-

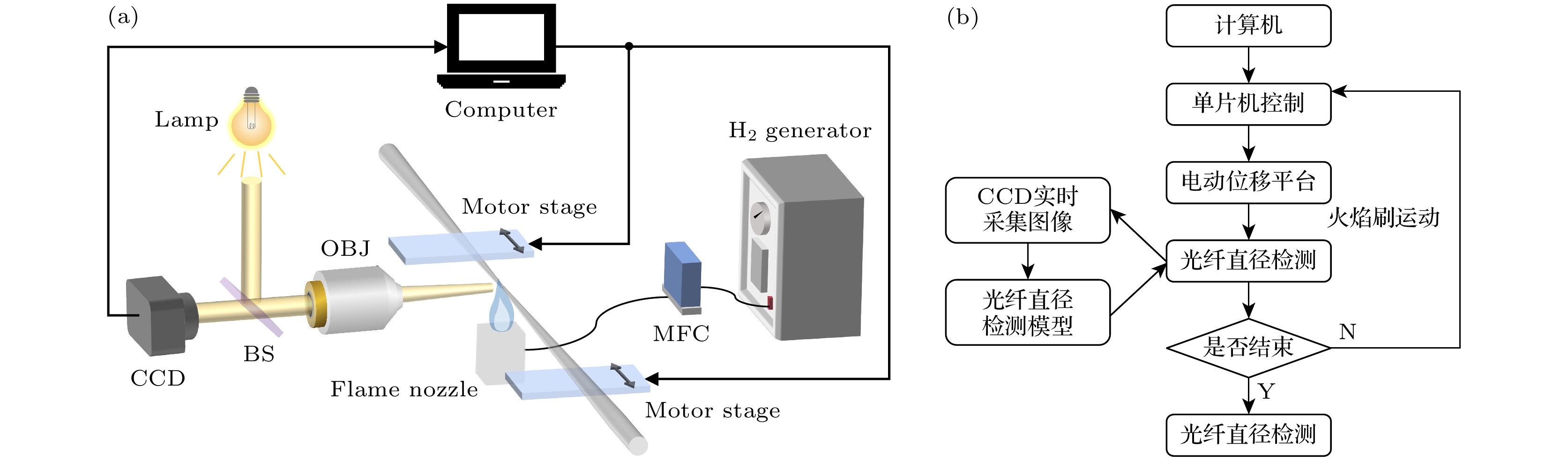

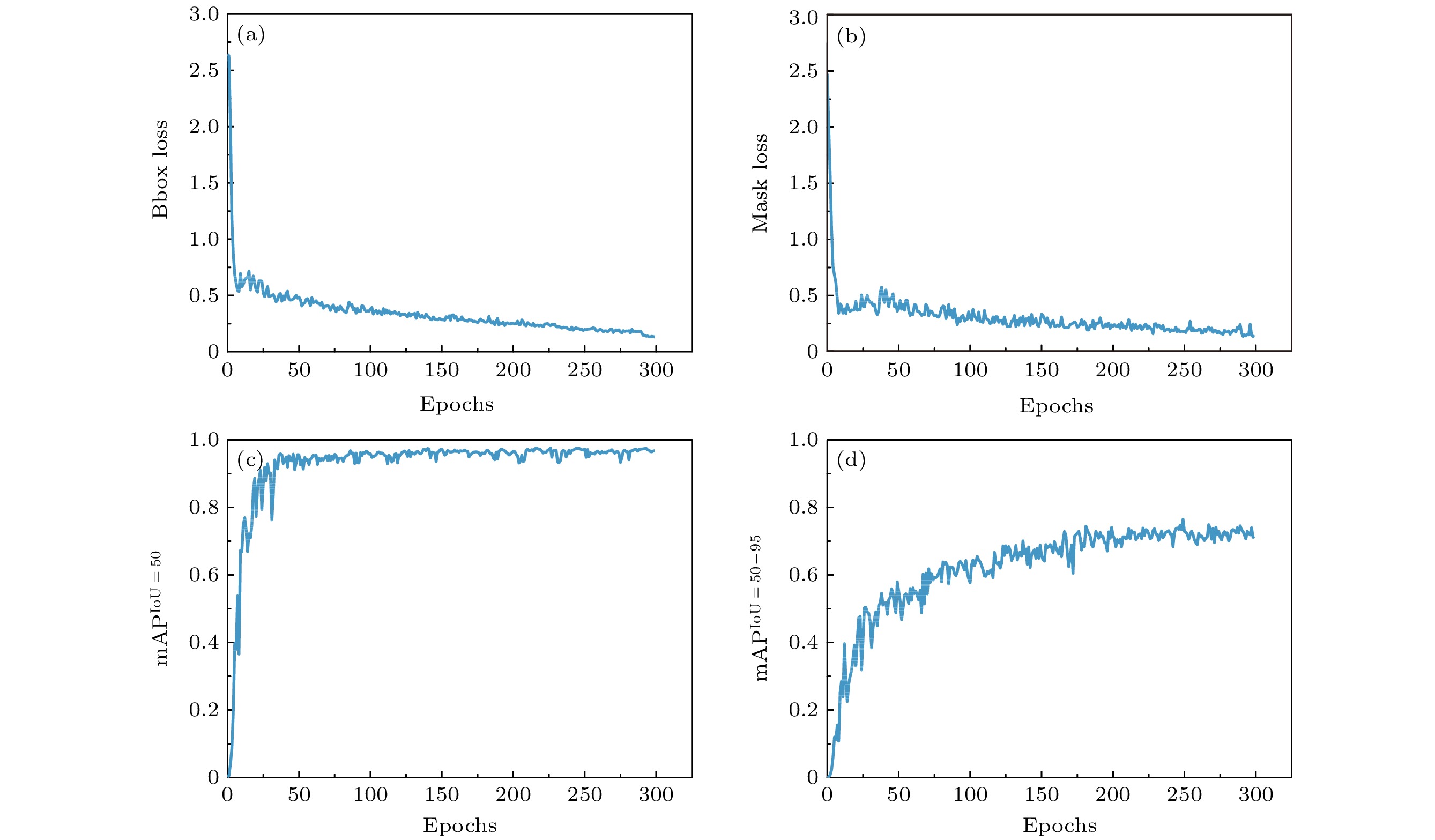

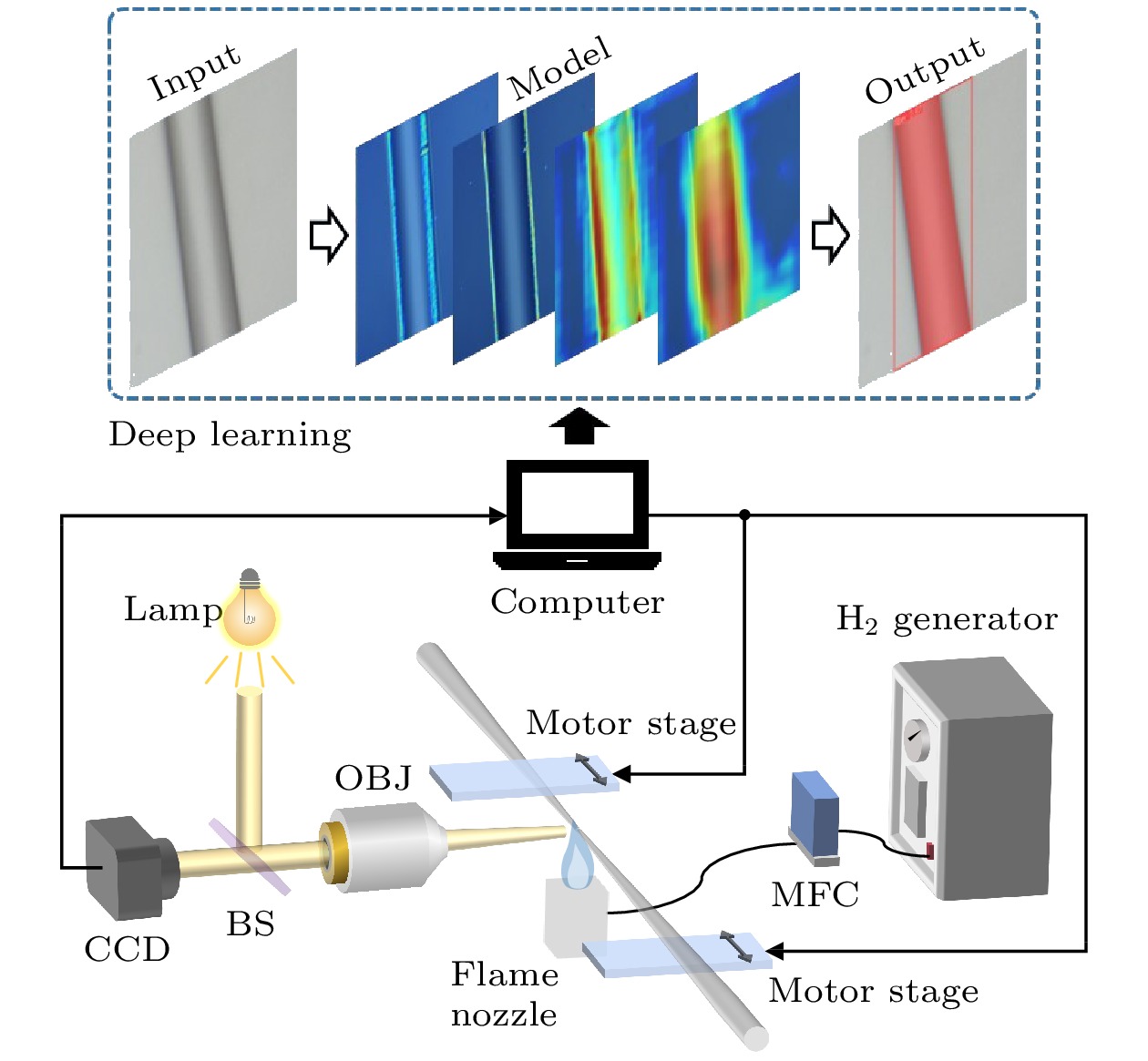

在微纳光纤拉锥制备过程中, 对直径的大范围、高精度和动态实时性测量是实现低损耗传输和色散调控的关键. 针对现有传统制备方法直径调控范围小、操作复杂及耗时长等问题, 本文基于深度学习神经网络算法实现了微纳光纤自动检测系统. 利用计算机视觉中的图像分割方法, 通过制作高质量多尺度微纳光纤数据集, 使用基于小目标检测改进的YOLOv8−FD算法对微纳光纤直径进行自动检测. 在数据集中获得了平均均值精度高达mAPIoU=50 = 0.975和mAPIoU=50—95 = 0.765的性能参数. 实验结果表明, 该系统可实现微纳光纤直径462 nm—125 μm范围, 误差2.95%以内的测量和自动化制备, 并随着光纤直径增长, 误差逐渐缩小, 且该系统光学成像单个像素分辨率为65.97 nm, 平均检测时间为9.6 ms. 本文工作适用于对微纳光纤的高精度实时测量和自动精确制备, 为低损耗传输和色散可调的微纳光纤器件发展提供新的思路.

The wide range, high precision, and dynamic real-time measurement of micro-/nanofiber diameter are crucial for achieving low loss transmission and controlling dispersion in the preparation process of micro-nanofiber. In view of the problems of small diameter regulation range, complex operation and long-time consumption of the existing preparation methods, the automatic detection system of micro-nanofiber is realized based on deep learning neural network algorithm in this work. The image segmentation method in computer vision is used to make high-quality multi-scale micro-/nanofiber datasets, and the improved YOLOv8-FD (You Only Look Once version 8-Fiber Detection) algorithm based on small target detection is used to automatically detect the diameter of micro-nanofiber. Through image segmentation and identification of the target of single pixel size in the microscopic image, the diameter detection of micro-nanofiber is finally realized. In this process, the real-time diameter of micro-nanofiber is obtained through image information, and then the micro-nanofiber small target is accurately segmented to achieve the precise detection of mAPIoU=50 = 0.975 and mAPIoU=50—95 = 0.765 on the micro-nanofiber multi-scale target dataset with extremely high accuracy. The algorithm-based construction of a high-precision micro-nanofiber automatic preparation system enables real-time accurate segmentation of fiber edges, calculation of fiber diameter, and feedback to the control system for achieving automated preparation of fibers with arbitrary diameters. Additionally, it facilitates the detection of micro-nanofiber in a range from 462 nm to 125 μm. The average response time for reasoning is 9.6 ms, and the detection error is kept below 2.95%. In addition, compared with other micro-/nanofiber diameter detection methods based on optical imaging and mode cutoff, this method shows advantages of high precision, high speed and arbitrary diameter preparation for diameter detection based on deep learning neural networks. The system is very suitable for high-precision real-time measurement and automatic and accurate preparation of micro-/nanofibers, thereby providing a novel method of developing micro-nanofiber devices with low-loss transmission and adjustable dispersion. -

Keywords:

- micro-nanofiber /

- diameter measurement /

- deep learning /

- image segmentation

[1] 童利民 2022 光学学报 42 17

Google Scholar

Google Scholar

Tong L M 2022 Acta Opt. Sin. 42 17

Google Scholar

Google Scholar

[2] Zhang L, Pan J, Zhang Z, Wu H, Yao N, Cai D W, Xu Y X, Zhang J, Sun G F, Wang L Q, Geng W D, Jin W G, Fang W, Di D W, Tong L M 2020 Opto-Electron Adv. 3 190022

Google Scholar

Google Scholar

[3] Yan Z Y, Wang J J, Wang C Y, Yu R W, Shi L, Xiao L M 2022 Opt. Express 30 18044

Google Scholar

Google Scholar

[4] Cen Q Q, Pian S J, Liu X H, Tang Y W, He X Y, Ma Y G 2023 eLight 3 9

Google Scholar

Google Scholar

[5] Li Y H, Wang L Z, Li L J, Tong L M 2019 Appl. Phys. B 125 192

Google Scholar

Google Scholar

[6] Lu J S, Li Q, Qiu C W, Hong Y, Ghosh P, Qiu M 2019 Sci. Adv. 5 8271

Google Scholar

Google Scholar

[7] Tkachenko G, Toftul I, Esporlas C, Maimaiti A, Kien F L, Truong V G, Chormaic S N 2020 Optica 7 59

Google Scholar

Google Scholar

[8] Linghu S Y, Gu Z Q, Lu J S, Fang W, Yang Z Y, Yu H K, Li Z Y, Zhu R L, Peng J, Zhan Q W, Zhuang S L, Gu M, Gu F X 2021 Nat. Commun. 12 385

Google Scholar

Google Scholar

[9] Hao Z, Jiang B Q, Ma Y X, Yi R X, Gan X T, Zhao J L 2023 Opto-Electron Adv. 6 230012

Google Scholar

Google Scholar

[10] Zhang J B, Kang Y, Guo X, Li Y H, Liu K Y, Xie Y, Wu H, Cai D W, Gong J, Shi Z X, Jin Y Y, Wang P, Fang W, Zhang L, Tong L M 2023 Light Sci. Appl. 12 89

Google Scholar

Google Scholar

[11] Chen J H, Xiong Y F, Xu F, Lu Y Q 2021 Light Sci. Appl. 10 78

Google Scholar

Google Scholar

[12] Zhou J, Li Y, Ma Y, Yang Q, Liu Q 2021 Opt. Lett. 46 1570

Google Scholar

Google Scholar

[13] Linghu S Y, Ma Y N, Gu Z Q, Zhu R L, Liu Y F, Liu H J, Gu F X 2022 Opt. Express 30 22755

Google Scholar

Google Scholar

[14] Liao F, Yu J X, Gu Z Q, Yang Z Y, Hasan T, Linghu S Y, Pang J, Fang W, Zhuang S L, Gu M, Gu F X 2019 Sci. Adv. 5 7398

Google Scholar

Google Scholar

[15] 康仪, 刘可盈, 谢宇, 龚珏, 姚妮, 方伟, 郭欣, 张磊, 王攀, 童利民 2020 中国科学: 物理学 力学 天文学 50 084212

Google Scholar

Google Scholar

Kang Y, Liu K Y, Xie Y, Gong Y, Yao N, Fang W, Guo X, Zhang L, Wang P, Tong L M 2020 Sci. Sin. Phys. Mech. As. 50 084212

Google Scholar

Google Scholar

[16] Ni Y, Linghu S L, Xu Y X, Zhu R L, Zhou N, Gu F X, Zhang L, Fang W, Ding W, Tong L M 2020 IEEE Photon. Technol. Lett. 32 1069

Google Scholar

Google Scholar

[17] Warken F, Giessen H 2004 Opt. Lett. 29 1727

Google Scholar

Google Scholar

[18] Little D J, Kane D M 2014 Opt. Lett. 39 5196

Google Scholar

Google Scholar

[19] Yu Y, Zhang X L, Song Z Q, Wang J F, Meng Z 2014 Appl. Opt. 53 8222

Google Scholar

Google Scholar

[20] Xu Y X, Fang W, Tong L M 2017 Opt. Express 25 10434

Google Scholar

Google Scholar

[21] Kang Y, Gong J, Xu Y X, Yao N, Fang W, Guo X, Tong L M 2020 IEEE Photon. Technol. Lett. 32 219

Google Scholar

Google Scholar

[22] Azzoune A, Delaye P, Pauliat G 2019 Opt. Express 27 24403

Google Scholar

Google Scholar

[23] 李华, 麻艳娜, 谷付星 2022 光学仪器 44 1005

Google Scholar

Google Scholar

Li H, Ma Y N, Gu F X 2022 Opt. Instruments 44 1005

Google Scholar

Google Scholar

[24] Woo S, Park J, Lee J Y 2017 ECCV 3 19

Google Scholar

Google Scholar

[25] 应大卫, 张思慧, 邓书金, 武海斌 2023 72 144201

Google Scholar

Google Scholar

Ying D W, Zhang S H, Deng S J, Wu H B 2023 Acta Phys. Sin. 72 144201

Google Scholar

Google Scholar

[26] 南虎, 麻晓晶, 赵海博, 汤少杰, 刘卫华, 王大威, 贾春林 2021 70 076803

Google Scholar

Google Scholar

Nan H, Ma X J, Zhao H B, Tang S J, Liu W H, Wang D W, Jia C L 2021 Acta Phys. Sin. 70 076803

Google Scholar

Google Scholar

[27] He K M, Gkioxari G, Dollar P, Girshick R 2017 ICCV 17 2980

Google Scholar

Google Scholar

[28] Gu Z, Zhu R L, Shen T C, Dou L, Liu H J, Liu Y F, Liu X, Liu J, Zhuang S L, Gu F X 2023 Nat. Commun. 14 7663

Google Scholar

Google Scholar

-

图 4 YOLOv8-FD热图可视化及结果 (a)第1层卷积层; (b)第4层卷积层; (c)第7层卷积层; (d)第10层卷积层; (e) 1280$ \times $1024 pixel微纳光纤图; (f) 640$ \times $512 pixel微纳光纤图; (g)图像分割时间9.8 ms; (h)图像分割时间9.5 ms

Fig. 4. YOLOv8-FD heatmap visualization and segmentation results: (a) Layer 1 convolution layer; (b) layer 4 convolution layer; (c) layer 7 convolution layer; (d) layer 10 convolution layer; (e) 1280$ \times $1024 pixel micro-nanofiber image; (f) 640$ \times $512 pixel micro-nanofiber image; (g) image segmentation time 9.8 ms; (h) image segmentation time 9.5 ms.

图 5 原始YOLOv8与YOLOv8-FD图像分割结果对比 (a)—(d) YOLOv8不同尺度目标图像分割结果; (e)—(h) YOLOv8-FD不同尺度目标图像分割结果

Fig. 5. Comparison of segmentation results between original YOLOv8 and YOLOv8-FD images: (a)–(d) Original YOLOv8 different scale target image segmentation results; (e)–(h) YOLOv8-FD different scale target image segmentation results.

图 6 (a)—(c)不同直径微纳光纤的原子力显微镜(AFM)扫描图; (d)—(f) 相应的光学显微图, 红色方框标记出AFM的扫描位置和ROI

Fig. 6. (a)–(c) Atomic force microscope (AFM) scanning of micro-nanofiber of different diameters; (d)–(f) optical imaging of micro-nanofiber with different diameters and AFM scanning position, and the red box marks the scan location for AFM and ROI.

表 1 标定系数测量结果

Table 1. Measurement results of micro-nanofiber diameter.

标定次数 1 2 3 4 像素个数/pixel 845.01 843.52 844.25 843.24 标定系数/(nm·pixel–1) 65.89 66.01 65.95 66.03 表 2 微纳光纤直径测量结果

Table 2. Measurement results of micro-nanofiber diameter.

-

[1] 童利民 2022 光学学报 42 17

Google Scholar

Google Scholar

Tong L M 2022 Acta Opt. Sin. 42 17

Google Scholar

Google Scholar

[2] Zhang L, Pan J, Zhang Z, Wu H, Yao N, Cai D W, Xu Y X, Zhang J, Sun G F, Wang L Q, Geng W D, Jin W G, Fang W, Di D W, Tong L M 2020 Opto-Electron Adv. 3 190022

Google Scholar

Google Scholar

[3] Yan Z Y, Wang J J, Wang C Y, Yu R W, Shi L, Xiao L M 2022 Opt. Express 30 18044

Google Scholar

Google Scholar

[4] Cen Q Q, Pian S J, Liu X H, Tang Y W, He X Y, Ma Y G 2023 eLight 3 9

Google Scholar

Google Scholar

[5] Li Y H, Wang L Z, Li L J, Tong L M 2019 Appl. Phys. B 125 192

Google Scholar

Google Scholar

[6] Lu J S, Li Q, Qiu C W, Hong Y, Ghosh P, Qiu M 2019 Sci. Adv. 5 8271

Google Scholar

Google Scholar

[7] Tkachenko G, Toftul I, Esporlas C, Maimaiti A, Kien F L, Truong V G, Chormaic S N 2020 Optica 7 59

Google Scholar

Google Scholar

[8] Linghu S Y, Gu Z Q, Lu J S, Fang W, Yang Z Y, Yu H K, Li Z Y, Zhu R L, Peng J, Zhan Q W, Zhuang S L, Gu M, Gu F X 2021 Nat. Commun. 12 385

Google Scholar

Google Scholar

[9] Hao Z, Jiang B Q, Ma Y X, Yi R X, Gan X T, Zhao J L 2023 Opto-Electron Adv. 6 230012

Google Scholar

Google Scholar

[10] Zhang J B, Kang Y, Guo X, Li Y H, Liu K Y, Xie Y, Wu H, Cai D W, Gong J, Shi Z X, Jin Y Y, Wang P, Fang W, Zhang L, Tong L M 2023 Light Sci. Appl. 12 89

Google Scholar

Google Scholar

[11] Chen J H, Xiong Y F, Xu F, Lu Y Q 2021 Light Sci. Appl. 10 78

Google Scholar

Google Scholar

[12] Zhou J, Li Y, Ma Y, Yang Q, Liu Q 2021 Opt. Lett. 46 1570

Google Scholar

Google Scholar

[13] Linghu S Y, Ma Y N, Gu Z Q, Zhu R L, Liu Y F, Liu H J, Gu F X 2022 Opt. Express 30 22755

Google Scholar

Google Scholar

[14] Liao F, Yu J X, Gu Z Q, Yang Z Y, Hasan T, Linghu S Y, Pang J, Fang W, Zhuang S L, Gu M, Gu F X 2019 Sci. Adv. 5 7398

Google Scholar

Google Scholar

[15] 康仪, 刘可盈, 谢宇, 龚珏, 姚妮, 方伟, 郭欣, 张磊, 王攀, 童利民 2020 中国科学: 物理学 力学 天文学 50 084212

Google Scholar

Google Scholar

Kang Y, Liu K Y, Xie Y, Gong Y, Yao N, Fang W, Guo X, Zhang L, Wang P, Tong L M 2020 Sci. Sin. Phys. Mech. As. 50 084212

Google Scholar

Google Scholar

[16] Ni Y, Linghu S L, Xu Y X, Zhu R L, Zhou N, Gu F X, Zhang L, Fang W, Ding W, Tong L M 2020 IEEE Photon. Technol. Lett. 32 1069

Google Scholar

Google Scholar

[17] Warken F, Giessen H 2004 Opt. Lett. 29 1727

Google Scholar

Google Scholar

[18] Little D J, Kane D M 2014 Opt. Lett. 39 5196

Google Scholar

Google Scholar

[19] Yu Y, Zhang X L, Song Z Q, Wang J F, Meng Z 2014 Appl. Opt. 53 8222

Google Scholar

Google Scholar

[20] Xu Y X, Fang W, Tong L M 2017 Opt. Express 25 10434

Google Scholar

Google Scholar

[21] Kang Y, Gong J, Xu Y X, Yao N, Fang W, Guo X, Tong L M 2020 IEEE Photon. Technol. Lett. 32 219

Google Scholar

Google Scholar

[22] Azzoune A, Delaye P, Pauliat G 2019 Opt. Express 27 24403

Google Scholar

Google Scholar

[23] 李华, 麻艳娜, 谷付星 2022 光学仪器 44 1005

Google Scholar

Google Scholar

Li H, Ma Y N, Gu F X 2022 Opt. Instruments 44 1005

Google Scholar

Google Scholar

[24] Woo S, Park J, Lee J Y 2017 ECCV 3 19

Google Scholar

Google Scholar

[25] 应大卫, 张思慧, 邓书金, 武海斌 2023 72 144201

Google Scholar

Google Scholar

Ying D W, Zhang S H, Deng S J, Wu H B 2023 Acta Phys. Sin. 72 144201

Google Scholar

Google Scholar

[26] 南虎, 麻晓晶, 赵海博, 汤少杰, 刘卫华, 王大威, 贾春林 2021 70 076803

Google Scholar

Google Scholar

Nan H, Ma X J, Zhao H B, Tang S J, Liu W H, Wang D W, Jia C L 2021 Acta Phys. Sin. 70 076803

Google Scholar

Google Scholar

[27] He K M, Gkioxari G, Dollar P, Girshick R 2017 ICCV 17 2980

Google Scholar

Google Scholar

[28] Gu Z, Zhu R L, Shen T C, Dou L, Liu H J, Liu Y F, Liu X, Liu J, Zhuang S L, Gu F X 2023 Nat. Commun. 14 7663

Google Scholar

Google Scholar

计量

- 文章访问数: 5961

- PDF下载量: 198

- 被引次数: 0

下载:

下载: