-

介电电容器具有功率密度高、充放电速度快、损耗低及循环稳定性好等优点, 在先进电子和电力系统中发挥了重要的应用. 聚合物电介质凭借其高击穿强度、柔性和易加工等优点, 成为高电压电容器的首选材料. 然而, 其较低的温度稳定性难以满足新能源汽车和光伏发电等新兴领域对高工作温度的需求. 本文利用物理气相沉积技术, 在具有高玻璃化转变温度(Tg)的热塑性聚酰亚胺(TPI)薄膜表面沉积氧化铝(Al2O3)镀层, 制备了有机/无机三明治结构的Al2O3/TPI/Al2O3电介质薄膜. 研究结果显示, 氧化铝镀层不仅与TPI之间具有优异的界面结合性, 还提高了肖特基势垒, 抑制了电极电荷的注入, 从而降低了高温下的漏电流, 并提高了击穿强度. 制备的Al2O3/TPI/Al2O3三明治结构薄膜在高温下获得了优异的放电能量密度(Ud)和充放电效率(η). 例如, 在150和200 ℃高温下, η > 90%时的Ud分别达到4.06和2.72 J/cm³, 相比纯TPI薄膜提升了98.0%和349.4%.Dielectric capacitors are essential components in advanced electronic and power systems due to their high power densities, fast charge-discharge rates, low losses, and excellent cycling stabilities. Polymer dielectrics, such as biaxially oriented polypropylene (BOPP), are preferred dielectric materials for high-voltage capacitors because of their high breakdown strength, flexibility, and easy processing. However, their relatively low thermal stability limits their applications in high-temperature environments, such as in electric vehicles and photovoltaic power generation systems. In this study, sandwich-structured dielectric films are prepared by using physical vapor deposition (PVD) to deposit aluminum oxide (Al2O3) layers onto thermoplastic polyimide (TPI) films to achieve high capacitive energy storage at high temperatures. The TPI films are chosen for their high glass transition temperature (Tg), while Al2O3 layers are deposited to enhance the Schottky barrier, thereby suppressing electrode charge injection, reducing leakage current, and improving breakdown strength at high temperatures. Various characterization techniques are employed to assess the microstructure, dielectric properties, and energy storage performance of the prepared Al2O3/TPI/Al2O3 sandwich-structured films. The results demonstrate that the Al2O3 coating exhibits excellent interfacial adhesion with TPI films, successfully inhibiting charge injection and thereby reducing leakage current. For instance, at 150 °C and 250 MV/m, the leakage current density of TPI film is 3.19×10–7 A/cm², whereas for Al2O3/TPI/Al2O3 sandwich-structured film, its leakage current density is 2.77×10–8 A/cm², a decrease of one order of magnitude. The suppression of charge injection and reduction of leakage current contribute to outstanding discharge energy density (Ud) and charge-discharge efficiency (η) at high temperatures. Specifically, at high temperatures of 150 and 200 °C, the Ud reaches 4.06 and 2.72 J/cm³, respectively, with η > 90%, i.e. increasing 98.0% and 349.4% compared with those of pure TPI films. Furthermore, the PVD process used for fabricating these sandwich-structured films is highly compatible with existing methods of producing metal electrodes in capacitors, offering significant advantages in production efficiency and cost control. This study suggests that the Al2O3/TPI/Al2O3 sandwich-structured films, prepared by using the PVD process and exhibiting exceptional high-temperature capacitive energy storage performance, are highly promising for applications in environments with high temperatures and high electric fields.

[1] 查俊伟, 查磊军, 郑明胜 2023 72 018401

Google Scholar

Google Scholar

Zha J W, Zha L J, Zheng M S 2023 Acta Phys. Sin. 72 018401

Google Scholar

Google Scholar

[2] Zhang M, Lan S, Yang B B, Pan H, Liu Y Q, Zhang Q H, Qi J L, Chen D, Su H, Yi D, Yang Y Y, Wei R, Cai H D, Han H J, Gu L, Nan C W, Lin Y H 2024 Science 384 185

Google Scholar

Google Scholar

[3] Luo H, Wang F, Guo R, Zhang D, He G H, Chen S, Wang Q 2022 Adv. Sci. 9 2202438

Google Scholar

Google Scholar

[4] Chen J, Pei Z T, Chai B, Jiang P K, Ma L, Zhu L, Huang X Y 2023 Adv. Mater. 2308670

Google Scholar

Google Scholar

[5] Ho J, Jow T R 2012 IEEE Trans. Dielect. Electr. Insul. 19 990

Google Scholar

Google Scholar

[6] Zhang Q, Chen X, Zhang B, Zhang T, Lu W, Chen Z, Liu Z, Kim S H, Donovan B, Warzoha R J, Gomez E D, Bernholc J, Zhang Q M 2021 Matter 4 2448

Google Scholar

Google Scholar

[7] Li Q, Yao F Z, Liu Y, Zhang G, Wang H, Wang Q 2018 Annu. Rev. Mater. Res. 48 219

Google Scholar

Google Scholar

[8] Ho J S, Greenbaum S G 2018 ACS Appl. Mater. Interfaces 10 29189

Google Scholar

Google Scholar

[9] Zhang Q, Chen X, Zhang T, Zhang Q M 2019 Nano Energy 64 103916

Google Scholar

Google Scholar

[10] Zhang Q, Li D, Zhong Y, Hu Y, Huang S, Dong S, Zhang Q 2024 Energy Environ. Sci. In Press

Google Scholar

Google Scholar

[11] Wang R, Zhu Y, Fu J, Yang M, Ran Z, Li J, Li M, Hu J, He J, Li Q 2023 Nat. Commun. 14 2406

Google Scholar

Google Scholar

[12] Zhang T, Chen X, Thakur Y, Lu B, Zhang Q, Runt J, Zhang Q M 2020 Sci. Adv. 6 eaax6622

Google Scholar

Google Scholar

[13] 董久锋, 邓星磊, 牛玉娟, 潘子钊, 汪宏 2020 69 217701

Google Scholar

Google Scholar

Dong J F, Deng X L, Niu Y J, Pan Z Z, Wang H 2020 Acta Phys. Sin. 69 217701

Google Scholar

Google Scholar

[14] Li Q, Chen L, Gadinski M R, Zhang S, Zhang G, Li H U, Iagodkine E, Haque A, Chen L Q, Jackson T N, Wang Q 2015 Nature 523 576

Google Scholar

Google Scholar

[15] Pei J, Yin L, Zhong S, Dang Z 2023 Adv. Mater. 35 2203623

Google Scholar

Google Scholar

[16] Wu F, Xie A, Jiang L, Mukherjee S, Gao H, Shi J, Wu J, Shang H, Sheng Z, Guo R, Wu L, Liu J, Suss M E, Terzis A, Li W, Zeng H 2023 Adv. Funct. Mater. 33 2212861

Google Scholar

Google Scholar

[17] Min D, Ji M, Li P, Gao Z, Liu W, Li S, Liu J 2021 IEEE Trans. Dielectr. Electr. Insul. 28 2011

Google Scholar

Google Scholar

[18] Li H, Ai D, Ren L, Yao B, Han Z, Shen Z, Wang J, Chen L, Wang Q 2019 Adv. Mater. 31 1900875

Google Scholar

Google Scholar

[19] Li Q, Cheng S 2020 IEEE Electr. Insul. Mag. 36 7

Google Scholar

Google Scholar

[20] Rui G C, Bernholc J, Zhang S H, Zhang Q M 2024 Adv. Mater. 2311739

Google Scholar

Google Scholar

[21] Yuan C, Zhou Y, Zhu Y, Liang J, Wang S, Peng S, Li Y, Cheng S, Yang M, Hu J, Zhang B, Zeng R, He J, Li Q 2020 Nat. Commun. 11 3919

Google Scholar

Google Scholar

[22] Zhou Y, Zhu Y, Xu W, Wang Q 2023 Adv. Energy Mater. 13 2203961

Google Scholar

Google Scholar

[23] Li Z, Zhang Y, Pan Z, Fan X, Li P, Chen W, Liu J, Li W 2024 ACS Appl. Mater. Interfaces 16 10756

Google Scholar

Google Scholar

[24] Ai D, Li H, Zhou Y, Ren L, Han Z, Yao B, Zhou W, Zhao L, Xu J, Wang Q 2020 Adv. Energy Mater. 10 1903881

Google Scholar

Google Scholar

[25] Tan D Q 2020 Adv. Funct. Mater. 30 1808567

Google Scholar

Google Scholar

[26] Zhang T, Sun H, Yin C, Jung Y H, Min S, Zhang Y, Zhang C, Chen Q, Lee K J, Chi Q 2023 Prog. Mater. Sci. 140 101207

Google Scholar

Google Scholar

[27] Zhou Y, Li Q, Dang B, Yang Y, Shao T, Li H, Hu J, Zeng R, He J, Wang Q 2018 Adv. Mater. 30 1805672

Google Scholar

Google Scholar

[28] Li H, Chang B S, Kim H, Xie Z, Lainé A, Ma L, Xu T, Yang C, Kwon J, Shelton S W, Klivansky L M, Altoé V, Gao B, Schwartzberg A M, Peng Z, Ritchie R O, Xu T, Salmeron M, Ruiz R, Sharpless K B, Wu P, Liu Y 2023 Joule 7 95

Google Scholar

Google Scholar

[29] Cheng S, Zhou Y, Hu J, He J, Li Q 2020 IEEE Trans. Dielectr. Electr. Insul. 27 498

Google Scholar

Google Scholar

[30] Cheng S, Zhou Y, Li Y S, Yuan C, Yang M C, Fu J, Hu J, He J L 2021 Energy Storage Mater. 42 445

Google Scholar

Google Scholar

[31] Wu X, Song G, Zhang X, Lin X, Ivry Y, Tan D Q 2022 Chem. Eng. J. 450 137940

Google Scholar

Google Scholar

[32] Azizi A, Gadinski M R, Li Q, AlSaud M A, Wang J, Wang Y, Wang B, Liu F, Chen L, Alem N, Wang Q 2017 Adv. Mater. 29 1701864

Google Scholar

Google Scholar

[33] 李雨凡, 薛文清, 李玉超, 战艳虎, 谢倩, 李艳凯, 查俊伟 2024 73 027702

Google Scholar

Google Scholar

Li Y F, Xue W Q, Li Y C, Zhan Y H, Xie Q, Li Y K, Zha J W 2024 Acta Phys. Sin. 73 027702

Google Scholar

Google Scholar

[34] Pan L, Wang F, He Y, Du G 2022 2022 IEEE International Conference on High Voltage Engineering and Applications (ICHVE) Chongqing, China , 2022-09-25, 2022 pp1–4

[35] Li J, Ren G K, Chen J, Chen X, Wu W, Liu Y, Chen X, Song J, Lin Y H, Shi Y 2022 JOM 74 3069

Google Scholar

Google Scholar

[36] Bao Z, Du X, Ding S, Chen J, Dai Z, Liu C, Wang Y, Yin Y, Li X 2022 ACS Appl. Energy Mater. 5 3119

Google Scholar

Google Scholar

[37] Dissado L, Fothergill J, Wolfe S, Hill R 1984 IEEE Trans. Electr. Insul. EI-19 227

Google Scholar

Google Scholar

-

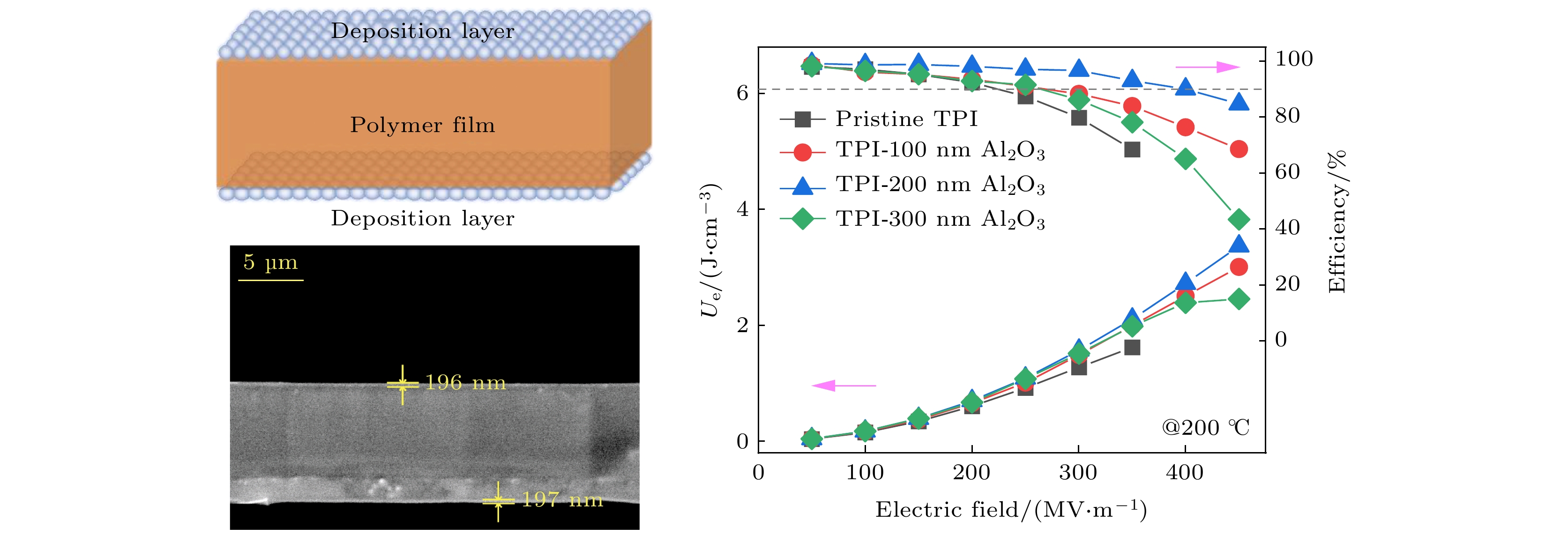

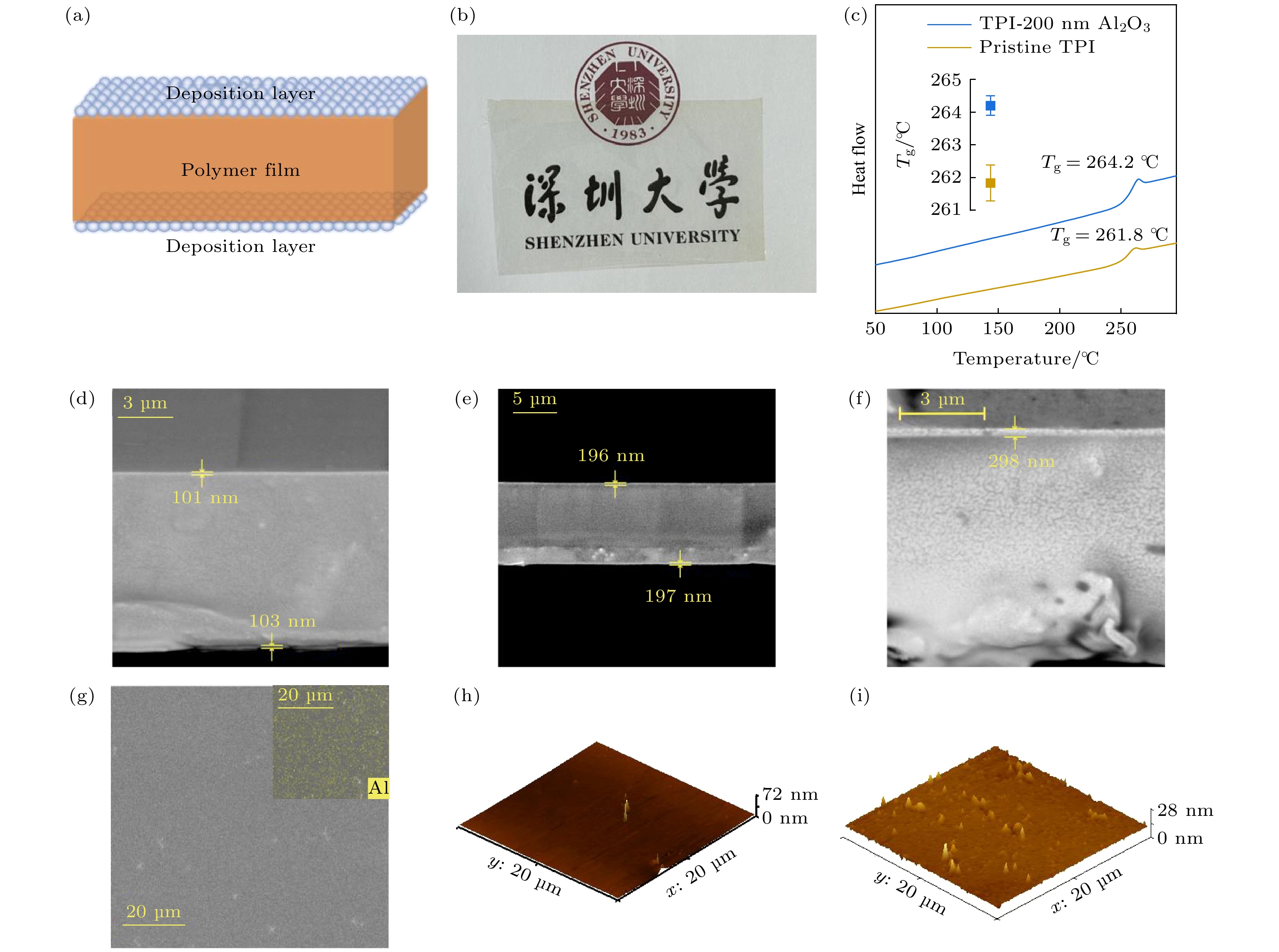

图 1 (a) 三明治结构电介质薄膜的结构示意图; (b) Al2O3/TPI/Al2O3三明治结构薄膜的实物图; (c) TPI沉积氧化铝镀层前后的DSC升温曲线; 不同镀层厚度Al2O3/TPI/Al2O3薄膜的SEM图 (d) 100 nm; (e) 200 nm; (f) 300 nm; (g) Al2O3/TPI/ Al2O3薄膜的表面SEM照片及EDS分析图片; (h) Al2O3/TPI/ Al2O3薄膜表面AFM三维照片; (i) 纯TPI薄膜表面AFM三维照片

Fig. 1. (a) Schematic diagram of the sandwich-structured dielectric films; (b) photograph of TPI coated with aluminum oxide layer; (c) DSC heating curves of TPI films before and after Al2O3 deposition; scanning electron microscope (SEM) images of TPI films with Al2O3 coating layers of (d) 100, (e) 200, and (f) 300 nm thickness; (g) SEM images and EDS analysis of the Al2O3/TPI/Al2O3 films; 3D AFM images of the surface of (h) the Al2O3/TPI/Al2O3 films and (i) pristine TPI films.

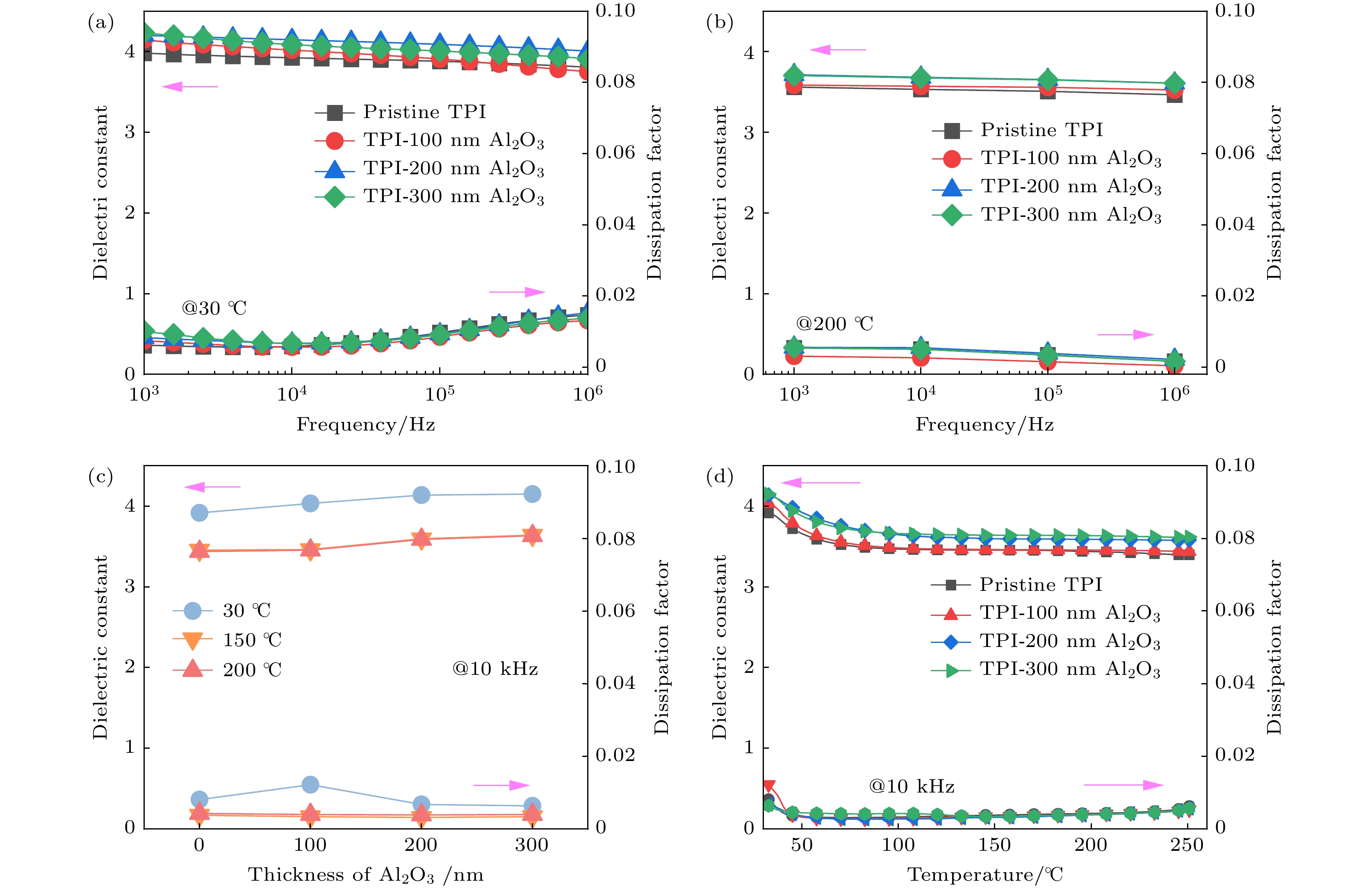

图 2 (a) 常温和(b) 200 ℃温度下TPI及其三明治结构薄膜的介电常数与介电损耗随频率的变化; (c) 10 kHz下样品的介电常数和介电损耗随Al2O3镀层厚度的变化; (d) TPI及其三明治结构薄膜在10 kHz下介电常数与介电损耗随温度的变化图

Fig. 2. Dielectric constant and dielectric loss of TPI and its sandwich-structured films as a function of frequency at (a) Room temperature and (b) 200 ℃; (c) dielectric constant and dielectric loss at 10 kHz as a function of Al2O3 coating thickness; (d) dielectric constant and dielectric loss of TPI and its sandwich-structured films as a function of temperature at 10 kHz.

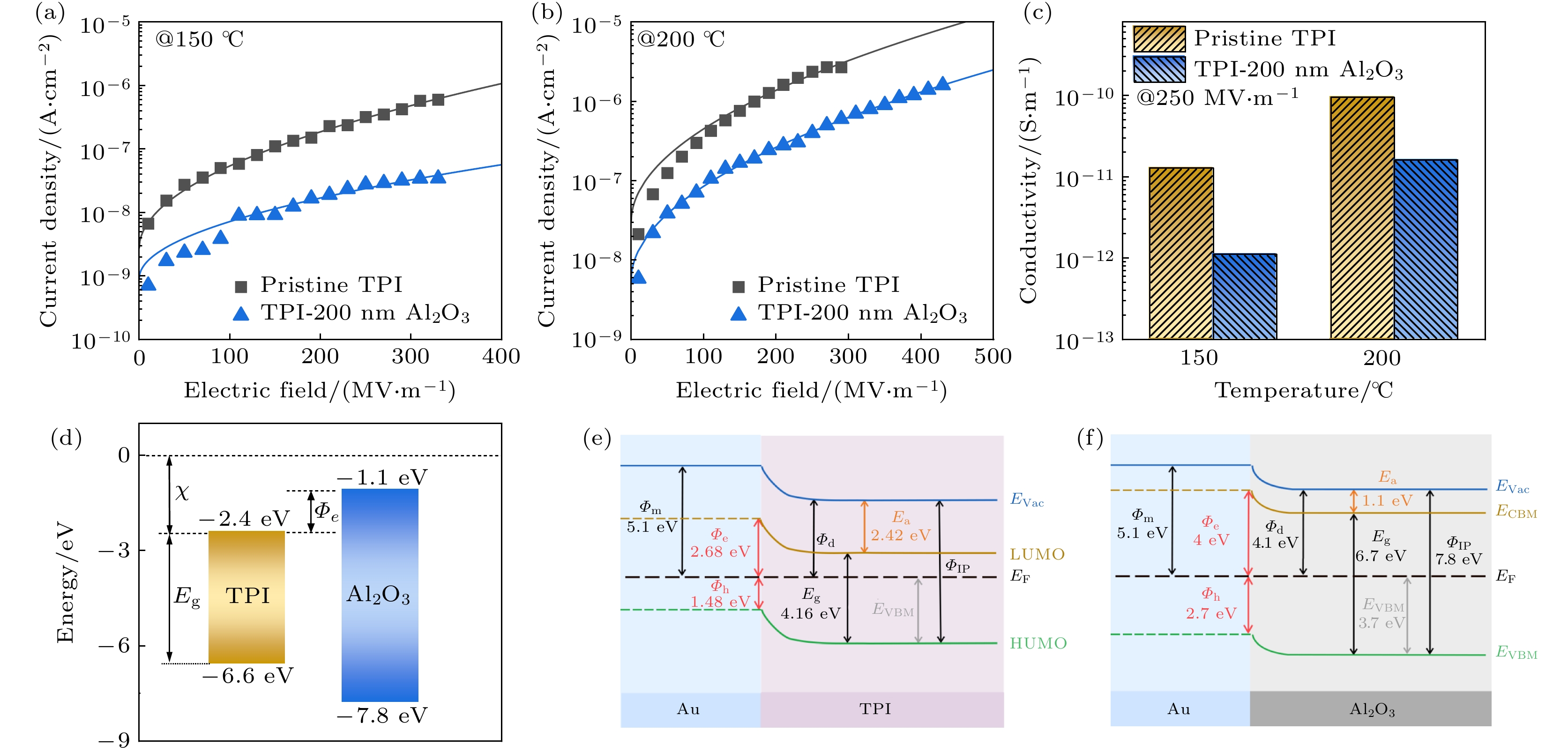

图 3 (a) 150和(b) 200 ℃下TPI薄膜在沉积Al2O3镀层前后漏电流密度随电场强度的变化; (c) 不同温度下TPI薄膜沉积Al2O3前后的电导率对比; (d) 密度泛函理论计算得到的TPI与Al2O3能带示意图; (e) 电极Au与电介质TPI界面处能带结构图; (f) 电极Au与镀层Al2O3界面处能带结构图

Fig. 3. Leakage current density of TPI films before and after Al2O3 deposition at (a) 150 and (b) 200 ℃; (c) comparation of electrical conductivity for TPI films before and after Al2O3 deposition at 150 and 200 ℃; (d) energy band diagram of TPI and Al2O3 obtained from density functional theory (DFT) calculations; (e) energy band structure at the interface between the Au electrode and the TPI dielectric; (f) energy band structure at the interface between the Au electrode and the Al2O3 coating.

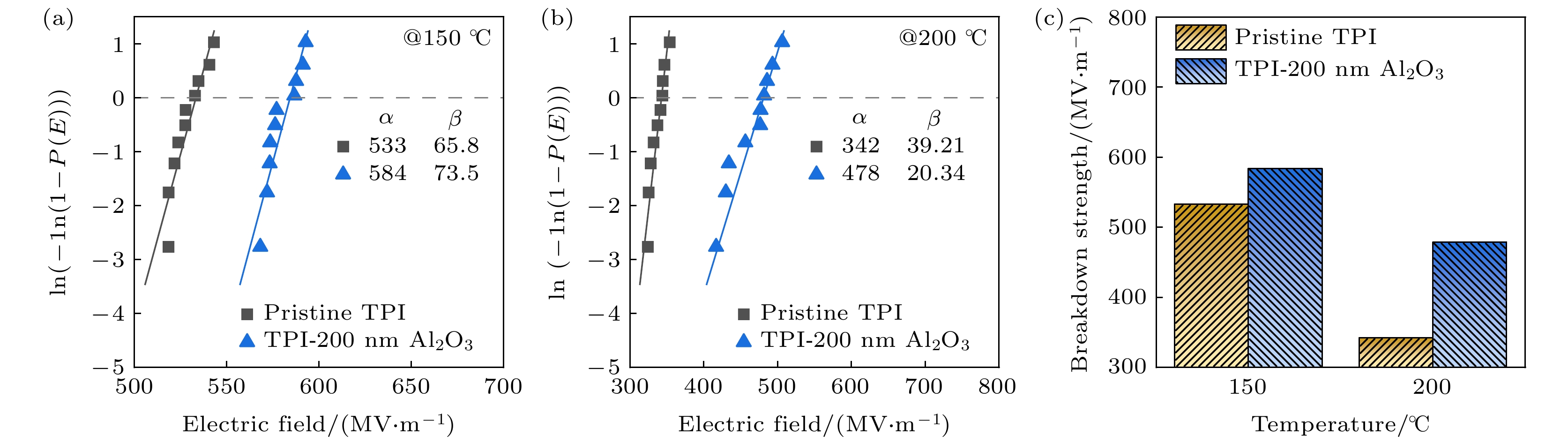

图 4 (a) 150和 (b) 200 ℃下TPI和TPI-200 nm Al2O3薄膜的韦伯分布击穿强度; (c) 不同温度下TPI和TPI-200 nm Al2O3薄膜击穿强度的对比

Fig. 4. Weibull distribution of breakdown strength for TPI and TPI-200 nm Al2O3 films at (a) 150 and 200 ℃; (c) comparation of the weibull breakdown strength for TPI and TPI-200 nm Al2O3 films at different temperatures.

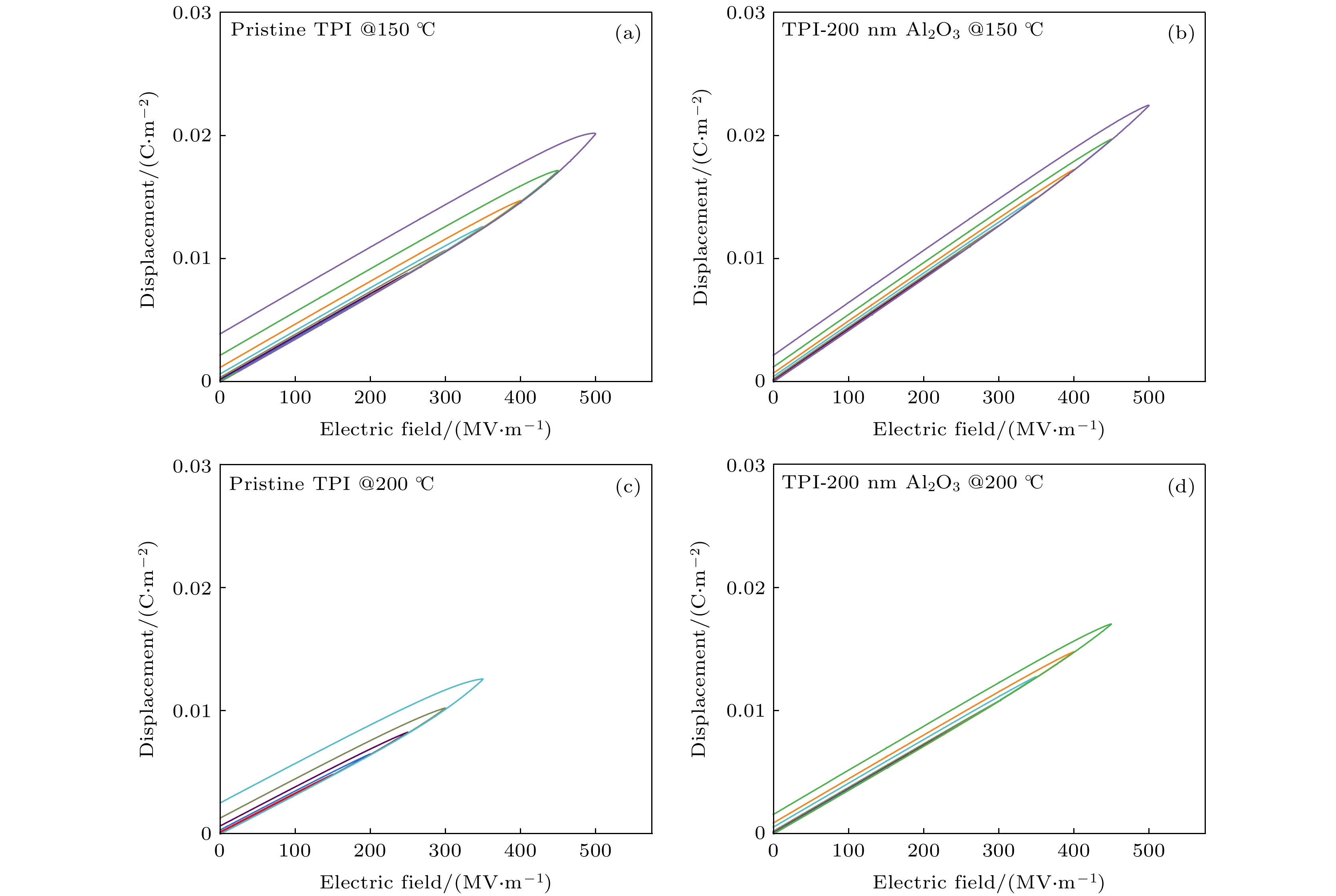

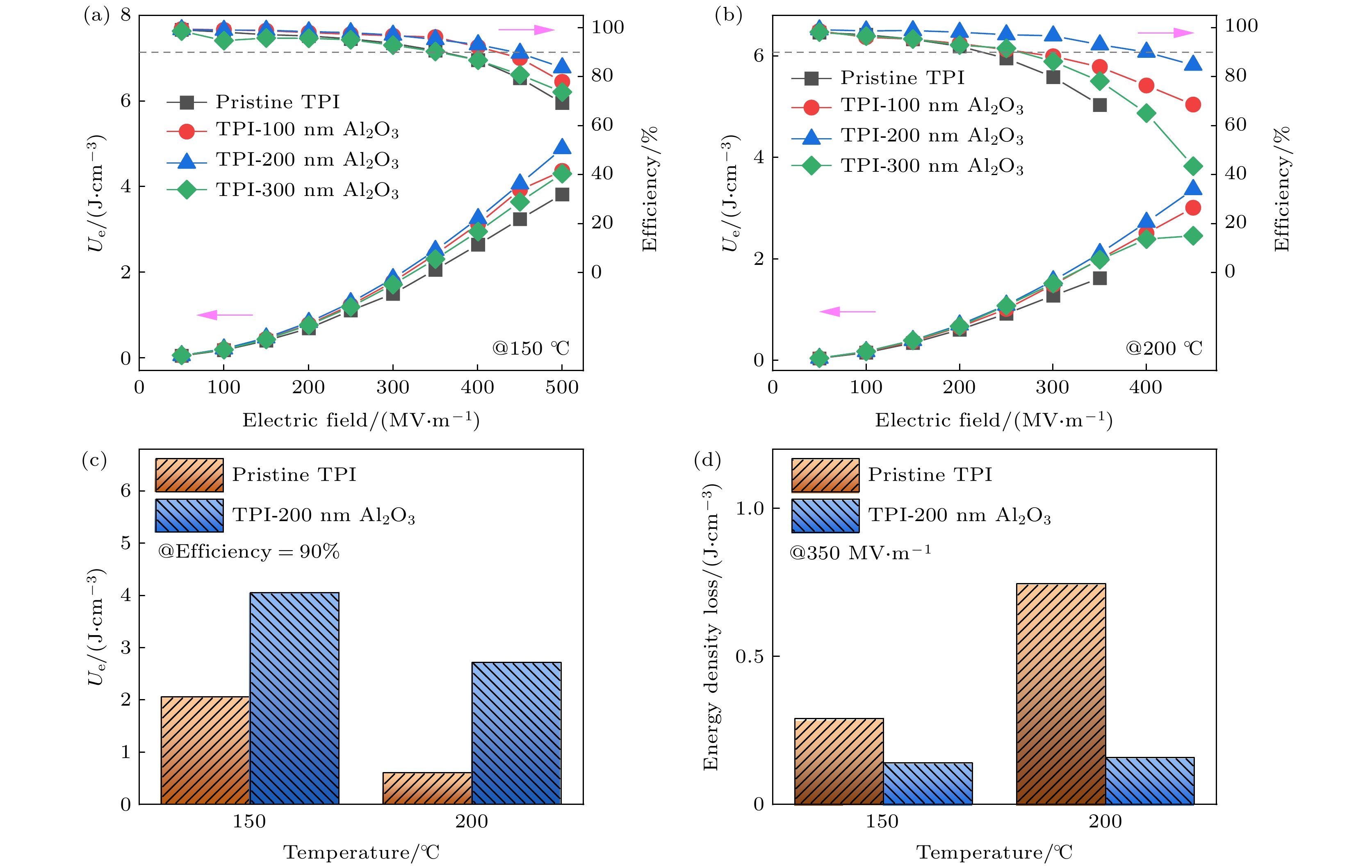

图 6 (a) 150 ℃ 和(b) 200 ℃温度下放电能量密度(Ue)和充放电效率随电场强度的变化曲线; (c) 不同温度下TPI-200 nm Al2O3和TPI电介质薄膜在90%效率时的放电能量密度对比; (d) 不同温度下TPI-200 nm Al2O3和TPI电介质薄膜在电场强度350 MV/m下能量密度损失的对比

Fig. 6. Discharge energy density (Ue) and charge-discharge efficiency (η) at different electric fields at (a) 150 ℃ and (b) 200 ℃; (c) comparation of the discharge energy density at 90% efficiency for TPI-200 nm Al2O3 and TPI films at 150 and 200 ℃; (d) comparation of energy density loss at 350 MV/m for TPI-200 nm Al2O3 and TPI films at 150 and 200 ℃.

-

[1] 查俊伟, 查磊军, 郑明胜 2023 72 018401

Google Scholar

Google Scholar

Zha J W, Zha L J, Zheng M S 2023 Acta Phys. Sin. 72 018401

Google Scholar

Google Scholar

[2] Zhang M, Lan S, Yang B B, Pan H, Liu Y Q, Zhang Q H, Qi J L, Chen D, Su H, Yi D, Yang Y Y, Wei R, Cai H D, Han H J, Gu L, Nan C W, Lin Y H 2024 Science 384 185

Google Scholar

Google Scholar

[3] Luo H, Wang F, Guo R, Zhang D, He G H, Chen S, Wang Q 2022 Adv. Sci. 9 2202438

Google Scholar

Google Scholar

[4] Chen J, Pei Z T, Chai B, Jiang P K, Ma L, Zhu L, Huang X Y 2023 Adv. Mater. 2308670

Google Scholar

Google Scholar

[5] Ho J, Jow T R 2012 IEEE Trans. Dielect. Electr. Insul. 19 990

Google Scholar

Google Scholar

[6] Zhang Q, Chen X, Zhang B, Zhang T, Lu W, Chen Z, Liu Z, Kim S H, Donovan B, Warzoha R J, Gomez E D, Bernholc J, Zhang Q M 2021 Matter 4 2448

Google Scholar

Google Scholar

[7] Li Q, Yao F Z, Liu Y, Zhang G, Wang H, Wang Q 2018 Annu. Rev. Mater. Res. 48 219

Google Scholar

Google Scholar

[8] Ho J S, Greenbaum S G 2018 ACS Appl. Mater. Interfaces 10 29189

Google Scholar

Google Scholar

[9] Zhang Q, Chen X, Zhang T, Zhang Q M 2019 Nano Energy 64 103916

Google Scholar

Google Scholar

[10] Zhang Q, Li D, Zhong Y, Hu Y, Huang S, Dong S, Zhang Q 2024 Energy Environ. Sci. In Press

Google Scholar

Google Scholar

[11] Wang R, Zhu Y, Fu J, Yang M, Ran Z, Li J, Li M, Hu J, He J, Li Q 2023 Nat. Commun. 14 2406

Google Scholar

Google Scholar

[12] Zhang T, Chen X, Thakur Y, Lu B, Zhang Q, Runt J, Zhang Q M 2020 Sci. Adv. 6 eaax6622

Google Scholar

Google Scholar

[13] 董久锋, 邓星磊, 牛玉娟, 潘子钊, 汪宏 2020 69 217701

Google Scholar

Google Scholar

Dong J F, Deng X L, Niu Y J, Pan Z Z, Wang H 2020 Acta Phys. Sin. 69 217701

Google Scholar

Google Scholar

[14] Li Q, Chen L, Gadinski M R, Zhang S, Zhang G, Li H U, Iagodkine E, Haque A, Chen L Q, Jackson T N, Wang Q 2015 Nature 523 576

Google Scholar

Google Scholar

[15] Pei J, Yin L, Zhong S, Dang Z 2023 Adv. Mater. 35 2203623

Google Scholar

Google Scholar

[16] Wu F, Xie A, Jiang L, Mukherjee S, Gao H, Shi J, Wu J, Shang H, Sheng Z, Guo R, Wu L, Liu J, Suss M E, Terzis A, Li W, Zeng H 2023 Adv. Funct. Mater. 33 2212861

Google Scholar

Google Scholar

[17] Min D, Ji M, Li P, Gao Z, Liu W, Li S, Liu J 2021 IEEE Trans. Dielectr. Electr. Insul. 28 2011

Google Scholar

Google Scholar

[18] Li H, Ai D, Ren L, Yao B, Han Z, Shen Z, Wang J, Chen L, Wang Q 2019 Adv. Mater. 31 1900875

Google Scholar

Google Scholar

[19] Li Q, Cheng S 2020 IEEE Electr. Insul. Mag. 36 7

Google Scholar

Google Scholar

[20] Rui G C, Bernholc J, Zhang S H, Zhang Q M 2024 Adv. Mater. 2311739

Google Scholar

Google Scholar

[21] Yuan C, Zhou Y, Zhu Y, Liang J, Wang S, Peng S, Li Y, Cheng S, Yang M, Hu J, Zhang B, Zeng R, He J, Li Q 2020 Nat. Commun. 11 3919

Google Scholar

Google Scholar

[22] Zhou Y, Zhu Y, Xu W, Wang Q 2023 Adv. Energy Mater. 13 2203961

Google Scholar

Google Scholar

[23] Li Z, Zhang Y, Pan Z, Fan X, Li P, Chen W, Liu J, Li W 2024 ACS Appl. Mater. Interfaces 16 10756

Google Scholar

Google Scholar

[24] Ai D, Li H, Zhou Y, Ren L, Han Z, Yao B, Zhou W, Zhao L, Xu J, Wang Q 2020 Adv. Energy Mater. 10 1903881

Google Scholar

Google Scholar

[25] Tan D Q 2020 Adv. Funct. Mater. 30 1808567

Google Scholar

Google Scholar

[26] Zhang T, Sun H, Yin C, Jung Y H, Min S, Zhang Y, Zhang C, Chen Q, Lee K J, Chi Q 2023 Prog. Mater. Sci. 140 101207

Google Scholar

Google Scholar

[27] Zhou Y, Li Q, Dang B, Yang Y, Shao T, Li H, Hu J, Zeng R, He J, Wang Q 2018 Adv. Mater. 30 1805672

Google Scholar

Google Scholar

[28] Li H, Chang B S, Kim H, Xie Z, Lainé A, Ma L, Xu T, Yang C, Kwon J, Shelton S W, Klivansky L M, Altoé V, Gao B, Schwartzberg A M, Peng Z, Ritchie R O, Xu T, Salmeron M, Ruiz R, Sharpless K B, Wu P, Liu Y 2023 Joule 7 95

Google Scholar

Google Scholar

[29] Cheng S, Zhou Y, Hu J, He J, Li Q 2020 IEEE Trans. Dielectr. Electr. Insul. 27 498

Google Scholar

Google Scholar

[30] Cheng S, Zhou Y, Li Y S, Yuan C, Yang M C, Fu J, Hu J, He J L 2021 Energy Storage Mater. 42 445

Google Scholar

Google Scholar

[31] Wu X, Song G, Zhang X, Lin X, Ivry Y, Tan D Q 2022 Chem. Eng. J. 450 137940

Google Scholar

Google Scholar

[32] Azizi A, Gadinski M R, Li Q, AlSaud M A, Wang J, Wang Y, Wang B, Liu F, Chen L, Alem N, Wang Q 2017 Adv. Mater. 29 1701864

Google Scholar

Google Scholar

[33] 李雨凡, 薛文清, 李玉超, 战艳虎, 谢倩, 李艳凯, 查俊伟 2024 73 027702

Google Scholar

Google Scholar

Li Y F, Xue W Q, Li Y C, Zhan Y H, Xie Q, Li Y K, Zha J W 2024 Acta Phys. Sin. 73 027702

Google Scholar

Google Scholar

[34] Pan L, Wang F, He Y, Du G 2022 2022 IEEE International Conference on High Voltage Engineering and Applications (ICHVE) Chongqing, China , 2022-09-25, 2022 pp1–4

[35] Li J, Ren G K, Chen J, Chen X, Wu W, Liu Y, Chen X, Song J, Lin Y H, Shi Y 2022 JOM 74 3069

Google Scholar

Google Scholar

[36] Bao Z, Du X, Ding S, Chen J, Dai Z, Liu C, Wang Y, Yin Y, Li X 2022 ACS Appl. Energy Mater. 5 3119

Google Scholar

Google Scholar

[37] Dissado L, Fothergill J, Wolfe S, Hill R 1984 IEEE Trans. Electr. Insul. EI-19 227

Google Scholar

Google Scholar

计量

- 文章访问数: 5447

- PDF下载量: 131

- 被引次数: 0

下载:

下载: