-

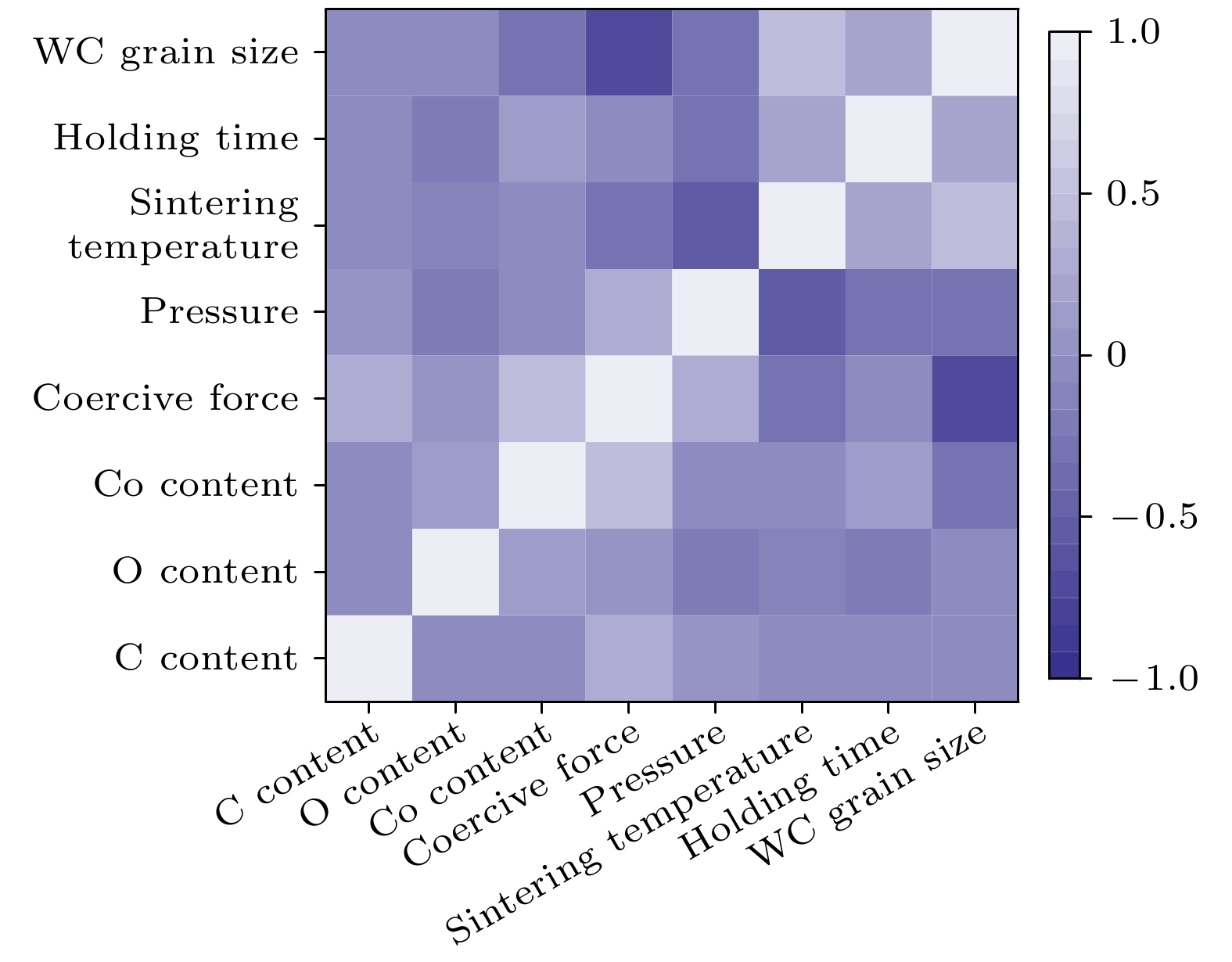

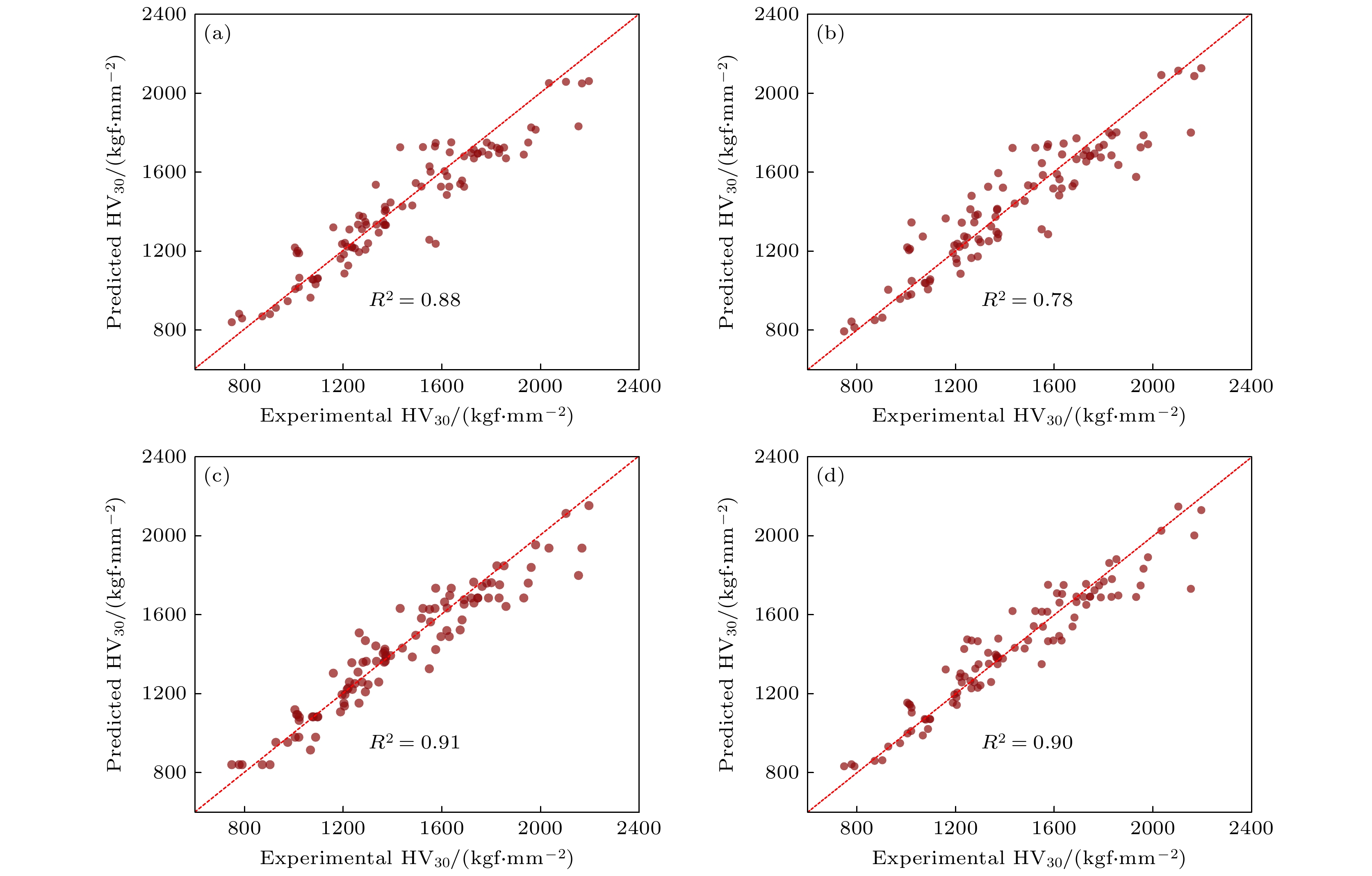

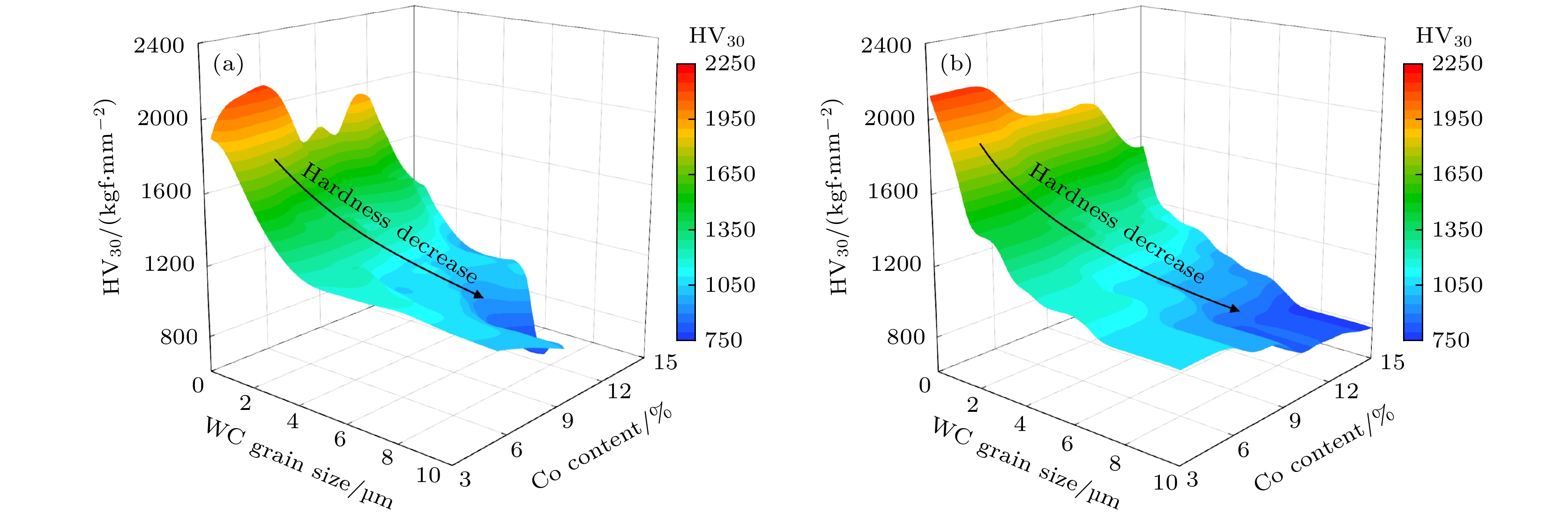

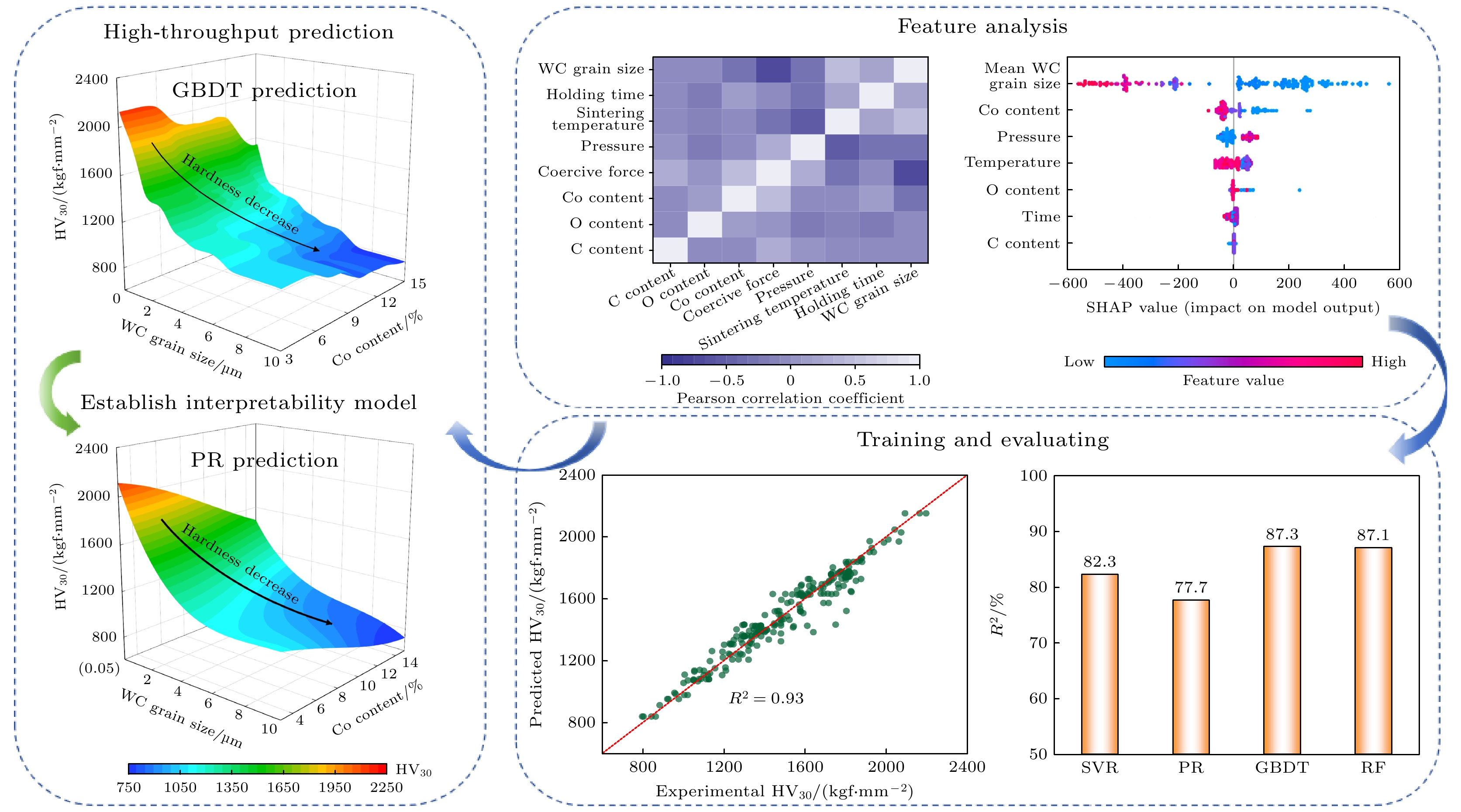

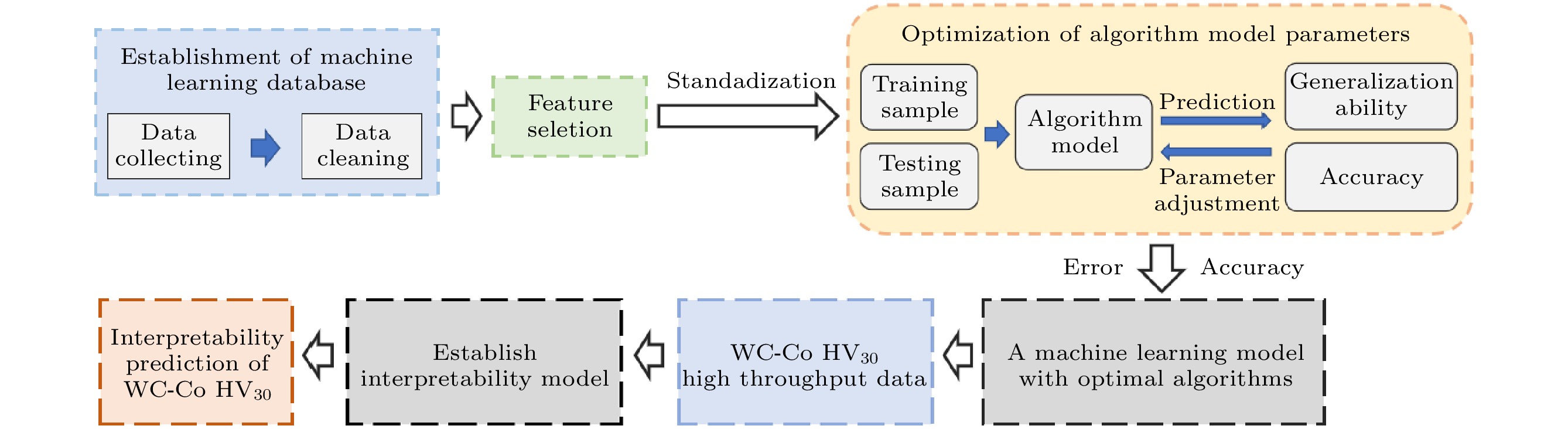

硬度是硬质合金材料的一项典型代表性能, 受多种因素的影响且各因素间常存在关联关系. 本文旨在获得WC-Co硬质合金硬度的关键影响因素并实现硬度的高通量预测. 建立了以硬质合金硬度为目标变量, 以原料成分、烧结工艺和烧结体表征信息为特征的数据集; 通过对特征的皮尔逊相关系数和SHAP分析, 发现WC晶粒尺寸和Co含量对硬质合金硬度的影响最为显著. 基于机器学习的支持向量机、多项式回归、梯度提升决策树、随机森林等算法, 分别构建了硬质合金硬度预测模型. 采用10折交叉验证方法对模型进行定量评估, 结果表明梯度提升决策树算法模型具有最高的精度和较强的泛化能力, 是最适合硬质合金硬度预测的机器学习方法. 基于优选模型的高通量预测数据, 采用多项式回归算法确定了硬质合金硬度与Co含量和WC晶粒尺寸之间的定量关系, 预测准确率达到0.946. 本研究为硬质合金性能的准确高效预测提供了数据驱动方法, 可为高性能硬质合金材料的设计研发提供重要参考.The hardness of cemented carbides is a fundamental property that plays a significant role in their design, preparation, and application evaluation. This study aims to identify the critical factors affecting the hardness of WC-Co cemented carbides and develop a high-throughput predictive model for hardness. A dataset consisting of raw material composition, sintering parameters and characterization results of cemented carbides is constructed in which the hardness of cemented carbide is set as the target variable. By analyzing the Pearson correlation coefficient, Shapley additive explanations (SHAP) results, WC grain size and Co content are determined to be the key characteristics influencing the hardness of cemented carbide. Subsequently, machine learning models such as support vector regression (SVR), polynomial regression (PR), gradient boosting decision tree (GBDT), and random forest (RF) are optimized to construct prediction models for hardness. Evaluations using 10-fold cross-validation demonstrate that the GBDT algorithm model exhibits the highest accuracy and strong generalization capability, making it most suitable for predicting and analyzing the hardness of cemented carbides. Based on predictions from GBDT algorithm model, PR algorithm model is established to achieve high-precision interpretable prediction of the hardness of cemented carbides. As a result, a quantitative relationship between hardness and Co content and WC grain size is obtained, demonstrating that reducing grain size and Co content is the key to obtaining high hardness of cemented carbide. This research provides a data-driven method for accurately and efficiently predicting cemented carbide properties, presenting valuable insights for the design and development of high-performance cemented carbide materials.

-

Keywords:

- cemented carbide /

- hardness /

- machine learning /

- high-throughput prediction

[1] 丁业章, 叶寅, 李多生, 徐锋, 朗文昌, 刘俊红, 温鑫 2023 72 068703

Google Scholar

Google Scholar

Ding Y Z, Ye Y, Li D S, Xu F, Lang W C, Liu J H, Wen X 2023 Acta Phys. Sin. 72 068703

Google Scholar

Google Scholar

[2] Useldinger R, Schleinkofer U 2017 Int. J. Refract. Met. Hard Mater. 62 170

Google Scholar

Google Scholar

[3] Springs G E 1995 Int. J. Refract. Met. Hard Mater. 13 241

Google Scholar

Google Scholar

[4] Ghasali E, Orooji Y, Tahamtan H, Asadian K, Alizadeh M, Ebadzadeh T 2020 Ceram. Int. 46 29199

Google Scholar

Google Scholar

[5] Ezquerra B L, Lozada L, Berg H V D, Wolf M, Sánchez J M 2018 Int. J. Refract. Met. Hard Mater. 72 89

Google Scholar

Google Scholar

[6] Sun L, Yang T E, Jia C C, Xiong J 2011 Int. J. Refract. Met. Hard Mater. 29 147

Google Scholar

Google Scholar

[7] Ding Q J, Zheng Y, Ke Z, Zhang G T, Wu H, Xu X Y, Lu X P, Zhu X G 2020 Int. J. Refract. Met. Hard Mater. 87 105166

Google Scholar

Google Scholar

[8] Hu H X, Liu X M, Chen J H, Lu H, Liu C, Wang H B, Luan J H, Jiao Z B, Liu Y, Song X Y 2022 J. Mater. Sci. Technol. 104 8

Google Scholar

Google Scholar

[9] Yu S B, Min F L, Ying G B, Noudem J G, Liu S J, Zhang J F 2021 Mater. Charact. 180 111386

Google Scholar

Google Scholar

[10] Tang Y Y, Wang S N, Xu F Y, Hong Y K, Luo X, He S M, Chen L Y, Zhong Z Q, Chen H, Xu G Z, Yang Q M 2021 J. Alloy Compd. 882 160638

Google Scholar

Google Scholar

[11] Jafari M, Enayati M H, Salehi M, Nahvi S M, Park C G 2014 Ceram. Int. 40 11031

Google Scholar

Google Scholar

[12] Wang H, Zeng M Q, Liu J W, Lu Z C, Shi Z H, Ouyang L Z, Zhu M 2015 Int. J. Refract. Met. Hard Mater. 48 97

Google Scholar

Google Scholar

[13] Singla G, Singh K, Pandey O P 2014 Ceram. Int. 40 5157

Google Scholar

Google Scholar

[14] Liu W H, Wu Y, He J Y, Nieh T G, Lu Z P 2013 Scripta Mater. 68 526

Google Scholar

Google Scholar

[15] Liu X M, Song X Y, Wei C B, Gao Y, Wang H B 2012 Scripta Mater. 66 825

Google Scholar

Google Scholar

[16] Song X Y, Gao Y, Liu X M, Wei C B, Wang H B, Xu W W 2013 Acta Mater. 61 2154

Google Scholar

Google Scholar

[17] Bonache V, Salvador M D, Fernández A, Borrell A 2011 Int. J. Refract. Met. Hard Mater. 29 202

Google Scholar

Google Scholar

[18] Fang Z , Maheshwari P, Wang X, Sohn H Y, Griffo A, Riley R 2005 Int. J. Refract. Met. Hard Mater. 23 249

Google Scholar

Google Scholar

[19] Fang Z Z, Wang X, Ryu T, Hwang K S, Sohn H Y 2009 Int. J. Refract. Met. Hard Mater. 27 288

Google Scholar

Google Scholar

[20] Liu K, Wang Z H, Yin Z B, Cao L Y, Yuan J T 2018 Ceram. Int. 44 18711

Google Scholar

Google Scholar

[21] 赵世贤, 宋晓艳, 刘雪梅, 魏崇斌, 王海滨, 高杨 2011 金属学报 47 1188

Google Scholar

Google Scholar

Zhao S X, Song X Y, Liu X M, Wei C B, Wang H B, Gao Y 2011 Acta Metall. Sin. 47 1188

Google Scholar

Google Scholar

[22] Roy A, Babuska T, Krick B, Balasubramanian G 2020 Scripta Mater. 185 152

Google Scholar

Google Scholar

[23] Chanda B, Jana P P, Das J 2021 Comp. Mater. Sci. 197 110619

Google Scholar

Google Scholar

[24] George K, Haoyan D, Chanho L, Samaei A T, Tu P, Maarten J, Ke A, Dong M, Peter K L, Wei C 2019 Acta Mater. 181 124

Google Scholar

Google Scholar

[25] Bakr M, Syarif J, Hashem I A T 2022 Mater. Today. Commun. 31 103407

Google Scholar

Google Scholar

[26] Ozerdem M S, Kolukisa S 2009 Mater. Design 30 764

Google Scholar

Google Scholar

[27] Sun Y, Zeng W D, Han Y F, Ma X, Zhao Y Q, Guo P, Wang G, Dargusch M S 2012 Comp. Mater. Sci. 60 239

Google Scholar

Google Scholar

[28] Zhang X Y, Dong R F, Guo Q W, Hou H, Zhao Y H 2023 J. Mater. Res. Technol. 26 4813

Google Scholar

Google Scholar

[29] Catal A A, Bedir E, Yilmaz R, Swider M A, Lee C, El-Atwani O, Maier H J, Ozdemir H C, Canadinc D 2024 Comp. Mater. Sci. 231 112612

Google Scholar

Google Scholar

[30] Guan Z H, Tian H X, Li N, Long J Z, Zhang W B, Du Y 2023 Ceram. Int. 49 613

Google Scholar

Google Scholar

[31] Guan Z H, Li N, Zhang W B, Wang J J, Wang C B, Shen Q, Xu Z G, Peng J, Du Y 2022 Int. J. Refract. Met. Hard Mater. 104 105798

Google Scholar

Google Scholar

[32] Rahadian H, Bandong S, Widyotriatmo A, Joelianto E 2023 Alex. Eng. J. 82 304

Google Scholar

Google Scholar

[33] Zhong L, Guo X, Ding M, Ye Y C, Jiang Y F, Zhu Q, Li J L 2024 Comput. Electron. Agr. 217 108627

Google Scholar

Google Scholar

[34] Someh N G, Pishvaee M S, Sadjadi S J, Soltani R 2020 J. Eval. Clin. Pract. 26 1498

Google Scholar

Google Scholar

[35] Cervantes J, Lamont F G, Mazahua L R, Lopez A 2020 Neurocomputing 408 189

Google Scholar

Google Scholar

[36] Tsai C Y, Kim J, Jin F, Jun M, Cheong M, Yammarino F J 2022 Leadership Quart. 33 101592

Google Scholar

Google Scholar

[37] Khakurel H, Tanfique M F N, Roy A, Balasubramanian G, Ouyang G, Cui J, Johson D D, Devanathan R 2021 Sci. Rep. 1117149

Google Scholar

Google Scholar

[38] Genuer R, Poggi J M, Malot C T, Vialaneix N V 2017 Big Data Res. 9 28

Google Scholar

Google Scholar

-

图 4 典型参数对GBDT算法模型的测试集准确率(R2)、偏差(Bias)和方差(Var)的影响 (a) 弱学习器数量; (b) 树的最大深度; (c) 叶子节点最少样本数; (d) 内部节点再划分所需最小样本数

Fig. 4. Performance of typical parameters on the testing set in terms of accuracy (R2)、bias (Bias) and variance (Var) based on GBDT model: (a) Number of estimator; (b) max depth; (c) min sample leaf; (d) min sample split.

-

[1] 丁业章, 叶寅, 李多生, 徐锋, 朗文昌, 刘俊红, 温鑫 2023 72 068703

Google Scholar

Google Scholar

Ding Y Z, Ye Y, Li D S, Xu F, Lang W C, Liu J H, Wen X 2023 Acta Phys. Sin. 72 068703

Google Scholar

Google Scholar

[2] Useldinger R, Schleinkofer U 2017 Int. J. Refract. Met. Hard Mater. 62 170

Google Scholar

Google Scholar

[3] Springs G E 1995 Int. J. Refract. Met. Hard Mater. 13 241

Google Scholar

Google Scholar

[4] Ghasali E, Orooji Y, Tahamtan H, Asadian K, Alizadeh M, Ebadzadeh T 2020 Ceram. Int. 46 29199

Google Scholar

Google Scholar

[5] Ezquerra B L, Lozada L, Berg H V D, Wolf M, Sánchez J M 2018 Int. J. Refract. Met. Hard Mater. 72 89

Google Scholar

Google Scholar

[6] Sun L, Yang T E, Jia C C, Xiong J 2011 Int. J. Refract. Met. Hard Mater. 29 147

Google Scholar

Google Scholar

[7] Ding Q J, Zheng Y, Ke Z, Zhang G T, Wu H, Xu X Y, Lu X P, Zhu X G 2020 Int. J. Refract. Met. Hard Mater. 87 105166

Google Scholar

Google Scholar

[8] Hu H X, Liu X M, Chen J H, Lu H, Liu C, Wang H B, Luan J H, Jiao Z B, Liu Y, Song X Y 2022 J. Mater. Sci. Technol. 104 8

Google Scholar

Google Scholar

[9] Yu S B, Min F L, Ying G B, Noudem J G, Liu S J, Zhang J F 2021 Mater. Charact. 180 111386

Google Scholar

Google Scholar

[10] Tang Y Y, Wang S N, Xu F Y, Hong Y K, Luo X, He S M, Chen L Y, Zhong Z Q, Chen H, Xu G Z, Yang Q M 2021 J. Alloy Compd. 882 160638

Google Scholar

Google Scholar

[11] Jafari M, Enayati M H, Salehi M, Nahvi S M, Park C G 2014 Ceram. Int. 40 11031

Google Scholar

Google Scholar

[12] Wang H, Zeng M Q, Liu J W, Lu Z C, Shi Z H, Ouyang L Z, Zhu M 2015 Int. J. Refract. Met. Hard Mater. 48 97

Google Scholar

Google Scholar

[13] Singla G, Singh K, Pandey O P 2014 Ceram. Int. 40 5157

Google Scholar

Google Scholar

[14] Liu W H, Wu Y, He J Y, Nieh T G, Lu Z P 2013 Scripta Mater. 68 526

Google Scholar

Google Scholar

[15] Liu X M, Song X Y, Wei C B, Gao Y, Wang H B 2012 Scripta Mater. 66 825

Google Scholar

Google Scholar

[16] Song X Y, Gao Y, Liu X M, Wei C B, Wang H B, Xu W W 2013 Acta Mater. 61 2154

Google Scholar

Google Scholar

[17] Bonache V, Salvador M D, Fernández A, Borrell A 2011 Int. J. Refract. Met. Hard Mater. 29 202

Google Scholar

Google Scholar

[18] Fang Z , Maheshwari P, Wang X, Sohn H Y, Griffo A, Riley R 2005 Int. J. Refract. Met. Hard Mater. 23 249

Google Scholar

Google Scholar

[19] Fang Z Z, Wang X, Ryu T, Hwang K S, Sohn H Y 2009 Int. J. Refract. Met. Hard Mater. 27 288

Google Scholar

Google Scholar

[20] Liu K, Wang Z H, Yin Z B, Cao L Y, Yuan J T 2018 Ceram. Int. 44 18711

Google Scholar

Google Scholar

[21] 赵世贤, 宋晓艳, 刘雪梅, 魏崇斌, 王海滨, 高杨 2011 金属学报 47 1188

Google Scholar

Google Scholar

Zhao S X, Song X Y, Liu X M, Wei C B, Wang H B, Gao Y 2011 Acta Metall. Sin. 47 1188

Google Scholar

Google Scholar

[22] Roy A, Babuska T, Krick B, Balasubramanian G 2020 Scripta Mater. 185 152

Google Scholar

Google Scholar

[23] Chanda B, Jana P P, Das J 2021 Comp. Mater. Sci. 197 110619

Google Scholar

Google Scholar

[24] George K, Haoyan D, Chanho L, Samaei A T, Tu P, Maarten J, Ke A, Dong M, Peter K L, Wei C 2019 Acta Mater. 181 124

Google Scholar

Google Scholar

[25] Bakr M, Syarif J, Hashem I A T 2022 Mater. Today. Commun. 31 103407

Google Scholar

Google Scholar

[26] Ozerdem M S, Kolukisa S 2009 Mater. Design 30 764

Google Scholar

Google Scholar

[27] Sun Y, Zeng W D, Han Y F, Ma X, Zhao Y Q, Guo P, Wang G, Dargusch M S 2012 Comp. Mater. Sci. 60 239

Google Scholar

Google Scholar

[28] Zhang X Y, Dong R F, Guo Q W, Hou H, Zhao Y H 2023 J. Mater. Res. Technol. 26 4813

Google Scholar

Google Scholar

[29] Catal A A, Bedir E, Yilmaz R, Swider M A, Lee C, El-Atwani O, Maier H J, Ozdemir H C, Canadinc D 2024 Comp. Mater. Sci. 231 112612

Google Scholar

Google Scholar

[30] Guan Z H, Tian H X, Li N, Long J Z, Zhang W B, Du Y 2023 Ceram. Int. 49 613

Google Scholar

Google Scholar

[31] Guan Z H, Li N, Zhang W B, Wang J J, Wang C B, Shen Q, Xu Z G, Peng J, Du Y 2022 Int. J. Refract. Met. Hard Mater. 104 105798

Google Scholar

Google Scholar

[32] Rahadian H, Bandong S, Widyotriatmo A, Joelianto E 2023 Alex. Eng. J. 82 304

Google Scholar

Google Scholar

[33] Zhong L, Guo X, Ding M, Ye Y C, Jiang Y F, Zhu Q, Li J L 2024 Comput. Electron. Agr. 217 108627

Google Scholar

Google Scholar

[34] Someh N G, Pishvaee M S, Sadjadi S J, Soltani R 2020 J. Eval. Clin. Pract. 26 1498

Google Scholar

Google Scholar

[35] Cervantes J, Lamont F G, Mazahua L R, Lopez A 2020 Neurocomputing 408 189

Google Scholar

Google Scholar

[36] Tsai C Y, Kim J, Jin F, Jun M, Cheong M, Yammarino F J 2022 Leadership Quart. 33 101592

Google Scholar

Google Scholar

[37] Khakurel H, Tanfique M F N, Roy A, Balasubramanian G, Ouyang G, Cui J, Johson D D, Devanathan R 2021 Sci. Rep. 1117149

Google Scholar

Google Scholar

[38] Genuer R, Poggi J M, Malot C T, Vialaneix N V 2017 Big Data Res. 9 28

Google Scholar

Google Scholar

计量

- 文章访问数: 1323

- PDF下载量: 42

- 被引次数: 0

下载:

下载: