-

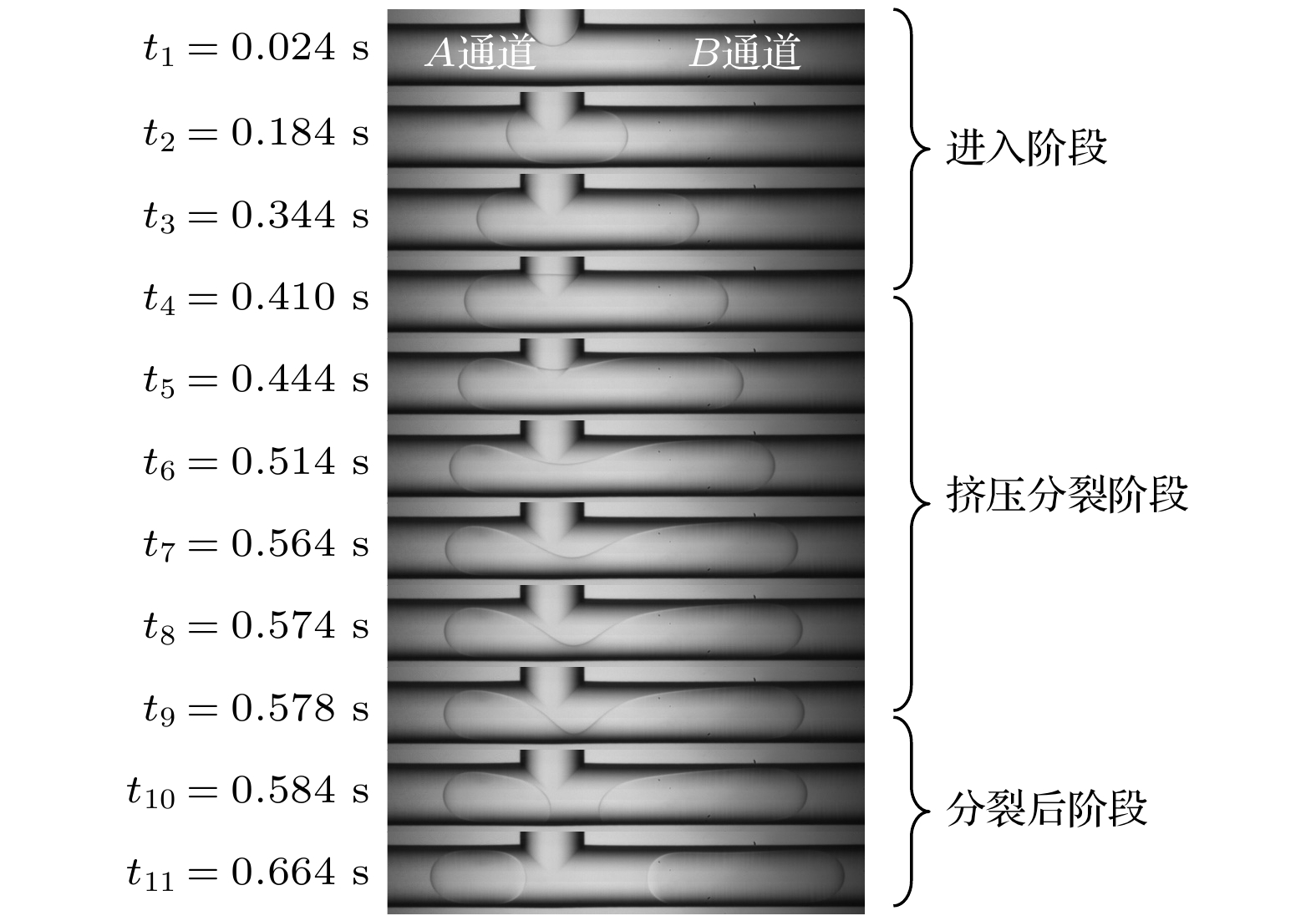

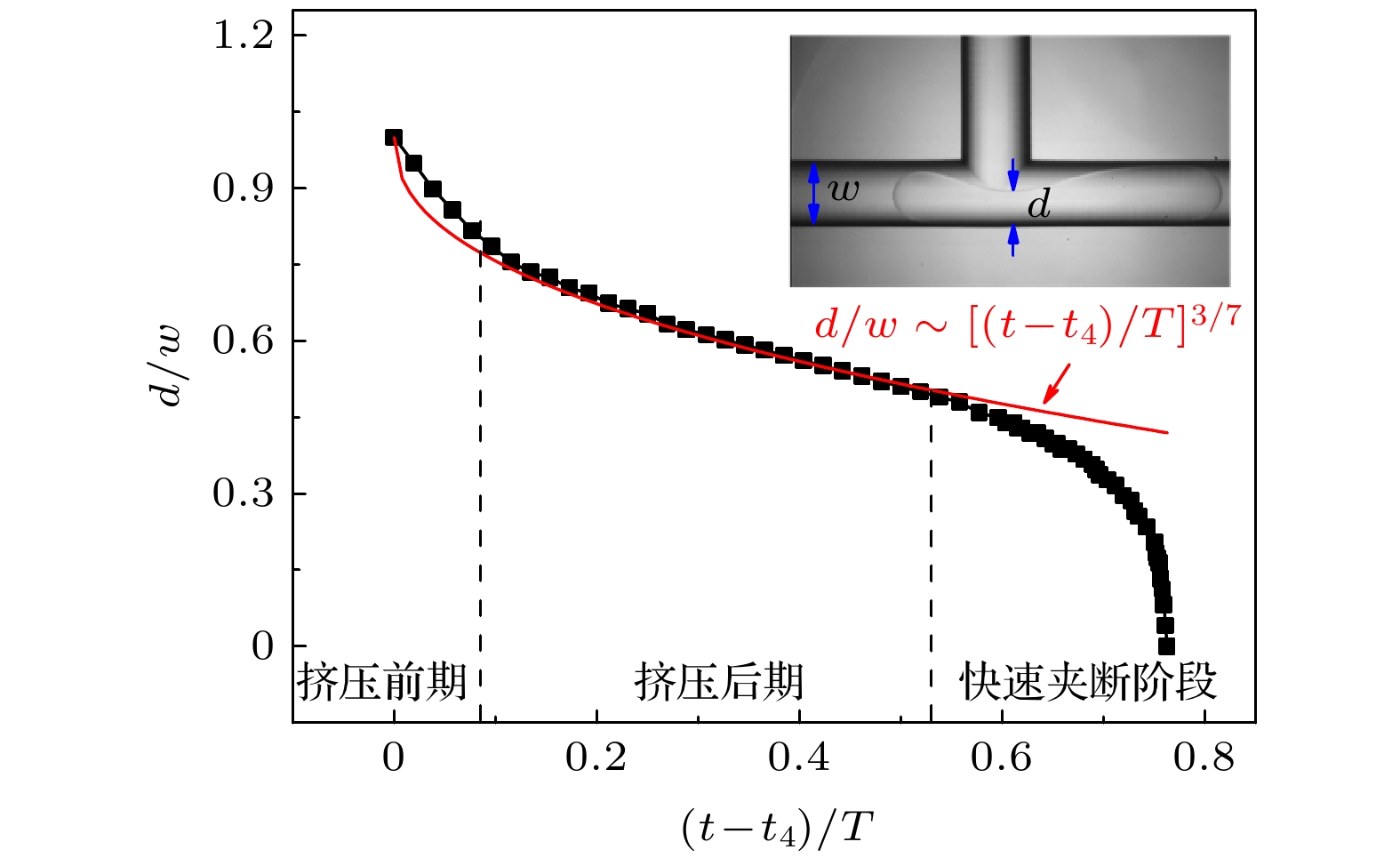

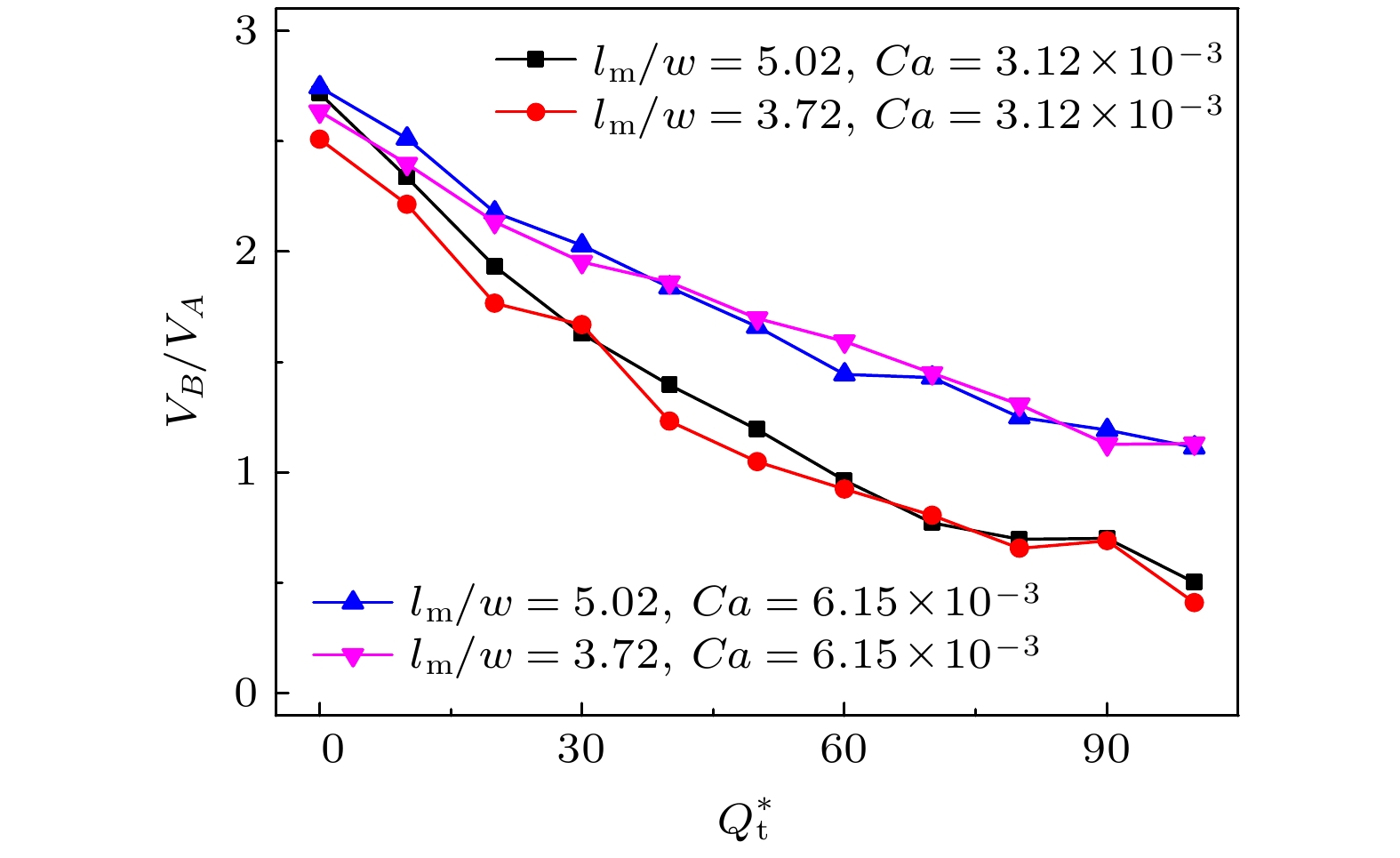

液滴不对称分裂是获得不同尺寸微液滴的优选方法, 研究液滴不对称分裂行为对于生物医学、能源化工及食品工程等领域具有重要意义. 本文研制T型微通道芯片并设计搭建T型微通道液滴半阻塞不对称分裂行为可视化实验平台, 研究流量调控对微液滴分裂比的影响规律, 并建立理论模型对分裂比进行预测, 得到以下结论: 液滴不对称挤压分裂过程分为挤压前期、挤压后期和快速夹断阶段, 在挤压前期, 液滴颈部宽度随时间呈线性变化, 在挤压后期, 颈部宽度随时间呈指数关系, 而在快速夹断阶段, 液滴颈部向心收缩的界面附加压力占主导, 液滴颈部宽度剧烈收缩, 呈断崖式减小; 调控分支通道流量可对液滴不对称分裂比进行调控, 且调控作用受毛细数影响较大; 基于液液流动压降模型的液滴分裂比预测模型能够有效预测液滴分裂比.Asymmetric droplet splitting is a common method to obtain micro-droplets of different sizes. The study of droplet asymmetric splitting behaviors is of great significance to the fields of biomedicine, energy, chemical industry and food engineering. In this paper, the control flow is introduced into a branch of the T-shaped microchannel to control the pressure distribution in the channel and precisely control the size of the daughter droplets. The method is simple to operate and is a preferred method for asymmetric microfluidic splitting. Existing studies have analyzed droplet splitting modes, critical conditions for flow pattern transitions, and splitting dynamics, but the theoretical prediction of droplet asymmetric splitting behaviors needs to be strengthened. Moreover, compared with tunnel splitting and obstructed splitting, which are more abundantly studied, neither semi-obstructed splitting as an intermediate state of tunnel splitting nor obstructed splitting is analyzed sufficiently. Therefore, a microfluidic T-junction chip is designed and fabricated, with which asymmetrical splitting behaviors of droplets with a tunnel in a microfluidic T-junction are investigated experimentally. The influence of flow rate regulation on the droplet splitting ratio is studied. And a theoretical model is also established to predict the splitting ratio. The results are concluded as follows: 1) the process of asymmetrical droplet splitting is divided into three stages i.e. early squeezing, late squeezing and rapid pinch-off stage. In the early stage of squeezing, the radius of curvature of the droplet neck is sizable, and the additional pressure of interfacial tension is minor. Compared with the additional pressure that hinders neck contraction, the upstream continuous phase driving force is dominant, and the width of the neck changes linearly with time; in the process of late squeezing, the upstream pressure driving effect is still greater than the hindering effect of the additional tension, and the neck width changes exponentially with time; However, in the rapid pinch-off stage, the interfacial tension pointing to the center of the cross section of droplet neck dominates the pinch-off stage. Then, the droplet neck shrinks sharply. 2) Adjusting the flow rate of the branch channel can effectively control the asymmetric splitting ratio of the droplets, and under the current semi-obstructed asymmetric splitting of the droplets, the regulation effect is less affected by the size of the mother droplet, but more affected by the capillary number. 3) The prediction model of droplet splitting ratio based on the pressure drop model can effectively predict the droplet splitting ratio.

-

Keywords:

- microfluidic /

- droplet /

- asymmetric /

- breakup

[1] Chen Y P, Zhang C B, Shi M H, Yang Y C 2010 AlChE J. 56 2018

[2] Wang J, Gao W, Zhang H, Zou M H, Chen Y P, Zhao Y J 2018 Sci. Adv. 4 eaat7392

Google Scholar

Google Scholar

[3] Pan D, Liu M, Li F, Chen Q, Liu X, Liu Y, Zhang Z, Huang W, Li B 2018 Chem. Eng. Sci. 176 254

Google Scholar

Google Scholar

[4] Sharei A, Zoldan J, Adamo A, et al. 2013 Proc. Natl. Acad Sci. USA 110 2082

Google Scholar

Google Scholar

[5] Tao Y, Rotem A, Zhang H, et al. 2015 Lab Chip 15 3934

Google Scholar

Google Scholar

[6] Holland-Moritz D A, Wismer M K, Mann B F, et al. 2020 Angew. Chem. Int. Ed. Engl. 59 4470

Google Scholar

Google Scholar

[7] Wang J, Sun L Y, Zou M H, Gao W, Liu C H, Shang L R, Gu Z Z, Zhao Y J 2017 Sci. Adv. 3 e1700004

Google Scholar

Google Scholar

[8] Zuo Y, He X, Yang Y, Wei D, Sun J, Zhong M, Xie R, Fan H, Zhang X 2016 Acta Biomater. 38 153

Google Scholar

Google Scholar

[9] Lan K, Liu J, Li Z C, et al. 2016 Matter and Radiat. at Extremes 1 8

Google Scholar

Google Scholar

[10] Liu M F, Su L, Li J, Chen S F, Liu Y Y, Li J, Li B, Chen Y P, Zhang Z W 2016 Matter and Radiat. at Extremes 1 213

Google Scholar

Google Scholar

[11] Zhang C B, Gao W, Zhao Y J, Chen Y P 2018 Appl. Phys. Lett. 113 203702

Google Scholar

Google Scholar

[12] Shang L, Cheng Y, Zhao Y 2017 Chem. Rev. 117 7964

Google Scholar

Google Scholar

[13] Park J, Jung J H, Park K, Destgeer G, Ahmed H, Ahmad R, Sung H J 2018 Lab Chip 18 422

Google Scholar

Google Scholar

[14] Jung J H, Destgeer G, Ha B, Park J, Sung H J 2016 Lab Chip 16 3235

Google Scholar

Google Scholar

[15] Chaudhuri J, Timung S, Dandamudi C B, Mandal T K, Bandyopadhyay D 2017 Electrophoresis 38 278

Google Scholar

Google Scholar

[16] 崔于桐, 王宁宁, 刘海湖 2017 工程热 38 1564

Cui Y T, Wang N N, Liu H H 2017 J. Eng. Thermophys. 38 1564

[17] Cui Y T, Wang N N, Liu H H 2019 Phys. Fluids 31 022105

Google Scholar

Google Scholar

[18] Rogers C I, Oxborrow J B, Anderson R R, Tsai L F, Nordin G P, Woolley A T 2014 Sens. Actuators B Chem. 191 438

Google Scholar

Google Scholar

[19] Raveshi M R, Agnihotri S N, Sesen M, Bhardwaj R, Neild A 2019 Sensors Actuators B: Chem. 292 233

Google Scholar

Google Scholar

[20] 高崴, 于程, 姚峰 2020 中国物理B 29 054702

Google Scholar

Google Scholar

Gao W, Yu C, Yao F 2020 Chin. Phys. B 29 054702

Google Scholar

Google Scholar

[21] Chen Y P, Gao W, Zhang C B, Zhao Y J 2016 Lab Chip 16 1332

Google Scholar

Google Scholar

[22] Yamada M, Doi S, Maenaka H, Yasuda M, Seki M 2008 J. Colloid Interface Sci. 321 401

Google Scholar

Google Scholar

[23] 王维萌, 马一萍, 王澎, 陈斌 2015 工程热 36 338

Wang W M, Ma Y P, Wang P, Chen B 2015 J. Eng. Thermophys. 36 338

[24] Wang X, Liu Z M, Pang Y 2018 Chem. Eng. Sci. 188 11

Google Scholar

Google Scholar

[25] 梁宏, 柴振华, 施保昌 2016 65 204701

Google Scholar

Google Scholar

Liang H, Chai Z H, Shi B C 2016 Acta Phys. Sin. 65 204701

Google Scholar

Google Scholar

[26] Fu Y H, Bai L, Jin Y, Cheng Y 2017 Phys. Fluids 29 032003

Google Scholar

Google Scholar

[27] Cheng W L, Sadr R, Dai J, Han A 2018 Biomed. Microdevices 20 72

Google Scholar

Google Scholar

[28] Chen B, Li G, Wang W, Wang P 2015 Appl. Therm. Eng. 88 94

Google Scholar

Google Scholar

[29] 俞炜, 邓梓龙, 吴苏晨, 于程, 王超 2019 68 054701

Google Scholar

Google Scholar

Yu W, Deng Z L, Wu S C, Yu C, Wang C 2019 Acta Phys. Sin. 68 054701

Google Scholar

Google Scholar

[30] Leshansky A M, Afkhami S, Jullien M C, Tabeling P 2012 Phys. Rev. Lett. 108 264502

Google Scholar

Google Scholar

[31] Jousse F, Lian G, Janes R, Melrose J 2005 Lab Chip 5 646

Google Scholar

Google Scholar

[32] Fuerstman M J, Lai A, Thurlow M E, Shevkoplyas S S, Stone H A, Whitesides G M 2007 Lab Chip 7 1479

Google Scholar

Google Scholar

[33] Ladosz A, von Rohr P R 2018 Chem. Eng. Sci. 191 398

Google Scholar

Google Scholar

[34] Mortensen N A, Okkels F, Bruus H 2005 Phys. Rev. E Stat Nonlin. Soft Matter Phys. 71 057301

Google Scholar

Google Scholar

[35] Warnier M J F, de Croon M, Rebrov E V, Schouten J C 2010 Microfluid. Nanofluid. 8 33

Google Scholar

Google Scholar

[36] Wong H, Radke C J, Morris S 1995 J. Fluid Mech. 292 95

Google Scholar

Google Scholar

-

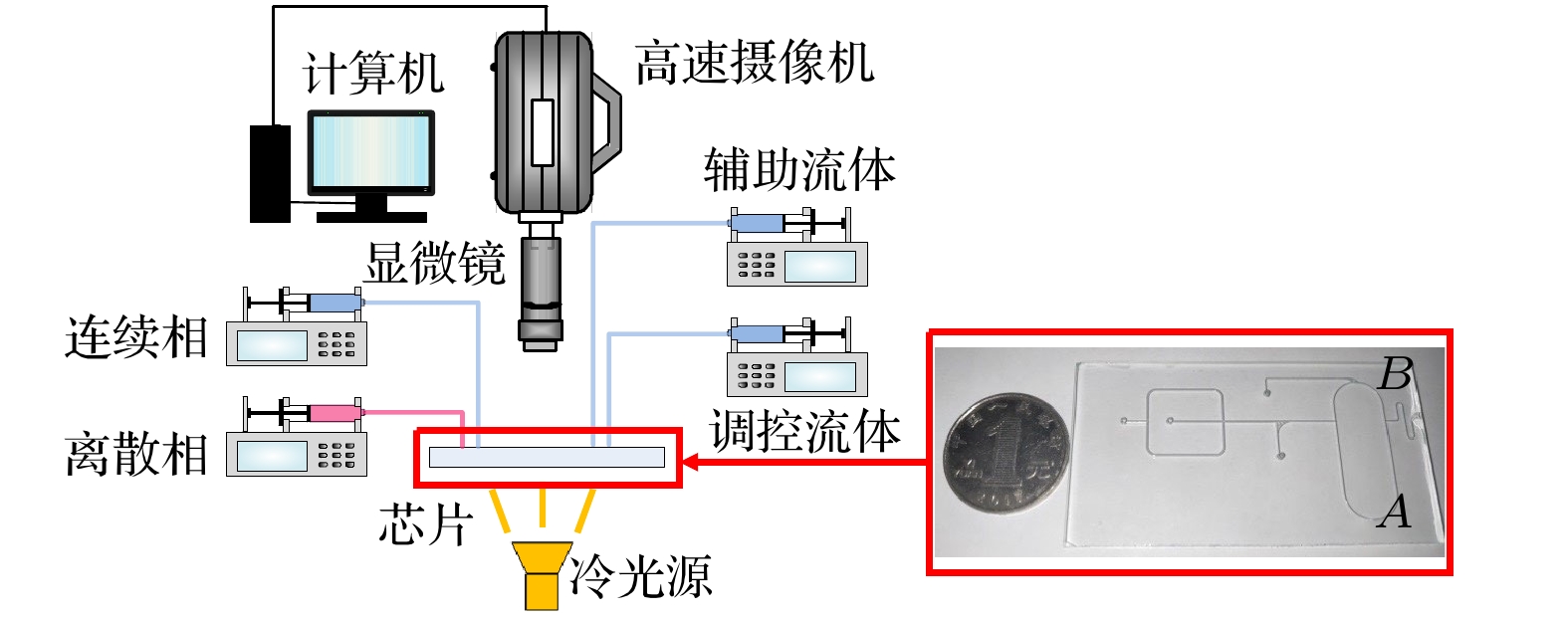

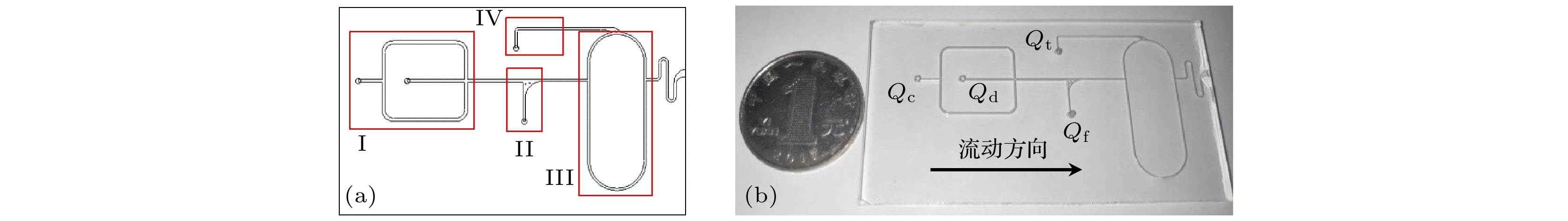

图 1 微流控芯片结构 (a)示意图, I-流动聚焦微通道, II-辅助微通道, III-T型分裂微通道, IV-调控微通道; (b)实物图, 其中Qc为连续相体积流量, Qd为离散相体积流量, Qf为辅助流量, Qt为调控流量

Fig. 1. Geometric structure of the microfluidic chip: (a) Schematic diagram, I-flow focusing microchannel, II-T-shaped splitting microchannel, III-tuning microchannel; (b) actual chip, Qc is volumetric flow rate of continuous phase, Qd is volumetric flow rate of dispersed phase, Qf is volumetric flow rate of supporting continuous phase, Qt is volumetric flow rate of controlling continuous phase

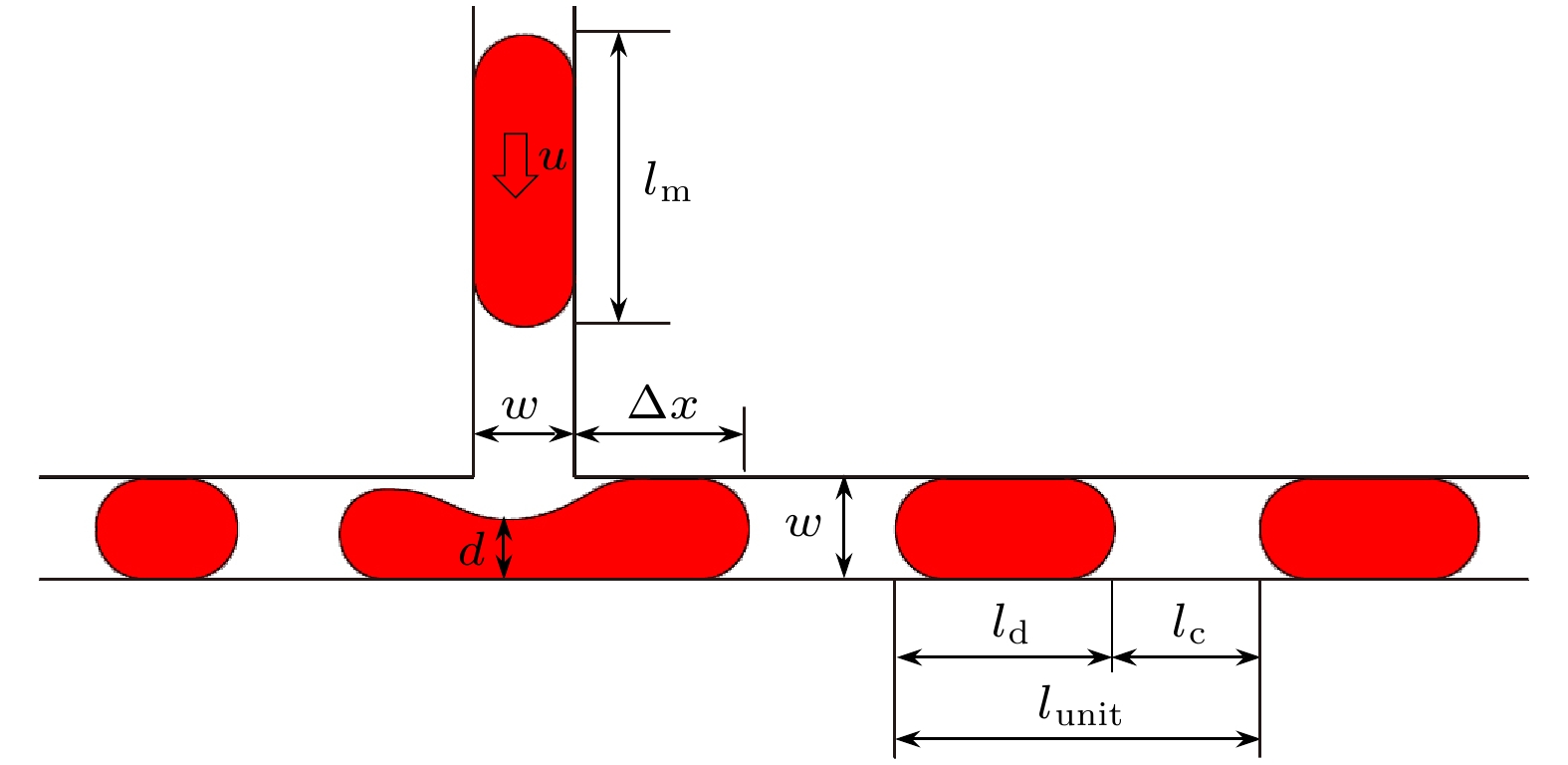

图 2 液滴半阻塞不对称分裂示意图(u为流体速度, lm为母液滴长度, w为微通道宽度, Δx为子液滴头部位移, d为液滴颈部宽度, ld为子液滴长度, lc为子液滴间距)

Fig. 2. Schematic of droplet asymmetrical splitting with a tunnel in a T-junciton (u is velocity of the fluid, lm is length of the mother droplet, w is width of the microchannel, Δx is displacement of the head of the daughter droplets, d is width of the droplet neck, ld is length of the daughter droplet, lc is interval of daughter droplets).

图 5 液滴颈部宽度演变过程(Qc = 400 μL/h, Qd = 40 μL/h, Qt = 0 μL/h, Ca = 5.53 × 10–4, lm /w = 4.08, T = 0.2592 s), 其中(t–t4)/T = 0时表示颈部刚开始收缩

Fig. 5. Evolution of neck width d/w with dimensionless time (t–t4)/T (Qc = 400 μL/h, Qd = 40 μL/h, Qt = 0 μL/h, Ca = 5.53 × 10–4, lm/w = 4.08, T = 0.2592 s), where (t–t4)/T = 0 represents the neck starts contracting.

图 6 分裂过程中液滴前端位移(Qc = 400 μL/h, Qd = 40 μL/h, Qt = 0 μL/h, Ca = 5.53 × 10–4, lm/w = 4.08, T = 0.2592 s), 其中(t–t4)/T = 0表示液滴头部刚开始进入分支通道

Fig. 6. Motion of droplet front cap during splitting process (Qc = 400 μL/h, Qd = 40 μL/h, Qt = 0 μL/h, Ca = 5.53 × 10–4, lm/w = 4.08, T = 0.2592 s), where (t–t4)/T = 0 represents the head of the droplet has just entered the branch channel.

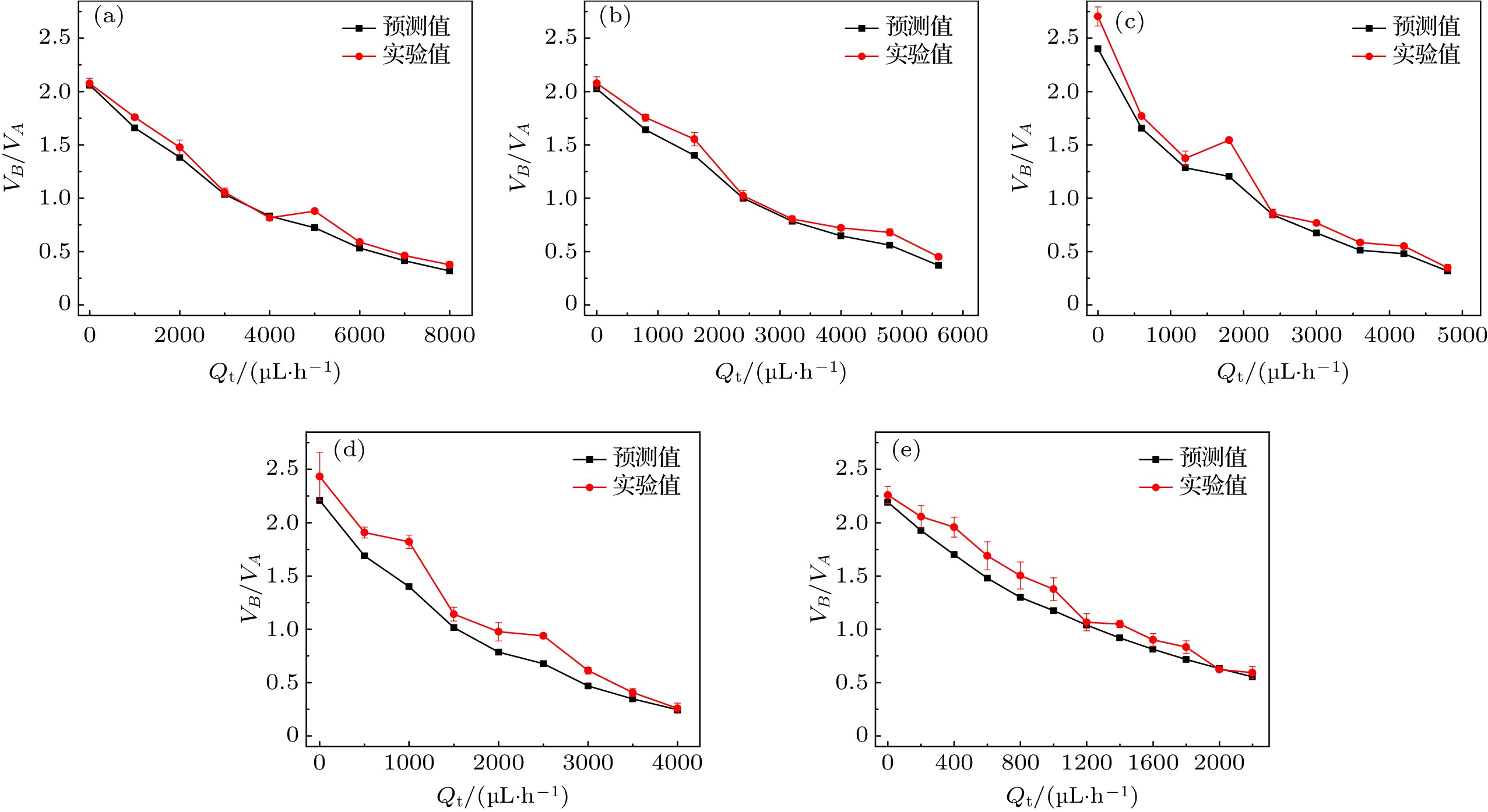

图 9 调控流量Qt变化时液滴不对称分裂比预测值与实验值对比 (a) lm/w = 4.37, Ca = 5.24 × 10–3; (b) lm/w = 4.99, Ca = 3.88 × 10–3; (c) lm/w = 5.44, Ca = 3.04 × 10–3; (d) lm/w = 6.24, Ca = 2.22 × 10–3; (e) lm/w = 7.50, Ca = 1.32 × 10–3

Fig. 9. Comparison of predicted value and experimental value of droplet asymmetric split ratio when Qt changes: (a) lm/w = 4.37, Ca = 5.24 × 10–3; (b) lm/w = 4.99, Ca = 3.88 × 10–3; (c) lm/w = 5.44, Ca = 3.04 × 10–3; (d) lm/w = 6.24, Ca = 2.22 × 10–3; (e) lm/w = 7.50, Ca = 1.32 × 10–3.

-

[1] Chen Y P, Zhang C B, Shi M H, Yang Y C 2010 AlChE J. 56 2018

[2] Wang J, Gao W, Zhang H, Zou M H, Chen Y P, Zhao Y J 2018 Sci. Adv. 4 eaat7392

Google Scholar

Google Scholar

[3] Pan D, Liu M, Li F, Chen Q, Liu X, Liu Y, Zhang Z, Huang W, Li B 2018 Chem. Eng. Sci. 176 254

Google Scholar

Google Scholar

[4] Sharei A, Zoldan J, Adamo A, et al. 2013 Proc. Natl. Acad Sci. USA 110 2082

Google Scholar

Google Scholar

[5] Tao Y, Rotem A, Zhang H, et al. 2015 Lab Chip 15 3934

Google Scholar

Google Scholar

[6] Holland-Moritz D A, Wismer M K, Mann B F, et al. 2020 Angew. Chem. Int. Ed. Engl. 59 4470

Google Scholar

Google Scholar

[7] Wang J, Sun L Y, Zou M H, Gao W, Liu C H, Shang L R, Gu Z Z, Zhao Y J 2017 Sci. Adv. 3 e1700004

Google Scholar

Google Scholar

[8] Zuo Y, He X, Yang Y, Wei D, Sun J, Zhong M, Xie R, Fan H, Zhang X 2016 Acta Biomater. 38 153

Google Scholar

Google Scholar

[9] Lan K, Liu J, Li Z C, et al. 2016 Matter and Radiat. at Extremes 1 8

Google Scholar

Google Scholar

[10] Liu M F, Su L, Li J, Chen S F, Liu Y Y, Li J, Li B, Chen Y P, Zhang Z W 2016 Matter and Radiat. at Extremes 1 213

Google Scholar

Google Scholar

[11] Zhang C B, Gao W, Zhao Y J, Chen Y P 2018 Appl. Phys. Lett. 113 203702

Google Scholar

Google Scholar

[12] Shang L, Cheng Y, Zhao Y 2017 Chem. Rev. 117 7964

Google Scholar

Google Scholar

[13] Park J, Jung J H, Park K, Destgeer G, Ahmed H, Ahmad R, Sung H J 2018 Lab Chip 18 422

Google Scholar

Google Scholar

[14] Jung J H, Destgeer G, Ha B, Park J, Sung H J 2016 Lab Chip 16 3235

Google Scholar

Google Scholar

[15] Chaudhuri J, Timung S, Dandamudi C B, Mandal T K, Bandyopadhyay D 2017 Electrophoresis 38 278

Google Scholar

Google Scholar

[16] 崔于桐, 王宁宁, 刘海湖 2017 工程热 38 1564

Cui Y T, Wang N N, Liu H H 2017 J. Eng. Thermophys. 38 1564

[17] Cui Y T, Wang N N, Liu H H 2019 Phys. Fluids 31 022105

Google Scholar

Google Scholar

[18] Rogers C I, Oxborrow J B, Anderson R R, Tsai L F, Nordin G P, Woolley A T 2014 Sens. Actuators B Chem. 191 438

Google Scholar

Google Scholar

[19] Raveshi M R, Agnihotri S N, Sesen M, Bhardwaj R, Neild A 2019 Sensors Actuators B: Chem. 292 233

Google Scholar

Google Scholar

[20] 高崴, 于程, 姚峰 2020 中国物理B 29 054702

Google Scholar

Google Scholar

Gao W, Yu C, Yao F 2020 Chin. Phys. B 29 054702

Google Scholar

Google Scholar

[21] Chen Y P, Gao W, Zhang C B, Zhao Y J 2016 Lab Chip 16 1332

Google Scholar

Google Scholar

[22] Yamada M, Doi S, Maenaka H, Yasuda M, Seki M 2008 J. Colloid Interface Sci. 321 401

Google Scholar

Google Scholar

[23] 王维萌, 马一萍, 王澎, 陈斌 2015 工程热 36 338

Wang W M, Ma Y P, Wang P, Chen B 2015 J. Eng. Thermophys. 36 338

[24] Wang X, Liu Z M, Pang Y 2018 Chem. Eng. Sci. 188 11

Google Scholar

Google Scholar

[25] 梁宏, 柴振华, 施保昌 2016 65 204701

Google Scholar

Google Scholar

Liang H, Chai Z H, Shi B C 2016 Acta Phys. Sin. 65 204701

Google Scholar

Google Scholar

[26] Fu Y H, Bai L, Jin Y, Cheng Y 2017 Phys. Fluids 29 032003

Google Scholar

Google Scholar

[27] Cheng W L, Sadr R, Dai J, Han A 2018 Biomed. Microdevices 20 72

Google Scholar

Google Scholar

[28] Chen B, Li G, Wang W, Wang P 2015 Appl. Therm. Eng. 88 94

Google Scholar

Google Scholar

[29] 俞炜, 邓梓龙, 吴苏晨, 于程, 王超 2019 68 054701

Google Scholar

Google Scholar

Yu W, Deng Z L, Wu S C, Yu C, Wang C 2019 Acta Phys. Sin. 68 054701

Google Scholar

Google Scholar

[30] Leshansky A M, Afkhami S, Jullien M C, Tabeling P 2012 Phys. Rev. Lett. 108 264502

Google Scholar

Google Scholar

[31] Jousse F, Lian G, Janes R, Melrose J 2005 Lab Chip 5 646

Google Scholar

Google Scholar

[32] Fuerstman M J, Lai A, Thurlow M E, Shevkoplyas S S, Stone H A, Whitesides G M 2007 Lab Chip 7 1479

Google Scholar

Google Scholar

[33] Ladosz A, von Rohr P R 2018 Chem. Eng. Sci. 191 398

Google Scholar

Google Scholar

[34] Mortensen N A, Okkels F, Bruus H 2005 Phys. Rev. E Stat Nonlin. Soft Matter Phys. 71 057301

Google Scholar

Google Scholar

[35] Warnier M J F, de Croon M, Rebrov E V, Schouten J C 2010 Microfluid. Nanofluid. 8 33

Google Scholar

Google Scholar

[36] Wong H, Radke C J, Morris S 1995 J. Fluid Mech. 292 95

Google Scholar

Google Scholar

计量

- 文章访问数: 7981

- PDF下载量: 133

- 被引次数: 0

下载:

下载: