-

Abundant novel physical properties have been observed in thin-flake samples of two-dimensional correlated electronic systems prepared by mechanical exfoliation. Developing new methods of preparing bulk two-dimensional samples can further understand the low-dimensional system by combining traditional bulk characterization methods like X-ray diffraction, magnetic susceptibility and specific heat measurements. It is possible to maintain the novel properties of thin-flake samples in bulk state and promote these novel physical properties for potential applications. This article introduces a class of organic molecular intercalation methods to regulate two-dimensional correlated electronic systems, focusing on the changes of structure and physical properties of two-dimensional materials after organic molecular intercalation. The applications of organic molecular intercalation method in regulating thermoelectricity, two-dimensional magnetism, charge density wave and two-dimensional superconductivity are also presented.

-

Keywords:

- organic molecular intercalation /

- two-dimensional superconductivity /

- low dimensional magnetism /

- organic-inorganic hybrid materials

[1] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol. 6 147

Google Scholar

Google Scholar

[2] Li L, Yu Y, Ye G J, Ge Q, Ou X, Wu H, Feng D, Chen X H, Zhang Y 2014 Nat. Nanotechnol. 9 372

Google Scholar

Google Scholar

[3] Wang E Y, Ding H, Fedorov A V, Yao W, Li Z, Lv Y F, Zhao K, Zhang L G, Xu Z J, Schneeloch J, Zhong R D, Ji S H, Wang L L, He K, Ma X C, Gu G D, Yao H, Xue Q K, Chen X, Zhou S Y 2013 Nat. Phys. 9 621

Google Scholar

Google Scholar

[4] Zhang Z C, Wang Y H, Song Q, Liu C, Peng R, Moler K A, Feng D L, Wang Y Y 2015 Sci. Bull. 60 1301

Google Scholar

Google Scholar

[5] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X 2017 Nature 546 270

Google Scholar

Google Scholar

[6] Deng Y, Yu Y, Song Y, Zhang J, Wang N Z, Sun Z, Yi Y, Wu Y Z, Wu S, Zhu J, Wang J, Chen X H, Zhang Y 2018 Nature 563 94

Google Scholar

Google Scholar

[7] Kamysbayev V, Filatov A S, Hu H, Rui X, Lagunas F, Wang D, Klie R F, Talapin D V 2020 Science 369 979

Google Scholar

Google Scholar

[8] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[9] Liu H, Neal A T, Zhu Z, Luo Z, Xu X, Tomanek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[10] Lu X, Stepanov P, Yang W, Xie M, Aamir M A, Das I, Urgell C, Watanabe K, Taniguchi T, Zhang G, Bachtold A, MacDonald A H, Efetov D K 2019 Nature 574 653

Google Scholar

Google Scholar

[11] Wang N Z, Shi M Z, Shang C, Meng F B, Ma L K, Luo X G, Chen X H 2018 New J. Phys. 20 023014

Google Scholar

Google Scholar

[12] Shi M Z, Wang N Z, Lei B, Ying J J, Zhu C S, Sun Z L, Cui J H, Meng F B, Hang C S, Ma L K, Chen X H 2018 New J. Phys. 20 123007

Google Scholar

Google Scholar

[13] Kang B L, Shi M Z, Li S J, Wang H H, Zhang Q, Zhao D, Li J, Song D W, Zheng L X, Nie L P, Wu T, Chen X H 2020 Phys. Rev. Lett. 125 097003

Google Scholar

Google Scholar

[14] Zhao Y C, Su Y Q, Guo Y Q, Peng J, Zhao J Y, Wang C Y, Wang L J, Wu C Z, Xie Y 2021 ACS Mater. Lett. 3 210

Google Scholar

Google Scholar

[15] Zhu R L, Zhu L Z, Zhu J X, Xu L H 2008 Appl. Clay Sci. 42 224

Google Scholar

Google Scholar

[16] Ganter P, Schoop L M, Lotsch B V 2017 Adv. Mater. 29 1604884

Google Scholar

Google Scholar

[17] Gamble F R, Osiecki J H, Cais M, Pisharody R, Disalvo F J, Geballe T H 1971 Science 174 493

Google Scholar

Google Scholar

[18] Li Z, Zhao Y, Mu K, Shan H, Guo Y, Wu J, Su Y, Wu Q, Sun Z, Zhao A, Cui X, Wu C, Xie Y 2017 J. Am. Chem. Soc. 139 16398

Google Scholar

Google Scholar

[19] Gao Z, Zeng S Y, Zhu B C, Li B A, Hao Q Y, Hu Y W, Wang D K, Tang K B 2018 Sci. Chin. -Mater. 61 977

Google Scholar

Google Scholar

[20] Bartlett N, McQuillan B W (Whittingham M S, Jacobson A J, Eds) 1982 Intercalation Chemistry (New York: Academic Press) pp19–53

[21] Yoo H D, Liang Y L, Dong H, Lin J H, Wang H, Liu Y S, Ma L, Wu T P, Li Y F, Ru Q, Jing Y, An Q Y, Zhou W, Guo J H, Lu J, Pantelides S T, Qian X F, Yao Y 2017 Nat. Commun. 8 339

Google Scholar

Google Scholar

[22] Rendenbach B, Hohl T, Harm S, Hoch C, Johrendt D 2021 J. Am. Chem. Soc. 143 3043

Google Scholar

Google Scholar

[23] Wan C, Gu X, Dang F, Itoh T, Wang Y, Sasaki H, Kondo M, Koga K, Yabuki K, Snyder G J, Yang R, Koumoto K 2015 Nat. Mater. 14 622

Google Scholar

Google Scholar

[24] Jin S F, Fan X, Wu X Z, Sun R J, Wu H, Huang Q Z, Shi C L, Xi X K, Li Z L, Chen X L 2017 Chem. Commun. 53 9729

Google Scholar

Google Scholar

[25] Wang N, Tang H, Shi M, Zhang H, Zhuo W, Liu D, Meng F, Ma L, Ying J, Zou L, Sun Z, Chen X 2019 J. Am. Chem. Soc. 141 17166

Google Scholar

Google Scholar

[26] Ma L K, Shi M Z, Kang B L, Peng K L, Meng F B, Zhu C S, Cui J H, Sun Z L, Wang H H, Lei B, Wu T, Chen X H 2020 Phys. Rev. Mater. 4 124803

Google Scholar

Google Scholar

[27] Meng F B, Liu Z, Yang L X, Shi M Z, Ge B H, Zhang H, Ying J J, Wang Z F, Wang Z Y, Wu T, Chen X H 2020 Phys. Rev. B 102 165410

Google Scholar

Google Scholar

[28] Gong C, Li L, Li Z, Ji H, Stern A, Xia Y, Cao T, Bao W, Wang C, Wang Y, Qiu Z Q, Cava R J, Louie S G, Xia J, Zhang X 2017 Nature 546 265

Google Scholar

Google Scholar

[29] Wang Q Y, Li Z, Zhang W H, Zhang Z C, Zhang J S, Li W, Ding H, Ou Y B, Deng P, Chang K, Wen J, Song C L, He K, Jia J F, Ji S H, Wang Y Y, Wang L L, Chen X, Ma X C, Xue Q K 2012 Chin. Phys. Lett. 29 037402

Google Scholar

Google Scholar

[30] Hu G B, Shi M Z, Wang W X, Zhu C S, Luo X G, Chen X H 2022 New J. Phys. 24 043035

Google Scholar

Google Scholar

-

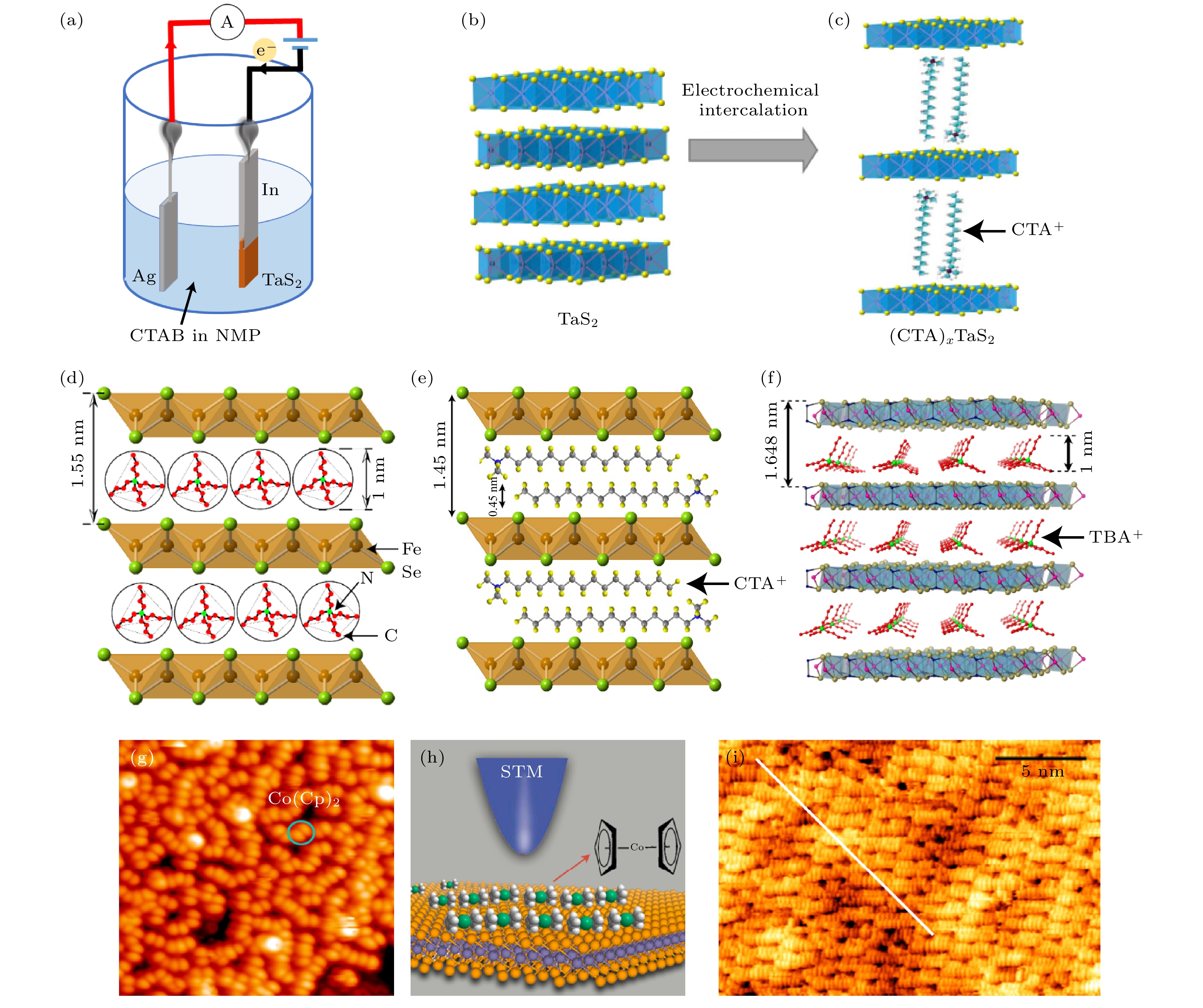

图 1 电化学有机分子插层的过程及结构演化 (a)电化学电解池的结构及电荷流动示意图, 包括工作电极(固定有二维材料的In丝)、对电极(Ag片)和电解液(溶有季铵盐的有机溶液); (b), (c) CTA+插层TaS2前后的结构示意图, 其中有机分子CTA+垂直于TaS2的ab面[11]; (d), (e), (f) (TBA)xFeSe[12], (CTA)xFeSe[13]以及(TBA)xCr2Ge2Te6[25]的结构示意图, 其中TBA+在层间单层排列, CTA+在层间以双层平行排列; (g), (h) (Cp)2Co插层SnSe2的STM形貌图和其对应的结构示意图, 有机分子(Cp)2Co的五元环平面与SnSe2的ab面垂直[18]; (i) (CTA)xFeSe的STM形貌图, 其中CTA+分子在FeSe层间紧密排列, 且CTA+分子的长链与FeSe的ab面平行[13]

Fig. 1. Process of the electrochemical intercalation and the structure of the intercalated materials: (a) The illustration of the electrolytic cell which includes the working electrode (In wire fixed with two-dimensional material), counter electrode (Ag sheet) and the electrolyte (organic solution containing quaternary ammonium salt). (b), (c) The structure of TaS2 and (CTA)xTaS2 , respectively. The organic molecule CTA+ is perpendicular to the ab plane of TaS2[11]. (d), (e), (f) The structure of (TBA)xFeSe[12], (CTA)xFeSe[13] and (TBA)xCr2Ge2Te6[25], respectively. The TBA+ is arranged in a monolayer mode, while CTA+ is arranged in a double-layer mode. (g), (h) The STM image and surface structure of (Cp)2Co intercalated SnSe2. The five-membered ring plane of organic molecule (Cp)2Co is perpendicular to the ab plane of SnSe2[18]. (i) The STM image of (CTA)xFeSe. The CTA+ molecules are closely arranged in the interlayer of FeSe, and the long chain of CTA+ molecules is parallel to the ab plane of FeSe[13].

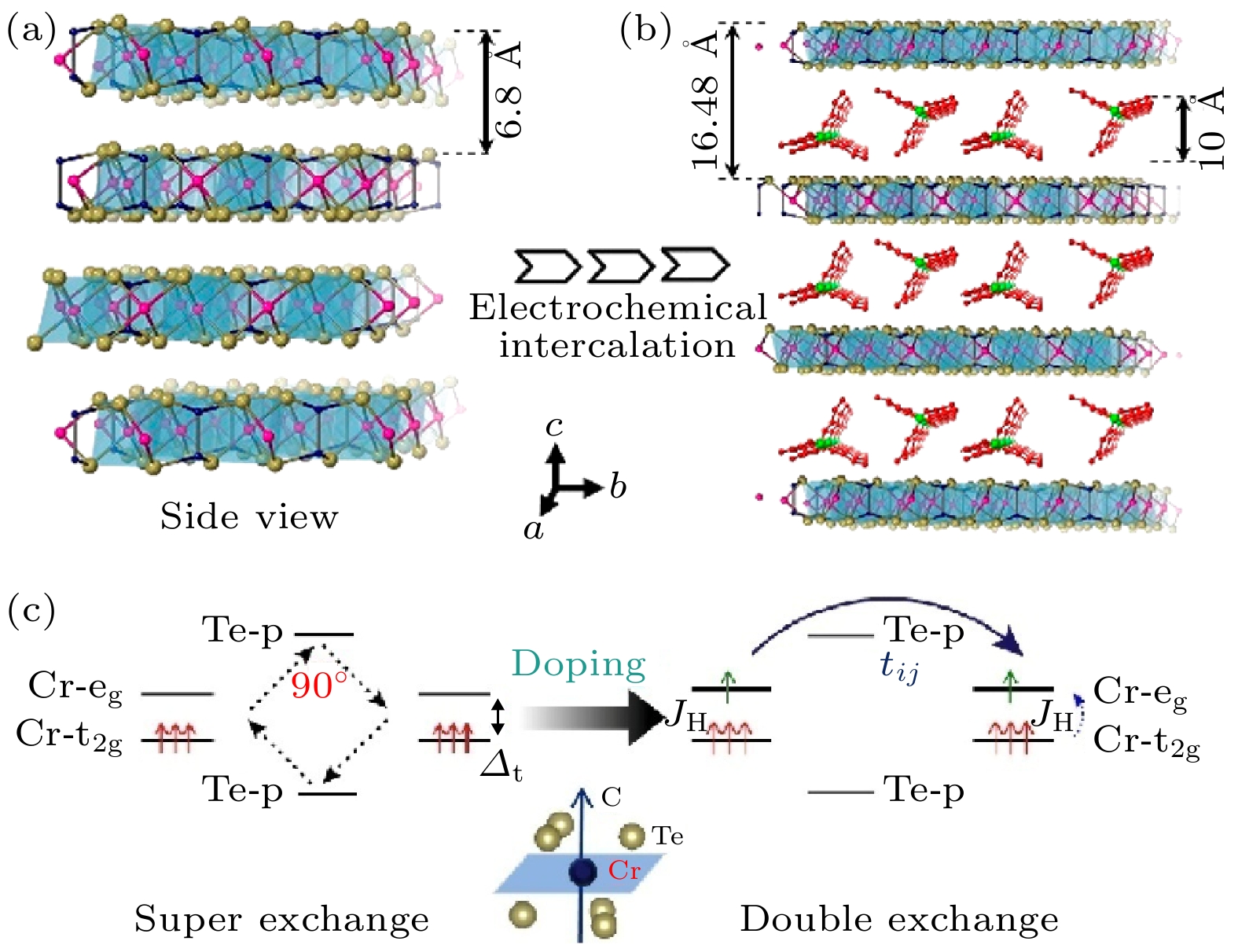

图 2 Cr2Ge2Te6中插层TBA+分子后的结构和磁作用机制变化 (a), (b) Cr2Ge2Te6插层TBA+分子前后的结构示意图[25]; (c) Cr2Ge2Te6插层TBA+分子前(左图)和插层TBA+分子后(右图)的磁性作用机制示意图[25]

Fig. 2. Changes of structure and magnetism origin in TBA+ intercalated Cr2Ge2Te6: (a), (b) The structure of Cr2Ge2Te6 and (TBA)xCr2Ge2Te6[25]; (c) the magnetism exchange interaction of Cr2Ge2Te6 (left panel) and (TBA)xCr2Ge2Te6 (right panel)[25].

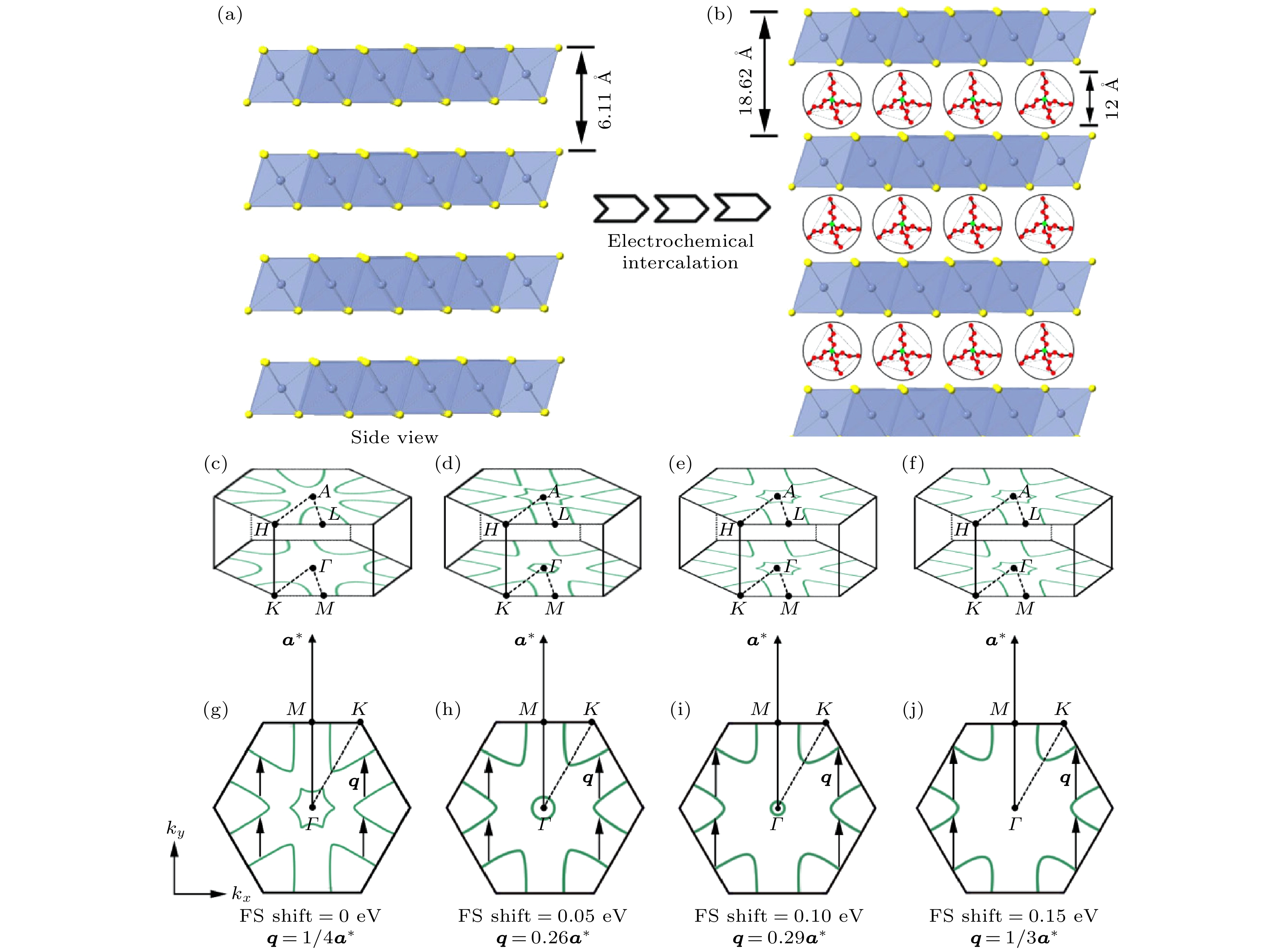

图 3 VSe2中插层TBA+分子后的结构和能带结构变化 (a), (b) VSe2和(TBA)xVSe2的结构示意图[27]; (c)—(f) 第一性原理计算的VSe2的层间距离为6.12, 8.62, 11.02, 18.62 Å时对应的能带结构[27]; (g)—(j) 第一性原理计算的VSe2的层间距离为18.62 Å时, 费米面移动0, 0.05, 0.1, 0.15 eV后, 能带结构的演化, 其对应的费米面嵌套波失分别为1/4a*, 0.26a*, 0.29a*, 1/3a*[27]

Fig. 3. Changes of crystal structure and Fermi surface topology in the TBA+ intercalated VSe2: (a), (b) The crystal structure of VSe2 and (TBA)xVSe2[27]. (c)–(f) The calculated Fermi surface topology of VSe2 with the interlayer distance of 6.12, 8.62, 11.02 and 18.62 Å[27]. (g)–(j) The calculated Fermi surface topology of VSe2 with the different amount of Fermi surface shift with the interlayer distance at 18.62 Å. The shift amount is 0, 0.05, 0.1 and 0.15 eV, respectively. The nesting vectors are 1/4a*, 0.26a*, 0.29a*, 1/3a*[27]

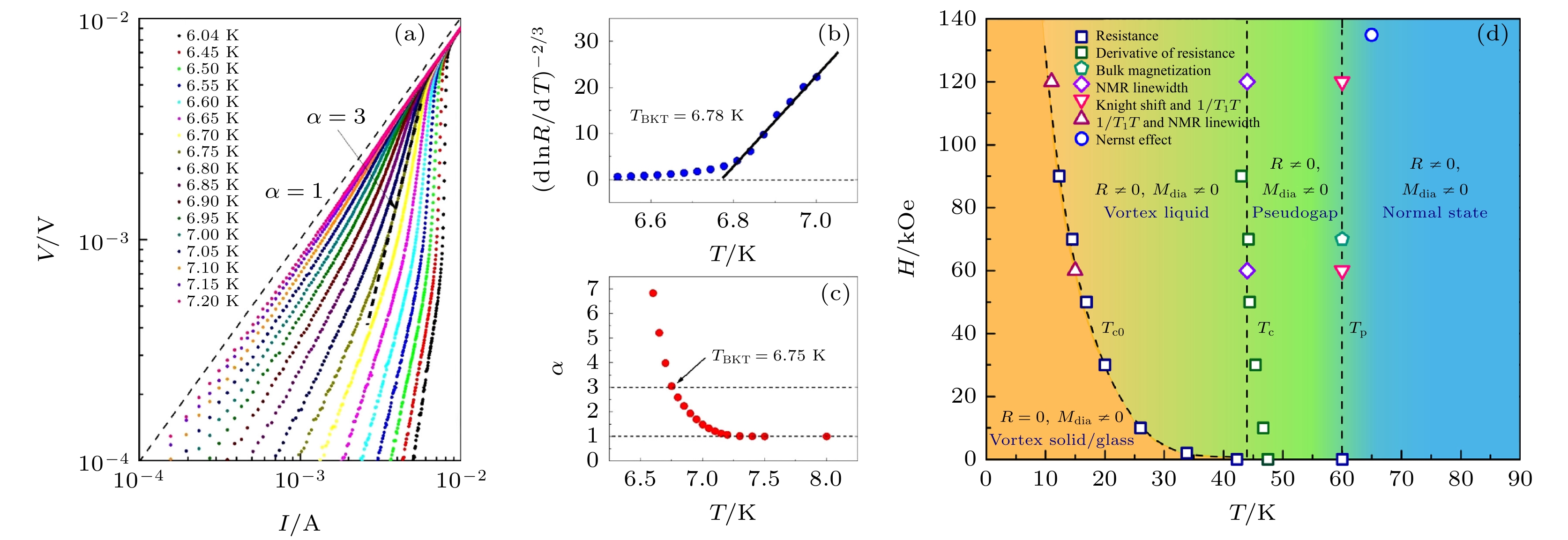

图 4 (CTA)xSnSe2中的二维超导与(TBA)xFeSe中的赝能隙相图 (a) (CTA)xSnSe2在超导转变温度附近的I-V曲线[26]; (b) (CTA)xSnSe2的R(T)曲线, 其中纵坐标是(d lnR(T)/dT)–2/3 [26]; (c)从(CTA)xSnSe2的I-V曲线中分离出来的幂指数α; (d) (TBA)xFeSe的磁场-温度相图, 其中Tc0是零电阻温度, Tc是通过NMR谱线展宽和电阻曲线一阶微分定义的超导转变温度, Tp是电子预配对的温度[13]

Fig. 4. Quasi-two-dimensional superconductivity in (CTA)xSnSe2 and the pseudogap behavior in (TBA)xFeSe: (a) The I-V curves of (CTA)xSnSe2 around the Tc[26]; (b) the R(T) curve of (CTA)xSnSe2 with the Y axis at the scale of (d lnR(T)/dT)–2/3 [26]; (c) the temperature dependent index α of (CTA)xSnSe2 using the fitting formula

$ V \propto {I^\alpha } $ [26]; (d) the Field-Temperature phase diagram of (TBA)xFeSe. The Tc0 is the zero-resistance critical temperature; Tc is the superconducting temperature defined by the onset temperature of NMR line broadening and the first derivative of resistance data; Tp is the onset temperature of the pseudogap behavior[13]. -

[1] Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A 2011 Nat. Nanotechnol. 6 147

Google Scholar

Google Scholar

[2] Li L, Yu Y, Ye G J, Ge Q, Ou X, Wu H, Feng D, Chen X H, Zhang Y 2014 Nat. Nanotechnol. 9 372

Google Scholar

Google Scholar

[3] Wang E Y, Ding H, Fedorov A V, Yao W, Li Z, Lv Y F, Zhao K, Zhang L G, Xu Z J, Schneeloch J, Zhong R D, Ji S H, Wang L L, He K, Ma X C, Gu G D, Yao H, Xue Q K, Chen X, Zhou S Y 2013 Nat. Phys. 9 621

Google Scholar

Google Scholar

[4] Zhang Z C, Wang Y H, Song Q, Liu C, Peng R, Moler K A, Feng D L, Wang Y Y 2015 Sci. Bull. 60 1301

Google Scholar

Google Scholar

[5] Huang B, Clark G, Navarro-Moratalla E, Klein D R, Cheng R, Seyler K L, Zhong D, Schmidgall E, McGuire M A, Cobden D H, Yao W, Xiao D, Jarillo-Herrero P, Xu X 2017 Nature 546 270

Google Scholar

Google Scholar

[6] Deng Y, Yu Y, Song Y, Zhang J, Wang N Z, Sun Z, Yi Y, Wu Y Z, Wu S, Zhu J, Wang J, Chen X H, Zhang Y 2018 Nature 563 94

Google Scholar

Google Scholar

[7] Kamysbayev V, Filatov A S, Hu H, Rui X, Lagunas F, Wang D, Klie R F, Talapin D V 2020 Science 369 979

Google Scholar

Google Scholar

[8] Mak K F, Lee C, Hone J, Shan J, Heinz T F 2010 Phys. Rev. Lett. 105 136805

Google Scholar

Google Scholar

[9] Liu H, Neal A T, Zhu Z, Luo Z, Xu X, Tomanek D, Ye P D 2014 ACS Nano 8 4033

Google Scholar

Google Scholar

[10] Lu X, Stepanov P, Yang W, Xie M, Aamir M A, Das I, Urgell C, Watanabe K, Taniguchi T, Zhang G, Bachtold A, MacDonald A H, Efetov D K 2019 Nature 574 653

Google Scholar

Google Scholar

[11] Wang N Z, Shi M Z, Shang C, Meng F B, Ma L K, Luo X G, Chen X H 2018 New J. Phys. 20 023014

Google Scholar

Google Scholar

[12] Shi M Z, Wang N Z, Lei B, Ying J J, Zhu C S, Sun Z L, Cui J H, Meng F B, Hang C S, Ma L K, Chen X H 2018 New J. Phys. 20 123007

Google Scholar

Google Scholar

[13] Kang B L, Shi M Z, Li S J, Wang H H, Zhang Q, Zhao D, Li J, Song D W, Zheng L X, Nie L P, Wu T, Chen X H 2020 Phys. Rev. Lett. 125 097003

Google Scholar

Google Scholar

[14] Zhao Y C, Su Y Q, Guo Y Q, Peng J, Zhao J Y, Wang C Y, Wang L J, Wu C Z, Xie Y 2021 ACS Mater. Lett. 3 210

Google Scholar

Google Scholar

[15] Zhu R L, Zhu L Z, Zhu J X, Xu L H 2008 Appl. Clay Sci. 42 224

Google Scholar

Google Scholar

[16] Ganter P, Schoop L M, Lotsch B V 2017 Adv. Mater. 29 1604884

Google Scholar

Google Scholar

[17] Gamble F R, Osiecki J H, Cais M, Pisharody R, Disalvo F J, Geballe T H 1971 Science 174 493

Google Scholar

Google Scholar

[18] Li Z, Zhao Y, Mu K, Shan H, Guo Y, Wu J, Su Y, Wu Q, Sun Z, Zhao A, Cui X, Wu C, Xie Y 2017 J. Am. Chem. Soc. 139 16398

Google Scholar

Google Scholar

[19] Gao Z, Zeng S Y, Zhu B C, Li B A, Hao Q Y, Hu Y W, Wang D K, Tang K B 2018 Sci. Chin. -Mater. 61 977

Google Scholar

Google Scholar

[20] Bartlett N, McQuillan B W (Whittingham M S, Jacobson A J, Eds) 1982 Intercalation Chemistry (New York: Academic Press) pp19–53

[21] Yoo H D, Liang Y L, Dong H, Lin J H, Wang H, Liu Y S, Ma L, Wu T P, Li Y F, Ru Q, Jing Y, An Q Y, Zhou W, Guo J H, Lu J, Pantelides S T, Qian X F, Yao Y 2017 Nat. Commun. 8 339

Google Scholar

Google Scholar

[22] Rendenbach B, Hohl T, Harm S, Hoch C, Johrendt D 2021 J. Am. Chem. Soc. 143 3043

Google Scholar

Google Scholar

[23] Wan C, Gu X, Dang F, Itoh T, Wang Y, Sasaki H, Kondo M, Koga K, Yabuki K, Snyder G J, Yang R, Koumoto K 2015 Nat. Mater. 14 622

Google Scholar

Google Scholar

[24] Jin S F, Fan X, Wu X Z, Sun R J, Wu H, Huang Q Z, Shi C L, Xi X K, Li Z L, Chen X L 2017 Chem. Commun. 53 9729

Google Scholar

Google Scholar

[25] Wang N, Tang H, Shi M, Zhang H, Zhuo W, Liu D, Meng F, Ma L, Ying J, Zou L, Sun Z, Chen X 2019 J. Am. Chem. Soc. 141 17166

Google Scholar

Google Scholar

[26] Ma L K, Shi M Z, Kang B L, Peng K L, Meng F B, Zhu C S, Cui J H, Sun Z L, Wang H H, Lei B, Wu T, Chen X H 2020 Phys. Rev. Mater. 4 124803

Google Scholar

Google Scholar

[27] Meng F B, Liu Z, Yang L X, Shi M Z, Ge B H, Zhang H, Ying J J, Wang Z F, Wang Z Y, Wu T, Chen X H 2020 Phys. Rev. B 102 165410

Google Scholar

Google Scholar

[28] Gong C, Li L, Li Z, Ji H, Stern A, Xia Y, Cao T, Bao W, Wang C, Wang Y, Qiu Z Q, Cava R J, Louie S G, Xia J, Zhang X 2017 Nature 546 265

Google Scholar

Google Scholar

[29] Wang Q Y, Li Z, Zhang W H, Zhang Z C, Zhang J S, Li W, Ding H, Ou Y B, Deng P, Chang K, Wen J, Song C L, He K, Jia J F, Ji S H, Wang Y Y, Wang L L, Chen X, Ma X C, Xue Q K 2012 Chin. Phys. Lett. 29 037402

Google Scholar

Google Scholar

[30] Hu G B, Shi M Z, Wang W X, Zhu C S, Luo X G, Chen X H 2022 New J. Phys. 24 043035

Google Scholar

Google Scholar

计量

- 文章访问数: 12273

- PDF下载量: 479

- 被引次数: 0

下载:

下载: