-

本文使用静态扩散法结合常规X射线粉末衍射和电子探针技术, 在Ag-In-Se体系中发现了AgyIn3.33–y/3Se5新化合物. 其结构属于三方晶系, 空间群为P3m1, 是二维层状结构, 单层晶胞由9个原子量子层按照Se1-In1-Se2-In2-Se3-Ag/In3 -Se4-In4-Se5顺序排布构成, 层间由弱范德瓦耳斯力结合. 烧结的块体样品表现出强烈的取向性, 在平行压力方向上具有极低的晶格热导率(在873 K为0.15 W·m–1·K–1). 这种本征低的晶格热导率主要源于材料的低声速和低频光学支声子与声学支声子强耦合作用. AgyIn3.33–y/3Se5样品表现为n型传导, 室温下电导率约为4 × 104 S·m–1, Seebeck系数约为–80 μV·K–1, 样品在宽温度范围内均表现出较好的电传输性能, 在450—800 K范围内的功率因子为5 μW·cm–1·K–2左右. 由于在平行压力方向上低的晶格热导率, 最终Ag0.407In3.198Se5样品在873 K达到最大热电优值ZT为1.01, 在300—850 K的平均ZT为0.45. 该化合物的发现, 扩充了铜属硫基化合物体系的n型材料, 为铜属硫基化合物体系的应用奠定了重要基础.

-

关键词:

- Ag-In-Se基化合物 /

- 二维层状结构 /

- 超低晶格热导率 /

- 热电性能

In this study, we find new AgyIn3.33–y/3Se5 compounds in Ag-In-Se system by static diffusion method combined with common X-ray diffraction and backscattering electron analysis. The crystal structure belongs to the trilateral system with the P3m1 space group, which features a two-dimensional layered structure. The unit cell is composed of 9-atom quantum layers arranged in the sequence of Se1-In1-Se2-In2-Se3-Ag/In3-Se4-In4-Se5, and in-between these layers are bonded by the weak van der Waals force. The sintered bulk samples show highly anisotropic transport properties and have an ultra-low lattice thermal conductivity along the direction parallel to sintering pressure about 0.15 W·m–1·K–1 at 873 K. The intrinsically ultra-low lattice thermal conductivity mainly comes from low phonon velocity and the strong coupling between low frequency optical phonon and acoustic phonons. The AgyIn3.33–y/3Se5 compounds behave as an n-type conduction. The electrical conductivity is 4×104 S·m–1 and the Seebeck coefficient is –80 μV·K–1 at room temperature. Therefore, AgyIn3.33–y/3Se5 compounds show high electrical transport properties in a wide temperature range, and the power factor is around 5 μW·cm–1·K–2 in a range of 450–800 K. Owing to the ultra-low lattice thermal conductivity along the direction parallel to sintering pressure, Ag0.407In3.198Se5 reaches a maximum ZT of 1.01 at 873 K and an average ZT of 0.45 at 300–850 K. The discovery of AgyIn3.33–y/3Se5 expands the n-type copper based chalcogenide and lays an important foundation for the application of copper based chalcogenide.-

Keywords:

- Ag-In-Se based compounds /

- two-dimensional layered structure /

- ultralow lattice thermal conductivity /

- thermoelectric properties

[1] Qin B, Wang D, Liu X, Qin Y, Dong J-F, Luo J, Li J-W, Liu W, Tan G, Tang X, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[2] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[3] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[4] Su X, Wei P, Li H, Liu W, Yan Y, Li P, Su C, Xie C, Zhao W, Zhai P, Zhang Q, Tang X, Uher C 2017 Adv. Mater. 29 23

Google Scholar

Google Scholar

[5] Deng R, Su X, Hao S, Zheng Z, Zhang M, Xie H, Liu W, Yan Y, Wolverton C, Uher C, Kanatzidis M G, Tang X 2018 Energy Environ. Sci. 11 1520

Google Scholar

Google Scholar

[6] Tao Q, Deng R, Li J, Yan Y, Su X, Poudeu P F P, Tang X 2020 ACS Appl. Mater. Interfaces 12 26330

Google Scholar

Google Scholar

[7] Tang X, Li Z, Liu W, Zhang Q, Uher C 2022 Interdiscip. Mater. 1 88

Google Scholar

Google Scholar

[8] Chen Z G, Shi X, Zhao L-D, Zou J 2018 Prog. Mater. Sci. 97 283

Google Scholar

Google Scholar

[9] Mangavati S, Pal A, Rao A, Jiang Z Z, Kuo Y K 2022 J. Phys. Chem. Solids. 160 110301

Google Scholar

Google Scholar

[10] Zhao X, Ning S, Qi N, Li Y, Dong Y, Zhang H, Liu J, Ye B, Chen Z 2021 ACS Appl. Mater. Interfaces 13 58936

Google Scholar

Google Scholar

[11] Zhang J, Zhu T, Zhang C, Yan Y, Tan G, Liu W, Su X, Tang X 2021 J. Alloy. Compd. 881 160639

Google Scholar

Google Scholar

[12] Zhang Q, Ti Z, Zhu Y, Zhang Y, Cao Y, Li S, Wang M, Li D, Zou B, Hou Y, Wang P, Tang G 2021 ACS Nano. 15 19345

Google Scholar

Google Scholar

[13] Zhang R, Pei J, Shan Z, Zhou W, Wu Y, Han Z, Zhao Y H, Li J F, Ge Z H, Zhang B P 2022 Chem. Eng. J. 429 132275

Google Scholar

Google Scholar

[14] 杨枭, 苏贤礼, 鄢永高, 唐新峰 2021 无机材料学报 36 75

Google Scholar

Google Scholar

Yang X, Su X L, Yan Y G, Tang X F 2021 J. Inorg. Mater. 36 75

Google Scholar

Google Scholar

[15] Cao Y, Bai H, Li Z, Zhang Z, Tang Y, Su X, Wu J, Tang X 2021 ACS Appl. Mater. Interfaces 13 43134

Google Scholar

Google Scholar

[16] Su X, Hao S, Bailey T P, Wang S, Hadar I, Tan G, Song T B, Zhang Q, Uher C, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Energy Mater. 8 1800659

Google Scholar

Google Scholar

[17] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[18] Cai S, Hao S, Luo Y, Su X, Luo Z-Z, Hu X, Wolverton C, Dravid V P, Kanatzidis M G 2020 Chem. Mater. 32 3561

Google Scholar

Google Scholar

[19] Ma N, Li F, Li J G, Liu X, Zhang D B, Li Y Y, Chen L, Wu L M 2021 J. Am. Chem. Soc. 143 18490

Google Scholar

Google Scholar

[20] Xia Y, Ozolins V, Wolverton C 2020 Phys. Rev. Lett. 125 085901

Google Scholar

Google Scholar

[21] Chen X, Carrete J, Sullivan S, van Roekeghem A, Li Z, Li X, Zhou J, Mingo N, Shi L 2019 Phys. Rev. Lett. 122 185901

Google Scholar

Google Scholar

[22] Zhang H, Liu H, Wei K, Kurakevych O O, Le Godec Y, Liu Z, Martin J, Guerrette M, Nolas G S, Strobel T A 2017 Phys. Rev. Lett. 118 146601

Google Scholar

Google Scholar

[23] Ren W, Geng H, Zhang Z, Zhang L 2017 Phys. Rev. Lett. 118 245901

Google Scholar

Google Scholar

[24] He J, Amsler M, Xia Y, Naghavi S S, Hegde V I, Hao S, Goedecker S, Ozolins V, Wolverton C 2016 Phys. Rev. Lett. 117 046602

Google Scholar

Google Scholar

[25] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[26] Su X, Zhao N, Hao S, Stoumpos C C, Liu M, Chen H, Xie H, Zhang Q, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Funct. Mater. 29 1806534

Google Scholar

Google Scholar

[27] Shen X, Wang G, Li S, Yang C C, Tan H, Zhang Y, Lu X, He J, Wang G, Zhou X 2019 J. Alloy. Compd. 805 444

Google Scholar

Google Scholar

[28] Shen X, Shaheen N, Zhang A, Yang D, Yao W, Wang G, Lu X, Zhou X 2017 RSC Advances 7 12719

Google Scholar

Google Scholar

[29] Panda R, Naik R, Mishra N C 2019 J. Alloy. Compd. 778 819

Google Scholar

Google Scholar

[30] Shen X, Zhang B, Chen Q, Tan H, Zhang X, Wang G, Lu X, Zhou X 2019 Inorg. Chem. Front. 6 3545

Google Scholar

Google Scholar

[31] Ying P Z, Zhou H, Gao Y L, Li Y Y, Li Y P, Lian X L, Cui J L 2012 Key Eng. Mater. 519 188

Google Scholar

Google Scholar

[32] Xie H, Hao S, Cai S, Bailey T P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2020 Energy Environ. Sci. 13 3693

Google Scholar

Google Scholar

[33] Xie H, Hao S, Bailey T P, Cai S, Zhang Y, Slade T J, Snyder G J, Dravid V P, Uher C, Wolverton C, Kanatzidis M G 2021 J. Am. Chem. Soc. 143 5978

Google Scholar

Google Scholar

[34] Zhu Y, Wei B, Liu J, Koocher N Z, Li Y, Hu L, He W, Deng G, Xu W, Wang X, Rondinelli J M, Zhao L-D, Snyder G J, Hong J 2021 Mater. Today Phys. 19 100428

Google Scholar

Google Scholar

[35] Qiu P, Qin Y, Zhang Q, Li R, Yang J, Song Q, Tang Y, Bai S, Shi X, Chen L 2018 Adv. Sci. 5 1700727

Google Scholar

Google Scholar

[36] 骆军, 何世洋, 李志立, 李永博, 王风, 张继业 2019 无机材料学报 34 247

Google Scholar

Google Scholar

Luo J, He S Y, Li Z L, Li Y B, Wang F, Zhang J Y 2019 J. Inorg. Mater. 34 247

Google Scholar

Google Scholar

[37] Deng T, Xing T, Brod M K, Sheng Y, Qiu P, Veremchuk I, Song Q, Wei T-R, Yang J, Snyder G J, Grin Y, Chen L, Shi X 2020 Energy Environ. Sci. 13 3041

Google Scholar

Google Scholar

[38] Aikebaier Y, Kurosaki K, Sugahara T, Ohishi Y, Muta H, Yamanaka S 2012 M. S. E.: B 177 999

[39] Yang N, Chen C, Pan L, Zhao Y, Wang Y 2020 J. Alloy. Compd. 847 156410

Google Scholar

Google Scholar

[40] Zhong Y, Luo Y, Li X, Cui J 2020 Appl. Energ. Mater. 3 12468

Google Scholar

Google Scholar

[41] Ying P, Li X, Wang Y, Yang J, Fu C, Zhang W, Zhao X, Zhu T 2017 Adv. Funct. Mater. 27 188

Google Scholar

Google Scholar

[42] Xie H, Su X, Zhang X, Hao S, Bailey T P, Stoumpos C C, Douvalis A P, Hu X, Wolverton C, Dravid V P, Uher C, Tang X, Kanatzidis M G 2019 J. Am. Chem. Soc. 141 10905

Google Scholar

Google Scholar

[43] Li Y, Li Z, Zhang C, Yang D, Liu T, Yan Y, Liu W, Tan G, Su X, Uher C, Tang X 2019 Mater. Today Phys. 9 10905

Google Scholar

Google Scholar

[44] Zhu Y, Liu Y, Wood M, Koocher N Z, Liu Y, Liu L, Hu T, Rondinelli J M, Hong J, Snyder G J, Xu W 2019 Chem. Mater. 31 8182

Google Scholar

Google Scholar

-

图 2 (a) (Ag2Se)x(In2Se3)100–x (x = 0—20)的粉末XRD图谱; (b) x = 0, 3.3, 5.3, 10.9, 13.6和16的背散射图片; (c) 所合成x = 0, 3.3, 5.3, 8.3, 10.9, 13.6和16的样品不同衬度区域电子能谱组成Ag/In比, 紫色虚线为合成样品名义组成线, 红色圆圈标出的为单相组成

Fig. 2. (a) Powder XRD pattern of (Ag2Se)x(In2Se3)100–x (x = 0–20); (b) backscattering electron (BSE) image of the samples with x = 0, 3.3, 5.3, 10.9, 13.6 and 16; (c) the ratio of Ag/In in x = 0, 3.3, 5.3, 8.3, 10.9, 13.6 and 16, the purple dotted line is the nominal composition line, and the red circle is marked as single-phase composition.

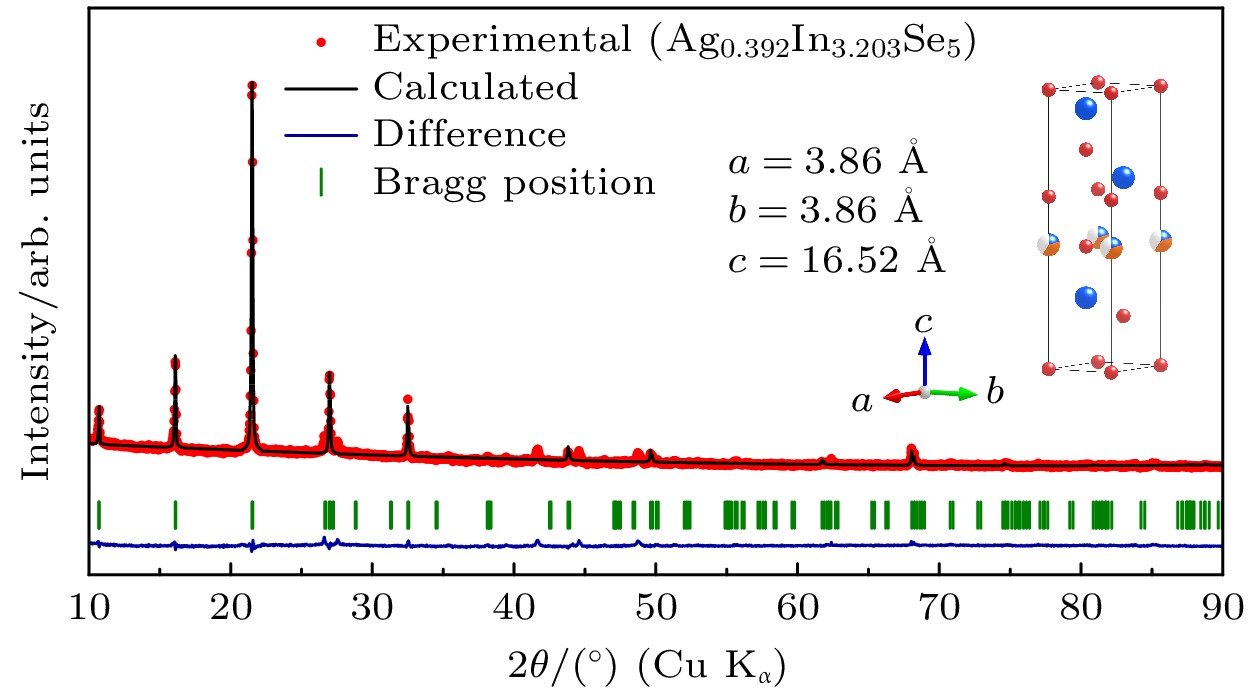

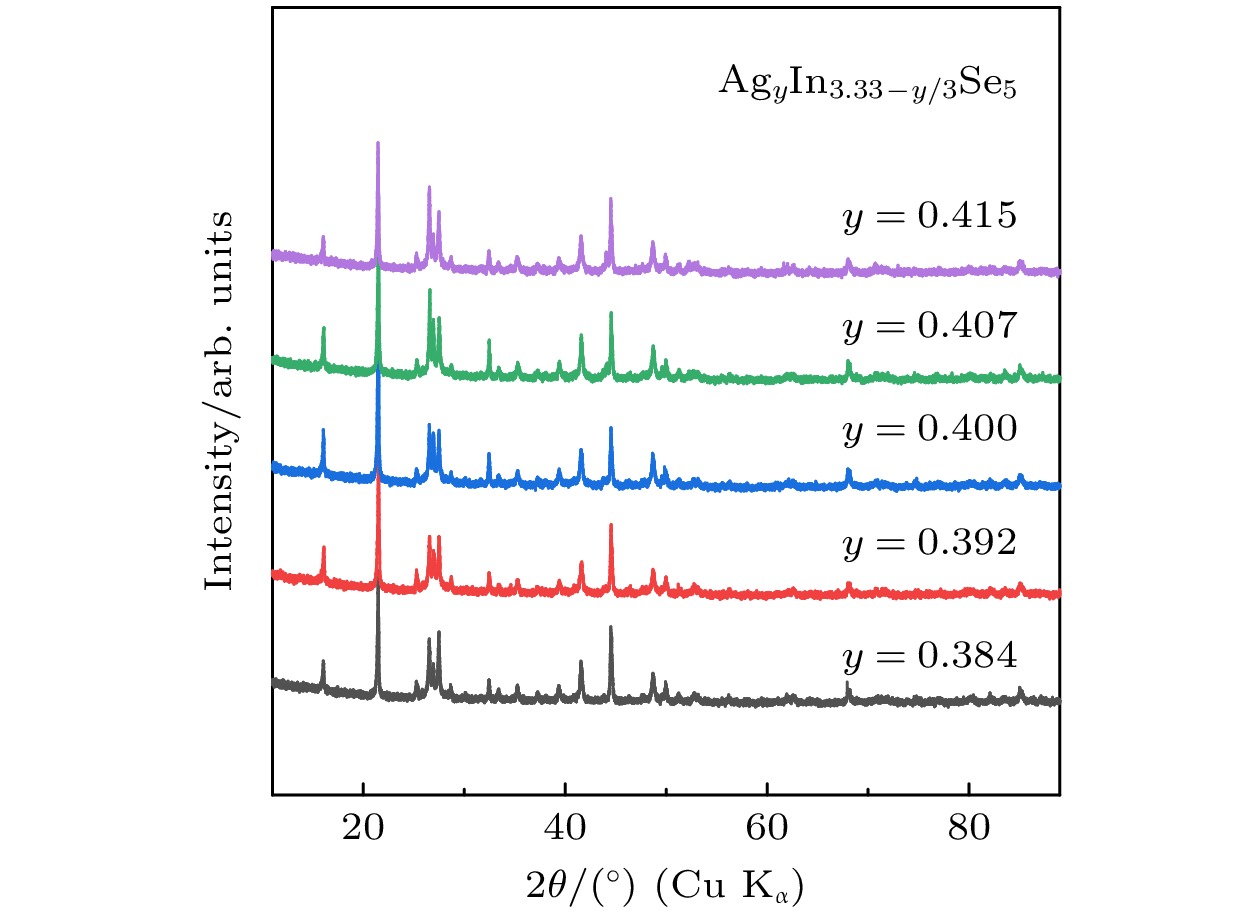

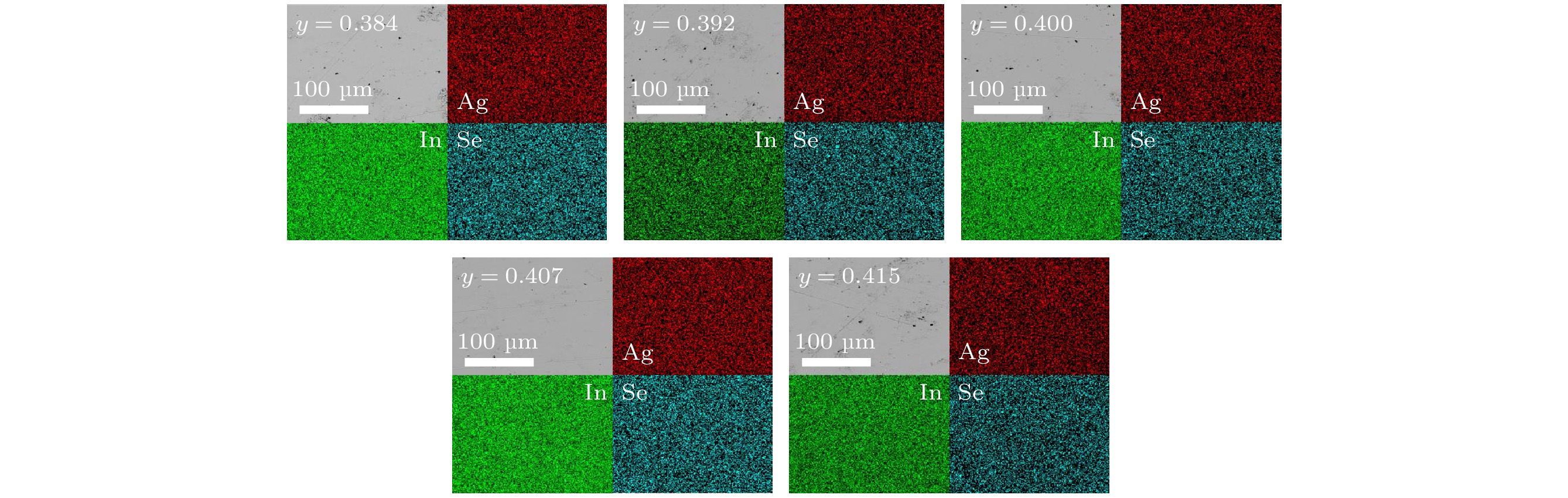

图 3 (Ag2Se)x(In2Se3)100–x (x = 10.9)样品的慢扫XRD(红色)(10°—90°), 精修得到的衍射峰(黑色), Bragg 峰位 (绿色), 衍射峰的差异(蓝色), Rp = 6.84%, Rwp = 9.31%.

Fig. 3. Rietveld refinement of (Ag2Se)x(In2Se3)100–x (x = 10.9), experimental (red point), calculated (black), Bragg position (green), defference (blue) Rp = 6.84%, Rwp = 9.31%.

图 7 Ag0.392In3.203Se5 样品的微观图像 (a) [001]晶向的高倍高角度环形暗场像(HAADF-STEM); (b) 图(a)区域的选取电子衍射(SAED)和模拟的选取电子衍射(SAED); (c) [010] 晶向的高倍高角度环形暗场像(HAADF-STEM); (d) 图(c)区域的选取电子衍射(SAED)和模拟的选取电子衍射(SAED); (e), (f) 图(c)的染色放大图

Fig. 7. Microstructure of Ag0.392In3.203Se5: (a) High-magnification HAADF-STEM image along the [001]; (b) SAED pattern and calculation of (a); (c) high-magnification HAADF-STEM image along the [010]; (d) SAED pattern and calculation of (c); (e), (f) enlarged image of Fig.7 (c).

图 8 AgyIn3.33–y/3Se5 (y = 0.384, 0.392, 0.400, 0.407, 0.415)电输运性能 (a) 电导率; (b) 赛贝克系数; (c) 功率因子; (d) 单抛带模型计算载流子有效质量

Fig. 8. Temperature dependences of (a) the electrical conductivity, (b) Seebeck coefficient, and (c) power factor for the AgyIn3.33–y/3Se5 (y = 0.384, 0.392, 0.400, 0.407, 0.415) samples; (d) Seebeck coefficients as a function of the charge carrier concentration at 300 K, where the dashed lines are Pisarenko plots based on the SPB model.

图 9 AgyIn3.33–y/3Se5 (y = 0.384, 0.392, 0.400, 0.407, 0.415) 热输运性能和热电优值 (a) 热导率; (b) AgyIn3.33–y/3Se5 与AgInSe2[35], AgInTe2[38], AgIn5Se8[30]和CuInSe2[39]的晶格热导率; (c) AgyIn3.33–y/3Se5, AgInSe2[35], AgIn5Se8[30], Ag1.03In5Se8[30], Ag0.9Cd0.1InSe8[35], Ag1.02InSe2[35], Ag1.6InSe2.3[40]的ZT值, 300—873 K; (d) 300—850 K的平均ZTavg值

Fig. 9. (a) The temperature-dependent of the total thermal conductivity for AgyIn3.33–y/3Se5; (b) the lattice thermal conductivity for AgyIn3.33–y/3Se5, AgInSe2[35], AgInTe2[38], AgIn5Se8[30] and CuInSe2[39]; (c) merit ZT for AgyIn3.33–y/3Se5, AgInSe2[35], AgIn5Se8[30], Ag1.03In5Se8[30], Ag0.9Cd0.1InSe8[35], Ag1.02InSe2[35], Ag1.6InSe2.3[40], at 300-873 K; (d) the average ZT at 300–850 K.

表 1 AgyIn3.33–y/3Se5样品的室温载流子浓度和迁移率

Table 1. The carrier concentration and Hall mobility of AgyIn3.33–y/3Se5 at room temperature.

Sample y = 0.384 y = 0.392 y = 0.400 y = 0.407 y = 0.415 μH / (cm2·V–1·s–1) 136.42 141.21 144.80 131.40 130.69 nH /(1019 cm–3) 1.88 1.70 1.68 1.93 1.85 表 2 Ag0.392In0.203Se5样品使用德拜-爱因斯坦模型拟合低温热容的参数

Table 2. Parameters obtained by fitting the experimental low-temperature heat capacity data to the Debye-Einstein model of Ag0.392In0.203Se5.

Sample γ/

(mJ·mol–1·K–2)b/

(mJ·mol–1·K–4)A1 θE1/K A2 θE1/K θD/K y = 0.392 0.02813 2.95 × 10–4 13.43 40.18 57.01 82.63 164 表 3 Ag0.392In0.203Se5, AgInSe2[44]和AgIn5Se8[30]的室温杨氏模量E、格林艾森常数常数γ对比

Table 3. Comparisons of Elastic properties and Grüneisen parameters at room temperature between Ag0.392In0.203Se5, AgInSe2[44], and AgIn5Se8[30].

Parameter Ag0.392In3.203Se5 AgInSe2 AgIn5Se8 vl/(m·s–1) 3058 3584 3778 vs/(m·s–1) 1527 1530 1803 va/(m·s–1) 1713 1729 2028 E /GPa 35.0 52.5 50.6 γ 2.00 2.87 2.20 -

[1] Qin B, Wang D, Liu X, Qin Y, Dong J-F, Luo J, Li J-W, Liu W, Tan G, Tang X, Li J F, He J, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[2] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[3] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, Wang B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[4] Su X, Wei P, Li H, Liu W, Yan Y, Li P, Su C, Xie C, Zhao W, Zhai P, Zhang Q, Tang X, Uher C 2017 Adv. Mater. 29 23

Google Scholar

Google Scholar

[5] Deng R, Su X, Hao S, Zheng Z, Zhang M, Xie H, Liu W, Yan Y, Wolverton C, Uher C, Kanatzidis M G, Tang X 2018 Energy Environ. Sci. 11 1520

Google Scholar

Google Scholar

[6] Tao Q, Deng R, Li J, Yan Y, Su X, Poudeu P F P, Tang X 2020 ACS Appl. Mater. Interfaces 12 26330

Google Scholar

Google Scholar

[7] Tang X, Li Z, Liu W, Zhang Q, Uher C 2022 Interdiscip. Mater. 1 88

Google Scholar

Google Scholar

[8] Chen Z G, Shi X, Zhao L-D, Zou J 2018 Prog. Mater. Sci. 97 283

Google Scholar

Google Scholar

[9] Mangavati S, Pal A, Rao A, Jiang Z Z, Kuo Y K 2022 J. Phys. Chem. Solids. 160 110301

Google Scholar

Google Scholar

[10] Zhao X, Ning S, Qi N, Li Y, Dong Y, Zhang H, Liu J, Ye B, Chen Z 2021 ACS Appl. Mater. Interfaces 13 58936

Google Scholar

Google Scholar

[11] Zhang J, Zhu T, Zhang C, Yan Y, Tan G, Liu W, Su X, Tang X 2021 J. Alloy. Compd. 881 160639

Google Scholar

Google Scholar

[12] Zhang Q, Ti Z, Zhu Y, Zhang Y, Cao Y, Li S, Wang M, Li D, Zou B, Hou Y, Wang P, Tang G 2021 ACS Nano. 15 19345

Google Scholar

Google Scholar

[13] Zhang R, Pei J, Shan Z, Zhou W, Wu Y, Han Z, Zhao Y H, Li J F, Ge Z H, Zhang B P 2022 Chem. Eng. J. 429 132275

Google Scholar

Google Scholar

[14] 杨枭, 苏贤礼, 鄢永高, 唐新峰 2021 无机材料学报 36 75

Google Scholar

Google Scholar

Yang X, Su X L, Yan Y G, Tang X F 2021 J. Inorg. Mater. 36 75

Google Scholar

Google Scholar

[15] Cao Y, Bai H, Li Z, Zhang Z, Tang Y, Su X, Wu J, Tang X 2021 ACS Appl. Mater. Interfaces 13 43134

Google Scholar

Google Scholar

[16] Su X, Hao S, Bailey T P, Wang S, Hadar I, Tan G, Song T B, Zhang Q, Uher C, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Energy Mater. 8 1800659

Google Scholar

Google Scholar

[17] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[18] Cai S, Hao S, Luo Y, Su X, Luo Z-Z, Hu X, Wolverton C, Dravid V P, Kanatzidis M G 2020 Chem. Mater. 32 3561

Google Scholar

Google Scholar

[19] Ma N, Li F, Li J G, Liu X, Zhang D B, Li Y Y, Chen L, Wu L M 2021 J. Am. Chem. Soc. 143 18490

Google Scholar

Google Scholar

[20] Xia Y, Ozolins V, Wolverton C 2020 Phys. Rev. Lett. 125 085901

Google Scholar

Google Scholar

[21] Chen X, Carrete J, Sullivan S, van Roekeghem A, Li Z, Li X, Zhou J, Mingo N, Shi L 2019 Phys. Rev. Lett. 122 185901

Google Scholar

Google Scholar

[22] Zhang H, Liu H, Wei K, Kurakevych O O, Le Godec Y, Liu Z, Martin J, Guerrette M, Nolas G S, Strobel T A 2017 Phys. Rev. Lett. 118 146601

Google Scholar

Google Scholar

[23] Ren W, Geng H, Zhang Z, Zhang L 2017 Phys. Rev. Lett. 118 245901

Google Scholar

Google Scholar

[24] He J, Amsler M, Xia Y, Naghavi S S, Hegde V I, Hao S, Goedecker S, Ozolins V, Wolverton C 2016 Phys. Rev. Lett. 117 046602

Google Scholar

Google Scholar

[25] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[26] Su X, Zhao N, Hao S, Stoumpos C C, Liu M, Chen H, Xie H, Zhang Q, Wolverton C, Tang X, Kanatzidis M G 2018 Adv. Funct. Mater. 29 1806534

Google Scholar

Google Scholar

[27] Shen X, Wang G, Li S, Yang C C, Tan H, Zhang Y, Lu X, He J, Wang G, Zhou X 2019 J. Alloy. Compd. 805 444

Google Scholar

Google Scholar

[28] Shen X, Shaheen N, Zhang A, Yang D, Yao W, Wang G, Lu X, Zhou X 2017 RSC Advances 7 12719

Google Scholar

Google Scholar

[29] Panda R, Naik R, Mishra N C 2019 J. Alloy. Compd. 778 819

Google Scholar

Google Scholar

[30] Shen X, Zhang B, Chen Q, Tan H, Zhang X, Wang G, Lu X, Zhou X 2019 Inorg. Chem. Front. 6 3545

Google Scholar

Google Scholar

[31] Ying P Z, Zhou H, Gao Y L, Li Y Y, Li Y P, Lian X L, Cui J L 2012 Key Eng. Mater. 519 188

Google Scholar

Google Scholar

[32] Xie H, Hao S, Cai S, Bailey T P, Uher C, Wolverton C, Dravid V P, Kanatzidis M G 2020 Energy Environ. Sci. 13 3693

Google Scholar

Google Scholar

[33] Xie H, Hao S, Bailey T P, Cai S, Zhang Y, Slade T J, Snyder G J, Dravid V P, Uher C, Wolverton C, Kanatzidis M G 2021 J. Am. Chem. Soc. 143 5978

Google Scholar

Google Scholar

[34] Zhu Y, Wei B, Liu J, Koocher N Z, Li Y, Hu L, He W, Deng G, Xu W, Wang X, Rondinelli J M, Zhao L-D, Snyder G J, Hong J 2021 Mater. Today Phys. 19 100428

Google Scholar

Google Scholar

[35] Qiu P, Qin Y, Zhang Q, Li R, Yang J, Song Q, Tang Y, Bai S, Shi X, Chen L 2018 Adv. Sci. 5 1700727

Google Scholar

Google Scholar

[36] 骆军, 何世洋, 李志立, 李永博, 王风, 张继业 2019 无机材料学报 34 247

Google Scholar

Google Scholar

Luo J, He S Y, Li Z L, Li Y B, Wang F, Zhang J Y 2019 J. Inorg. Mater. 34 247

Google Scholar

Google Scholar

[37] Deng T, Xing T, Brod M K, Sheng Y, Qiu P, Veremchuk I, Song Q, Wei T-R, Yang J, Snyder G J, Grin Y, Chen L, Shi X 2020 Energy Environ. Sci. 13 3041

Google Scholar

Google Scholar

[38] Aikebaier Y, Kurosaki K, Sugahara T, Ohishi Y, Muta H, Yamanaka S 2012 M. S. E.: B 177 999

[39] Yang N, Chen C, Pan L, Zhao Y, Wang Y 2020 J. Alloy. Compd. 847 156410

Google Scholar

Google Scholar

[40] Zhong Y, Luo Y, Li X, Cui J 2020 Appl. Energ. Mater. 3 12468

Google Scholar

Google Scholar

[41] Ying P, Li X, Wang Y, Yang J, Fu C, Zhang W, Zhao X, Zhu T 2017 Adv. Funct. Mater. 27 188

Google Scholar

Google Scholar

[42] Xie H, Su X, Zhang X, Hao S, Bailey T P, Stoumpos C C, Douvalis A P, Hu X, Wolverton C, Dravid V P, Uher C, Tang X, Kanatzidis M G 2019 J. Am. Chem. Soc. 141 10905

Google Scholar

Google Scholar

[43] Li Y, Li Z, Zhang C, Yang D, Liu T, Yan Y, Liu W, Tan G, Su X, Uher C, Tang X 2019 Mater. Today Phys. 9 10905

Google Scholar

Google Scholar

[44] Zhu Y, Liu Y, Wood M, Koocher N Z, Liu Y, Liu L, Hu T, Rondinelli J M, Hong J, Snyder G J, Xu W 2019 Chem. Mater. 31 8182

Google Scholar

Google Scholar

计量

- 文章访问数: 6833

- PDF下载量: 105

- 被引次数: 0

下载:

下载: