-

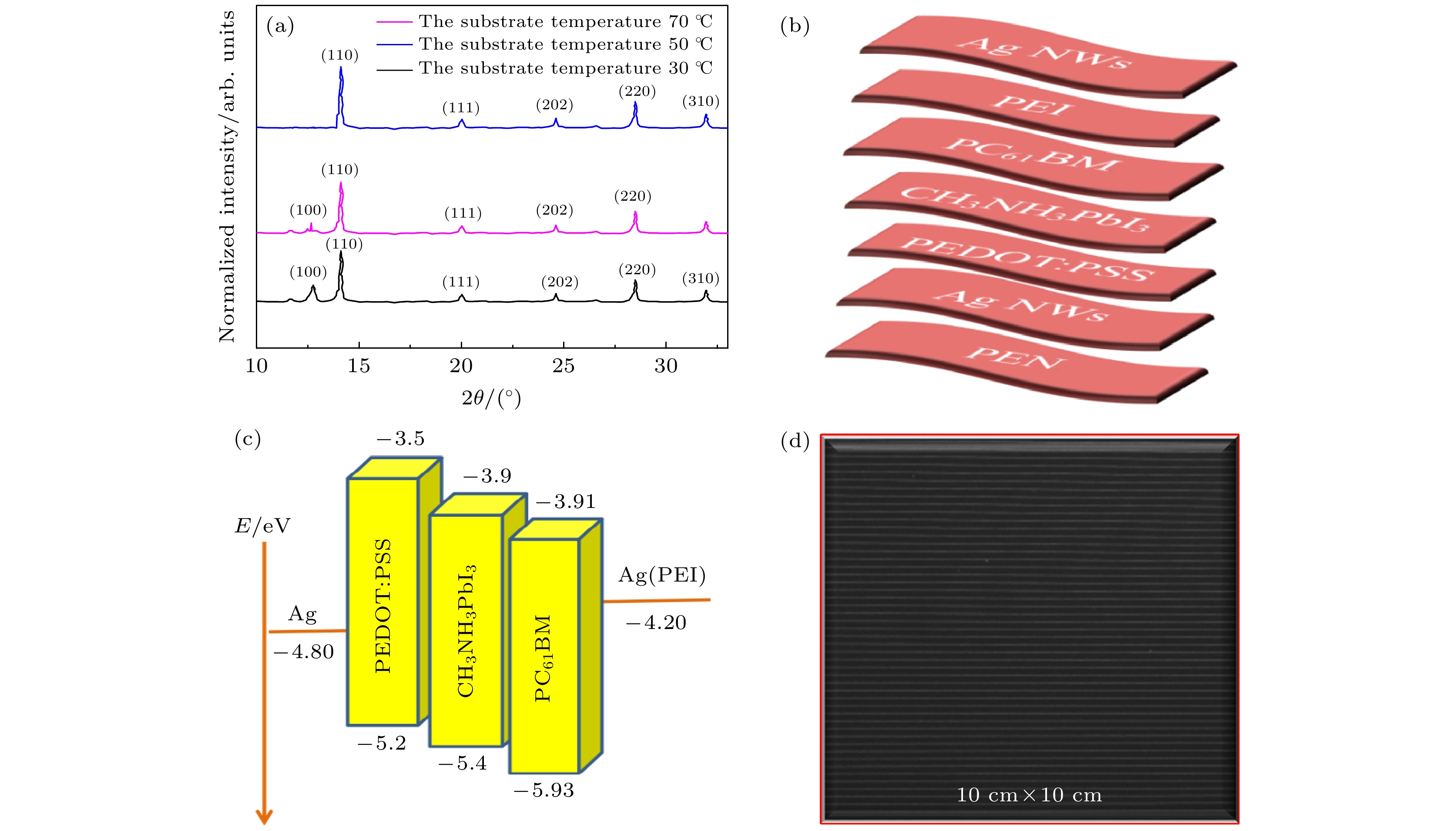

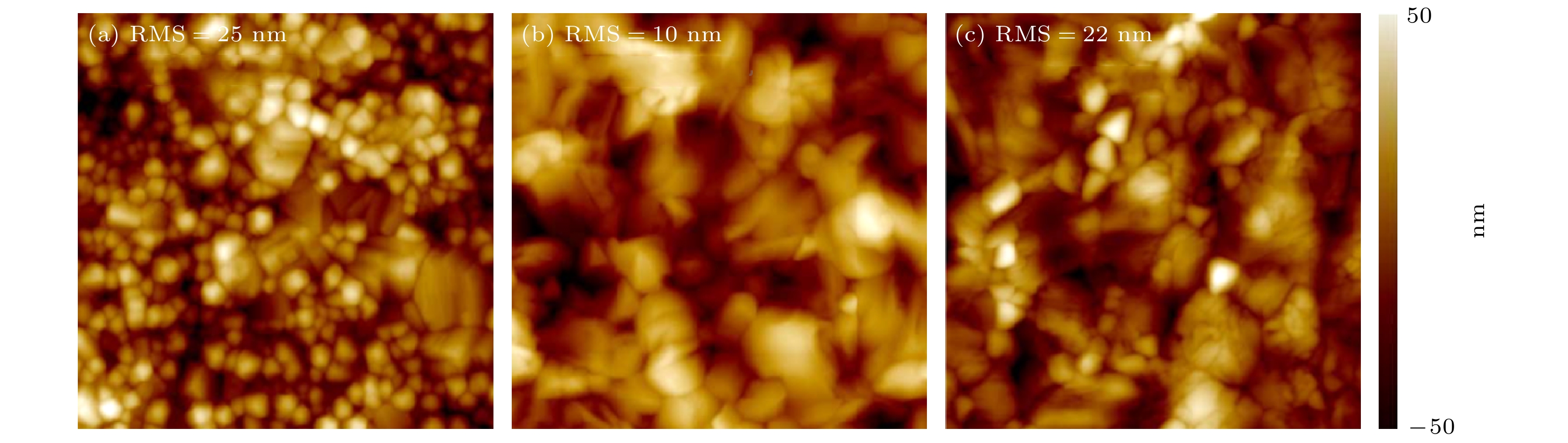

目前基于喷墨打印制备大面积CH3NH3PbI3钙钛矿型太阳能电池的报道较多, 主要集中在钙钛矿活性层薄膜的喷墨打印和电极打印两个方面, 电池结构中空穴传输层和电子传输层以及其他修饰层仍采用旋涂或涂布等工艺完成. 我们成功实现了基于全喷墨打印的大面积CH3NH3PbI3钙钛矿太阳能电池, 包括喷墨打印PEN/Ag NWs底电极, Ag NWs顶电极, PEDOT:PSS 空穴传输层等. 研究发现全喷墨打印可以极大地节约材料成本和简化生产工艺流程, 并且可以获得密度高、均匀性好的PC61BM层、PEDOT:PSS层、PEI层和CH3NH3PbI3钙钛矿薄膜, 在此基础上制备了面积分别为60, 80和100 cm2的CH3NH3PbI3钙钛矿型太阳电池. 结果表明, 当钙钛矿油墨浓度为1 mol/L时, 打印速度设置为30 mm/s, 衬底温度为50 ℃时, 打印生成的钙钛矿薄膜表面光滑, 晶粒均匀生长有序, 晶粒尺寸接近500—600 nm. 晶粒具有规则的扁平形状, 薄膜的表面粗糙度仅为10 nm, 可以获得高质量的钙钛矿薄膜. 采用绿色反溶剂萃取和热退火处理的有效面积为60 cm2的钙钛矿型太阳能电池的功率转换效率高达14.25% (Voc = 1.03 V, Jsc = 19.21 mA/cm2, FF = 72%), 这是迄今为止报道的用全喷墨打印法制备钙钛矿型太阳能电池的最高效率之一. 此外, 当器件在不封装时放置空气中12个月, 光电转换效率降低到初始值的80%. 然而采用含氟热塑性聚氨酯FTPU封装, 光电转换效率仅降低5%, 表现出良好的器件稳定性.

-

关键词:

- 全喷墨打印 /

- 银纳米线电极 /

- 绿色反溶剂萃取和热退火 /

- 大面积制备 /

- 柔性钙钛矿太阳能电池

At present, there are many reports on the preparation of large area CH3NH3PbI3 perovskite solar cells based on ink-jet printing. These researches focus mainly on the ink-jet printing and electrode printing of perovskite active layer films. The hole transport layer, electron transport layer and other modified layers in the cell structure are still completed by spin coating or coating. In this work, we successfully realize large area CH3NH3PbI3 perovskite solar cells based on full ink-jet printing, including pen/Ag NWs bottom electrode, agnws top electrode, PEDOT: PSS hole transport layer, etc. It is found that the full inkjet printing can greatly reduce the material cost and simplify the production process, and obtain PC61BM layer, PEDOT: PSS layer, PEI layer and CH3NH3PbI3 perovskite thin film with high density and good uniformity. On this basis, we prepare the CH3NH3PbI3 perovskite solar cells with areas of 60, 80 and 100 cm2, respectively. The results show that when the concentration of perovskite ink is 1 mol/L, the printing speed is 30 mm/s and the substrate temperature is 50 ℃, the surface of perovskite film is smooth and the grain size is in a range of 500–600 nm. The surface roughness of the film is only 10 nm, so high-quality perovskite film can be obtained. The power conversion efficiency of the perovskite solar cell with an effective area of 60 cm2 is as high as 14.25% (VOC = 1.03 V, JSC = 19.21 mA/cm2, FF = 72%), which is the highest efficiency of perovskite solar cell prepared by full ink-jet printing method reported so far. In addition, when the device is placed in the air for 12 months without packaging, the photoelectric conversion efficiency is reduced to 80% of the initial value. However, the photoelectric conversion efficiency of FTPU package is reduced only by 5%, demonstrating good device stability.-

Keywords:

- all ink jet printing /

- silver nanowire electrode /

- green anti-solvent extraction and thermal annealing /

- large area preparation /

- flexible perovskite solar cell

[1] Liang C, Li P, Gu H, Zhang Y, Li F, Song Y, Shao G, Mathews N, Xing G 2018 Solar RRL 2 1700217

Google Scholar

Google Scholar

[2] Li P, Liang C, Bao B, Li Y, Hu X, Wang Y, Zhang Y, Li F, Shao G, Song Y 2018 Nano Energy 46 203

Google Scholar

Google Scholar

[3] Mathies F, Eggers H, Richards B S, Hernandez-Sosa G, Lemmer U, Paetzold U W 2018 ACS Appl. Energy Mater. 1 1834

Google Scholar

Google Scholar

[4] Schlisske S, Mathies F, Busko D, Strobel N, Lemmer U, Paetzold U W, Hernandez-Sosa G, Klampaftis E 2019 ACS Appl. Energy Mater. 2 764

Google Scholar

Google Scholar

[5] Abzieher T, Moghadamzadeh S, Schackmar F, Eggers H, Sutterlüti F, Farooq A, Kojda D, Paetzold U W 2019 Adv. Energy Mater. 9 1802995

Google Scholar

Google Scholar

[6] Sahli F, Werner J, Kamino B A, et al. 2018 Nat. Mater. 17 820

Google Scholar

Google Scholar

[7] Chen B, Yu Z J, Manzoor S, Wang S, Weigand W, Yu Z H, Yang G, Ni Z Y, Dai X Z, Holman Z C, Huang J S 2020 Joule 4 850

Google Scholar

Google Scholar

[8] Mazzarella L, Lin Y H, Kirner S, Morales-Vilches A B, Korte L, Albrecht S, Crossland E, Stannowski B, Case C, Snaith H J, Schlatmann R 2019 Adv. Energy Mater. 9 1803241

Google Scholar

Google Scholar

[9] Bush K A, Manzoor S, Frohna K, Yu Z J, Raiford J A, Palmstrom A F, Wang H P, Prasanna R, Bent S F, Holman Z C, McGehee M D 2018 ACS Energy Lett. 3 2173

Google Scholar

Google Scholar

[10] Stolterfoht M, Caprioglio P, Wolff C M, et al. 2019 Energy Environ. Sci. 12 2778

Google Scholar

Google Scholar

[11] Correa-Baena J B, Luo Y Q, Huang L B, Buonassisi T, Fenning D P 2019 Science 363 627

Google Scholar

Google Scholar

[12] Beal R E, Hagström N Z, Barrier J, McGehee M D, Toney M F, Nogueira A F 2020 Matter 2 207

Google Scholar

Google Scholar

[13] Mehrabian M, Dalir S, Mahmoudi G, Safin D A 2019 Eur. J. Inorg. Chem. 2019 3699

[14] Gao B W, Meng J 2020 Solar Energy 211 1223

Google Scholar

Google Scholar

[15] Gao B W, Meng J 2020 ACS Appl. Energy Mater. 3 8249

Google Scholar

Google Scholar

[16] Gao B W, Meng J 2020 Appl. Surf.Sci. 530 147240

Google Scholar

Google Scholar

[17] Hashmi S G, Tiihonen, Martineau D, Zakeeruddin S M, Grätzel M 2017 J. Mater. Chem. A 5 4797

Google Scholar

Google Scholar

[18] Huckaba A J, Lee Y, Xia R, Paek S, Dyson P J, Girault H 2019 Energy Technol. 7 317

Google Scholar

Google Scholar

[19] Ye T, Han G F, Surendran A, Li J 2019 Solar Energy Materials and Solar Cells 201 110113

Google Scholar

Google Scholar

[20] Liang C, Zhao D, Li Y, Xing G 2018 Energy Environ. Mater. 1 221

Google Scholar

Google Scholar

-

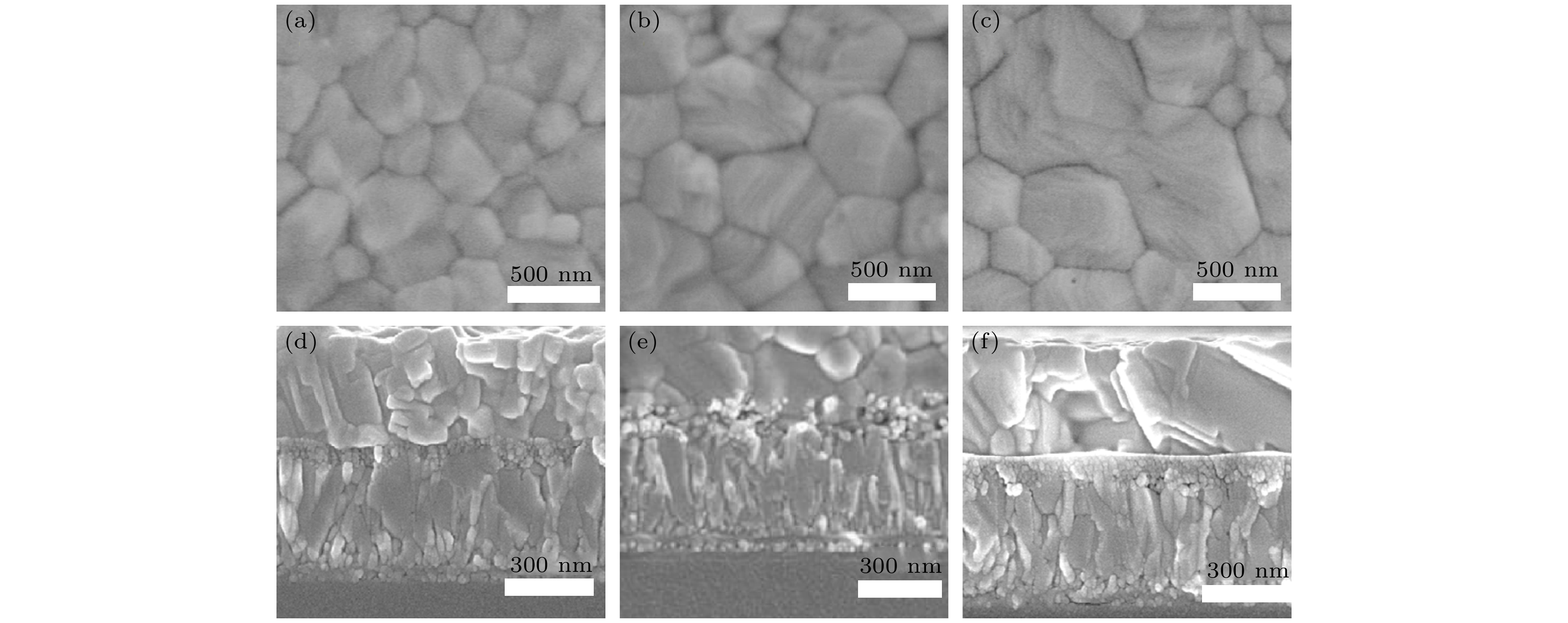

图 2 在PEN/AgNWs/PEDOT:PSS上以及30 mm/s和50 ℃条件下不同浓度的钙钛矿薄膜SEM表面形貌图和器件部分截面图 (a), (d) 0.5 mol/L; (b), (e) 1.0 mol/L; (c), (f) 1.5 mol/L

Fig. 2. SEM surface morphologies of perovskite thin films with different concentrations on PEN/AgNWs/PEDOT: PSS at 30 mm/s and 50 ℃: (a), (d) 0.5 mol/L; (b), (e) 1.0 mol/L; (c), (f) 1.5 mol/L.

表 1 不同直径和长度的Ag NWs透明电极的方阻和透射率

Table 1. Square resistance and transmittance of Ag NWS transparent electrodes with different diameters and lengths.

印刷速度/

(mm·s–1)直径/nm 长度/μm 透射率/% 方阻/

(Ω·sq–1)10 80 40 90 80 15 60 50 92 60 20 50 60 95 30 30 30 80 90 40 表 2 不同有效面积的钙钛矿电池光伏特性和器件参数

Table 2. Photovoltaic characteristics and device parameters of perovskite cells with different effective areas.

电池有效

面积/cm2串联电阻

/(Ω·cm2)并联电阻

/(Ω·cm2)Voc/V Jsc/(mA·cm–2) FF/% PCE/% 60 80 1600 1.03 19.21 72 14.25 80 100 1000 1.02 16.95 68 11.82 100 120 800 1.01 13.90 66 9.26 -

[1] Liang C, Li P, Gu H, Zhang Y, Li F, Song Y, Shao G, Mathews N, Xing G 2018 Solar RRL 2 1700217

Google Scholar

Google Scholar

[2] Li P, Liang C, Bao B, Li Y, Hu X, Wang Y, Zhang Y, Li F, Shao G, Song Y 2018 Nano Energy 46 203

Google Scholar

Google Scholar

[3] Mathies F, Eggers H, Richards B S, Hernandez-Sosa G, Lemmer U, Paetzold U W 2018 ACS Appl. Energy Mater. 1 1834

Google Scholar

Google Scholar

[4] Schlisske S, Mathies F, Busko D, Strobel N, Lemmer U, Paetzold U W, Hernandez-Sosa G, Klampaftis E 2019 ACS Appl. Energy Mater. 2 764

Google Scholar

Google Scholar

[5] Abzieher T, Moghadamzadeh S, Schackmar F, Eggers H, Sutterlüti F, Farooq A, Kojda D, Paetzold U W 2019 Adv. Energy Mater. 9 1802995

Google Scholar

Google Scholar

[6] Sahli F, Werner J, Kamino B A, et al. 2018 Nat. Mater. 17 820

Google Scholar

Google Scholar

[7] Chen B, Yu Z J, Manzoor S, Wang S, Weigand W, Yu Z H, Yang G, Ni Z Y, Dai X Z, Holman Z C, Huang J S 2020 Joule 4 850

Google Scholar

Google Scholar

[8] Mazzarella L, Lin Y H, Kirner S, Morales-Vilches A B, Korte L, Albrecht S, Crossland E, Stannowski B, Case C, Snaith H J, Schlatmann R 2019 Adv. Energy Mater. 9 1803241

Google Scholar

Google Scholar

[9] Bush K A, Manzoor S, Frohna K, Yu Z J, Raiford J A, Palmstrom A F, Wang H P, Prasanna R, Bent S F, Holman Z C, McGehee M D 2018 ACS Energy Lett. 3 2173

Google Scholar

Google Scholar

[10] Stolterfoht M, Caprioglio P, Wolff C M, et al. 2019 Energy Environ. Sci. 12 2778

Google Scholar

Google Scholar

[11] Correa-Baena J B, Luo Y Q, Huang L B, Buonassisi T, Fenning D P 2019 Science 363 627

Google Scholar

Google Scholar

[12] Beal R E, Hagström N Z, Barrier J, McGehee M D, Toney M F, Nogueira A F 2020 Matter 2 207

Google Scholar

Google Scholar

[13] Mehrabian M, Dalir S, Mahmoudi G, Safin D A 2019 Eur. J. Inorg. Chem. 2019 3699

[14] Gao B W, Meng J 2020 Solar Energy 211 1223

Google Scholar

Google Scholar

[15] Gao B W, Meng J 2020 ACS Appl. Energy Mater. 3 8249

Google Scholar

Google Scholar

[16] Gao B W, Meng J 2020 Appl. Surf.Sci. 530 147240

Google Scholar

Google Scholar

[17] Hashmi S G, Tiihonen, Martineau D, Zakeeruddin S M, Grätzel M 2017 J. Mater. Chem. A 5 4797

Google Scholar

Google Scholar

[18] Huckaba A J, Lee Y, Xia R, Paek S, Dyson P J, Girault H 2019 Energy Technol. 7 317

Google Scholar

Google Scholar

[19] Ye T, Han G F, Surendran A, Li J 2019 Solar Energy Materials and Solar Cells 201 110113

Google Scholar

Google Scholar

[20] Liang C, Zhao D, Li Y, Xing G 2018 Energy Environ. Mater. 1 221

Google Scholar

Google Scholar

计量

- 文章访问数: 7772

- PDF下载量: 167

- 被引次数: 0

下载:

下载: