-

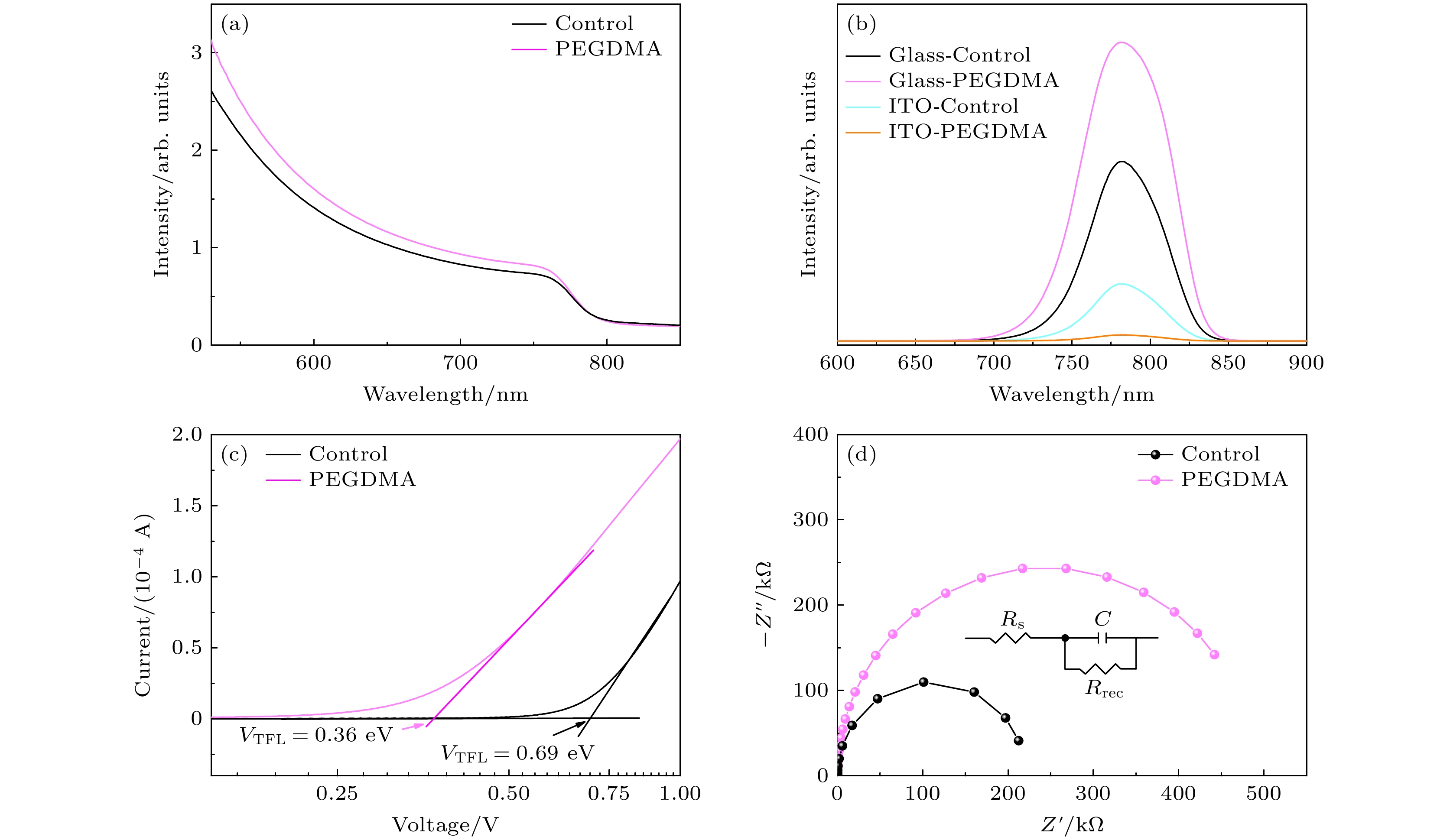

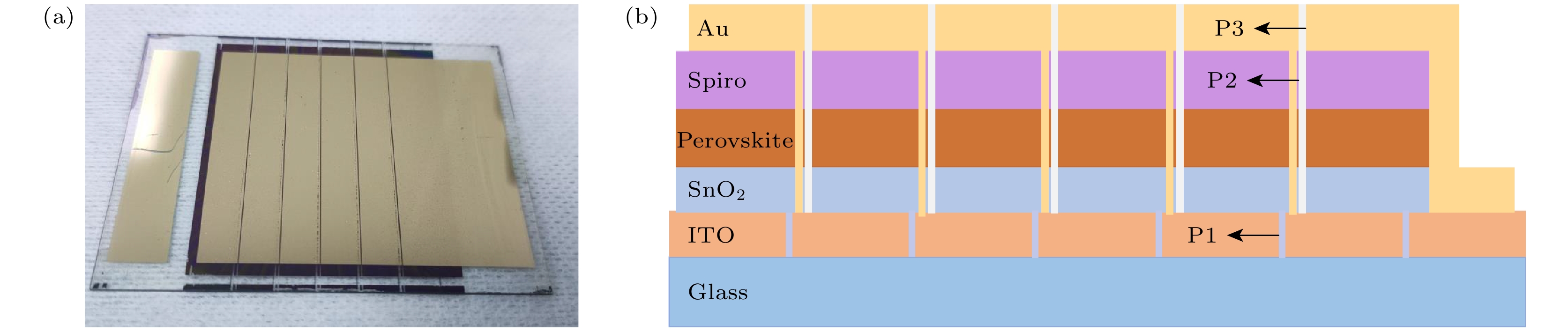

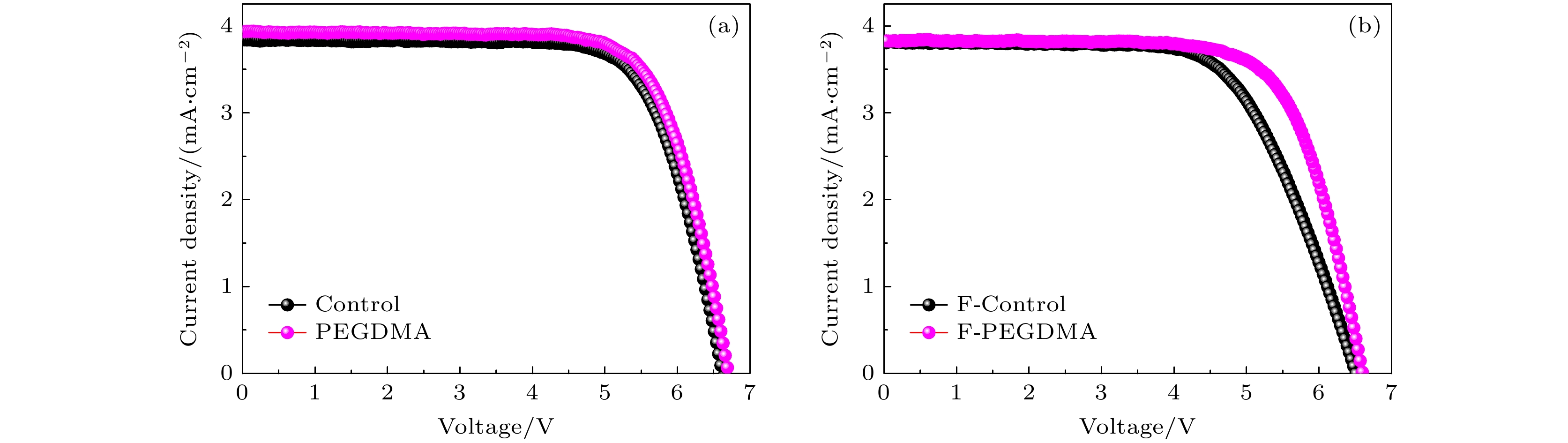

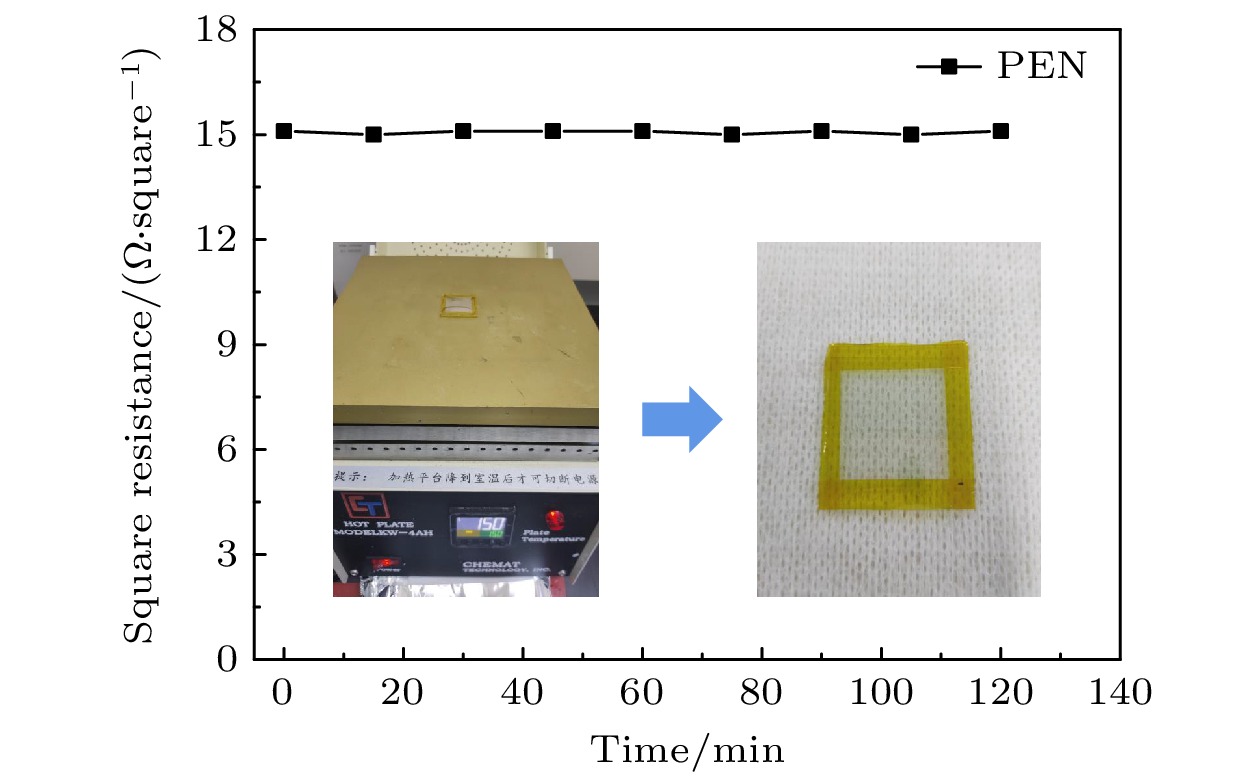

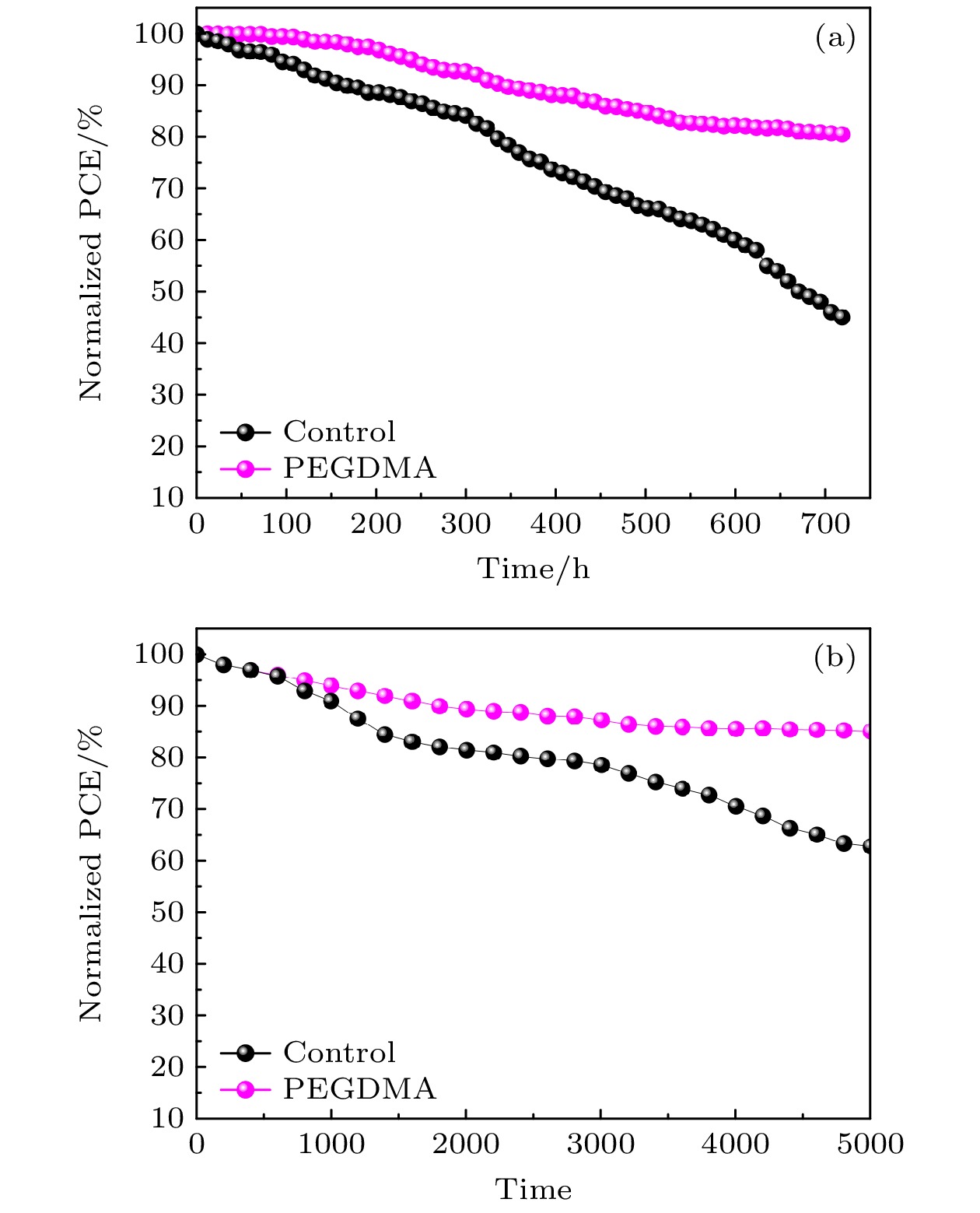

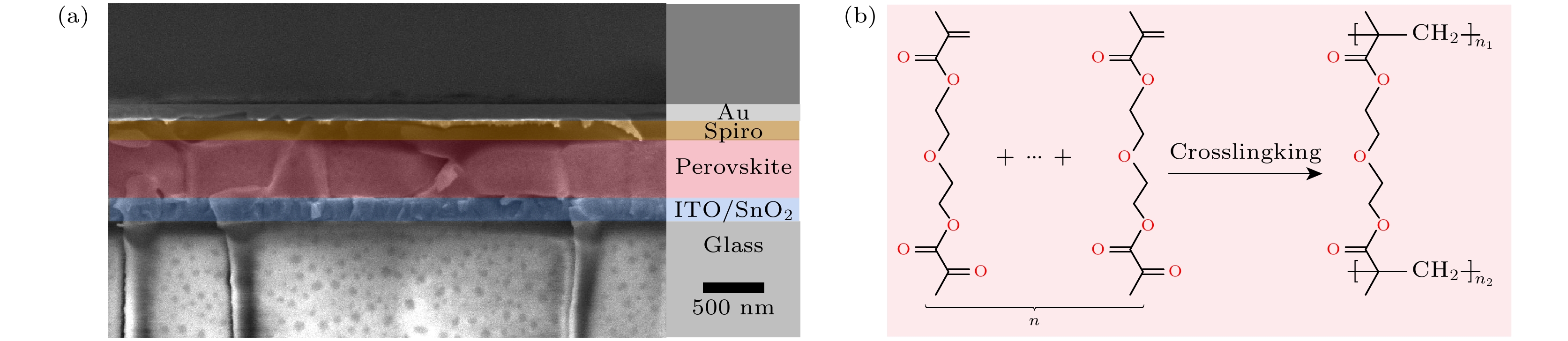

传统的高效率钙钛矿太阳能电池, 需要在具有氮气保护的严苛条件下方可实现. 高湿度(55%)空气环境中, 大面积钙钛矿成膜工艺开发及器件结构优化对模组器件效率和稳定性的提高至关重要. 本工作采用一种真空抽气萃取方法在空气中实现了高质量钙钛矿薄膜的制备, 并研究了双端可低温光聚合单体分子对钙钛矿薄膜内封装的可行性. 研究发现, 当抽气时间为60 s, 在空气中可以形成均匀、致密的钙钛矿薄膜. 通过调控单体分子浓度, 能够在内封装的同时, 实现对钙钛矿表面缺陷的钝化, 当浓度为1 mg/mL时, 对应钙钛矿薄膜的形貌及荧光强度达到最优. 最终, 基于聚合物内封装修饰的刚性和柔性模组(有效面积: 18 cm2)器件分别实现了19.51%和18.17%的室外光电转化效率(34.5%和30.2%的室内弱光转化效率). 此外, 聚合物内封装提升器件湿度稳定性及抑制铅泄漏的同时, 也显著提升了柔性模组的耐弯折稳定性. 聚合物内封装技术为未来大面积模组器件的发展及进一步产业应用提供了新的方向和可能.The preparation of traditional organic-inorganic lead-halogen hybrid perovskite solar cells often requires strict nitrogen glove box conditions, thus hindering their industrial scalability. This study develops a large-area perovskite film formation process and designs a novel device structure to achieve a dual enhancement of module device efficiency and stability in a high humidity air environment (55%). High-quality perovskite thin films are successfully prepared by vacuum extraction in ambient air, followed by a double-end low-temperature photopolymerization process utilizing acrylate monomer molecules for inner encapsulation modification of the freshly formed perovskite thin films. The influences of these techniques on the photoelectric characteristics of perovskite thin films and devices are investigated. The results indicate that uniform and dense perovskite films can be achieved in ambient air with a pumping time of 60 s. By adjusting the concentration of ethylene glycol dimethacrylate monomer molecules used in the low-temperature photopolymerization process, the surface defects on the perovskite film can be effectively controlled. The optimal concentration of 1 mg/mL results in perovskite film with optimal morphology and fluorescence intensity. Furthermore, rigid module device and flexible module device (effective area: 18 cm²), based on the polymer inner encapsulation, demonstrate outstanding outdoor photoelectric conversion efficiencies of 19.51% and 18.17%, respectively (with the highest indoor low-light conversion efficiencies of 34.5% and 30.2%, respectively). Notably, the untreated flexible device exhibits a significant decline in photoelectric conversion efficiency, falling below 50% of the initial value after one month of exposure to air. In contrast, device incorporating the polymer inner encapsulation layer maintains over 90% of their original efficiency, highlighting their excellent humidity resistance stability. Moreover, the polymer encapsulation layer also greatly improves the bending stability of the flexible device. This research paves the way for industrial-scale producing perovskite solar cells and addressing the challenges associated with humidity and large-area fabrication. The findings contribute to advancing perovskite solar cell technology and offering a pathway for high-efficiency and stable devices suitable for practical applications.

-

Keywords:

- perovskite solar cell /

- module /

- low temperature photopolymerization /

- polymer internal encapsulation

[1] Brenner T M, Egger D A, Kronik L, Hodes G, Cahen D 2016 Nat. Rev. Mater. 1 15007

Google Scholar

Google Scholar

[2] Wolf S D, Holovsky J, Moon S J, Löper P, Niesen B, Ledinsky M, Haug F J, Yum J H, Ballif C 2014 J. Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[3] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J P, Leijtens T, Herz L, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[4] Xing G C, Mathews N, Sun S Y, Lim S S, Lam Y M, Grätzel M, Mhaisalkar S, Sum T C 2013 Science 342 344

Google Scholar

Google Scholar

[5] Leijtens T, Lim J, Teuscher J, Park T, Snaith H 2013 Adv. Mater. 25 3227

Google Scholar

Google Scholar

[6] https://www.nrel.gov/pv/interactive-cell-efficiency.html

[7] Ding Y, Ding B, Kanda H, Usiobo O J, Gallet T, Yang Z H, Liu Y, Huang H, Sheng J, Liu C, Yang Y, Queloz V I E, Zhang X F, Audinot J N, Redinger A, Dang W, Mosconic E, Luo W, Angelis F D, Wang M K, Dörflinger P, Armer M, Schmid V, Wang R, Brooks K G, Wu J H, Dyakonov V, Yang G J, Dai S Y, Dyson P J, Nazeeruddin M K 2022 Nat. Nanotechnol. 17 598

Google Scholar

Google Scholar

[8] Rana P J S, Febriansyah B, Koh T M, Muhammad B T, Salim T, Hooper T J N, Kanwat A, Ghosh B, Kajal P, Lew J H, Aw Y C, Yantara N, Bruno A, Pullarkat S A, Ager J W, Leong W L, Mhaisalkar S G, Mathews N 2022 Adv. Funct. Mater. 32 2113026

Google Scholar

Google Scholar

[9] Wang Y, Yang H, Zhang K, Tao M Q, Li M Z, Song Y L 2022 ACS Energy Lett. 7 3646

Google Scholar

Google Scholar

[10] Zhang K, Wang Y, Tao M Q, Guo L T, Yang Y R, Shao J Y, Zhang Y Y, Wang F Y, Song Y L 2023 Adv. Mater. 35 2211593

Google Scholar

Google Scholar

[11] Brooks K G, Nazeeruddin M K 2021 Adv. Energy Mater. 11 2101149

Google Scholar

Google Scholar

[12] Castriotta L A, Zendehdel M, Nia N Y, Leonardi E, Löfffer M, Paci B, Generosi A, Rellinghaus B, Carlo A D 2022 Adv. Energy Mater. 12 2103420

Google Scholar

Google Scholar

[13] Babayigit A, Haen J D, Boyen H G, Conings B 2018 Joule 2 1205

Google Scholar

Google Scholar

[14] Konstantakou M, Perganti D, Falaras P, Stergiopoulos T 2017 Crystals 7 291

Google Scholar

Google Scholar

[15] Gu L, Wang S, Fang X, Liu D, Xu Y, Yuan N, Ding J 2020 ACS Appl. Mater. Interfaces 12 33870

Google Scholar

Google Scholar

[16] Jang G, Kwon H C, Ma S, Yun S C, Yang H, Moon J 2019 Adv. Energy Mater. 9 1901719

Google Scholar

Google Scholar

[17] Gu L L, Fei F, Xu Y B, Wang S B, Yuan N Y, Ding J N 2022 ACS Appl. Mater. Interfaces 14 2949

Google Scholar

Google Scholar

[18] Li H Y, Bu T L, Li J, Lin Z P, Pan J Y, Li Q H, Zhang X L, Ku Z L, Cheng Y B, Huang F Z 2021 ACS Appl. Mater. Interfaces 13 18724

Google Scholar

Google Scholar

[19] Vesce L, Stefanelli M, Herterich J P, Castriotta L A, Kohlstädt M, Würfel U, Carlo A D 2021 Solar RRL 5 2100073

Google Scholar

Google Scholar

[20] Xu J, Dong H, Xi J, Yang Y, Yu Y, Ma L, Chen J B, Jiao B, Hou X, Li J R, Wu Z X 2020 Nano Energy 75 104940

Google Scholar

Google Scholar

[21] Xu J, Xi J, Dong H, Ahn N, Zhu Z L, Chen J B, Li P Z, Zhu X Y, Dai J F, Hu Z Y, Jiao B, Hou X, Li J R, Wu Z X 2021 Nano Energy 88 106286

Google Scholar

Google Scholar

[22] Zhu X Y, Dong H, Chen J B, Xu J, Li Z J, Yuan F, Dai J F, Jiao B, Hou X, Xi J, Wu Z X 2022 Adv. Funct. Mater. 32 2202408

Google Scholar

Google Scholar

-

图 2 空气中真空萃取制备的钙钛矿薄膜的表面SEM和AFM形貌图 (a), (e) 0 mg/mL; (b), (f) 1.0 mg/mL; (c), (g) 2.0 mg/mL; (d), (h) 5.0 mg/mL

Fig. 2. SEM and AFM morphologies of perovskite films prepared by vacuuming in air with different weight concentrations: (a), (e) 0 mg/mL; (b), (f) 1.0 mg/mL; (c), (g) 2.0 mg/mL; (d), (h) 5.0 mg/mL.

表 1 聚合物层修饰的刚性和柔性模组器件室外光电参数比较

Table 1. Comparison of optoelectronic parameters of polymer layer modified rigid and flexible perovskite module devices.

器件 JSC/(mA·cm–2) VOC/V FF/% PCE/% Glass/ITO-控制组 (in air) 3.84 6.62 73.6 18.71 Glass/ITO-PEGDMA (in air) 3.94 6.70 73.9 19.51 Glass/ITO-PEGDMA (in N2) 4.02 6.65 73.3 19.59 PEN/ITO-控制组 (in air) 3.81 6.51 65.6 16.26 PEN/ITO-PEGDMA (in air) 3.83 6.60 71.9 18.17 PEN/ITO-PEGDMA (in N2) 3.89 6.63 71.3 18.39 -

[1] Brenner T M, Egger D A, Kronik L, Hodes G, Cahen D 2016 Nat. Rev. Mater. 1 15007

Google Scholar

Google Scholar

[2] Wolf S D, Holovsky J, Moon S J, Löper P, Niesen B, Ledinsky M, Haug F J, Yum J H, Ballif C 2014 J. Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[3] Stranks S D, Eperon G E, Grancini G, Menelaou C, Alcocer M J P, Leijtens T, Herz L, Petrozza A, Snaith H J 2013 Science 342 341

Google Scholar

Google Scholar

[4] Xing G C, Mathews N, Sun S Y, Lim S S, Lam Y M, Grätzel M, Mhaisalkar S, Sum T C 2013 Science 342 344

Google Scholar

Google Scholar

[5] Leijtens T, Lim J, Teuscher J, Park T, Snaith H 2013 Adv. Mater. 25 3227

Google Scholar

Google Scholar

[6] https://www.nrel.gov/pv/interactive-cell-efficiency.html

[7] Ding Y, Ding B, Kanda H, Usiobo O J, Gallet T, Yang Z H, Liu Y, Huang H, Sheng J, Liu C, Yang Y, Queloz V I E, Zhang X F, Audinot J N, Redinger A, Dang W, Mosconic E, Luo W, Angelis F D, Wang M K, Dörflinger P, Armer M, Schmid V, Wang R, Brooks K G, Wu J H, Dyakonov V, Yang G J, Dai S Y, Dyson P J, Nazeeruddin M K 2022 Nat. Nanotechnol. 17 598

Google Scholar

Google Scholar

[8] Rana P J S, Febriansyah B, Koh T M, Muhammad B T, Salim T, Hooper T J N, Kanwat A, Ghosh B, Kajal P, Lew J H, Aw Y C, Yantara N, Bruno A, Pullarkat S A, Ager J W, Leong W L, Mhaisalkar S G, Mathews N 2022 Adv. Funct. Mater. 32 2113026

Google Scholar

Google Scholar

[9] Wang Y, Yang H, Zhang K, Tao M Q, Li M Z, Song Y L 2022 ACS Energy Lett. 7 3646

Google Scholar

Google Scholar

[10] Zhang K, Wang Y, Tao M Q, Guo L T, Yang Y R, Shao J Y, Zhang Y Y, Wang F Y, Song Y L 2023 Adv. Mater. 35 2211593

Google Scholar

Google Scholar

[11] Brooks K G, Nazeeruddin M K 2021 Adv. Energy Mater. 11 2101149

Google Scholar

Google Scholar

[12] Castriotta L A, Zendehdel M, Nia N Y, Leonardi E, Löfffer M, Paci B, Generosi A, Rellinghaus B, Carlo A D 2022 Adv. Energy Mater. 12 2103420

Google Scholar

Google Scholar

[13] Babayigit A, Haen J D, Boyen H G, Conings B 2018 Joule 2 1205

Google Scholar

Google Scholar

[14] Konstantakou M, Perganti D, Falaras P, Stergiopoulos T 2017 Crystals 7 291

Google Scholar

Google Scholar

[15] Gu L, Wang S, Fang X, Liu D, Xu Y, Yuan N, Ding J 2020 ACS Appl. Mater. Interfaces 12 33870

Google Scholar

Google Scholar

[16] Jang G, Kwon H C, Ma S, Yun S C, Yang H, Moon J 2019 Adv. Energy Mater. 9 1901719

Google Scholar

Google Scholar

[17] Gu L L, Fei F, Xu Y B, Wang S B, Yuan N Y, Ding J N 2022 ACS Appl. Mater. Interfaces 14 2949

Google Scholar

Google Scholar

[18] Li H Y, Bu T L, Li J, Lin Z P, Pan J Y, Li Q H, Zhang X L, Ku Z L, Cheng Y B, Huang F Z 2021 ACS Appl. Mater. Interfaces 13 18724

Google Scholar

Google Scholar

[19] Vesce L, Stefanelli M, Herterich J P, Castriotta L A, Kohlstädt M, Würfel U, Carlo A D 2021 Solar RRL 5 2100073

Google Scholar

Google Scholar

[20] Xu J, Dong H, Xi J, Yang Y, Yu Y, Ma L, Chen J B, Jiao B, Hou X, Li J R, Wu Z X 2020 Nano Energy 75 104940

Google Scholar

Google Scholar

[21] Xu J, Xi J, Dong H, Ahn N, Zhu Z L, Chen J B, Li P Z, Zhu X Y, Dai J F, Hu Z Y, Jiao B, Hou X, Li J R, Wu Z X 2021 Nano Energy 88 106286

Google Scholar

Google Scholar

[22] Zhu X Y, Dong H, Chen J B, Xu J, Li Z J, Yuan F, Dai J F, Jiao B, Hou X, Xi J, Wu Z X 2022 Adv. Funct. Mater. 32 2202408

Google Scholar

Google Scholar

计量

- 文章访问数: 5959

- PDF下载量: 111

- 被引次数: 0

下载:

下载: