-

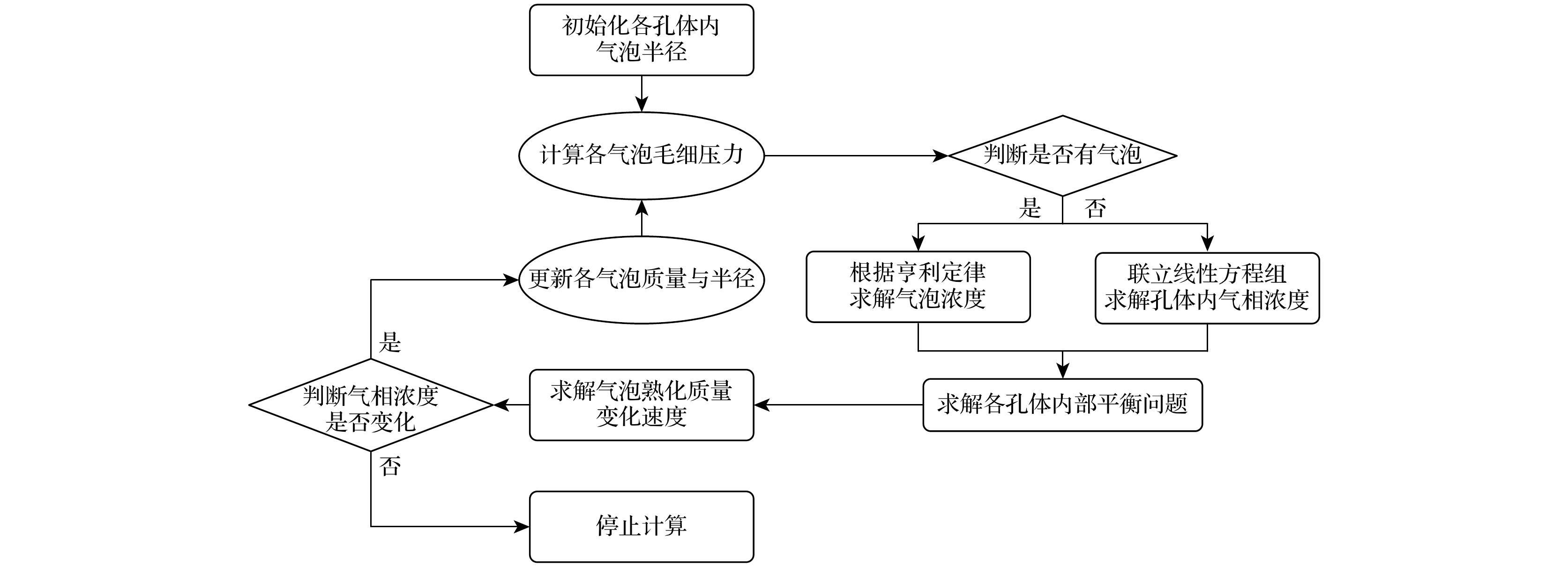

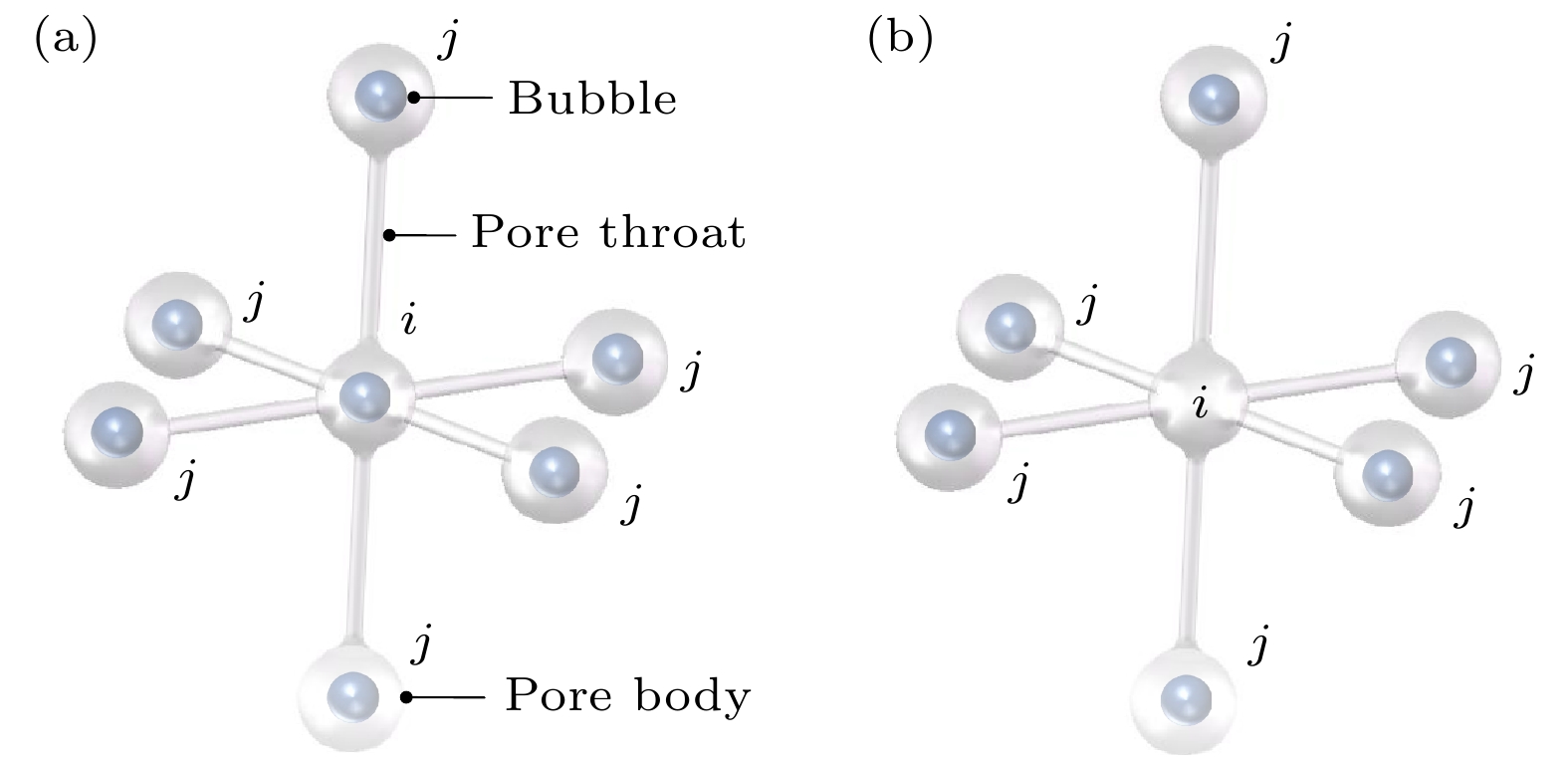

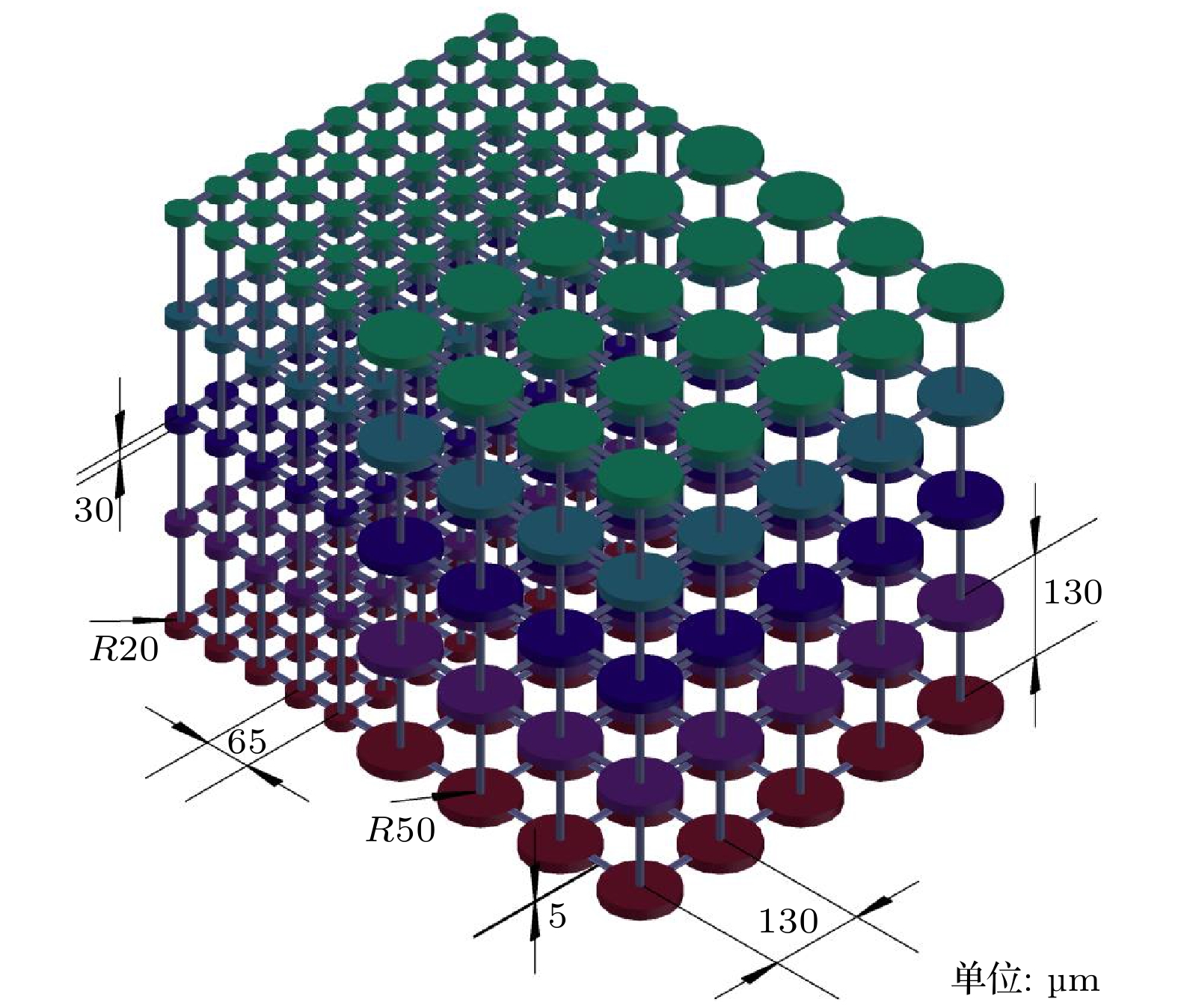

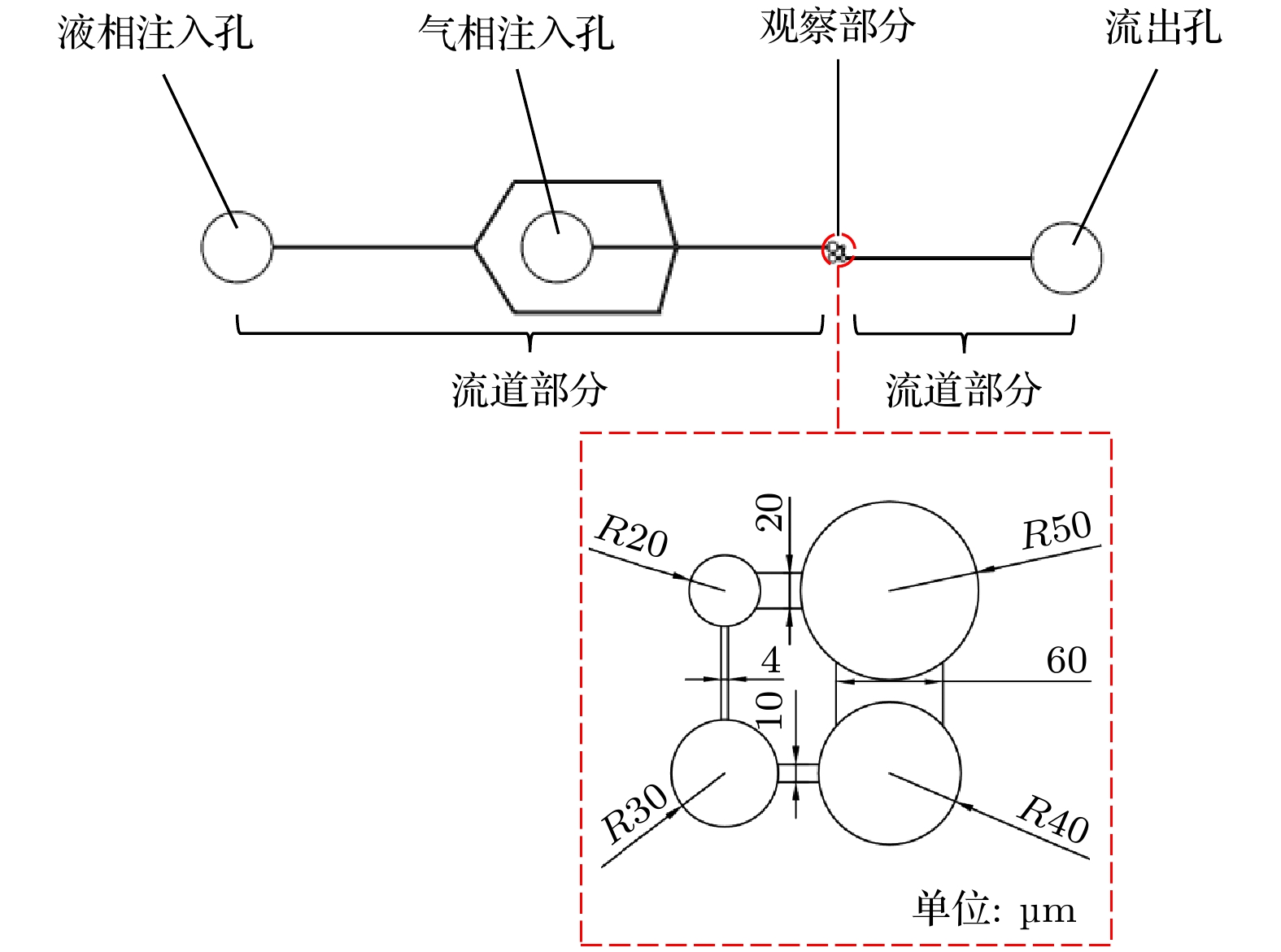

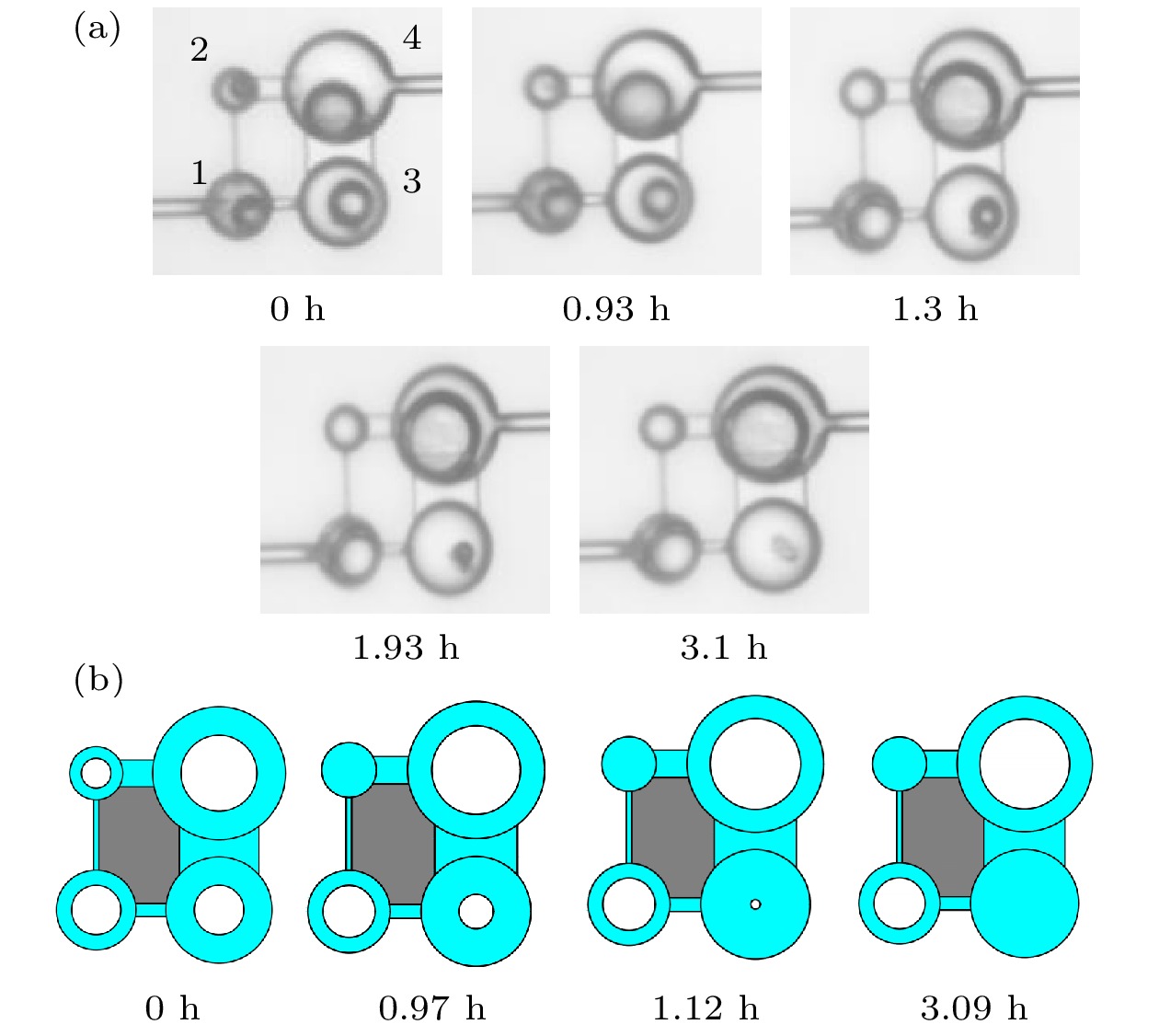

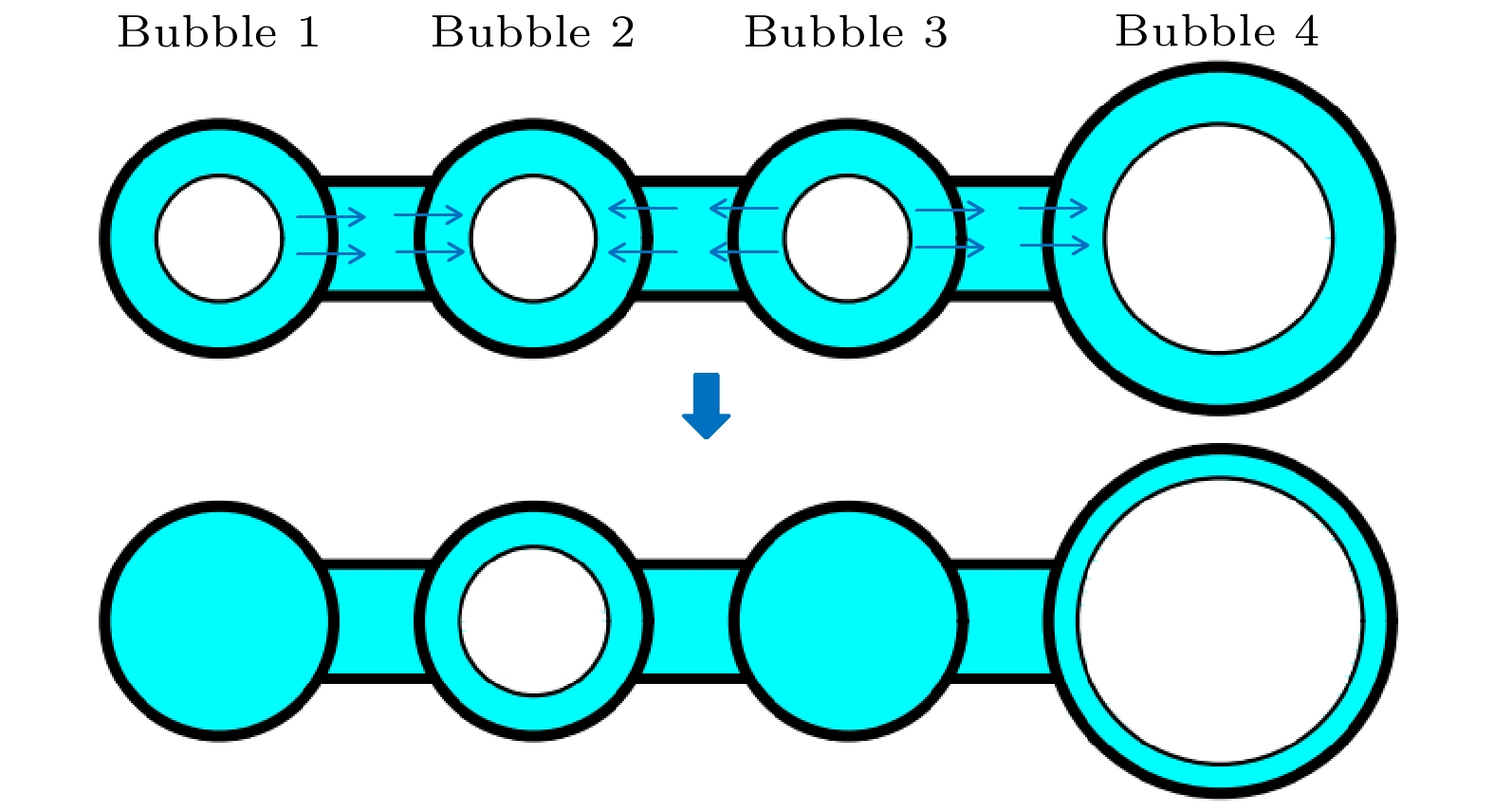

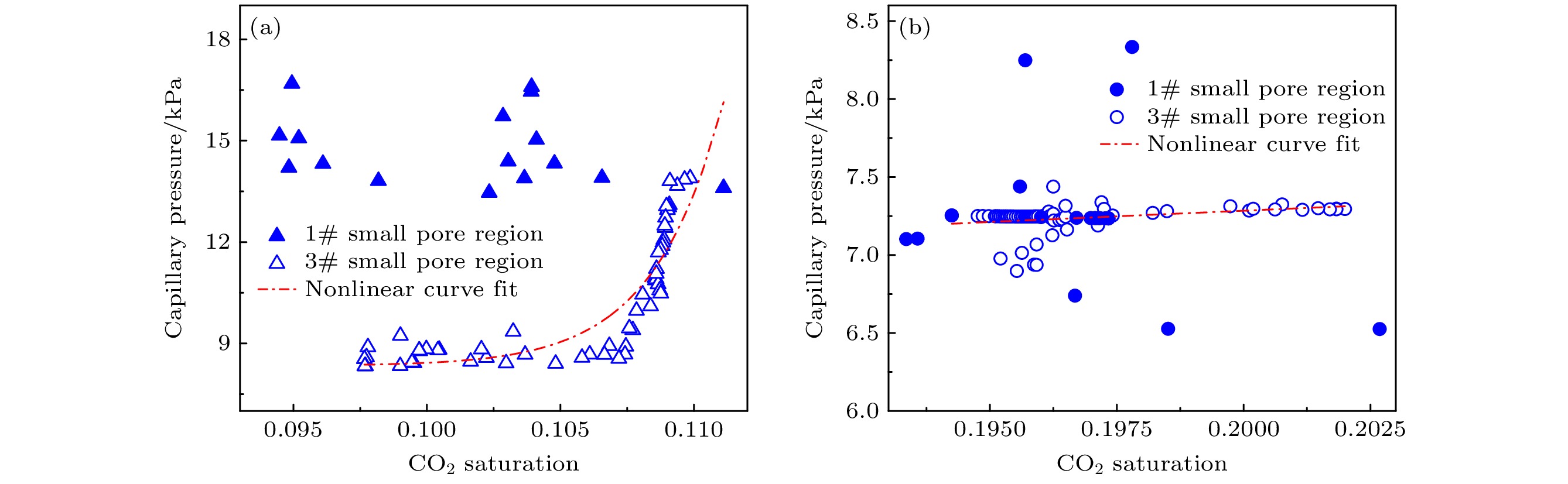

多孔介质内气泡的Ostwald熟化行为广泛存在于CO2地质封存、多孔材料制备、燃料电池等领域. 为探究孔隙尺度下多孔介质内气泡的熟化特性, 建立了基于浓度耦合计算的三维孔隙网络模型, 该模型考虑了气泡形态、多孔介质结构以及气液之间的传质, 通过求解三维孔隙网络内各孔体的气相浓度, 得到各气泡的演化过程, 并采用四孔隙结构微流体芯片可视化实验验证了模型的可靠性. 为分析多孔介质非均质性对气泡熟化过程影响, 构建了两种不同孔隙尺寸的三维孔网结构, 对两个区域内的气泡熟化过程进行了数值模拟. 结果表明: 气泡初始分布会对熟化过程产生影响, 当气泡非均匀分布时, 气泡从小孔隙区域传输至大孔隙区域的同时, 也会各自向自身区域的大气泡区域传质; 气泡初始尺寸的差异, 会加速熟化进程, 使熟化时间明显短于均匀分布状态. 孔隙数的选取对平均毛细力、饱和度等连续尺度等效参数具有显著影响, 孔隙数增加时毛细力与饱和度呈现更具规律性的非线性变化. 该模型的建立可以预测地质封存过程中CO2的演化过程, 为CO2长期封存过程中非均质性的影响机制研究提供指导.Ostwald ripening behaviors of bubbles in porous medium are observed commonly in various fields, including CO2 geological storage, preparation of porous materials, and fuel cells. A three-dimensional pore network model based on concentration coupling calculation has been developed to investigate the ripening characteristics of bubbles in porous medium on a pore scale. This model takes into account the shape of bubble, the structure of porous medium, and mass transfer between gas and liquid. By solving the gas phase concentration of each pore body in the three-dimensional pore network, the model can track the evolution process of each bubble. A microfluidic chip with a four-pore structure is used to validate the reliability of the model through visual experiments. To analyze the effect of porous medium heterogeneity on the bubble ripening process, two different three-dimensional pore network structures with varying pore sizes are constructed and the ripening processes of bubbles in two regions are simulated numerically. The results show that the initial distribution of bubbles can affect the ripening process of porous medium. When bubbles are uniformly distributed, in the ripening process, they exhibit regular and systematic changes in their spacing. However, in the case of uneven bubble distribution, as the bubbles transfer from smaller pore region to larger pore region, they also undergo individual mass transfer towards the larger bubble region in their respective areas. Consequently, the remaining bubbles no longer maintain a spaced distribution pattern. Additionally, the differences in initial size among bubbles can accelerate the ripening process, resulting in a significantly shorter ripening time than that in a uniform distribution. The choice of pore number has a significant influence on continuous-scale equivalent parameters, such as average capillary pressure and saturation. As the number of pores increases, the capillary pressure and saturation exhibit a more regular, nonlinear variation. A relationship between capillary pressure and saturation in the small pore region and in the large pore region are established, which deviate from the assumptions made in the existing literature. This result provides important guidance for constructing the continuous-scale ripening model that can be used to predict the evolution process of CO2 during geological storage and provide guidance for studying the influence mechanism of heterogeneity during long-term CO2 storage.

-

Keywords:

- porous media /

- bubbles /

- Ostwald ripening /

- pore network model

[1] Chang F M, Sheng Y J, Cheng S L, Tsao H K 2008 Appl. Phys. Lett. 92 264102

Google Scholar

Google Scholar

[2] 宋保维, 任峰, 胡海豹, 郭云鹤 2014 63 054708

Google Scholar

Google Scholar

Song B W, Ren F, Hu H B, Guo Y H 2014 Acta Phys. Sin. 63 054708

Google Scholar

Google Scholar

[3] Feng L, Zhang Z Y, Mai Z H, Ma Y M, Liu B Q, Jiang L, Zhu D B 2004 Angew. Chem. Int. Ed. 43 2012

Google Scholar

Google Scholar

[4] Lautze N C, Sisson T W, Mangan M T, Grove T L 2010 Contrib. Mineral Petrol. 161 331

Google Scholar

Google Scholar

[5] Masotta M, Ni H, Keppler H 2014 Contrib. Mineral. Petrol. 167 976

Google Scholar

Google Scholar

[6] Huang Z D, Su M, Yang Q, Li Z, Chen S R, Li Y F, Zhou X, Li F Y, Song Y L 2017 Nat. Commun. 8 14110

Google Scholar

Google Scholar

[7] 严达利, 李申予, 刘士余, 竺云 2015 64 137104

Google Scholar

Google Scholar

Yan D L, Li S Y, Liu S Y, Zhu Y 2015 Acta Phys. Sin. 64 137104

Google Scholar

Google Scholar

[8] Bachu S 2008 Prog. Energy Combust. Sci. 34 254

Google Scholar

Google Scholar

[9] Singh D, Friis H A, Jettestuen E, Helland J O 2022 Transport Porous Med. 145 441

Google Scholar

Google Scholar

[10] Iglauer S, Pentland C H, Busch A 2015 Water Resour Res. 51 729

Google Scholar

Google Scholar

[11] Rahman T, Lebedev M, Barifcani A, Iglauer S 2016 J. Colloid Interface Sci. 469 63

Google Scholar

Google Scholar

[12] Lifshitz I M, Slyozov V V 1961 J. Phys. Chem. Solids. 19 35

Google Scholar

Google Scholar

[13] Voorhees P W 1992 Annu. Rev. Mater. Sci. 22 197

Google Scholar

Google Scholar

[14] Burlakov V M 2006 Phys. Rev. Lett. 97 155703

Google Scholar

Google Scholar

[15] Schmelzer J, Schweitzer F 1987 J. Non-Equilib. Thermodyn. 12 255

Google Scholar

Google Scholar

[16] Xu R N, Li R, Huang F, Jiang P X 2017 Sci. Bull. 62 795

Google Scholar

Google Scholar

[17] Xu K, Liang T B, Zhu P X, Qi P P, Lu J, Huh C, Balhoff M 2017 Lab. Chip. 17 640

Google Scholar

Google Scholar

[18] Li Y, Garing C, Benson S M 2020 J. Fluid Mech. 889 A14

Google Scholar

Google Scholar

[19] Blunt M J, Bijeljic B, Dong H, Gharbi O, Iglauer S, Mostaghimi P, Paluszny A, Pentland C 2013 Adv. Water Resour. 51 197

Google Scholar

Google Scholar

[20] Golparvar A, Zhou Y, Wu K, Ma J, Yu Z 2018 Adv. Geo. Energy Res. 2 418

Google Scholar

Google Scholar

[21] Kohanpur A H, Valocchi A J 2020 Transport. Porous Med. 135 659

Google Scholar

Google Scholar

[22] Xu K, Mehmani Y, Shang L, Xiong Q 2019 Geophy. Res. Lett. 46 13804

Google Scholar

Google Scholar

[23] Xu K, Bonnecaze R, Balhoff M 2017 Phys. Rev. Lett. 119 264502

Google Scholar

Google Scholar

[24] Mehmani Y, Xu K 2022 J. Comput. Phys. 457 111041

Google Scholar

Google Scholar

[25] de Chalendar J A, Garing C, Benson S M 2017 Energy Procedia. 114 4857

Google Scholar

Google Scholar

[26] Vorst H A 1992 SIAM J. Sci. Stat. Comput. 13 631

Google Scholar

Google Scholar

[27] Pallas N R, Pethica B A 1983 Colloid Surface 6 221

Google Scholar

Google Scholar

[28] Versteeg G F, Van Swaaij W P M 1988 J. Chem. Eng. Data. 33 29

Google Scholar

Google Scholar

[29] 周志毅, 王进卿, 王广鑫, 池作和, 翁煜侃 2022 化工进展 41 1265

Google Scholar

Google Scholar

Zhou Z Y, Wang J Q, Wang G X, Chi Z H, Weng Y K 2022 Chem. Ind. Eng. Prog. 41 1265

Google Scholar

Google Scholar

[30] Blunt M J 2022 Phys. Rev. E 106 045103

Google Scholar

Google Scholar

[31] McClure J E, Berrill M A, Gray W G, Miller C T 2016 Phys. Rev. E 94 033102

Google Scholar

Google Scholar

-

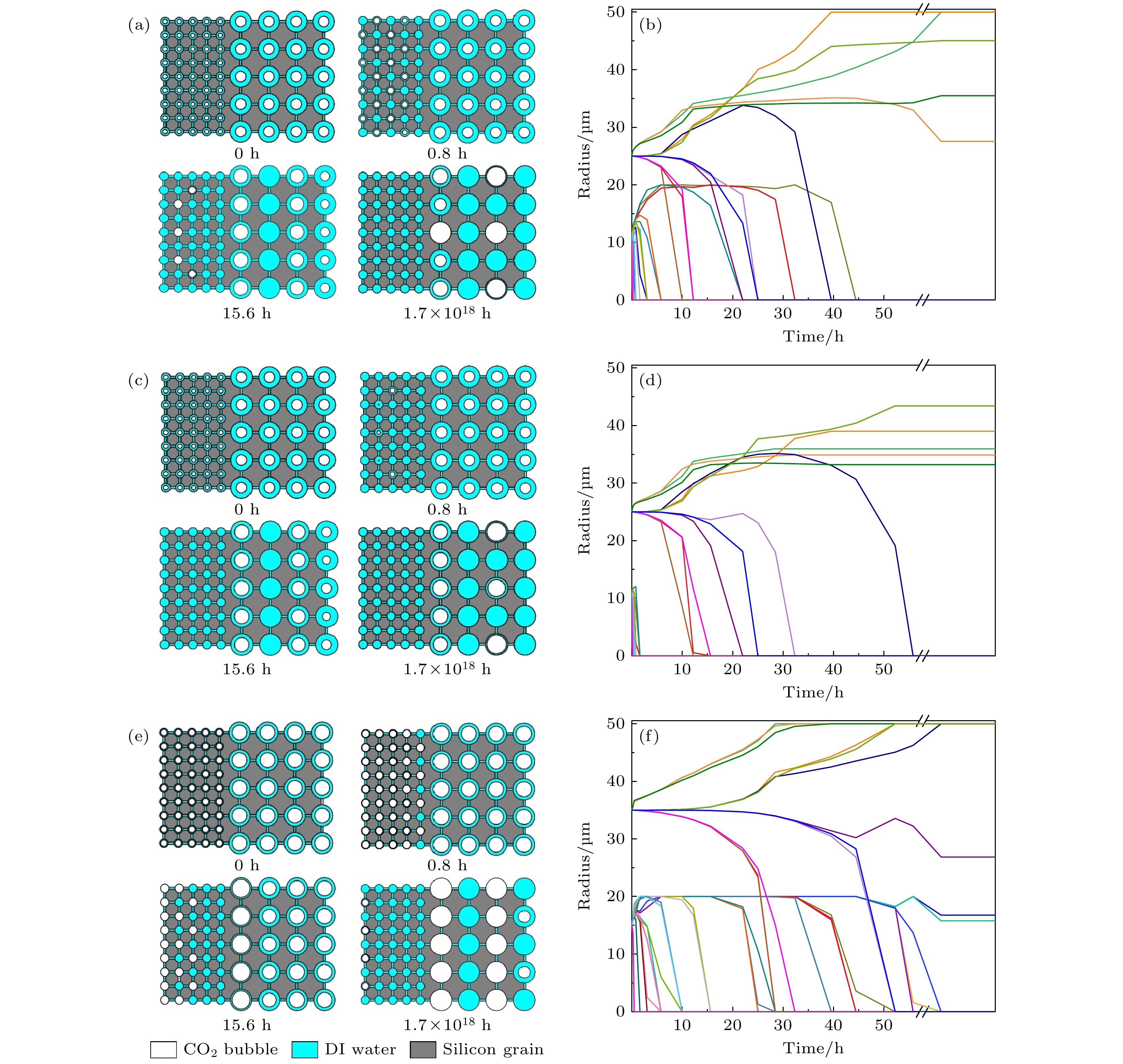

图 8 工况1#模拟结果 (a)气泡演化过程, 其中白色区域为CO2气泡, 蓝色区域为去离子水, 灰色区域为硅颗粒; (b) CO2气泡曲率半径变化图

Fig. 8. Simulation results of condition 1#: (a) Bubble evolution process, where the white regions are CO2 bubble, blue regions are filled with DI water, and the gray regions are silicon grains; (b) curvature radius variation diagram of each CO2 bubble.

图 10 工况2#模拟结果 (a)第1层和第5层气泡演化过程; (b)第1层和第5层CO2气泡曲率半径变化; (c)第2层和第4层气泡演化过程; (d)第2层和第4层CO2气泡曲率半径变化; (e)第3层气泡演化过程; (f)第3层CO2气泡曲率半径变化

Fig. 10. Simulation results of condition 2#: (a) Bubble evolution process in layers 1 and 5; (b) curvature radius variation of each CO2 bubble in layers 1 and 5; (c) bubble evolution process in layers 2 and 4; (d) curvature radius variation of each CO2 bubble in layers 2 and 4; (e) bubble evolution process in layer 3; (f) curvature radius variation of each CO2 bubble in layer 3.

表 1 模拟工况参数

Table 1. Simulation parameters of three conditions.

工况 行数 列数 层数 孔体总数 各层气泡初始半径 R/μm 1, 2 3 4, 5 1# 大孔隙区域 5 4 5 100 25 25 25 小孔隙区域 9 5 5 225 10 10 10 2# 大孔隙区域 5 4 5 100 25 35 25 小孔隙区域 9 5 5 225 10 15 10 3# 大孔隙区域 10 32 10 3200 25 25 25 小孔隙区域 19 40 10 7600 10 10 10 表 2 四孔隙及多孔隙结构气泡熟化模拟参数

Table 2. Simulation parameters of four bubble and muti bubble ripening system.

-

[1] Chang F M, Sheng Y J, Cheng S L, Tsao H K 2008 Appl. Phys. Lett. 92 264102

Google Scholar

Google Scholar

[2] 宋保维, 任峰, 胡海豹, 郭云鹤 2014 63 054708

Google Scholar

Google Scholar

Song B W, Ren F, Hu H B, Guo Y H 2014 Acta Phys. Sin. 63 054708

Google Scholar

Google Scholar

[3] Feng L, Zhang Z Y, Mai Z H, Ma Y M, Liu B Q, Jiang L, Zhu D B 2004 Angew. Chem. Int. Ed. 43 2012

Google Scholar

Google Scholar

[4] Lautze N C, Sisson T W, Mangan M T, Grove T L 2010 Contrib. Mineral Petrol. 161 331

Google Scholar

Google Scholar

[5] Masotta M, Ni H, Keppler H 2014 Contrib. Mineral. Petrol. 167 976

Google Scholar

Google Scholar

[6] Huang Z D, Su M, Yang Q, Li Z, Chen S R, Li Y F, Zhou X, Li F Y, Song Y L 2017 Nat. Commun. 8 14110

Google Scholar

Google Scholar

[7] 严达利, 李申予, 刘士余, 竺云 2015 64 137104

Google Scholar

Google Scholar

Yan D L, Li S Y, Liu S Y, Zhu Y 2015 Acta Phys. Sin. 64 137104

Google Scholar

Google Scholar

[8] Bachu S 2008 Prog. Energy Combust. Sci. 34 254

Google Scholar

Google Scholar

[9] Singh D, Friis H A, Jettestuen E, Helland J O 2022 Transport Porous Med. 145 441

Google Scholar

Google Scholar

[10] Iglauer S, Pentland C H, Busch A 2015 Water Resour Res. 51 729

Google Scholar

Google Scholar

[11] Rahman T, Lebedev M, Barifcani A, Iglauer S 2016 J. Colloid Interface Sci. 469 63

Google Scholar

Google Scholar

[12] Lifshitz I M, Slyozov V V 1961 J. Phys. Chem. Solids. 19 35

Google Scholar

Google Scholar

[13] Voorhees P W 1992 Annu. Rev. Mater. Sci. 22 197

Google Scholar

Google Scholar

[14] Burlakov V M 2006 Phys. Rev. Lett. 97 155703

Google Scholar

Google Scholar

[15] Schmelzer J, Schweitzer F 1987 J. Non-Equilib. Thermodyn. 12 255

Google Scholar

Google Scholar

[16] Xu R N, Li R, Huang F, Jiang P X 2017 Sci. Bull. 62 795

Google Scholar

Google Scholar

[17] Xu K, Liang T B, Zhu P X, Qi P P, Lu J, Huh C, Balhoff M 2017 Lab. Chip. 17 640

Google Scholar

Google Scholar

[18] Li Y, Garing C, Benson S M 2020 J. Fluid Mech. 889 A14

Google Scholar

Google Scholar

[19] Blunt M J, Bijeljic B, Dong H, Gharbi O, Iglauer S, Mostaghimi P, Paluszny A, Pentland C 2013 Adv. Water Resour. 51 197

Google Scholar

Google Scholar

[20] Golparvar A, Zhou Y, Wu K, Ma J, Yu Z 2018 Adv. Geo. Energy Res. 2 418

Google Scholar

Google Scholar

[21] Kohanpur A H, Valocchi A J 2020 Transport. Porous Med. 135 659

Google Scholar

Google Scholar

[22] Xu K, Mehmani Y, Shang L, Xiong Q 2019 Geophy. Res. Lett. 46 13804

Google Scholar

Google Scholar

[23] Xu K, Bonnecaze R, Balhoff M 2017 Phys. Rev. Lett. 119 264502

Google Scholar

Google Scholar

[24] Mehmani Y, Xu K 2022 J. Comput. Phys. 457 111041

Google Scholar

Google Scholar

[25] de Chalendar J A, Garing C, Benson S M 2017 Energy Procedia. 114 4857

Google Scholar

Google Scholar

[26] Vorst H A 1992 SIAM J. Sci. Stat. Comput. 13 631

Google Scholar

Google Scholar

[27] Pallas N R, Pethica B A 1983 Colloid Surface 6 221

Google Scholar

Google Scholar

[28] Versteeg G F, Van Swaaij W P M 1988 J. Chem. Eng. Data. 33 29

Google Scholar

Google Scholar

[29] 周志毅, 王进卿, 王广鑫, 池作和, 翁煜侃 2022 化工进展 41 1265

Google Scholar

Google Scholar

Zhou Z Y, Wang J Q, Wang G X, Chi Z H, Weng Y K 2022 Chem. Ind. Eng. Prog. 41 1265

Google Scholar

Google Scholar

[30] Blunt M J 2022 Phys. Rev. E 106 045103

Google Scholar

Google Scholar

[31] McClure J E, Berrill M A, Gray W G, Miller C T 2016 Phys. Rev. E 94 033102

Google Scholar

Google Scholar

计量

- 文章访问数: 7569

- PDF下载量: 113

- 被引次数: 0

下载:

下载: