-

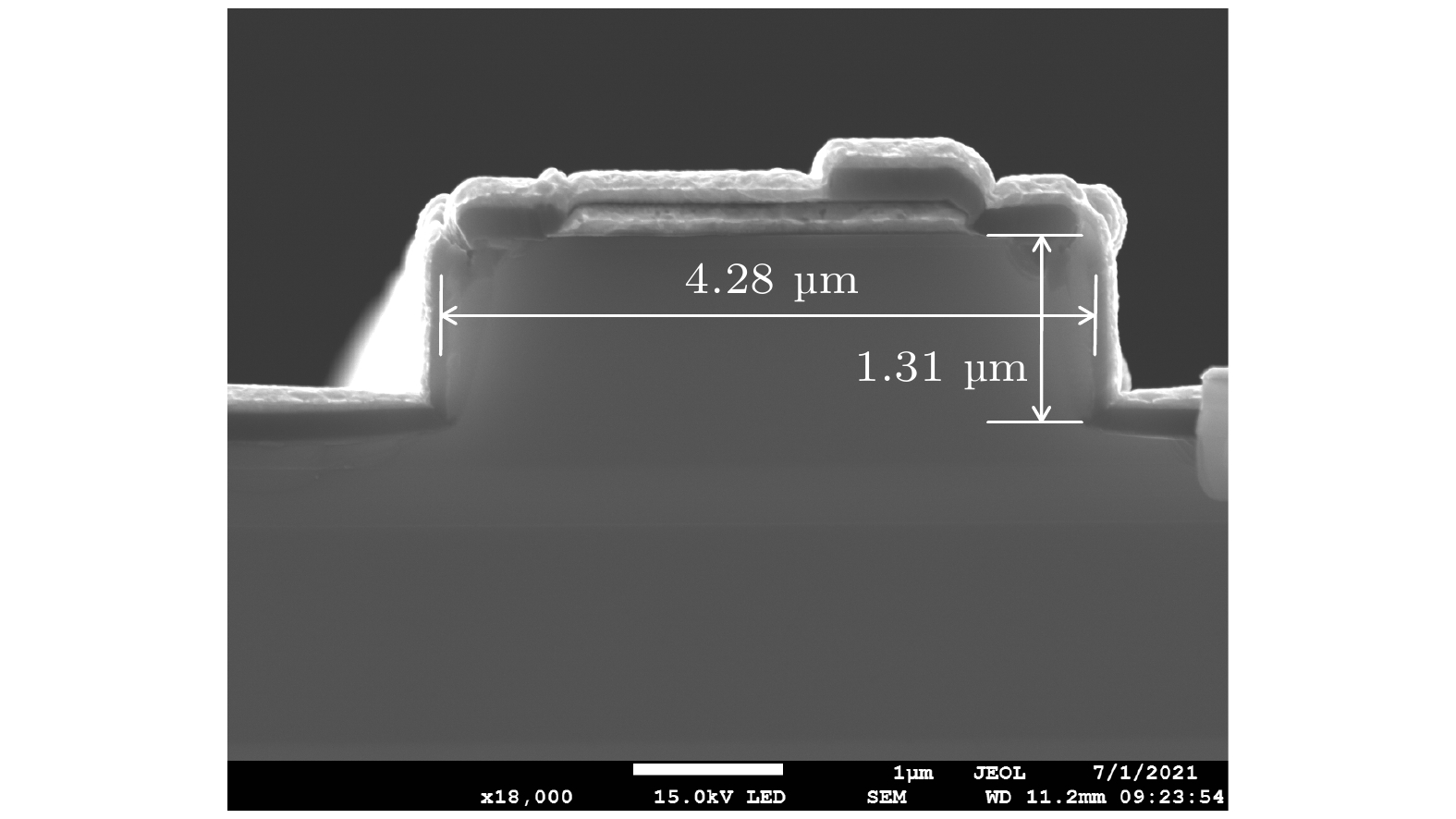

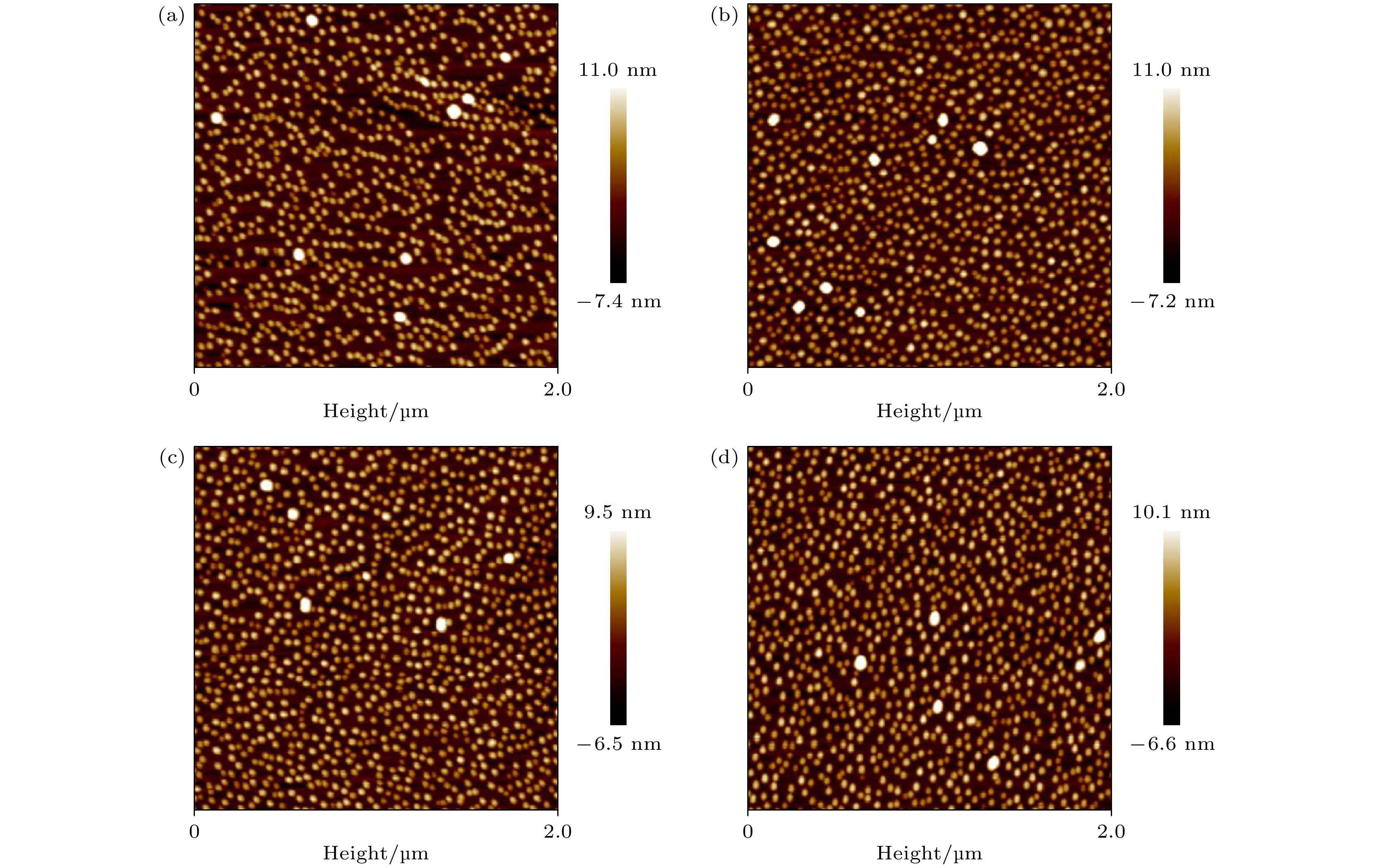

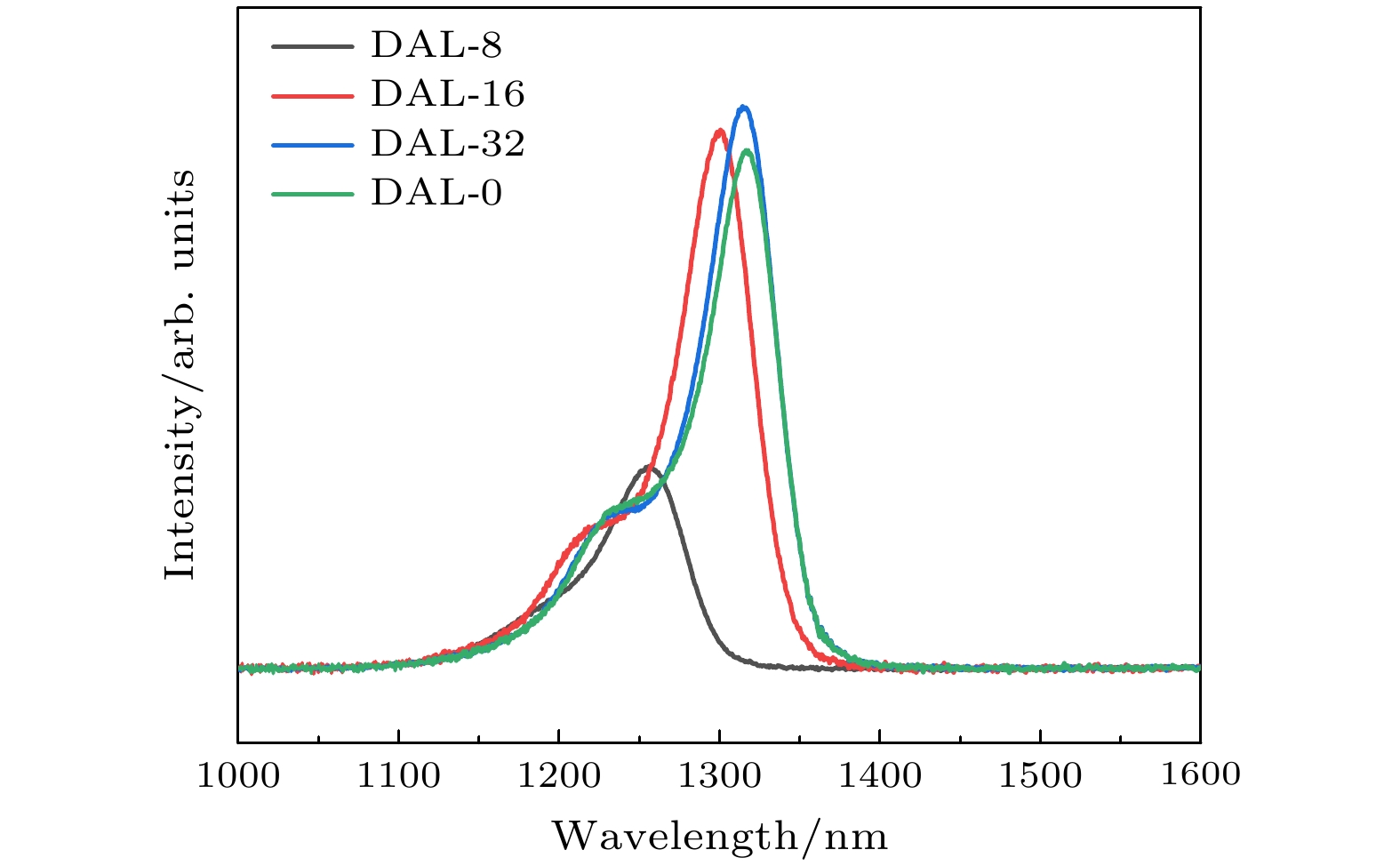

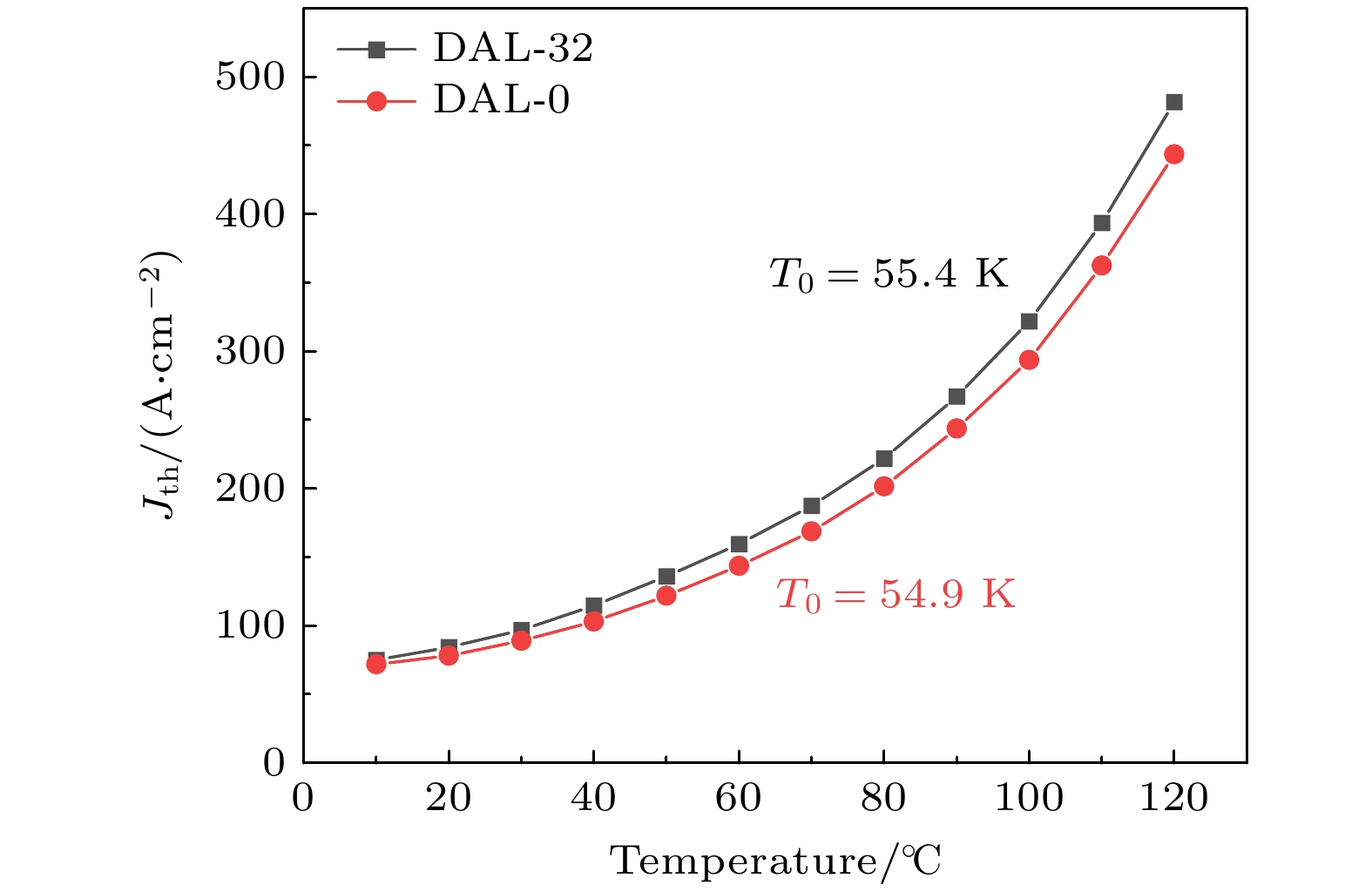

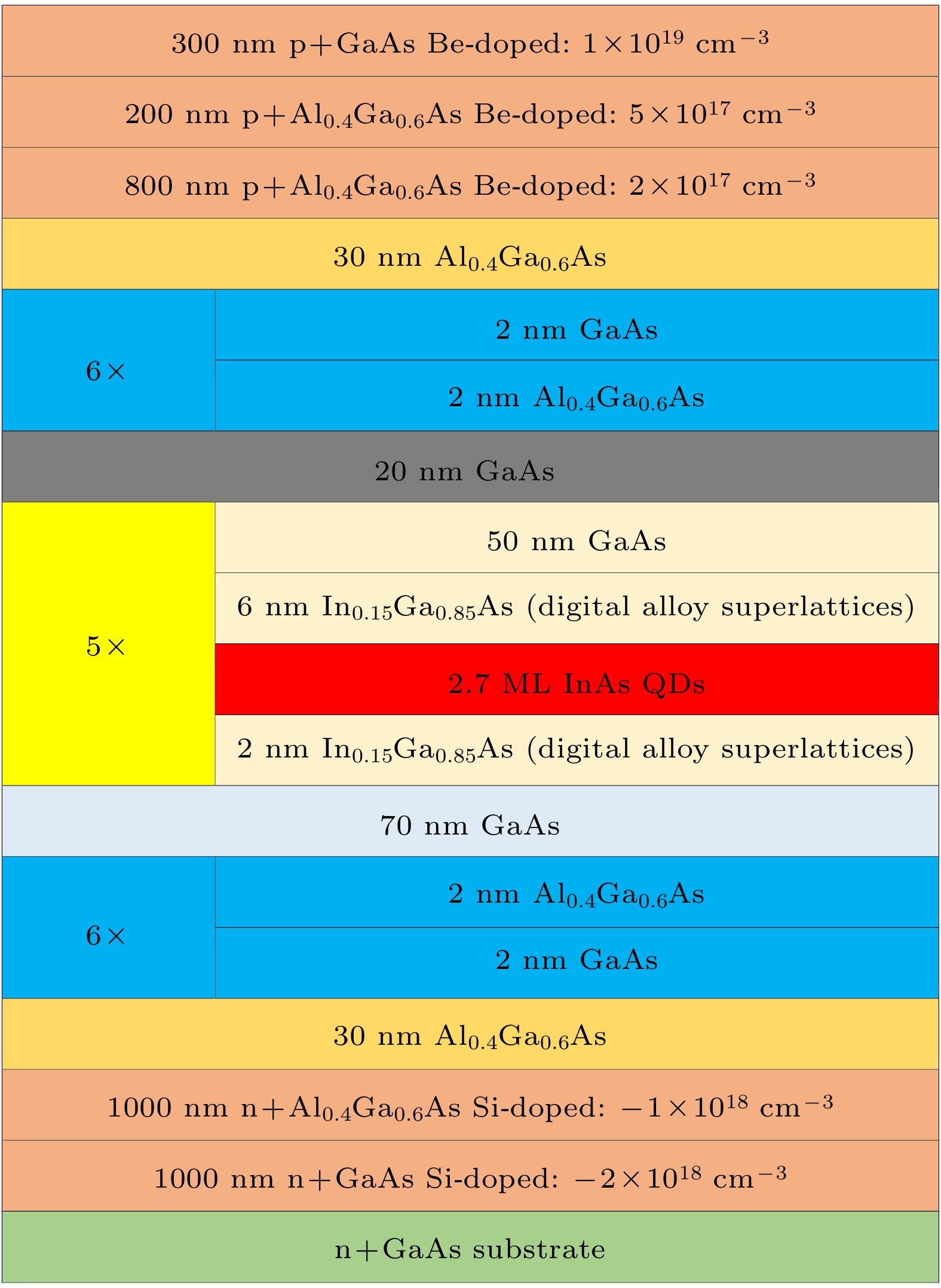

利用分子束外延技术, 通过InAs/GaAs数字合金超晶格代替传统的直接生长InGaAs层的方式, 在GaAs(100)衬底上生长了InAs量子点结构并成功制备了1.3 μm InAs量子点激光器. 通过原子力显微镜和光致荧光谱测试手段, 对传统生长模式和数字合金超晶格生长模式的两种样品进行了表征, 研究发现采用32周期InAs/GaAs数字合金超晶格样品的量子点密度非常高, 发光性能良好. 通过与常规生长方式所制备激光器的性能对比, 发现采用InAs/GaAs数字合金超晶格生长InAs量子点的有源区也可以得到高质量的激光器. 利用该方式生长的InAs量子点激光器的阈值电流为24 mA, 相应的阈值电流密度仅为75 A/cm2, 最高工作温度达到120 ℃. InAs/GaAs数字合金超晶格既可以保证生长过程中源炉的温度保持不变, 还可以对InGaAs层的组分实现灵活调控. 不需要改变生长速度, 通过改变InAs/GaAs数字合金超晶格的周期数以及InAs层和GaAs层的厚度, 便可以获得任意组分的InGaAs, 从而得到不同发光波长的激光器. 这种生长方式对量子点有源区的结构设计和外延生长提供了新思路.A 1.3-μm InAs quantum dot laser has been successfully fabricated on a GaAs(100) substrate by molecular beam epitaxy (MBE) technique through using InAs/GaAs digital alloy superlattices instead of the conventional InGaAs layer. The samples grown by conventional growth method and the digital alloy superlattice growth method are characterized by atomic force microscope (AFM) and photoluminescence (PL) spectroscopy. It is found that 8-period sample possesses a low quantum dot density and poor luminescence performance. With the increase of the number of growth periods, the quantum dot density of the sample increases and the luminous performance improves. This indicates that the quality of the grown sample improves with the increase of InAs/GaAs period of the InGaAs layer. When the total InAs/GaAs period is 32, the quantum dot density of the sample is high and the luminescence performance is good. After the experimental measurement, the sample DAL-0 fabricated by conventional growth method and the sample DAL-32 (32-periods InAs/GaAs digital alloy superlattices) are utilized to fabricate quantum dot laser by standard process. The performances of two types of quantum dot lasers obtained with different growth methods are characterized. It is found that the InAs quantum dot lasers fabricated by the sample grown by digital alloy superlattice method have good performances. Under continuous wave operation mode, the threshold current is 24 mA corresponding to a threshold current density of 75 A/cm2. The highest operation-temperature reaches 120 ℃. In addition, InAs quantum dot laser using digital alloy superlattice has good temperature stability. Its characteristic temperature is 55.4 K. Compared with the traditional laser, the InAs quantum dot laser grown by InAs/GaAs digital alloy superlattice has good performance in terms of threshold current density, output power and temperature stability, which indicates that high-quality laser can be obtained by this growth method. Using the InAs/GaAs digital alloy superlattice growth method, the InGaAs composition can be changed without changing the temperature of the source oven. Thus InAs quantum dot lasers with different luminescence wavelengths can be obtained through this growth method. The InAs/GaAs digital alloy superlattice structure can be used to realize different averaging of In content in the growth structure. The method provides a new idea for designing and growing the active region of quantum dot laser.

[1] 王海玲, 王霆, 张建军 2019 68 117301

Google Scholar

Google Scholar

Wang H L, Wang T, Zhang J J 2019 Acta Phys. Sin. 68 117301

Google Scholar

Google Scholar

[2] OzakiN, Ikuno D 2022 J. Cryst. Growth 588 126657

Google Scholar

Google Scholar

[3] Yang J, Liu Z, Jurczak P, Tang M, Li K, Pan S, Sanchez A, Beanland R, Zhang Z C, Wang H 2021 J. Phys. D Appl. Phys. 54 035103

Google Scholar

Google Scholar

[4] 王霆, 张建军, 刘会赟 2015 64 204209

Google Scholar

Google Scholar

Wang T, Zhang J J, Liu H Y 2015 Acta Phys. Sin. 64 204209

Google Scholar

Google Scholar

[5] Wang Z, Qi W, Feng Q, Wang T, Zhang J 2021 Opt. Express 29 674

[6] Bimberg D, Pohl U W 2011 Mater. Today 14 388

Google Scholar

Google Scholar

[7] Ruiz-Marín N, Reyes D F, Stanojević L, BenT, Braza V, Gallego-Carro A, Bárcena-González G, Ulloa J M, González D 2022 Appl. Surf. Sci. 573 151572

Google Scholar

Google Scholar

[8] 田芃, 黄黎蓉, 费淑萍, 余奕, 潘彬, 徐巍, 黄德修 2010 59 5738

Google Scholar

Google Scholar

Tian P, Huang L R, Fei S P, Yu Y, Pan B, Xu W, Huang D X 2010 Acta Phys. Sin. 59 5738

Google Scholar

Google Scholar

[9] Norman J C, Jung D, Zhang Z, Wan Y, Liu S, Shang C, Herrick R W, Chow W W, Gossard A C, Bowers J E 2019 IEEE J. Quantum Elect. 55 1

Google Scholar

Google Scholar

[10] Arsenijević D, Bimberg D 2017 Green Photonics and Electronics (Cham, Switzerland: Springer International Publishing) pp75–106

[11] Alexander R R, Childs D T D, Agarwal H, Groom K M, Liu H Y, Hopkinson M, Hogg R A, Ishida M, Yamamoto T, Sugawara M, Arakawa Y, Badcock T J, Royce R J, Mowbray D J 2007 IEEE J. Quantum Elect. 43 1129

Google Scholar

Google Scholar

[12] Coleman J J, Young J D, Garg A 2011 J. Lightwave Technol. 29 499

Google Scholar

Google Scholar

[13] Sugawara M, Usami M 2009 Nat. Photonics 3 30

Google Scholar

Google Scholar

[14] Yamaguchi K, Yujobo K, Kaizu T 2000 Jpn. J. Appl. Phys. 39 L1245

Google Scholar

Google Scholar

[15] Leonard D, Krishnamurthy M, Reaves C M, Denbaars S P, Petroff P M 1993 Appl. Phys. Lett. 63 3203

Google Scholar

Google Scholar

[16] Yang J, Tang M, Chen S, Liu H Y 2023 Light. Sci. Appl. 12 16

Google Scholar

Google Scholar

[17] Thomson D, Zilkie A, Bowers J E, Komljenovic T, Reed G T, Vivien L, Marris-Morini D, Cassan E, Virot L, Fédéli J M, Hartmann J M, Schmid J H, Xu D X, Boeuf F, O’Brien P, Mashanovich G Z, Nedeljkovic M 2016 J. Optics 18 073003

Google Scholar

Google Scholar

[18] Zhou Z, Ou X, Fang Y, Alkhazraji E, Xu R, Wan Y, Bowers J E 2023 eLight 3 1

Google Scholar

Google Scholar

[19] Liang D, Srinivasan S, Descos A, Zhang C, Kurczveil G, Huang Z, Beausoleil R 2021 Optica 8 591

Google Scholar

Google Scholar

[20] Xu B, Wang G, Du Y, Miao Y, Li B, Zhao X, Lin H, Yu J, Su J, Dong Y, Ye T, Radamson H H 2022 Nanomaterials 12 2704

Google Scholar

Google Scholar

[21] Tatebayashi J, Nishioka M, Arakawa Y 2002 J. Cryst. Growth 237 1296

[22] ZhangY, Yang C A, Shang J M, Chen Y, Niu Z 2021 Chin. Phys. B 30 094204

Google Scholar

Google Scholar

[23] Kumar R, Saha J, Tongbram B, Panda D, Gourishetty R, Kumar R, Gazi S A, Chakrabarti S 2023 Curr. Appl. Phys. 47 72

Google Scholar

Google Scholar

[24] Pötschke K, Müller-Kirsch L, Heitz R, Sellin R L, Pohl U W, Bimberg D, Zakharov N, Werner P 2004 Physica E 21 606

Google Scholar

Google Scholar

[25] Kim Y, Chu R J, Ryu G, Woo S, Lung Q N D, Ahn D H, Han J H, Choi W J, Jung D 2022 ACS Appl. Mater. Interfaces 14 45051

Google Scholar

Google Scholar

[26] Fathpour S, Mi Z, Bhattacharya P, Kovsh A R, Mikhrin S S, Krestnikov I L, Kozhukhov A V, Ledentsov N N 2004 Appl. Phys. Lett. 85 5164

Google Scholar

Google Scholar

-

-

[1] 王海玲, 王霆, 张建军 2019 68 117301

Google Scholar

Google Scholar

Wang H L, Wang T, Zhang J J 2019 Acta Phys. Sin. 68 117301

Google Scholar

Google Scholar

[2] OzakiN, Ikuno D 2022 J. Cryst. Growth 588 126657

Google Scholar

Google Scholar

[3] Yang J, Liu Z, Jurczak P, Tang M, Li K, Pan S, Sanchez A, Beanland R, Zhang Z C, Wang H 2021 J. Phys. D Appl. Phys. 54 035103

Google Scholar

Google Scholar

[4] 王霆, 张建军, 刘会赟 2015 64 204209

Google Scholar

Google Scholar

Wang T, Zhang J J, Liu H Y 2015 Acta Phys. Sin. 64 204209

Google Scholar

Google Scholar

[5] Wang Z, Qi W, Feng Q, Wang T, Zhang J 2021 Opt. Express 29 674

[6] Bimberg D, Pohl U W 2011 Mater. Today 14 388

Google Scholar

Google Scholar

[7] Ruiz-Marín N, Reyes D F, Stanojević L, BenT, Braza V, Gallego-Carro A, Bárcena-González G, Ulloa J M, González D 2022 Appl. Surf. Sci. 573 151572

Google Scholar

Google Scholar

[8] 田芃, 黄黎蓉, 费淑萍, 余奕, 潘彬, 徐巍, 黄德修 2010 59 5738

Google Scholar

Google Scholar

Tian P, Huang L R, Fei S P, Yu Y, Pan B, Xu W, Huang D X 2010 Acta Phys. Sin. 59 5738

Google Scholar

Google Scholar

[9] Norman J C, Jung D, Zhang Z, Wan Y, Liu S, Shang C, Herrick R W, Chow W W, Gossard A C, Bowers J E 2019 IEEE J. Quantum Elect. 55 1

Google Scholar

Google Scholar

[10] Arsenijević D, Bimberg D 2017 Green Photonics and Electronics (Cham, Switzerland: Springer International Publishing) pp75–106

[11] Alexander R R, Childs D T D, Agarwal H, Groom K M, Liu H Y, Hopkinson M, Hogg R A, Ishida M, Yamamoto T, Sugawara M, Arakawa Y, Badcock T J, Royce R J, Mowbray D J 2007 IEEE J. Quantum Elect. 43 1129

Google Scholar

Google Scholar

[12] Coleman J J, Young J D, Garg A 2011 J. Lightwave Technol. 29 499

Google Scholar

Google Scholar

[13] Sugawara M, Usami M 2009 Nat. Photonics 3 30

Google Scholar

Google Scholar

[14] Yamaguchi K, Yujobo K, Kaizu T 2000 Jpn. J. Appl. Phys. 39 L1245

Google Scholar

Google Scholar

[15] Leonard D, Krishnamurthy M, Reaves C M, Denbaars S P, Petroff P M 1993 Appl. Phys. Lett. 63 3203

Google Scholar

Google Scholar

[16] Yang J, Tang M, Chen S, Liu H Y 2023 Light. Sci. Appl. 12 16

Google Scholar

Google Scholar

[17] Thomson D, Zilkie A, Bowers J E, Komljenovic T, Reed G T, Vivien L, Marris-Morini D, Cassan E, Virot L, Fédéli J M, Hartmann J M, Schmid J H, Xu D X, Boeuf F, O’Brien P, Mashanovich G Z, Nedeljkovic M 2016 J. Optics 18 073003

Google Scholar

Google Scholar

[18] Zhou Z, Ou X, Fang Y, Alkhazraji E, Xu R, Wan Y, Bowers J E 2023 eLight 3 1

Google Scholar

Google Scholar

[19] Liang D, Srinivasan S, Descos A, Zhang C, Kurczveil G, Huang Z, Beausoleil R 2021 Optica 8 591

Google Scholar

Google Scholar

[20] Xu B, Wang G, Du Y, Miao Y, Li B, Zhao X, Lin H, Yu J, Su J, Dong Y, Ye T, Radamson H H 2022 Nanomaterials 12 2704

Google Scholar

Google Scholar

[21] Tatebayashi J, Nishioka M, Arakawa Y 2002 J. Cryst. Growth 237 1296

[22] ZhangY, Yang C A, Shang J M, Chen Y, Niu Z 2021 Chin. Phys. B 30 094204

Google Scholar

Google Scholar

[23] Kumar R, Saha J, Tongbram B, Panda D, Gourishetty R, Kumar R, Gazi S A, Chakrabarti S 2023 Curr. Appl. Phys. 47 72

Google Scholar

Google Scholar

[24] Pötschke K, Müller-Kirsch L, Heitz R, Sellin R L, Pohl U W, Bimberg D, Zakharov N, Werner P 2004 Physica E 21 606

Google Scholar

Google Scholar

[25] Kim Y, Chu R J, Ryu G, Woo S, Lung Q N D, Ahn D H, Han J H, Choi W J, Jung D 2022 ACS Appl. Mater. Interfaces 14 45051

Google Scholar

Google Scholar

[26] Fathpour S, Mi Z, Bhattacharya P, Kovsh A R, Mikhrin S S, Krestnikov I L, Kozhukhov A V, Ledentsov N N 2004 Appl. Phys. Lett. 85 5164

Google Scholar

Google Scholar

计量

- 文章访问数: 6349

- PDF下载量: 105

- 被引次数: 0

下载:

下载: