-

低活化马氏体钢具有较好的抗辐照性能, 然而对其抗辐照机理尚不清楚, 特别是嬗变气体存在的情况下辐照缺陷行为非常复杂. 本文通过对低活化马氏体钢预形变(10%和20%)后热处理(723 K, 1 h)保留位错缺陷, 随后对预留位错的样品进行室温氦辐照(50 keV, 1×1017 He/cm2), 采用同步辐射掠入射X射线衍射、慢正电子多普勒展宽谱和热脱附谱研究了位错与氦辐照缺陷的相互作用及位错对氦原子迁移、热脱附行为的影响. 结果表明, 高密度位错阻碍了氦和氦空位复合体的扩散, 进而减缓了辐照损伤的扩展, 这种现象随着位错密度的增大更加明显. 低活化马氏体钢在1179 K 时发生体心立方结构→面心立方结构相转变, 位错密度增加会导致由相转变引起的氦热脱附峰前移. 未形变、10%形变、20%形变样品中氦的滞留量分别为10.3%, 15.7%, 17.9%, 表明高密度位错更容易将氦保留到材料内部, 反映了位错对氦的滞留起到促进作用.Reduced-activation martensitic steel is a main candidate structural material for key components of advanced nuclear energy systems because of its good mechanical properties at room temperature, low neutron activation characteristics and satisfactory radiation resistance. In this work, we study the interaction between dislocations and helium-irradiation-induced defects in the steel and the effect of dislocations on the behavior of helium migration and desorption. The well-annealed samples are pre-deformed to 10% and 20% reductions in thickness by using cold rolling mill. After pre-deformation, samples are heat-treated to remove vacancy defects and retain dislocation defects. Then, the samples with reserved dislocations are irradiated with helium at room temperature (50 keV, 1×1017 He/cm2). After irradiation, the samples are characterized by synchrotron radiation grazing incident X-Ray diffraction, positron annihilation Doppler broadening spectroscopy, and thermal desorption spectroscopy. The results show that dislocations hinder the diffusion of helium and helium-vacancy complexes, and reduce the accumulation of radiation damage. Such an effect becomes more significant with the increase of dislocation density. The BCC → FCC phase transition of low activation martensitic steel occurs at 1179 K. The increase of dislocation density will lead to the forward shift of helium desorption peak induced by phase transition. The retention of helium in the undeformed sample, 10% deformed sample and 20% deformed sample is 10.3%, 15.7% and 17.9%, respectively, indicating that high density dislocations promote the retention of helium.

-

Keywords:

- helium irradiation /

- dislocation /

- positron annihilation /

- thermal desorption

[1] Baluc N, Abe K, Boutard J L, Chernov V M, Diegele E, Jitsukawa S, Kimura A, Klueh R L, Kohyama A, Kurtz R J, Lässer R, Matsui H, Möslang A, Muroga T, Odette G R, Tran M Q, van der Schaaf B, Wu Y, Yu J, Zinkle S J 2007 Nucl. Fusion 47 S696

Google Scholar

Google Scholar

[2] Kurtz R J, Alamo A, Lucon E, Huang Q, Jitsukawa S, Kimura A, Klueh R L, Odette G R, Petersen C, Sokolov M A, Spätig P, Rensman J W 2009 J. Nucl. Mater. 386−388 411

Google Scholar

Google Scholar

[3] Huang Q 2014 J. Nucl. Mater. 455 649

Google Scholar

Google Scholar

[4] Niwase K, Ezawa T, Tanabe T, Kiritani M, Fujita F E 1993 J. Nucl. Mater. 203 56

Google Scholar

Google Scholar

[5] Mansur L K, Coghlan W A 1983 J. Nucl. Mater. 119 1

Google Scholar

Google Scholar

[6] Chernov I I, Kalashnikov A N, Kalin B A, Binyukova S Y 2003 J. Nucl. Mater. 323 341

Google Scholar

Google Scholar

[7] Xu Q, Sugiura Y, Pan X Q, Sato K, Yoshiie T 2014 Mat. Sci. Eng. A-Struct. 612 41

Google Scholar

Google Scholar

[8] Woodford D A, Smith J P, Moteff J 1969 J. Nucl. Mater. 29 103

Google Scholar

Google Scholar

[9] van den Beukel A 1979 Scr. Metall. 13 83

Google Scholar

Google Scholar

[10] Cao Q, Ju X, Guo L P, Wang B 2014 Fusion Eng. Des. 89 1101

Google Scholar

Google Scholar

[11] van den Beukel A 2014 Chin. Phys. Lett. 31 036101

Google Scholar

Google Scholar

[12] Sarkar D K, Bera S, Narasimhan S V, Chowdhury S, Gupta A, Nair K G M 1998 Solid State Commun. 107 413

Google Scholar

Google Scholar

[13] Zhu T, Zhong Z H, Sato K, Song Y M, Ye F J, Wang Q Q, Dong Y, Zhang P, Yu R S, Wang B Y, Ngan A H W, Cao X Z, Xu Q 2022 Tungsten 4 212

Google Scholar

Google Scholar

[14] Zhang Z, Zhu T, Jin S, Zhang P, Kuang P, Guo L P, An X, Wang B Y, Yu R, Zhang S, Cao X Z 2020 Fusion Eng. Des. 161 111978

Google Scholar

Google Scholar

[15] Zhu T, Jin S, Gong Y, Lu E Y, Song L G, Xu Q, Guo L P, Cao X Z, Wang B Y 2017 J. Nucl. Mater. 495 244

Google Scholar

Google Scholar

[16] Sabelová V, Kršjak V, Kuriplach J, Petriska M, Slugeň V, Šimeg Veterníková J 2014 J. Nucl. Mater. 450 54

Google Scholar

Google Scholar

[17] Song Y M, Song L G, Lian X Y, Jin S X, Zhu T, Liu Y L, Zhang P, Wang B Y, Cao X Z 2023 JJAP Conference Proceedings 9 011103

Google Scholar

Google Scholar

[18] Jin S X, Zhang P, Lu E Y, Guo L P, Wang B Y, Cao X Z 2016 Acta Mater. 103 658

Google Scholar

Google Scholar

[19] King D A 1975 Surf. Sci. 47 384

Google Scholar

Google Scholar

[20] Lombardo S J, Bell A T 1988 Surf. Sci. 206 101

Google Scholar

Google Scholar

[21] Morishita K, Sugano R, Wirth B D, Diaz de la Rubia T 2003 Nucl. Instrum. Methods Phys. Res. Sect. B 202 76

Google Scholar

Google Scholar

[22] Zhang S, Cizek J, Yao Z, Oleksandr M, Kong X, Liu C, van Dijk N, van der Zwaag S 2020 J. Alloys Compd. 817 152765

Google Scholar

Google Scholar

[23] Morishita K, Sugano R, Wirth B D 2003 J. Nucl. Mater. 323 243

Google Scholar

Google Scholar

[24] Xu D, Bus T, Glade S C, Wirth B D 2007 J. Nucl. Mater. 367 483

Google Scholar

Google Scholar

[25] Zhu T, Cao X Z, Jin S X, Wu J P, Gong Y H, Lu E Y, Wang B Y, Yu R S, Wei L 2015 J. Nucl. Mater. 466 522

Google Scholar

Google Scholar

[26] Yonemura M, Inoue K 2016 Metall. Mater. Trans. A 47 6384

Google Scholar

Google Scholar

[27] Wang J R, Pan B C 2022 J. Nucl. Mater. 561 153540

Google Scholar

Google Scholar

-

图 1 低活化马氏体钢的TEM图 (a) 1013 K退火; (b) 10%变形; (c) 20%变形. 在1013 K退火后的样品中观察到少量缺陷, 将退火样品冷轧变形10%和20%发现大量位错

Fig. 1. (a) TEM micrographs of the well-annealed sample, a small number of defects are observed. (b), (c) The image of the annealed specimens after cold-worked, a number of dislocations induced by cold rolling to 10% (b) and 20% (c) of their original thickness are observed.

表 1 低活化马氏体钢的化学成分

Table 1. Chemical composition of the low activation martensitic steel.

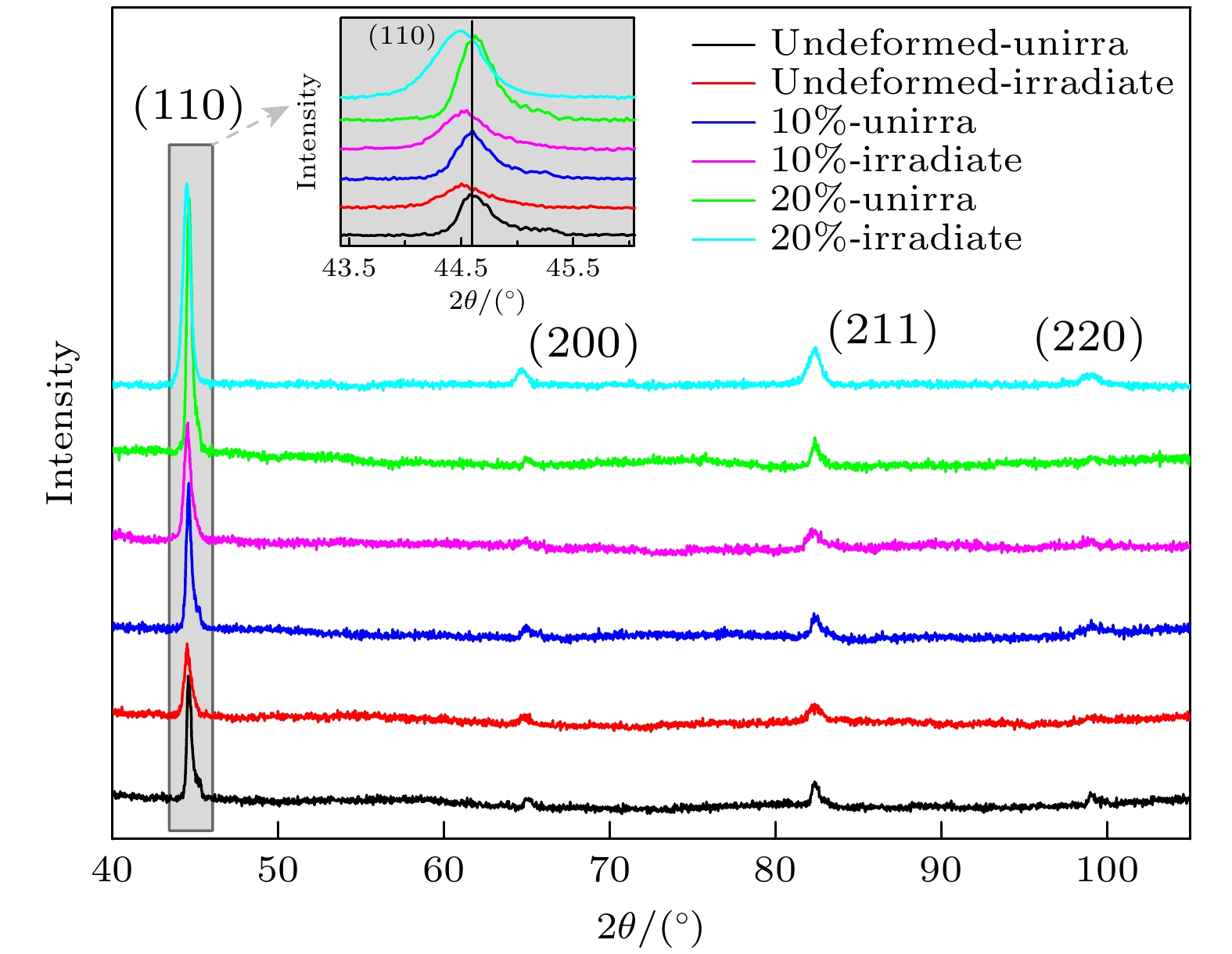

元素 Cr V Ta W C Mn Si P S Fe 质量分数/% 9.100 0.190 0.200 1.500 0.120 0.400 0.025 0.003 0.003 88.459 表 2 同步辐射X射线衍射数据, 即不同形变辐照条件下低活化马氏体钢的2θ和FWHM

Table 2. Synchrotron radiation X-ray diffraction data, namely, 2θ and FWHM of low activation martensitic steel with different conditions.

Sample 2θ/FWHM (110) (200) (211) (220) Undeform-unirra 44.553/0.302 64.894/0.355 82.327/0.401 98.9890/0.276 Undeform-irradiate 44.500/0.416 64.653/0.473 82.167/0.610 98.780/0.366 10%-unirra 44.566/0.359 64.902/0.466 82.330/0.583 99.008/0.355 10%-irradiate 44.524/0.465 64.801/0.544 82.127/0.663 98.554/0.397 20%-unirra 44.563/0.351 64.880/0.345 82.356/0.573 98.979/0.330 20%-irradiate 44.154/0.474 64.249/0.478 82.054/0.694 98.749/0.736 表 3 低活化马氏体钢氦的热脱附能

Table 3. Desorption temperature and desorption activation energy.

Peak Temperature/K Energy/eV Undeformed A2 1164 3.38 A3 1179 3.41 10% deformation B1 1073 3.11 B2 1128 3.27 B3 1149 3.33 20% deformation C1 1028 2.98 C2 1096 3.18 C3 1115 3.23 -

[1] Baluc N, Abe K, Boutard J L, Chernov V M, Diegele E, Jitsukawa S, Kimura A, Klueh R L, Kohyama A, Kurtz R J, Lässer R, Matsui H, Möslang A, Muroga T, Odette G R, Tran M Q, van der Schaaf B, Wu Y, Yu J, Zinkle S J 2007 Nucl. Fusion 47 S696

Google Scholar

Google Scholar

[2] Kurtz R J, Alamo A, Lucon E, Huang Q, Jitsukawa S, Kimura A, Klueh R L, Odette G R, Petersen C, Sokolov M A, Spätig P, Rensman J W 2009 J. Nucl. Mater. 386−388 411

Google Scholar

Google Scholar

[3] Huang Q 2014 J. Nucl. Mater. 455 649

Google Scholar

Google Scholar

[4] Niwase K, Ezawa T, Tanabe T, Kiritani M, Fujita F E 1993 J. Nucl. Mater. 203 56

Google Scholar

Google Scholar

[5] Mansur L K, Coghlan W A 1983 J. Nucl. Mater. 119 1

Google Scholar

Google Scholar

[6] Chernov I I, Kalashnikov A N, Kalin B A, Binyukova S Y 2003 J. Nucl. Mater. 323 341

Google Scholar

Google Scholar

[7] Xu Q, Sugiura Y, Pan X Q, Sato K, Yoshiie T 2014 Mat. Sci. Eng. A-Struct. 612 41

Google Scholar

Google Scholar

[8] Woodford D A, Smith J P, Moteff J 1969 J. Nucl. Mater. 29 103

Google Scholar

Google Scholar

[9] van den Beukel A 1979 Scr. Metall. 13 83

Google Scholar

Google Scholar

[10] Cao Q, Ju X, Guo L P, Wang B 2014 Fusion Eng. Des. 89 1101

Google Scholar

Google Scholar

[11] van den Beukel A 2014 Chin. Phys. Lett. 31 036101

Google Scholar

Google Scholar

[12] Sarkar D K, Bera S, Narasimhan S V, Chowdhury S, Gupta A, Nair K G M 1998 Solid State Commun. 107 413

Google Scholar

Google Scholar

[13] Zhu T, Zhong Z H, Sato K, Song Y M, Ye F J, Wang Q Q, Dong Y, Zhang P, Yu R S, Wang B Y, Ngan A H W, Cao X Z, Xu Q 2022 Tungsten 4 212

Google Scholar

Google Scholar

[14] Zhang Z, Zhu T, Jin S, Zhang P, Kuang P, Guo L P, An X, Wang B Y, Yu R, Zhang S, Cao X Z 2020 Fusion Eng. Des. 161 111978

Google Scholar

Google Scholar

[15] Zhu T, Jin S, Gong Y, Lu E Y, Song L G, Xu Q, Guo L P, Cao X Z, Wang B Y 2017 J. Nucl. Mater. 495 244

Google Scholar

Google Scholar

[16] Sabelová V, Kršjak V, Kuriplach J, Petriska M, Slugeň V, Šimeg Veterníková J 2014 J. Nucl. Mater. 450 54

Google Scholar

Google Scholar

[17] Song Y M, Song L G, Lian X Y, Jin S X, Zhu T, Liu Y L, Zhang P, Wang B Y, Cao X Z 2023 JJAP Conference Proceedings 9 011103

Google Scholar

Google Scholar

[18] Jin S X, Zhang P, Lu E Y, Guo L P, Wang B Y, Cao X Z 2016 Acta Mater. 103 658

Google Scholar

Google Scholar

[19] King D A 1975 Surf. Sci. 47 384

Google Scholar

Google Scholar

[20] Lombardo S J, Bell A T 1988 Surf. Sci. 206 101

Google Scholar

Google Scholar

[21] Morishita K, Sugano R, Wirth B D, Diaz de la Rubia T 2003 Nucl. Instrum. Methods Phys. Res. Sect. B 202 76

Google Scholar

Google Scholar

[22] Zhang S, Cizek J, Yao Z, Oleksandr M, Kong X, Liu C, van Dijk N, van der Zwaag S 2020 J. Alloys Compd. 817 152765

Google Scholar

Google Scholar

[23] Morishita K, Sugano R, Wirth B D 2003 J. Nucl. Mater. 323 243

Google Scholar

Google Scholar

[24] Xu D, Bus T, Glade S C, Wirth B D 2007 J. Nucl. Mater. 367 483

Google Scholar

Google Scholar

[25] Zhu T, Cao X Z, Jin S X, Wu J P, Gong Y H, Lu E Y, Wang B Y, Yu R S, Wei L 2015 J. Nucl. Mater. 466 522

Google Scholar

Google Scholar

[26] Yonemura M, Inoue K 2016 Metall. Mater. Trans. A 47 6384

Google Scholar

Google Scholar

[27] Wang J R, Pan B C 2022 J. Nucl. Mater. 561 153540

Google Scholar

Google Scholar

计量

- 文章访问数: 5515

- PDF下载量: 73

- 被引次数: 0

下载:

下载: