-

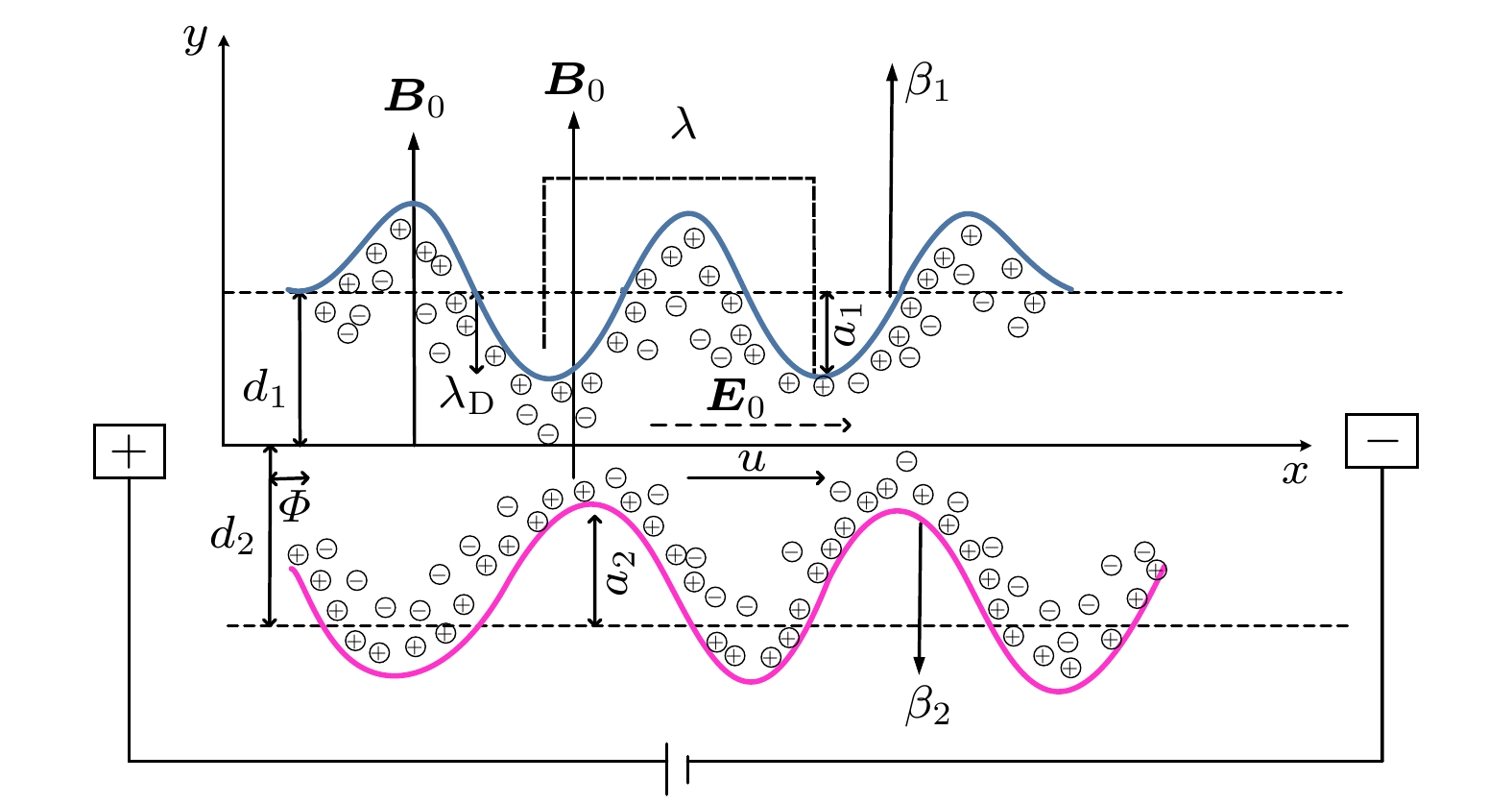

在高壁面Zeta势下, 研究滑移边界条件下满足牛顿流体模型的一类生物流体的电渗流动及传热特性, 流体在外加电场、磁场和焦耳加热共同作用下流动. 首先, 在不使用Debye-Hückel线性近似条件时, 利用切比雪夫谱方法给出非线性Poisson-Boltzmann方程和流函数满足的四阶微分方程及热能方程的数值解, 将所得结果与利用Debye-Hückel线性近似所得结果进行比较, 证明本文数值方法的有效性. 其次, 讨论电磁环境下壁面Zeta势、哈特曼数

$H$ 、电渗参数$m$ 、滑移参数$\beta $ 对流动特性、泵送特性和捕获现象的影响, 并探究焦耳加热参数$\gamma $ 和布林克曼数$Br$ 等参数对传热特性的影响. 结果表明, 壁面Zeta势、电渗参数$m$ 、滑移参数$\beta $ 的增大对流体速度有促进作用, 而哈特曼数$H$ 的增大会抵抗流体流动. 研究进一步表明, 焦耳加热参数$\gamma $ 和布林克曼数$Br$ 的增大会导致温度升高.Peristalsis is an important dynamic phenomenon in the field of biomedical research, and has great application prospects in microscale fluids. In recent years, this biomimetic (peristaltic) phenomenon has gained widespread attention due to its large-scale applications in various medical and industrial fields, such as radiation therapy, peristaltic blood pumps, and drug delivery systems. In this study, the electroosmotic flow and heat transfer characteristics are investigated under high wall Zeta potential and slip boundary conditions for a certain type of biological fluid that satisfies the Newtonian fluid model. Fluid flows under the joint action of external electric field, magnetic field, and Joule heating. Firstly, without using the Debye-Hückel linear approximation, the numerical solutions are given by using the Chebyshev spectral method for the nonlinear Poisson-Boltzmann equation, the fourth-order differential equation satisfied by the stream function, and the thermal energy equation. The results are compared with those obtained by using the Debye-Hückel linear approximation to demonstrate the effectiveness of the numerical method used in this study. Secondly, the effects of wall Zeta potential, Hartmann number$H$ , electroosmotic parameter$m$ , slip parameter$\beta $ are discussed on the flow characteristics, peristaltic pumping, and trapping phenomena under electromagnetic environments, and the influence of Joule heating parameter$\gamma $ and Brinkman number$Br$ is explored on heat transfer characteristics. The results show that 1) wall Zeta potential plays an important role in controlling the velocity of fluid peristaltic flow; 2) the increase of electroosmotic parameter$m$ and slip parameter$\beta $ increases the flow velocity in the central region of the channel, while the increase of Hartmann number$H$ hinders the flow of fluid; 3) these flow behaviors exhibit opposite trends near the channel walls; 4) the number of streamlines captured by peristaltic transport decreases with Hartmann number$H$ and electroosmotic parameter$m$ increasing; 5) the increase of Joule heating parameter$\gamma $ and Brinkman number$Br$ leads temperature to rise.-

Keywords:

- electroosmotic flow /

- heat transfer characteristics /

- high Zeta potential /

- Chebyshev spectral methods

[1] Maiti S, Pandey S K, Misra J C 2022 J. Eng. Math. 135 8

Google Scholar

Google Scholar

[2] Jaiswal S, Yadav P K 2022 Microfluid Nanofluid 26 100

Google Scholar

Google Scholar

[3] Patel H R, Patel S D, Darji R 2022 Int. J. Thermofluids 16 100232

Google Scholar

Google Scholar

[4] Sherief H H, Faltas M S, El-Sapa S 2019 Eur. J. Mech. B Fluids 77 211

Google Scholar

Google Scholar

[5] Chandra S, Kumar Pandey S 2018 J. Phys. Conf. Ser. 1141 012092

Google Scholar

Google Scholar

[6] Yasmin H, Nisar Z 2023 Mathematics 11 2673

Google Scholar

Google Scholar

[7] Mishra N K, Sharma B K, Sharma P, Muhammad T, Pérez L M 2023 Sci. Rep. 13 14483

Google Scholar

Google Scholar

[8] Guedri K, Lashin M M A, Abbasi A, Khan S U, Farooq W, Khan M I, Galal A M 2023 Chin. J. Phys. 83 650

Google Scholar

Google Scholar

[9] Maraj E N, Akbar N S, Zehra I, Butt A W, Ahmed Alghamdi H 2023 J. Magn. Magn. Mater. 576 170774

Google Scholar

Google Scholar

[10] Rafiq M, Shaheen S, Khan M I, Fadhl B M, Hassine S B H, ElDin S M 2023 Case Stud. Therm. Eng. 45 102990

Google Scholar

Google Scholar

[11] Alfwzan W, Riaz A, Alammari M, Hejazi H, Tag El-Din E M 2023 Front. Phys. 11 1121849

Google Scholar

Google Scholar

[12] Wang S, Li N, Zhao M, Azese M N 2018 Z. Naturforsch. A 73 825

Google Scholar

Google Scholar

[13] Sheikholeslami M, Chamkha A J 2016 Numer. Heat Tr. A-Appl. 69 781

Google Scholar

Google Scholar

[14] Tripathi D, Bhushan S, Bég O A 2016 Colloids Surf. A 506 32

Google Scholar

Google Scholar

[15] Shapiro A H, Jaffrin M Y, Weinberg S L 1969 J. Fluid Mech. Dig. Arch. 37 799

Google Scholar

Google Scholar

[16] Shit G C, Mondal A, Sinha A, Kundu P K 2016 Physica A 462 1040

Google Scholar

Google Scholar

[17] Chakraborty S 2007 Anal. Chim. Acta 605 175

Google Scholar

Google Scholar

[18] Bhardwaj A, Kumar A, Bhandari D S, Tripathi D 2024 Sensor. Actuat. A-Phys. 366 114956

[19] Verma L, Meher R 2023 Pramana 97 155

Google Scholar

Google Scholar

[20] Chen L, Abbas M A, Khudair W S, Sun B 2022 Symmetry 14 953

Google Scholar

Google Scholar

[21] Mahabub M, Ferdows M, Murtaza M G, Lorenzini G, Tzirtzilakis E E 2022 Mathem. Mod. Eng. Probl. 9 215

Google Scholar

Google Scholar

[22] Madkhali H A 2023 Case Stud. Therm. Eng. 41 102655

Google Scholar

Google Scholar

[23] Upreti H, Bartwal P, Pandey A K, Makinde O D 2023 Numer. Heat Transf. B: Fundam. 84 415

Google Scholar

Google Scholar

[24] Yashkun U, Zaimi K, Sufahani S F, Eid M R, Ferdows M 2023 Appl. Math J. Chin. Univ. 38 373

Google Scholar

Google Scholar

[25] Mishra N K, Sharma B K, Sharma P, Muhammad T, Pérez L M 2023 Sci. Rep. 13 1

Google Scholar

Google Scholar

[26] Cordwell A, Chapple A A, Chung S, Wells F S, Willmott G R 2023 Soft Matter 19 4676

Google Scholar

Google Scholar

[27] Ma N L, Sun Y, Jian Y 2023 Micromachines 14 1617

Google Scholar

Google Scholar

[28] Sarkar S, Ganguly S 2017 J. Non-Newtonian Fluid 250 18

Google Scholar

Google Scholar

[29] Kikuchi Y 1995 Microvasc. Res. 50 288

Google Scholar

Google Scholar

[30] Ranjit N K, Shit G C, Tripathi D 2018 Microvasc. Res. 117 74

Google Scholar

Google Scholar

[31] Sadeghi A, Kazemi Y, Saidi M H 2013 Nanosc. Microsc. Therm. 17 173

Google Scholar

Google Scholar

[32] Tripathi D 2013 Math. Comput. Model 57 1270

Google Scholar

Google Scholar

-

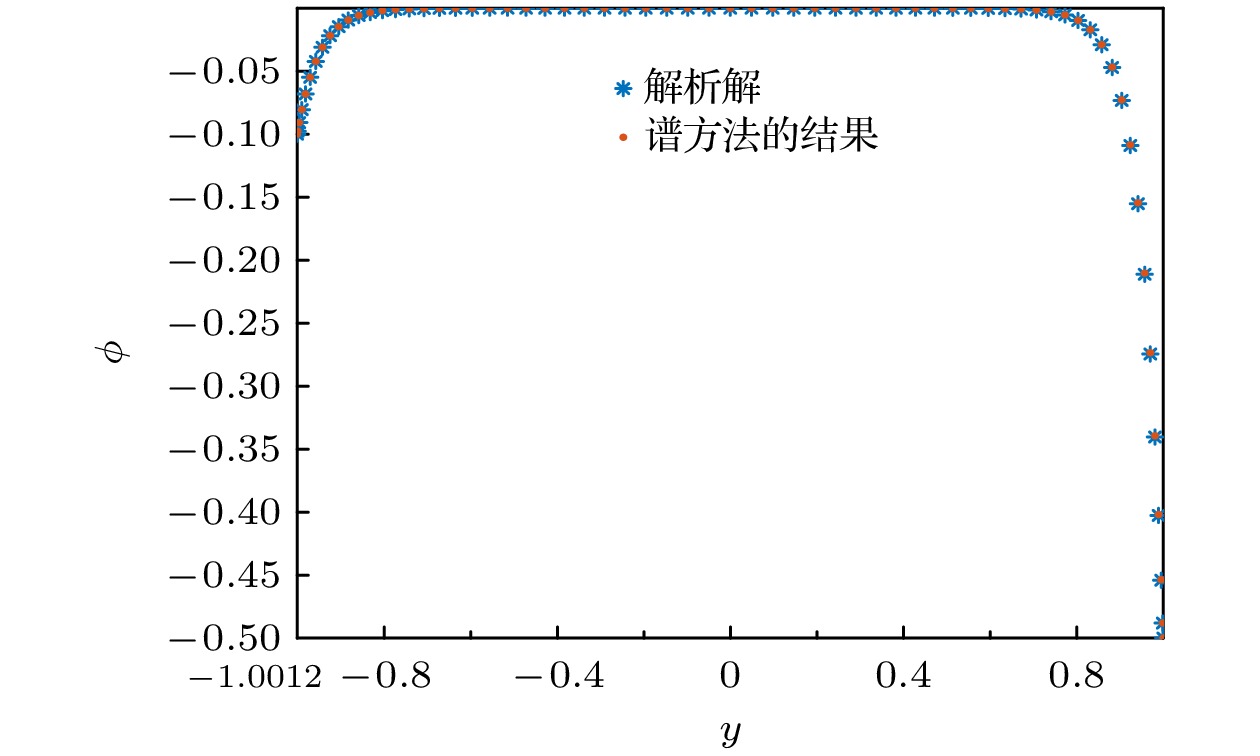

图 2 低Zeta势下P-B方程D-H近似解析解(蓝色)与切比雪夫谱方法(黄色)对比图, 其中$a = b = x = 0.5, \;\phi = $$ 0.05, \;d = 1.0, \;t = 0.0, \;F = 1.0$

Fig. 2. Comparison between approximate analytical solution of D-H for P-B equation (blue) and Chebyshev spectrum method (yellow) at low Zeta potential, $a = b = x = $$ 0.5, \;\phi = 0.05, \;d = 1.0, \;t = 0.0, \;F = 1.0$.

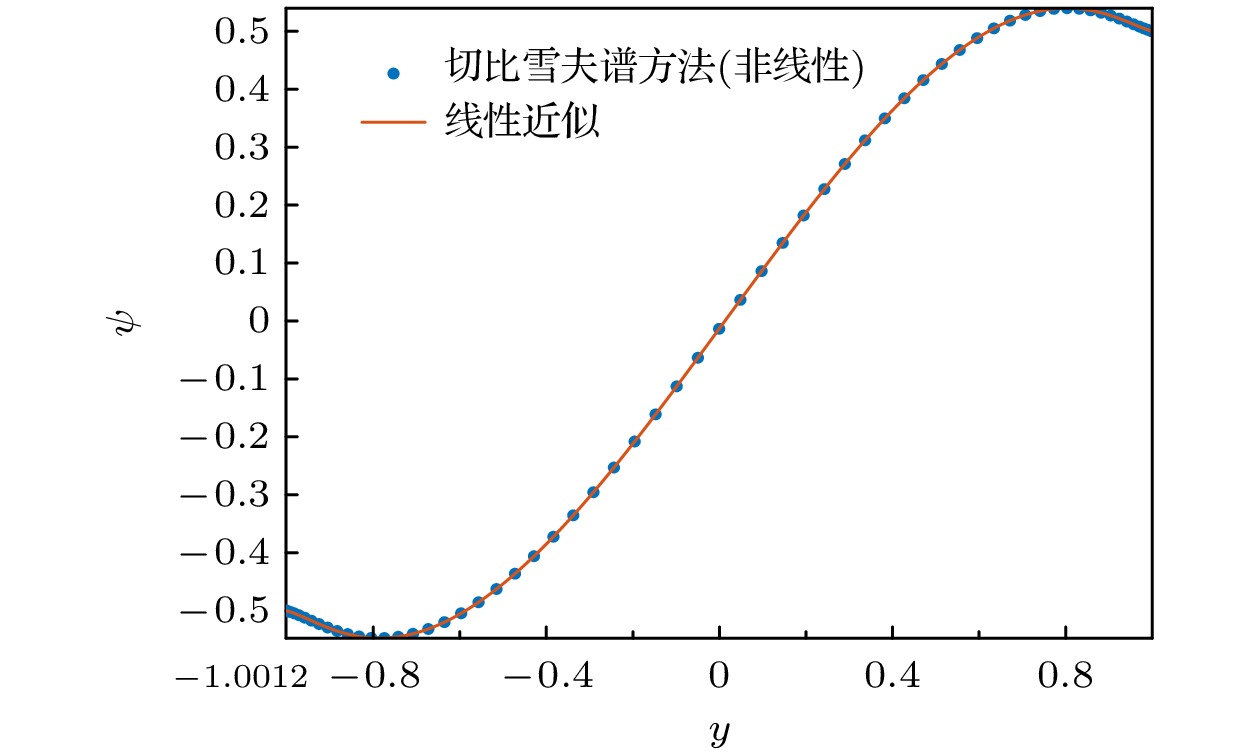

图 3 低Zeta势下流动方程D-H线性近似结果(实线)与切比雪夫谱方法(圆点)对比图, 其中$a = b = x = 0.5,\; \phi = $$ 0.05, \;d = 1.0, \;t = 0.0, \;F = 1.0$

Fig. 3. Comparison between the D-H approximate analytical solution (solid line) of nonlinear flow equation and Chebyshev-spectral method (dot) under the low Zeta potential, $a = b = x = 0.5, \, \;\phi = 0.05, \;d = 1.0, \;t = 0.0, \;F = 1.0$.

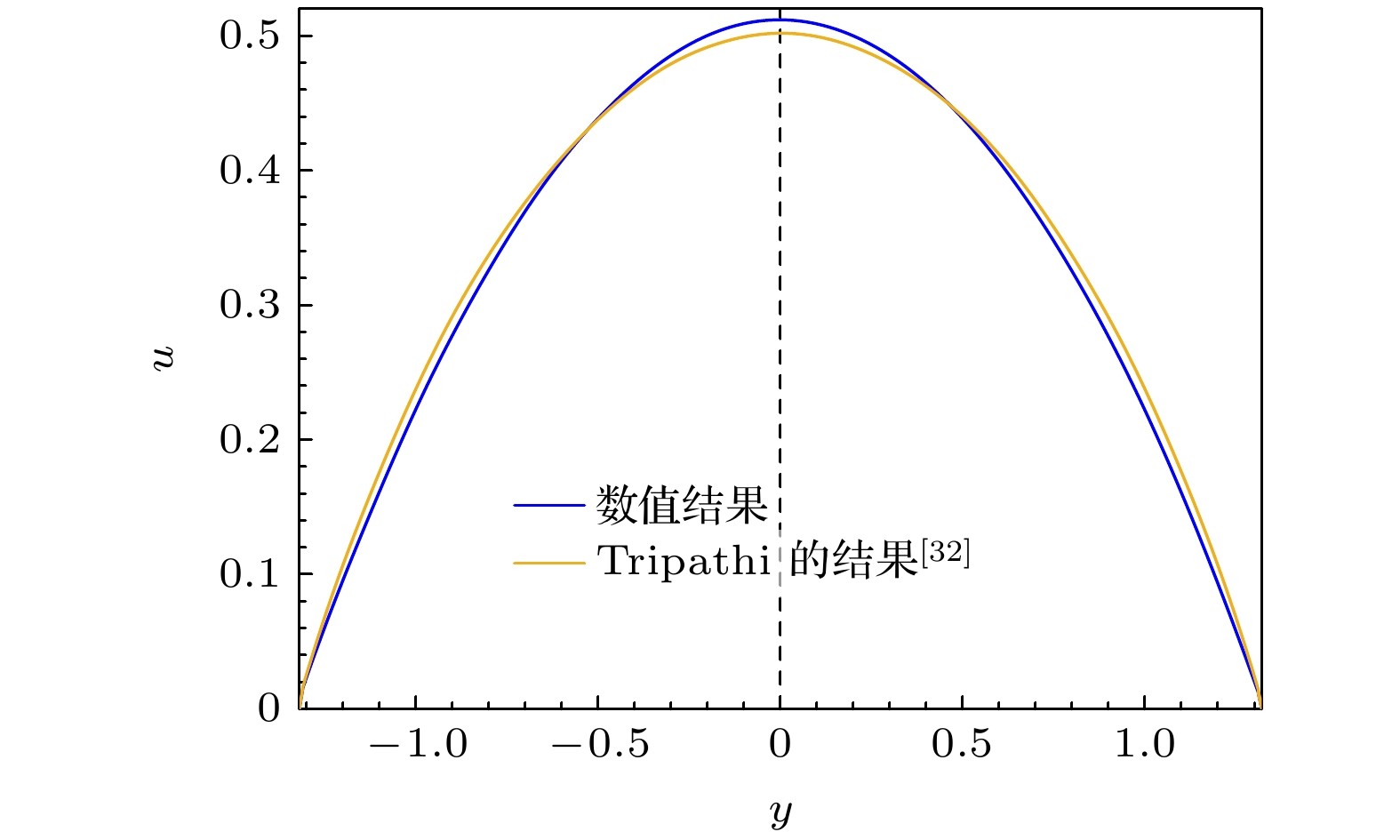

图 4 本文轴向速度分布与Tripathi[32]研究结果的比较, 其中${\zeta _1} \to 0, \;{\zeta _2} \to 0, \;H \to 0, \;{\beta _1} = {\beta _2} = \beta = 0$

Fig. 4. Comparison between axial velocity distributions obtained by this study and Tripathi[32], where ${\zeta _1} \to 0,\; {\zeta _2} \to 0, $$ H \to 0,\; {\beta _1} = {\beta _2} = \beta = 0$.

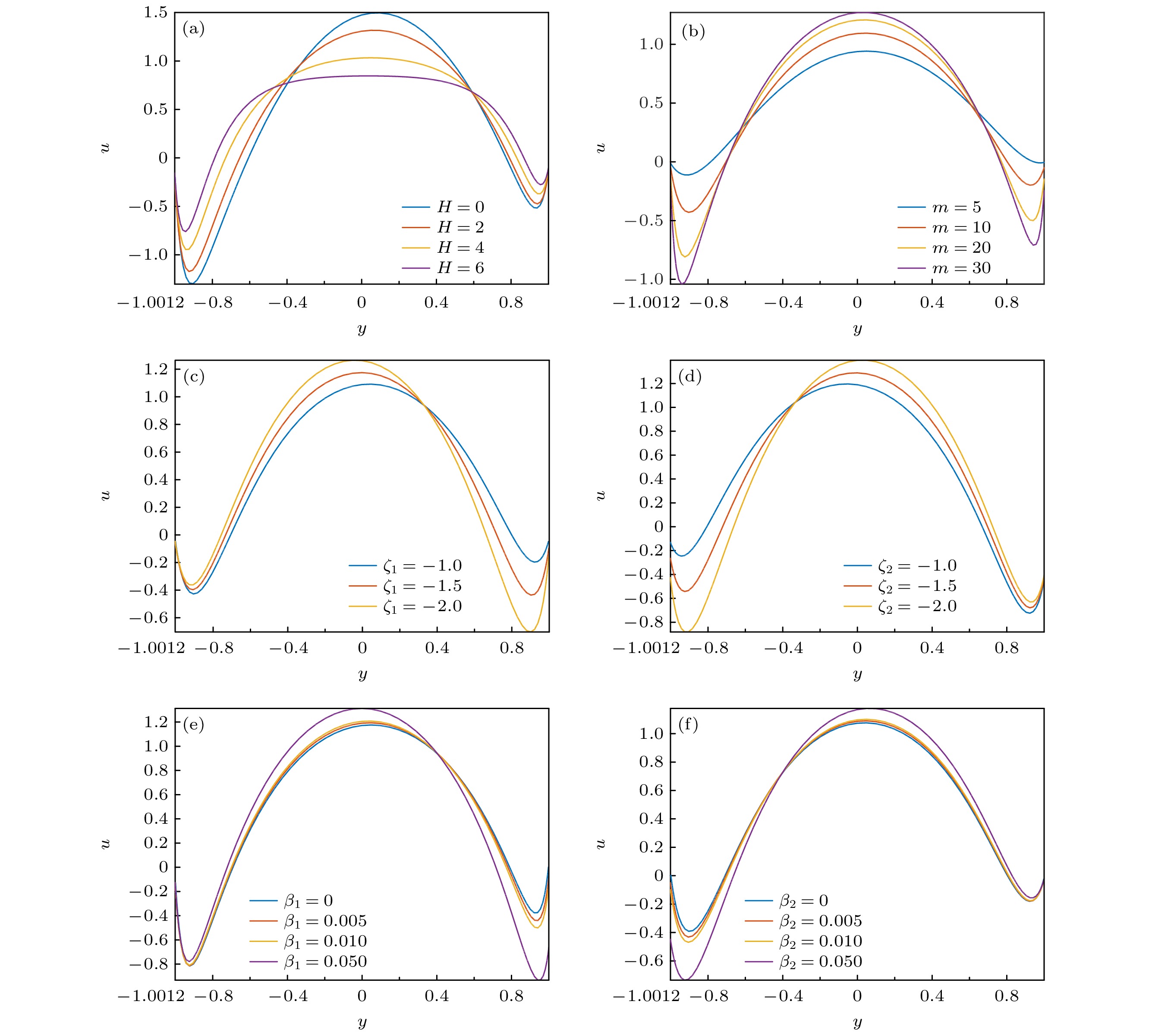

图 5 不同参数值对轴向速度的影响($a = b = x = 0.5, \;\phi = 0.05, \; d = 1.0, \;F = 1.0 $) (a) H; (b) m; (c) ${\zeta _1}$; (d) ${\zeta _2}$; (e) ${\beta _1}$; (f) ${\beta _2}$

Fig. 5. Effects of different parameter values on axial velocity: (a) H; (b) m; (c) ${\zeta _1}$; (d) ${\zeta _2}$; (e) ${\beta _1}$; (f) ${\beta _2}$. $a = b = x = 0.5, $$ \;\phi = 0.05, \;\; d = 1.0, \;F = 1.0$.

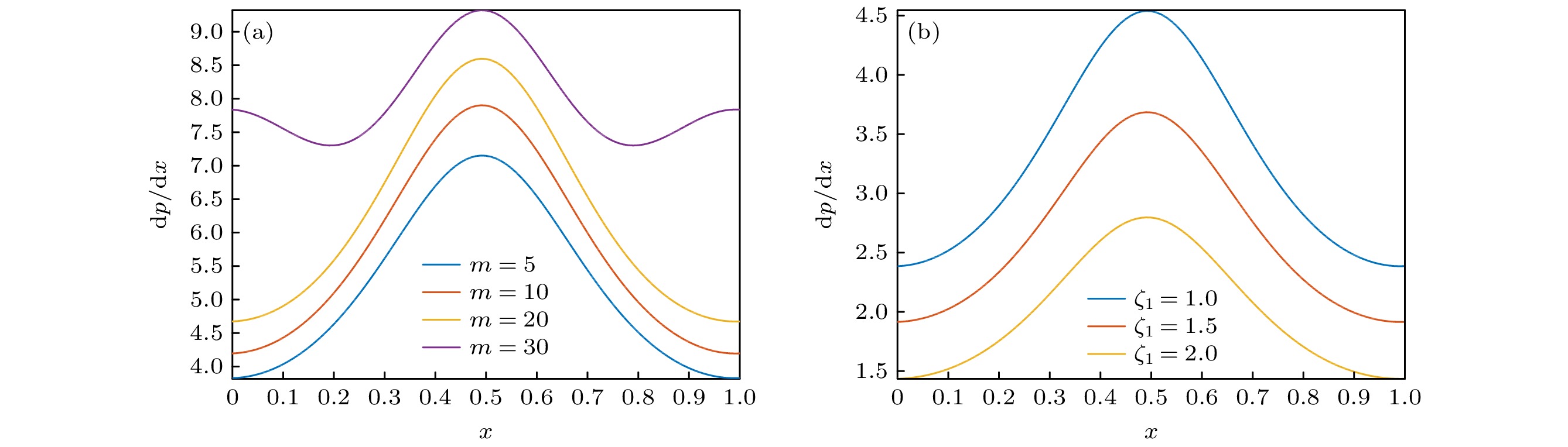

图 6 电渗参数$m$和Zeta电位对压力梯度的影响($ a = b = 0.5, {\text{ }}d = 1.0, {\text{ }}{\zeta _2} = - 1.5, {\text{ }}H = 2.0, \;{\beta _1} = 0.01, \;{\beta _2} = 0.005, {\text{ }}\phi {\text{ = 0}}{.05} $) (a) m; (b) ${\zeta _1}$

Fig. 6. Effects of electroosmotic parameters $m$ and potential Zeta on pressure gradients: (a) m; (b) ${\zeta _1}$. $ a = b = 0.5, {\text{ }}d = 1.0, $$ {\text{ }}{\zeta _2} = - 1.5, {\text{ }}H = 2.0, \;{\beta _1} = 0.01, \;{\beta _2} = 0.005, {\text{ }}\phi {\text{ = 0}}{.05} $.

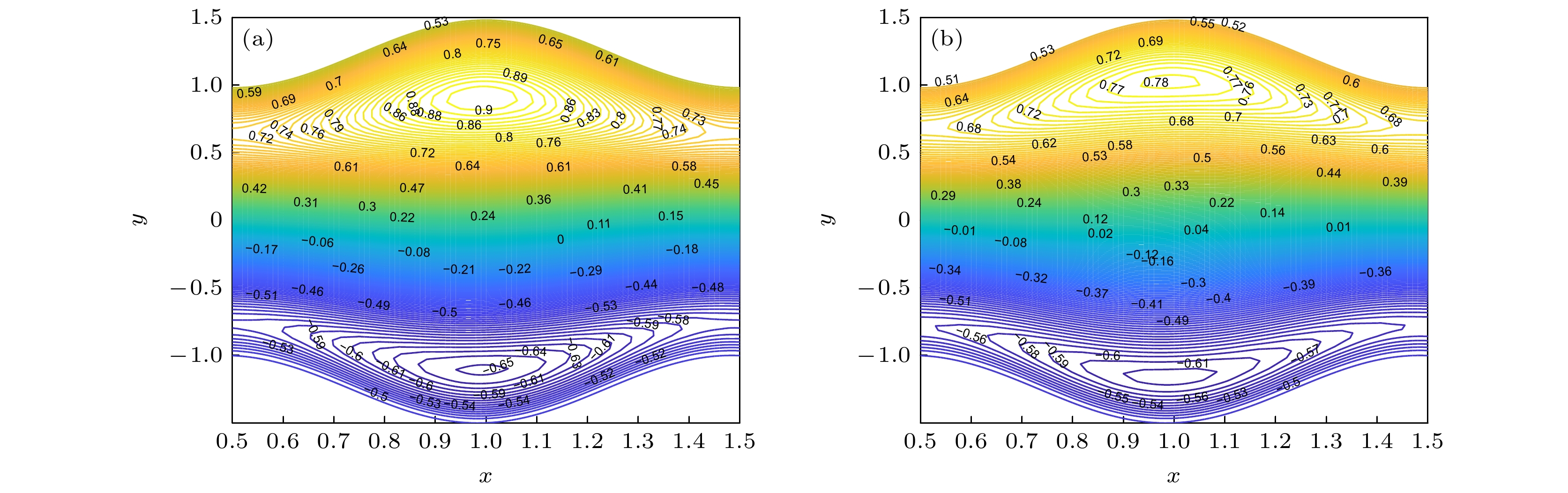

图 7 哈特曼数对流线分布$\psi $的影响($ \zeta_1 = - 1.5, ~\zeta_2 = -1, ~ m = 20, \beta_1 = 0.01, ~ \beta_2 = 0.005, ~\phi = 0.05 $) (a) $H \to 0\;$; (b) H = 2

Fig. 7. Effect of Hammett number on streamline distribution $\psi $: (a) $H \to 0\;$; (b) H = 2. $ {\text{ }}{\zeta _1} = - 1.5{\text{ }}, \;{\zeta _2} = - 1{\text{ }}, {\text{ }}m = 20, {\beta _1} = $$ 0.01{\text{ }}, \;{\beta _2} = 0.005{\text{ }}, \;\phi = 0.05 $.

图 8 电渗参数对流线分布$\psi $的影响(${\zeta _1} = - 1.5, \;{\zeta _2} = $$ - 1, \; H = 2.0, \; {\beta _1} = 0.01, \;{\beta _2} = 0.005,\; \phi = 0.05$) (a) m = 5; (b) m = 20

Fig. 8. Effects of electroosmotic parameters on the streamline distribution $\psi $: (a) m = 5; (b) m = 20.${\zeta _1} = - 1.5, \;{\zeta _2} = $$ - 1, \;H = 2.0, \;{\beta _1} = 0.01, \;{\beta _2} = 0.005, \;\phi = 0.05$

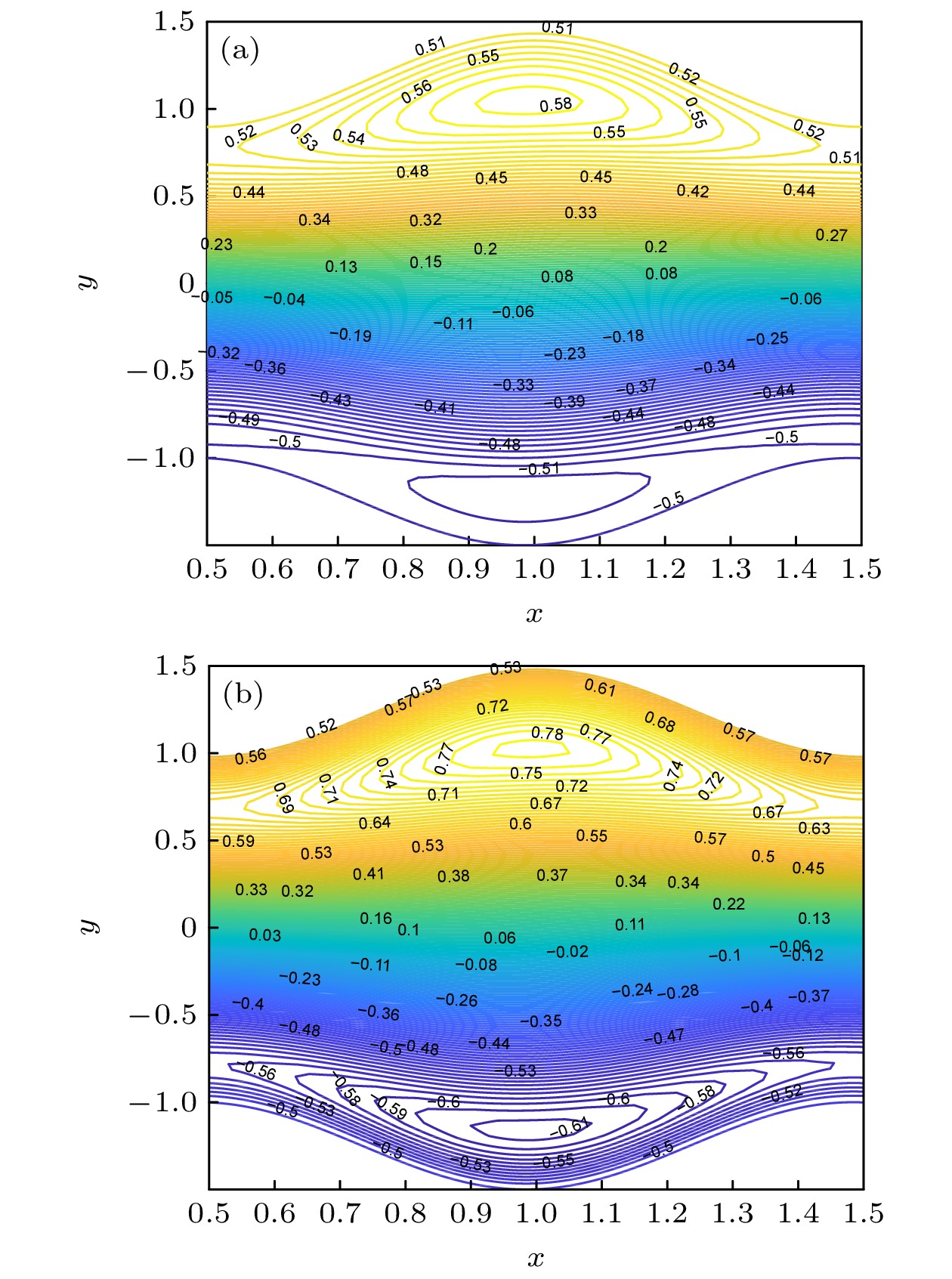

图 9 Zeta电位对流线分布$\psi $的影响($m = 20, \;H = 2.0, \; $$ {\beta _1} = 0.01, \;{\beta _2} = 0.005, \;\phi = 0.05$) (a) ${\zeta _1} = - 1$; (b) ${\zeta _1} = $$ - 1.5$; (c) ${\zeta _1} = - 2$

Fig. 9. Effect of Zeta potential on streamline distribution $\psi $: (a) ${\zeta _1} = - 1$; (b) ${\zeta _1} = - 1.5$; (c) ${\zeta _1} = - 2$. $m = 20, \;H = $$ 2.0, \;{\beta _1} = 0.01, \;{\beta _2} = 0.005, \;\phi = 0.05$.

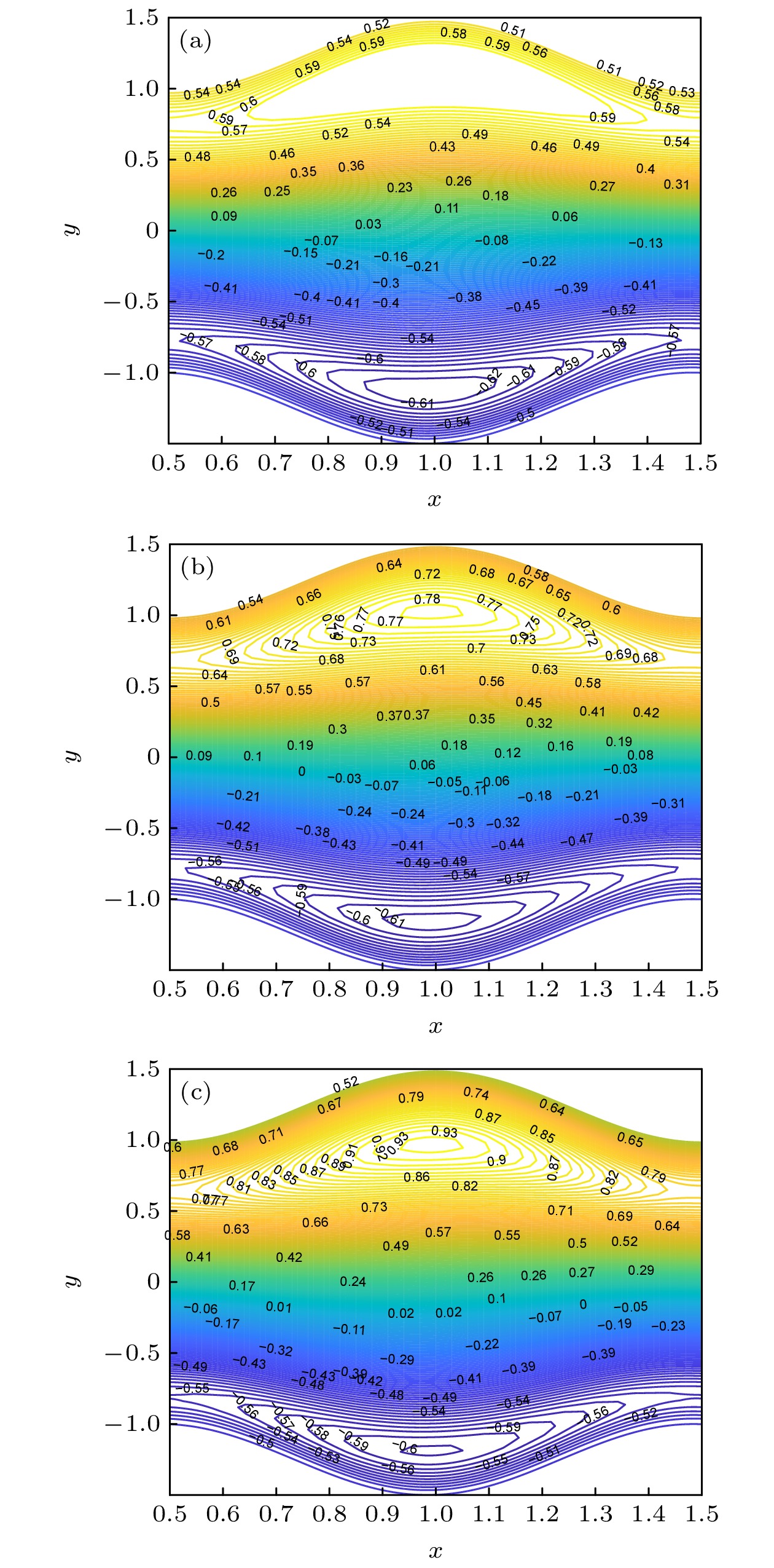

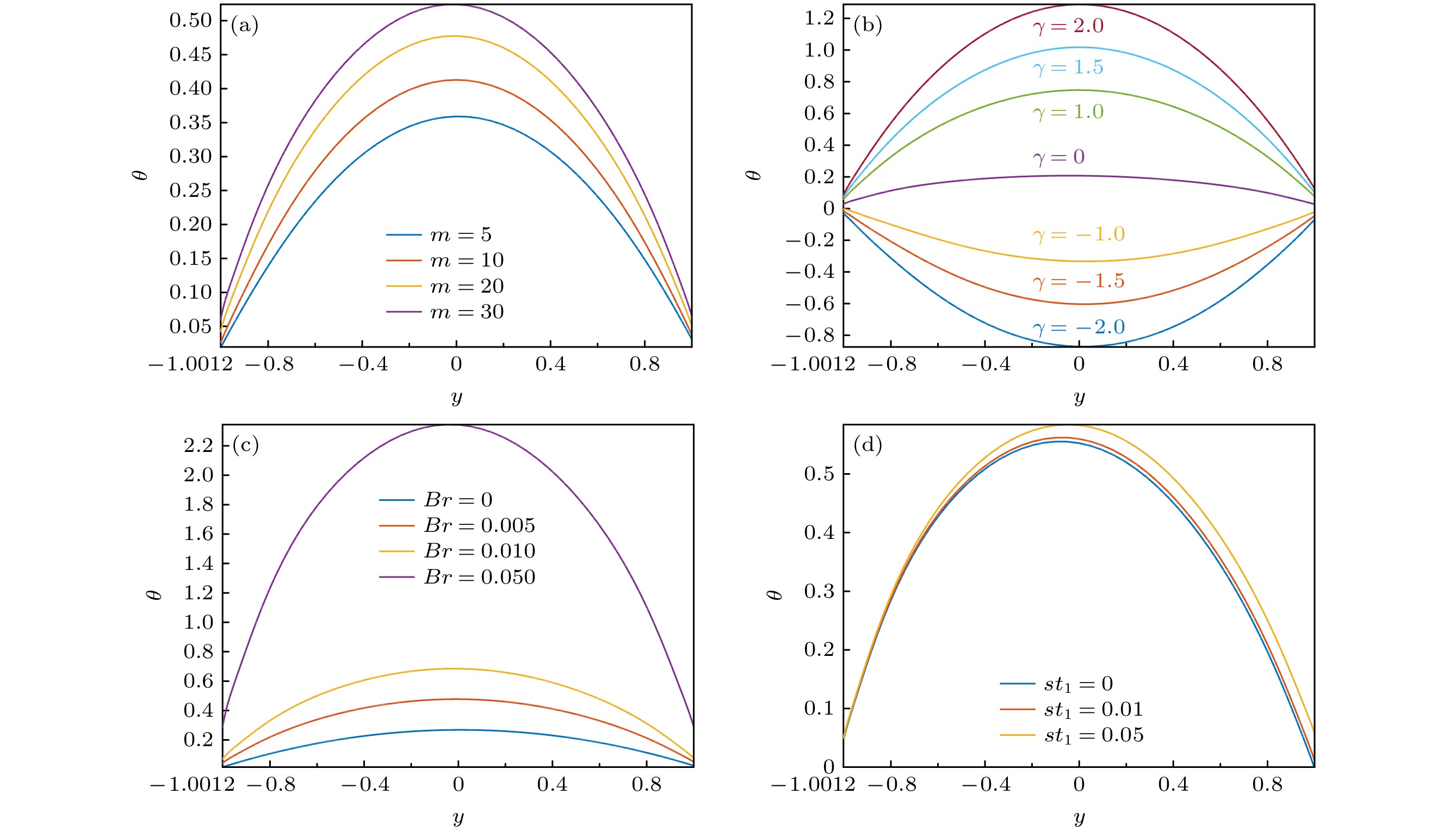

图 10 不同参数对温度分布$\theta $的影响($H = 2.0, \;{\beta _1} = 0.01, \;{\beta _2} = 0.005, \;\phi = s{t_2} = 0.05, \;{\zeta _1} = - 1.5, \;{\zeta _2} = - 1, x = 0.5, \;m = 20$) (a) m; (b) γ; (c) Br ; (d) st1

Fig. 10. Influences of different parameters on temperature distribution $\theta $: (a) m; (b) γ; (c) Br ; (d) st1. $H = 2.0, \;{\beta _1} = 0.01, $$ \;{\beta _2} = 0.005, \;\phi = s{t_2} = 0.05, \;{\zeta _1} = - 1.5, \;{\zeta _2} = - 1, x = 0.5, \;m = 20$.

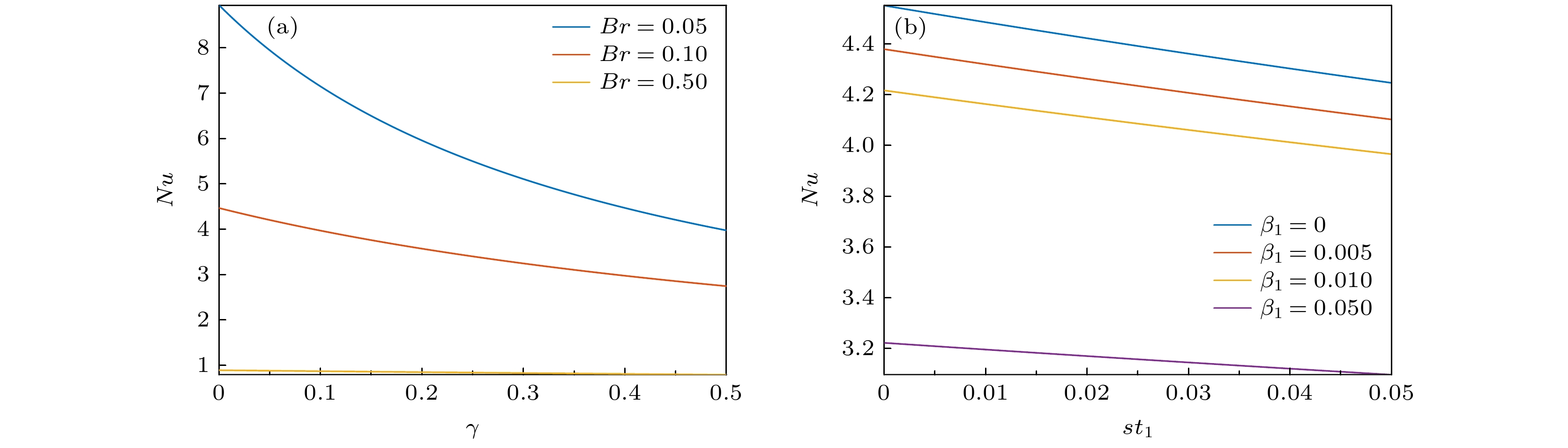

图 11 布林克曼数$Br$和速度滑移参数${\beta _1}$对努塞尔数$Nu$的影响($H = 2.0, \;{\beta _1} = 0.01, \;{\beta _2} = 0.005, \;\phi = s{t_2} = 0.05, \;{\zeta _1} = $$ - 1.5, \;{\zeta _2} = - 1, \;x = 0.5, \;m = 20$) (a) Br ; (b) β1

Fig. 11. Influences of Brinkman number Br and slip parameter β1 on Nussle number: (a) Br ; (b) β1. $H = 2.0, \;{\beta _1} = 0.01, $$ \;{\beta _2} = 0.005, \;\phi = s{t_2} = 0.05, \;{\zeta _1} = - 1.5, \;{\zeta _2} = - 1, \;x = 0.5, \;m = 20$.

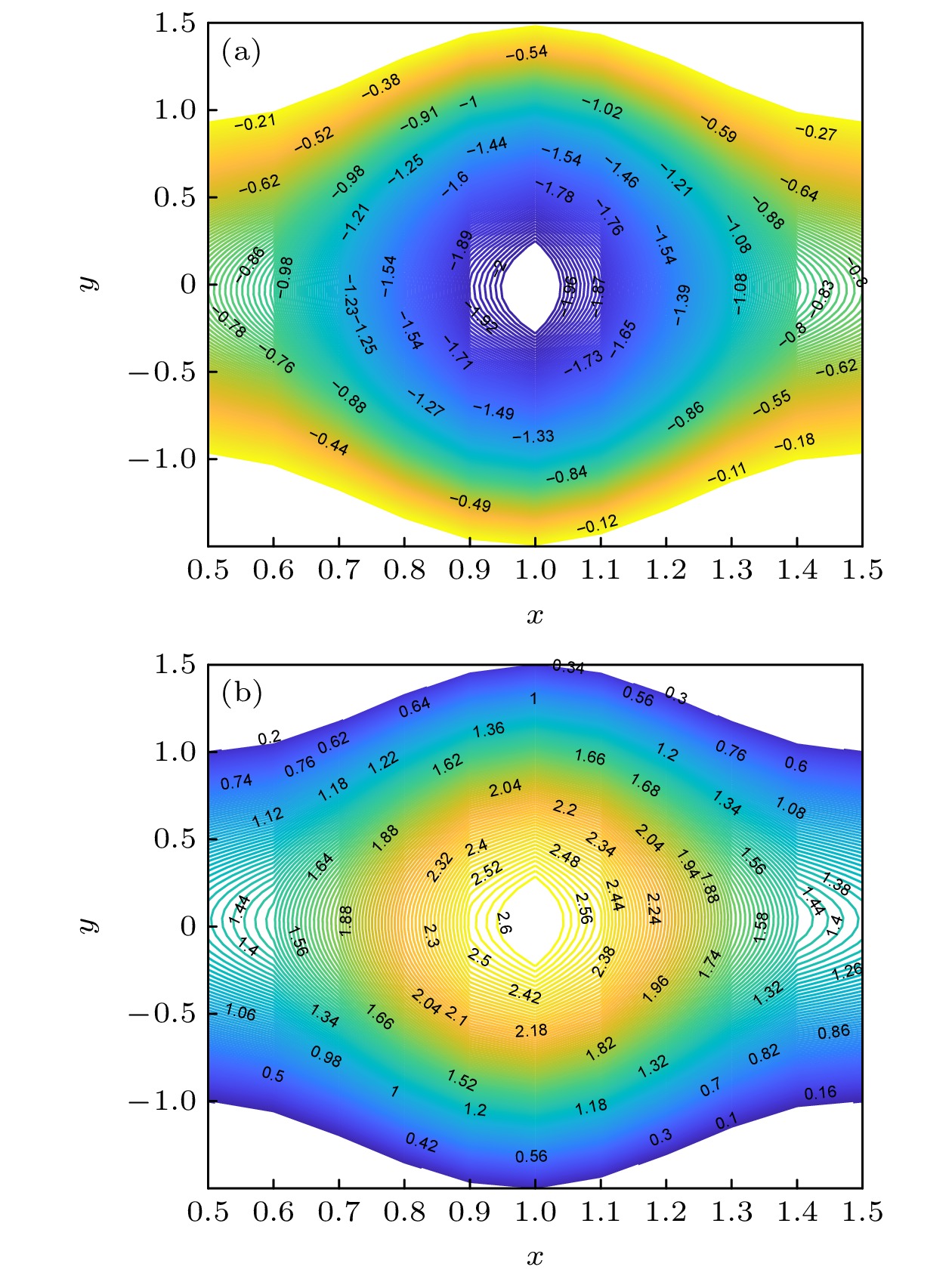

图 12 不同焦耳加热参数$\gamma $的等温图($H = 2.0, {\beta _1} = 0.01,$ ${\beta _2} = 0.005, $ $\phi = s{t_2} = 0.05, $ ${\zeta _1} = - 1.5, $ $ {\zeta _2} = - 1, $ $\;x = 0.5, $$ m = 20$) (a) $\gamma = - 2$; (b) $\gamma = 2$

Fig. 12. Isothermal diagram of different joule heating parameters $\gamma $: (a) $\gamma = - 2$; (b) $\gamma = 2$. $H = 2.0, \;{\beta _1} = 0.01, $ $ {\beta _2} = 0.005,$ $ \phi = s{t_2} = 0.05, $ $ {\zeta _1} = - 1.5, $ ${\zeta _2} = - 1, $ $x = $$ 0.5, $ $ m = 20 $.

-

[1] Maiti S, Pandey S K, Misra J C 2022 J. Eng. Math. 135 8

Google Scholar

Google Scholar

[2] Jaiswal S, Yadav P K 2022 Microfluid Nanofluid 26 100

Google Scholar

Google Scholar

[3] Patel H R, Patel S D, Darji R 2022 Int. J. Thermofluids 16 100232

Google Scholar

Google Scholar

[4] Sherief H H, Faltas M S, El-Sapa S 2019 Eur. J. Mech. B Fluids 77 211

Google Scholar

Google Scholar

[5] Chandra S, Kumar Pandey S 2018 J. Phys. Conf. Ser. 1141 012092

Google Scholar

Google Scholar

[6] Yasmin H, Nisar Z 2023 Mathematics 11 2673

Google Scholar

Google Scholar

[7] Mishra N K, Sharma B K, Sharma P, Muhammad T, Pérez L M 2023 Sci. Rep. 13 14483

Google Scholar

Google Scholar

[8] Guedri K, Lashin M M A, Abbasi A, Khan S U, Farooq W, Khan M I, Galal A M 2023 Chin. J. Phys. 83 650

Google Scholar

Google Scholar

[9] Maraj E N, Akbar N S, Zehra I, Butt A W, Ahmed Alghamdi H 2023 J. Magn. Magn. Mater. 576 170774

Google Scholar

Google Scholar

[10] Rafiq M, Shaheen S, Khan M I, Fadhl B M, Hassine S B H, ElDin S M 2023 Case Stud. Therm. Eng. 45 102990

Google Scholar

Google Scholar

[11] Alfwzan W, Riaz A, Alammari M, Hejazi H, Tag El-Din E M 2023 Front. Phys. 11 1121849

Google Scholar

Google Scholar

[12] Wang S, Li N, Zhao M, Azese M N 2018 Z. Naturforsch. A 73 825

Google Scholar

Google Scholar

[13] Sheikholeslami M, Chamkha A J 2016 Numer. Heat Tr. A-Appl. 69 781

Google Scholar

Google Scholar

[14] Tripathi D, Bhushan S, Bég O A 2016 Colloids Surf. A 506 32

Google Scholar

Google Scholar

[15] Shapiro A H, Jaffrin M Y, Weinberg S L 1969 J. Fluid Mech. Dig. Arch. 37 799

Google Scholar

Google Scholar

[16] Shit G C, Mondal A, Sinha A, Kundu P K 2016 Physica A 462 1040

Google Scholar

Google Scholar

[17] Chakraborty S 2007 Anal. Chim. Acta 605 175

Google Scholar

Google Scholar

[18] Bhardwaj A, Kumar A, Bhandari D S, Tripathi D 2024 Sensor. Actuat. A-Phys. 366 114956

[19] Verma L, Meher R 2023 Pramana 97 155

Google Scholar

Google Scholar

[20] Chen L, Abbas M A, Khudair W S, Sun B 2022 Symmetry 14 953

Google Scholar

Google Scholar

[21] Mahabub M, Ferdows M, Murtaza M G, Lorenzini G, Tzirtzilakis E E 2022 Mathem. Mod. Eng. Probl. 9 215

Google Scholar

Google Scholar

[22] Madkhali H A 2023 Case Stud. Therm. Eng. 41 102655

Google Scholar

Google Scholar

[23] Upreti H, Bartwal P, Pandey A K, Makinde O D 2023 Numer. Heat Transf. B: Fundam. 84 415

Google Scholar

Google Scholar

[24] Yashkun U, Zaimi K, Sufahani S F, Eid M R, Ferdows M 2023 Appl. Math J. Chin. Univ. 38 373

Google Scholar

Google Scholar

[25] Mishra N K, Sharma B K, Sharma P, Muhammad T, Pérez L M 2023 Sci. Rep. 13 1

Google Scholar

Google Scholar

[26] Cordwell A, Chapple A A, Chung S, Wells F S, Willmott G R 2023 Soft Matter 19 4676

Google Scholar

Google Scholar

[27] Ma N L, Sun Y, Jian Y 2023 Micromachines 14 1617

Google Scholar

Google Scholar

[28] Sarkar S, Ganguly S 2017 J. Non-Newtonian Fluid 250 18

Google Scholar

Google Scholar

[29] Kikuchi Y 1995 Microvasc. Res. 50 288

Google Scholar

Google Scholar

[30] Ranjit N K, Shit G C, Tripathi D 2018 Microvasc. Res. 117 74

Google Scholar

Google Scholar

[31] Sadeghi A, Kazemi Y, Saidi M H 2013 Nanosc. Microsc. Therm. 17 173

Google Scholar

Google Scholar

[32] Tripathi D 2013 Math. Comput. Model 57 1270

Google Scholar

Google Scholar

计量

- 文章访问数: 4879

- PDF下载量: 72

- 被引次数: 0

下载:

下载: