-

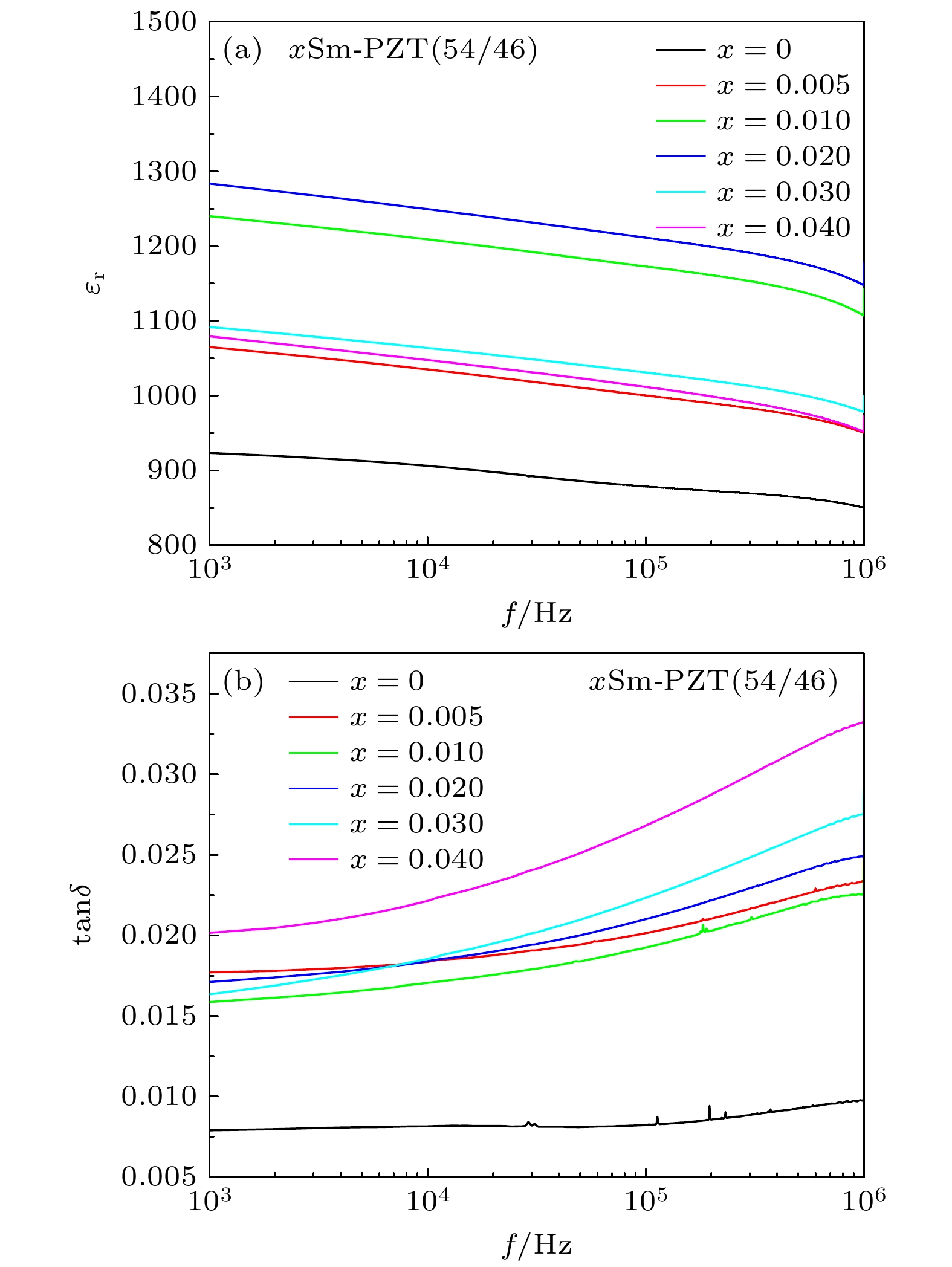

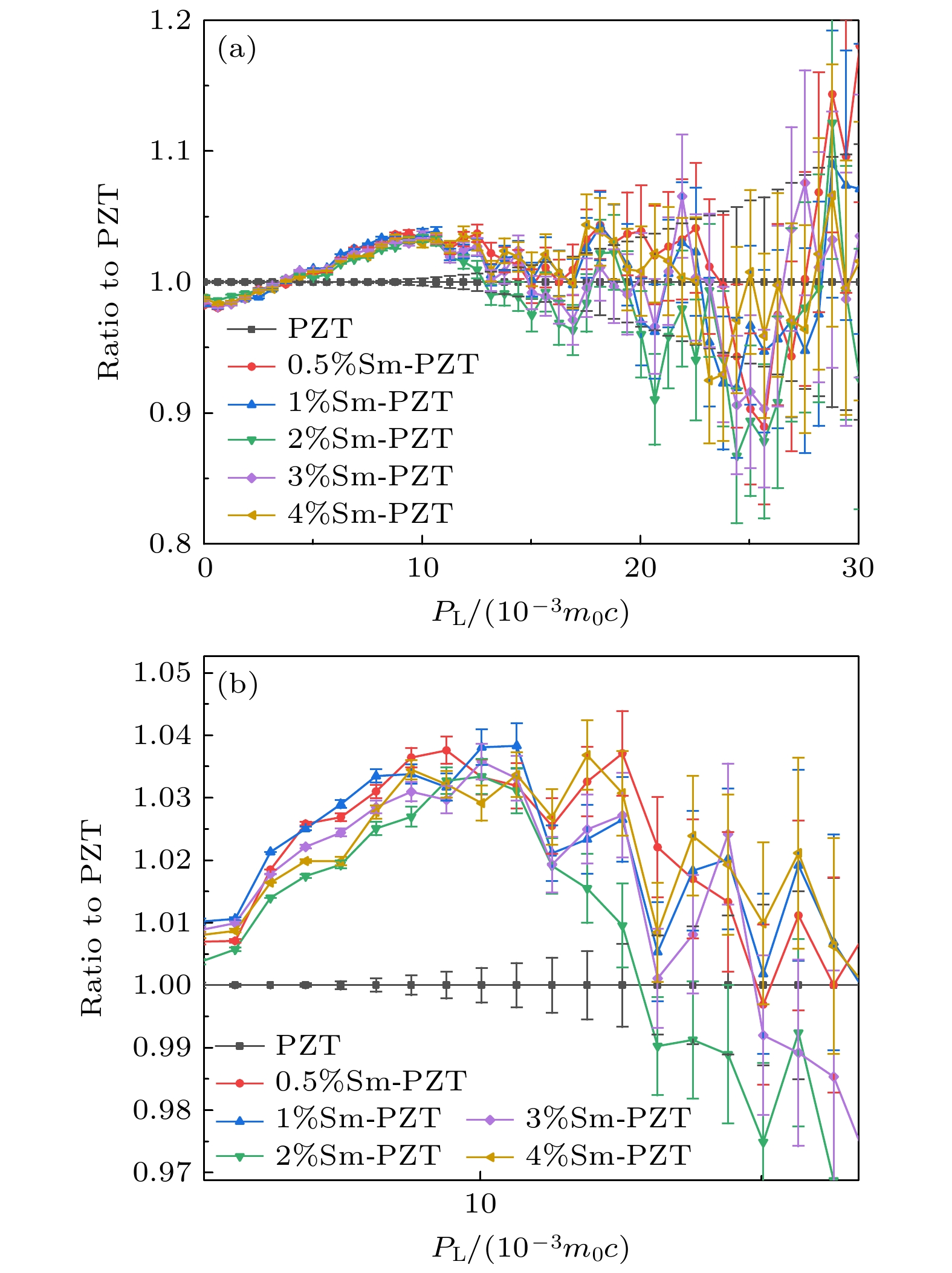

用固相反应法制备了B位空位补偿型钐掺杂非准同型相界组分PZT(54/46)陶瓷. 通过正电子湮没寿命谱(PALS)和符合多普勒展宽能谱(CDBS)对陶瓷中的缺陷结构进行综合表征, 结合常规表征手段如X射线衍射(XRD), 电子扫描显微镜(SEM), 介电、铁电和压电性能测量, 研究缺陷对陶瓷压电性能的影响. XRD结果显示所有陶瓷均为纯钙钛矿相, 掺杂诱导了菱方-四方(R-T)相变, 准同型相界位于Sm掺杂量x = 0.01

$- $ 0.02. 电学测量结果反映: 介电、铁电和压电性能均先增强后减弱, MPB附近两个样品都有优异的介电和铁电性能, 但其压电性能差别很大. x = 0.01给出最优压电性能d33 = 572 pC/N, 较未掺杂样品增强了一倍. PALS结果表明掺杂使陶瓷中缺陷类型发生变化, x ≤ 0.01, 样品中同时含有A位空位与B位空位; x ≥ 0.02, 样品中以A位相关缺陷为主, B位空位浓度很低. CDBS结果进一步证实x = 0.01和0.02中B位空位浓度分别是该体系中最高和最低的. 由以上结果推断出: x = 0.01获得的最优压电性能与其中较高浓度的B位空位有关, B位空位可稀释A位空位浓度, 降低氧空位浓度, 从而降低A位空位与氧空位形成缺陷偶极子的几率, 促进畴壁运动, 使压电性能增强.Rare earth dopping, especially samarium (Sm) dopping is considered as an effective way to obtain high piezoelectricity by increasing local structure heterogeneity in Pb-containing ABO3 perovskite ceramics. Defects play an significant role in determining piezoelectric properties in aliovalent ion doping systems. In order to obtain an insight into the effect of defects, especially B-site vacancies on piezoelectricity, Sm-doped PZT(54/46) ceramics compensated by B-site vacancies are fabricated by conventional solid state reaction method. The influence of defects on piezoelectric properties is studied by positron annihilation lifetime spectroscopy (PALS), coincidence Doppler broadening spectroscopy (CDBS), and conventional methods such as X-ray diffraction (XRD), scanning electron microscope (SEM), electrical performance testing on dielectricity, ferroelectricity and pizoelectricity. The XRD results show that all ceramics crystallize in a pure perovskite phase, Sm3+ doping causes a transformation from the rhombohedral to tetragonal phase and the morphotropic phase boundary (MPB) lies near Sm3+ doping content x = 0.01–0.02. Electrical performance testing results indicate that with the increase of x, all of the dielectricity, ferroelectricity and pizoelectricity first increase and then decrease, the sample with x = 0.01 and 0.02 exhibit similar excellent dielectricity and ferroelectricity, while their pizoelectricity differs greatly, the optimal piezoelectric coefficient d33 = 572 pC/N (nearly double that of undoped sample) is obtained in the sample with x = 0.01. The PALS results show that Sm doping leads the defect types to change from the coexistence of A-site and B-site vacancies for x ≤ 0.01 to mainly A-site related defects for x ≥ 0.02. The CDBS results further verify that the concentration of B-site vacancies is highest for x = 0.01 and lowest for x = 0.02. It is inferred that the high pizoelectricity for x = 0.01 is related to its high concentration of B-site vacancies, which can dilute the number of A-site vacancies and oxygen vacancies, reducing the chance of forming defect dipoles between an A-site vacancy and an oxygen vacancy, facilitating domain wall motion, and enhancing piezoelectricity. This study indicates that B-site vacancies can enhance piezoelectricity to some extent, which will provide some guidance for defect engineering.-

Keywords:

- PZT ceramics /

- positron annihilation /

- vacancies

[1] Jaffe B, Roth R S, Marzullo S 1954 J. Appl. Phys. 25 809

Google Scholar

Google Scholar

[2] Yan Y, Li Z, Jin L, Du H, Zhang M, Zhang D, Hao Y 2021 ACS Appl. Mater. Interfaces 13 38517

Google Scholar

Google Scholar

[3] Li F, Lin D, Chen Z, Cheng Z, Wang J, Li C, Xu Z, Huang Q, Liao X, Chen L, Shrout T R, Zhang S 2018 Nat. Mater. 17 349

Google Scholar

Google Scholar

[4] Fang Z, Tian X, Zheng F, Jiang X, Ye W, Qin Y, Wang X, Zhang Y 2022 Ceram. Int. 48 7550

Google Scholar

Google Scholar

[5] Guo Q, Li F, Xia F, Gao X, Wang P, Hao H, Sun H, Liu H, Zhang S 2019 ACS Appl. Mater. Interfaces 11 43359

Google Scholar

Google Scholar

[6] Seshadri S B, Nolan M M, Tutuncu G, Forrester J S, Sapper E, Esteves G, Granzow T, Thomas P A, Nino J C, Rojac T, Jones J L 2018 Sci. Rep. 8 4120

Google Scholar

Google Scholar

[7] Gao B, Yao Z, Lai D, Guo Q, Pan W, Hao H, Cao M, Liu H 2020 J. Alloys Compd. 836 155474

Google Scholar

Google Scholar

[8] Yan P, Qin Y, Xu Z, Han F, Wang Y, Wen Z, Zhang Y, Zhang S 2021 ACS Appl. Mater. Interfaces 13 54210

Google Scholar

Google Scholar

[9] Guo Q, Hou L, Li F, Xia F, Wang P, Hao H, Sun H, Liu H, Zhang S 2019 J. Am. Ceram. Soc. 102 7428

Google Scholar

Google Scholar

[10] Qin Y, Yan P, Han F, Zhang Y, Lü Z, Zhou C 2022 J. Alloys Compd. 891 161959

Google Scholar

Google Scholar

[11] Li C, Xu B, Lin D, Zhang S, Bellaiche L, Shrout T R, Li F 2020 Phys. Rev. B 101 140102

Google Scholar

Google Scholar

[12] Peng G, Zheng D, Cheng C, Zhang J, Zhang H 2017 J Alloys Compd. 693 1250

Google Scholar

Google Scholar

[13] Cheng C, Zheng D Y, Peng G G, Hu S M, Zhang H, Zhang J 2016 J. Mater. Sci. 28 1624

Google Scholar

Google Scholar

[14] Kim T Y, Jang H M 2000 Appl. Phys. Lett. 77 3824

Google Scholar

Google Scholar

[15] Garcia-Zaldivar O, Pelaiz-Barranco A, Guerra J D S, Mendoza M E, Calderon-Pinar F, Hall D A 2011 Physica B 406 1622

Google Scholar

Google Scholar

[16] Pandey A H, Gupta S M 2020 Mater. Sci. Eng., B 253 114495

Google Scholar

Google Scholar

[17] Damjanovic D 2005 J. Am. Ceram. Soc. 88 2663

Google Scholar

Google Scholar

[18] Li Z, Thong H C, Zhang Y F, Xu Z, Zhou Z, Liu Y X, Cheng Y Y S, Wang S H, Zhao C, Chen F, Bi K, Han B, Wang K 2021 Adv. Funct. Mater. 31 2005012

Google Scholar

Google Scholar

[19] Keeble D J, Singh S, Mackie R A, Morozov M, McGuire S, Damjanovic D 2007 Phys. Rev. B 76 144109

Google Scholar

Google Scholar

[20] Asoka-Kumar P, Alatalo M, Ghosh V J, Kruseman A C, Nielsen B, Lynn K G 1996 Phys. Rev. Lett. 77 2097

Google Scholar

Google Scholar

[21] 熊涛, 高传波, 陈祥磊, 周先意, 翁惠民, 曹方宇, 叶邦角, 韩荣典, 杜淮江 2009 58 6946

Google Scholar

Google Scholar

Xiong T, Gao C B, Chen X L, Zhou X Y, Weng H M, Cao F Y, Ye B J, Han R D, Du H J 2009 Acta Phys. Sin. 58 6946

Google Scholar

Google Scholar

[22] Qin M, Gao F, Cizek J, Yang S, Fan X, Zhao L, Xu J, Dong G, Reece M, Yan H 2019 Acta Mater. 164 76

Google Scholar

Google Scholar

[23] Chakrabarti M, Bhowmick D, Sarkar A, Chattopadhyay S, Dechoudhury S, Sanyal D, Chakrabarti A 2005 J. Mater. Sci. 40 5265

Google Scholar

Google Scholar

[24] Čížek J, Melikhova O, Procházka I, Kuriplach J, Kužel R, Brauer G, Anwand W, Konstantinova T E, Danilenko I A 2010 Phys. Rev. B 81 024116

Google Scholar

Google Scholar

[25] Li K, Sun E, Zhang Y, Song Z, Qi X, Sun Y, Li J, Yang B, Liu J, Cao W 2021 J. Mater. Chem. C 9 2426

Google Scholar

Google Scholar

[26] Bellaiche L, Íñiguez J, Cockayne E, Burton B P 2007 Phys. Rev. B 75 014111

Google Scholar

Google Scholar

[27] Zhu W, Fujii I, Ren W, Trolier-McKinstry S 2012 J. Am. Ceram. Soc. 95 2906

Google Scholar

Google Scholar

-

表 1 xSm-PZT(54/46)陶瓷的铁电性能指标

Table 1. Ferroelectric parameters of xSm-PZT(54/46) ceramics

样品 矫顽场Ec/(kV·cm–1) 最大极化值Pm/(µC·cm–2) 剩余极化2Pr/(µC·cm–2) 0.000 Sm-PZT(54/46) 6.50543 22.9362 17.8235 0.005 Sm-PZT(54/46) 9.07716 28.9513 41.7151 0.010 Sm-PZT(54/46) 11.96854 29.7117 43.8174 0.020 Sm-PZT(54/46) 16.22384 30.0491 45.7736 0.030 Sm-PZT(54/46) 19.54932 26.0871 40.9861 0.040 Sm-PZT(54/46) 12.44085 21.0489 28.7527 表 2 xSm-PZT(54/46)陶瓷PALS解谱结果(τ1固定为160 ps)

Table 2. Decomposed PALS results of xSm-PZT(54/46) ceramics (with τ1 fixed to 160 ps).

Sample τ1/ps I1/% τ2/ps I2/% τ3/ps I3/% Fit’s variance 0.000 Sm-PZT(54/46) 160 41.01 ± 0.24 272.5 ± 1.1 58.02 ± 0.24 1386 ± 58 0.97 ± 0.05 1.0526 0.005 Sm-PZT(54/46) 160 33.69 ± 0.64 275.9 ± 1.4 65.37 ± 0.64 1531 ± 33 0.94 ± 0.03 1.0155 0.010 Sm-PZT(54/46) 160 31.61 ± 0.20 276.3 ± 0.4 67.45 ± 0.20 1477 ± 34 0.94 ± 0.02 0.9946 0.020 Sm-PZT(54/46) 160 23.01 ± 0.65 293.0 ± 1.5 75.97 ± 0.65 1531 ± 39 1.01 ± 0.04 1.0727 0.030 Sm-PZT(54/46) 160 24.25 ± 0.53 289.9 ± 1.2 74.87 ± 0.53 1457 ± 81 0.88 ± 0.06 0.9906 0.040 Sm-PZT(54/46) 160 31.33 ± 0.42 286.3 ± 1.3 67.57 ± 0.42 1402 ± 34 1.09 ± 0.04 1.0466 表 3 xSm-PZT(54/46)陶瓷归一化PALS解谱结果

Table 3. Normalized parameters of decomposed PALS results of xSm-PZT(54/46) ceramics.

Sample τ1/ps I1/% τ2/ps I2/% Fit’s variance 0.000 Sm-PZT(54/46) 160 41.41 ± 0.24 272.5 ± 1.1 58.59 ± 0.24 1.047 0.005 Sm-PZT(54/46) 160 34.01 ± 0.64 275.9 ± 1.4 65.99 ± 0.64 1.0155 0.010 Sm-PZT(54/46) 160 31.91 ± 0.20 276.3 ± 0.4 68.09 ± 0.20 0.9954 0.020 Sm-PZT(54/46) 160 23.25 ± 0.65 293.0 ± 1.5 76.75 ± 0.65 1.0683 0.030 Sm-PZT(54/46) 160 24.47 ± 0.53 289.9 ± 1.2 75.53 ± 0.53 0.9928 0.040 Sm-PZT(54/46) 160 31.68 ± 0.42 286.3 ± 1.3 68.32 ± 0.42 1.0511 -

[1] Jaffe B, Roth R S, Marzullo S 1954 J. Appl. Phys. 25 809

Google Scholar

Google Scholar

[2] Yan Y, Li Z, Jin L, Du H, Zhang M, Zhang D, Hao Y 2021 ACS Appl. Mater. Interfaces 13 38517

Google Scholar

Google Scholar

[3] Li F, Lin D, Chen Z, Cheng Z, Wang J, Li C, Xu Z, Huang Q, Liao X, Chen L, Shrout T R, Zhang S 2018 Nat. Mater. 17 349

Google Scholar

Google Scholar

[4] Fang Z, Tian X, Zheng F, Jiang X, Ye W, Qin Y, Wang X, Zhang Y 2022 Ceram. Int. 48 7550

Google Scholar

Google Scholar

[5] Guo Q, Li F, Xia F, Gao X, Wang P, Hao H, Sun H, Liu H, Zhang S 2019 ACS Appl. Mater. Interfaces 11 43359

Google Scholar

Google Scholar

[6] Seshadri S B, Nolan M M, Tutuncu G, Forrester J S, Sapper E, Esteves G, Granzow T, Thomas P A, Nino J C, Rojac T, Jones J L 2018 Sci. Rep. 8 4120

Google Scholar

Google Scholar

[7] Gao B, Yao Z, Lai D, Guo Q, Pan W, Hao H, Cao M, Liu H 2020 J. Alloys Compd. 836 155474

Google Scholar

Google Scholar

[8] Yan P, Qin Y, Xu Z, Han F, Wang Y, Wen Z, Zhang Y, Zhang S 2021 ACS Appl. Mater. Interfaces 13 54210

Google Scholar

Google Scholar

[9] Guo Q, Hou L, Li F, Xia F, Wang P, Hao H, Sun H, Liu H, Zhang S 2019 J. Am. Ceram. Soc. 102 7428

Google Scholar

Google Scholar

[10] Qin Y, Yan P, Han F, Zhang Y, Lü Z, Zhou C 2022 J. Alloys Compd. 891 161959

Google Scholar

Google Scholar

[11] Li C, Xu B, Lin D, Zhang S, Bellaiche L, Shrout T R, Li F 2020 Phys. Rev. B 101 140102

Google Scholar

Google Scholar

[12] Peng G, Zheng D, Cheng C, Zhang J, Zhang H 2017 J Alloys Compd. 693 1250

Google Scholar

Google Scholar

[13] Cheng C, Zheng D Y, Peng G G, Hu S M, Zhang H, Zhang J 2016 J. Mater. Sci. 28 1624

Google Scholar

Google Scholar

[14] Kim T Y, Jang H M 2000 Appl. Phys. Lett. 77 3824

Google Scholar

Google Scholar

[15] Garcia-Zaldivar O, Pelaiz-Barranco A, Guerra J D S, Mendoza M E, Calderon-Pinar F, Hall D A 2011 Physica B 406 1622

Google Scholar

Google Scholar

[16] Pandey A H, Gupta S M 2020 Mater. Sci. Eng., B 253 114495

Google Scholar

Google Scholar

[17] Damjanovic D 2005 J. Am. Ceram. Soc. 88 2663

Google Scholar

Google Scholar

[18] Li Z, Thong H C, Zhang Y F, Xu Z, Zhou Z, Liu Y X, Cheng Y Y S, Wang S H, Zhao C, Chen F, Bi K, Han B, Wang K 2021 Adv. Funct. Mater. 31 2005012

Google Scholar

Google Scholar

[19] Keeble D J, Singh S, Mackie R A, Morozov M, McGuire S, Damjanovic D 2007 Phys. Rev. B 76 144109

Google Scholar

Google Scholar

[20] Asoka-Kumar P, Alatalo M, Ghosh V J, Kruseman A C, Nielsen B, Lynn K G 1996 Phys. Rev. Lett. 77 2097

Google Scholar

Google Scholar

[21] 熊涛, 高传波, 陈祥磊, 周先意, 翁惠民, 曹方宇, 叶邦角, 韩荣典, 杜淮江 2009 58 6946

Google Scholar

Google Scholar

Xiong T, Gao C B, Chen X L, Zhou X Y, Weng H M, Cao F Y, Ye B J, Han R D, Du H J 2009 Acta Phys. Sin. 58 6946

Google Scholar

Google Scholar

[22] Qin M, Gao F, Cizek J, Yang S, Fan X, Zhao L, Xu J, Dong G, Reece M, Yan H 2019 Acta Mater. 164 76

Google Scholar

Google Scholar

[23] Chakrabarti M, Bhowmick D, Sarkar A, Chattopadhyay S, Dechoudhury S, Sanyal D, Chakrabarti A 2005 J. Mater. Sci. 40 5265

Google Scholar

Google Scholar

[24] Čížek J, Melikhova O, Procházka I, Kuriplach J, Kužel R, Brauer G, Anwand W, Konstantinova T E, Danilenko I A 2010 Phys. Rev. B 81 024116

Google Scholar

Google Scholar

[25] Li K, Sun E, Zhang Y, Song Z, Qi X, Sun Y, Li J, Yang B, Liu J, Cao W 2021 J. Mater. Chem. C 9 2426

Google Scholar

Google Scholar

[26] Bellaiche L, Íñiguez J, Cockayne E, Burton B P 2007 Phys. Rev. B 75 014111

Google Scholar

Google Scholar

[27] Zhu W, Fujii I, Ren W, Trolier-McKinstry S 2012 J. Am. Ceram. Soc. 95 2906

Google Scholar

Google Scholar

计量

- 文章访问数: 4170

- PDF下载量: 268

- 被引次数: 0

下载:

下载: