-

自由流体层和多孔介质层交界处同时存在温度梯度和盐度梯度会导致盐指型双扩散对流的发生, 改变流体的运动状态, 进而影响物质输移规律. 本文建立了流体层与多孔介质层界面双扩散耦合模型, 模型采用统一域法, 在上下层分别计算水动力-温度-浓度输运方程, 用快速傅里叶变换求解统一域内流函数方程. 计算分析了

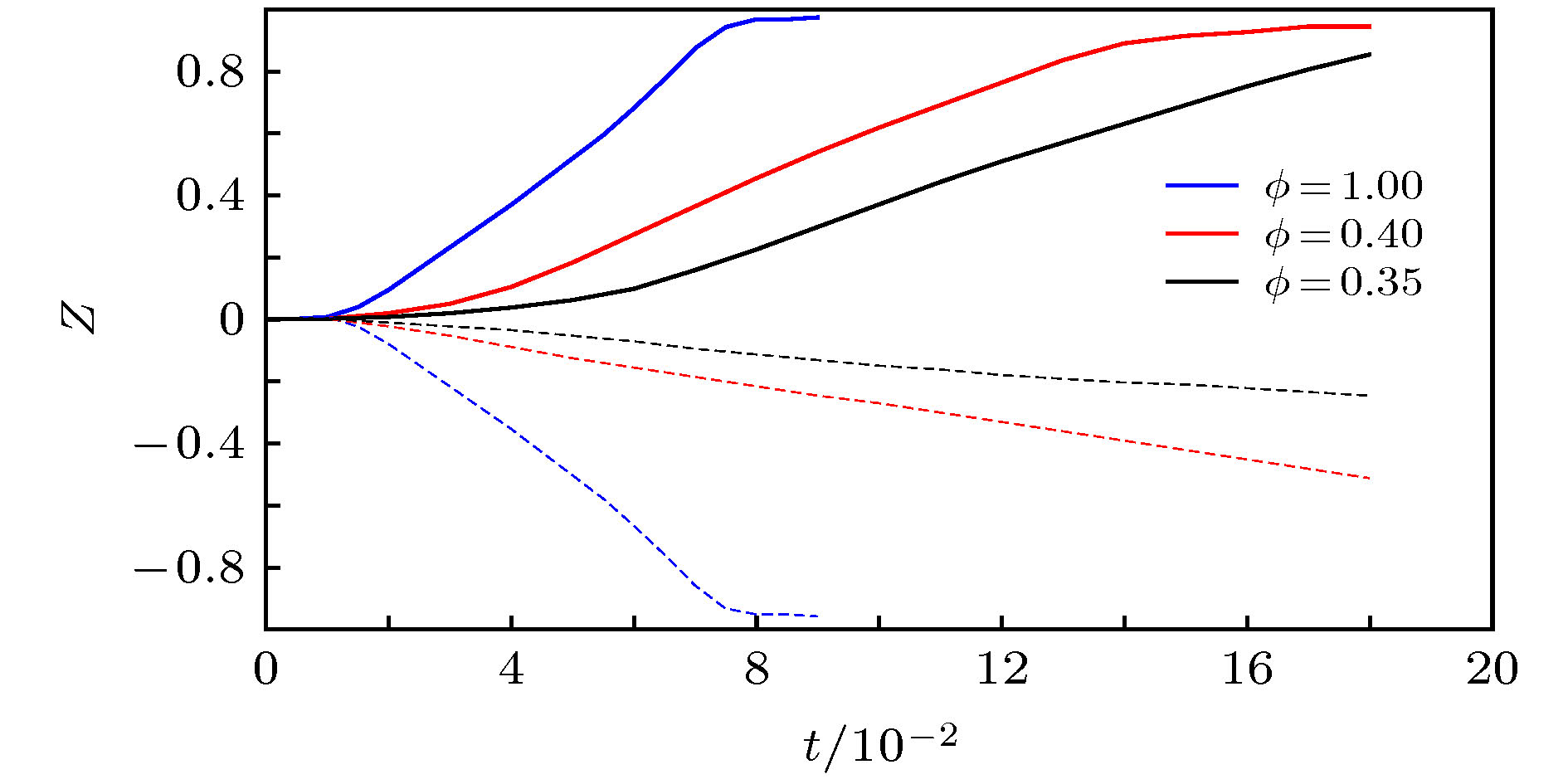

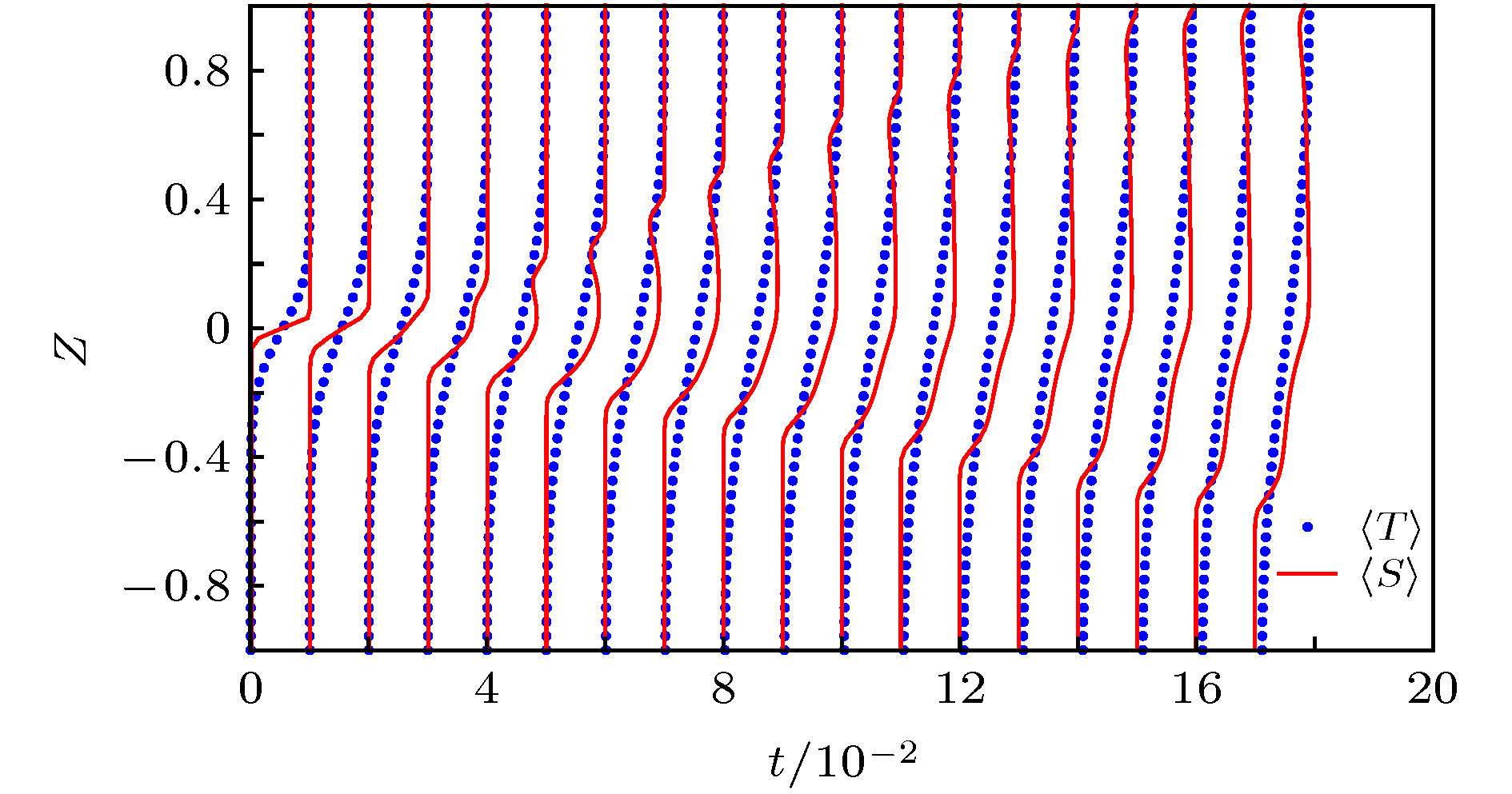

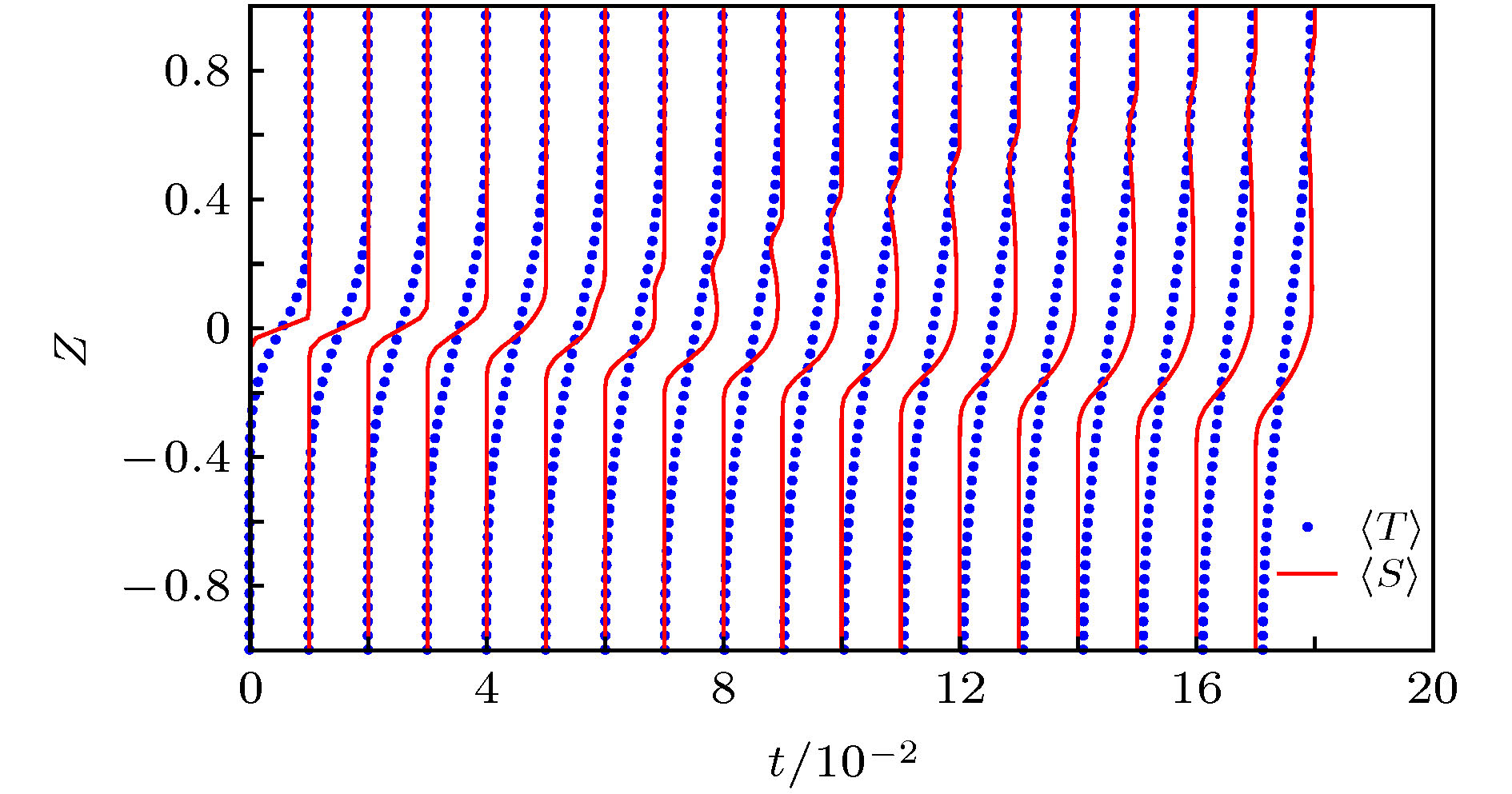

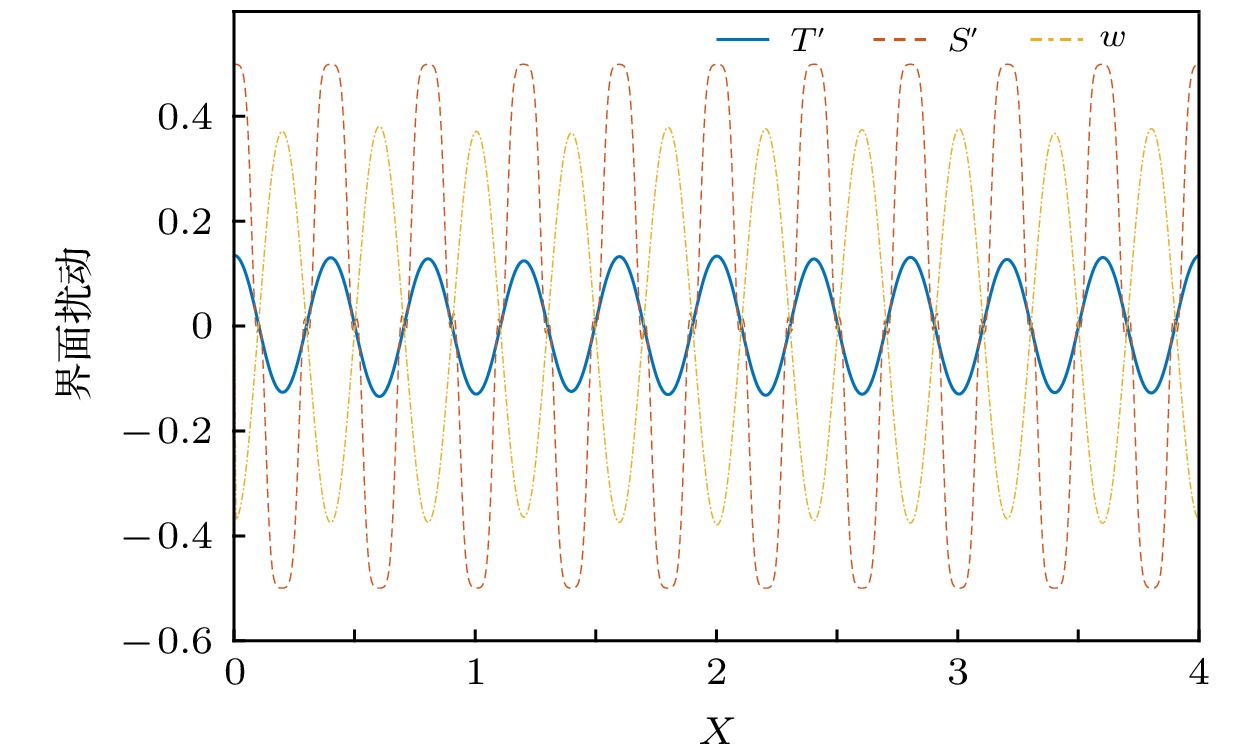

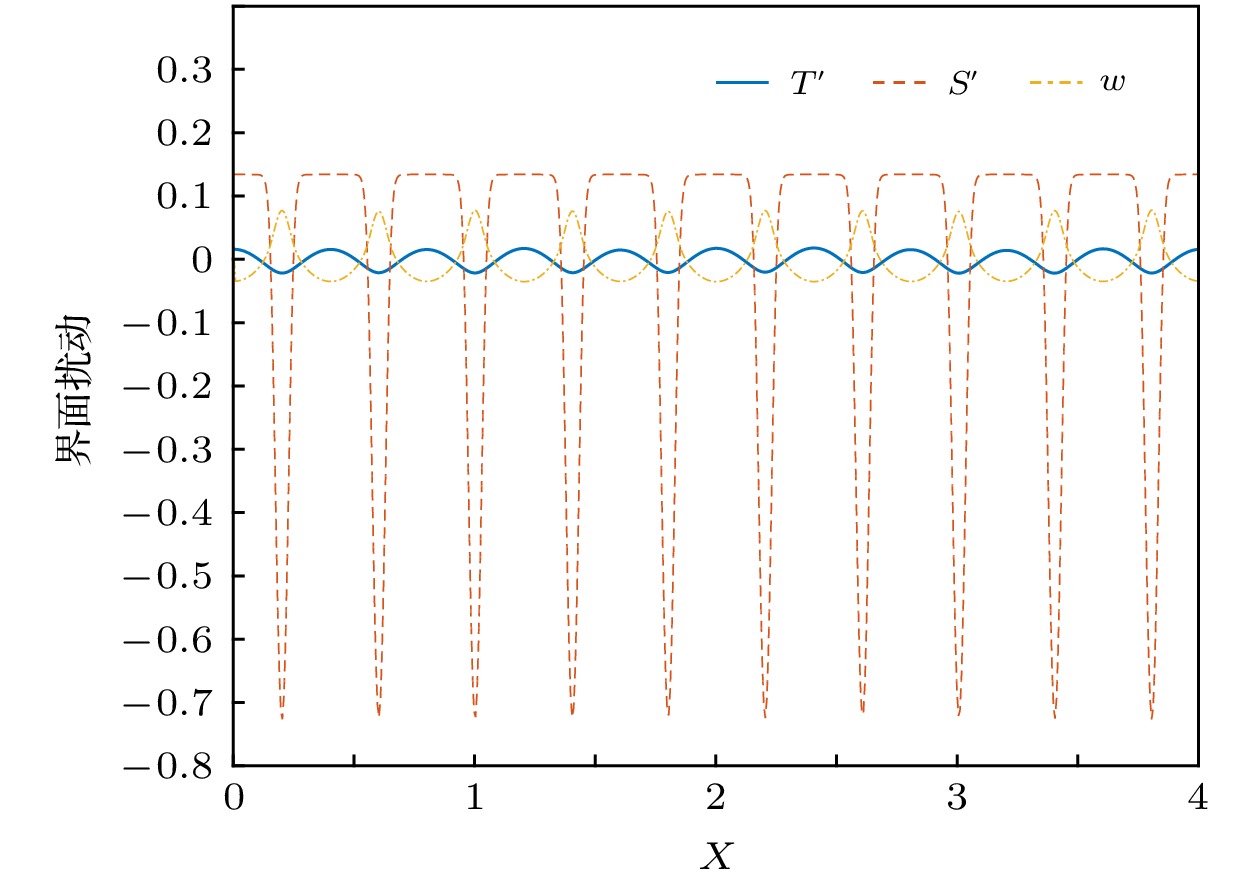

$ \phi = 0.3{{5}},\;0.4{{0}},\;1 $ 的三个典型工况, 研究在多孔介质层不同孔隙率下盐指的对流结构和演变过程, 讨论了稳定密度分层下物质输移现象及其输运特性. 结果表明, 与分层水体中的盐指不同, 流体层和多孔介质层界面的盐指具有非对称结构, 多孔介质层的下沉盐指较于上升盐指更宽, 生长速度慢, 在混合区域内具有更好的输运能力. 研究发现多孔介质中固体的存在极大地阻碍了盐指对流的生长, 同时影响了垂向的物质通量; 在孔隙率高的工况中, 由盐度的不稳定分层储存的潜在势能更多地转化为动能, 从而增加了垂直方向上的物质输运, 使盐指具有更强的混合能力.Simultaneous occurrence of temperature gradient and solute gradient at the fluid-sediment interface is conducive to the onset of salt-finger convection, which may in turn cause adverse effects on fluid mechanism. Ignoring the existence of salt finger would lead to numerical errors or sometimes even qualitative error in calculation of vertical mass fluxes. In this paper, a single-domain approach is adopted for the two-dimensional numerical model of flow coupled temperature and solute in a composite region made up of an upper fluid layer and an underlying saturated porous layer to investigate the evolution of the double diffusion convection of salt-finger form at the fluid-saturated porous interface. Darcian model describing the porous medium and incompressible Navier-Stokes equations in the fluid layer are solved at the same time, where different heat capacities, thermal conductivities and solute diffusion coefficients are considered. Three cases for$ \phi = 0.3{{5}},\;0.4{{0}},\;1 $ are considerded to study the evolution process and structure of salt fingers. The evolution process of salt finger is divided into three stages: diffusion stage, linear growth stage and slow growth stage. For all cases, the kinetic energy is transformed rapidly at linear growth stage, which promotes the mixture of momentum, temperature and salinity at the interface. Then at the slow growth stage, the kinetic energy conversion rate becomes slower before finally the kinetic energy is dissipated by the viscosity and friction. The results show that unlike the salt finger structure in stratified fluid, an asymmetric structure of salt finger is discovered where finger in the porous medium is shorter and wider. The existence of solid skeleton in porous medium hinders the growth of salt finger and reduces the vertical mass flux. Compared with the temperature, the salinity fluctuates more greatly at the interface, which also means that the effect of salt finger on salinity is greater than that of temperature. It is found that the higher the porosity, the faster the growth of thickness of salt finger interface is. Under the condition of high porosity, the potential energy stored by the unstable stratification of salinity is converted much more into kinetic energy, which increases the transport of heat and mass in the vertical direction and thus enhances the mixture capability of salt finger in the vertical direction.-

Keywords:

- porous layer /

- interface /

- salt finger /

- laminar flow

[1] Schmitt R W 1983 Phys. Fluids 26 2373

Google Scholar

Google Scholar

[2] Slim A C, Bandi M M, Miller J C, Mahadevan L 2013 Phys. Fluids 25 024101

Google Scholar

Google Scholar

[3] Hage E, Tilgner A 2010 Phys. Fluids 22 11

Google Scholar

Google Scholar

[4] Rehman F, Singh O P 2017 Geophys. Astrophys. Fluid Dyn. 111 1

Google Scholar

Google Scholar

[5] Chen F, Chen C F 1993 Int. J. Heat Mass Transfer 36 793

Google Scholar

Google Scholar

[6] Piacsek S A, Toomre J 1980 Elsevier Oceanogr. Ser. 28 193

Google Scholar

Google Scholar

[7] Özgökmen T M, Esenkov O E, Olson D B 1998 J. Mar. Res. 56 463

Google Scholar

Google Scholar

[8] Kluikov Y Y, Karlin L N 1995 GMS 94 287

Google Scholar

Google Scholar

[9] Schmitt R W, Ledwell J R, Montgomery E T, Polzin K, Toole J 2005 Science 308 685

Google Scholar

Google Scholar

[10] 罗莹莹, 詹杰民, 李毓湘 2008 57 2306

Google Scholar

Google Scholar

Luo Y, Zhan J, Li S 2008 Acta Phys. Sin. 57 2306

Google Scholar

Google Scholar

[11] 郑来运, 赵秉新, 杨建青 2020 69 074701

Google Scholar

Google Scholar

Zheng L Y, Zhao B X, Yang J Q 2020 Acta Phys. Sin. 69 074701

Google Scholar

Google Scholar

[12] Chen F, Chen C F 1988 J. Heat Transfer 110 403

Google Scholar

Google Scholar

[13] Cooper C A, Glass R J, Tyler S W 2001 Water Resour. Res. 37 2323

Google Scholar

Google Scholar

[14] Werner C L 2007 Ph. D. Dissertation (Tallahassee: Florida State University)

[15] Singh O P, Srinivasan J 2014 Phys. Fluids 26 2373

Google Scholar

Google Scholar

[16] Shen C Y 1993 Phys. Fluids 5 2633

Google Scholar

Google Scholar

[17] Fernandes A M, Krishnamurti R 2010 J. Fluid Mech. 658 148

Google Scholar

Google Scholar

[18] Copley S M, Giamei A F, Johnson S M, Hornbecker M F 1970 Metall. Trans. 1 2193

Google Scholar

Google Scholar

[19] Basu A J, Khalili A 1999 Phys. Fluids 11 1395

Google Scholar

Google Scholar

[20] Shen C J, Jin G Q, Xin P, Kong J, Li L 2015 Water Resour. Res. 51 4301

Google Scholar

Google Scholar

[21] Beavers G S, Joseph D D 1967 J. Fluid Mech. 30 11

Google Scholar

Google Scholar

[22] Kuznetsov A V 1997 Int. Commun. Heat Mass Transfer 24 401

Google Scholar

Google Scholar

[23] 娄钦, 黄一帆, 李凌 2019 68 214702

Google Scholar

Google Scholar

Lou Q, Huang Y, Li L 2019 Acta Phys. Sin. 68 214702

Google Scholar

Google Scholar

[24] Caltagirone J P 1975 J. Fluid Mech. 72 269

Google Scholar

Google Scholar

[25] Zhan J M, Luo Y Y, Li Y S 2008 Appl. Math. Modell. 32 873

Google Scholar

Google Scholar

[26] Zhang X F, Wang L L, Lin C, Zhu H, Zeng C 2018 Phys. Fluids 30 022110

Google Scholar

Google Scholar

[27] Garaud P 2018 Annu. Rev. Fluid Mech. 50 275

Google Scholar

Google Scholar

[28] Kunze E 1987 J. Mar. Res. 45 533

Google Scholar

Google Scholar

-

表 1 无量纲参数取值

Table 1. Values of dimensionless parameters.

无量纲参数 Pr Le Ra N Φ 取值 7 100 50000 2 0.35, 0.4, 1 -

[1] Schmitt R W 1983 Phys. Fluids 26 2373

Google Scholar

Google Scholar

[2] Slim A C, Bandi M M, Miller J C, Mahadevan L 2013 Phys. Fluids 25 024101

Google Scholar

Google Scholar

[3] Hage E, Tilgner A 2010 Phys. Fluids 22 11

Google Scholar

Google Scholar

[4] Rehman F, Singh O P 2017 Geophys. Astrophys. Fluid Dyn. 111 1

Google Scholar

Google Scholar

[5] Chen F, Chen C F 1993 Int. J. Heat Mass Transfer 36 793

Google Scholar

Google Scholar

[6] Piacsek S A, Toomre J 1980 Elsevier Oceanogr. Ser. 28 193

Google Scholar

Google Scholar

[7] Özgökmen T M, Esenkov O E, Olson D B 1998 J. Mar. Res. 56 463

Google Scholar

Google Scholar

[8] Kluikov Y Y, Karlin L N 1995 GMS 94 287

Google Scholar

Google Scholar

[9] Schmitt R W, Ledwell J R, Montgomery E T, Polzin K, Toole J 2005 Science 308 685

Google Scholar

Google Scholar

[10] 罗莹莹, 詹杰民, 李毓湘 2008 57 2306

Google Scholar

Google Scholar

Luo Y, Zhan J, Li S 2008 Acta Phys. Sin. 57 2306

Google Scholar

Google Scholar

[11] 郑来运, 赵秉新, 杨建青 2020 69 074701

Google Scholar

Google Scholar

Zheng L Y, Zhao B X, Yang J Q 2020 Acta Phys. Sin. 69 074701

Google Scholar

Google Scholar

[12] Chen F, Chen C F 1988 J. Heat Transfer 110 403

Google Scholar

Google Scholar

[13] Cooper C A, Glass R J, Tyler S W 2001 Water Resour. Res. 37 2323

Google Scholar

Google Scholar

[14] Werner C L 2007 Ph. D. Dissertation (Tallahassee: Florida State University)

[15] Singh O P, Srinivasan J 2014 Phys. Fluids 26 2373

Google Scholar

Google Scholar

[16] Shen C Y 1993 Phys. Fluids 5 2633

Google Scholar

Google Scholar

[17] Fernandes A M, Krishnamurti R 2010 J. Fluid Mech. 658 148

Google Scholar

Google Scholar

[18] Copley S M, Giamei A F, Johnson S M, Hornbecker M F 1970 Metall. Trans. 1 2193

Google Scholar

Google Scholar

[19] Basu A J, Khalili A 1999 Phys. Fluids 11 1395

Google Scholar

Google Scholar

[20] Shen C J, Jin G Q, Xin P, Kong J, Li L 2015 Water Resour. Res. 51 4301

Google Scholar

Google Scholar

[21] Beavers G S, Joseph D D 1967 J. Fluid Mech. 30 11

Google Scholar

Google Scholar

[22] Kuznetsov A V 1997 Int. Commun. Heat Mass Transfer 24 401

Google Scholar

Google Scholar

[23] 娄钦, 黄一帆, 李凌 2019 68 214702

Google Scholar

Google Scholar

Lou Q, Huang Y, Li L 2019 Acta Phys. Sin. 68 214702

Google Scholar

Google Scholar

[24] Caltagirone J P 1975 J. Fluid Mech. 72 269

Google Scholar

Google Scholar

[25] Zhan J M, Luo Y Y, Li Y S 2008 Appl. Math. Modell. 32 873

Google Scholar

Google Scholar

[26] Zhang X F, Wang L L, Lin C, Zhu H, Zeng C 2018 Phys. Fluids 30 022110

Google Scholar

Google Scholar

[27] Garaud P 2018 Annu. Rev. Fluid Mech. 50 275

Google Scholar

Google Scholar

[28] Kunze E 1987 J. Mar. Res. 45 533

Google Scholar

Google Scholar

计量

- 文章访问数: 9662

- PDF下载量: 84

- 被引次数: 0

下载:

下载: