-

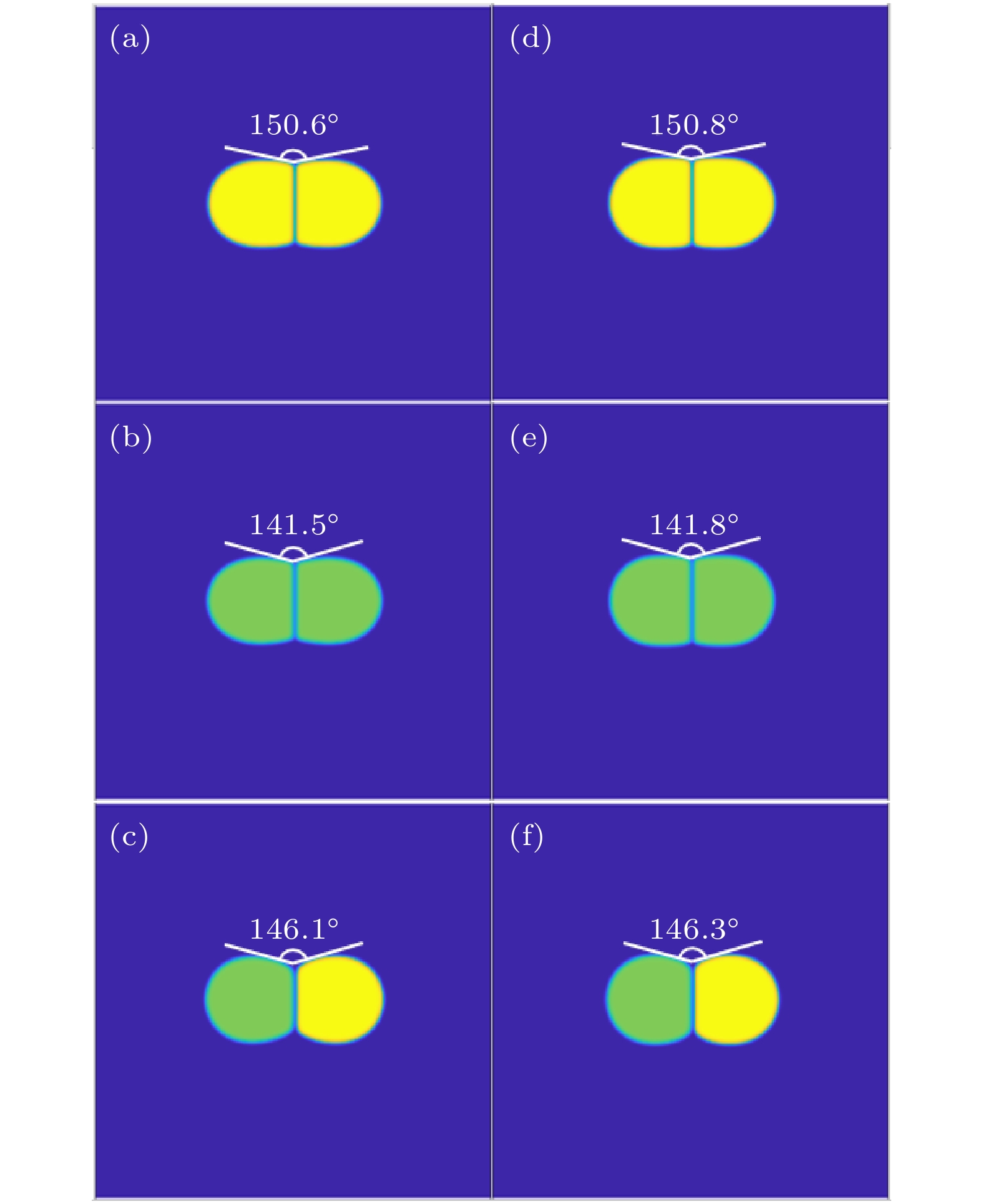

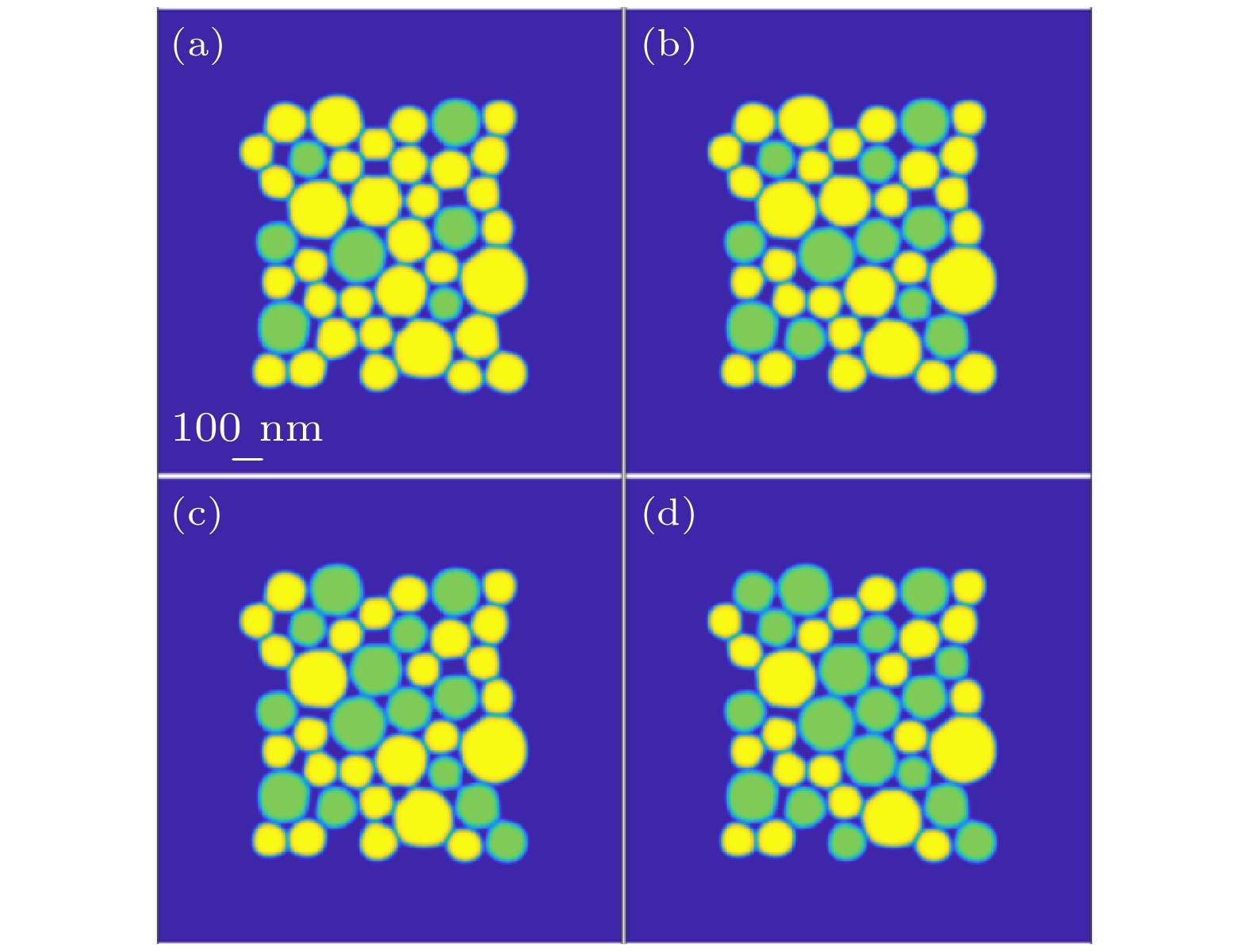

建立了陶瓷型复合燃料两相烧结过程的相场模型, 利用该模型模拟了UN-U3Si2复合燃料的烧结过程. 首先, 研究了两相双晶粒在烧结过程中的烧结颈的演化过程. 结果表明: 具有较高表面能的晶粒在烧结颈形成过程中的表面形变更明显; 两相双晶粒形成的平衡二面角的大小取决于两相的晶界能与表面能的比值; 两相不等大的双晶粒之间未发生大晶粒吞噬小晶粒现象. 然后, 研究了烧结过程中的两相三晶粒之间的气孔收缩和三叉晶界的演化, 以揭示符合燃料烧结过程中气孔的演变规律. 结果发现, 两相三晶粒形成的三叉晶界夹角偏离了120°, 晶界处的高能势垒阻碍了气孔的空位沿晶界的扩散, 导致三叉晶界处的气孔收缩速率减慢. 最后, 研究了两相陶瓷型复合燃料的多晶烧结过程. 不同体积分数比的两相多晶烧结组织形貌演化的模拟结果表明, 晶界扩散在两相烧结过程中起主要作用, 体积分数较大的相的晶粒生长占据主导地位, 两相晶粒之间存在阻碍晶界迁移的作用, 同相晶粒之间存在晶粒迁移现象.Due to the limitation of existing experimental techniques, it is difficult to observe the evolution of microstructure in the sintering process in real time, resulting in a lack of in-depth understanding of the sintering mechanism of two-phase composite fuels. Therefore, it is greatly important to carry out theoretical simulation studies in the sintering process of composite fuels. In this work, a phase-field model of the two-phase sintering process of ceramic composite fuel is established, and the sintering process of UN-U3Si2 composite fuel is simulated by using this method. The simulation results show that during the formation of sintering neck, the surface deformation of the grains with higher surface energy is significant. The size of the final equilibrium dihedral angle formed by the two-phase double grains depends on the ratio of the grain boundary energy to the surface energy of the two phases. The phenomenon of large grains swallowing small grains does not occur between the two unequal double grains. Subsequently, the pore shrinkage and the properties of the trident grain boundary among the two-phase three grains are investigated in the sintering process. It is found that the angle of the trident grain boundary formed by the two-phase three grains deviates from 120°. The high-energy barrier at the grain boundary hinders the diffusion of the pore vacancies along the grain boundary, resulting in a slow shrinkage rate of the pore vacancies at the trident grain boundary. In addition, the simulation results of the microstructure evolution of two-phase polycrystalline sintered tissue with different volume fraction ratios show that the grain boundary diffusion plays a major role in the two-phase sintering process. The grain growth of the phase with a higher volume fraction is dominant, and there exists a hindrance to the migration of grain boundaries between two-phase grains. The phenomenon of grain migration exists between grains of the same phase.

-

Keywords:

- phase field simulation /

- composite fuel /

- sintering /

- grain growth /

- grain boundary and interface boundary

[1] Kim H G, Yang J H, Kim W J, Koo Y H 2016 Nucl. Eng. Technol. 48 1

Google Scholar

Google Scholar

[2] Kurata M 2016 Nucl. Eng. Technol. 48 26

Google Scholar

Google Scholar

[3] Leenaers A, Van den Berghe S, Koonen E, Jacquet P, Jarousse C, Guigon B, Ballagny A, Sannen L 2004 J. Nucl. Mater. 327 121

Google Scholar

Google Scholar

[4] Zinkle S J, Terrani K A, Gehin J C, Ott L J, Snead L L 2014 J. Nucl. Mater. 448 374

Google Scholar

Google Scholar

[5] Terrani K A, Wang D, Ott L J, Montgomery R O 2014 J. Nucl. Mater. 448 512

Google Scholar

Google Scholar

[6] Johnson K D, Raftery A M, Lopes D A, Wallenius J 2016 J. Nucl. Mater. 477 18

Google Scholar

Google Scholar

[7] Watkins J K, Gonzales A, Wagner A R, Sooby E S, Jaques B J 2021 J. Nucl. Mater. 553 153048

Google Scholar

Google Scholar

[8] Wood E S, White J T, Nelson A T 2017 J. Nucl. Mater 484 245

Google Scholar

Google Scholar

[9] Ortega L H, Blamer B J, Evans J A, McDeavitt S M 2016 J. Nucl. Mater. 471 116

Google Scholar

Google Scholar

[10] White J T, Travis A W, Dunwoody J T, Nelson A T 2017 J. Nucl. Mater. 495 463

Google Scholar

Google Scholar

[11] Lopes D A, Uygur S, Johnson K D 2017 J. Nucl. Sci. Technol. 54 405

Google Scholar

Google Scholar

[12] 刘续希, 高士森, 喇永孝, 玉栋梁, 柳文波 2024 73 148201

Google Scholar

Google Scholar

Liu X X, Gao S S, La Y X, Yu D L, Liu W B 2024 Acta Phys. Sin. 73 148201

Google Scholar

Google Scholar

[13] 刘东昆, 王庆宇, 张田, 周羽, 王翔 2024 73 066102

Google Scholar

Google Scholar

Liu D K, Wang Q Y, Zhang T, Zhou Y, Wang X 2024 Acta Phys. Sin. 73 066102

Google Scholar

Google Scholar

[14] 王凯乐, 杨文奎, 史新成, 侯华, 赵宇宏 2023 72 076102

Google Scholar

Google Scholar

Wang K L, Yang W K, Shi X C, Hou H, Zhao Y H 2023 Acta Phys. Sin. 72 076102

Google Scholar

Google Scholar

[15] 刘明治, 张瑞杰, 方伟, 章书周, 曲选辉 2012 金属学报 48 1207

Google Scholar

Google Scholar

Liu M Z, Zhang R J, Fang W, Zhang S Z, Qu X H 2012 Acta. Metall. Sin. 48 1207

Google Scholar

Google Scholar

[16] Kumar V, Fang Z Z, Fife P C 2010 Mater. Sci. Eng. A 528 254

Google Scholar

Google Scholar

[17] Biswas S, Schwen D, Wang H, Okuniewski M, Tomar V 2018 Comput. Mater. Sci. 148 307

Google Scholar

Google Scholar

[18] Du L F, Yang S M, Zhu X W, Jiang J, Hui Q, Du H L 2018 J. Mater. Sci. 53 9567

Google Scholar

Google Scholar

[19] Hötzer J, Seiz M, Kellner M, Rheinheimer W, Nestler B 2019 Acta Mater. 164 184

Google Scholar

Google Scholar

[20] Wang Y U 2006 Acta Mater. 54 953

Google Scholar

Google Scholar

[21] Fan D, Chen L Q 1997 Acta Mater. 45 611

Google Scholar

Google Scholar

[22] Moelans N, Blanpain B, Wollants P 2008 Phys. Rev. B 78 024113

Google Scholar

Google Scholar

[23] Ahmed K, Yablinsky C A, Schulte A, Allen T, El-Azab A 2013 Modell. Simul. Mater. Sci. Eng. 21 065005

Google Scholar

Google Scholar

[24] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[25] Allen S M, Cahn J W 1979 Acta Metall. 27 1085

Google Scholar

Google Scholar

[26] Biner S B 2017 Programming Phase-Field Modeling (Switzerland: Springer International Publishing) p18

[27] Holt J B, Almassy M Y 1969 J. Am. Ceram. Soc. 52 631

Google Scholar

Google Scholar

[28] 戚晓勇, 柳文波, 何宗倍, 王一帆, 恽迪 2023 金属学报 59 1513

Google Scholar

Google Scholar

Qi X Y, Liu W B, He Z B, Wang Y F, Yun D 2023 Acta Metall. Sin. 59 1513

Google Scholar

Google Scholar

[29] Bocharov D, Gryaznov D, Zhukovskii Y F, Kotomin E A 2013 J. Nucl. Mater. 435 102

Google Scholar

Google Scholar

[30] Cooper M W D, Gamble K A, Capolungo L, Matthews C, Andersson D A, Beeler B, Stanek C R, Metzger K 2021 J. Nucl. Mater. 555 153129

Google Scholar

Google Scholar

[31] Beeler B, Baskes M, Andersson D, Cooper M W D, Zhang Y F 2019 J. Nucl. Mater. 514 290

Google Scholar

Google Scholar

[32] Cheniour A, Tonks M R, Gong B, Yao T K, He L F, Harp J M, Beeler B, Zhang Y F, Lian J 2020 J. Nucl. Mater 532 152069

Google Scholar

Google Scholar

[33] Chockalingam K, Kouznetsova V G, van der Sluis O, Geers M G D 2016 Comput. Methods Appl. Mech. Eng. 312 492

Google Scholar

Google Scholar

[34] Rahaman M N 1995 Ceramic Processing and Sintering (New York: Marcel Dekker) p446

[35] Riedel H, Svoboda J 1993 Acta Metall. Mater. 41 1929

Google Scholar

Google Scholar

[36] 孙正阳, 杨超, 柳文波 2020 金属学报 56 1295

Google Scholar

Google Scholar

Sun Z Y, Yang C, Liu W B 2020 Acta Metall. Sin. 56 1295

Google Scholar

Google Scholar

[37] Ahmed K, Allen T, El-Azab A 2016 J. Mater. Sci. 51 1261

Google Scholar

Google Scholar

[38] Yadav V, Vanherpe L, Moelans N 2016 Comput. Mater. Sci. 125 297

Google Scholar

Google Scholar

-

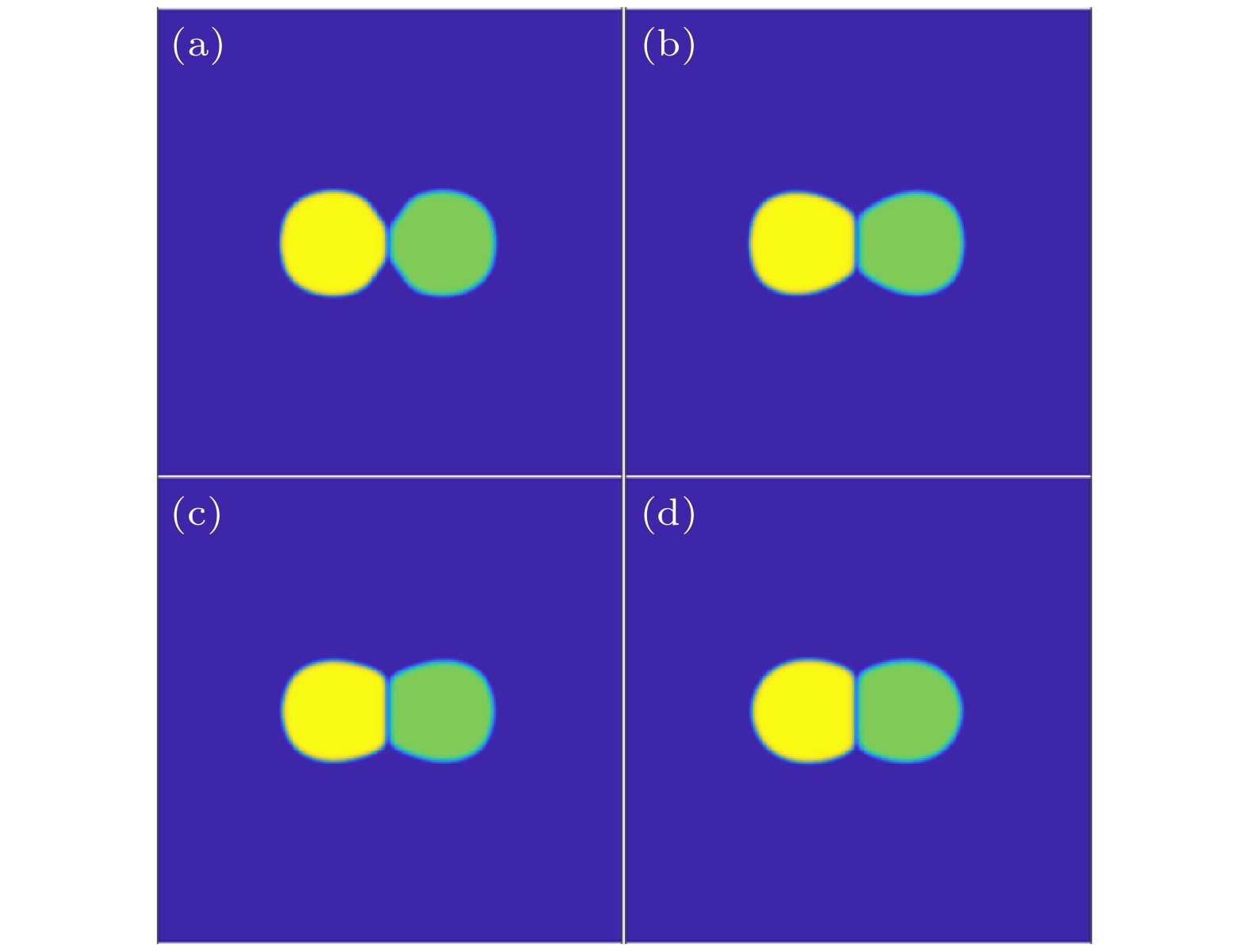

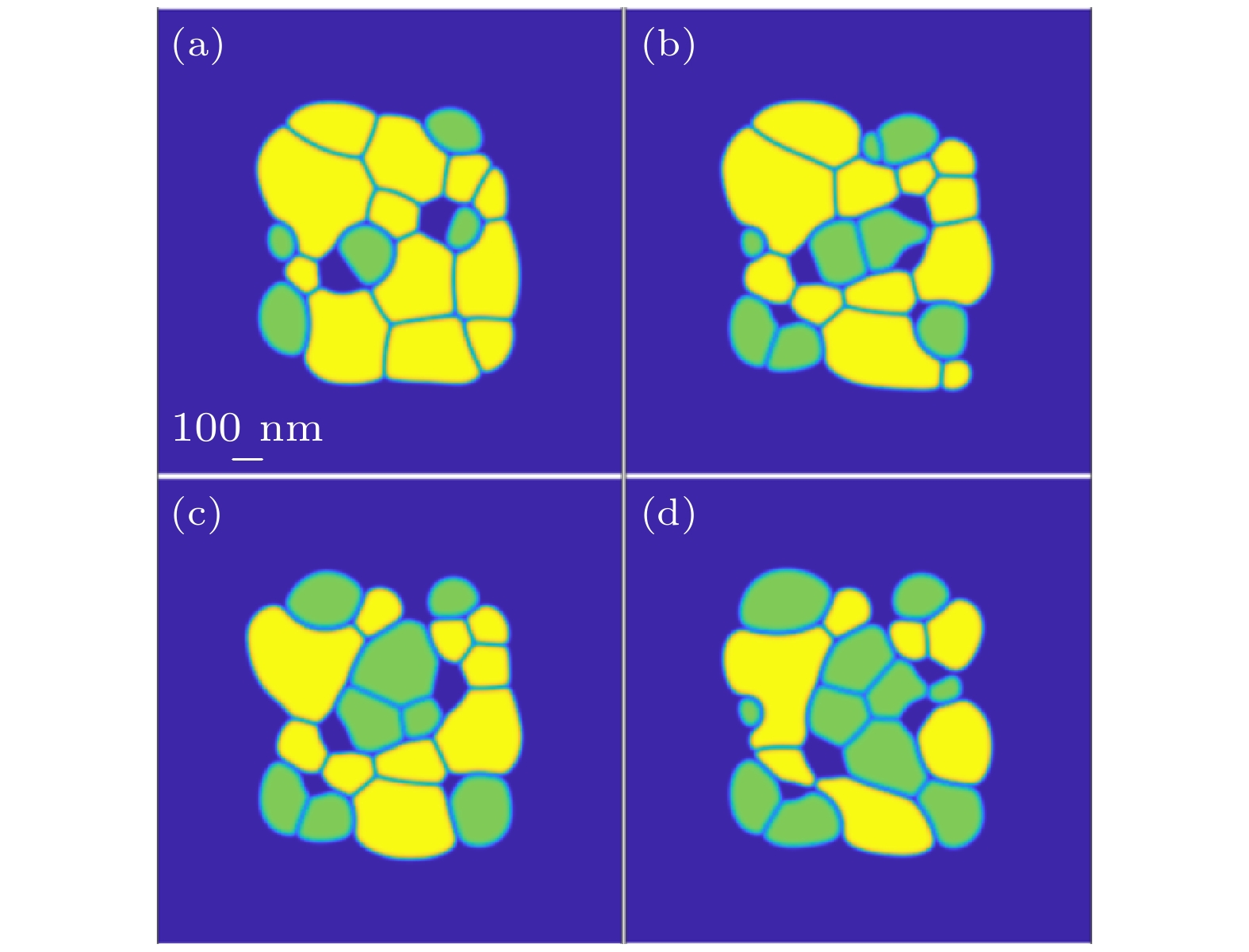

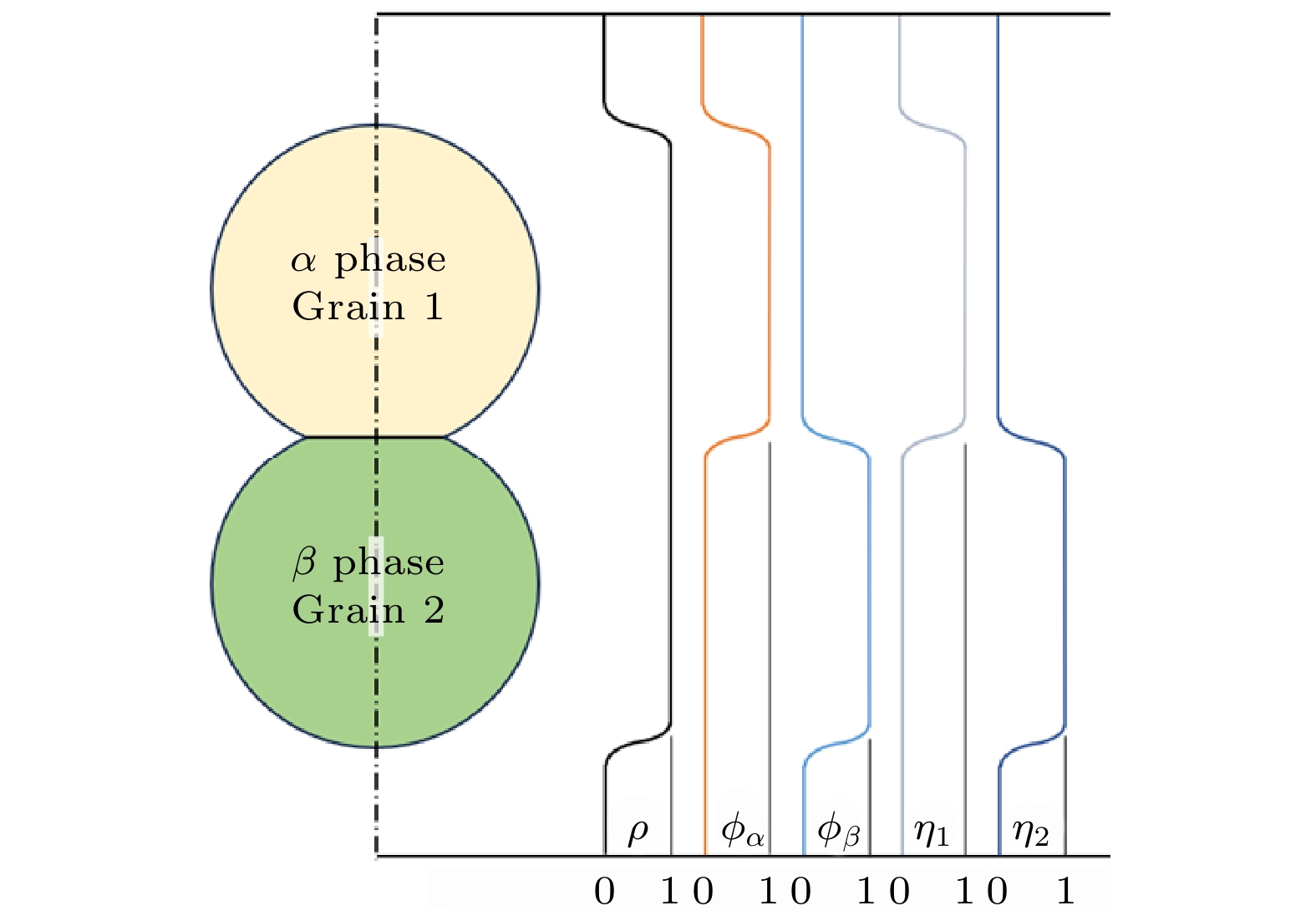

图 2 两个不同相等大圆形晶粒演化的相场模拟 (a) 6 × 104 $ \Delta t $; (b) 50 × 104 $ \Delta t $; (c) 200 × 104 $ \Delta t $; (d) 500 × 104$ \Delta t $

Fig. 2. Phase-field simulation of the evolution of two equal-sized circular grains with different phases: (a) 6 × 104 $ \Delta t $; (b) 50 × 104 $ \Delta t $; (c) 200 × 104 $ \Delta t $; (d) 500 × 104 $ \Delta t $.

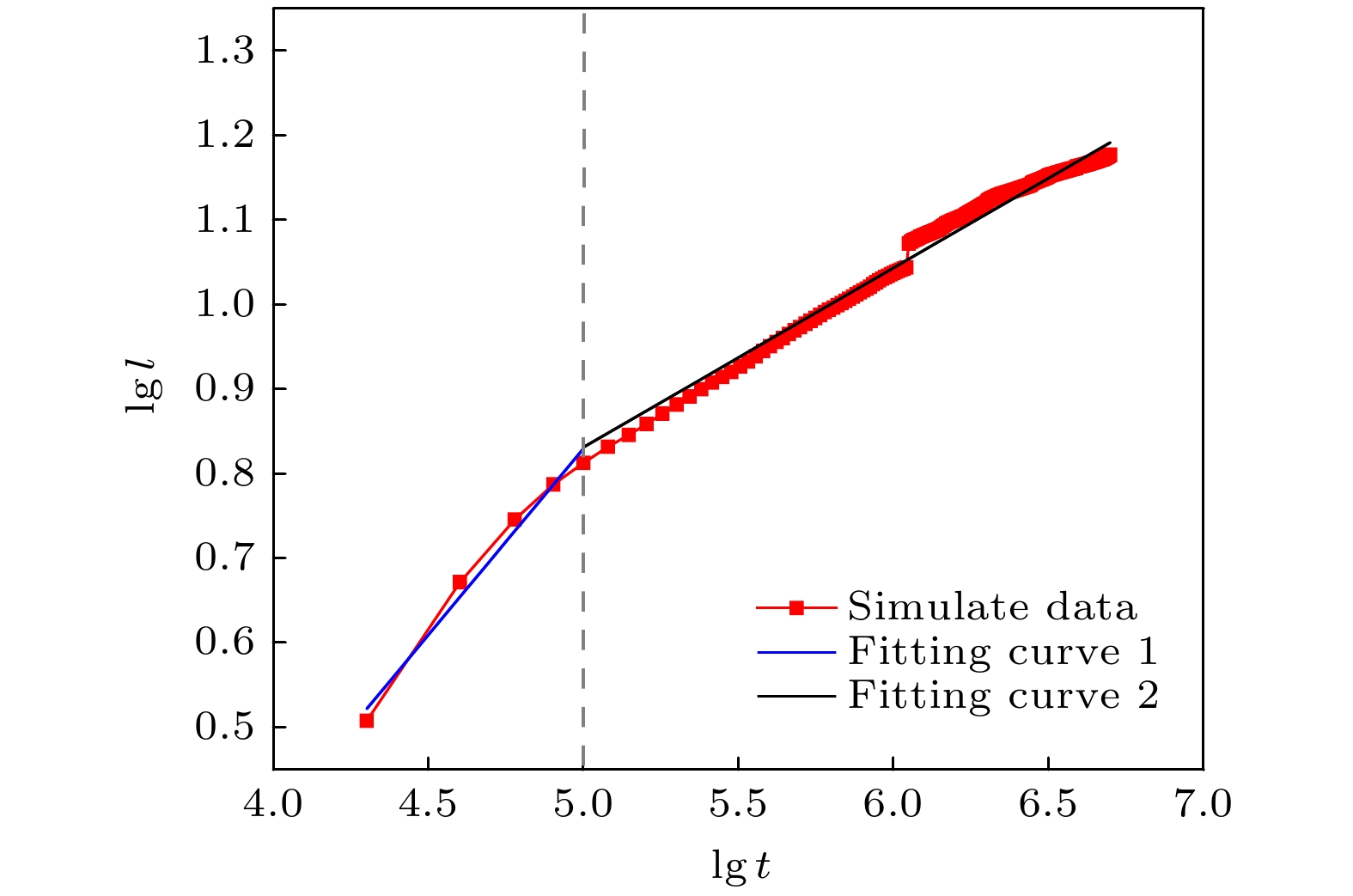

图 4 演化时间500 × 104 $ \Delta t $((a)—(c))与1500 × 104 $ \Delta t $((d)—(f))下的平衡二面角 (a), (d) 2个UN晶粒; (b), (e) 2个U3Si2晶粒; (c), (f) 1个UN晶粒和1个U3Si2晶粒

Fig. 4. Equilibrium dihedral angles at evolution times 500 × 104 $ \Delta t $((a)–(c)) and 1500 × 104 $ \Delta t $((d)–(f)): (a), (d) Two UN grains; (b), (e) two U3Si2 grains; (c), (f) one UN grain and one U3Si2 grain.

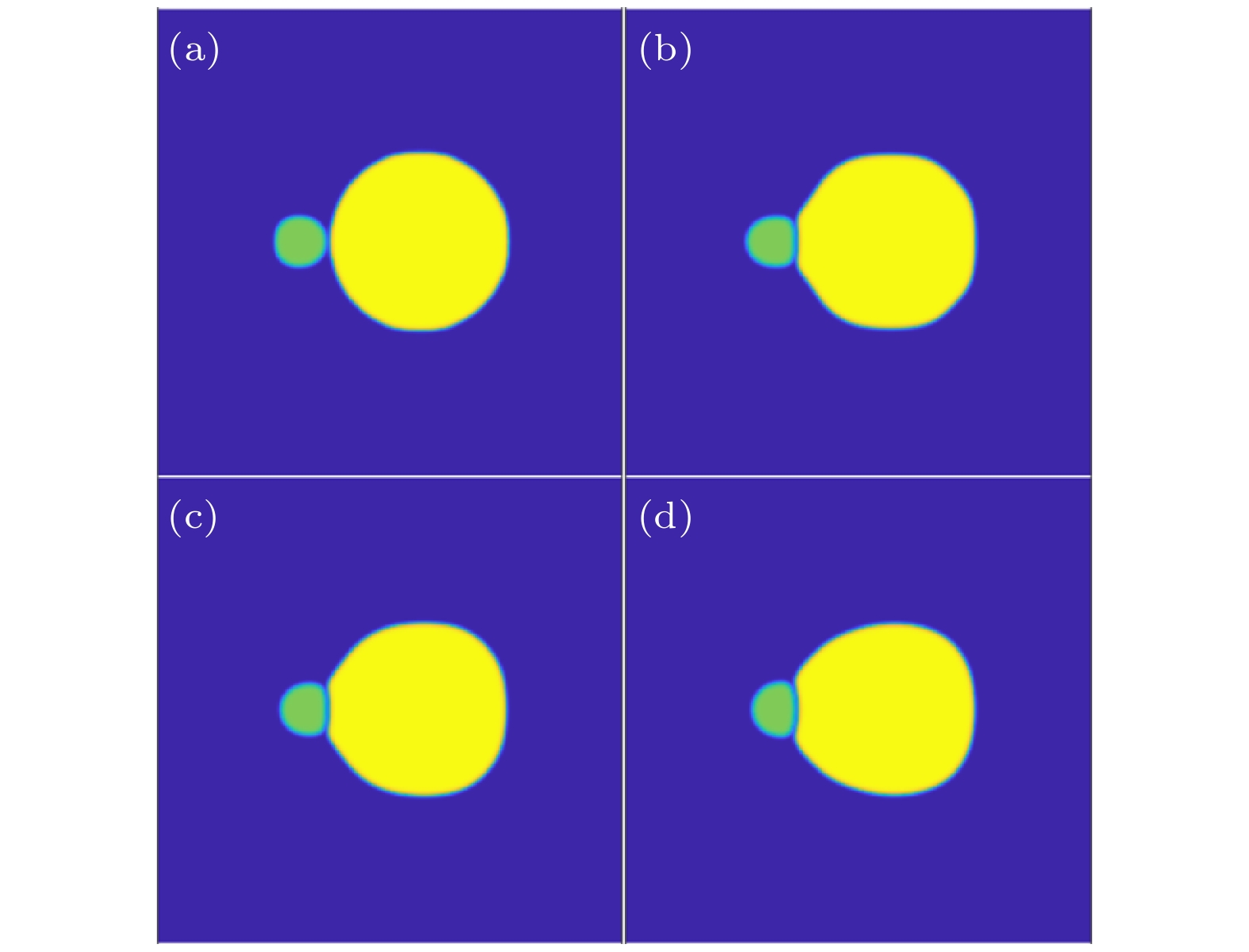

图 5 两个不同相不等大圆形晶粒演化的相场模拟 (a) 2 × 104 $ \Delta t $; (b) 50 × 104 $ \Delta t $; (c) 100 × 104 $ \Delta t $; (d) 500 × 104 $ \Delta t $.

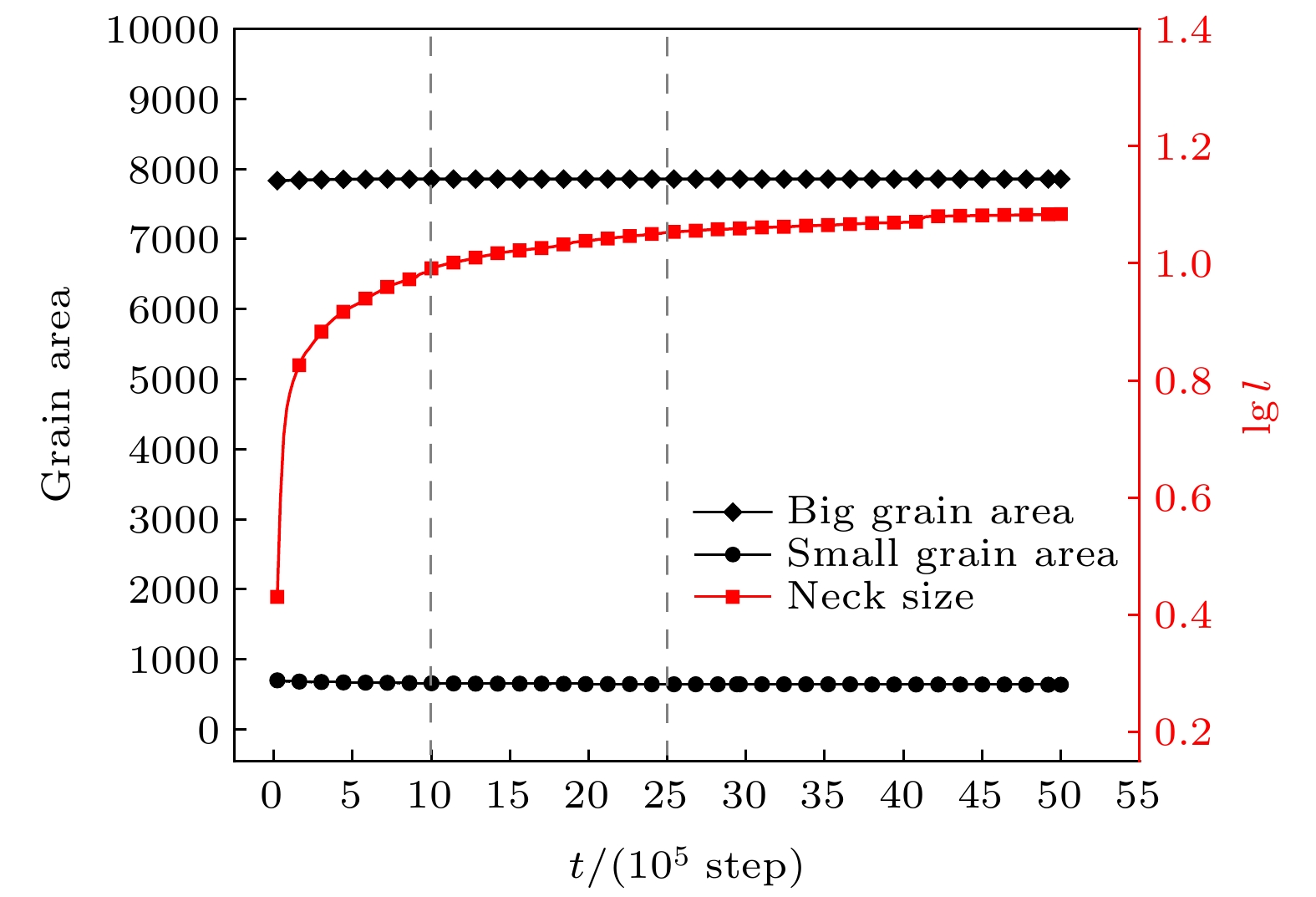

Fig. 5. Phase-field simulation of the evolution of two unequal-sized circular grains with different phases: (a) 2 × 104 $ \Delta t $; (b) 50 × 104 $ \Delta t $; (c) 100 × 104 $ \Delta t $; (d) 500 × 104 $ \Delta t $.

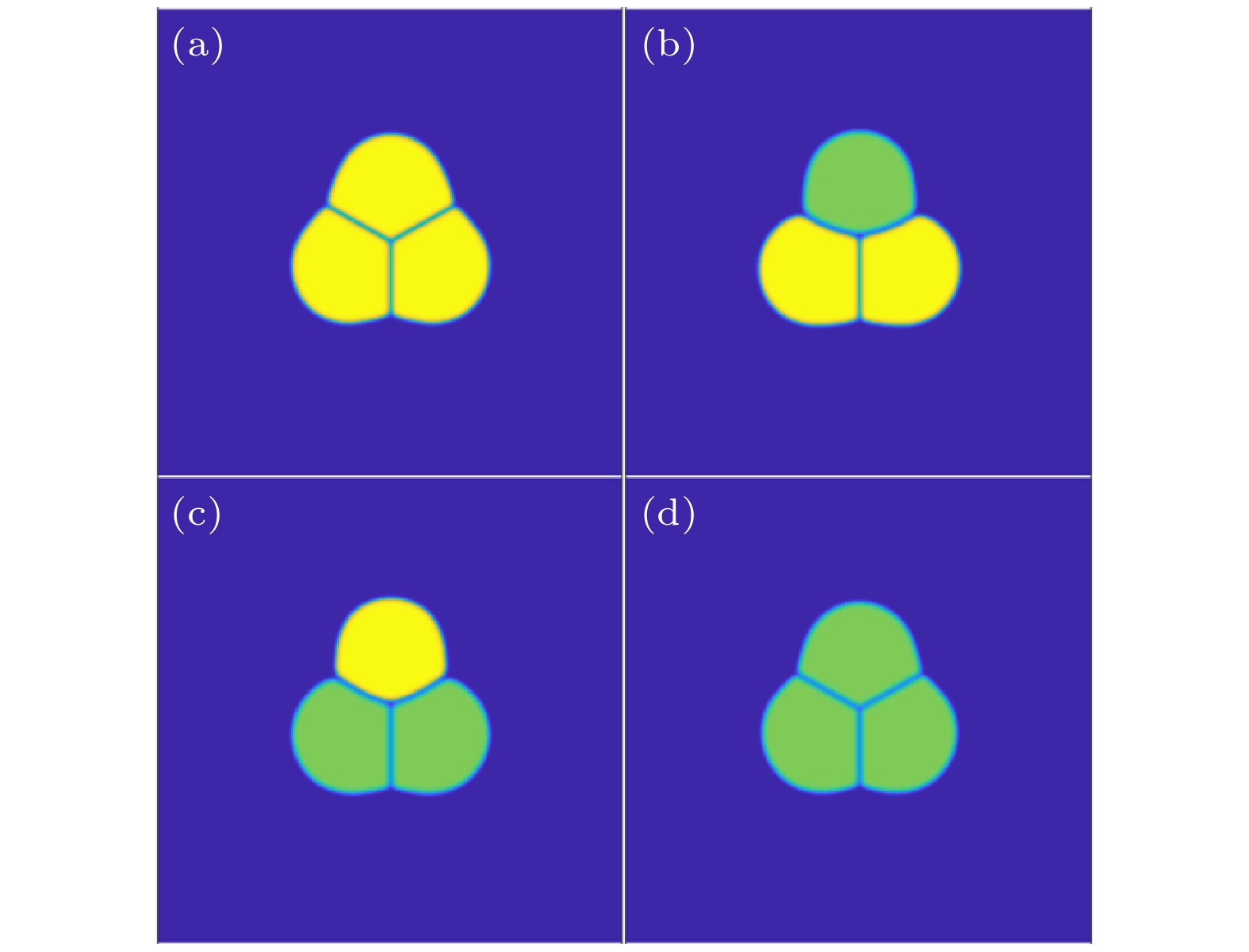

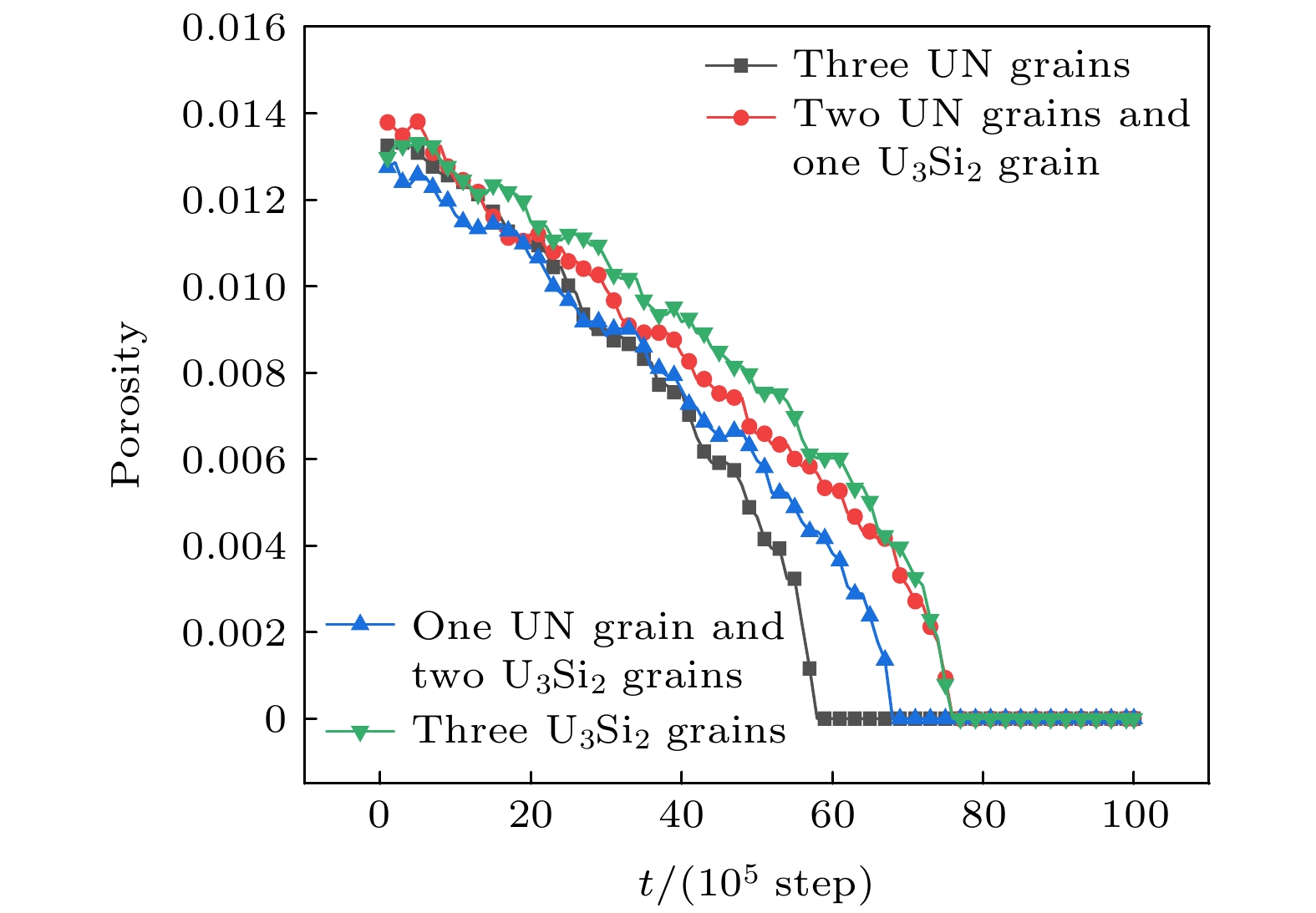

图 7 四种不同相晶粒个数比例下3个晶粒烧结的三叉晶界 (a) 3个UN晶粒; (b) 2个UN晶粒和 1个U3Si2晶粒; (c) 1个UN晶粒和2个U3Si2晶粒; (d) 3个U3Si2晶粒

Fig. 7. Trident grain boundaries of the sintering of three grains with four different phase grain number ratios: (a) Three UN grains; (b) two UN grains and one U3Si2 grain; (c) one UN grain and two U3Si2 grains; (d) three U3Si2 grains.

Parameter Value Unit Ref. $ D_\beta ^{\text{s}} $ 100$ D_\beta ^{{\text{gb}}} $ m2·s–1 $ D_\beta ^{{\text{gb}}} $ 6.5923 × 10–10 m2·s–1 [30] $ \gamma _{\text{s}}^\beta $ 2.0 J·m–2 [31] $ \gamma _{{\text{gb}}}^\beta $ 1.3 J·m–2 [32] δ 6 nm [32] Note: $ D_\alpha ^{\text{s}} $, $ D_\beta ^{\text{s}} $— surface diffusivity; $ D_\alpha ^{{\text{gb}}} $, $ D_\beta ^{{\text{gb}}} $— grain-boundary diffusivity; $ \gamma _{\text{s}}^\alpha $, $ \gamma _{\text{s}}^\beta $— surface energy; $ \gamma _{{\text{gb}}}^\alpha $, $ \gamma _{{\text{gb}}}^\beta $— grain-boundary energy; δ — diffuse interface width. 表 3 模拟中的无量纲参数表

Table 3. Non-dimensional parameters used in simulation.

Parameter Value Parameter Value $ \tilde A({\varphi _\alpha } = 1, {\text{ }}{\varphi _\beta } = 0) $ 17 $ {\tilde \kappa _\eta } $ 6.75 $ \tilde A({\varphi _\alpha } = 0, {\text{ }}{\varphi _\beta } = 1) $ 11.5 $\tilde {\boldsymbol{M}}({\varphi _\alpha } = 1, {\text{ }}{\varphi _\beta } = 0)$ 6817.5 $ \tilde B $ 1 $\tilde {\boldsymbol{M}}({\varphi _\alpha } = 0, {\varphi _\beta } = 1)$ 6817.5 $ {\tilde \kappa _\rho }({\varphi _\alpha } = 1, {\varphi _\beta } = 0) $ 20.25 $ \tilde L $ 1 $ {\tilde \kappa _\rho }({\varphi _\alpha } = 0, {\text{ }}{\varphi _\beta } = 1) $ 14 $ \Delta x = \Delta y $ 1 $ {\tilde \kappa _\phi }({\varphi _\alpha } = 1, {\text{ }}{\varphi _\beta } = 0) $ 20.25 $ \Delta t $ 2 × 10–5 $ {\tilde \kappa _\phi }({\varphi _\alpha } = 0, {\text{ }}{\varphi _\beta } = 1) $ 14 Note: $\tilde A$, $\tilde B$, $ {\tilde \kappa _\rho } $, $ {\tilde \kappa _\phi } $, $ {\tilde \kappa _\eta } $— non-dimensional parameters of free energy function; $ \tilde {\boldsymbol{M}} $— non-dimensional mobility; $\tilde L$—non-dimensional Allen-Cahn mobility; ∆x, ∆y — space scale; ∆t — time scale. -

[1] Kim H G, Yang J H, Kim W J, Koo Y H 2016 Nucl. Eng. Technol. 48 1

Google Scholar

Google Scholar

[2] Kurata M 2016 Nucl. Eng. Technol. 48 26

Google Scholar

Google Scholar

[3] Leenaers A, Van den Berghe S, Koonen E, Jacquet P, Jarousse C, Guigon B, Ballagny A, Sannen L 2004 J. Nucl. Mater. 327 121

Google Scholar

Google Scholar

[4] Zinkle S J, Terrani K A, Gehin J C, Ott L J, Snead L L 2014 J. Nucl. Mater. 448 374

Google Scholar

Google Scholar

[5] Terrani K A, Wang D, Ott L J, Montgomery R O 2014 J. Nucl. Mater. 448 512

Google Scholar

Google Scholar

[6] Johnson K D, Raftery A M, Lopes D A, Wallenius J 2016 J. Nucl. Mater. 477 18

Google Scholar

Google Scholar

[7] Watkins J K, Gonzales A, Wagner A R, Sooby E S, Jaques B J 2021 J. Nucl. Mater. 553 153048

Google Scholar

Google Scholar

[8] Wood E S, White J T, Nelson A T 2017 J. Nucl. Mater 484 245

Google Scholar

Google Scholar

[9] Ortega L H, Blamer B J, Evans J A, McDeavitt S M 2016 J. Nucl. Mater. 471 116

Google Scholar

Google Scholar

[10] White J T, Travis A W, Dunwoody J T, Nelson A T 2017 J. Nucl. Mater. 495 463

Google Scholar

Google Scholar

[11] Lopes D A, Uygur S, Johnson K D 2017 J. Nucl. Sci. Technol. 54 405

Google Scholar

Google Scholar

[12] 刘续希, 高士森, 喇永孝, 玉栋梁, 柳文波 2024 73 148201

Google Scholar

Google Scholar

Liu X X, Gao S S, La Y X, Yu D L, Liu W B 2024 Acta Phys. Sin. 73 148201

Google Scholar

Google Scholar

[13] 刘东昆, 王庆宇, 张田, 周羽, 王翔 2024 73 066102

Google Scholar

Google Scholar

Liu D K, Wang Q Y, Zhang T, Zhou Y, Wang X 2024 Acta Phys. Sin. 73 066102

Google Scholar

Google Scholar

[14] 王凯乐, 杨文奎, 史新成, 侯华, 赵宇宏 2023 72 076102

Google Scholar

Google Scholar

Wang K L, Yang W K, Shi X C, Hou H, Zhao Y H 2023 Acta Phys. Sin. 72 076102

Google Scholar

Google Scholar

[15] 刘明治, 张瑞杰, 方伟, 章书周, 曲选辉 2012 金属学报 48 1207

Google Scholar

Google Scholar

Liu M Z, Zhang R J, Fang W, Zhang S Z, Qu X H 2012 Acta. Metall. Sin. 48 1207

Google Scholar

Google Scholar

[16] Kumar V, Fang Z Z, Fife P C 2010 Mater. Sci. Eng. A 528 254

Google Scholar

Google Scholar

[17] Biswas S, Schwen D, Wang H, Okuniewski M, Tomar V 2018 Comput. Mater. Sci. 148 307

Google Scholar

Google Scholar

[18] Du L F, Yang S M, Zhu X W, Jiang J, Hui Q, Du H L 2018 J. Mater. Sci. 53 9567

Google Scholar

Google Scholar

[19] Hötzer J, Seiz M, Kellner M, Rheinheimer W, Nestler B 2019 Acta Mater. 164 184

Google Scholar

Google Scholar

[20] Wang Y U 2006 Acta Mater. 54 953

Google Scholar

Google Scholar

[21] Fan D, Chen L Q 1997 Acta Mater. 45 611

Google Scholar

Google Scholar

[22] Moelans N, Blanpain B, Wollants P 2008 Phys. Rev. B 78 024113

Google Scholar

Google Scholar

[23] Ahmed K, Yablinsky C A, Schulte A, Allen T, El-Azab A 2013 Modell. Simul. Mater. Sci. Eng. 21 065005

Google Scholar

Google Scholar

[24] Cahn J W 1961 Acta Metall. 9 795

Google Scholar

Google Scholar

[25] Allen S M, Cahn J W 1979 Acta Metall. 27 1085

Google Scholar

Google Scholar

[26] Biner S B 2017 Programming Phase-Field Modeling (Switzerland: Springer International Publishing) p18

[27] Holt J B, Almassy M Y 1969 J. Am. Ceram. Soc. 52 631

Google Scholar

Google Scholar

[28] 戚晓勇, 柳文波, 何宗倍, 王一帆, 恽迪 2023 金属学报 59 1513

Google Scholar

Google Scholar

Qi X Y, Liu W B, He Z B, Wang Y F, Yun D 2023 Acta Metall. Sin. 59 1513

Google Scholar

Google Scholar

[29] Bocharov D, Gryaznov D, Zhukovskii Y F, Kotomin E A 2013 J. Nucl. Mater. 435 102

Google Scholar

Google Scholar

[30] Cooper M W D, Gamble K A, Capolungo L, Matthews C, Andersson D A, Beeler B, Stanek C R, Metzger K 2021 J. Nucl. Mater. 555 153129

Google Scholar

Google Scholar

[31] Beeler B, Baskes M, Andersson D, Cooper M W D, Zhang Y F 2019 J. Nucl. Mater. 514 290

Google Scholar

Google Scholar

[32] Cheniour A, Tonks M R, Gong B, Yao T K, He L F, Harp J M, Beeler B, Zhang Y F, Lian J 2020 J. Nucl. Mater 532 152069

Google Scholar

Google Scholar

[33] Chockalingam K, Kouznetsova V G, van der Sluis O, Geers M G D 2016 Comput. Methods Appl. Mech. Eng. 312 492

Google Scholar

Google Scholar

[34] Rahaman M N 1995 Ceramic Processing and Sintering (New York: Marcel Dekker) p446

[35] Riedel H, Svoboda J 1993 Acta Metall. Mater. 41 1929

Google Scholar

Google Scholar

[36] 孙正阳, 杨超, 柳文波 2020 金属学报 56 1295

Google Scholar

Google Scholar

Sun Z Y, Yang C, Liu W B 2020 Acta Metall. Sin. 56 1295

Google Scholar

Google Scholar

[37] Ahmed K, Allen T, El-Azab A 2016 J. Mater. Sci. 51 1261

Google Scholar

Google Scholar

[38] Yadav V, Vanherpe L, Moelans N 2016 Comput. Mater. Sci. 125 297

Google Scholar

Google Scholar

计量

- 文章访问数: 2265

- PDF下载量: 83

- 被引次数: 0

下载:

下载: