-

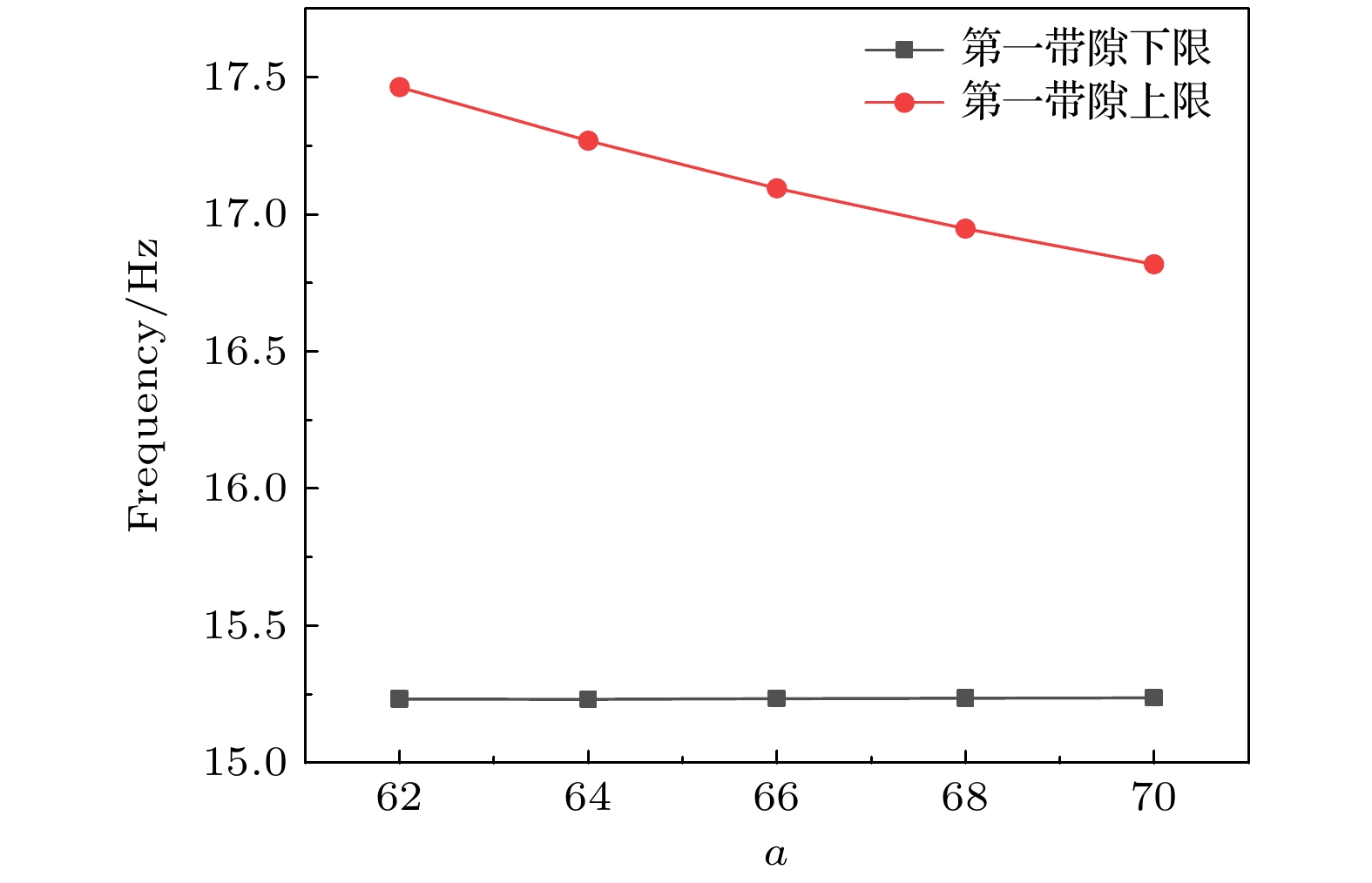

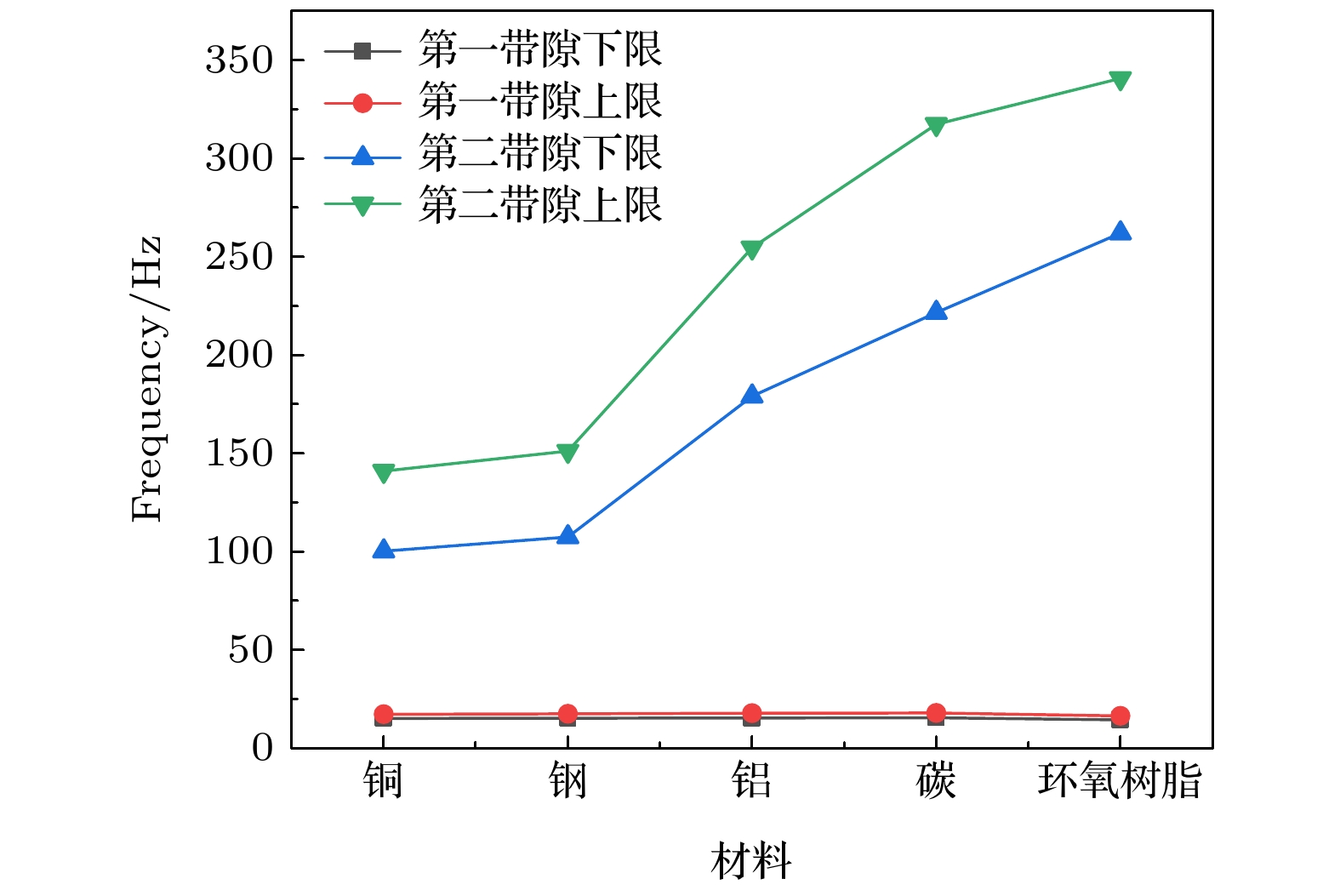

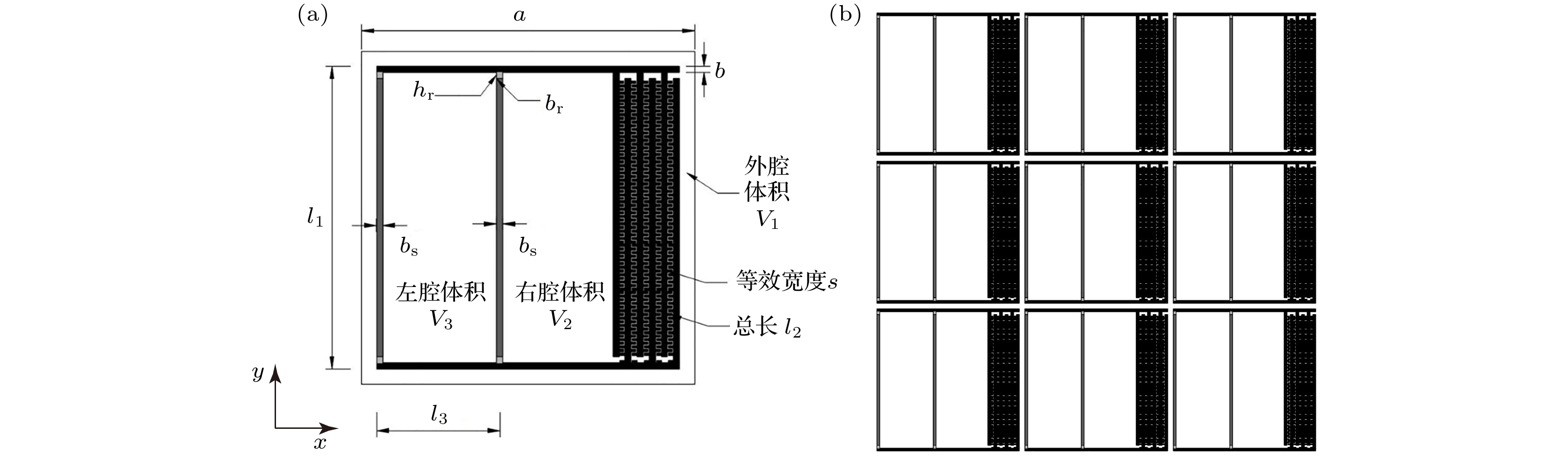

为了解决军用飞机舱室内产生的低频噪声问题, 构建了一种新型的Helmholtz型二维声子晶体, 该结构采用迷宫型开口通道, 并在结构加入了刚性振子. 研究发现, 该结构在晶格常数为62 mm条件下, 将第一低频带隙的下限降至15 Hz左右, 且在100 Hz频率左右形成一条宽度为93 Hz的带隙宽带, 表现出较好的低频隔声特性. 首先, 通过振型及声压场分析了其带隙成因, 采用“力-声类比”的方法建立了该结构的等效模型, 最后利用有限元法和传递矩阵法对第一低频的带隙范围进行了计算, 两种方法所得结果基本相符; 其次, 通过有限元法探究了晶格常数、空气通道长度及振子材料等结构参数对低频带隙的影响. 研究表明, 增加开口通道长度和晶格常数都会降低第一带隙下限, 增加振子材料密度能够有效降低第二带隙的上下限, 进一步揭示了该结构带隙形成的实质, 验证了等效模型的准确性. 该研究为低频噪声控制方面提供了一定的理论支持, 为低频声子晶体的设计提供了新的思路.

-

关键词:

- Helmholtz共振腔 /

- 声子晶体 /

- 低频带隙 /

- 隔声降噪

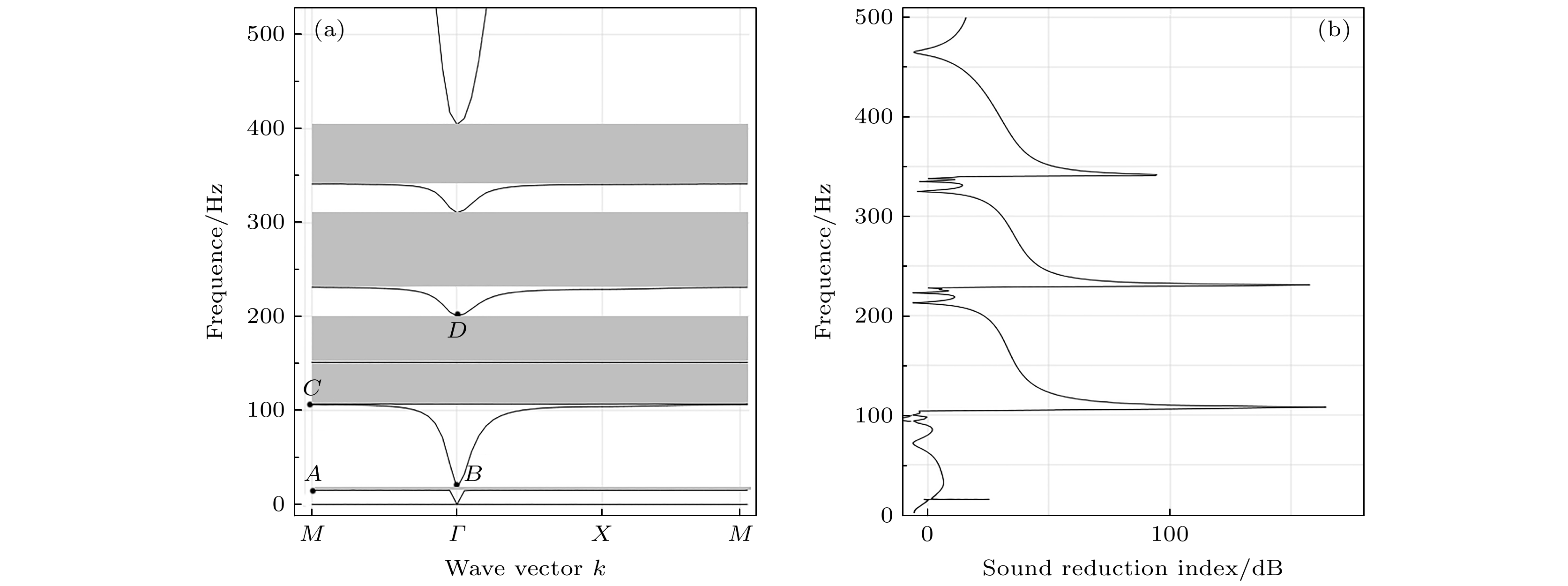

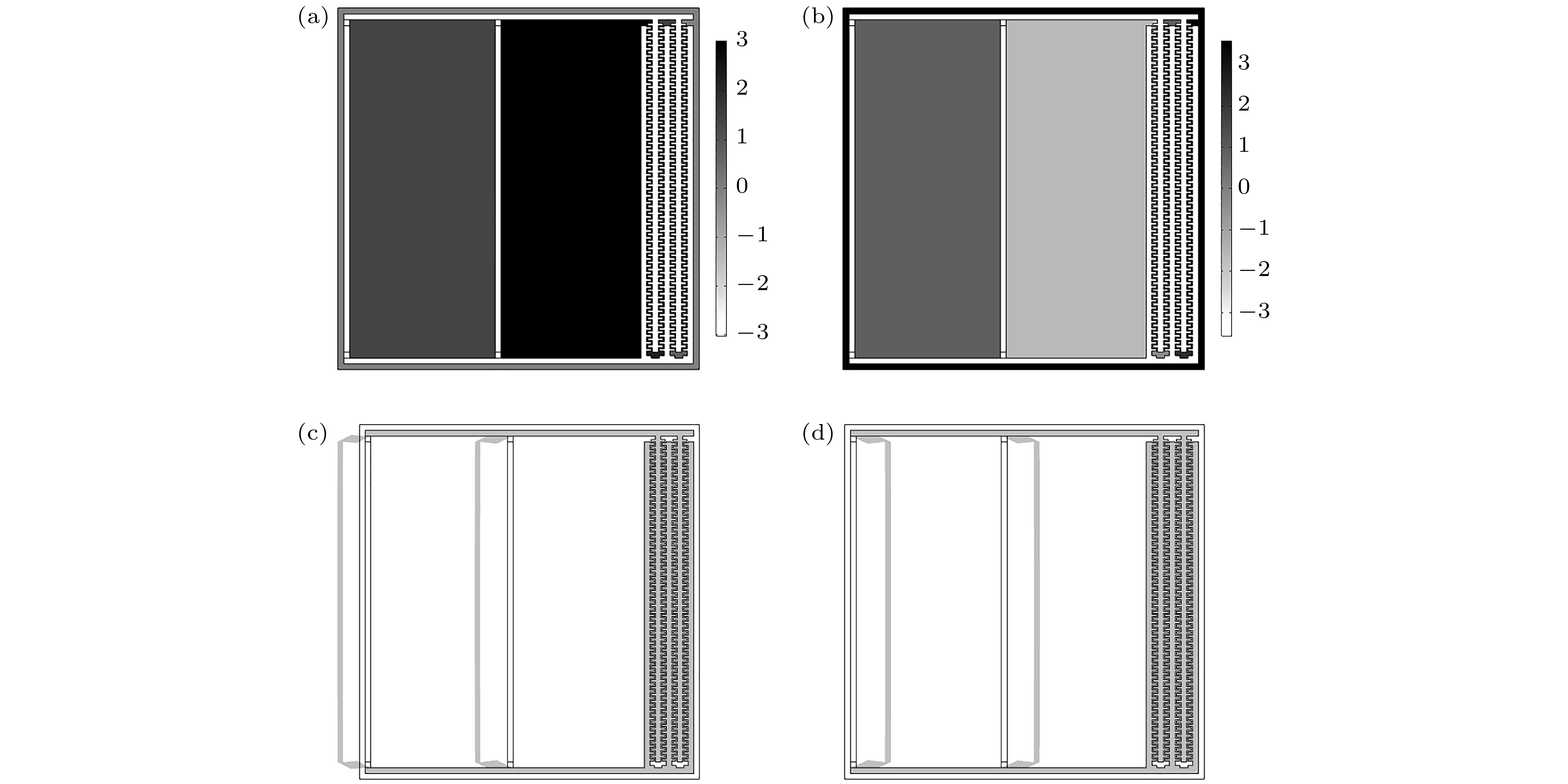

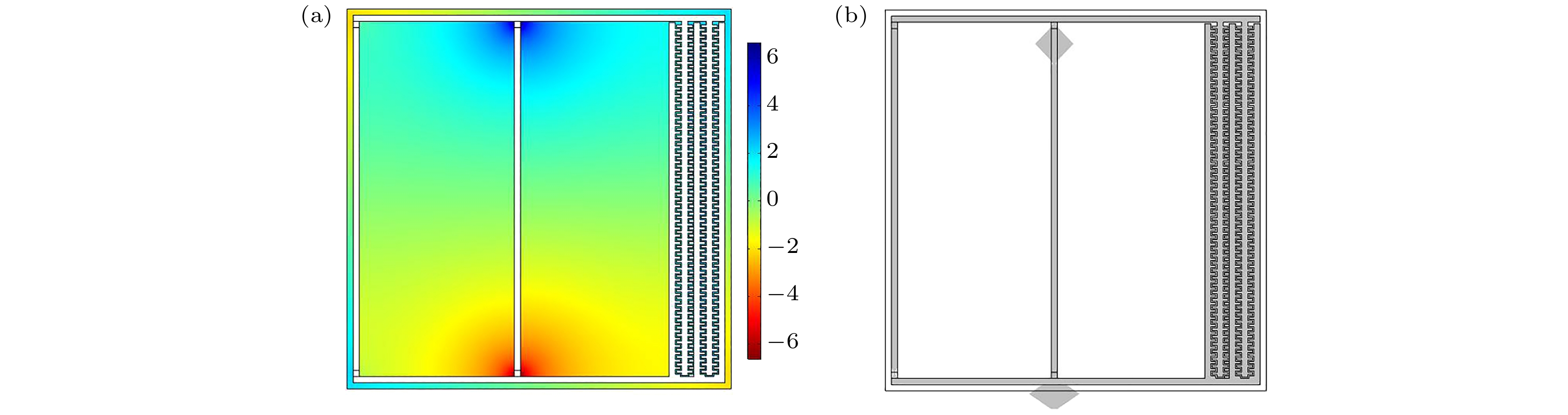

In recent years, the vibration and noise reduction performance of military aircraft has become an important index to measure its performance. In order to solve the problem of low-frequency noise generated by military aircraft, a novel Helmholtz two-dimensional phononic crystal is constructed in this paper. The structure adopts maze-shaped air channel and adds rigid oscillators. On condition that the lattice constant is 62 mm, the lower limit of the first band gap is reduced to about 15 Hz. The structure has four complete band gaps in a range of 0–500 Hz, specifically, they being 15.223–17.464 Hz, 107.46–200.68 Hz, 231.18–310.68 Hz, and 341.14–404.49 Hz. In addition, the sound reduction index of the structure reaches 25 dB at 15 Hz, and two peaks higher than 150 dB appear at about 107 Hz and 231 Hz. which shows distinct sound insulation capability in the low-frequency range. It has engineering significance in controlling the low-frequency noise in the aircraft cabin. The cause of the band gap is explored by analyzing the vibration mode and sound pressure field. The “spring-oscillator” of the structure model is established by the method of “Mechanical-acoustic analogy”. The finite element method and transfer matrix method are used to calculate the upper limit and the lower limit of the first band gap. It is shown that for the first gap of the structure, the results obtained by the two methods are similar, which indicates the correctness of the model hypothesis. Secondly, the effects of structural parameters such as the lattice constant, the length of the air channel and the oscillator material on the first band gap are investigated by finite element method and equivalent model method. It is obtained that the increase of the length of air channel and lattice constant will reduce the lower limit of the first band gap, with other structural parameters remaining unchanged. Moreover, the increase of the density of the oscillator material can effectively reduce the upper limit and lower limit of the second band gap, which further reveals the essence of the formation of the band gap of the structure and verifies the accuracy of the equivalent model. This study provides theoretical support for low frequency noise control and broadens the design of low-frequency phononic crystals.-

Keywords:

- Helmholtz resonator /

- phononic crystal /

- low-frequency bandgap /

- noise insulation and reduction

[1] 吴永祥, 丁传东 1998 航天医学与医学工程 11 54

Wu Y X, Ding C D 1998 Space Med. Med. Eng. 11 54

[2] Kuo C Y, Hung C L, Chen H C, Shih C P, Lu R H, Chen C W, Hung L W, Lin Y C, Chen H K, Chu D M, Lin Y Y, Chen Y C, Wang C H 2021 Int. J. Environ. Res. Public. Health. 18 2982

Google Scholar

Google Scholar

[3] Wolfe H F, Camden M P, Byrd L W, Paul D B, Simmons L W 2015 J. Aircr. 37 319

[4] Bagherzadeh S A, Salehi M 2021 Appl. Acoust. 178 108020

Google Scholar

Google Scholar

[5] Atak O, Huybrechs D, Pluymers B, Desmet W 2014 J. Sound Vibr. 333 3367

Google Scholar

Google Scholar

[6] 张佳龙, 姚宏, 杜军, 赵静波, 董亚科, 祁鹏山 2016 硅酸盐学报 44 1440

Zhang J L, Yao H, Du J, Zhao J B, DongY K, Qi P S 2016 J. Chin. Ceram. Soc. 44 1440

[7] Han D H, Zhao J B, Zhang G J, Yao H 2021 Symmetry 13 1379

Google Scholar

Google Scholar

[8] Li X, Ning S, Liu Z, Yan Z, Luo C, Zhuang Z 2019 Comput. Methods Appl. Mech. Engrg. 361 112737

[9] Chen L, Guo Y, Yi H 2021 Phys. Lett. A 388 127054

Google Scholar

Google Scholar

[10] Shao H, He H, He C, Chen G 2020 J. Mater. Res. 35 3021

Google Scholar

Google Scholar

[11] 田源, 葛浩, 卢明辉, 陈延峰 2019 68 194301

Google Scholar

Google Scholar

Tian Y, Ge H, Lu M H, Chen Y F 2019 Acta Phys. Sin. 68 194301

Google Scholar

Google Scholar

[12] 廖涛, 孙小伟, 宋婷, 田俊红, 康太凤, 孙伟彬 2018 67 214208

Google Scholar

Google Scholar

Liao T, Sun X W, Song T, Tian J H, Kang T F, Sun W B 2018 Acta Phys. Sin. 67 214208

Google Scholar

Google Scholar

[13] Chen J S, Chen Y B, Cheng Y H, Chou L C 2020 Phys. Lett. A 384 126887

Google Scholar

Google Scholar

[14] Kim M J 2019 Int. J. Mod. Phys. B 33 1950138

Google Scholar

Google Scholar

[15] Gao N, Qu S, Li J, Wang J, Chen W 2021 Int. J. Mech. Sci. 208 106695

Google Scholar

Google Scholar

[16] Wang Z G, Lee S H, Kim C K, Park C M, Nahm K, Nikitov S A 2008 J. Appl. Phys. 103 064907

Google Scholar

Google Scholar

[17] Liu C R, Wu J H, Chen X, Ma F Y 2019 J. Phys. D:Appl. Phys. 52 105302

Google Scholar

Google Scholar

[18] 陈鑫, 姚宏, 赵静波, 张帅, 贺子厚, 蒋娟娜 2019 68 084302

Google Scholar

Google Scholar

Chen X, Yao H, Zhao J B, Zhang S, He Z H, Jiang J N 2019 Acta Phys. Sin. 68 084302

Google Scholar

Google Scholar

[19] Dai H, Liu T, Jiao J, Xia B, Yu D 2017 J. Appl. Phys. 121 135105

Google Scholar

Google Scholar

[20] Li Y, Chen T, Wang X, Yu K, Song R 2015 Physica B (Amsterdam, Neth.) 456 261

Google Scholar

Google Scholar

[21] Elford D P, Chalmers L, Kusmartsev F V, Swallowe G M 2011 J. Acoust. Soc. Am. 130 2746

Google Scholar

Google Scholar

-

表 1 两种方法所得的带隙范围

Table 1. The low-frequency band gap range obtained by the two methods.

计算方法 第一带隙下限 第一带隙上限 有限元法 15.223 17.464 传递矩阵法 15.959 17.131 误差/% 4.83 1.91 表 2 材料参数

Table 2. Material parameters.

材料名称 铜 钢 铝 碳 环氧树脂 密度/(kg·m–3) 8950 7780 2730 1750 1180 杨氏模量/(1010 Pa) 16.46 21.06 7.76 23.01 0.45 泊松比 0.326 0.300 0.352 0.300 0.370 -

[1] 吴永祥, 丁传东 1998 航天医学与医学工程 11 54

Wu Y X, Ding C D 1998 Space Med. Med. Eng. 11 54

[2] Kuo C Y, Hung C L, Chen H C, Shih C P, Lu R H, Chen C W, Hung L W, Lin Y C, Chen H K, Chu D M, Lin Y Y, Chen Y C, Wang C H 2021 Int. J. Environ. Res. Public. Health. 18 2982

Google Scholar

Google Scholar

[3] Wolfe H F, Camden M P, Byrd L W, Paul D B, Simmons L W 2015 J. Aircr. 37 319

[4] Bagherzadeh S A, Salehi M 2021 Appl. Acoust. 178 108020

Google Scholar

Google Scholar

[5] Atak O, Huybrechs D, Pluymers B, Desmet W 2014 J. Sound Vibr. 333 3367

Google Scholar

Google Scholar

[6] 张佳龙, 姚宏, 杜军, 赵静波, 董亚科, 祁鹏山 2016 硅酸盐学报 44 1440

Zhang J L, Yao H, Du J, Zhao J B, DongY K, Qi P S 2016 J. Chin. Ceram. Soc. 44 1440

[7] Han D H, Zhao J B, Zhang G J, Yao H 2021 Symmetry 13 1379

Google Scholar

Google Scholar

[8] Li X, Ning S, Liu Z, Yan Z, Luo C, Zhuang Z 2019 Comput. Methods Appl. Mech. Engrg. 361 112737

[9] Chen L, Guo Y, Yi H 2021 Phys. Lett. A 388 127054

Google Scholar

Google Scholar

[10] Shao H, He H, He C, Chen G 2020 J. Mater. Res. 35 3021

Google Scholar

Google Scholar

[11] 田源, 葛浩, 卢明辉, 陈延峰 2019 68 194301

Google Scholar

Google Scholar

Tian Y, Ge H, Lu M H, Chen Y F 2019 Acta Phys. Sin. 68 194301

Google Scholar

Google Scholar

[12] 廖涛, 孙小伟, 宋婷, 田俊红, 康太凤, 孙伟彬 2018 67 214208

Google Scholar

Google Scholar

Liao T, Sun X W, Song T, Tian J H, Kang T F, Sun W B 2018 Acta Phys. Sin. 67 214208

Google Scholar

Google Scholar

[13] Chen J S, Chen Y B, Cheng Y H, Chou L C 2020 Phys. Lett. A 384 126887

Google Scholar

Google Scholar

[14] Kim M J 2019 Int. J. Mod. Phys. B 33 1950138

Google Scholar

Google Scholar

[15] Gao N, Qu S, Li J, Wang J, Chen W 2021 Int. J. Mech. Sci. 208 106695

Google Scholar

Google Scholar

[16] Wang Z G, Lee S H, Kim C K, Park C M, Nahm K, Nikitov S A 2008 J. Appl. Phys. 103 064907

Google Scholar

Google Scholar

[17] Liu C R, Wu J H, Chen X, Ma F Y 2019 J. Phys. D:Appl. Phys. 52 105302

Google Scholar

Google Scholar

[18] 陈鑫, 姚宏, 赵静波, 张帅, 贺子厚, 蒋娟娜 2019 68 084302

Google Scholar

Google Scholar

Chen X, Yao H, Zhao J B, Zhang S, He Z H, Jiang J N 2019 Acta Phys. Sin. 68 084302

Google Scholar

Google Scholar

[19] Dai H, Liu T, Jiao J, Xia B, Yu D 2017 J. Appl. Phys. 121 135105

Google Scholar

Google Scholar

[20] Li Y, Chen T, Wang X, Yu K, Song R 2015 Physica B (Amsterdam, Neth.) 456 261

Google Scholar

Google Scholar

[21] Elford D P, Chalmers L, Kusmartsev F V, Swallowe G M 2011 J. Acoust. Soc. Am. 130 2746

Google Scholar

Google Scholar

计量

- 文章访问数: 6560

- PDF下载量: 120

- 被引次数: 0

下载:

下载: