-

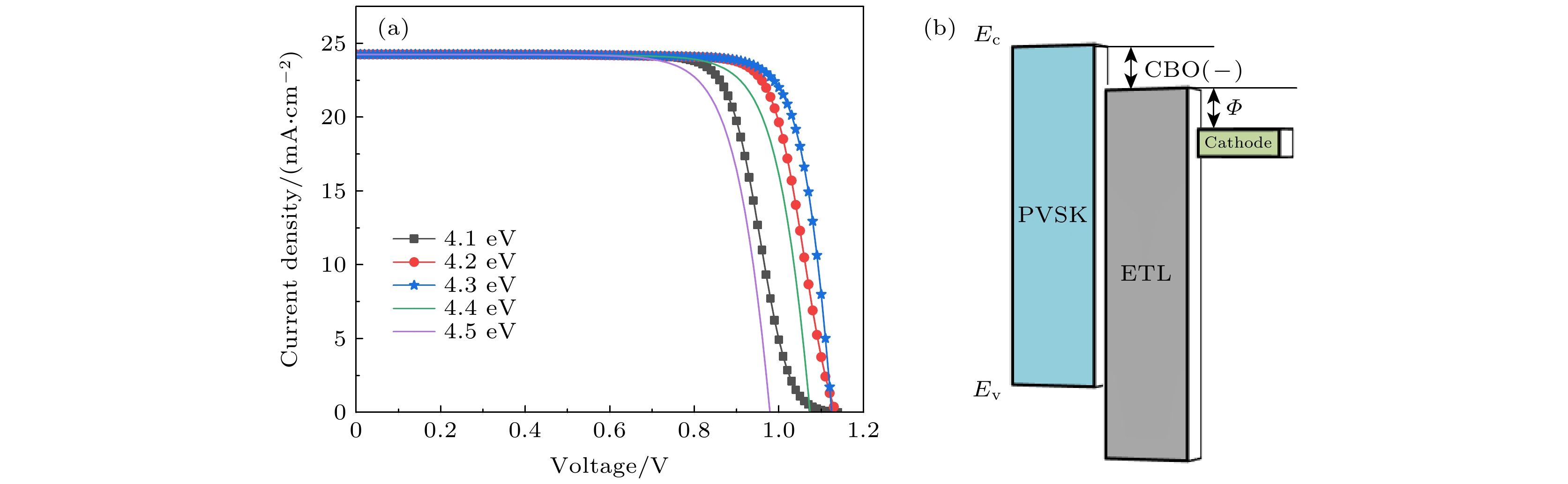

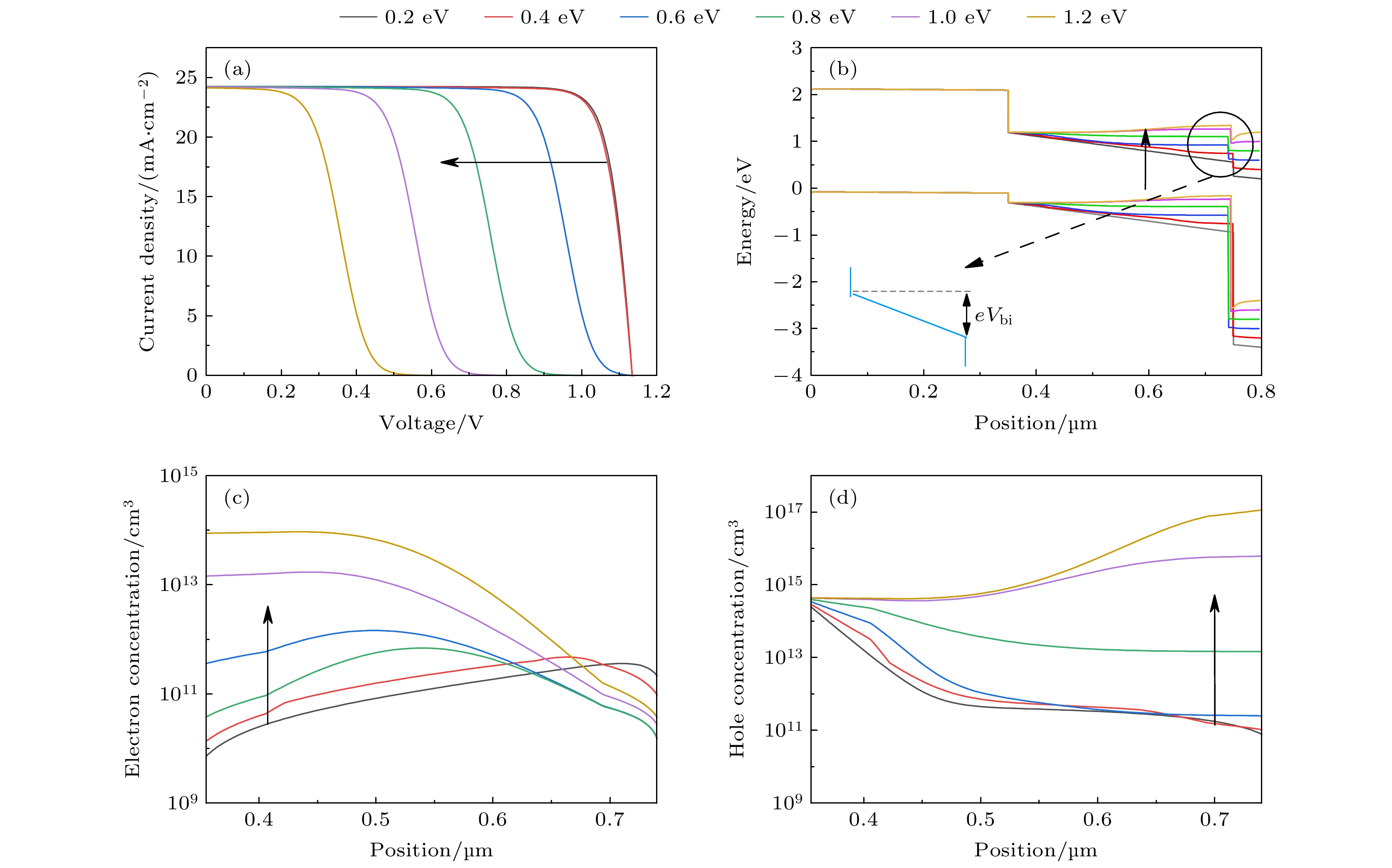

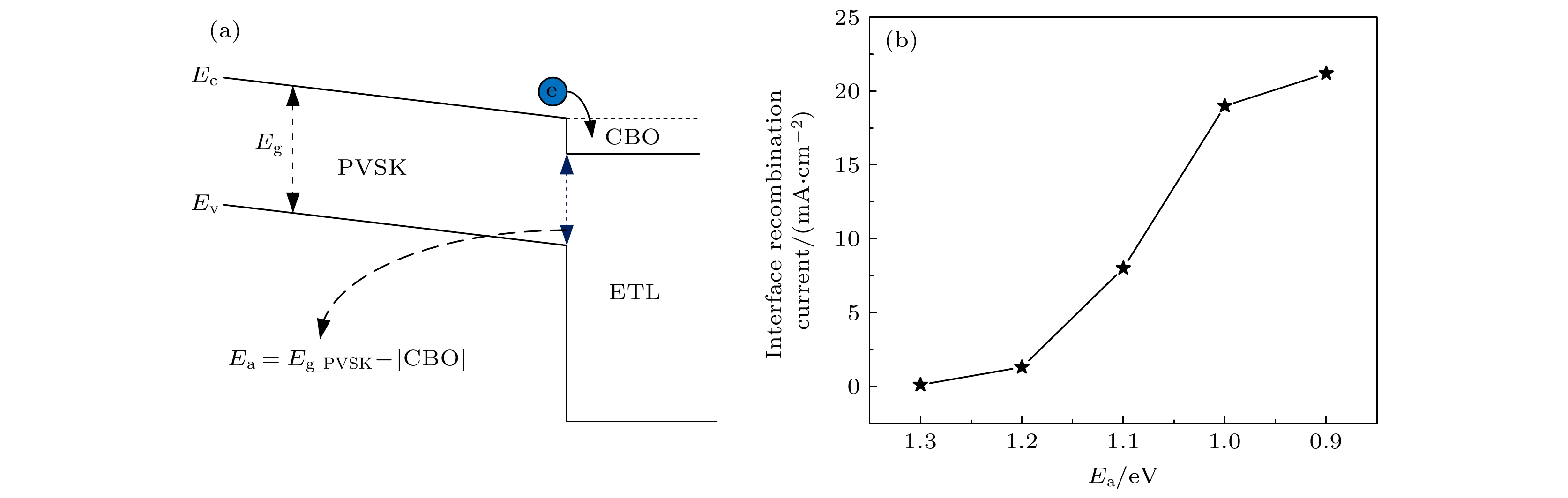

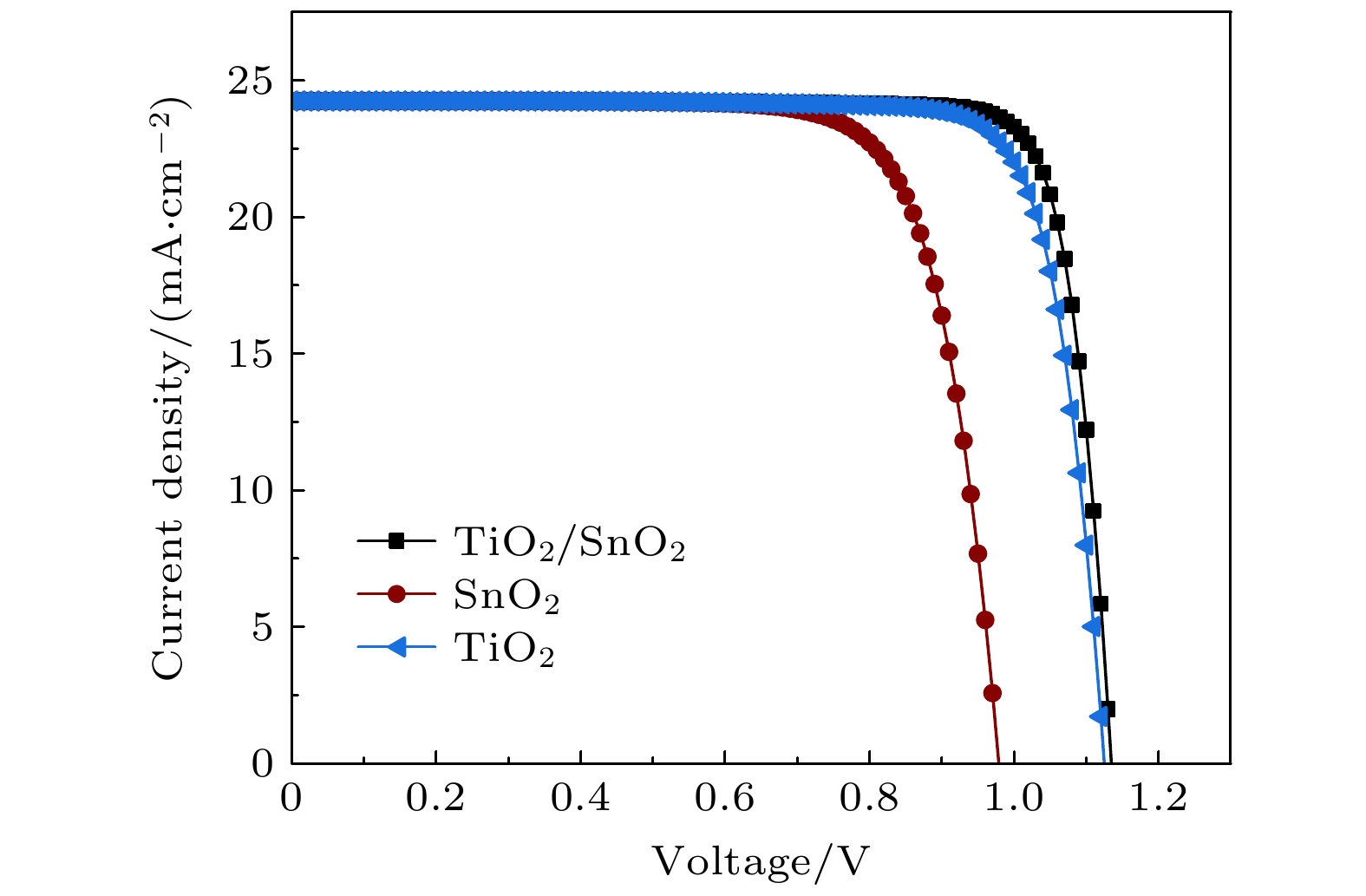

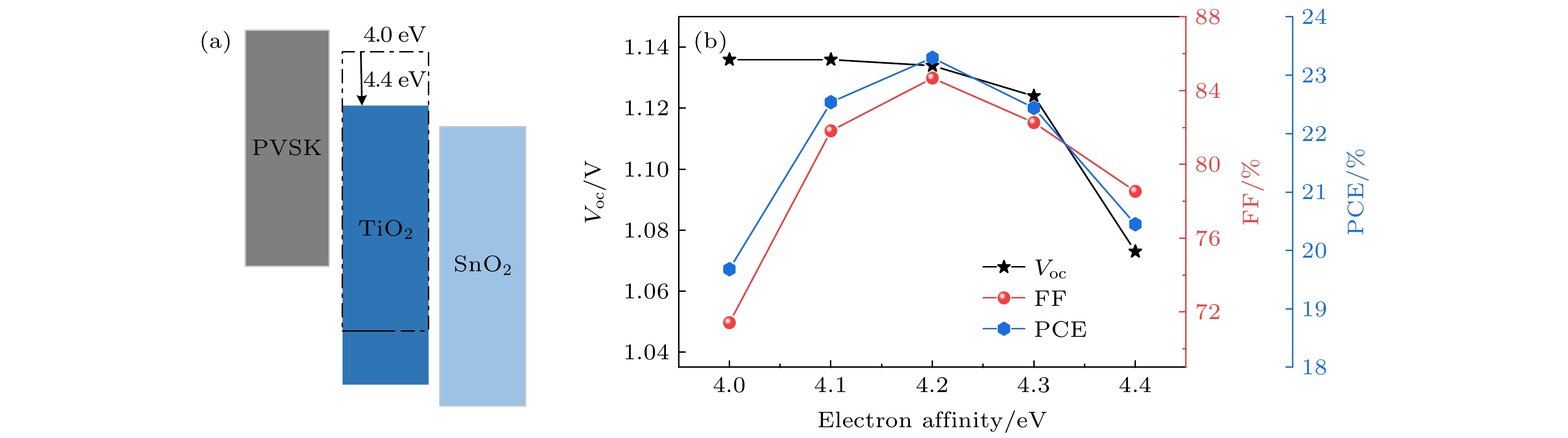

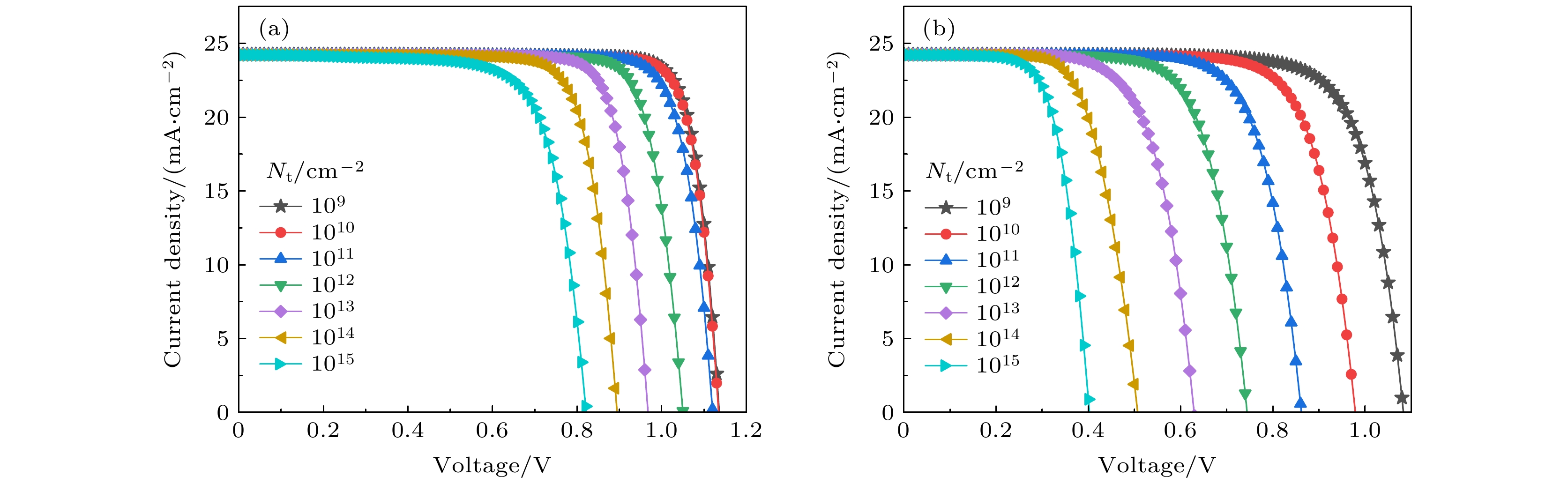

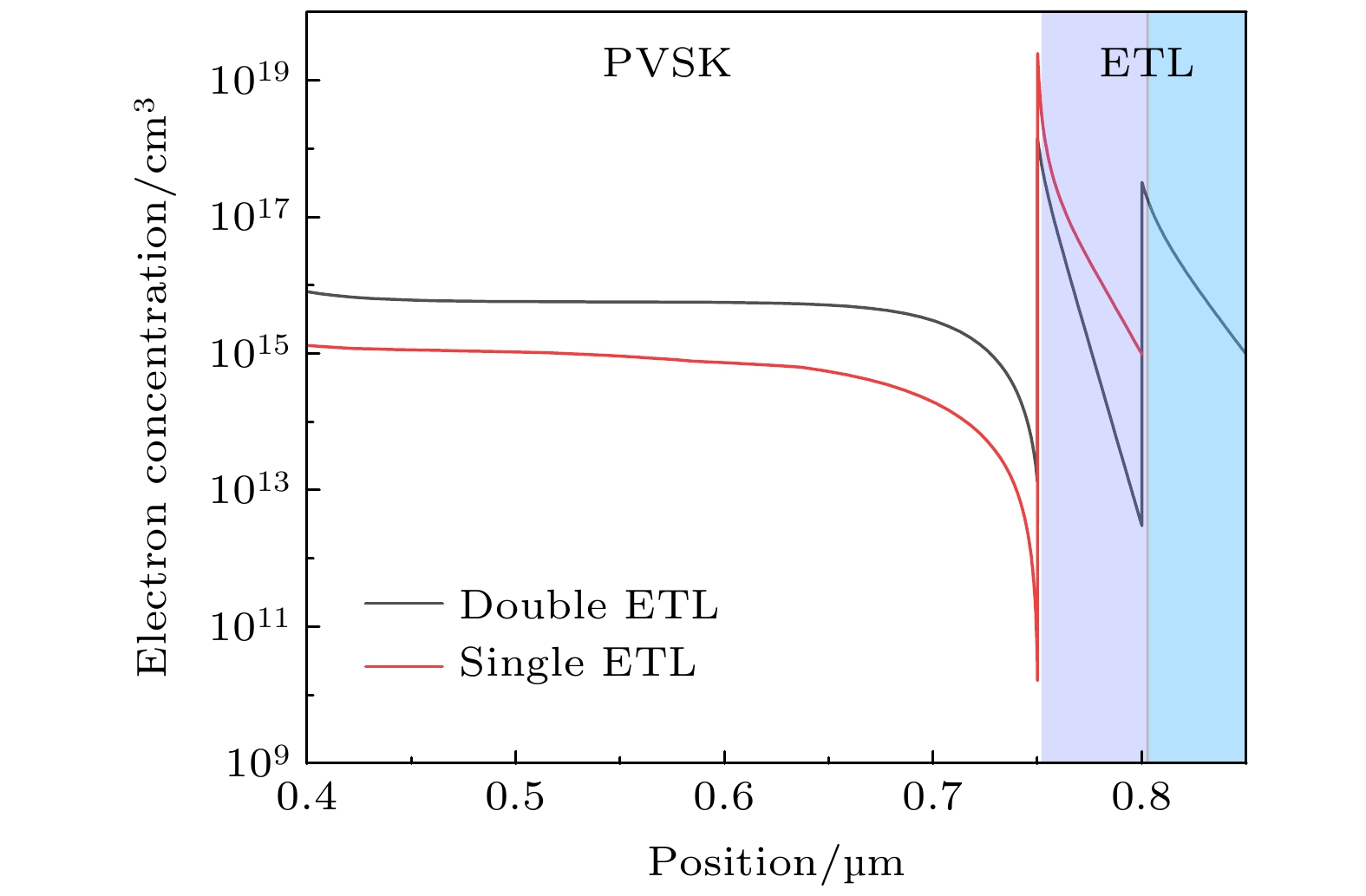

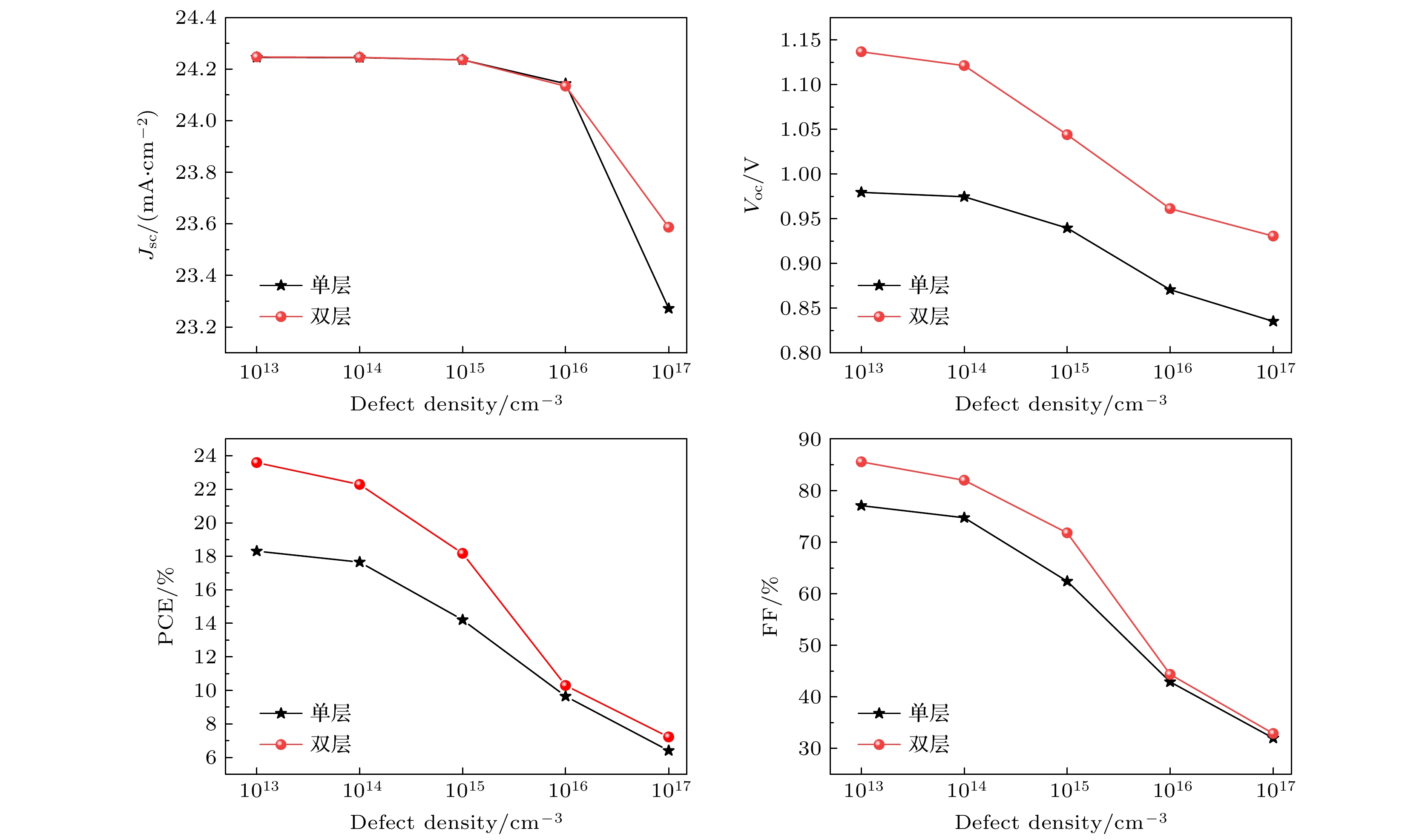

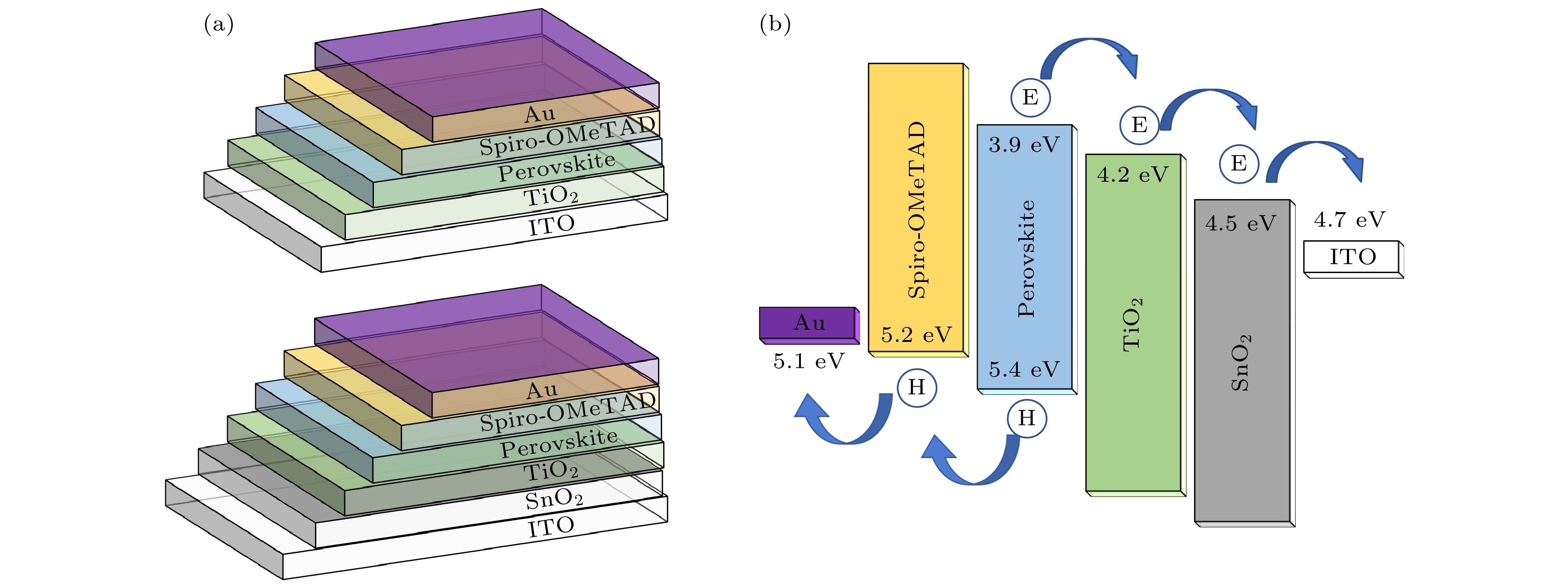

近年来基于钙钛矿材料的太阳能电池以其优异的光电转换效率, 成为了最具有发展潜力的光伏器件. 受制于制备工艺及界面传输层的材料, 钙钛矿太阳能电池存在体内、界面缺陷和能级错位等问题, 导致非辐射复合损耗增加, 妨碍其效率进一步提升及工作稳定性. 因此, 降低能级错位及界面缺陷态等损耗对于实现高效钙钛矿太阳能电池至关重要. 本文研究了钙钛矿太阳能电池中双层电子传输层及其阶梯状导带结构对器件性能的影响, 揭示了活性层与传输层之间的导带偏移量对两者之间界面复合及性能提升的机理. 另外, 研究了体内与界面缺陷态密度对单层及双层电子传输层结构下电池性能的影响, 发现在高缺陷态密度下, 双层结构比单层结构具有更高的效率. 研究表明双层电子传输层结构不仅能改善界面能级错位损耗, 还可以降低电池性能受体内及界面缺陷影响, 对制备高性能太阳能电池具有指导意义.With their excellent photoelectric properties, perovskite solar cells have become the most promising photovoltaic devices in recent years. However, owing to defects and energy level misalignment, the non-radiative recombination loss of the perovskite solar cell will increase, which hinders the its efficiency and operational stability from being improved further. Therefore, it is very important to reduce the loss caused by energy level misalignment for realizing high-efficiency perovskite solar cells. In order to solve the above-mentioned problems, perovskite solar cell with dual electron transport layer (ETL) is studied in this work. The dual-layer structure forms a stepped conduction band structure to reduce the conduction band offset between the active layer and the transport layer, which reduces the interface recombination between the two structures and improves device performance. In addition, the influences of the defect density on the cell performance for the two ETL structures are also discussed. With the continuous increase of the defect density, the performance of the single-layer structure decreases more obviously. While the dual ETL structure can alleviate the performance dependence on the defect density in comparison with the single ETL structure. Therefore, the use of dual ETL can improve the performance of perovskite solar cells and defect tolerance, which provides guidance for designing high-performance solar cells.

-

Keywords:

- perovskite solar cell /

- double electron transport layer /

- interface recombination /

- defect density

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Akkerman Q A, Raino G, Kovalenko M V, Manna L 2018 Nat. Mater 17 394

Google Scholar

Google Scholar

[3] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J P, Leijtens T, Herz L M, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[4] Mazzarella L, Lin Y H, Kirner S, et al. 2019 Adv. Energy Mater. 9 14

Google Scholar

Google Scholar

[5] Kim M, Jeong J, Lu H Z, et al. 2022 Science 375 302

Google Scholar

Google Scholar

[6] Jena A K, Kulkarni A, Miyasaka T 2019 Chem. Rev. 119 3036

Google Scholar

Google Scholar

[7] Kim J Y, Lee J W, Jung H S, Shin H, Park N G 2020 Chem. Rev. 120 7867

Google Scholar

Google Scholar

[8] Ma S, Cai M L, Cheng T, Ding X H, Shi X Q, Alsaedi A, Hayat T, Ding Y, Tan Z, Dai S Y 2018 Sci. China Mater. 61 1257

Google Scholar

Google Scholar

[9] Shi P, Ding Y, Liu C, Yang Y, Arain Z, Cai M, Ren Y, Hayat T, Alsaedi A, Dai S 2019 Sci. China Mater. 62 1846

Google Scholar

Google Scholar

[10] Shi X Q, Chen J Q, Wu Y H, Cai M L, Shi P J, Ma S, Liu C, Liu X P, Dai S Y 2020 ACS Sustain. Chem. Eng. 8 4267

Google Scholar

Google Scholar

[11] Bi D Q, Yi C Y, Luo J S, Decoppet J D, Zhang F, Zakeeruddin S M, Li X, Hagfeldt A, Gratzel M 2016 Nat. Energy 1 16142

Google Scholar

Google Scholar

[12] Shubham, Raghvendra, Pathak C, Pandey S K 2020 IEEE Trans. Electro. Dev. 67 2837

Google Scholar

Google Scholar

[13] Son D Y, Lee J W, Choi Y J, Jang I H, Lee S, Yoo P J, Shin H, Ahn N, Choi M, Kim D, Park N G 2016 Nat. Energy 1 16081

Google Scholar

Google Scholar

[14] Zheng X P, Chen B, Dai J, Fang Y J, Bai Y, Lin Y Z, Wei H T, Zeng X C, Huang J S 2017 Nat. Energy 2 17102

Google Scholar

Google Scholar

[15] Kim G W, Kang G, Kim J, Lee G Y, Kim H I, Pyeon L, Lee J, Park T 2016 Energ. Environ. Sci. 9 2326

Google Scholar

Google Scholar

[16] Liu M Z, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[17] 甘永进, 蒋曲博, 覃斌毅, 毕雪光, 李清流 2021 70 038801

Google Scholar

Google Scholar

Gan Y J, Jiang Q B, Qin B Y, Bi X G, Li Q L 2021 Acta Phys. Sin. 70 038801

Google Scholar

Google Scholar

[18] Gao Y, Wu Y, Liu Y, Chen C, Shen X, Bai X, Shi Z, Yu W W, Dai Q, Zhang Y 2019 Solar RRL 3 1900314

Google Scholar

Google Scholar

[19] Li N, Yan J, Ai Y, Jiang E, Lin L, Shou C, Yan B, Sheng J, Ye J 2019 Sci. China Mater. 63 207

Google Scholar

Google Scholar

[20] Shi X, Tao Y, Li Z, Peng H, Cai M, Liu X, Zhang Z, Dai S 2021 Sci. China Mater. 64 1858

Google Scholar

Google Scholar

[21] 丁雄傑, 倪露, 马圣博, 马英壮, 肖立新, 陈志坚 2015 64 038802

Google Scholar

Google Scholar

Ding X J, Ni L, Ma S B, Ma Y Z, Xiao L X, Chen Z J 2015 Acta Phys. Sin. 64 038802

Google Scholar

Google Scholar

[22] Wang D, Wu C, Luo W, Guo X, Qu B, Xiao L, Chen Z 2018 Acs Appl. Energ. Mater. 1 2215

Google Scholar

Google Scholar

[23] Wang Y, Duan C, Zhang X, Rujisamphan N, Liu Y, Li Y, Yuan J, Ma W 2020 ACS Appl. Mater. Inter. 12 31659

Google Scholar

Google Scholar

[24] Ren X, Wang Z, Sha W E I, Choy W C H 2017 ACS Photonics 4 934

Google Scholar

Google Scholar

[25] Singh N, Agarwal A, Agarwal M 2021 Superlattice. Microst 149 106750

Google Scholar

Google Scholar

[26] Azri F, Meftah A, Sengouga N, Meftah A 2019 Solar Energy 181 372

Google Scholar

Google Scholar

[27] Ahmed S, Jannat F, Khan M A K, Alim M A 2021 Optik 225 165765

Google Scholar

Google Scholar

[28] Tan K, Lin P, Wang G, Liu Y, Xu Z C, Lin Y X 2016 Solid State Electron 126 75

Google Scholar

Google Scholar

[29] Zhao P, Lin Z H, Wang J P, Yue M, Su J, Zhang J C, Chang J J, Hao Y 2019 ACS Appl. Energy Mater. 2 4504

Google Scholar

Google Scholar

-

表 1 仿真结构中材料参数

Table 1. Simulation structure parameters.

Layer properties Spiro-OMeTAD CH3NH3PbI3 SnO2 TiO2 厚度 L/nm 350[25] 400[26] 50[27] 50[27] 电子亲和能 χ/eV 3.0[25] 3.9[26] 4.5[23] 4.2[23] 介电常数 εr 3.0[25] 6.5[26] 9.0[27] 9.0[27] 禁带宽度 Eg/eV 2.2[25] 1.5[26] 4.0[23] 3.6[23] 受主掺杂浓度 NA/cm–3 1.0 × 1018[25] 5.21 × 109[26] 0[27] 0[27] 施主掺杂浓度 ND/cm–3 0[25] 5.21 × 109[26] 1.0 × 1018[27] 1.0 × 1018[27] 电子迁移率 μn/(cm2·V–1·s–1) 2.0 × 10–4[25] 20[26] 20[27] 20[27] 空穴迁移率 μp/(cm2·V–1·s–1) 2.0 × 10–4[25] 20[26] 10[27] 10[27] 缺陷态密度 Nt/cm–3 1.0 × 1013[25] 2.5 × 1013[26] 1.0 × 1015[27] 1.0 × 1015[27] 导带有效密度 Nc/cm–3 2.2 × 1018[25] 2.2 × 1018[26] 2.2 × 1018[28] 2.2 × 1018[28] 价带有效密度 Nv/cm–3 1.8 × 1019[25] 1.8 × 1019[26] 1.8 × 1019[28] 1.8 × 1019[28] -

[1] Kojima A, Teshima K, Shirai Y, Miyasaka T 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[2] Akkerman Q A, Raino G, Kovalenko M V, Manna L 2018 Nat. Mater 17 394

Google Scholar

Google Scholar

[3] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J P, Leijtens T, Herz L M, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[4] Mazzarella L, Lin Y H, Kirner S, et al. 2019 Adv. Energy Mater. 9 14

Google Scholar

Google Scholar

[5] Kim M, Jeong J, Lu H Z, et al. 2022 Science 375 302

Google Scholar

Google Scholar

[6] Jena A K, Kulkarni A, Miyasaka T 2019 Chem. Rev. 119 3036

Google Scholar

Google Scholar

[7] Kim J Y, Lee J W, Jung H S, Shin H, Park N G 2020 Chem. Rev. 120 7867

Google Scholar

Google Scholar

[8] Ma S, Cai M L, Cheng T, Ding X H, Shi X Q, Alsaedi A, Hayat T, Ding Y, Tan Z, Dai S Y 2018 Sci. China Mater. 61 1257

Google Scholar

Google Scholar

[9] Shi P, Ding Y, Liu C, Yang Y, Arain Z, Cai M, Ren Y, Hayat T, Alsaedi A, Dai S 2019 Sci. China Mater. 62 1846

Google Scholar

Google Scholar

[10] Shi X Q, Chen J Q, Wu Y H, Cai M L, Shi P J, Ma S, Liu C, Liu X P, Dai S Y 2020 ACS Sustain. Chem. Eng. 8 4267

Google Scholar

Google Scholar

[11] Bi D Q, Yi C Y, Luo J S, Decoppet J D, Zhang F, Zakeeruddin S M, Li X, Hagfeldt A, Gratzel M 2016 Nat. Energy 1 16142

Google Scholar

Google Scholar

[12] Shubham, Raghvendra, Pathak C, Pandey S K 2020 IEEE Trans. Electro. Dev. 67 2837

Google Scholar

Google Scholar

[13] Son D Y, Lee J W, Choi Y J, Jang I H, Lee S, Yoo P J, Shin H, Ahn N, Choi M, Kim D, Park N G 2016 Nat. Energy 1 16081

Google Scholar

Google Scholar

[14] Zheng X P, Chen B, Dai J, Fang Y J, Bai Y, Lin Y Z, Wei H T, Zeng X C, Huang J S 2017 Nat. Energy 2 17102

Google Scholar

Google Scholar

[15] Kim G W, Kang G, Kim J, Lee G Y, Kim H I, Pyeon L, Lee J, Park T 2016 Energ. Environ. Sci. 9 2326

Google Scholar

Google Scholar

[16] Liu M Z, Johnston M B, Snaith H J 2013 Nature 501 395

Google Scholar

Google Scholar

[17] 甘永进, 蒋曲博, 覃斌毅, 毕雪光, 李清流 2021 70 038801

Google Scholar

Google Scholar

Gan Y J, Jiang Q B, Qin B Y, Bi X G, Li Q L 2021 Acta Phys. Sin. 70 038801

Google Scholar

Google Scholar

[18] Gao Y, Wu Y, Liu Y, Chen C, Shen X, Bai X, Shi Z, Yu W W, Dai Q, Zhang Y 2019 Solar RRL 3 1900314

Google Scholar

Google Scholar

[19] Li N, Yan J, Ai Y, Jiang E, Lin L, Shou C, Yan B, Sheng J, Ye J 2019 Sci. China Mater. 63 207

Google Scholar

Google Scholar

[20] Shi X, Tao Y, Li Z, Peng H, Cai M, Liu X, Zhang Z, Dai S 2021 Sci. China Mater. 64 1858

Google Scholar

Google Scholar

[21] 丁雄傑, 倪露, 马圣博, 马英壮, 肖立新, 陈志坚 2015 64 038802

Google Scholar

Google Scholar

Ding X J, Ni L, Ma S B, Ma Y Z, Xiao L X, Chen Z J 2015 Acta Phys. Sin. 64 038802

Google Scholar

Google Scholar

[22] Wang D, Wu C, Luo W, Guo X, Qu B, Xiao L, Chen Z 2018 Acs Appl. Energ. Mater. 1 2215

Google Scholar

Google Scholar

[23] Wang Y, Duan C, Zhang X, Rujisamphan N, Liu Y, Li Y, Yuan J, Ma W 2020 ACS Appl. Mater. Inter. 12 31659

Google Scholar

Google Scholar

[24] Ren X, Wang Z, Sha W E I, Choy W C H 2017 ACS Photonics 4 934

Google Scholar

Google Scholar

[25] Singh N, Agarwal A, Agarwal M 2021 Superlattice. Microst 149 106750

Google Scholar

Google Scholar

[26] Azri F, Meftah A, Sengouga N, Meftah A 2019 Solar Energy 181 372

Google Scholar

Google Scholar

[27] Ahmed S, Jannat F, Khan M A K, Alim M A 2021 Optik 225 165765

Google Scholar

Google Scholar

[28] Tan K, Lin P, Wang G, Liu Y, Xu Z C, Lin Y X 2016 Solid State Electron 126 75

Google Scholar

Google Scholar

[29] Zhao P, Lin Z H, Wang J P, Yue M, Su J, Zhang J C, Chang J J, Hao Y 2019 ACS Appl. Energy Mater. 2 4504

Google Scholar

Google Scholar

计量

- 文章访问数: 8752

- PDF下载量: 229

- 被引次数: 0

下载:

下载: