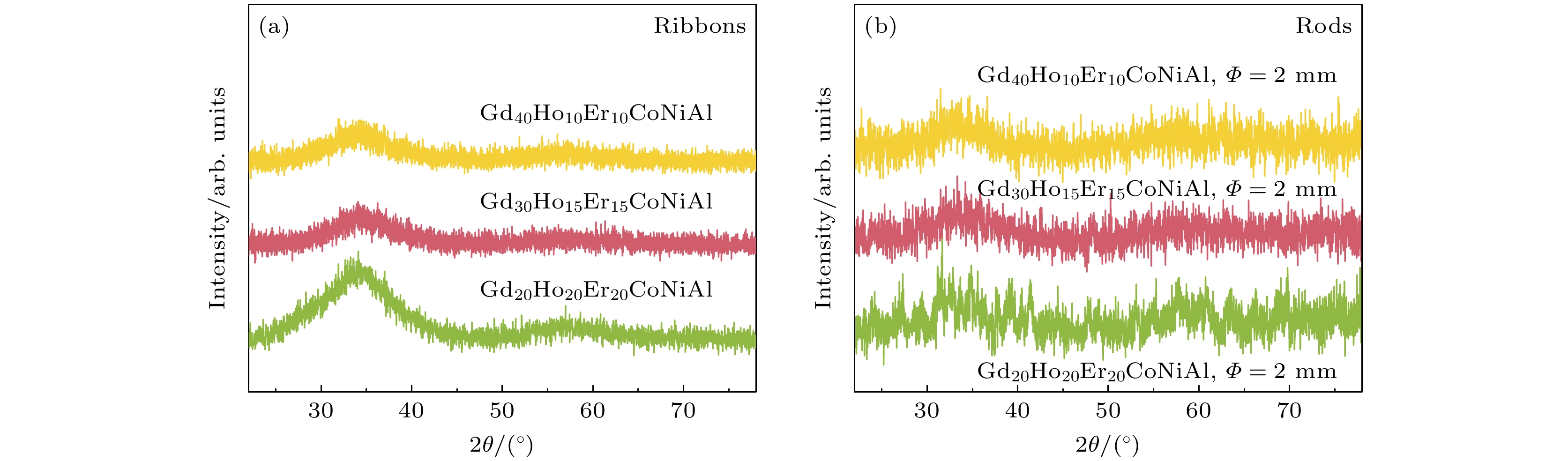

通过对Gd, Ho和Er进行元素替换, 成功设计制备出临界尺寸为2 mm的Gd20+2xHo20–xEr20–xCo20Ni10Al10 (x = 0, 5, 10) 块体高熵非晶合金体系, 系统研究了稀土元素种类和含量对高熵非晶合金的微观结构、热力学性能和磁热性能的影响及调控机理. 研究结果表明, 随着Ho和Er逐步被Gd取代, 体系的热稳定性略有下降, 其中, 玻璃转变温度Tg和初始晶化温度Tx逐渐降低. 与此同时, 液相线温度Tl升高, 导致玻璃形成能力的热力学判据, 如约化玻璃转变温度Trg, γ和γm降低. X射线和高分辨透射电子显微镜的结果分析表明, 随着Gd含量的增大, 体系的有序度减小, 有利于非晶相的生成. 另一方面, 随着Gd元素的加入, 磁热性能参量如居里温度Tc、峰值磁熵变($ | {\Delta S_{\text{M}}^{{\text{pk}}}} | $)和相对制冷能力(relative cooling power, RCP)均逐渐升高, 其中Gd40Ho10Er10CoNiAl的$ | {\Delta S_{\text{M}}^{{\text{pk}}}} | $和RCP最大, 分别为8.31 J/(kg·K)和740.82 J/kg. 研究结果表明, 稀土基高熵非晶合金体系的磁热效应包括RCP, Tc和$ | {\Delta S_{\text{M}}^{{\text{pk}}}} | $主要依赖于de Gennes因子, 与材料内部的有效磁矩并无直接关系, 而热力学性能主要受到4f电子引起的f-d杂化效应影响, 随着4f电子数的增加非晶合金体系的热稳定逐步增加. 综上所述, 我们可以借助稀土元素替换进行成分优选, 通过调控4f电子数获得具有较高热稳定性且Tc可调的稀土基非晶合金磁热材料.In this work, Gd20+2xHo20–xEr20–xCo20Ni10Al10 (x = 0, 5, 10) high-entropy metallic glasses (MGs) with a critical diameter of 2 mm are successfully designed and fabricated by substituting Gd, Ho and Er. The effects of type and content of rare-earth (RE) elements on the microstructure, thermodynamic behaviors, and magnetocaloric effect (MCE) are investigated systematically. The amorphous structures of the ribbons and as-cast rods are confirmed by X-ray diffraction (XRD) with Cu Kα radiation (2θ = 20°–80°). The atomic-scale ordered configurations are examined by using high-resolution transmission electron microscope (HRTEM). Thermal analysis is carried out on differential scanning calorimeter (DSC) with a heating rate of 20 K/min by using ribbons. The magnetic measurements are conducted by using magnetometer in a temperature range of 5–180 K. According to DSC traces, it is suggested that as Ho and Er are replaced by Gd, the thermal stability of MGs slightly decreases, for example, both glass transition temperature (Tg) and initial crystallization temperature (Tx) decrease gradually, meanwhile the liquidus temperature (Tl) increases, which results in a reduction of glass-forming ability criteria such as the reduced glass transition temperatures Trg (Trg = Tg/Tl), γ (γ = Tx/(Tg + Tl)), and γm (γm = (2Tx – Tg)/Tl), thermodynamically. The analyses based on XRD and HRTEM show that the degree of order in MGs decreases with Gd content increasing, which facilitates the glass formation. The magnetocaloric parameters such as Curie temperature (Tc), maximum magnetic entropy change ($ | {\Delta S_{\text{M}}^{{\text{pk}}}} | $) and relative cooling power (RCP) all increase gradually with the addition of Gd. The Gd40Ho10Er10CoNiAl exhibits the best refrigeration performance in all studied systems, where the peak value of $ |{\Delta S}_{{\mathrm{M}}}| $ is 8.31 J/(kg·K) and RCP is 740.82 J/kg. The results indicate that MCEs of MGs including RCP, Tc and $ | {\Delta S_{\text{M}}^{{\text{pk}}}} | $, mainly depend on the de Gennes factor rather than the effective magnetic moment, while thermodynamic properties are more affected by the f-d hybridization effect. As the number of 4f electrons increases, the thermal stability increases with the degree f-d orbital hybridization increasing. In summary, the RE-based MG with high thermal stability and adjustable Tc can be achieved by the RE substitution via adjusting the number of 4f electrons.

-

Keywords:

- rare-earth based high-entropy metallic glasses /

- thermodynamic properties /

- magnetocaloric effect /

- glass forming ability

[1] Gschneidner K A, Pecharsky V, Tsokol A 2005 Rep. Prog. Phys. 68 1479

Google Scholar

Google Scholar

[2] Uporov S, Ryltsev R, Bykov V, Uporova N, Estemirova S K, Chtchelkatchev N 2021 J. Alloys Compd. 854 157170

Google Scholar

Google Scholar

[3] Warburg E 1881 Ann. Der. Phys. 249 141

Google Scholar

Google Scholar

[4] Debye P 1926 Ann. Der. Phys. 386 1154

Google Scholar

Google Scholar

[5] Giauque W F 1927 J. Am. Chem. Soc. 49 1864

Google Scholar

Google Scholar

[6] Pecharsky V K, Gschneidner Jr K A 1997 Phys. Rev. Lett. 78 4494

Google Scholar

Google Scholar

[7] Pecharsky V K, Gschneidner Jr K A 1997 Appl. Phys. Lett. 70 3299

Google Scholar

Google Scholar

[8] Jia Y S, Zhao X Y, Liu X L, Li L W 2020 J. Alloys Compd. 813 152177

Google Scholar

Google Scholar

[9] Zhang Y K, Zhu J, Li S, Zhang B, Wang Y M, Wang J, Ren Z M 2022 J. Alloys Compd. 895 162633

Google Scholar

Google Scholar

[10] Wang Q, Pan L L, Tang B Z, Ding D, Xia L 2022 J. Non-Cryst. Solids 580 121394

Google Scholar

Google Scholar

[11] Luo Q, Zhao D Q, Pan M X, Wang W H 2007 Appl. Phys. Lett. 90 211903

Google Scholar

Google Scholar

[12] Lim X 2016 Nature 533 306

Google Scholar

Google Scholar

[13] Huo J T, Huo L S, Li J W, Men H, Wang X M, Inoue A, Chang C T, Wang J Q, Li R W 2015 J. Appl. Phys. 117 073902

Google Scholar

Google Scholar

[14] Huo J T, Huo L S, Men H, Wang X M, Inoue A, Wang J, Chang C T, Li R W 2015 Intermetallics 58 31

Google Scholar

Google Scholar

[15] Sheng W, Wang J Q, Wang G, Huo J T, Wang X, Li R W 2018 Intermetallics 96 79

Google Scholar

Google Scholar

[16] Li J W, Xue L, Yang W, Yuan C, Huo J T, Shen B 2018 Intermetallics 96 90

Google Scholar

Google Scholar

[17] Zhang Y K, Zhu J, Li S, Wang J, Ren Z M 2022 J. Mater. Sci. Technol. 102 66

Google Scholar

Google Scholar

[18] Li L W, Xu C, Yuan Y, Zhou S Q 2018 Materialia 3 74

Google Scholar

Google Scholar

[19] Yang Y, Chen Y, Yu P, Qian L J, Wu F F, Cui Y T, Wu Z M, Ding D, Xia L 2015 J. Nanosci. Nanotechnol. 15 3295

Google Scholar

Google Scholar

[20] Li L W, Xu C, Yuan Y, Zhou S Q 2018 Mater. Res. Lett. 6 413

Google Scholar

Google Scholar

[21] Dong Z Q, Wang Z J, Yin S H 2020 J. Magn. Magn. Mater. 514 167270

Google Scholar

Google Scholar

[22] Luo L, Shen H X, Bao Y, Yin H B, Jiang S D, Huang Y J, Guo S Y, Gao S, Xing D W, Li Z, Sun J F 2020 J. Magn. Magn. Mater. 507 166856

Google Scholar

Google Scholar

[23] Zhang Y K, Xu P, Zhu J, Yan S, Zhang J, Li L W 2023 Mater. Today Phys. 32 101031

Google Scholar

Google Scholar

[24] Zhang Y K, Zhu J, Hao Z, Hao W, Mo Z, Li L W 2023 Mater. Des. 229 111894

Google Scholar

Google Scholar

[25] Civan E, Sarlar K, Kucuk I 2017 Philos. Mag. 97 1464

Google Scholar

Google Scholar

[26] Johnson F, Shull R D 2006 J. Appl. Phys. 99 08K909

Google Scholar

Google Scholar

[27] Kucuk I, Sarlar K, Adam A, Civan E 2016 Philos. Mag. 96 3120

Google Scholar

Google Scholar

[28] Wu K N, Liu C, Li Q, Huo J T, Li M C, Chang C T, Sun Y F 2019 J. Magn. Magn. Mater. 489 165404

Google Scholar

Google Scholar

[29] Wang G F, Li H L, Zhao Z R, Zhang X F 2017 J. Alloys Compd. 692 793

Google Scholar

Google Scholar

[30] Lv Y B, Chen Q J, Huang Y L 2019 J. Rare Earth. 37 404

Google Scholar

Google Scholar

[31] Guo D, Moreno-Ramírez L M, Romero-Muñiz C, Zhang Y K, Law J Y, Franco V, Wang J, Ren Z M 2021 Sci. China Mater. 64 2846

Google Scholar

Google Scholar

[32] Xue L, Shao L L, Li Z, Han Z D, Zhang B S, Huo J T, Wang X M, Zhu S S, Qian B, Cheng J B, Shen B L 2022 J. Mater. Res. Technol. 18 5301

Google Scholar

Google Scholar

[33] Lindner N, Śniadecki Z, Kołodziej M, Grenèche J M, Marcin J, Škorvánek I, Idzikowski B 2022 J. Mater. Sci. 57 553

Google Scholar

Google Scholar

[34] Zheng Z G, Qiu Z G, Zeng D C 2019 Mater. Res. Express 6 096109

Google Scholar

Google Scholar

[35] Law J Y, Ramanujan R V, Franco V 2010 J. Alloys Compd. 508 14

Google Scholar

Google Scholar

[36] 糜晓磊, 胡亮, 武博文, 龙强, 魏炳波 2024 73 097102

Google Scholar

Google Scholar

Mi X L, Hu L, Wu B W, Long Q, Wei B B 2024 Acta Phys. Sin. 73 097102

Google Scholar

Google Scholar

[37] Xue L, Shao L L, Luo Q, Shen B L 2019 J. Alloys Compd. 790 633

Google Scholar

Google Scholar

[38] Wei S J, Shen H X, Zhang L Y, Luo L, Tang X X, Sun J F, Li X Q 2024 Rare Metals 43 1234

Google Scholar

Google Scholar

[39] Lu S F, Ma L, Wang J, Du Y S, Li L W, Zhao J T, Rao G H 2021 J. Alloys Compd. 874 159918

Google Scholar

Google Scholar

[40] Yeh J W 2013 JOM 65 1759

Google Scholar

Google Scholar

[41] Ma E, Wu X L 2019 Nat. Commun. 10 5623

Google Scholar

Google Scholar

[42] Gu J L, Luan H W, Zhao S F, Bu H T, Si J J, Shao Y, Yao K F 2020 Mater. Sci. Eng. A 786 139417

Google Scholar

Google Scholar

[43] Xue L, Shao L L, Zhang B S, Li Z, Cheng J B, Shen B L 2024 J. Rare Earth. 42 129

Google Scholar

Google Scholar

[44] Pang C M, Yuan C C, Chen L, Xu H, Guo K, He J C, Li Y, Wei M S, Wang X M, Huo J T, Shen B L 2020 J. Non-Cryst. Solids 549 120354

Google Scholar

Google Scholar

[45] Pang C M, Chen L, Xu H, Guo W, Lv Z W, Huo J T, Cai M J, Shen B L, Wang X L, Yuan C C 2020 J. Alloys Compd. 827 154101

Google Scholar

Google Scholar

[46] Wang X, Tang B Z, Wang Q, Yu P, Ding D, Xia L 2020 J. Non-Cryst. Solids 544 120146

Google Scholar

Google Scholar

[47] Hao F, Lin H, Zhou C, Liu Y Z, Li J B 2011 Phys. Chem. Chem. Phys. 13 15918

Google Scholar

Google Scholar

[48] Wang Q, Liu C T, Yang Y, Liu J B, Dong Y D, Lu J 2014 Sci. Rep. 4 4648

Google Scholar

Google Scholar

[49] Imafuku M, Yaoita K, Sato S, Zhang W, Inoue A, Waseda Y 2001 Mater. Sci. Eng. A 304 660

Google Scholar

Google Scholar

[50] Wang W H 2009 Adv. Mater. 21 4524

Google Scholar

Google Scholar

[51] Yuan C C, Shen X, Cui J, Gu L, Yu R C, Xi X K 2012 Appl. Phys. Lett. 101 021902

Google Scholar

Google Scholar

[52] Liu Z H, Zhang Y K J, Liu E K, Liu G D, Ma X Q, Wu G H 2015 J. Phys. D Appl. Phys. 48 325001

Google Scholar

Google Scholar

[53] Yuan C C, Yang F, Xi X K, Shi C L, Holland-Moritz D, Li M Z, Hu F, Shen B L, Wang X L, Meyer A, Wang W H 2020 Mater. Today 32 26

Google Scholar

Google Scholar

[54] Jin F, Pang C M, Wang X M, Yuan C C 2023 J. Non-Cryst. Solids 600 121992

Google Scholar

Google Scholar

[55] Inoue A 2000 Acta Mater. 48 279

Google Scholar

Google Scholar

[56] Lu Z P, Tan H, Ng S C, Li Y 2000 Scr. Mater. 42 667

Google Scholar

Google Scholar

[57] Lu Z P, Liu C T 2002 Acta Mater. 50 3501

Google Scholar

Google Scholar

[58] Lu Z P, Liu C T 2003 Phys. Rev. Lett. 91 115505

Google Scholar

Google Scholar

[59] Du X H, Huang J C, Liu C T, Lu Z P 2007 J. Appl. Phys. 101 086108

Google Scholar

Google Scholar

[60] Zhang W, Jia F, Zhang X, Xie G, Inoue A 2010 Metall. Mater. Trans. A 41 1685

Google Scholar

Google Scholar

[61] Zhang Y K, Guo D, Wu B B, Wang H F, Guan R G, Li X, Ren Z M 2020 J. Appl. Phys. 127 033905

Google Scholar

Google Scholar

[62] Yin H, Wang J Q, Huang Y, Shen H X, Guo S, Fan H, Huo J T, Sun J 2023 J. Mater. Sci. Technol. 149 167

Google Scholar

Google Scholar

[63] Zhong H X, Li K, Zhang Q, Wang J, Meng F L, Wu Z J, Yan J M, Zhang X B 2016 NPG Asia Mater. 8 e308

Google Scholar

Google Scholar

[64] Franco V, Blázquez J, Conde A 2006 J. Appl. Phys. 89 222512

Google Scholar

Google Scholar

[65] Zhang H Y, Li R, Zhang L L, Zhang T 2014 J. Appl. Phys. 115 133903

Google Scholar

Google Scholar

[66] Yosida K 1957 Phys. Rev. 107 396

Google Scholar

Google Scholar

[67] Banerjee B 1964 Phys. Lett. 12 16

Google Scholar

Google Scholar

[68] Franco V, Conde A, Romero-Enrique J M, Blázquez J S 2008 J. Phys. Condens. Matter 20 285207

Google Scholar

Google Scholar

[69] Oesterreicher H, Parker F 1984 J. Appl. Phys. 55 4334

Google Scholar

Google Scholar

[70] Guo D, Zhang Y K, Geng S H, Xu H, Ren Z M, Wilde G 2018 J. Mater. Sci. 53 9816

Google Scholar

Google Scholar

[71] Zhang Y K, Li H D, Geng S H, Lu X G, Wilde G 2019 J. Alloys Compd. 770 849

Google Scholar

Google Scholar

[72] Dong Z Q, Yin S H 2020 J. Magn. Magn. Mater. 495 165888

Google Scholar

Google Scholar

[73] Huo J T, Zhao D Q, Bai H Y, Axinte E, Wang W H 2013 J. Non-Cryst. Solids 359 1

Google Scholar

Google Scholar

-

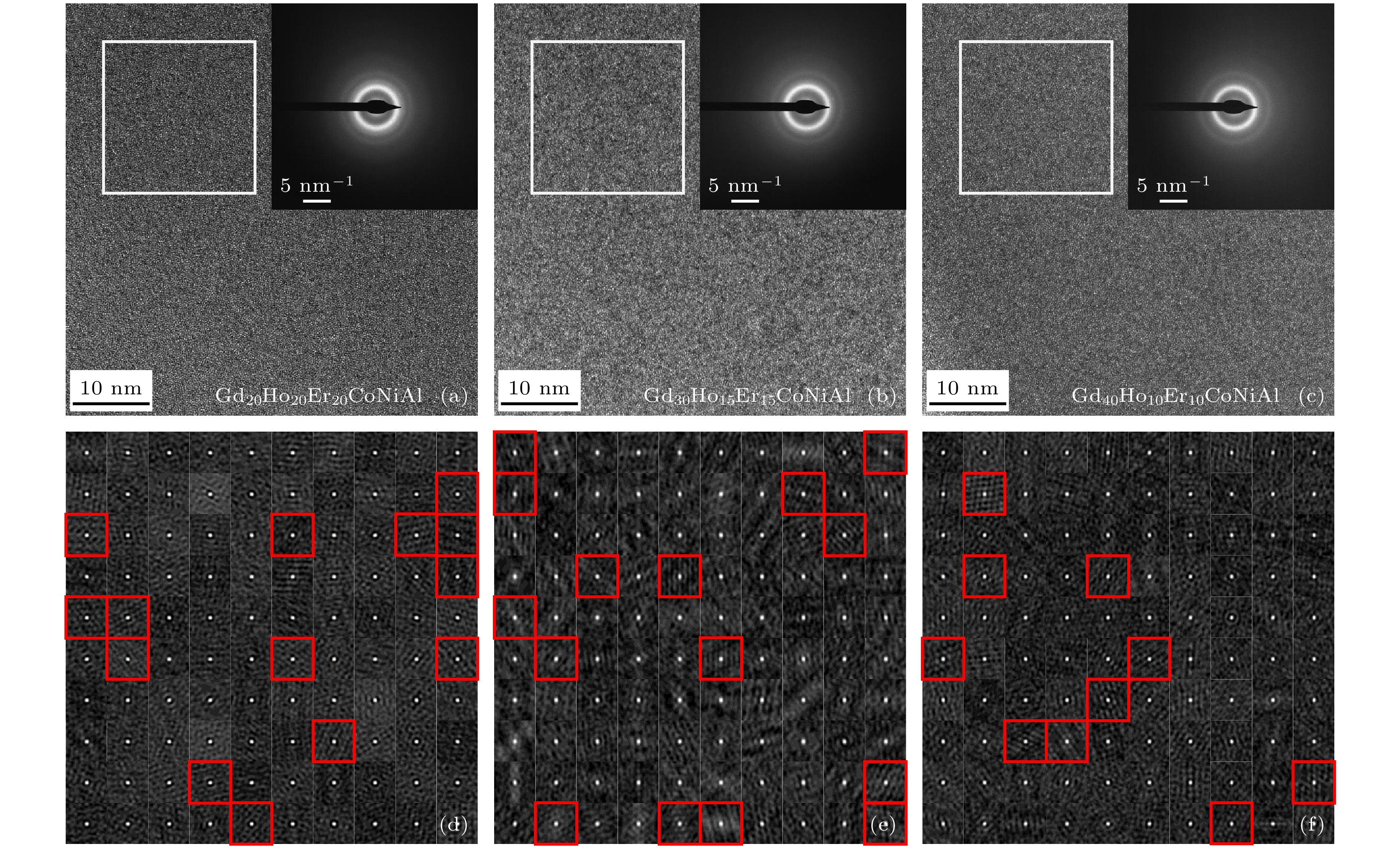

图 2 Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10)非晶合金条带HRTEM图(a)—(c)及选区二维自相关处理图(d)—(f), 插图为选区电子衍射图

Fig. 2. (a)−(c) HRTEM image of Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10) ribbons and (d)−(f) 2D auto-correlation processing image of selected area. The inset shows the selected area electron diffraction pattern.

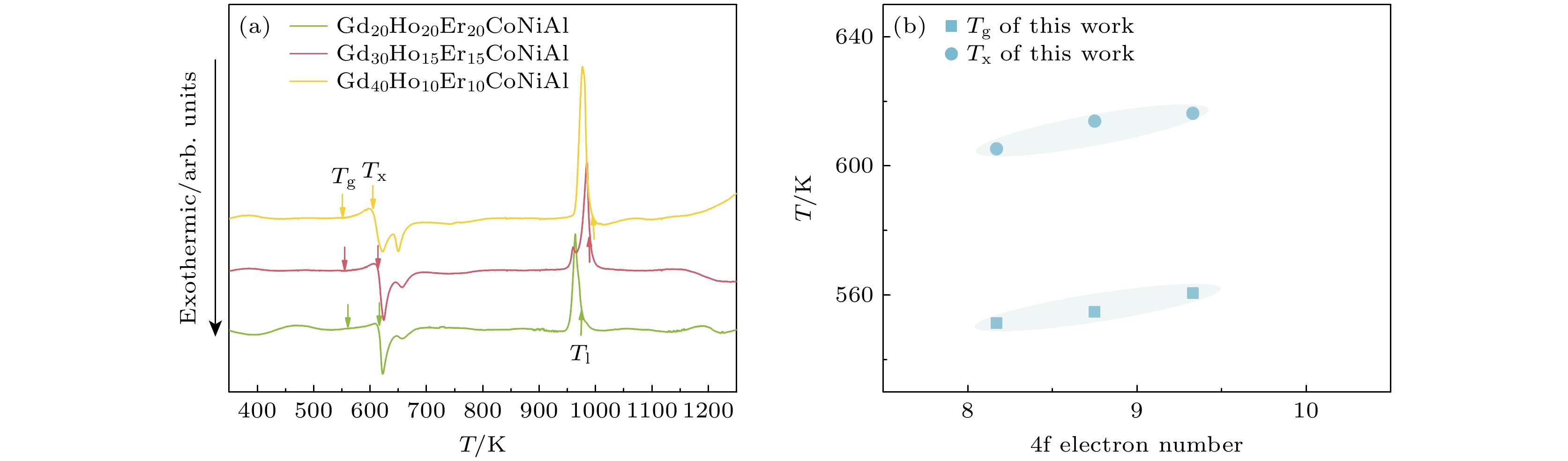

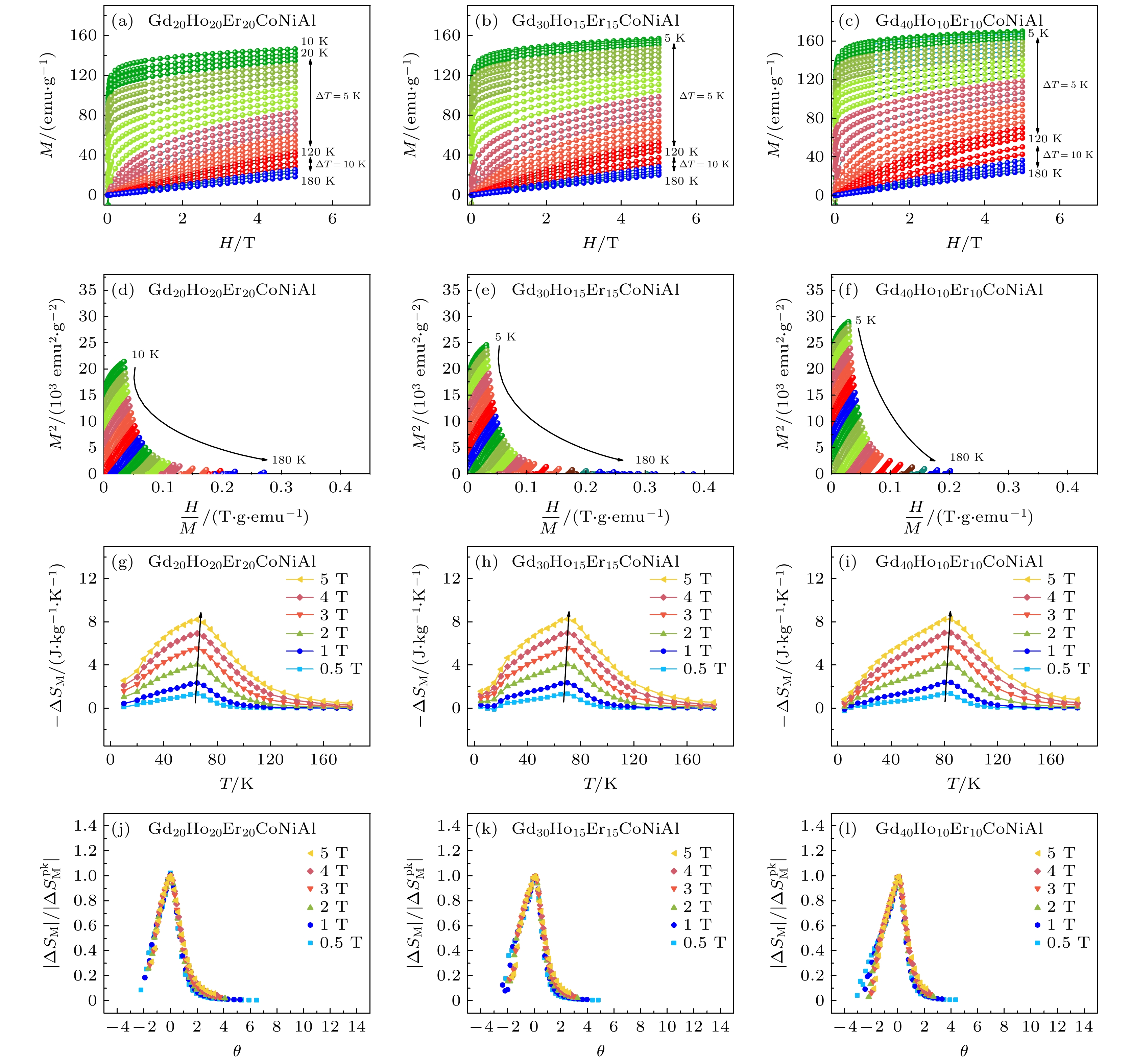

图 4 (a) Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10)非晶合金200 Oe外场场冷和零场冷磁化强度与温度关系图; (b) 200 Oe外场下的$ {1 {/ } {\chi \left( T \right)}} $随温度变化曲线; (c)场冷曲线求导图; (d) Tc与G因子的关系

Fig. 4. (a) Temperature dependence of ZFC and FC magnetization curves (M-T) of Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10) under 200 Oe; (b) $ {1 {/ } {\chi \left( T \right)}} $ curves at H = 200 Oe; (c) dM/dT-T curves; (d) Tc as a function of G factor.

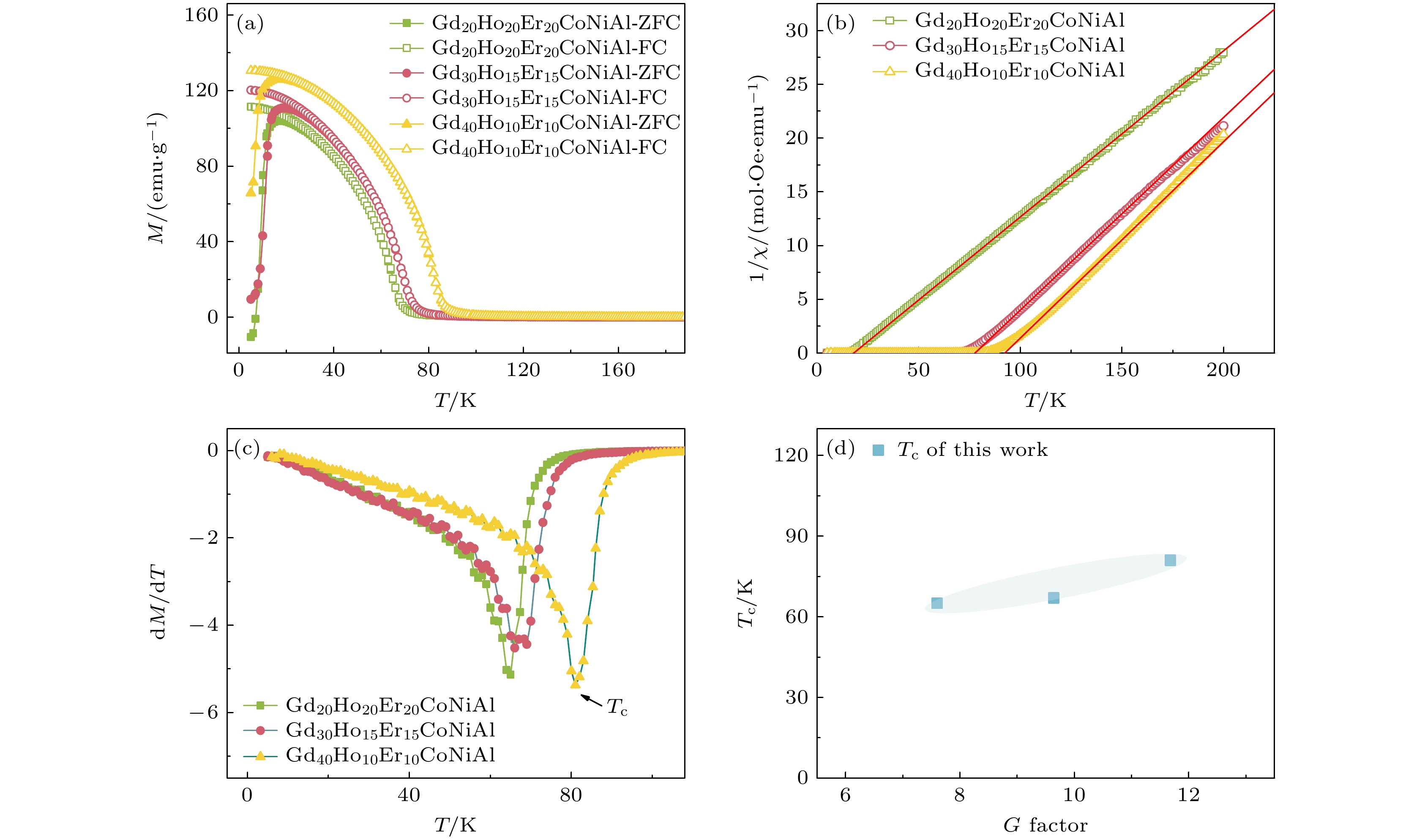

图 5 Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10)非晶合金不同温度下磁化强度与外场关系图(a)—(c)和Arrott图(d)—(f); 不同外场下的磁熵变与温度关系图(g)—(i)和$|\Delta S_{\text{M}}/ | {\Delta S_{\text{M}}^{{\text{pk}}}} |\text{-}\theta$图(j)—(l)

Fig. 5. Isothermal magnetization curves (M-H ) (a)–(c) and Arrott plots (d)–(f); magnetic entropy changes as a function of temperature (|ΔSM|-T ) (g)–(i) and $|\Delta S_{\text{M}}/ | {\Delta S_{\text{M}}^{{\text{pk}}}} |\text{-}\theta$ curves (j)–(l) for Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10).

图 7 Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10)非晶合金(a)峰值磁熵变和(b)相对制冷能力与外场关系图, 实线为指数函数拟合曲线

Fig. 7. (a) Maximum magnetic entropy changes and (b) relative cooling power as a function of applied field ($ | {\Delta S_{\text{M}}^{{\text{pk}}}} | $/RCP-H ) for Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10). The solid lines are the exponential function fitting curves.

表 1 Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10)非晶合金热力学参数(R为气体常数)

Table 1. Thermodynamic parameters and GFA criteria of Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10).

Compositions ΔSconf 4f electron number Tg/K Tx/K Tl/K ΔTx/K Trg γ γm x = 0 1.748R 9.33 560.6 616.3 973.0 55.7 0.576 0.402 0.691 x = 5 1.713R 8.75 554.8 613.9 989.6 59.1 0.561 0.398 0.680 x = 10 1.609R 8.17 551.3 605.3 985.6 54.0 0.559 0.394 0.669 表 2 Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10)非晶合金的磁热参数

Table 2. Magnetocaloric parameters of Gd20+2xHo20–xEr20–xCoNiAl (x = 0, 5, 10).

x ΔSconf G-factor Tc/K θ/K μeff/μB(实验) μeff/μB(理论) $ | {\Delta S_{\text{M}}^{{\text{pk}}}} | $/(J·kg–1·K–1) δTFWHM/K RCP/(J·kg–1) n N 0 1.748R 7.60 65 17.968 7.18 7.75 8.21 73.99 607.20 0.80 1.00 5 1.713R 9.64 67 77.788 6.68 7.45 8.28 80.43 665.67 0.78 1.00 10 1.609R 11.68 81 92.191 6.61 7.14 8.31 89.17 740.82 0.76 1.01 -

[1] Gschneidner K A, Pecharsky V, Tsokol A 2005 Rep. Prog. Phys. 68 1479

Google Scholar

Google Scholar

[2] Uporov S, Ryltsev R, Bykov V, Uporova N, Estemirova S K, Chtchelkatchev N 2021 J. Alloys Compd. 854 157170

Google Scholar

Google Scholar

[3] Warburg E 1881 Ann. Der. Phys. 249 141

Google Scholar

Google Scholar

[4] Debye P 1926 Ann. Der. Phys. 386 1154

Google Scholar

Google Scholar

[5] Giauque W F 1927 J. Am. Chem. Soc. 49 1864

Google Scholar

Google Scholar

[6] Pecharsky V K, Gschneidner Jr K A 1997 Phys. Rev. Lett. 78 4494

Google Scholar

Google Scholar

[7] Pecharsky V K, Gschneidner Jr K A 1997 Appl. Phys. Lett. 70 3299

Google Scholar

Google Scholar

[8] Jia Y S, Zhao X Y, Liu X L, Li L W 2020 J. Alloys Compd. 813 152177

Google Scholar

Google Scholar

[9] Zhang Y K, Zhu J, Li S, Zhang B, Wang Y M, Wang J, Ren Z M 2022 J. Alloys Compd. 895 162633

Google Scholar

Google Scholar

[10] Wang Q, Pan L L, Tang B Z, Ding D, Xia L 2022 J. Non-Cryst. Solids 580 121394

Google Scholar

Google Scholar

[11] Luo Q, Zhao D Q, Pan M X, Wang W H 2007 Appl. Phys. Lett. 90 211903

Google Scholar

Google Scholar

[12] Lim X 2016 Nature 533 306

Google Scholar

Google Scholar

[13] Huo J T, Huo L S, Li J W, Men H, Wang X M, Inoue A, Chang C T, Wang J Q, Li R W 2015 J. Appl. Phys. 117 073902

Google Scholar

Google Scholar

[14] Huo J T, Huo L S, Men H, Wang X M, Inoue A, Wang J, Chang C T, Li R W 2015 Intermetallics 58 31

Google Scholar

Google Scholar

[15] Sheng W, Wang J Q, Wang G, Huo J T, Wang X, Li R W 2018 Intermetallics 96 79

Google Scholar

Google Scholar

[16] Li J W, Xue L, Yang W, Yuan C, Huo J T, Shen B 2018 Intermetallics 96 90

Google Scholar

Google Scholar

[17] Zhang Y K, Zhu J, Li S, Wang J, Ren Z M 2022 J. Mater. Sci. Technol. 102 66

Google Scholar

Google Scholar

[18] Li L W, Xu C, Yuan Y, Zhou S Q 2018 Materialia 3 74

Google Scholar

Google Scholar

[19] Yang Y, Chen Y, Yu P, Qian L J, Wu F F, Cui Y T, Wu Z M, Ding D, Xia L 2015 J. Nanosci. Nanotechnol. 15 3295

Google Scholar

Google Scholar

[20] Li L W, Xu C, Yuan Y, Zhou S Q 2018 Mater. Res. Lett. 6 413

Google Scholar

Google Scholar

[21] Dong Z Q, Wang Z J, Yin S H 2020 J. Magn. Magn. Mater. 514 167270

Google Scholar

Google Scholar

[22] Luo L, Shen H X, Bao Y, Yin H B, Jiang S D, Huang Y J, Guo S Y, Gao S, Xing D W, Li Z, Sun J F 2020 J. Magn. Magn. Mater. 507 166856

Google Scholar

Google Scholar

[23] Zhang Y K, Xu P, Zhu J, Yan S, Zhang J, Li L W 2023 Mater. Today Phys. 32 101031

Google Scholar

Google Scholar

[24] Zhang Y K, Zhu J, Hao Z, Hao W, Mo Z, Li L W 2023 Mater. Des. 229 111894

Google Scholar

Google Scholar

[25] Civan E, Sarlar K, Kucuk I 2017 Philos. Mag. 97 1464

Google Scholar

Google Scholar

[26] Johnson F, Shull R D 2006 J. Appl. Phys. 99 08K909

Google Scholar

Google Scholar

[27] Kucuk I, Sarlar K, Adam A, Civan E 2016 Philos. Mag. 96 3120

Google Scholar

Google Scholar

[28] Wu K N, Liu C, Li Q, Huo J T, Li M C, Chang C T, Sun Y F 2019 J. Magn. Magn. Mater. 489 165404

Google Scholar

Google Scholar

[29] Wang G F, Li H L, Zhao Z R, Zhang X F 2017 J. Alloys Compd. 692 793

Google Scholar

Google Scholar

[30] Lv Y B, Chen Q J, Huang Y L 2019 J. Rare Earth. 37 404

Google Scholar

Google Scholar

[31] Guo D, Moreno-Ramírez L M, Romero-Muñiz C, Zhang Y K, Law J Y, Franco V, Wang J, Ren Z M 2021 Sci. China Mater. 64 2846

Google Scholar

Google Scholar

[32] Xue L, Shao L L, Li Z, Han Z D, Zhang B S, Huo J T, Wang X M, Zhu S S, Qian B, Cheng J B, Shen B L 2022 J. Mater. Res. Technol. 18 5301

Google Scholar

Google Scholar

[33] Lindner N, Śniadecki Z, Kołodziej M, Grenèche J M, Marcin J, Škorvánek I, Idzikowski B 2022 J. Mater. Sci. 57 553

Google Scholar

Google Scholar

[34] Zheng Z G, Qiu Z G, Zeng D C 2019 Mater. Res. Express 6 096109

Google Scholar

Google Scholar

[35] Law J Y, Ramanujan R V, Franco V 2010 J. Alloys Compd. 508 14

Google Scholar

Google Scholar

[36] 糜晓磊, 胡亮, 武博文, 龙强, 魏炳波 2024 73 097102

Google Scholar

Google Scholar

Mi X L, Hu L, Wu B W, Long Q, Wei B B 2024 Acta Phys. Sin. 73 097102

Google Scholar

Google Scholar

[37] Xue L, Shao L L, Luo Q, Shen B L 2019 J. Alloys Compd. 790 633

Google Scholar

Google Scholar

[38] Wei S J, Shen H X, Zhang L Y, Luo L, Tang X X, Sun J F, Li X Q 2024 Rare Metals 43 1234

Google Scholar

Google Scholar

[39] Lu S F, Ma L, Wang J, Du Y S, Li L W, Zhao J T, Rao G H 2021 J. Alloys Compd. 874 159918

Google Scholar

Google Scholar

[40] Yeh J W 2013 JOM 65 1759

Google Scholar

Google Scholar

[41] Ma E, Wu X L 2019 Nat. Commun. 10 5623

Google Scholar

Google Scholar

[42] Gu J L, Luan H W, Zhao S F, Bu H T, Si J J, Shao Y, Yao K F 2020 Mater. Sci. Eng. A 786 139417

Google Scholar

Google Scholar

[43] Xue L, Shao L L, Zhang B S, Li Z, Cheng J B, Shen B L 2024 J. Rare Earth. 42 129

Google Scholar

Google Scholar

[44] Pang C M, Yuan C C, Chen L, Xu H, Guo K, He J C, Li Y, Wei M S, Wang X M, Huo J T, Shen B L 2020 J. Non-Cryst. Solids 549 120354

Google Scholar

Google Scholar

[45] Pang C M, Chen L, Xu H, Guo W, Lv Z W, Huo J T, Cai M J, Shen B L, Wang X L, Yuan C C 2020 J. Alloys Compd. 827 154101

Google Scholar

Google Scholar

[46] Wang X, Tang B Z, Wang Q, Yu P, Ding D, Xia L 2020 J. Non-Cryst. Solids 544 120146

Google Scholar

Google Scholar

[47] Hao F, Lin H, Zhou C, Liu Y Z, Li J B 2011 Phys. Chem. Chem. Phys. 13 15918

Google Scholar

Google Scholar

[48] Wang Q, Liu C T, Yang Y, Liu J B, Dong Y D, Lu J 2014 Sci. Rep. 4 4648

Google Scholar

Google Scholar

[49] Imafuku M, Yaoita K, Sato S, Zhang W, Inoue A, Waseda Y 2001 Mater. Sci. Eng. A 304 660

Google Scholar

Google Scholar

[50] Wang W H 2009 Adv. Mater. 21 4524

Google Scholar

Google Scholar

[51] Yuan C C, Shen X, Cui J, Gu L, Yu R C, Xi X K 2012 Appl. Phys. Lett. 101 021902

Google Scholar

Google Scholar

[52] Liu Z H, Zhang Y K J, Liu E K, Liu G D, Ma X Q, Wu G H 2015 J. Phys. D Appl. Phys. 48 325001

Google Scholar

Google Scholar

[53] Yuan C C, Yang F, Xi X K, Shi C L, Holland-Moritz D, Li M Z, Hu F, Shen B L, Wang X L, Meyer A, Wang W H 2020 Mater. Today 32 26

Google Scholar

Google Scholar

[54] Jin F, Pang C M, Wang X M, Yuan C C 2023 J. Non-Cryst. Solids 600 121992

Google Scholar

Google Scholar

[55] Inoue A 2000 Acta Mater. 48 279

Google Scholar

Google Scholar

[56] Lu Z P, Tan H, Ng S C, Li Y 2000 Scr. Mater. 42 667

Google Scholar

Google Scholar

[57] Lu Z P, Liu C T 2002 Acta Mater. 50 3501

Google Scholar

Google Scholar

[58] Lu Z P, Liu C T 2003 Phys. Rev. Lett. 91 115505

Google Scholar

Google Scholar

[59] Du X H, Huang J C, Liu C T, Lu Z P 2007 J. Appl. Phys. 101 086108

Google Scholar

Google Scholar

[60] Zhang W, Jia F, Zhang X, Xie G, Inoue A 2010 Metall. Mater. Trans. A 41 1685

Google Scholar

Google Scholar

[61] Zhang Y K, Guo D, Wu B B, Wang H F, Guan R G, Li X, Ren Z M 2020 J. Appl. Phys. 127 033905

Google Scholar

Google Scholar

[62] Yin H, Wang J Q, Huang Y, Shen H X, Guo S, Fan H, Huo J T, Sun J 2023 J. Mater. Sci. Technol. 149 167

Google Scholar

Google Scholar

[63] Zhong H X, Li K, Zhang Q, Wang J, Meng F L, Wu Z J, Yan J M, Zhang X B 2016 NPG Asia Mater. 8 e308

Google Scholar

Google Scholar

[64] Franco V, Blázquez J, Conde A 2006 J. Appl. Phys. 89 222512

Google Scholar

Google Scholar

[65] Zhang H Y, Li R, Zhang L L, Zhang T 2014 J. Appl. Phys. 115 133903

Google Scholar

Google Scholar

[66] Yosida K 1957 Phys. Rev. 107 396

Google Scholar

Google Scholar

[67] Banerjee B 1964 Phys. Lett. 12 16

Google Scholar

Google Scholar

[68] Franco V, Conde A, Romero-Enrique J M, Blázquez J S 2008 J. Phys. Condens. Matter 20 285207

Google Scholar

Google Scholar

[69] Oesterreicher H, Parker F 1984 J. Appl. Phys. 55 4334

Google Scholar

Google Scholar

[70] Guo D, Zhang Y K, Geng S H, Xu H, Ren Z M, Wilde G 2018 J. Mater. Sci. 53 9816

Google Scholar

Google Scholar

[71] Zhang Y K, Li H D, Geng S H, Lu X G, Wilde G 2019 J. Alloys Compd. 770 849

Google Scholar

Google Scholar

[72] Dong Z Q, Yin S H 2020 J. Magn. Magn. Mater. 495 165888

Google Scholar

Google Scholar

[73] Huo J T, Zhao D Q, Bai H Y, Axinte E, Wang W H 2013 J. Non-Cryst. Solids 359 1

Google Scholar

Google Scholar

计量

- 文章访问数: 3123

- PDF下载量: 55

- 被引次数: 0

下载:

下载: