-

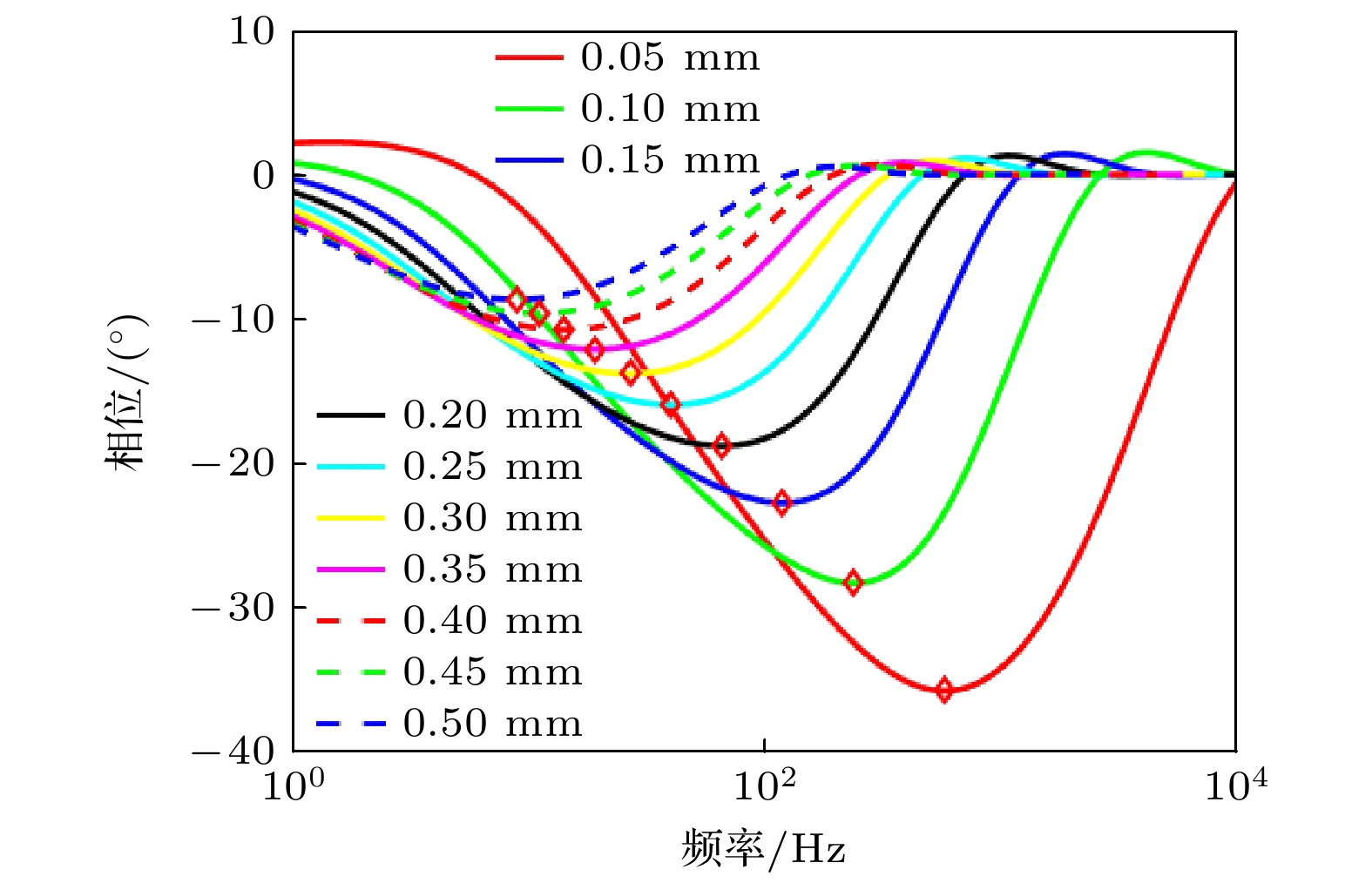

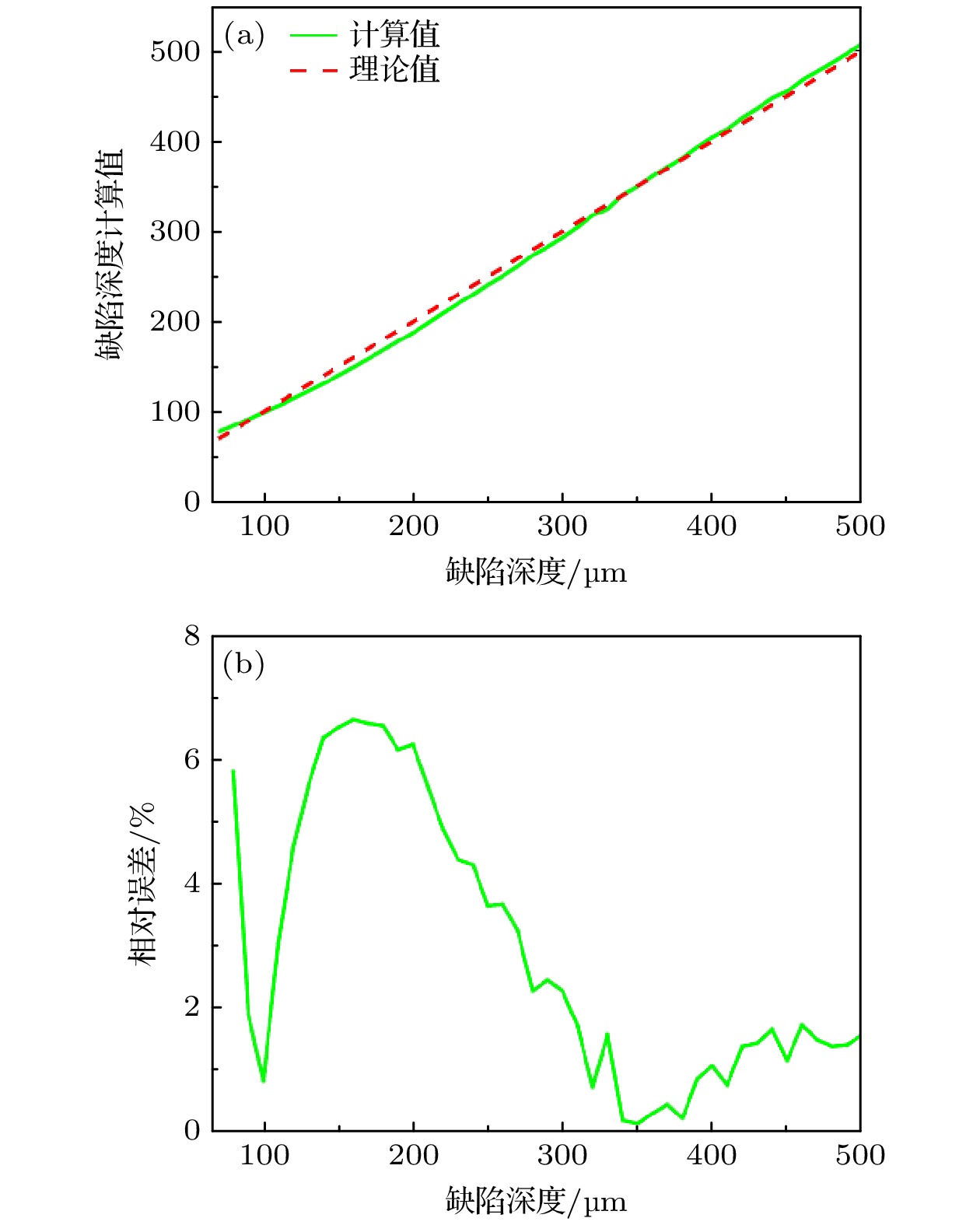

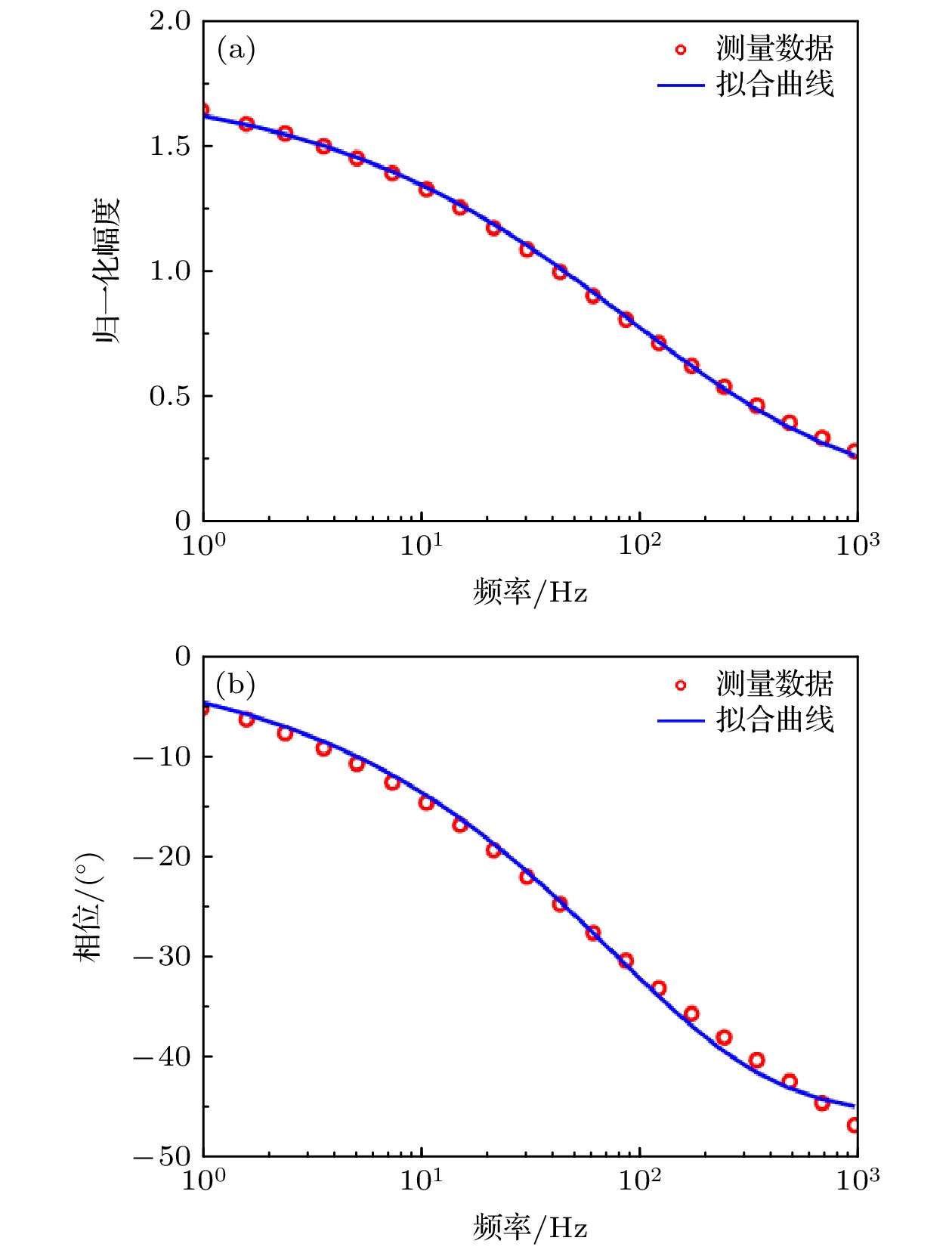

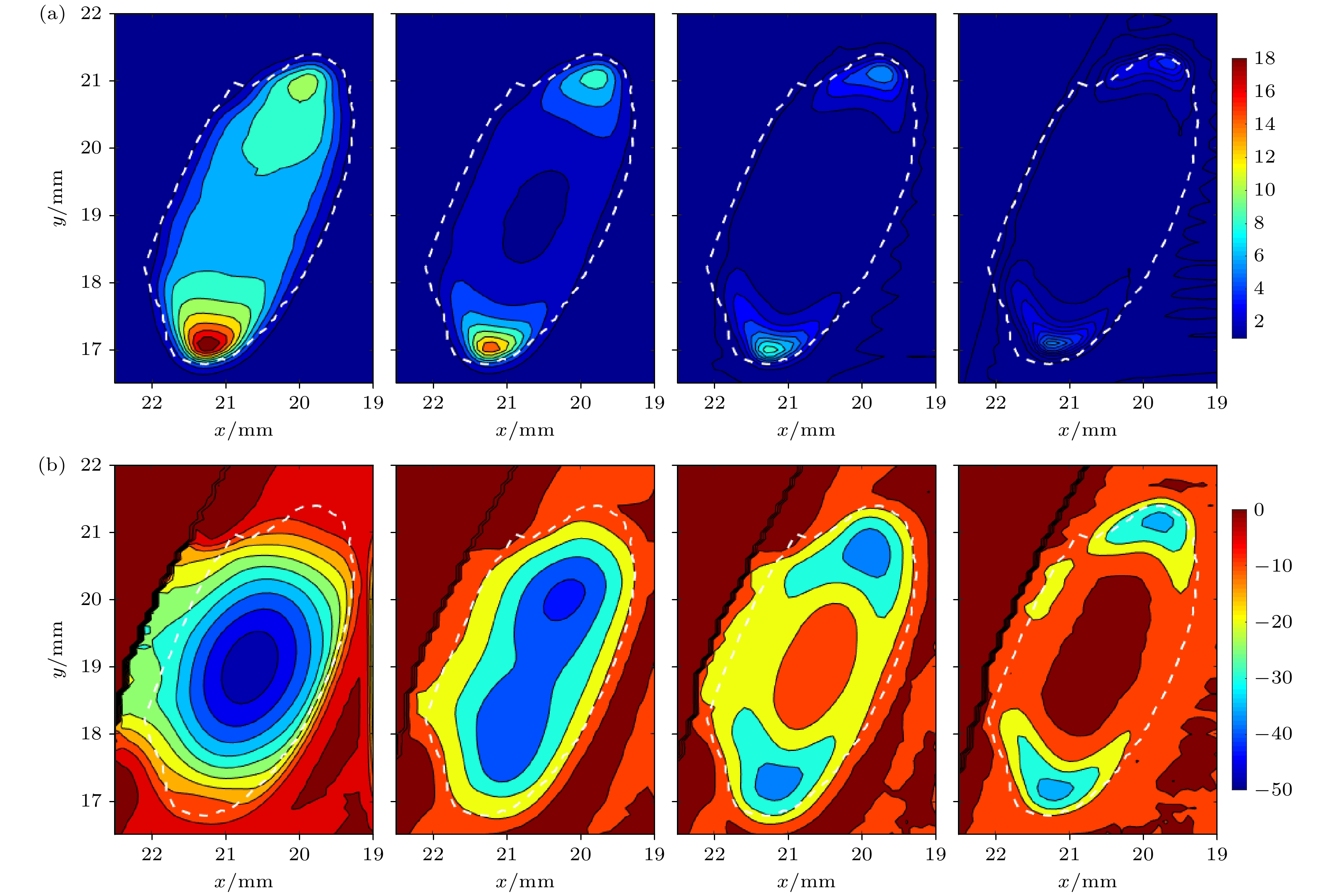

SiC以优异的物理性能和良好的工艺性能, 逐渐成为大型空间成像光学系统主镜的首选轻量化光学材料. SiC镜坯制备及加工过程中引入的亚表面缺陷会严重影响最终的镜面质量以及光学系统的成像品质. 针对SiC材料亚表面缺陷的检测问题, 本文采用光热辐射技术进行分析: 分别建立均匀样品的单层理论模型和含空气层缺陷的三层理论模型, 用于计算无缺陷和存在缺陷区域的光热辐射信号. 通过对三层理论模型信号的相位仿真分析, 提出利用相位差-频率曲线的特征频率估算缺陷深度的经验公式; 利用光热辐射装置测量存在亚表面缺陷的SiC样品, 分析缺陷区域的光热辐射信号分布, 利用经验公式计算缺陷深度, 并与缺陷实际深度分布进行对比分析. 实验与计算结果显示, 光热辐射技术能有效探测SiC镜坯的亚表面缺陷及其形貌, 并且对于界面与样品相对平行且较为平缓的亚表面缺陷, 其缺陷深度可通过经验公式准确确定.

With excellent physical, mechanical and processing properties, silicon carbide (SiC) has gradually become a preferred lightweight optical material for primary mirrors of large space optical systems. The subsurface defects generated during the preparation and processing procedures of SiC will affect the optical quality of the primary mirrors and the imaging performance of the corresponding optical systems employing the SiC primary mirror as well. In this work, photothermal radiation (PTR), a powerful nondestructive testing technique for detecting sub-surface defects of solid materials, is employed to characterize the subsurface defects of bulk SiC material for primary mirrors. Theoretically, three-dimensional one-layer and three-layer PTR theoretical models are developed to describe the defect-free and defect regions of an SiC bulk material. By analyzing the frequency dependence of PTR phase of the SiC bulk material with different defect depths, an empirical formula for estimating the defect depth via a characteristic frequency (appearing at the minimum of the PTR phase-frequency curve) defined thermal diffusion length is proposed, and simulation results show reasonably good agreement between the estimated and simulated defect depths in a depth range of 0.05–0.50 mm. Experimentally, an SiC bulk sample with a subsurface defect region is tested by the PTR via position scanning and modulation frequency scanning to obtain the position and frequency dependent PTR amplitude and phase. From the spatial distributions of PTR amplitude and phase measured at different frequencies and the phase difference frequency curves of measurement positions in the defect region, the depth and shape of the defect region are estimated and found to be in good agreement with the actual shape of the defect region, which is destructively measured via a depth profiler. The experimental and calculated results demonstrate that the PTR is capable of detecting non-destructively the subsurface defects of SiC bulk material. In addition, for subsurface defects with relatively flat interface, the defect depth can be determined accurately by the developed empirical formula. -

Keywords:

- SiC /

- subsurface defects /

- photothermal radiometry

[1] Jiang F, Liu Y, Yang Y, Huang Z R, Li D, Liu G L, Liu X J 2012 J. Nano Mater. 2012 7

Google Scholar

Google Scholar

[2] 韩媛媛, 张宇民, 韩杰才, 张剑寒, 姚旺, 周玉峰 2005 材料工程 06 59

Google Scholar

Google Scholar

Han Y Y, Zhang Y M, Han J C, Zhang J H, Yao W, Zhou Y F 2005 J. Mater. Eng. 06 59

Google Scholar

Google Scholar

[3] Sein E, Toulemont Y, Safa F, Duran M, Deny P, Chambure D, Passvogel T, Pilbratt G L 2003 SPIE IR Space Telescopes and Instruments 4850 606

Google Scholar

Google Scholar

[4] Rodolfo J P 2008 SPIE Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation 7018 70180E

Google Scholar

Google Scholar

[5] Kaneda H, Nakagawa T, Onaka T, Enya K, Kataza H, Makiuti S, Matsuhara H, Miyamoto M, Murakami H, Saruwatari H, Watarai H, Yui Y Y 2007 SPIE Optical Materials and Structures Technologies III 6666 666607

Google Scholar

Google Scholar

[6] Ebizuka N, Dai Y, Eto H, Lin W, Ebisuzaki T, Omori H, Handa T, Takami H, Takahashi Y 2003 SPIE Specialized Optical Developments in Astronomy 4842 329

Google Scholar

Google Scholar

[7] 周岩 2020 硕士学位论文 (长春: 长春工业大学)

Zhou Y 2020 M. S. Thesis (Changchun: Changchun University of Technology) (in Chinese)

[8] Goela J S, Pickering M A, Tayler R L 1991 SPIE Optical Surfaces Resistant to Severe Environments 1330 25

Google Scholar

Google Scholar

[9] Zappellini G B, Martin H M, Miller S M, Smith B K, Cuerden B, Gasho V, Sosa R G, Montoya M, Riccardi A 2007 SPIE Astronomical Adaptive Optics Systems and Applications III 6991 66910U

Google Scholar

Google Scholar

[10] Xie J, Li Q, Sun J X, Li Y H 2015 J. Mater. Process. Tech. 222 422

Google Scholar

Google Scholar

[11] Yoo H K, Ko J H, Lim K Y, Kwon W T, Kim Y W 2015 Ceram. Int. 41 3490

Google Scholar

Google Scholar

[12] 李改灵, 孙开元, 冯仁余, 刘永军, 常林枫 2008 煤矿机械 12 99

Google Scholar

Google Scholar

Li G L, Sun K Y, Feng R Y, Liu Y J, Chang L F 2008 Coal Mine Machinery 12 99

Google Scholar

Google Scholar

[13] Neauport J, Ambard C, Cormont P, Darbois N, Destribats J, Luitot C, Rondeau O 2009 Opt. Express 17 20448

Google Scholar

Google Scholar

[14] Fahnle O W, Wons T, Koch E, Debruyne S, Meeder M, Booij S M, Braat J J M 2002 Applied Optics 41 4036

Google Scholar

Google Scholar

[15] Wuttig A, Steinert J, Duparre A, Truckenbrodt H 1999 SPIE Optical Fabrication and Testing 3739 369

Google Scholar

Google Scholar

[16] 刘红婕, 王凤蕊, 耿峰, 周晓燕, 黄进, 叶鑫, 蒋晓东, 吴卫东, 杨李茗 2020 光学精密工程 28 50

Google Scholar

Google Scholar

Liu H J, Wang F R, Geng F, Zhou X Y, Huang J, Ye X, Jiang X D, Wu W D, Yang L M 2020 Optics Precis. Eng. 28 50

Google Scholar

Google Scholar

[17] Nordal P E, Kanstad S O 1979 Phys. Scr. 20 659

Google Scholar

Google Scholar

[18] Nakamura H, Tsubouchi K, Mikoshiba N 1985 Jpn. J. Appl. Phys. 24 222

Google Scholar

Google Scholar

[19] 李佩赞 1989 红外技术 11 97

Li P Z 1989 Infrared Technology 11 97

[20] 范春利, 孙丰瑞, 杨立 2005 激光与红外 35 504

Google Scholar

Google Scholar

Fan C L, Sun F R, Yang L 2005 Laser & Infrared 35 504

Google Scholar

Google Scholar

[21] 王心觉, 刘恒彪, 胡文祥 2017 激光与光电子学进展 54 101201

[22] 曹丹, 屈惠明 2013 激光与红外 43 513

Cao D, Qu H M 2013 Laser & Infrared 43 513

[23] Muramatsu M, Nakasumi S, Harada Y 2016 Adv. Compos. Mater. 25 541

Google Scholar

Google Scholar

[24] 马晓波, 王青青 2018 红外技术 40 85

Ma X B, Wang Q Q 2018 Infrared Technology 40 85

[25] 尹国应, 李爱珠 2020 光学与光电技术 18 18

Yin G Y, Li A Z 2020 Optics & Optoelectronic Technology 18 18

[26] 李佩赞, 王钦华 1994 仪器仪表学报 15 265

Google Scholar

Google Scholar

Li P Z, Wang Q H 1994 Chin. J. Sci. Instrum. 15 265

Google Scholar

Google Scholar

[27] 管国兴, 郑小明, 李佩赞 1988 红外研究 7A 201

Guan G X, Zheng X M, Li P Z 1988 Chin. J. Infrared Res. 7A 201

[28] 李佩赞, 王钦华 1996 物理 25 426

Li P Z, Wang Q H 1996 Physics 25 426

[29] 江海军, 陈力, 张淑仪 2014 无损检测 36 20

Jiang H J, Chen L, Zhang S Y 2014 Nondestructive Testing 36 20

[30] 江海军, 陈力, 苏清风, 邢建湘 2018 无损检测 40 15

Google Scholar

Google Scholar

Jiang H J, Chen L, Su Q F, Xing J X 2018 Nondestructive Testing 40 15

Google Scholar

Google Scholar

[31] 江海军, 陈力 2018 红外技术 40 946

Google Scholar

Google Scholar

Jiang H J, Chen L 2018 Infrared Technology 40 946

Google Scholar

Google Scholar

-

表 1 测量点的缺陷深度估算结果

Table 1. Estimated results of defect depth at measuring points.

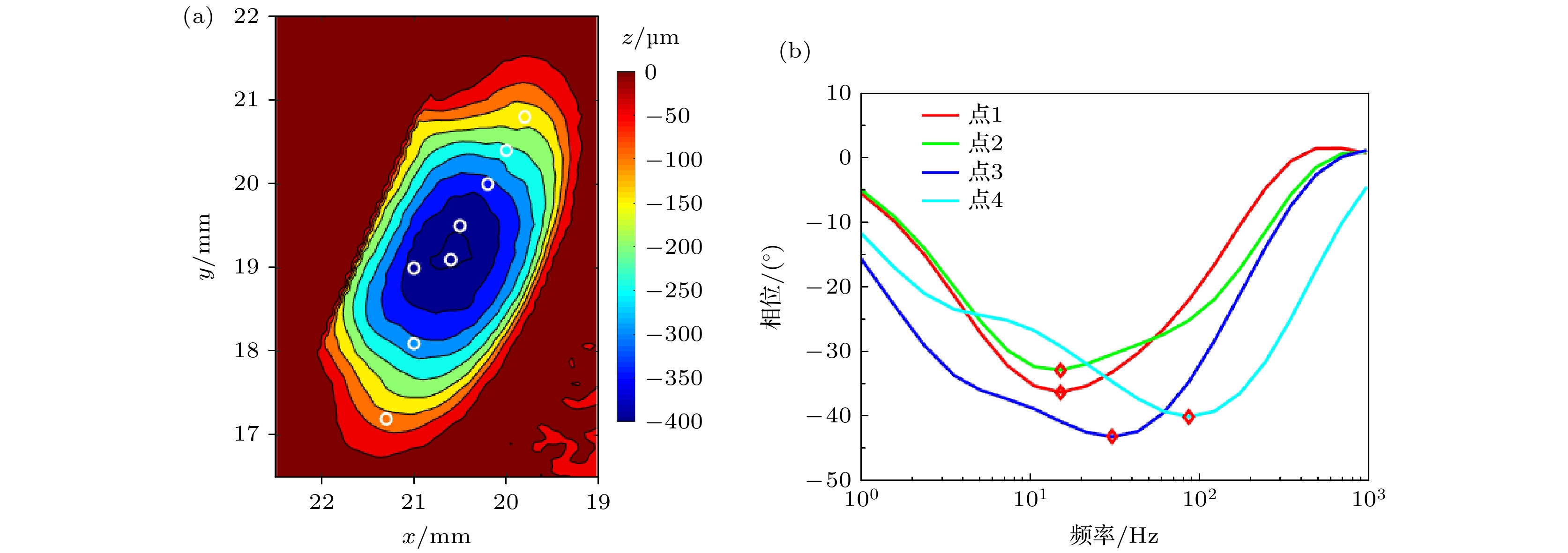

点 坐标 缺陷深度/μm 误差 实际值 测量值 绝对误差/μm 相对误差/% 1 (21.0, 19.0) 371.6 392.0 20.4 5.5 2 (20.5, 19.5) 392.0 392.0 0 0 3 (20.2, 20.0) 291.0 276.0 15.0 5.2 4 (20.0, 20.4) 186.9 164.0 22.9 12.3 5 (21.3, 17.2) 80.9 58.5 21.7 27.7 6 (21.0, 18.1) 284.0 392.0 108.0 38.1 7 (20.6, 19.1) 413.9 560.0 146.0 35.5 8 (19.8, 20.8) 118.0 58.5 59.5 50.4 -

[1] Jiang F, Liu Y, Yang Y, Huang Z R, Li D, Liu G L, Liu X J 2012 J. Nano Mater. 2012 7

Google Scholar

Google Scholar

[2] 韩媛媛, 张宇民, 韩杰才, 张剑寒, 姚旺, 周玉峰 2005 材料工程 06 59

Google Scholar

Google Scholar

Han Y Y, Zhang Y M, Han J C, Zhang J H, Yao W, Zhou Y F 2005 J. Mater. Eng. 06 59

Google Scholar

Google Scholar

[3] Sein E, Toulemont Y, Safa F, Duran M, Deny P, Chambure D, Passvogel T, Pilbratt G L 2003 SPIE IR Space Telescopes and Instruments 4850 606

Google Scholar

Google Scholar

[4] Rodolfo J P 2008 SPIE Advanced Optical and Mechanical Technologies in Telescopes and Instrumentation 7018 70180E

Google Scholar

Google Scholar

[5] Kaneda H, Nakagawa T, Onaka T, Enya K, Kataza H, Makiuti S, Matsuhara H, Miyamoto M, Murakami H, Saruwatari H, Watarai H, Yui Y Y 2007 SPIE Optical Materials and Structures Technologies III 6666 666607

Google Scholar

Google Scholar

[6] Ebizuka N, Dai Y, Eto H, Lin W, Ebisuzaki T, Omori H, Handa T, Takami H, Takahashi Y 2003 SPIE Specialized Optical Developments in Astronomy 4842 329

Google Scholar

Google Scholar

[7] 周岩 2020 硕士学位论文 (长春: 长春工业大学)

Zhou Y 2020 M. S. Thesis (Changchun: Changchun University of Technology) (in Chinese)

[8] Goela J S, Pickering M A, Tayler R L 1991 SPIE Optical Surfaces Resistant to Severe Environments 1330 25

Google Scholar

Google Scholar

[9] Zappellini G B, Martin H M, Miller S M, Smith B K, Cuerden B, Gasho V, Sosa R G, Montoya M, Riccardi A 2007 SPIE Astronomical Adaptive Optics Systems and Applications III 6991 66910U

Google Scholar

Google Scholar

[10] Xie J, Li Q, Sun J X, Li Y H 2015 J. Mater. Process. Tech. 222 422

Google Scholar

Google Scholar

[11] Yoo H K, Ko J H, Lim K Y, Kwon W T, Kim Y W 2015 Ceram. Int. 41 3490

Google Scholar

Google Scholar

[12] 李改灵, 孙开元, 冯仁余, 刘永军, 常林枫 2008 煤矿机械 12 99

Google Scholar

Google Scholar

Li G L, Sun K Y, Feng R Y, Liu Y J, Chang L F 2008 Coal Mine Machinery 12 99

Google Scholar

Google Scholar

[13] Neauport J, Ambard C, Cormont P, Darbois N, Destribats J, Luitot C, Rondeau O 2009 Opt. Express 17 20448

Google Scholar

Google Scholar

[14] Fahnle O W, Wons T, Koch E, Debruyne S, Meeder M, Booij S M, Braat J J M 2002 Applied Optics 41 4036

Google Scholar

Google Scholar

[15] Wuttig A, Steinert J, Duparre A, Truckenbrodt H 1999 SPIE Optical Fabrication and Testing 3739 369

Google Scholar

Google Scholar

[16] 刘红婕, 王凤蕊, 耿峰, 周晓燕, 黄进, 叶鑫, 蒋晓东, 吴卫东, 杨李茗 2020 光学精密工程 28 50

Google Scholar

Google Scholar

Liu H J, Wang F R, Geng F, Zhou X Y, Huang J, Ye X, Jiang X D, Wu W D, Yang L M 2020 Optics Precis. Eng. 28 50

Google Scholar

Google Scholar

[17] Nordal P E, Kanstad S O 1979 Phys. Scr. 20 659

Google Scholar

Google Scholar

[18] Nakamura H, Tsubouchi K, Mikoshiba N 1985 Jpn. J. Appl. Phys. 24 222

Google Scholar

Google Scholar

[19] 李佩赞 1989 红外技术 11 97

Li P Z 1989 Infrared Technology 11 97

[20] 范春利, 孙丰瑞, 杨立 2005 激光与红外 35 504

Google Scholar

Google Scholar

Fan C L, Sun F R, Yang L 2005 Laser & Infrared 35 504

Google Scholar

Google Scholar

[21] 王心觉, 刘恒彪, 胡文祥 2017 激光与光电子学进展 54 101201

[22] 曹丹, 屈惠明 2013 激光与红外 43 513

Cao D, Qu H M 2013 Laser & Infrared 43 513

[23] Muramatsu M, Nakasumi S, Harada Y 2016 Adv. Compos. Mater. 25 541

Google Scholar

Google Scholar

[24] 马晓波, 王青青 2018 红外技术 40 85

Ma X B, Wang Q Q 2018 Infrared Technology 40 85

[25] 尹国应, 李爱珠 2020 光学与光电技术 18 18

Yin G Y, Li A Z 2020 Optics & Optoelectronic Technology 18 18

[26] 李佩赞, 王钦华 1994 仪器仪表学报 15 265

Google Scholar

Google Scholar

Li P Z, Wang Q H 1994 Chin. J. Sci. Instrum. 15 265

Google Scholar

Google Scholar

[27] 管国兴, 郑小明, 李佩赞 1988 红外研究 7A 201

Guan G X, Zheng X M, Li P Z 1988 Chin. J. Infrared Res. 7A 201

[28] 李佩赞, 王钦华 1996 物理 25 426

Li P Z, Wang Q H 1996 Physics 25 426

[29] 江海军, 陈力, 张淑仪 2014 无损检测 36 20

Jiang H J, Chen L, Zhang S Y 2014 Nondestructive Testing 36 20

[30] 江海军, 陈力, 苏清风, 邢建湘 2018 无损检测 40 15

Google Scholar

Google Scholar

Jiang H J, Chen L, Su Q F, Xing J X 2018 Nondestructive Testing 40 15

Google Scholar

Google Scholar

[31] 江海军, 陈力 2018 红外技术 40 946

Google Scholar

Google Scholar

Jiang H J, Chen L 2018 Infrared Technology 40 946

Google Scholar

Google Scholar

计量

- 文章访问数: 6314

- PDF下载量: 105

- 被引次数: 0

下载:

下载: