-

通过固体表面改性可对液滴热毛细迁移过程进行调控. 基于润滑理论和滑移模型建立了均匀温度梯度作用下液滴在润湿性受限轨道上运动的数学模型, 通过将基底划分成亲水区域和疏水区域构建了润湿性受限轨道. 结合接触线动力学提出了三维液滴在不同方向上接触线移动速度的计算方法, 得到了液滴热毛细迁移的演化历程, 分析了轨道宽度和润湿性对液滴迁移特性的影响. 研究表明: 液滴主体受温度梯度作用由高温区向低温区迁移, 液滴后缘在移动过程中与主体部分间形成一层薄液膜, 即薄液膜拖尾. 液滴在垂直于轨道方向上的铺展受到抑制, 收缩到轨道边缘后保持定扎状态. 前进接触线移动速度开始时迅速减小, 后缓慢降低趋于平稳; 前进接触线移动速度与轨道宽度呈负相关. 垂直于轨道方向上的壁面润湿性限制导致的排挤作用, 在初始的短暂时刻对液滴在轨道上的热毛细迁移具有加速作用. 液滴前进接触线移动速度与轨道润湿性呈正相关. 增强轨道润湿性使得后退接触线移动速度的初始值增大, 但对其稳定值影响不大. 相比于改变轨道润湿性, 改变轨道宽度更易于调控液滴热毛细迁移过程.The thermocapillary migration of droplets on a solid surface is widely used in daily life and industrial fields. Regulating droplet thermocapillary migration by changing surface wettability has received extensive attention. According to the lubrication theory and slip boundary conditions, we establish a mathematical model of the thermocapillary migration dynamics of a droplet on wettability-confined tracks subjected to a uniform temperature gradient. Combined with the contact line dynamics, a method of determining the velocity of the contact line in a different direction of the three-dimensional droplet is proposed, the simulation is carried out with FreeFEM++. The evolution of droplet migration is examined, and the effects of track width and wettability on the droplet migration dynamics are emphatically investigated. The results show that the main part of the droplet moves from the high-temperature region to the low-temperature region, the trailing edge of the droplet forms a small bulge during the movement, and a thin liquid film is formed between the bulge and the main part of the droplet. The droplet spreading perpendicular to the track direction is inhibited and remains pinned after shrinking to the track edge. Negative correlation between the velocity of the advancing contact line and the track width is observed. The velocity of the advancing line first rapidly and then slowly decrease to a steady state. The squeezing effect caused by the wettability confined perpendicular to the track direction accelerates the thermocapillary migration of the droplet on the track in the initial short time. The enhanced track wettability increases the initial velocity of the receding contact line but has little effect on its stable value. The velocity of the advancing contact line is positively correlated with track wettability. Changing the track width is possibly easier to regulate the thermocapillary migration of a droplet than varying the track wettability.

-

Keywords:

- thermocapillary migration /

- wettability /

- droplet /

- lubrication theory

[1] Daniel S, Chaudhury M K, Chen J C 2001 Science 291 633

Google Scholar

Google Scholar

[2] Bakli C, PD S H, Chakraborty S 2017 Nanoscale 9 12509

Google Scholar

Google Scholar

[3] Musin A, Grynyov R, Frenkel M, Bormashenko E 2016 J. Colloid Interface Sci. 479 182

Google Scholar

Google Scholar

[4] Dhiman S, Jayaprakash K, Iqbal R, Sen A 2018 Langmuir 34 12359

Google Scholar

Google Scholar

[5] 王飞, 彭岚, 张全壮, 刘佳 2015 64 140202

Google Scholar

Google Scholar

Wang F, Peng L, Zhang Q Z, Liu J 2015 Acta Phys. Sin. 64 140202

Google Scholar

Google Scholar

[6] Karapetsas G, Chamakos N T, Papathanasiou A G 2017 Langmuir 33 10838

Google Scholar

Google Scholar

[7] Dai Q W, Huang W, Wang X L 2014 Exp. Therm. Fluid Sci. 57 200

Google Scholar

Google Scholar

[8] Chaudhury M K, Whitesides G M 1992 Science 256 1539

Google Scholar

Google Scholar

[9] Qi L, Niu Y, Ruck C, Zhao Y 2019 Lab Chip 19 223

Google Scholar

Google Scholar

[10] 石自媛, 胡国辉, 周哲玮 2010 59 2595

Google Scholar

Google Scholar

Shi Z Y, Hu G H, Zhou Z W 2010 Acta Phys. Sin. 59 2595

Google Scholar

Google Scholar

[11] Dai Q W, Huang W, Wang X L, Khonsari M M 2021 Tribol. Int. 154 106749

Google Scholar

Google Scholar

[12] Ghosh A, Ganguly R, Schutzius T M, Megaridis C M 2014 Lab Chip 14 1538

Google Scholar

Google Scholar

[13] Sen U, Chatterjee S, Ganguly R, Dodge R, Yu L, Megaridis C M 2018 Langmuir 34 1899

Google Scholar

Google Scholar

[14] 姚祎, 周哲玮, 胡国辉 2013 62 134701

Google Scholar

Google Scholar

Yao W, Zhou Z W, Hu G H 2013 Acta Phys. Sin. 62 134701

Google Scholar

Google Scholar

[15] Wang M, Liu Q, Zhang H R, Wang C, Wang L, Xiang B X, Fan Y T, Guo C F, Ruan S C 2017 ACS Appl. Mater. Interfaces 9 29248

Google Scholar

Google Scholar

[16] Dai Q W, Ji Y J, Chong Z J, Huang W, Wang X L 2019 J. Colloid Interface Sci. 557 837

Google Scholar

Google Scholar

[17] Fu X J, Sun J J, Ba Y 2022 Phys. Fluids 34 012119

Google Scholar

Google Scholar

[18] Diddens C, Kuerten J G, Van der Geld C, Wijshoff H 2017 J. Colloid Interface Sci. 487 426

Google Scholar

Google Scholar

[19] 李春曦, 程冉, 叶学民 2021 70 204701

Google Scholar

Google Scholar

Li C X, Cheng R, Ye X M 2021 Acta Phys. Sin. 70 204701

Google Scholar

Google Scholar

[20] Ye X M, Zhang N K, Cheng R, Li C X 2022 J. Appl. Fluid Mech. 15 1361

[21] Gomba J M, Homsy G M 2010 J. Fluid Mech. 647 125

Google Scholar

Google Scholar

[22] Beltrame P, Knobloch E, Hänggi P, Thiele U 2011 Phys. Rev. E 83 016305

Google Scholar

Google Scholar

[23] Ehrhard P, Davis S H 1991 J. Fluid Mech. 229 365

Google Scholar

Google Scholar

[24] Smith M K 1995 J. Fluid Mech. 294 209

Google Scholar

Google Scholar

[25] Karapetsas G, Sahu K C, Matar O K 2013 Langmuir 29 8892

Google Scholar

Google Scholar

[26] 叶学民, 李永康, 李春曦 2016 65 104704

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 104704

Google Scholar

Google Scholar

[27] 叶学民, 张湘珊, 李明兰, 李春曦 2018 67 184704

Google Scholar

Google Scholar

Ye X M, Zhang X S, Li M L, Li C X 2018 Acta Phys. Sin. 67 184704

Google Scholar

Google Scholar

[28] Nagy M, Škvarla J 2013 Acta Montanistica Slovaca 18 125

[29] Dai Q W, Khonsari M M, Shen C, Huang W, Wang X L 2016 Langmuir 32 7485

Google Scholar

Google Scholar

[30] Mukhopadhyay S, Murisic N, Behringer R P, Kondic L 2011 Phys. Rev. E 83 046302

[31] Chowdhury I U, Mahapatra P S, Sen A K 2019 Phys. Fluids 31 042111

Google Scholar

Google Scholar

[32] 宋金龙, 徐文骥 2017 金属加工: 冷加工 2017 65

Song J L, Xu W J 2017 Metal Working: Metal Cutting 2017 65

-

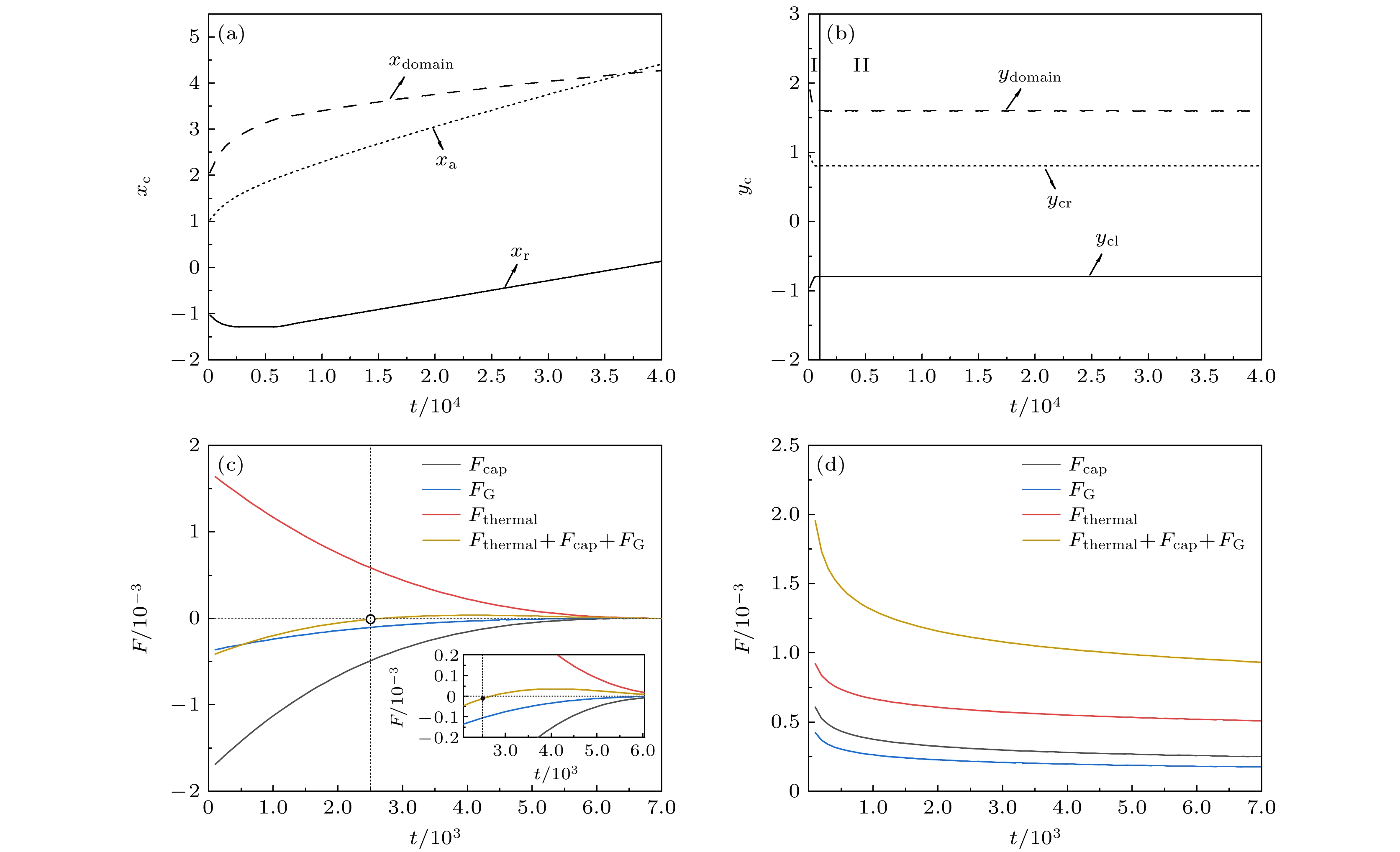

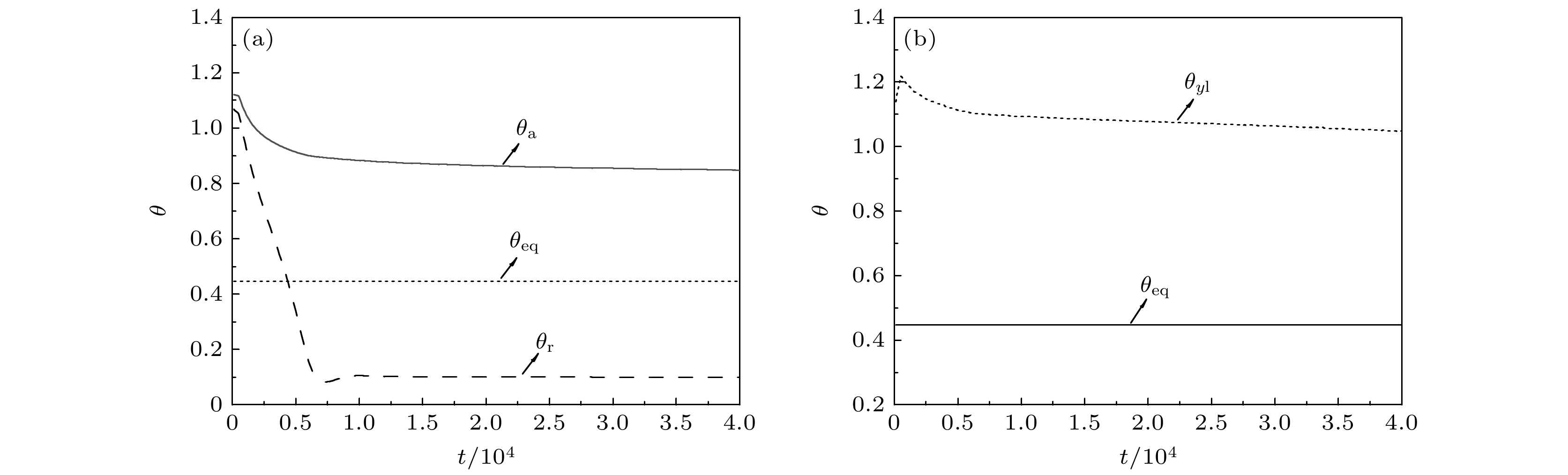

图 7 接触线随时间的变化 (a) 前进接触线和后退接触线; (b) 左右两侧接触线; (c)后退接触线处的不同主导因素; (d) 前进接触线处的不同主导因素

Fig. 7. Temporal evolution of droplet contact lines: (a) The advancing and receding contact lines; (b) left and right contact lines; (c) effects of capillarity, gravity and thermal Marangoni at the receding contact line; (d) effects of capillarity, gravity and thermal Marangoni at the advancing contact line.

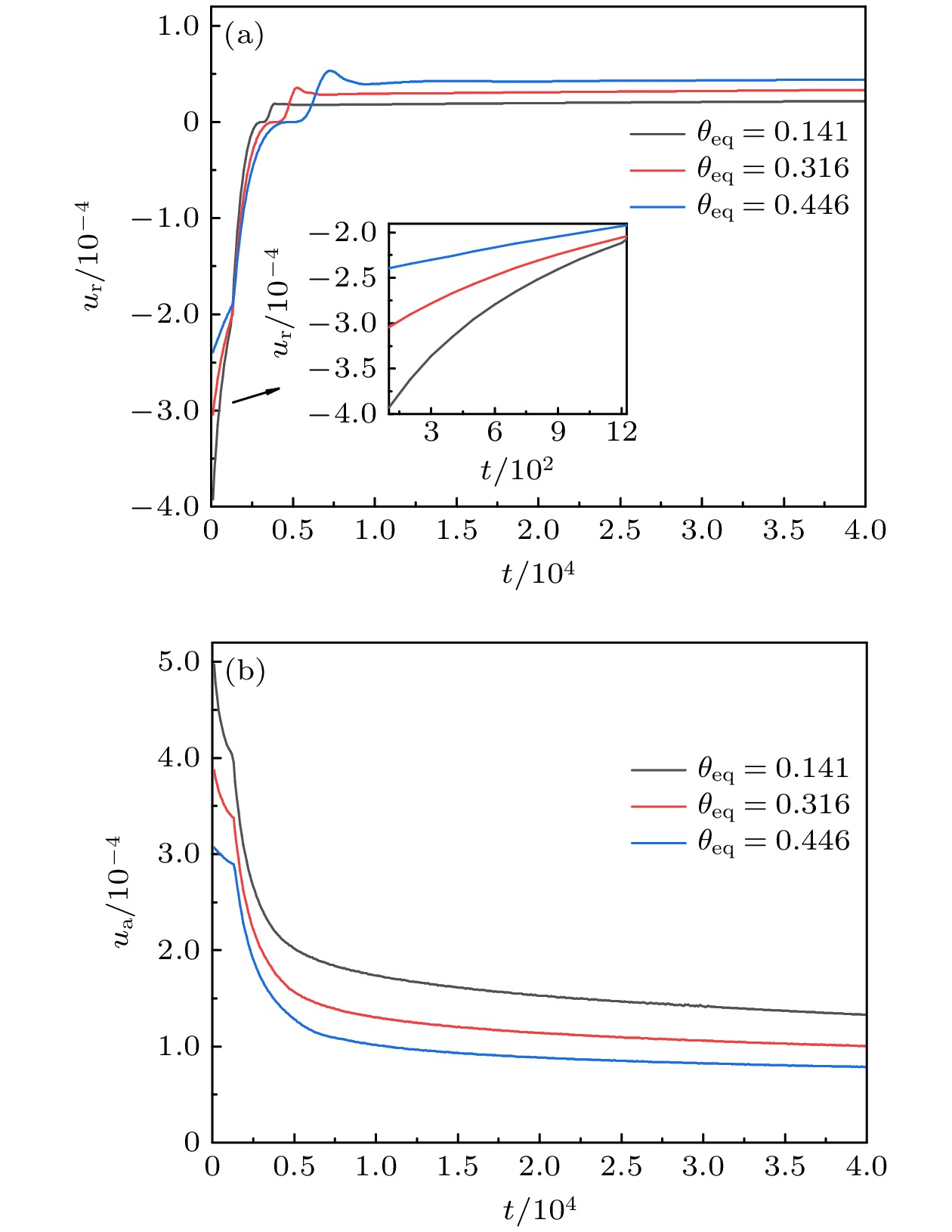

图 9 轨道宽度E对接触线位置、移动速度和接触角的影响 (a) 后退接触线; (b) 前进接触线; (c) 后退接触线移动速度; (d) 前进接触线移动速度; (e) 右侧接触线; (f) 前进和后退接触角

Fig. 9. The effect of E on the position, velocity of contact lines and contact angles: (a) Receding contact line position; (b) advancing contact line position; (c) the velocity of receding contact line; (d) the velocity of advancing contact line; (e) right contact line; (f) the advancing and receding contact angles.

表 1 网格无关性验证

Table 1. Validation of grid independence.

网格数目 液滴前进

接触角 θa液滴前进接触线

移动速度 ua/10–4计算所需

CPU时长/h4584 0.1506 1.721 3.15 10028 0.1534 1.779 8.02 15578 0.1536 1.781 14.21 表 2 有量纲参数及典型数量级

Table 2. Typical order of dimension parameters.

物性参数 符号 / 单位 典型数量级 液滴厚度 $ \widetilde{H}/ {\rm{m}}$ 10–4 长度特征尺度 $ \widetilde{L}/ {\rm{m}}$ 10–3 液体黏度 $\widetilde{\mu }/ ({\rm{Pa} }{\cdot} {\rm{s} })$ 10–3 液体密度 $\widetilde{\rho }/ ({\rm{kg} }{\cdot} {\rm{m} }^{-3} )$ 103 传热系数 $\widetilde{\alpha }/({\rm{kW} }{\cdot}{\rm{m} }^{-2}{\cdot}{\rm{K} }^{-1} )$ 1—10 壁面温度 $ \widetilde{T}/{\rm{K}} $ 103—102 界面张力 $\widetilde{\sigma }/ ({\rm{N} }{\cdot} {\rm{m} }^{-1} )$ 10–2 特征速度 $\widetilde{U}=\dfrac{\widetilde{\sigma }_{ {T}_{0} }-\widetilde{\sigma }_{ {T}_{\rm{m} } } }{\widetilde{H}/\left(\tilde{\mu }\tilde{L}\right)}/ ({\rm{m} }{\cdot} {\rm{s} }^{-1}$) 10–4—1 表 3 无量纲参数取值范围

Table 3. Range of dimensionless parameters.

无量纲参数 定义式 取值范围 小量ε ${\varepsilon }=\widetilde{H}/\widetilde{L}$ 10–2—10–1 邦德数Bo $ Bo=\widetilde{\rho }g{\widetilde{H}}^{2}/\widetilde{\mu }U $ 10–2—10–1 温度梯度$ \varGamma $ $\varGamma =\dfrac{(d{\widetilde{T} }_{\rm{w} }/{\rm{d}}\widetilde{x})\widetilde{L} }{ {\widetilde{T} }_{\rm{m} }-{\widetilde{T} }_{0} }$ 10–3—10–2 毛细数C $ C=\dfrac{{\varepsilon }^{2}{\widetilde{\sigma }}_{{\widetilde{T}}_{\rm{m}}}}{{\widetilde{\sigma }}_{{\widetilde{T}}_{0}}-{\widetilde{\sigma }}_{{\widetilde{T}}_{\rm{m}}}} $ 10–2—10–1 界面温度敏感系数$\varOmega_{\rm{i}} $ $ {\varOmega }_{\rm{i}}=\dfrac{{\widetilde{\alpha }}_{T\rm{i}}({\widetilde{T}}_{\rm{m}}-{\widetilde{T}}_{0})}{{\widetilde{\sigma }}_{{\rm{i}, \widetilde{T}}_{0}}-{\widetilde{\sigma }}_{{\rm{l}\rm{g}, \widetilde{T}}_{\rm{m}}}} $ 0—102 -

[1] Daniel S, Chaudhury M K, Chen J C 2001 Science 291 633

Google Scholar

Google Scholar

[2] Bakli C, PD S H, Chakraborty S 2017 Nanoscale 9 12509

Google Scholar

Google Scholar

[3] Musin A, Grynyov R, Frenkel M, Bormashenko E 2016 J. Colloid Interface Sci. 479 182

Google Scholar

Google Scholar

[4] Dhiman S, Jayaprakash K, Iqbal R, Sen A 2018 Langmuir 34 12359

Google Scholar

Google Scholar

[5] 王飞, 彭岚, 张全壮, 刘佳 2015 64 140202

Google Scholar

Google Scholar

Wang F, Peng L, Zhang Q Z, Liu J 2015 Acta Phys. Sin. 64 140202

Google Scholar

Google Scholar

[6] Karapetsas G, Chamakos N T, Papathanasiou A G 2017 Langmuir 33 10838

Google Scholar

Google Scholar

[7] Dai Q W, Huang W, Wang X L 2014 Exp. Therm. Fluid Sci. 57 200

Google Scholar

Google Scholar

[8] Chaudhury M K, Whitesides G M 1992 Science 256 1539

Google Scholar

Google Scholar

[9] Qi L, Niu Y, Ruck C, Zhao Y 2019 Lab Chip 19 223

Google Scholar

Google Scholar

[10] 石自媛, 胡国辉, 周哲玮 2010 59 2595

Google Scholar

Google Scholar

Shi Z Y, Hu G H, Zhou Z W 2010 Acta Phys. Sin. 59 2595

Google Scholar

Google Scholar

[11] Dai Q W, Huang W, Wang X L, Khonsari M M 2021 Tribol. Int. 154 106749

Google Scholar

Google Scholar

[12] Ghosh A, Ganguly R, Schutzius T M, Megaridis C M 2014 Lab Chip 14 1538

Google Scholar

Google Scholar

[13] Sen U, Chatterjee S, Ganguly R, Dodge R, Yu L, Megaridis C M 2018 Langmuir 34 1899

Google Scholar

Google Scholar

[14] 姚祎, 周哲玮, 胡国辉 2013 62 134701

Google Scholar

Google Scholar

Yao W, Zhou Z W, Hu G H 2013 Acta Phys. Sin. 62 134701

Google Scholar

Google Scholar

[15] Wang M, Liu Q, Zhang H R, Wang C, Wang L, Xiang B X, Fan Y T, Guo C F, Ruan S C 2017 ACS Appl. Mater. Interfaces 9 29248

Google Scholar

Google Scholar

[16] Dai Q W, Ji Y J, Chong Z J, Huang W, Wang X L 2019 J. Colloid Interface Sci. 557 837

Google Scholar

Google Scholar

[17] Fu X J, Sun J J, Ba Y 2022 Phys. Fluids 34 012119

Google Scholar

Google Scholar

[18] Diddens C, Kuerten J G, Van der Geld C, Wijshoff H 2017 J. Colloid Interface Sci. 487 426

Google Scholar

Google Scholar

[19] 李春曦, 程冉, 叶学民 2021 70 204701

Google Scholar

Google Scholar

Li C X, Cheng R, Ye X M 2021 Acta Phys. Sin. 70 204701

Google Scholar

Google Scholar

[20] Ye X M, Zhang N K, Cheng R, Li C X 2022 J. Appl. Fluid Mech. 15 1361

[21] Gomba J M, Homsy G M 2010 J. Fluid Mech. 647 125

Google Scholar

Google Scholar

[22] Beltrame P, Knobloch E, Hänggi P, Thiele U 2011 Phys. Rev. E 83 016305

Google Scholar

Google Scholar

[23] Ehrhard P, Davis S H 1991 J. Fluid Mech. 229 365

Google Scholar

Google Scholar

[24] Smith M K 1995 J. Fluid Mech. 294 209

Google Scholar

Google Scholar

[25] Karapetsas G, Sahu K C, Matar O K 2013 Langmuir 29 8892

Google Scholar

Google Scholar

[26] 叶学民, 李永康, 李春曦 2016 65 104704

Google Scholar

Google Scholar

Ye X M, Li Y K, Li C X 2016 Acta Phys. Sin. 65 104704

Google Scholar

Google Scholar

[27] 叶学民, 张湘珊, 李明兰, 李春曦 2018 67 184704

Google Scholar

Google Scholar

Ye X M, Zhang X S, Li M L, Li C X 2018 Acta Phys. Sin. 67 184704

Google Scholar

Google Scholar

[28] Nagy M, Škvarla J 2013 Acta Montanistica Slovaca 18 125

[29] Dai Q W, Khonsari M M, Shen C, Huang W, Wang X L 2016 Langmuir 32 7485

Google Scholar

Google Scholar

[30] Mukhopadhyay S, Murisic N, Behringer R P, Kondic L 2011 Phys. Rev. E 83 046302

[31] Chowdhury I U, Mahapatra P S, Sen A K 2019 Phys. Fluids 31 042111

Google Scholar

Google Scholar

[32] 宋金龙, 徐文骥 2017 金属加工: 冷加工 2017 65

Song J L, Xu W J 2017 Metal Working: Metal Cutting 2017 65

计量

- 文章访问数: 5119

- PDF下载量: 96

- 被引次数: 0

下载:

下载: