-

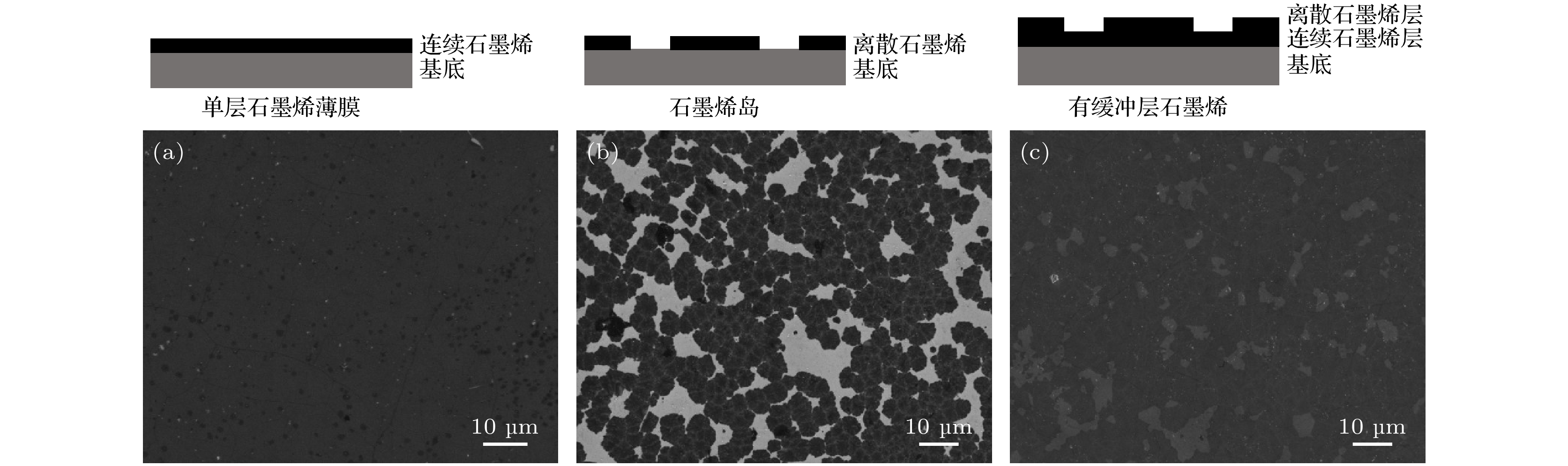

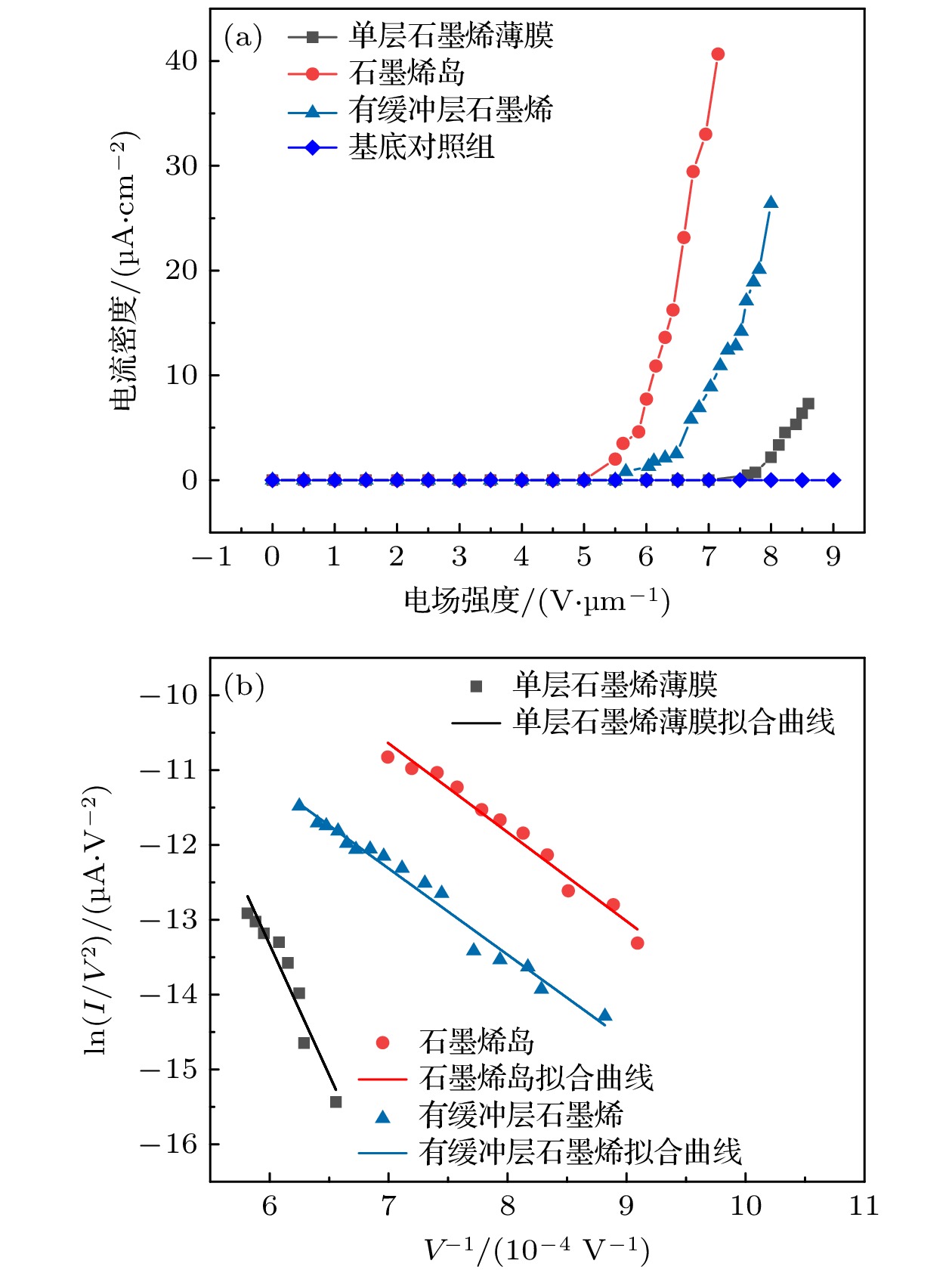

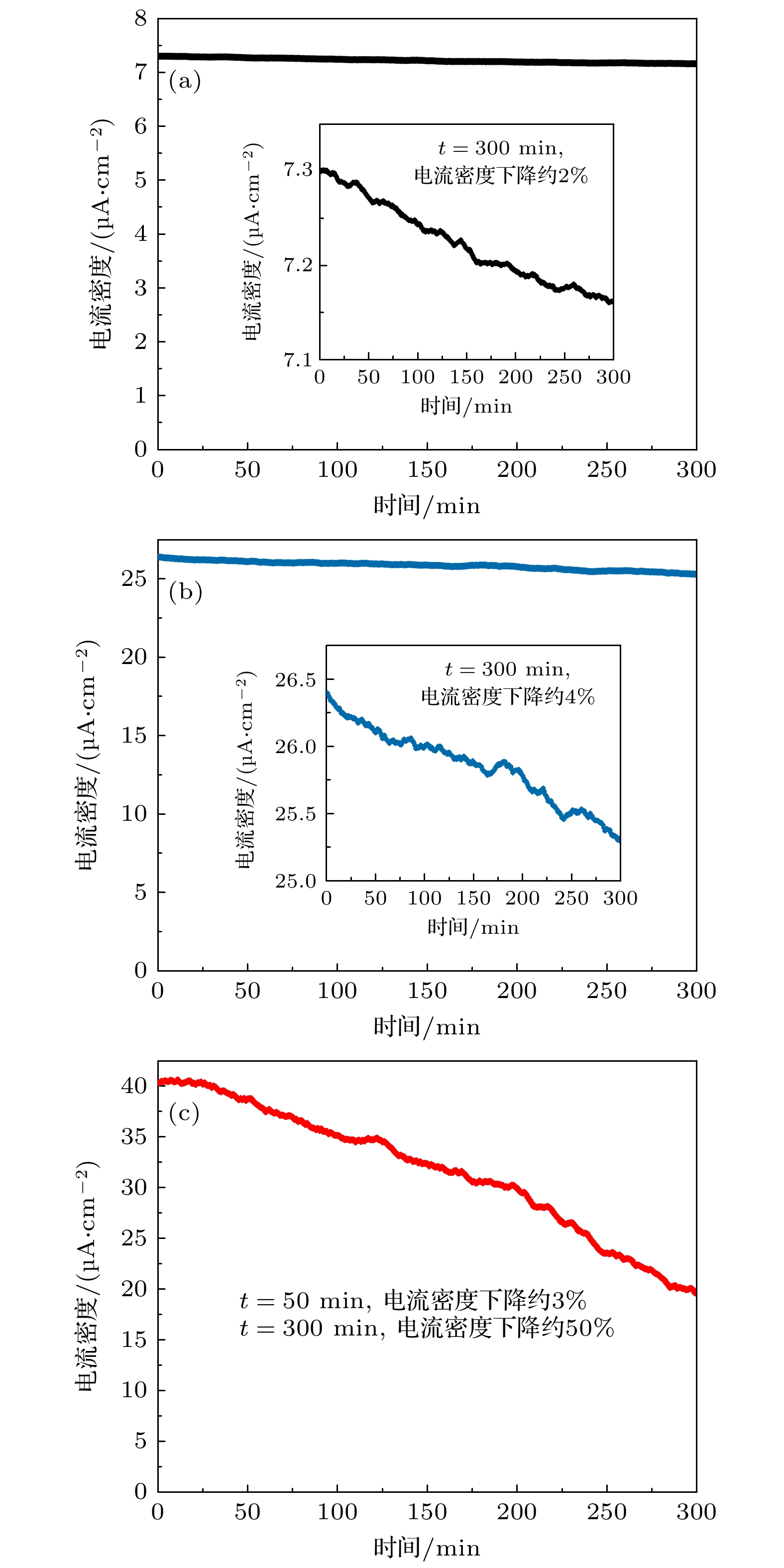

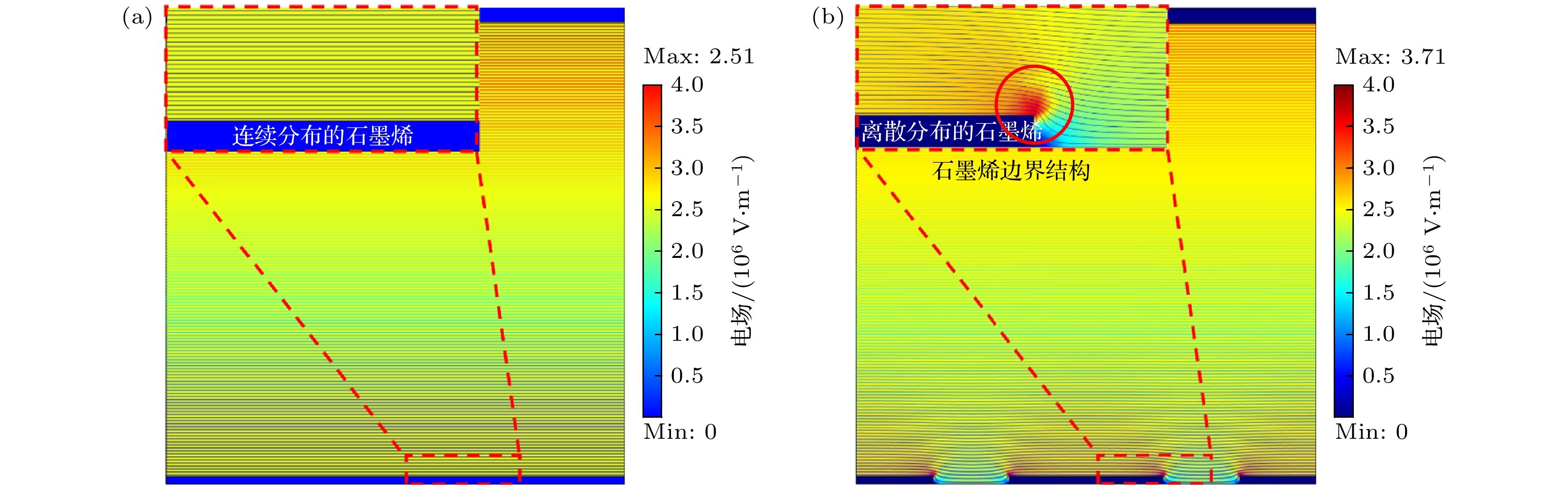

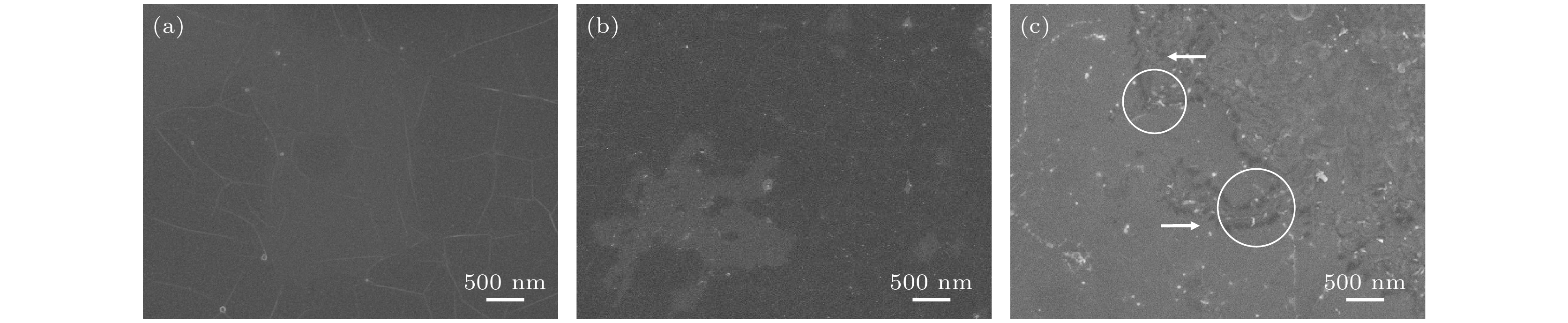

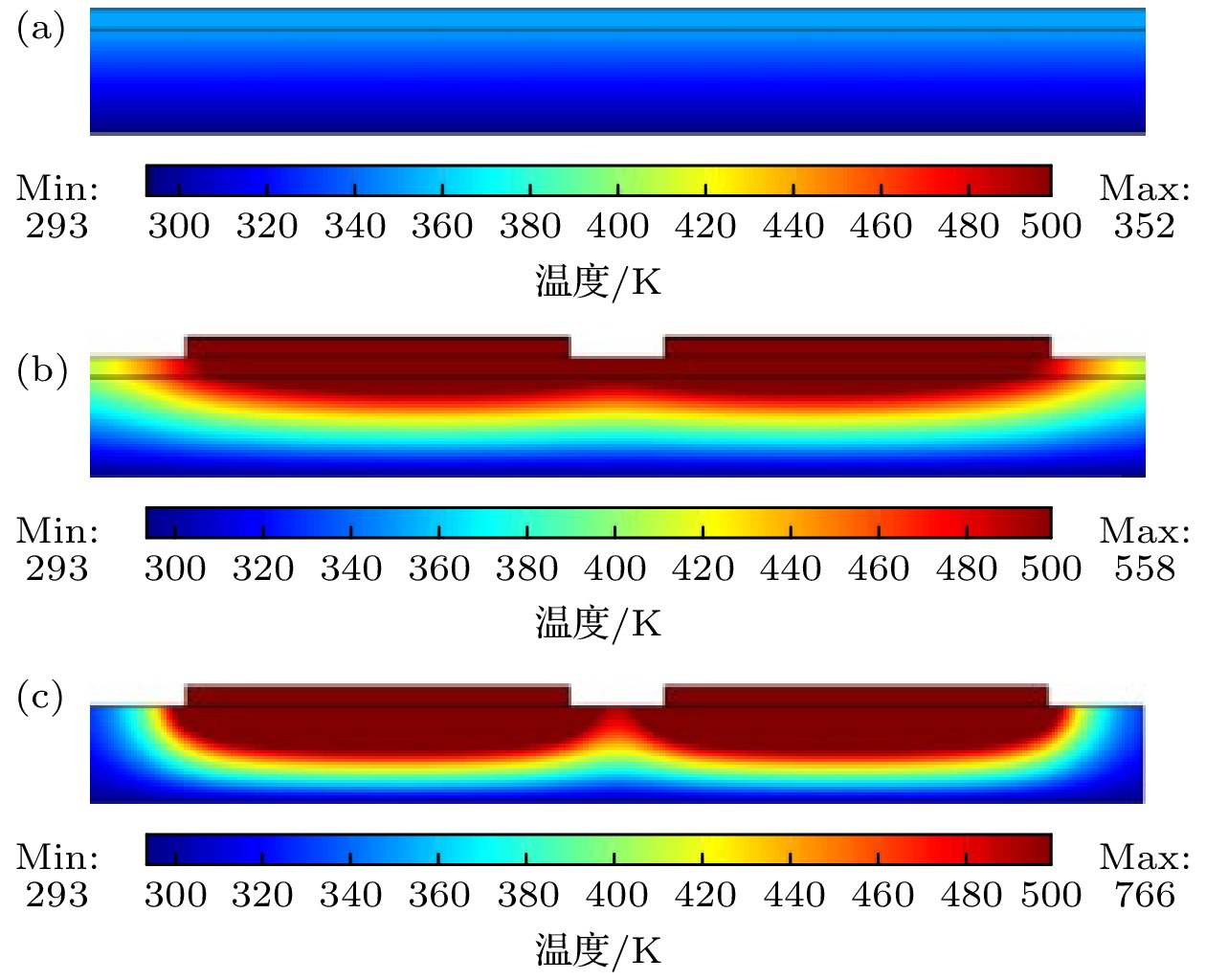

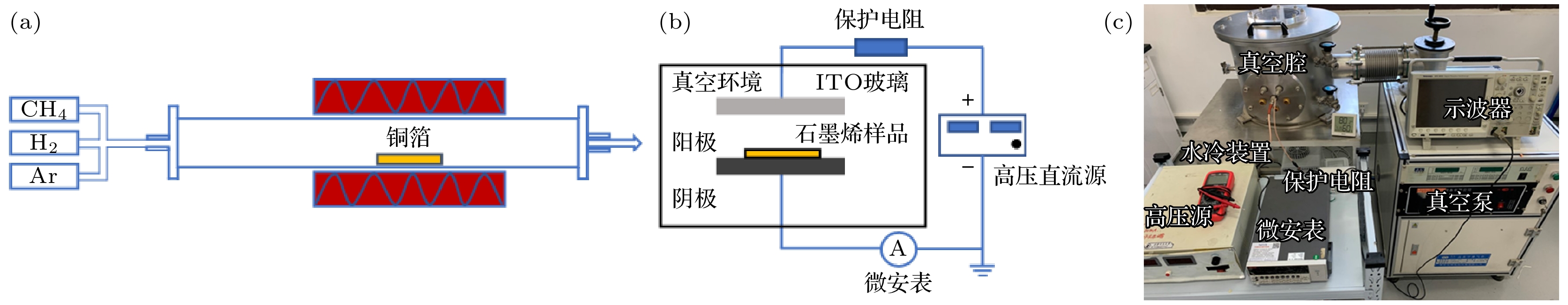

石墨烯具有优异的电学、热学和力学特性以及丰富的电子隧穿边缘, 是场发射阴极的良好材料. 本文通过调控化学气相沉积法制备石墨烯的生长参数, 分别制备了单层石墨烯薄膜、石墨烯岛、有缓冲层石墨烯等3种形貌石墨烯, 探究了石墨烯的形貌特征对其场发射性能的影响, 并结合COMSOL多物理场仿真分析了石墨烯的形貌特征对其场发射性能的影响机制. 实验结果表明, 相比于单层石墨烯薄膜, 石墨烯岛和有缓冲层石墨烯的开启场强分别降低至5.55 V/μm和5.83 V/μm, 最大场发射电流密度也分别提升至40.3 μA/cm2和26.4 μA/cm2. 另一方面, 在基底上连续分布的单层石墨烯薄膜和有缓冲层石墨烯场发射电流更稳定, 在5 h的测试中, 电流密度分别仅下降2%和4%. 结合仿真结果可知, 石墨烯的形貌特征对其场发射过程中的电场分布特性和散热能力具有重要的影响. 石墨烯岛和有缓冲层石墨烯存在边界结构, 使得场发射过程中局部电场集中, 进而提升了场发射性能. 石墨烯岛在基底上离散分布, 未形成连续石墨烯薄膜, 缺乏焦耳热横向散热通道, 热量的积累将导致石墨烯岛发射体受到损伤, 并影响其场发射电流稳定性. 本文探究了石墨烯的形貌特征对其场发射性能的影响, 并分析了相关影响机制, 对石墨烯材料场发射性能的提高具有重要的意义.

-

关键词:

- 石墨烯 /

- 形貌 /

- 场发射 /

- COMSOL多物理场耦合

Graphene is one of the most potential field emission cathode materials due to its excellent electrical, thermal, and mechanical properties, as well as rich edge structures. In this paper, we study the growth parameters of graphene prepared by chemical vapor deposition, and prepare three kinds of morphologies of graphene: single-layer graphene, graphene islands, and graphene with buffer layers, and then we explore the influence of the morphological characteristics of graphene on its field emission properties, and analyze the mechanism of influence of the morphological characteristics of graphene on its field emission properties through COMSOL. Comparing with single-layer graphene, the turn-on field of graphene islands and that of graphene with buffer layers decrease to 5.55 V/μm and 5.85 V/μm, respectively. The current densities also increase to 40.3 μA/cm2 and 26.4 μA/cm2, respectively. On the other hand, the field emission currents of single-layer graphene and graphene with buffer layers are more stable. In a 5-hour test, the current densities only decrease by 2% and 4%, respectively. COMSOL simulation shows that the morphological characteristics of graphene have significant influences on the electric field distribution characteristics and heat dissipation capacity. Graphene islands and graphene with buffer layers have exposed edges, leading to local electric field concentration, and thus improving field emission properties. The graphene islands are distributed discretely on the substrate, forming no continuous graphene film and lacking transverse heat dissipation channels, so the accumulation of heat will cause damage to the graphene emitter, and affect the stability of its field emission current. This study will be of great benefit to the understanding of the influence of the morphological characteristics of graphene on its field emission properties, and improving the field emission properties of graphene materials.-

Keywords:

- graphene /

- morphology /

- field emission /

- COMSOL multiphysics

[1] Zhang Y B, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[2] Prasher R 2010 Science 328 185

Google Scholar

Google Scholar

[3] Lee C G, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[4] Novoselov K S, Fal′ko V I, Colombo L, Gellert P R, Schwab M G, Kim K 2012 Nature 490 192

Google Scholar

Google Scholar

[5] Chen Y C, Chen J, Li Z B 2023 Nanomaterials 13 2437

Google Scholar

Google Scholar

[6] Patra A, More M A, Late D J, Rout C S 2021 J. Mater. Chem. C 9 11059

Google Scholar

Google Scholar

[7] Shao X Y, Srinivasan A, Ang W K, Khursheed A 2018 Nat. Commun. 9 1288

Google Scholar

Google Scholar

[8] Yamaguchi H, Murakami K, Eda G, Fujita T, Guan P, Wang W H, Gong C, Boisse J, Miller S, Acik M, Cho K, Chabal Y J, Chen M W, Wakaya F, Takai M, Chhowalla M 2011 ACS Nano 5 4945

Google Scholar

Google Scholar

[9] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[10] 陈浩, 彭同江, 刘波, 孙红娟, 雷德会 2017 66 080701

Google Scholar

Google Scholar

Chen H, Peng T J, Liu B, Sun H J, Lie D H 2017 Acta Phys. Sin. 66 080701

Google Scholar

Google Scholar

[11] Berger C, Song Z, Li X, Wu X, Brown N, Naud C, Mayou D, Li T, Hass J, Marchenkov A N, Conrad E H, First P N, Heer W A D 2006 Science 312 1191

Google Scholar

Google Scholar

[12] Li X, Cai W, Colombo L, Ruoff R S 2009 Nano Lett. 9 4268

Google Scholar

Google Scholar

[13] Meng G D, Zhan F Z, She J Y, Xie J A, Zheng Q R, Cheng Y H, Yin Z Y 2023 Nanoscale 15 15994

Google Scholar

Google Scholar

[14] Xie J A, Meng G D, Chen B Y, Li Z, Yin Z Y, Cheng Y H 2022 ACS Appl. Mater. Interfaces 14 45716

Google Scholar

Google Scholar

[15] Regmi M, Chisholm M F, Eres G 2012 Carbon 50 134

Google Scholar

Google Scholar

[16] Liu W, Li H, Xu C, Khatami Y, Banerjee K 2011 Carbon 49 4122

Google Scholar

Google Scholar

[17] Deokar G, Avila J, Razado-Colambo I, Codron J L, Boyaval C, Galopin E, Asensio M C, Vignaud D 2015 Carbon 89 82

Google Scholar

Google Scholar

[18] Kleshch V I, Bandurin D A, Orekhov A S, Purcell S T, Obraztsov A N 2015 Appl. Surf. Sci. 357 1967

Google Scholar

Google Scholar

[19] 成桂霖, 杨健君, 全盛, 钟健, 于军胜 2022 真空科学与技术学报 42 290

Cheng G L, Yang J J, Quan S, Zhong J, Yu J S 2022 Vacuum Sci. Tech. 42 290

[20] Li Z B 2015 Ultramicroscopy 159 162

Google Scholar

Google Scholar

[21] 张晓波, 青芳竹, 李雪松 2019 68 096801

Google Scholar

Google Scholar

Zhang X B, Qing F Z, Li X S 2019 Acta Phys. Sin. 68 096801

Google Scholar

Google Scholar

[22] Graf D, Molitor F, Ensslin K, Stampfer C, Jungen A, Hierold C, Wirtz L 2007 Nano Lett. 7 238

Google Scholar

Google Scholar

[23] Wang Y Y, Ni Z H, Yu T, Shen Z X, Wang H M, Wu Y H, Chen W, Shen Wee A T 2008 J. Phys. Chem. C 112 10637

Google Scholar

Google Scholar

[24] Fowler R H, Nordheim L 1928 Proc. R. Soc. Lond. A 119 173

Google Scholar

Google Scholar

[25] Zhang X, Wang L, Xin J, Yakobson B I, Ding F 2014 J. Am. Chem. Soc. 136 3040

Google Scholar

Google Scholar

[26] Lee S W, Lee S S, Yang E H 2009 Nanoscale Res. Lett. 4 1218

Google Scholar

Google Scholar

[27] Qian M, Feng T, Ding H, Lin L, Li H, Chen Y, Sun Z 2009 Nanotechnology 20 425702

Google Scholar

Google Scholar

[28] Liu J, Zeng B, Wu Z, Zhu J, Liu X 2010 Appl. Phys. Lett. 97 033109

Google Scholar

Google Scholar

[29] Xiao Z M, She J C, Deng S Z, Tang Z K, Li Z B, Lu J M, Xu N S 2010 ACS Nano 4 6332

Google Scholar

Google Scholar

[30] Tang S, Zhang Y, Zhao P, Zhan R, Chen J, Deng S 2021 Nanoscale 13 5234

Google Scholar

Google Scholar

-

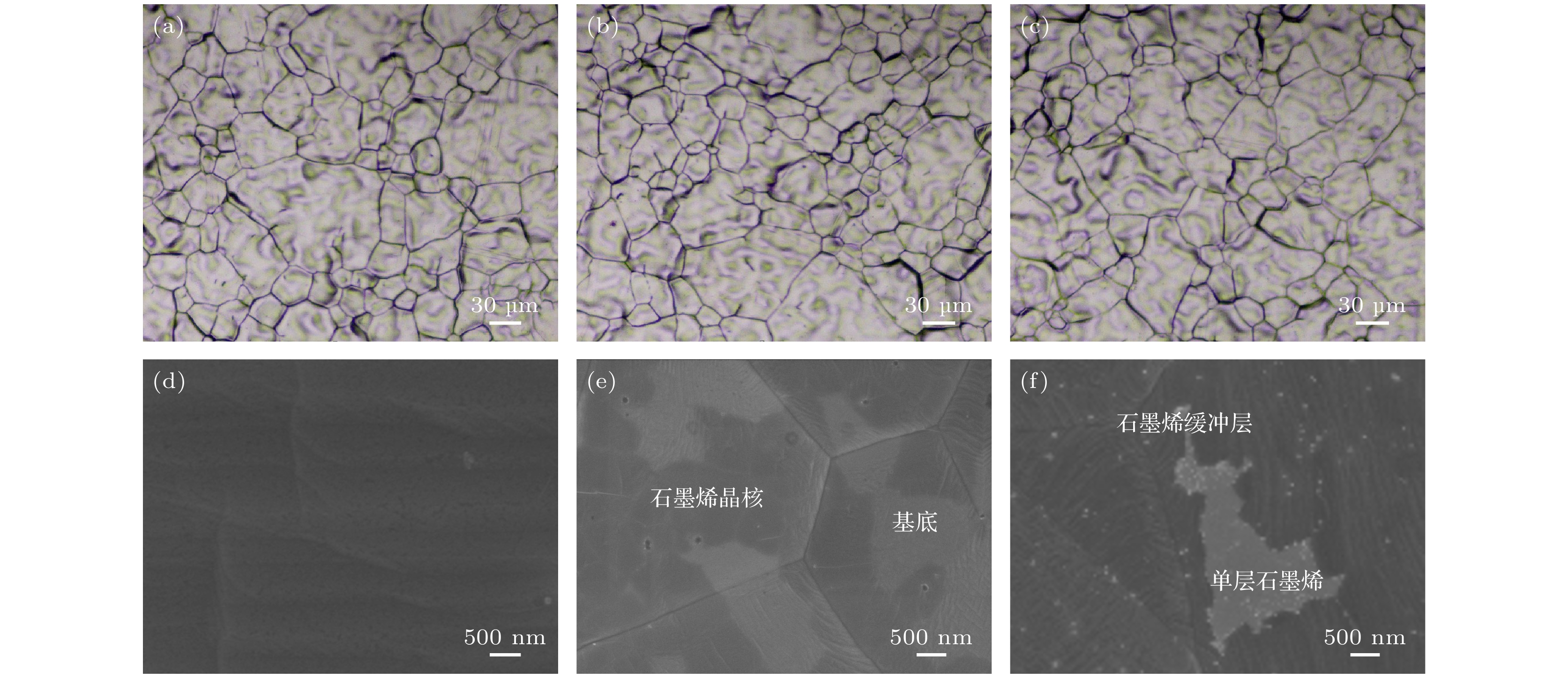

图 2 转移前的石墨烯. 光镜图 (a)单层石墨烯薄膜; (b)石墨烯岛; (c)有缓冲层石墨烯. 电镜图 (d)单层石墨烯薄膜; (e)石墨烯岛; (f)有缓冲层石墨烯

Fig. 2. Graphene before transferring. Optical microscope images of (a) single-layer grapheme, (b) graphene islands, (c) graphene with buffer layers. Scanning electron microscope images of (d) single-layer grapheme, (e) graphene islands, (f) graphene with buffer layers.

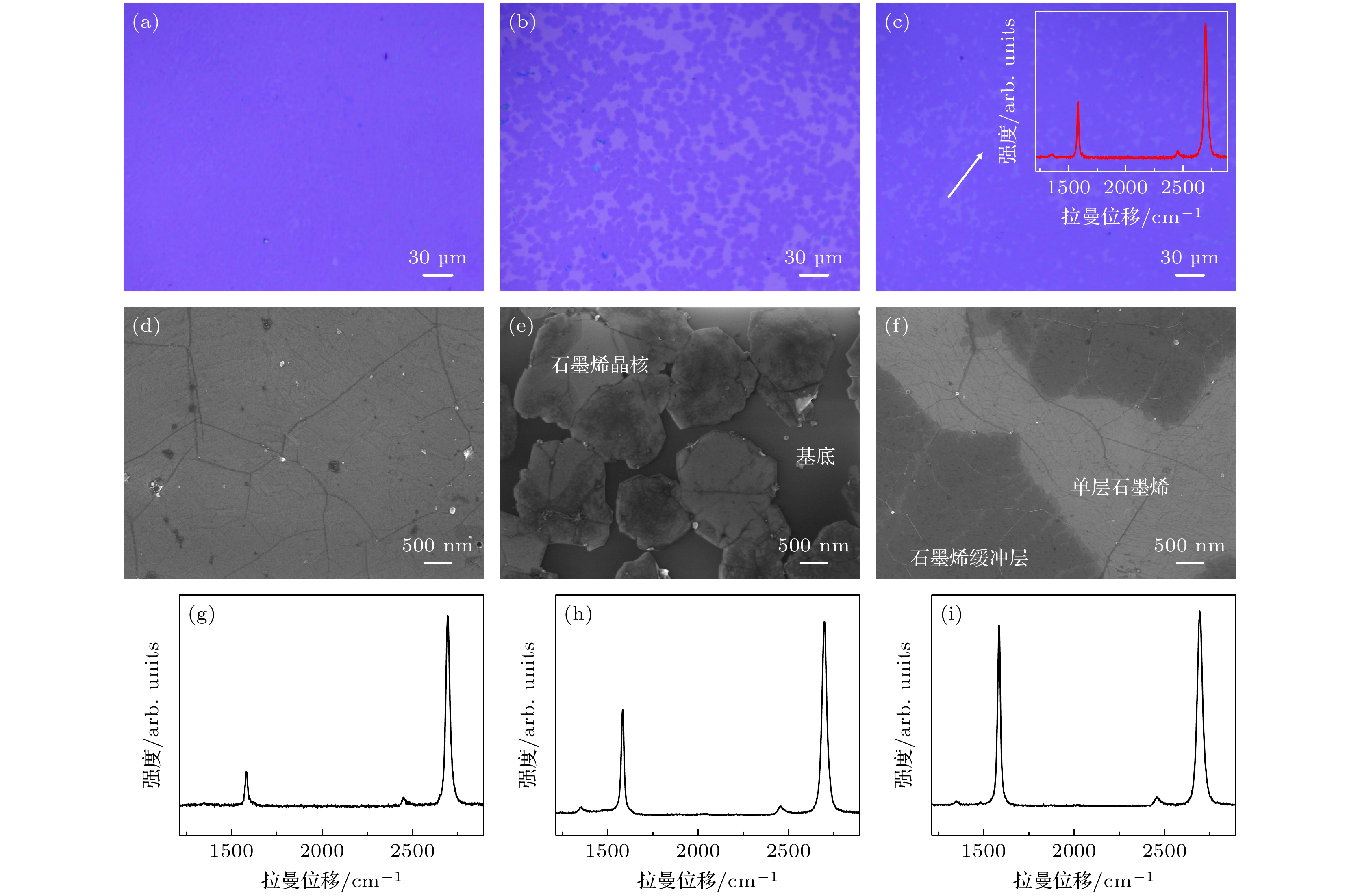

图 3 转移后的石墨烯. 光镜图 (a)单层石墨烯薄膜; (b)石墨烯岛; (c)有缓冲层石墨烯. 电镜图 (d)单层石墨烯薄膜; (e)石墨烯岛; (f)有缓冲层石墨烯. 拉曼光谱图 (g)单层石墨烯薄膜; (h)石墨烯岛; (i)有缓冲层石墨烯

Fig. 3. Graphene after transferring. Optical microscope images of (a) single-layer grapheme, (b) graphene islands, (c) graphene with buffer layers. Scanning electron microscope images of (d) single-layer grapheme, (e) graphene islands, (f) graphene with buffer layers. Raman spectra images of (g) single-layer grapheme, (h) graphene islands, (i) graphene with buffer layers.

表 1 不同形貌石墨烯的CVD生长参数

Table 1. CVD growth parameters of graphene with different morphologies.

石墨烯形貌类型 生长温度/

℃甲烷浓度/

sccm氢气浓度/

sccm生长时间/

min单层石墨烯薄膜 1030 2 20 5 石墨烯岛 1030 2 30 5 有缓冲层石墨烯 1030 5 20 5 -

[1] Zhang Y B, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[2] Prasher R 2010 Science 328 185

Google Scholar

Google Scholar

[3] Lee C G, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[4] Novoselov K S, Fal′ko V I, Colombo L, Gellert P R, Schwab M G, Kim K 2012 Nature 490 192

Google Scholar

Google Scholar

[5] Chen Y C, Chen J, Li Z B 2023 Nanomaterials 13 2437

Google Scholar

Google Scholar

[6] Patra A, More M A, Late D J, Rout C S 2021 J. Mater. Chem. C 9 11059

Google Scholar

Google Scholar

[7] Shao X Y, Srinivasan A, Ang W K, Khursheed A 2018 Nat. Commun. 9 1288

Google Scholar

Google Scholar

[8] Yamaguchi H, Murakami K, Eda G, Fujita T, Guan P, Wang W H, Gong C, Boisse J, Miller S, Acik M, Cho K, Chabal Y J, Chen M W, Wakaya F, Takai M, Chhowalla M 2011 ACS Nano 5 4945

Google Scholar

Google Scholar

[9] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[10] 陈浩, 彭同江, 刘波, 孙红娟, 雷德会 2017 66 080701

Google Scholar

Google Scholar

Chen H, Peng T J, Liu B, Sun H J, Lie D H 2017 Acta Phys. Sin. 66 080701

Google Scholar

Google Scholar

[11] Berger C, Song Z, Li X, Wu X, Brown N, Naud C, Mayou D, Li T, Hass J, Marchenkov A N, Conrad E H, First P N, Heer W A D 2006 Science 312 1191

Google Scholar

Google Scholar

[12] Li X, Cai W, Colombo L, Ruoff R S 2009 Nano Lett. 9 4268

Google Scholar

Google Scholar

[13] Meng G D, Zhan F Z, She J Y, Xie J A, Zheng Q R, Cheng Y H, Yin Z Y 2023 Nanoscale 15 15994

Google Scholar

Google Scholar

[14] Xie J A, Meng G D, Chen B Y, Li Z, Yin Z Y, Cheng Y H 2022 ACS Appl. Mater. Interfaces 14 45716

Google Scholar

Google Scholar

[15] Regmi M, Chisholm M F, Eres G 2012 Carbon 50 134

Google Scholar

Google Scholar

[16] Liu W, Li H, Xu C, Khatami Y, Banerjee K 2011 Carbon 49 4122

Google Scholar

Google Scholar

[17] Deokar G, Avila J, Razado-Colambo I, Codron J L, Boyaval C, Galopin E, Asensio M C, Vignaud D 2015 Carbon 89 82

Google Scholar

Google Scholar

[18] Kleshch V I, Bandurin D A, Orekhov A S, Purcell S T, Obraztsov A N 2015 Appl. Surf. Sci. 357 1967

Google Scholar

Google Scholar

[19] 成桂霖, 杨健君, 全盛, 钟健, 于军胜 2022 真空科学与技术学报 42 290

Cheng G L, Yang J J, Quan S, Zhong J, Yu J S 2022 Vacuum Sci. Tech. 42 290

[20] Li Z B 2015 Ultramicroscopy 159 162

Google Scholar

Google Scholar

[21] 张晓波, 青芳竹, 李雪松 2019 68 096801

Google Scholar

Google Scholar

Zhang X B, Qing F Z, Li X S 2019 Acta Phys. Sin. 68 096801

Google Scholar

Google Scholar

[22] Graf D, Molitor F, Ensslin K, Stampfer C, Jungen A, Hierold C, Wirtz L 2007 Nano Lett. 7 238

Google Scholar

Google Scholar

[23] Wang Y Y, Ni Z H, Yu T, Shen Z X, Wang H M, Wu Y H, Chen W, Shen Wee A T 2008 J. Phys. Chem. C 112 10637

Google Scholar

Google Scholar

[24] Fowler R H, Nordheim L 1928 Proc. R. Soc. Lond. A 119 173

Google Scholar

Google Scholar

[25] Zhang X, Wang L, Xin J, Yakobson B I, Ding F 2014 J. Am. Chem. Soc. 136 3040

Google Scholar

Google Scholar

[26] Lee S W, Lee S S, Yang E H 2009 Nanoscale Res. Lett. 4 1218

Google Scholar

Google Scholar

[27] Qian M, Feng T, Ding H, Lin L, Li H, Chen Y, Sun Z 2009 Nanotechnology 20 425702

Google Scholar

Google Scholar

[28] Liu J, Zeng B, Wu Z, Zhu J, Liu X 2010 Appl. Phys. Lett. 97 033109

Google Scholar

Google Scholar

[29] Xiao Z M, She J C, Deng S Z, Tang Z K, Li Z B, Lu J M, Xu N S 2010 ACS Nano 4 6332

Google Scholar

Google Scholar

[30] Tang S, Zhang Y, Zhao P, Zhan R, Chen J, Deng S 2021 Nanoscale 13 5234

Google Scholar

Google Scholar

计量

- 文章访问数: 3802

- PDF下载量: 348

- 被引次数: 0

下载:

下载: