-

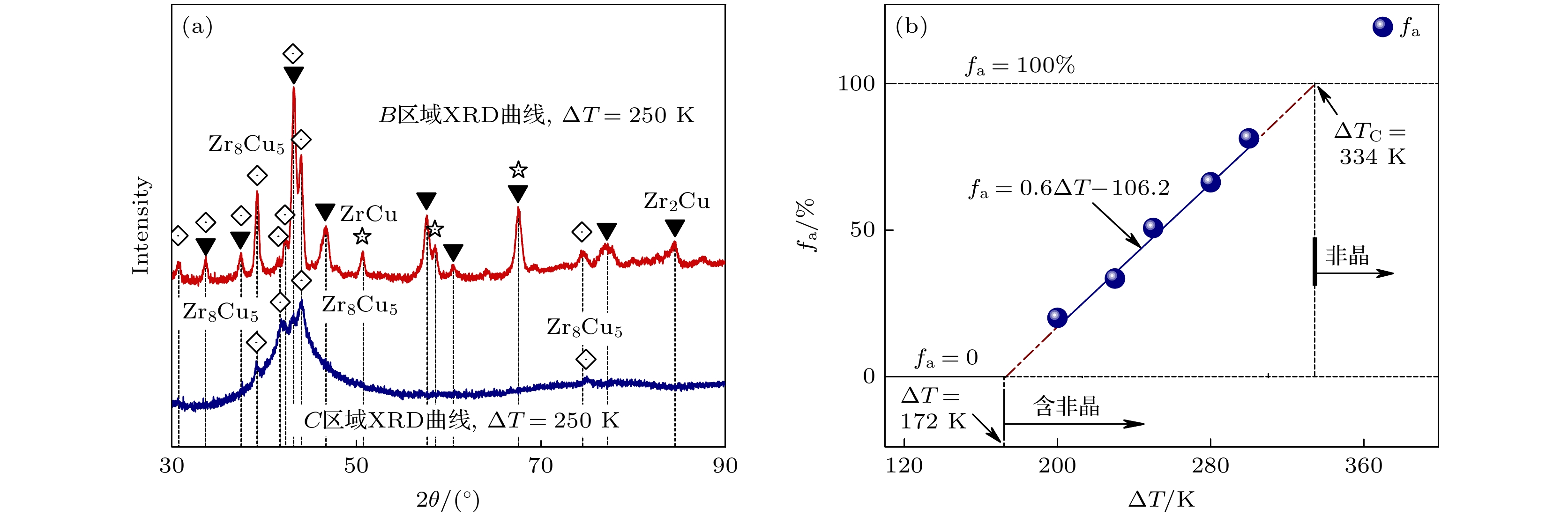

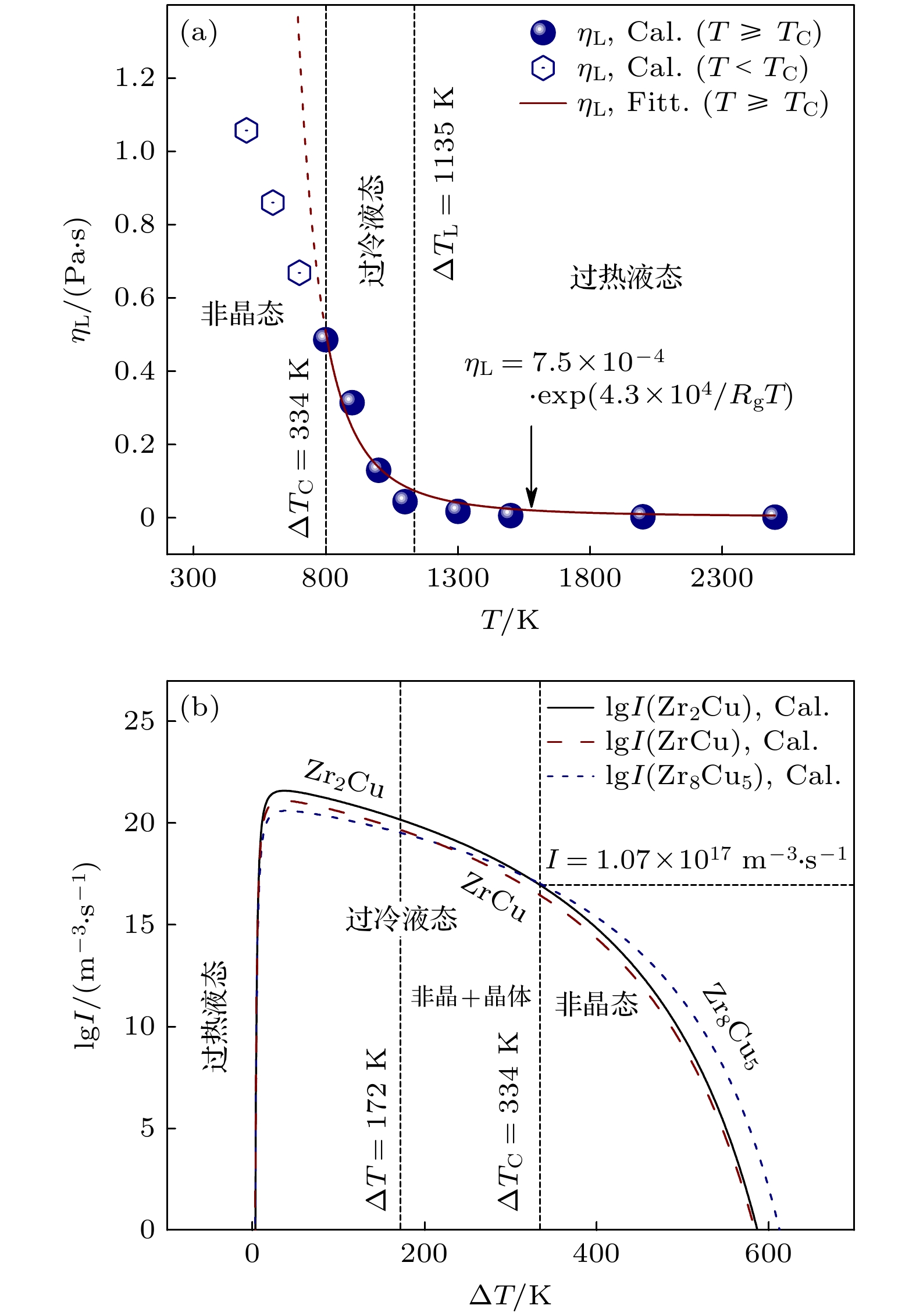

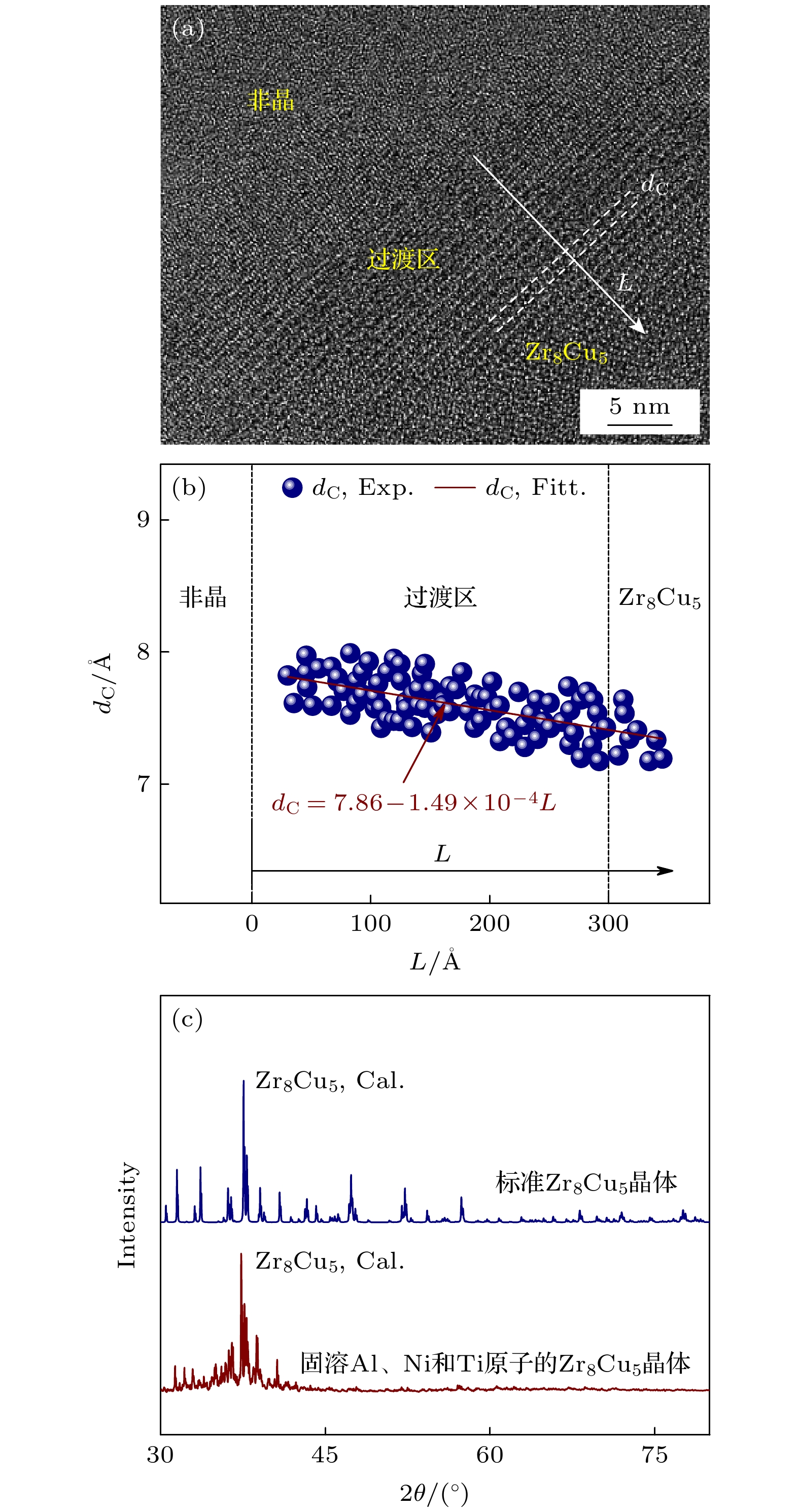

利用电磁悬浮无容器处理技术实现了液态五元Zr57Cu20Al10Ni8Ti5合金的深过冷与快速凝固, 同时通过分子动力学模拟计算揭示了非晶形成的微观机制. 实验发现, 凝固组织具有明显的核-壳结构特征, 核区为非晶相, 壳区主要由ZrCu, Zr2Cu和Zr8Cu5晶体相组成. 非晶体积分数随合金过冷度的升高逐渐增大, 当达到实验最大过冷度300 K (0.26TL)时, 非晶体积分数增至81.3%. 由此导出完全非晶凝固所需临界过冷度为334 K. TEM分析显示, 过冷度增大并接近临界过冷度时, 合金凝固组织中晶体相主要为Zr8Cu5相, 而ZrCu和Zr2Cu相的生长被抑制. 在达到临界过冷度后, 过冷液相的凝固路径由Zr8Cu5结晶生长转变为非晶凝固. 此外, 合金的晶体壳中存在少量的晶间非晶相, 而非晶核中亦有微量的非晶间Zr8Cu5纳米晶团簇. 模拟结果表明, 晶间非晶相的形成主要源于近临界过冷度下偏析行为诱发的成分过冷, 而非晶间纳米晶团簇的出现则主要归因于深过冷液相中的微观热起伏效应.The substantial undercooling and rapid solidification of liquid quinary Zr57Cu20Al10Ni8Ti5 alloy are achieved by electromagnetic levitation (EML) technique. The amorphous solidification mechanism is revealed with molecular dynamics (MD) simulation. It is observed in EML experiment that the containerlessly solidified alloy is characterized by a core-shell structure, with mainly amorphous phase becoming the core and crystalline ZrCu, Zr2Cu and Zr8Cu5 phases forming the shell. The volume fraction of amorphous core structure increases with undercooling and attains a value up to 81.3% at the maximum experimental undercooling of 300 K, which indicates that the critical undercooling required for complete amorphous solidification is 334 K. TEM analyses show that the alloy microstructure is mainly composed of Zr8Cu5 phase, whereas the ZrCu phase and Zr2Cu phase are suppressed when liquid undercooling approaches this threshold. Once the critical undercooling is reached, amorphous solidification prevails over the crystallization of Zr8Cu5 phase. In addition, a small quantity of amorphous phases are found in the crystalline shell and a little trace of Zr8Cu5 nano-cluster is detected among the amorphous core. It is further verified by MD simulation that the formation of amorphous phase in the shell is caused by the microsegregation-induced solutal undercooling when liquid alloy attains the critical undercooling, while the nano-clusters within the core is mainly ascribed to the micro-thermal fluctuation effect inside highly undercooled liquid phase.

-

Keywords:

- electromagnetic levitation /

- amorphous alloy /

- highly undercooling /

- rapid solidification /

- molecular dynamics

[1] Liu X F, Wang R J, Zhao D Q, Pan M X, Wang W H 2007 Appl. Phys. Lett. 91 041901

Google Scholar

Google Scholar

[2] Sniadecki Z, Mielniczuk B, Idzikowski B, Greneche J M, Robler U K 2010 J. Appl. Phys. 108 073516

Google Scholar

Google Scholar

[3] Zhao R, Jiang H Y, Luo P, Sun Y T, Li Z A, Wu W W, Shen L Q, Liu M, Zhao S F, Wen P, Zhang Q H, Gu L, Bai H Y, Wang W H 2020 Appl. Phys. Lett. 117 131903

Google Scholar

Google Scholar

[4] Shao L L, Xue L, Wang Q Q, Ma K L, Huang J D, Shen B L 2021 J. Alloy. Compd. 874 159964

Google Scholar

Google Scholar

[5] Wei B C, Zhang Y, Zhuang Y X, Zhao D Q, Pan M X, Wang W H 2001 J. Appl. Phys. 89 3529

Google Scholar

Google Scholar

[6] Nishiyama N, Takenaka K, Miura H, Saidoh N, Zeng Y Q, Inoue A 2012 Intermetallics 30 19

Google Scholar

Google Scholar

[7] Tang M Q, Zhang H F, Zhu Z W, Fu H M, Wang A M, Li H, Hu Z Q 2010 J. Mater. Sci. Technol. 26 481

Google Scholar

Google Scholar

[8] Haruyama O, Watanabe T, Yuki K, Horiuchi M, Kato H, Nishiyama N 2011 Phys. Rev. B 83 064201

Google Scholar

Google Scholar

[9] Liu C Y, Wang F, Rao F F, Hou Y 2013 J. Appl. Phys. 113 869

Google Scholar

Google Scholar

[10] Turci F, Tarjus G, Royall C P 2017 Phys. Rev. Lett 118 215501

Google Scholar

Google Scholar

[11] 陈季香, 周朔瑶 2014 63 066101

Google Scholar

Google Scholar

Chen J X, Zhou S Y 2014 Acta Phys. Sin. 63 066101

Google Scholar

Google Scholar

[12] Guerdane M, Teichler H 2001 Phys. Rev. B 65 014203

Google Scholar

Google Scholar

[13] Qi L, Zhang H F, Hu Z Q, Liaw P K 2004 Phys. Lett. A 327 506

Google Scholar

Google Scholar

[14] Brillo J, Pommrich A I, Meyer A 2011 Phys. Rev. Lett. 107 165902

Google Scholar

Google Scholar

[15] Wall J J, Weber R, Kim J, Liaw P K, Choo H 2007 Mat. Sci. Eng. A 445 219

Google Scholar

Google Scholar

[16] Lü P, Wang H P 2017 Scripta Mater. 137 31

Google Scholar

Google Scholar

[17] Hong S J, Chun H, Lee J, Kim B H, Seo M H, Kang J, Han B 2021 J. Phys. Chem. Lett. 12 6000

Google Scholar

Google Scholar

[18] Yao N, Chen X, Fu Z H, Zhang Q 2022 Chem. Rev. 122 10970

Google Scholar

Google Scholar

[19] Wang H, Zhang L F, Han J Q, E W N Deep 2018 Comput. Phys. Commun. 228 178

Google Scholar

Google Scholar

[20] Ketkaew R, Creazzo F, Luber S 2022 J. Phys. Chem. Lett. 13 1797

Google Scholar

Google Scholar

[21] 徐山森, 常健, 吴宇昊, 沙莎, 魏炳波 2019 68 196401

Google Scholar

Google Scholar

Xu S S, Chang J, Wu Y H, Sha S, Wei B B 2019 Acta Phys. Sin. 68 196401

Google Scholar

Google Scholar

[22] Xu S S, Chang J, Sha S, Wei B 2022 Metall. Mater. Trans. A 53 762

Google Scholar

Google Scholar

[23] Xing L Q, Ochina P 1997 Mater. Lett. 30 283

Google Scholar

Google Scholar

[24] Baskes M I 1992 Phys. Rev. B 46 2727

Google Scholar

Google Scholar

[25] Sun Q Q, Qin J Y, Li X X, Wang J, Pan S P 2021 J. Phase Equilib. Diff. 42 166

Google Scholar

Google Scholar

[26] Dai Y, Li J H, Liu B X 2011 J. Appl. Phys. 109 053505

Google Scholar

Google Scholar

[27] Garzon I L, Pasada-Amarillas A 1996 Phys. Rev. B 54 796

Google Scholar

Google Scholar

[28] Turnbull D, Fisher J C 1949 J. Chem. Phys. 1771

Google Scholar

Google Scholar

[29] Tsoutsouva M G, Duffar T, Chaussende D, Kamguem M 2016 J. Cryst. Growth 451 103

Google Scholar

Google Scholar

[30] Kim T H, Gangopadhyay A K, Xing L Q, Lee G W, Shen Y T, Kelton K F, Goldman A I, Hyers R W, Rogers J R 2005 Appl. Phys. Lett. 87 251924

Google Scholar

Google Scholar

[31] Kim S J, Kim Y H, Yang Y S 2001 Mat. Sci. Eng. A 304-306 767

Google Scholar

Google Scholar

[32] Bondi A 1964 J. Phys. Chem. Lett. 68 441

[33] Bondi A 1966 J. Phys. Chem. C 70 3006

Google Scholar

Google Scholar

[34] Launey M E, Kruzic J J, Li C, Busch R 2007 Appl. Phys. Lett. 91 51913

Google Scholar

Google Scholar

[35] 周边, 杨亮 2020 69 116101

Google Scholar

Google Scholar

Zhou B, Yang L 2020 Acta Phys. Sin. 69 116101

Google Scholar

Google Scholar

-

图 1 电磁悬浮条件下液态五元Zr57Cu20Al10Ni8Ti5合金的深过冷与快速凝固 (a) ΔT = 200 K; (b) ΔT = 250 K; (c) ΔT = 300 K; (d) 核-壳界面形貌

Fig. 1. High undercooling and rapid solidification of liqud quinary Zr57Cu20Al10Ni8Ti5 alloy under electromagnetic levitation condition: (a) ΔT = 200 K; (b) ΔT = 250 K; (c) ΔT = 300 K; (d) core-shell interface morphology.

图 4 液态Zr57Cu20Al10Ni8Ti5合金的微观结构特征 (a) 计算系统总能量; (b) 合金原子的扩散系数; (c)

$\langle0, 0, 12, 0\rangle $ 二十面体结构在多面体团簇中的比例Fig. 4. Microstructure characteristics of highly undercooled liquid Zr57Cu20Al10Ni8Ti5 alloy: (a) Calculated system total energy; (b) calculated atom diffusion coefficient; (c) calculated

$\langle0, 0, 12, 0\rangle $ icosahedron ratio in Voronoi polyhedral clusters.图 7 过冷度250 K时Zr57Cu20Al10Ni8Ti5合金壳区的元素分布 (a) 壳区微观组织; (b) Ni元素含量; (c) Ti元素含量; (d) 总双体分布函数; (e) Zr-Ni偏双体分布函数; (f) Zr-Ti偏双体分布函数

Fig. 7. Element distribution of Zr57Cu20Al10Ni8Ti5 alloy shell under 250 K undercooling: (a) Microstructure of alloy shell; (b) Ni content; (c) Ti content; (d) calculated total pair distribution function; (e) calculated Zr-Ni partial bipartite distribution function; (f) calculated Zr-Ti partial bipartite distribution function.

图 9 非晶凝固对合金平均显微硬度的影响 (a) Zr8Cu5结晶生长与非晶凝固的系统总体积; (b) Zr8Cu5结晶生长与非晶凝固的系统自由体积; (c) 非晶核平均显微硬度

Fig. 9. Effect of amorphous solidification on alloy average microhardness: (a) System total volume of Zr8Cu5 crystal growth and amorphous solidification; (b) system free volume of Zr8Cu5 crystal growth and amorphous solidification; (c) average microhardness of alloy amorphous core.

-

[1] Liu X F, Wang R J, Zhao D Q, Pan M X, Wang W H 2007 Appl. Phys. Lett. 91 041901

Google Scholar

Google Scholar

[2] Sniadecki Z, Mielniczuk B, Idzikowski B, Greneche J M, Robler U K 2010 J. Appl. Phys. 108 073516

Google Scholar

Google Scholar

[3] Zhao R, Jiang H Y, Luo P, Sun Y T, Li Z A, Wu W W, Shen L Q, Liu M, Zhao S F, Wen P, Zhang Q H, Gu L, Bai H Y, Wang W H 2020 Appl. Phys. Lett. 117 131903

Google Scholar

Google Scholar

[4] Shao L L, Xue L, Wang Q Q, Ma K L, Huang J D, Shen B L 2021 J. Alloy. Compd. 874 159964

Google Scholar

Google Scholar

[5] Wei B C, Zhang Y, Zhuang Y X, Zhao D Q, Pan M X, Wang W H 2001 J. Appl. Phys. 89 3529

Google Scholar

Google Scholar

[6] Nishiyama N, Takenaka K, Miura H, Saidoh N, Zeng Y Q, Inoue A 2012 Intermetallics 30 19

Google Scholar

Google Scholar

[7] Tang M Q, Zhang H F, Zhu Z W, Fu H M, Wang A M, Li H, Hu Z Q 2010 J. Mater. Sci. Technol. 26 481

Google Scholar

Google Scholar

[8] Haruyama O, Watanabe T, Yuki K, Horiuchi M, Kato H, Nishiyama N 2011 Phys. Rev. B 83 064201

Google Scholar

Google Scholar

[9] Liu C Y, Wang F, Rao F F, Hou Y 2013 J. Appl. Phys. 113 869

Google Scholar

Google Scholar

[10] Turci F, Tarjus G, Royall C P 2017 Phys. Rev. Lett 118 215501

Google Scholar

Google Scholar

[11] 陈季香, 周朔瑶 2014 63 066101

Google Scholar

Google Scholar

Chen J X, Zhou S Y 2014 Acta Phys. Sin. 63 066101

Google Scholar

Google Scholar

[12] Guerdane M, Teichler H 2001 Phys. Rev. B 65 014203

Google Scholar

Google Scholar

[13] Qi L, Zhang H F, Hu Z Q, Liaw P K 2004 Phys. Lett. A 327 506

Google Scholar

Google Scholar

[14] Brillo J, Pommrich A I, Meyer A 2011 Phys. Rev. Lett. 107 165902

Google Scholar

Google Scholar

[15] Wall J J, Weber R, Kim J, Liaw P K, Choo H 2007 Mat. Sci. Eng. A 445 219

Google Scholar

Google Scholar

[16] Lü P, Wang H P 2017 Scripta Mater. 137 31

Google Scholar

Google Scholar

[17] Hong S J, Chun H, Lee J, Kim B H, Seo M H, Kang J, Han B 2021 J. Phys. Chem. Lett. 12 6000

Google Scholar

Google Scholar

[18] Yao N, Chen X, Fu Z H, Zhang Q 2022 Chem. Rev. 122 10970

Google Scholar

Google Scholar

[19] Wang H, Zhang L F, Han J Q, E W N Deep 2018 Comput. Phys. Commun. 228 178

Google Scholar

Google Scholar

[20] Ketkaew R, Creazzo F, Luber S 2022 J. Phys. Chem. Lett. 13 1797

Google Scholar

Google Scholar

[21] 徐山森, 常健, 吴宇昊, 沙莎, 魏炳波 2019 68 196401

Google Scholar

Google Scholar

Xu S S, Chang J, Wu Y H, Sha S, Wei B B 2019 Acta Phys. Sin. 68 196401

Google Scholar

Google Scholar

[22] Xu S S, Chang J, Sha S, Wei B 2022 Metall. Mater. Trans. A 53 762

Google Scholar

Google Scholar

[23] Xing L Q, Ochina P 1997 Mater. Lett. 30 283

Google Scholar

Google Scholar

[24] Baskes M I 1992 Phys. Rev. B 46 2727

Google Scholar

Google Scholar

[25] Sun Q Q, Qin J Y, Li X X, Wang J, Pan S P 2021 J. Phase Equilib. Diff. 42 166

Google Scholar

Google Scholar

[26] Dai Y, Li J H, Liu B X 2011 J. Appl. Phys. 109 053505

Google Scholar

Google Scholar

[27] Garzon I L, Pasada-Amarillas A 1996 Phys. Rev. B 54 796

Google Scholar

Google Scholar

[28] Turnbull D, Fisher J C 1949 J. Chem. Phys. 1771

Google Scholar

Google Scholar

[29] Tsoutsouva M G, Duffar T, Chaussende D, Kamguem M 2016 J. Cryst. Growth 451 103

Google Scholar

Google Scholar

[30] Kim T H, Gangopadhyay A K, Xing L Q, Lee G W, Shen Y T, Kelton K F, Goldman A I, Hyers R W, Rogers J R 2005 Appl. Phys. Lett. 87 251924

Google Scholar

Google Scholar

[31] Kim S J, Kim Y H, Yang Y S 2001 Mat. Sci. Eng. A 304-306 767

Google Scholar

Google Scholar

[32] Bondi A 1964 J. Phys. Chem. Lett. 68 441

[33] Bondi A 1966 J. Phys. Chem. C 70 3006

Google Scholar

Google Scholar

[34] Launey M E, Kruzic J J, Li C, Busch R 2007 Appl. Phys. Lett. 91 51913

Google Scholar

Google Scholar

[35] 周边, 杨亮 2020 69 116101

Google Scholar

Google Scholar

Zhou B, Yang L 2020 Acta Phys. Sin. 69 116101

Google Scholar

Google Scholar

计量

- 文章访问数: 5684

- PDF下载量: 95

- 被引次数: 0

下载:

下载: