-

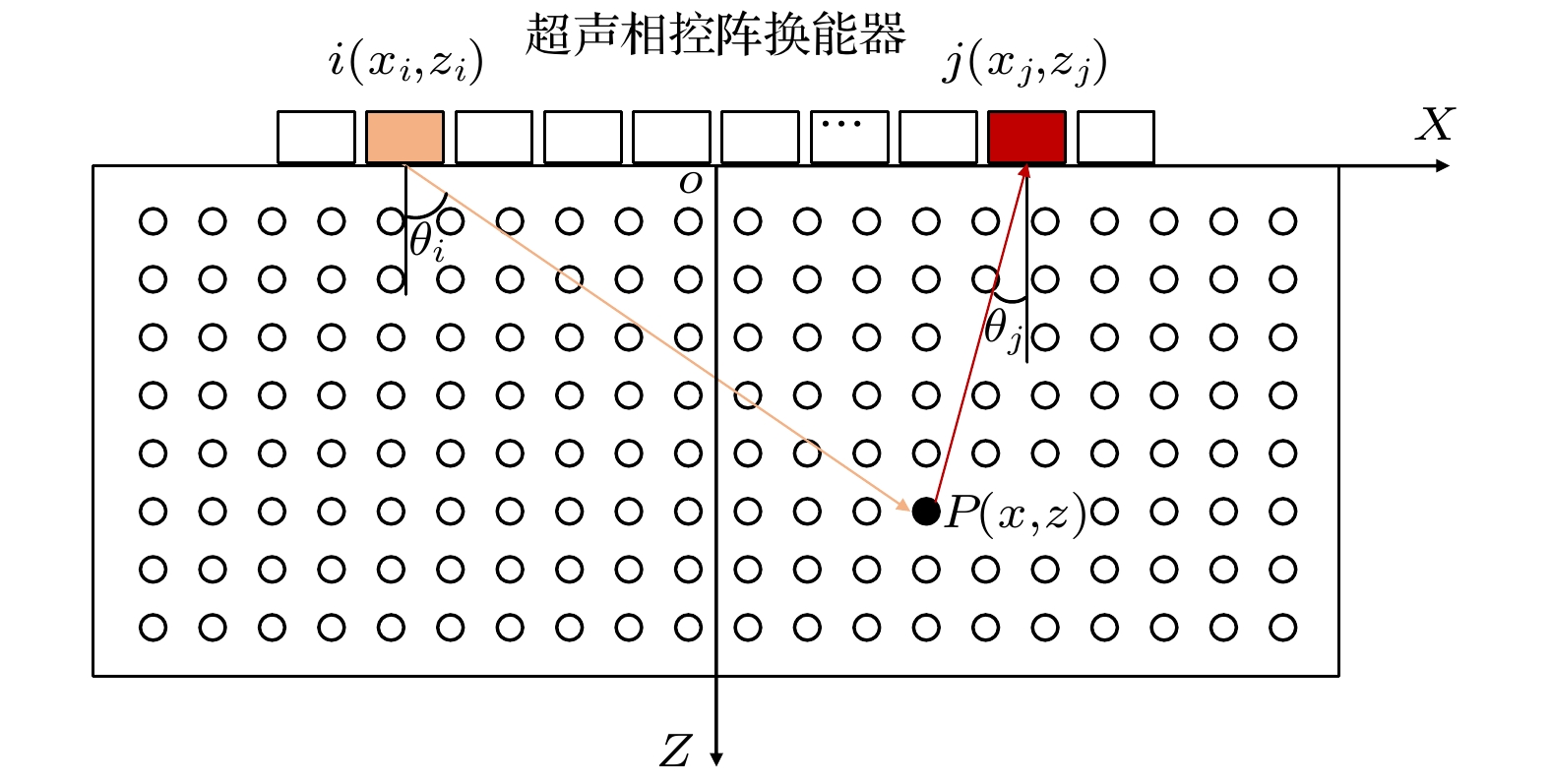

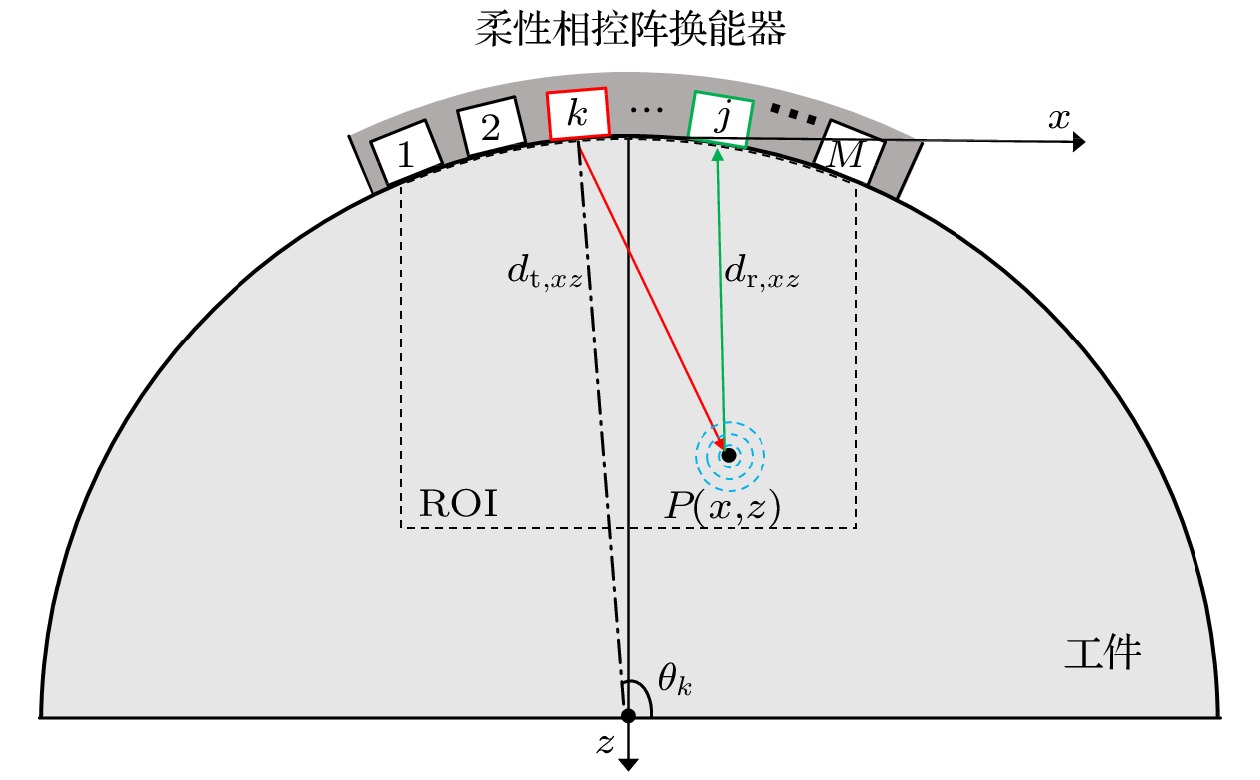

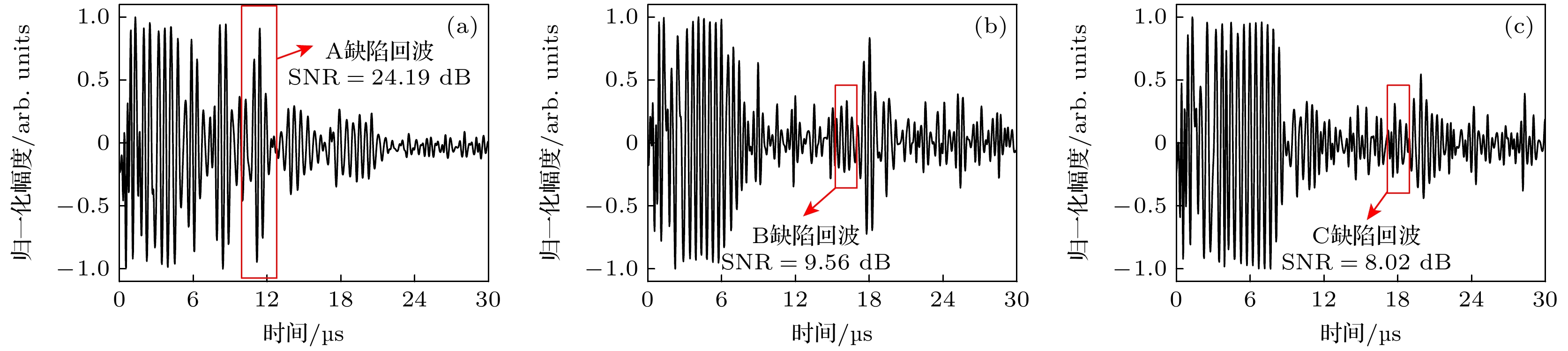

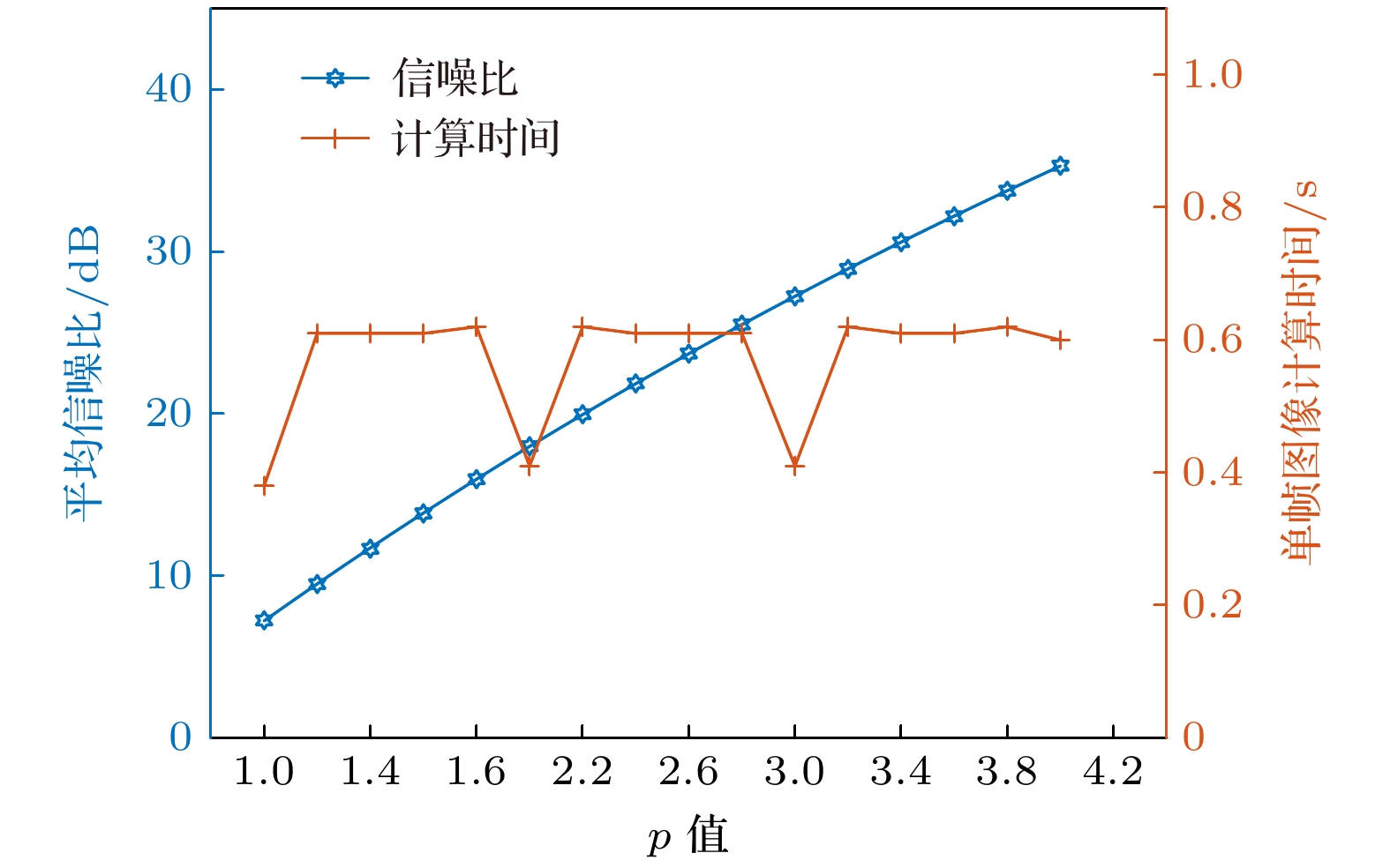

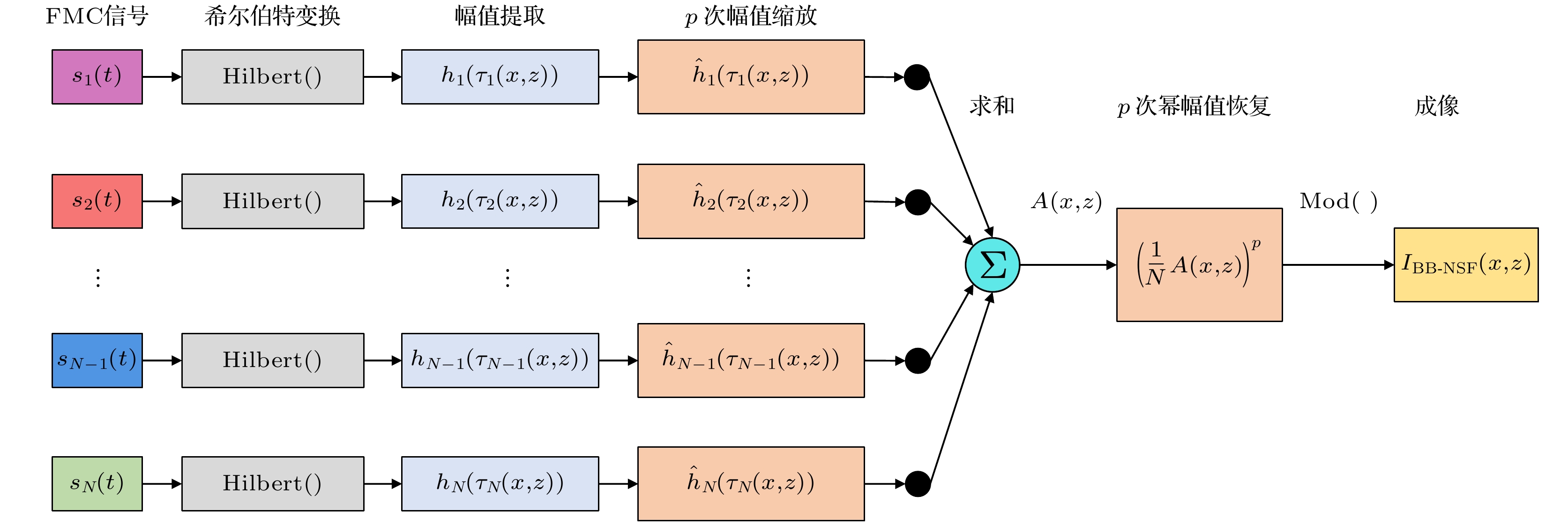

高聚物黏结炸药(PBX)是一类由炸药造型颗粒高度填充和少量黏结剂构成的复合材料, 其内部裂纹的有效检出对结构完整性评价和安全可靠性评估具有重要意义. PBX因其特殊的细观结构特征呈现出声速低、衰减强的特点, 利用传统线性超声聚焦成像时, 超声波在颗粒边界发生的多重反射会造成重构图像信噪比低, 裂纹特征淹没在背景噪声中, 难以有效识别. 为改善成像信噪比, 提出一种基带非线性合成聚焦(BB-NSF)超声相控阵成像算法, 充分利用全矩阵数据中各通道接收信号的空间相干性, 增强缺陷位置图像强度的同时抑制了背景噪声, 再结合PBX曲面构形特征对算法的延时法则进行修正, 实现了曲面构形PBX不同取向裂纹缺陷的高信噪比成像, 并对重构图像质量和成像效率进行了定量对比评价. 结果表明, BB-NSF算法可有效地抑制背景噪声, 显著地改善PBX裂纹检出能力. BB-NSF算法中的信号空间相干度p是影响图像信噪比的关键参数. p值大于2.0时, PBX裂纹缺陷超声重构图像的信噪比相比于传统的全聚焦成像算法可以提升10 dB以上. 随着p值增加, 重构图像的信噪比可以得到进一步提升, 而计算效率保持稳定, 体现出BB-NSF算法在强衰减复合材料内部缺陷成像方面的优势和应用前景.

-

关键词:

- 高聚物粘结炸药 /

- 裂纹缺陷 /

- 超声相控阵 /

- 基带非线性合成聚焦算法

Polymer bonded explosive (PBX) is a kind of composite material with highly filled molding explosive particles (normally more than 95%) and a small quantity of binders (less than 5%). The effective detection of internal cracks in PBX is of great significance in evaluating structural integrity and safety reliability. Ultrasonic phased array detection and imaging methods show great advantages and potential in detecting crack defects. But acoustic test results indicate that the PBX has unique characteristics with low longitudinal wave velocity (~3000 m·s–1) and strong attenuation (attenuation coefficient ~400 dB·m–1 for 2.5 MHz ultrasound). When the defect is imaged by traditional ultrasonic total focusing method (TFM), the structural noises at the boundaries between particles lead to low signal-to-noise ratio (SNR) in the FMC signals and strong background noise in reconstructed image, which will disturb the detection of cracks. To realize the high SNR imaging of crack defects in PBX, an ultrasonic imaging algorithm based on baseband nonlinear synthetic focusing (BB-NSF) is proposed. By utilizing the spatial coherence of the received signals in full matrix capture (FMC) data, the pixel intensity at defect position can be enhanced while the background noise can be drastically weakened. The delay rule of the algorithm is modified according to the characteristics of PBX surface configuration. In this way, the high SNR imaging of crack defects with different orientations of PBX surface configuration is realized, and the quality of the reconstructed images is compared and evaluated quantitatively. Meanwhile, the base band transformation in calculation process optimization could significantly reduce calculation burden and increase imaging efficiency. Experimental results show that the proposed algorithm can effectively suppress background noise and significantly improve the ability to detect the PBX cracks. The effective suppression to background noise makes the defect more highlighting and distinguished easily. For the BB-NSF algorithm, spatial coherence coefficient p is a crucial parameter used for dynamically regulating the SNR of reconstructed image. When p value is more than 2.0, the SNR of the ultrasonic reconstructed image of PBX crack defect is improved by more than 10 dB compared with that of the traditional linear synthetic focusing imaging. With the increase of p value, the SNR is further improved, while the calculation efficiency for a single image is almost kept stable. Moreover, the increase of SNR to some extent will improve the far-field detect capability. Besides, with the BB-NSF algorithm, flexible transducer inhibits different imaging characteristics of for cracks with different orientations and depths in curved PBX specimens. For defects with large orientation angle and buried depth, the tip, root and shape of cracks can be completely present. For defects with small orientation angle and buried depth, part of shape and contour features will be lost. In conclusion, the BB-NSF algorithm shows the advantage of high SNR and calculation efficiency in imaging PBX cracks, and exhibits great application prospect in imaging internal defects of other strongly attenuated composites. -

Keywords:

- polymer bonded explosives /

- crack defect /

- ultrasonic phased array /

- baseband nonlinear synthesis focusing algorithm

[1] 董海山, 周芬芬 1989 高能炸药及相关物性能 (北京: 科学出版社) 第20—32页

Dong H S, Zhou F F 1989 Performance of High-energy Explosives and Related Substances (Beijing: Science Press) pp20–32 (in Chinese)

[2] 范航, 何冠松, 杨志剑, 聂福德, 陈鹏万 2019 68 106201

Google Scholar

Google Scholar

Fan H, He G S, Yang Z J, Nie F D, Chen P W 2019 Acta Phys. Sin. 68 106201

Google Scholar

Google Scholar

[3] Yang Z F, Tian Y, Li W B, Zhou H Q, Zhang W B, Li J M 2017 Materials 10 660

Google Scholar

Google Scholar

[4] 宗和厚, 张伟斌, 肖丽, 周海强, 杨占锋 2016 含能材料 24 166

Google Scholar

Google Scholar

Zong H H, Zhang W B, Xiao L, Zhou H Q, Yang Z F 2016 Chin. J. Energ. Mater. 24 166

Google Scholar

Google Scholar

[5] 江畅, 杨占锋, 李卫彬, 张伟斌, 田勇 2020 含能材料 28 749

Google Scholar

Google Scholar

Jiang C, Yang Z F, Li W B, Zhang W B, Tian Y 2020 Chin. J. Energ. Mater. 28 749

Google Scholar

Google Scholar

[6] Drinkwater B W, Wilcox P D 2006 NDT & E Int. 39 525

Google Scholar

Google Scholar

[7] Li W, Zhou Z, Li Y 2019 Ultrasonics 96 75

Google Scholar

Google Scholar

[8] Holmes C, Drinkwater B W, Wilcox P D 2005 NDT & E Int. 38 701

Google Scholar

Google Scholar

[9] Peng C Y, Peng S, Wang Z X, Zhang J 2019 Far East NDT New Technology & Application Forum Qingdao, China, June 24–27, 2019 p11

[10] Wilcox P D, Holmes C, Drinkwater B W 2007 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 54 1541

Google Scholar

Google Scholar

[11] Zhang J, Drinkwater B W, Wilcox P D, Hunter A J 2010 NDT & E Int. 43 123

Google Scholar

Google Scholar

[12] 张海燕, 宋佳昕, 任燕, 朱琦, 马雪芬 2021 70 114301

Google Scholar

Google Scholar

Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 Acta Phys. Sin. 70 114301

Google Scholar

Google Scholar

[13] Nakahata K, Tokumasu S, Sakai A, Iwata Y, Ohira K, Ogura Y 2016 NDT & E Int. 82 13

Google Scholar

Google Scholar

[14] Pan Q, Xu X, Xu L, Jia Y, Liu X, Xiao D, Chang M 2019 IEEE International Conference on Mechatronics and Automation Tianjin, China, August 4–7, 2019 p2041

[15] 李萌, 徐尧, 肖盼, 张伟斌, 李丽, 蔡文路, 周海强, 陈振茂 2020 含能材料 29 29

Google Scholar

Google Scholar

Li M, Xu Y, Xiao P, Zhang W B, Li L, Cai W L, Zhou H Q, Chen Z M 2020 Chin. J. Energ. Mater. 29 29

Google Scholar

Google Scholar

[16] Jeon S, Park E Y, Choi W, Managuli R, Jong Lee K, Kim C 2019 Photoacoustics 15 100136

Google Scholar

Google Scholar

[17] Mozaffarzadeh M, Mahloojifar A, Periyasamy V, Pramanik M, Orooji M 2018 IEEE J. Sel. Top. Quantum Electron. 25 1

Google Scholar

Google Scholar

[18] Yang G, Amidi E, Zhu Q 2021 Biomed. Opt. Express 12 2250

Google Scholar

Google Scholar

[19] Mozaffarzadeh M, Mahloojifar A, Orooji M 2017 Iranian Conference on Electrical Engineering Tehran, Iran, May 2–4, 2017 p65

[20] Matrone G, Savoia A S, Caliano G, Magenes G 2015 IEEE Trans. Med. Imaging 34 940

Google Scholar

Google Scholar

[21] Matrone G, Savoia A S, Caliano G, Magenes G 2017 Ultrasonics 75 216

Google Scholar

Google Scholar

[22] Matrone G, Ramalli A, Savoia A S, Tortoli P, Magenes G 2016 IEEE Trans. Med. Imaging 36 478

Google Scholar

Google Scholar

[23] Luo L, Tan Y, Li J, Zhang Y, Gao X 2022 NDT & E Int. 127 102601

Google Scholar

Google Scholar

[24] Teng D, Liu L, Xiang Y, Xuan F Z 2022 Ultrasonics 128 106881

Google Scholar

Google Scholar

[25] Yu L, Song Y, Li X 2022 NDT & E Int. 130 102660

Google Scholar

Google Scholar

[26] Shen C C 2020 Biomed. Signal Process. 60 101964

Google Scholar

Google Scholar

[27] Shen C C 2021 Ultrasonics 96 165

Google Scholar

Google Scholar

[28] Kozai R, Okubo K, Tagawa N, Irie T, Yoshizawa M 2019 IEEE International Ultrasonics Symposium Glasgow, UK, October 6–9, 2019 p320

[29] Ji W, Liu L, Xing Z, Zhang D, Wang Y, Chen L, Chen Y, Sun X, Du Y 2021 IEEE Trans Ultrason. Ferroelectr. Freq. Control 68 1380

Google Scholar

Google Scholar

[30] 周正干, 彭地, 李洋, 胡宏伟 2015 机械工程学报 51 1

Google Scholar

Google Scholar

Zhou Z G, Peng D, Li Y, Hu H W 2015 Chin. J. Mech. Eng. 51 1

Google Scholar

Google Scholar

[31] Mozaffarzadeh M, Yan Y, Mehrmohammadi M, Makkiabadi B 2018 J. Biomed. Opt. 23 026005

Google Scholar

Google Scholar

-

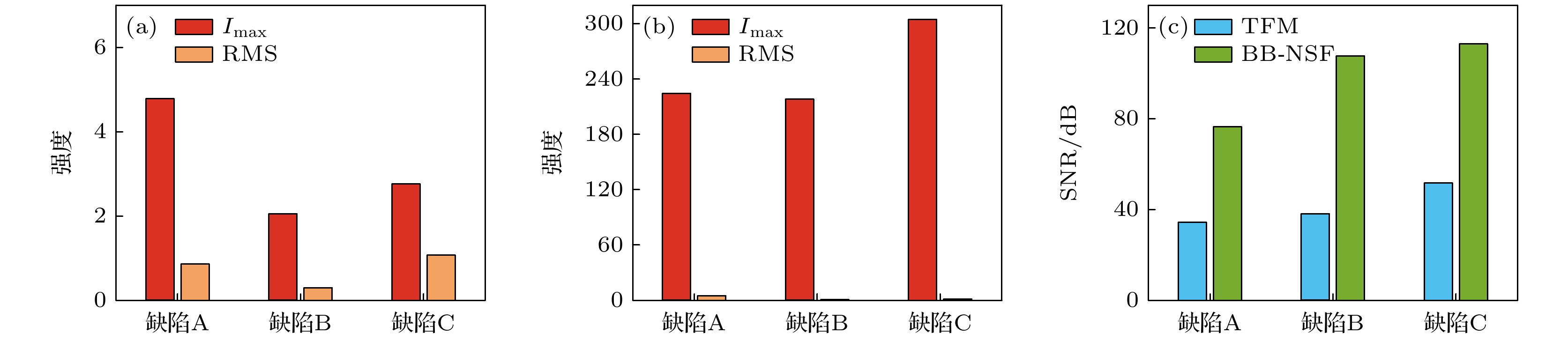

图 6 (a) TFM图像和(b) BB-NSF图像缺陷区域的像素峰值、背景噪声区域内像素强度的均方根; (c) TFM和BB-NSF缺陷的信噪比指标

Fig. 6. Pixel peak of the defect area and the root mean square of the pixel intensity in the background noise area of (a) TFM image and (b) BB-NSF image, respectively. (c) Comparison of SNR indictors for TFM and BB-NSF images.

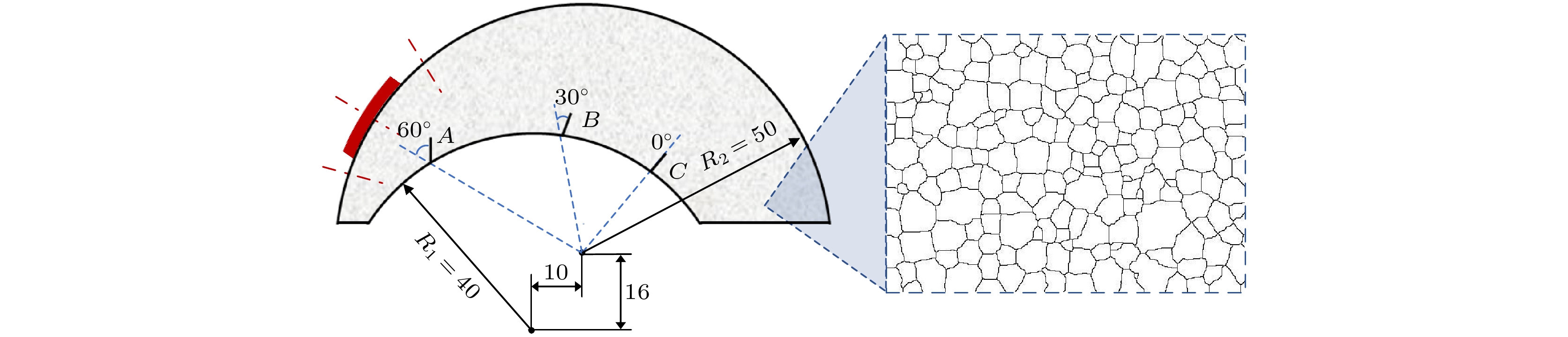

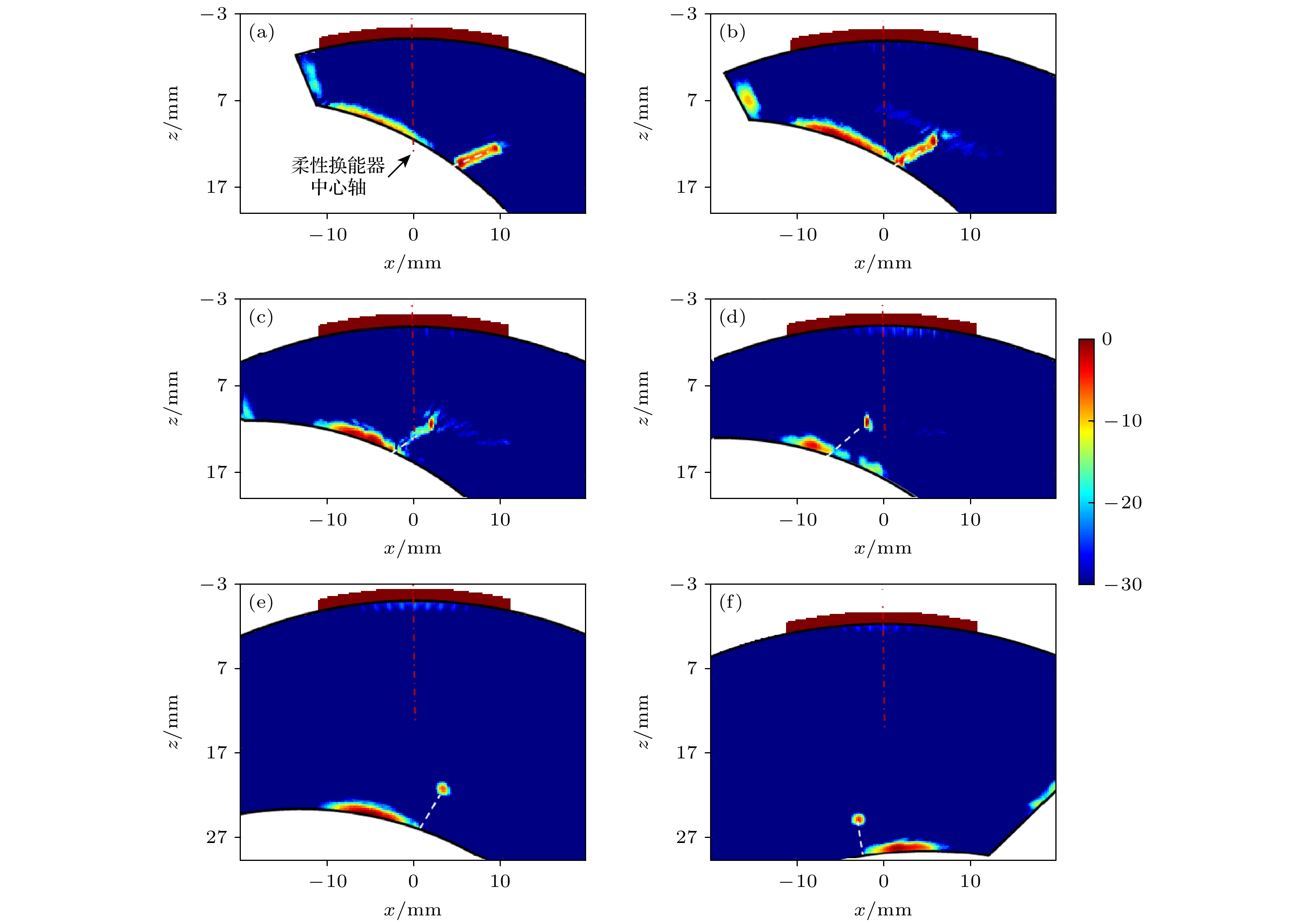

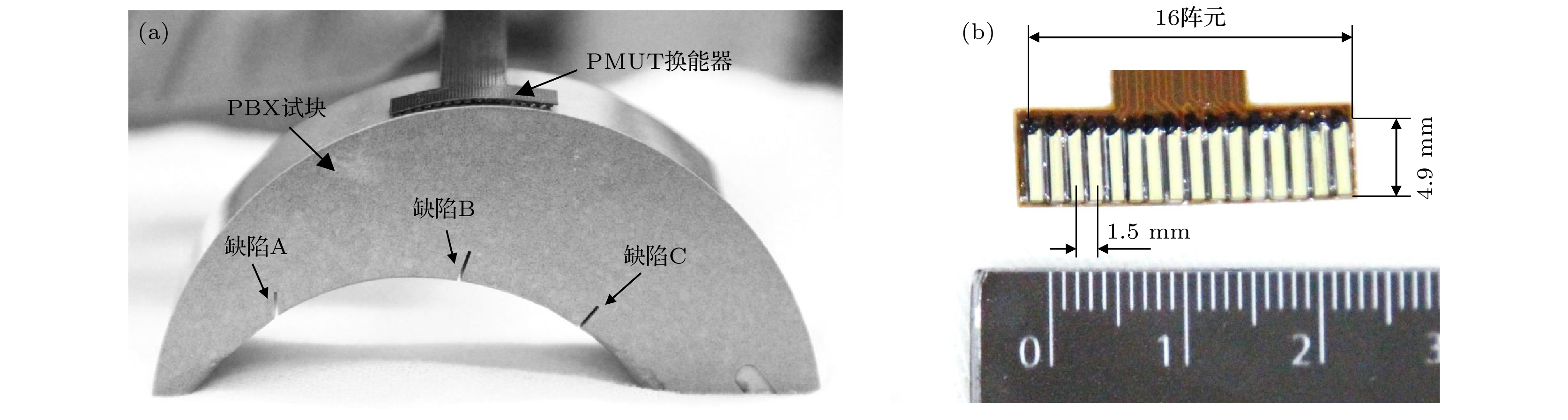

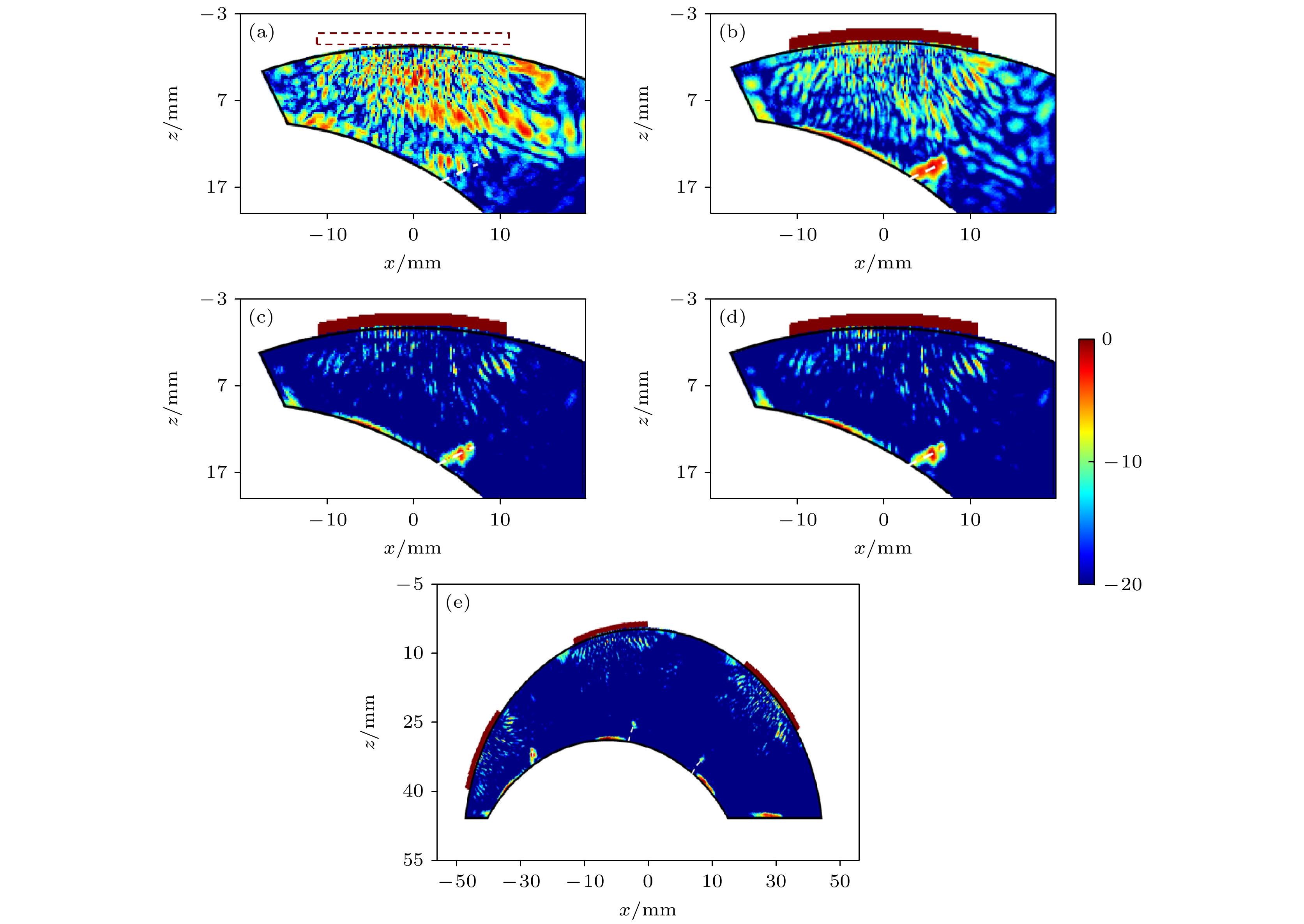

图 8 不同算法对PBX缺陷的成像结果对比 (a) 未延时修正TFM; (b) 延时修正后TFM; (c) F-DMAS; (d) BB-NSF算法; (e) 利用延时修正后BB-NSF算法重构的全场图像

Fig. 8. Comparison of cracks image with TFM algorithm: (a) Without time delay correction; (b) with time delay correction; (c) F-DMAS; (d) BB-NSF; (e) the reconstructed image of cracks A, B and C with BB-NSF algorithm.

表 1 超声换能器阵列和预制缺陷埋深参数

Table 1. Parameters of flexible transducers and prefabricated cracks.

换能器参数 取值 缺陷 裂尖埋深值/mm 阵元个数 16 缺陷A 16 阵元中心距/mm 1.5 缺陷B 23 中心频率/MHz 2.5 缺陷C 24 表 2 不同算法的PBX裂纹缺陷实测信噪比和计算效率对比

Table 2. Experimental comparison of SNR and consuming time for conventional and proposed algorithms.

-

[1] 董海山, 周芬芬 1989 高能炸药及相关物性能 (北京: 科学出版社) 第20—32页

Dong H S, Zhou F F 1989 Performance of High-energy Explosives and Related Substances (Beijing: Science Press) pp20–32 (in Chinese)

[2] 范航, 何冠松, 杨志剑, 聂福德, 陈鹏万 2019 68 106201

Google Scholar

Google Scholar

Fan H, He G S, Yang Z J, Nie F D, Chen P W 2019 Acta Phys. Sin. 68 106201

Google Scholar

Google Scholar

[3] Yang Z F, Tian Y, Li W B, Zhou H Q, Zhang W B, Li J M 2017 Materials 10 660

Google Scholar

Google Scholar

[4] 宗和厚, 张伟斌, 肖丽, 周海强, 杨占锋 2016 含能材料 24 166

Google Scholar

Google Scholar

Zong H H, Zhang W B, Xiao L, Zhou H Q, Yang Z F 2016 Chin. J. Energ. Mater. 24 166

Google Scholar

Google Scholar

[5] 江畅, 杨占锋, 李卫彬, 张伟斌, 田勇 2020 含能材料 28 749

Google Scholar

Google Scholar

Jiang C, Yang Z F, Li W B, Zhang W B, Tian Y 2020 Chin. J. Energ. Mater. 28 749

Google Scholar

Google Scholar

[6] Drinkwater B W, Wilcox P D 2006 NDT & E Int. 39 525

Google Scholar

Google Scholar

[7] Li W, Zhou Z, Li Y 2019 Ultrasonics 96 75

Google Scholar

Google Scholar

[8] Holmes C, Drinkwater B W, Wilcox P D 2005 NDT & E Int. 38 701

Google Scholar

Google Scholar

[9] Peng C Y, Peng S, Wang Z X, Zhang J 2019 Far East NDT New Technology & Application Forum Qingdao, China, June 24–27, 2019 p11

[10] Wilcox P D, Holmes C, Drinkwater B W 2007 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 54 1541

Google Scholar

Google Scholar

[11] Zhang J, Drinkwater B W, Wilcox P D, Hunter A J 2010 NDT & E Int. 43 123

Google Scholar

Google Scholar

[12] 张海燕, 宋佳昕, 任燕, 朱琦, 马雪芬 2021 70 114301

Google Scholar

Google Scholar

Zhang H Y, Song J X, Ren Y, Zhu Q, Ma X F 2021 Acta Phys. Sin. 70 114301

Google Scholar

Google Scholar

[13] Nakahata K, Tokumasu S, Sakai A, Iwata Y, Ohira K, Ogura Y 2016 NDT & E Int. 82 13

Google Scholar

Google Scholar

[14] Pan Q, Xu X, Xu L, Jia Y, Liu X, Xiao D, Chang M 2019 IEEE International Conference on Mechatronics and Automation Tianjin, China, August 4–7, 2019 p2041

[15] 李萌, 徐尧, 肖盼, 张伟斌, 李丽, 蔡文路, 周海强, 陈振茂 2020 含能材料 29 29

Google Scholar

Google Scholar

Li M, Xu Y, Xiao P, Zhang W B, Li L, Cai W L, Zhou H Q, Chen Z M 2020 Chin. J. Energ. Mater. 29 29

Google Scholar

Google Scholar

[16] Jeon S, Park E Y, Choi W, Managuli R, Jong Lee K, Kim C 2019 Photoacoustics 15 100136

Google Scholar

Google Scholar

[17] Mozaffarzadeh M, Mahloojifar A, Periyasamy V, Pramanik M, Orooji M 2018 IEEE J. Sel. Top. Quantum Electron. 25 1

Google Scholar

Google Scholar

[18] Yang G, Amidi E, Zhu Q 2021 Biomed. Opt. Express 12 2250

Google Scholar

Google Scholar

[19] Mozaffarzadeh M, Mahloojifar A, Orooji M 2017 Iranian Conference on Electrical Engineering Tehran, Iran, May 2–4, 2017 p65

[20] Matrone G, Savoia A S, Caliano G, Magenes G 2015 IEEE Trans. Med. Imaging 34 940

Google Scholar

Google Scholar

[21] Matrone G, Savoia A S, Caliano G, Magenes G 2017 Ultrasonics 75 216

Google Scholar

Google Scholar

[22] Matrone G, Ramalli A, Savoia A S, Tortoli P, Magenes G 2016 IEEE Trans. Med. Imaging 36 478

Google Scholar

Google Scholar

[23] Luo L, Tan Y, Li J, Zhang Y, Gao X 2022 NDT & E Int. 127 102601

Google Scholar

Google Scholar

[24] Teng D, Liu L, Xiang Y, Xuan F Z 2022 Ultrasonics 128 106881

Google Scholar

Google Scholar

[25] Yu L, Song Y, Li X 2022 NDT & E Int. 130 102660

Google Scholar

Google Scholar

[26] Shen C C 2020 Biomed. Signal Process. 60 101964

Google Scholar

Google Scholar

[27] Shen C C 2021 Ultrasonics 96 165

Google Scholar

Google Scholar

[28] Kozai R, Okubo K, Tagawa N, Irie T, Yoshizawa M 2019 IEEE International Ultrasonics Symposium Glasgow, UK, October 6–9, 2019 p320

[29] Ji W, Liu L, Xing Z, Zhang D, Wang Y, Chen L, Chen Y, Sun X, Du Y 2021 IEEE Trans Ultrason. Ferroelectr. Freq. Control 68 1380

Google Scholar

Google Scholar

[30] 周正干, 彭地, 李洋, 胡宏伟 2015 机械工程学报 51 1

Google Scholar

Google Scholar

Zhou Z G, Peng D, Li Y, Hu H W 2015 Chin. J. Mech. Eng. 51 1

Google Scholar

Google Scholar

[31] Mozaffarzadeh M, Yan Y, Mehrmohammadi M, Makkiabadi B 2018 J. Biomed. Opt. 23 026005

Google Scholar

Google Scholar

计量

- 文章访问数: 4638

- PDF下载量: 84

- 被引次数: 0

下载:

下载: