-

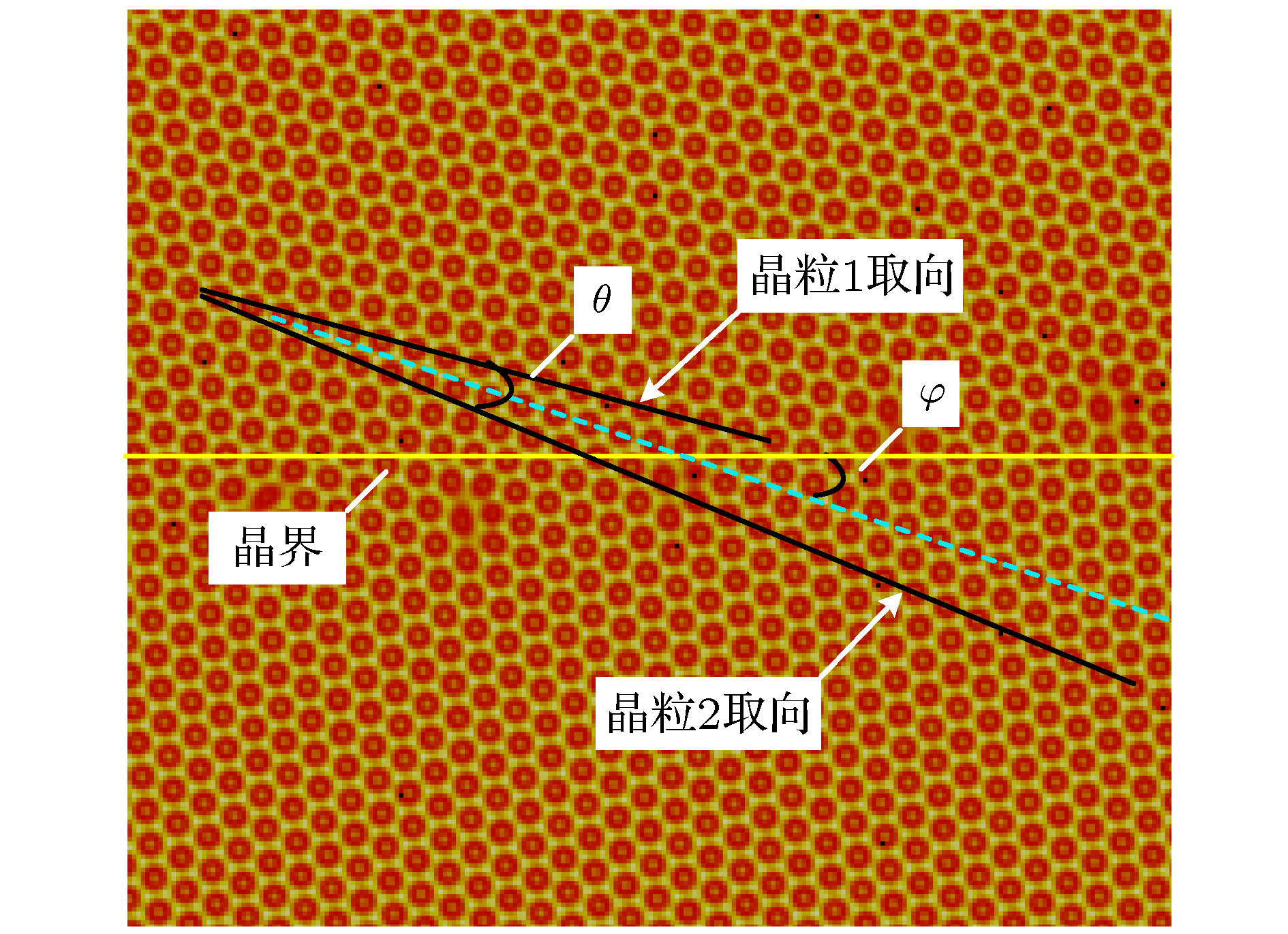

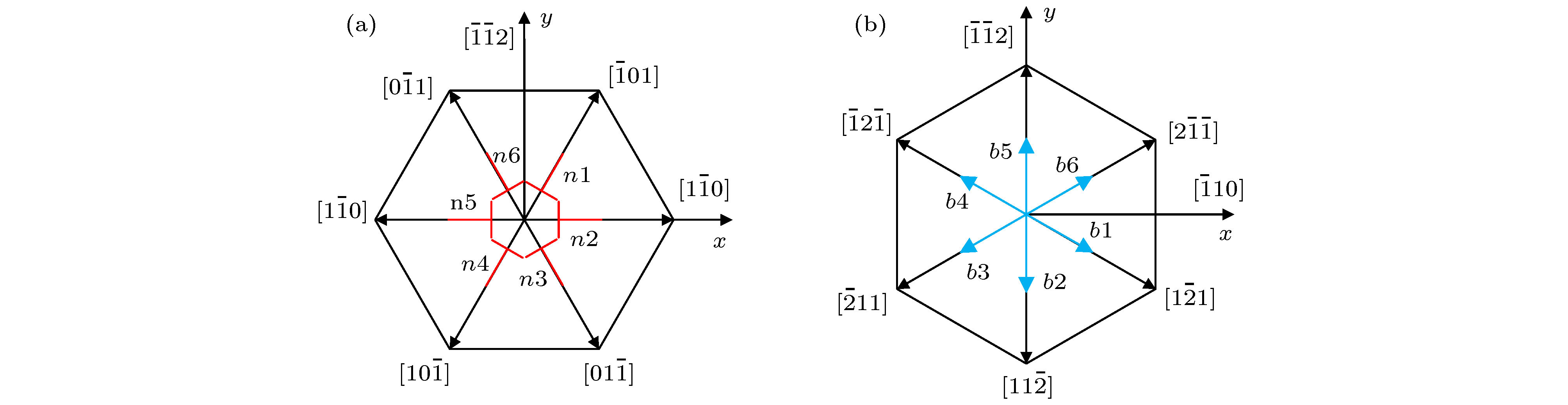

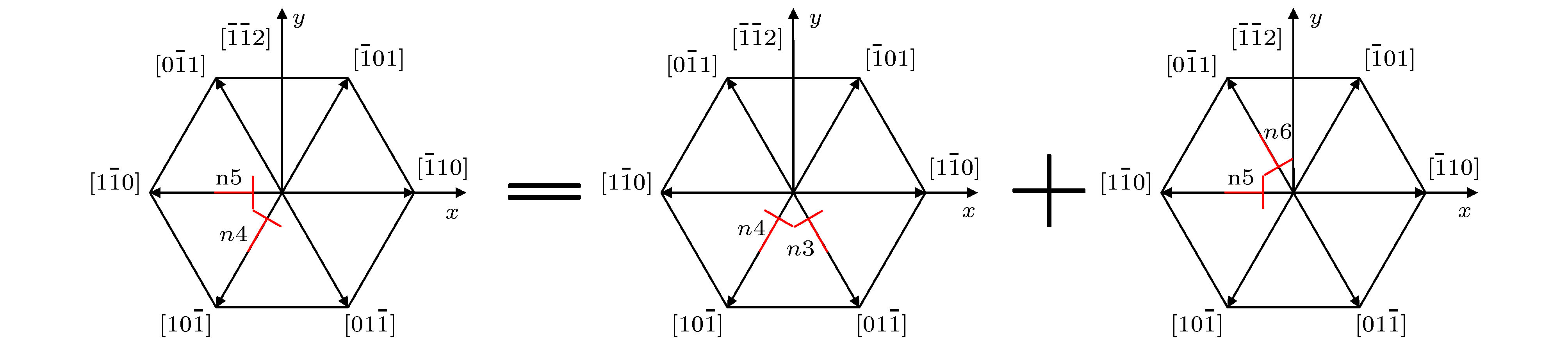

采用晶体相场法模拟纳米尺度下小角度非对称倾斜晶界结构和位错运动, 从外应力作用下晶界位错运动位置变化和晶体体系自由能变化角度, 分析取向角对小角度非对称倾斜晶界结构和晶界位错运动的影响规律. 研究表明, 不同取向角下组成小角度非对称倾斜晶界的位错对类型相同. 随取向角增大晶界位错对增加, 且晶界更易形成n1n2型和n4n5型位错对. 外应力作用下, 不同取向角晶界位错对初始运动状态均沿晶界进行攀移运动, 随体系能量积累, 取向角越大出现晶界位错对分解的个数越多, 且均为n1n2型和n4n5型位错对发生分解反应. 不同取向角下小角度非对称倾斜晶界体系自由能曲线都存在四个阶段, 分别对应位错对攀移、位错对滑移及分解、位错对反应抵消形成单晶和体系吸收能量自由能上升过程. 进一步对比发现随取向角增大, 晶界湮没形成的单晶体系所需时间增加.Grain boundary affects the microstructure of metal material, and thus further its macroscopic properties. As is well known, under the action of applied stress, the grain boundary migrates. The structures and arrangements of grain boundary dislocations at different misorientation angles are very different, which affects the macrophysical and chemical properties of metal crystal. Therefore, it is of great theoretical and practical significance to study the dislocation structure and reaction mechanism of grain boundary under different misorientations for further studying the material properties.The phase field crystal method is used to simulate the low-angle asymmetric tilt grain boundary structure and dislocation motion on a nanoscale. From the perspective of the change of the position of the grain boundary dislocation motion under the applied stress and the change of the free energy of the crystal system, the influences of the misorientation angle on the low-angle asymmetric tilt grain boundary structure and the motion of the grain boundary dislocation are analyzed. The results show that the types of dislocation pairs of low-angle asymmetric tilt grain boundaries at different misorientation angles are the same. With the increase of misorientation angle, the grain boundary dislocation pairs increase, and n1n2 and n4n5 type dislocation pairs are more easily formed at the grain boundaries. Under the action of applied stress, the initial movement states of the grain boundary dislocation pairs at different misorientation angles are all climbing along the grain boundaries. As the system energy accumulates, the larger the misorientation angle is, the more the number of decomposed grain boundary dislocation pairs decomposed will be, and only in the dislocation pairs of n1n2 and n4n5 type there occurs decomposition reaction. There are four stages in the free energy curve of the low-angle asymmetric tilt grain boundary system at different misorientation angles, which correspond to the dislocation pairs climbing, dislocation pairs sliding and decomposition, dislocation pairs reaction to form single crystal, and the free energy rising process of the system. Further research shows that as the misorientation angle increases, the time for the single crystal system formed by the dislocation of grain boundary pairs to annihilate is required to be long.

-

Keywords:

- phase field crystal /

- misorientation /

- grain boundary /

- dislocation

[1] Li X H, Wen X, Zhao H H, Ma Z Q, Yu L M, Li C, Liu C X, Guo Q Y, Liu Y C 2019 J. Alloys Compd. 779 175

Google Scholar

Google Scholar

[2] Chen Y Y, Hu Z P, Xu Y F, Wang J Y, Schützendübe P, Huang Y, Liu Y C, Wang Z M 2019 J. Mater. Sci. Technol. 35 512

Google Scholar

Google Scholar

[3] Elder K R, Katakowski M, Haataja M, Grant M 2002 Phys. Rev. Lett. 88 245701

Google Scholar

Google Scholar

[4] Elder K R, Grant M 2004 Phys. Rev. E 70 051605

Google Scholar

Google Scholar

[5] Elder K R, Provatas N, Berry J, Stefanovic P 2007 Phys. Rev. B 75 064107

Google Scholar

Google Scholar

[6] Wang J, Yu L M, Huang Y, Li H J, Liu Y C 2019 Comput. Mater. Sci. 160 105

Google Scholar

Google Scholar

[7] Zhao Y H, Zhang B, Hou H, Chen W P, Wang M 2019 J. Mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[8] Zhang B, Zhao Y H, Chen W P, Xu Q Y, Wang M, Hou H 2019 J. Cryst. Growth 522 183

Google Scholar

Google Scholar

[9] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Li X L 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[10] Fan D, Chen L Q 1997 Acta Mater. 45 611

Google Scholar

Google Scholar

[11] 孙远洋, 赵宇宏, 侯华, 郑晓娟, 郭慧俊 2018 稀有金属材料与工程 47 3000

Google Scholar

Google Scholar

Sun Y Y, Zhao Y H, Hou H, Zheng X J, Guo H J 2018 Rare Metal Mat. Eng. 47 3000

Google Scholar

Google Scholar

[12] 康永生, 赵宇宏, 侯华, 靳玉春, 陈利文 2016 65 188102

Google Scholar

Google Scholar

Kang Y S, Zhao Y H, Hou H, Jin Y C, Chen L W 2016 Acta Phys. Sin. 65 188102

Google Scholar

Google Scholar

[13] 田晓林, 赵宇宏, 田晋忠, 侯华 2018 67 230201

Google Scholar

Google Scholar

Tian X L, Zhao Y H, Tian J Z, Hou H 2018 Acta Phys. Sin. 67 230201

Google Scholar

Google Scholar

[14] Zhao Y H, Tian X L, Zhao B J, Sun Y Y, Guo H J, Dong M Y, Liu H, Wang X J, Guo Z H, Umar A, Hou H 2018 Sci. Adv. Mater. 10 1793

Google Scholar

Google Scholar

[15] 赵宝军, 赵宇宏, 孙远洋, 杨文奎, 侯华 2019 金属学报 55 593

Google Scholar

Google Scholar

Zhao B J, Zhao Y H, Sun Y Y, Yang W K, Hou H 2019 Acta Metall. Sin. 55 593

Google Scholar

Google Scholar

[16] 孙远洋, 赵宇宏, 侯华, 靳玉春, 郑晓娟 2018 中国有色金属学报 28 71

Sun Y Y, Zhao Y H, Hou H, Jin Y C, Zheng X J 2018 Chin. J. Nonferrous Met. 28 71

[17] Tian J Z, Zhao Y H, Hou H, Han P D 2017 Solid State Commun. 268 44

Google Scholar

Google Scholar

[18] Tian J Z, Zhao Y H, Wang B, Hou H, Zhang Y M 2018 Mater. Chem. Phys. 209 200

Google Scholar

Google Scholar

[19] Zhang J B, Wang H F, Kuang W W, Zhang Y C, Li H, Zhao Y H, Herlach D 2018 Acta Mater. 148 86

Google Scholar

Google Scholar

[20] Kuang W W, Wang H F, Li X, Zhang J B, Zhou Q, Zhao Y H 2018 Acta Mater. 159 16

Google Scholar

Google Scholar

[21] 方辉, 薛桦, 汤倩玉, 张庆宇, 潘诗琰, 朱鸣芳 2019 68 048102

Google Scholar

Google Scholar

Fang H, Xue H, Tang Q Y, Zhang Q Y, Pan S Y, Zhu M F 2019 Acta Phys. Sin. 68 048102

Google Scholar

Google Scholar

[22] Zhao Y H, Wang S, Zhang B, Yuan Y, Guo Q W, Hou H 2019 J. Solid State Chem. 276 232

Google Scholar

Google Scholar

[23] Wu K A, Voorhees P W 2012 Acta Mater. 60 407

Google Scholar

Google Scholar

[24] 祁科武, 赵宇宏, 郭慧俊, 田晓林, 侯华 2019 68 170504

Google Scholar

Google Scholar

Qi K W, Zhao Y H, Guo H J, Tian X L, Hou H 2019 Acta Phys. Sin. 68 170504

Google Scholar

Google Scholar

[25] Olmsted D L, Buta D, Adland A, Foiles S M, Asta M, Karma A 2011 Phys. Rev. Lett. 106 046101

Google Scholar

Google Scholar

[26] 高英俊, 秦河林, 周文权, 邓芊芊, 罗志荣, 黄创高 2015 64 106105

Google Scholar

Google Scholar

Gao Y J, Qin H L, Zhou W Q, Deng Q Q, Luo Z R, Huang C G 2015 Acta Phys. Sin. 64 106105

Google Scholar

Google Scholar

[27] Berry J, Elder K R, Grant M 2008 Phys. Rev. B 77 224114

Google Scholar

Google Scholar

[28] Nourian A, Asadi E 2018 Comput. Mater. Sci. 145 224

Google Scholar

Google Scholar

[29] ChanV W L, Pisutha-Arnond N, Thornton K 2017 Comput. Mater. Sci. 135 205

Google Scholar

Google Scholar

[30] Asadi E, Zaeem M A 2015 Jom 67 186

Google Scholar

Google Scholar

[31] Hu S, Xi W, Chen Z, Wang S, Zhang T H 2017 Comput. Mater. Sci. 132 125

Google Scholar

Google Scholar

[32] Hu S, Wang S 2019 Phys. B 552 104

Google Scholar

Google Scholar

[33] Gao Y J, Deng Q Q, Huang L L, Ye L, Wen Z C, Luo Z R 2017 Comput. Mater. Sci. 130 64

Google Scholar

Google Scholar

[34] Greenwood M, Ofori-Opoku N, Rottler J, Provatas N 2011 Phys. Rev. B 84 064104

Google Scholar

Google Scholar

[35] Greenwood M, Rottler J, Provatas N 2011 Phys. Rev. E 83 031601

[36] Elder K R, Thornton K, Hoyt J J 2011 Philos. Mag. 91 151

Google Scholar

Google Scholar

[37] Lu G M, Lu Y L, Hu T T, Chen Z 2015 Comput. Mater. Sci. 106 170

Google Scholar

Google Scholar

[38] Guo H J, Zhao Y H, Sun Y Y, Tian J Z, Hou H, Qi K W, Tian X L 2019 Superlattices Microstruct. 129 163

Google Scholar

Google Scholar

[39] Zhao Y H, Deng S J, Liu H, Zhang J X, Guo Z H, Hou H 2018 Comput. Mater. Sci. 154 365

Google Scholar

Google Scholar

[40] Wen Z Q, Hou H, Tian J Z, Zhao Y H, Li H J, Han P D 2018 Intermetallics 92 15

Google Scholar

Google Scholar

[41] Wen Z Q, Zhao Y H, Hou H, Wang B, Han P D 2017 Mater. Des. 114 398

Google Scholar

Google Scholar

[42] Zhao Y H, Qi L, Jin Y C, Wang K, Tian J Z, Han P D 2015 J. Alloys Compd. 647 1104

Google Scholar

Google Scholar

[43] Hirouchi T, Takaki T, Tomita Y 2009 Comput. Mater. Sci. 44 1192

Google Scholar

Google Scholar

-

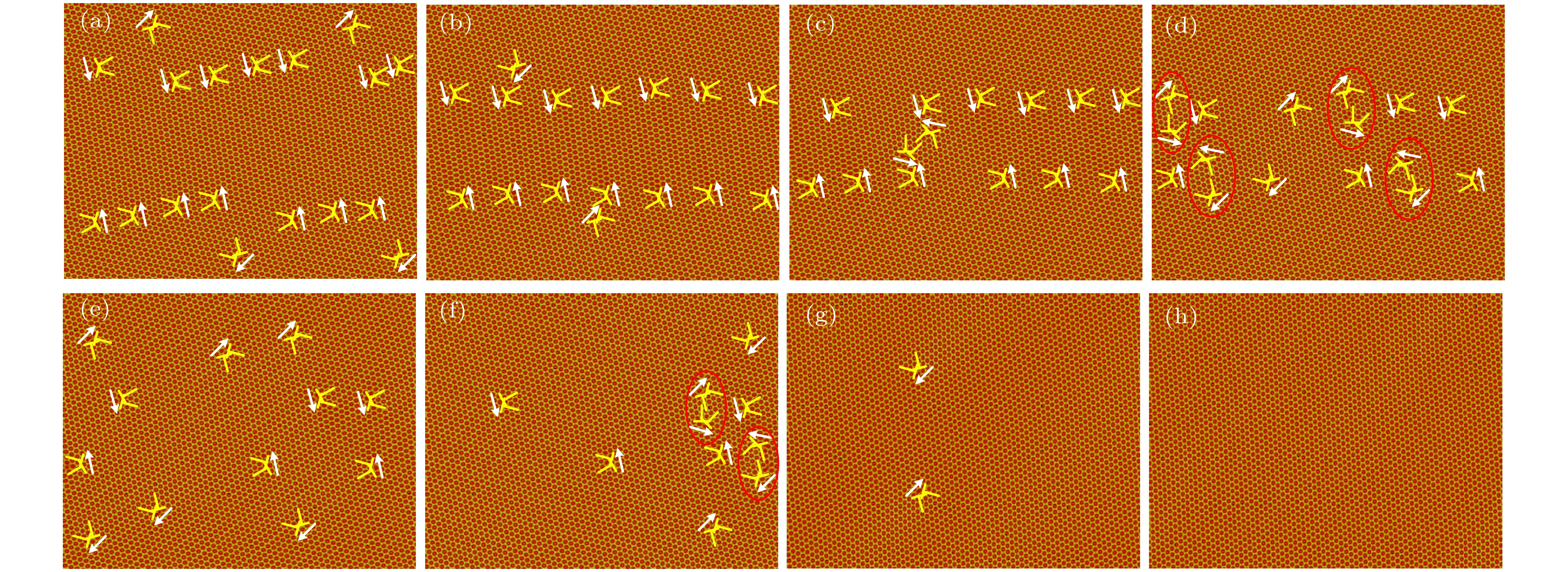

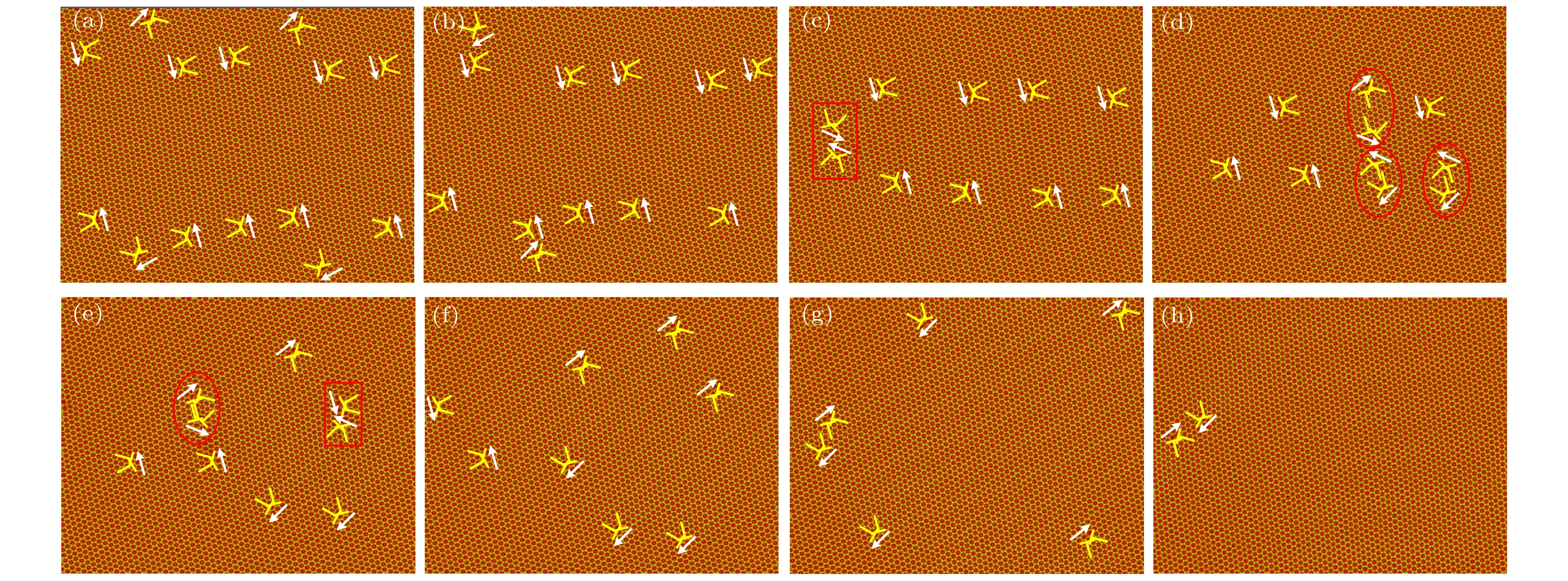

图 3 应力作用下θ = 8° 时晶界位错运动模拟图 (a) n = 400; (b) n = 11400; (c) n = 21200; (d) n = 21600; (e) n = 22000; (f) n = 22500; (g) n = 57050; (h) n = 57500

Fig. 3. Simulation diagram of grain boundary dislocation motion under stress with θ = 8°: (a) n = 400; (b) n = 11400; (c) n = 21200; (d) n = 21600; (e) n = 22000; (f) n = 22500; (g) n = 57050; (h) n = 57500

图 7 应力作用下θ = 6° 时晶界位错运动模拟图 (a) n = 9500; (b) n = 18500; (c) n = 20600; (d) n = 21500; (e) n = 23500; (f) n = 31100; (g) n = 31800; (h) n = 37500

Fig. 7. Simulation diagram of grain boundary dislocation motion under stress with θ = 6°: (a) n = 9500; (b) n = 18500; (c) n = 20600; (d) n = 21500; (e) n = 23500; (f) n = 31100; (g) n = 31800; (h) n = 37500

图 9 应力作用下θ = 9° 时晶界位错运动模拟图 (a) n = 10850; (b) n = 18750; (c) n = 21600; (d) n = 22550; (e)n = 24350; (f) n = 27000; (g) n = 54800; (h) n = 58000

Fig. 9. Simulation diagram of grain boundary dislocation motion under stress with θ = 9°: (a) n = 10850; (b) n = 18750; (c) n = 21600; (d) n = 22550; (e) n = 24350; (f) n = 27000; (g) n = 54800; (h) n = 58000

图 8 应力作用下θ = 7° 时晶界位错运动模拟图 (a) n = 9100; (b) n = 12950; (c) n = 18500; (d) n = 22500; (e) n = 23200; (f) n = 24050; (g) n = 26450; (h)n = 39600

Fig. 8. Simulation diagram of grain boundary dislocation motion under stress with θ = 7°: (a) n = 9100; (b) n = 12950; (c) n = 18500; (d) n = 22500; (e) n = 23200; (f) n = 24050; (g) n = 26450; (h) n = 39600

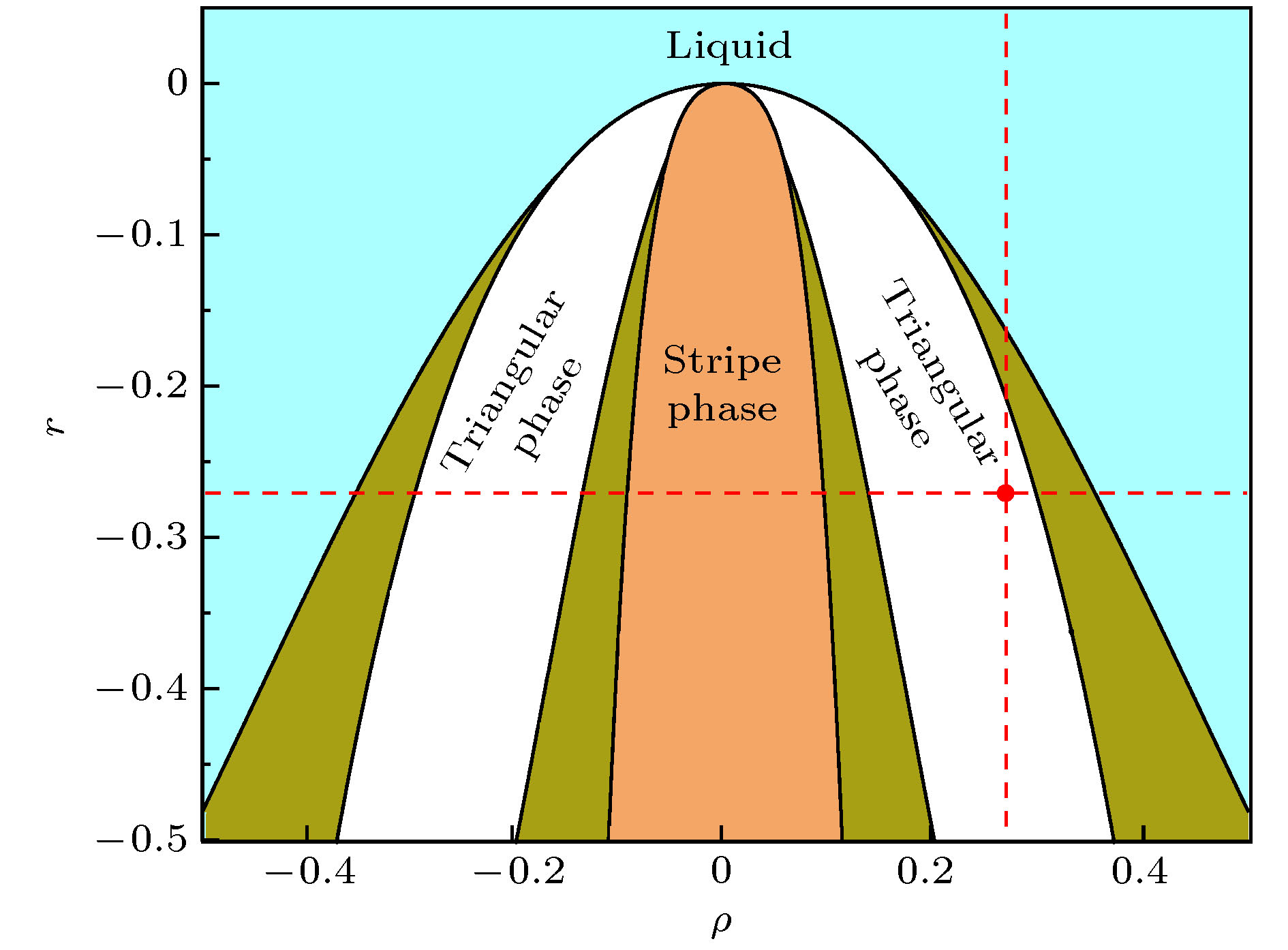

表 1 模拟所采用的参数

Table 1. Parameters used in the simulation.

方案 初始原子密度 ρ0 温度相关参量 r 取向角 θ(°) A 0.285 –0.27 6 B 0.285 –0.27 7 C 0.285 –0.27 8 D 0.285 –0.27 9 -

[1] Li X H, Wen X, Zhao H H, Ma Z Q, Yu L M, Li C, Liu C X, Guo Q Y, Liu Y C 2019 J. Alloys Compd. 779 175

Google Scholar

Google Scholar

[2] Chen Y Y, Hu Z P, Xu Y F, Wang J Y, Schützendübe P, Huang Y, Liu Y C, Wang Z M 2019 J. Mater. Sci. Technol. 35 512

Google Scholar

Google Scholar

[3] Elder K R, Katakowski M, Haataja M, Grant M 2002 Phys. Rev. Lett. 88 245701

Google Scholar

Google Scholar

[4] Elder K R, Grant M 2004 Phys. Rev. E 70 051605

Google Scholar

Google Scholar

[5] Elder K R, Provatas N, Berry J, Stefanovic P 2007 Phys. Rev. B 75 064107

Google Scholar

Google Scholar

[6] Wang J, Yu L M, Huang Y, Li H J, Liu Y C 2019 Comput. Mater. Sci. 160 105

Google Scholar

Google Scholar

[7] Zhao Y H, Zhang B, Hou H, Chen W P, Wang M 2019 J. Mater. Sci. Technol. 35 1044

Google Scholar

Google Scholar

[8] Zhang B, Zhao Y H, Chen W P, Xu Q Y, Wang M, Hou H 2019 J. Cryst. Growth 522 183

Google Scholar

Google Scholar

[9] Sun Y Y, Zhao Y H, Zhao B J, Yang W K, Li X L 2019 J. Mater. Sci. 54 11263

Google Scholar

Google Scholar

[10] Fan D, Chen L Q 1997 Acta Mater. 45 611

Google Scholar

Google Scholar

[11] 孙远洋, 赵宇宏, 侯华, 郑晓娟, 郭慧俊 2018 稀有金属材料与工程 47 3000

Google Scholar

Google Scholar

Sun Y Y, Zhao Y H, Hou H, Zheng X J, Guo H J 2018 Rare Metal Mat. Eng. 47 3000

Google Scholar

Google Scholar

[12] 康永生, 赵宇宏, 侯华, 靳玉春, 陈利文 2016 65 188102

Google Scholar

Google Scholar

Kang Y S, Zhao Y H, Hou H, Jin Y C, Chen L W 2016 Acta Phys. Sin. 65 188102

Google Scholar

Google Scholar

[13] 田晓林, 赵宇宏, 田晋忠, 侯华 2018 67 230201

Google Scholar

Google Scholar

Tian X L, Zhao Y H, Tian J Z, Hou H 2018 Acta Phys. Sin. 67 230201

Google Scholar

Google Scholar

[14] Zhao Y H, Tian X L, Zhao B J, Sun Y Y, Guo H J, Dong M Y, Liu H, Wang X J, Guo Z H, Umar A, Hou H 2018 Sci. Adv. Mater. 10 1793

Google Scholar

Google Scholar

[15] 赵宝军, 赵宇宏, 孙远洋, 杨文奎, 侯华 2019 金属学报 55 593

Google Scholar

Google Scholar

Zhao B J, Zhao Y H, Sun Y Y, Yang W K, Hou H 2019 Acta Metall. Sin. 55 593

Google Scholar

Google Scholar

[16] 孙远洋, 赵宇宏, 侯华, 靳玉春, 郑晓娟 2018 中国有色金属学报 28 71

Sun Y Y, Zhao Y H, Hou H, Jin Y C, Zheng X J 2018 Chin. J. Nonferrous Met. 28 71

[17] Tian J Z, Zhao Y H, Hou H, Han P D 2017 Solid State Commun. 268 44

Google Scholar

Google Scholar

[18] Tian J Z, Zhao Y H, Wang B, Hou H, Zhang Y M 2018 Mater. Chem. Phys. 209 200

Google Scholar

Google Scholar

[19] Zhang J B, Wang H F, Kuang W W, Zhang Y C, Li H, Zhao Y H, Herlach D 2018 Acta Mater. 148 86

Google Scholar

Google Scholar

[20] Kuang W W, Wang H F, Li X, Zhang J B, Zhou Q, Zhao Y H 2018 Acta Mater. 159 16

Google Scholar

Google Scholar

[21] 方辉, 薛桦, 汤倩玉, 张庆宇, 潘诗琰, 朱鸣芳 2019 68 048102

Google Scholar

Google Scholar

Fang H, Xue H, Tang Q Y, Zhang Q Y, Pan S Y, Zhu M F 2019 Acta Phys. Sin. 68 048102

Google Scholar

Google Scholar

[22] Zhao Y H, Wang S, Zhang B, Yuan Y, Guo Q W, Hou H 2019 J. Solid State Chem. 276 232

Google Scholar

Google Scholar

[23] Wu K A, Voorhees P W 2012 Acta Mater. 60 407

Google Scholar

Google Scholar

[24] 祁科武, 赵宇宏, 郭慧俊, 田晓林, 侯华 2019 68 170504

Google Scholar

Google Scholar

Qi K W, Zhao Y H, Guo H J, Tian X L, Hou H 2019 Acta Phys. Sin. 68 170504

Google Scholar

Google Scholar

[25] Olmsted D L, Buta D, Adland A, Foiles S M, Asta M, Karma A 2011 Phys. Rev. Lett. 106 046101

Google Scholar

Google Scholar

[26] 高英俊, 秦河林, 周文权, 邓芊芊, 罗志荣, 黄创高 2015 64 106105

Google Scholar

Google Scholar

Gao Y J, Qin H L, Zhou W Q, Deng Q Q, Luo Z R, Huang C G 2015 Acta Phys. Sin. 64 106105

Google Scholar

Google Scholar

[27] Berry J, Elder K R, Grant M 2008 Phys. Rev. B 77 224114

Google Scholar

Google Scholar

[28] Nourian A, Asadi E 2018 Comput. Mater. Sci. 145 224

Google Scholar

Google Scholar

[29] ChanV W L, Pisutha-Arnond N, Thornton K 2017 Comput. Mater. Sci. 135 205

Google Scholar

Google Scholar

[30] Asadi E, Zaeem M A 2015 Jom 67 186

Google Scholar

Google Scholar

[31] Hu S, Xi W, Chen Z, Wang S, Zhang T H 2017 Comput. Mater. Sci. 132 125

Google Scholar

Google Scholar

[32] Hu S, Wang S 2019 Phys. B 552 104

Google Scholar

Google Scholar

[33] Gao Y J, Deng Q Q, Huang L L, Ye L, Wen Z C, Luo Z R 2017 Comput. Mater. Sci. 130 64

Google Scholar

Google Scholar

[34] Greenwood M, Ofori-Opoku N, Rottler J, Provatas N 2011 Phys. Rev. B 84 064104

Google Scholar

Google Scholar

[35] Greenwood M, Rottler J, Provatas N 2011 Phys. Rev. E 83 031601

[36] Elder K R, Thornton K, Hoyt J J 2011 Philos. Mag. 91 151

Google Scholar

Google Scholar

[37] Lu G M, Lu Y L, Hu T T, Chen Z 2015 Comput. Mater. Sci. 106 170

Google Scholar

Google Scholar

[38] Guo H J, Zhao Y H, Sun Y Y, Tian J Z, Hou H, Qi K W, Tian X L 2019 Superlattices Microstruct. 129 163

Google Scholar

Google Scholar

[39] Zhao Y H, Deng S J, Liu H, Zhang J X, Guo Z H, Hou H 2018 Comput. Mater. Sci. 154 365

Google Scholar

Google Scholar

[40] Wen Z Q, Hou H, Tian J Z, Zhao Y H, Li H J, Han P D 2018 Intermetallics 92 15

Google Scholar

Google Scholar

[41] Wen Z Q, Zhao Y H, Hou H, Wang B, Han P D 2017 Mater. Des. 114 398

Google Scholar

Google Scholar

[42] Zhao Y H, Qi L, Jin Y C, Wang K, Tian J Z, Han P D 2015 J. Alloys Compd. 647 1104

Google Scholar

Google Scholar

[43] Hirouchi T, Takaki T, Tomita Y 2009 Comput. Mater. Sci. 44 1192

Google Scholar

Google Scholar

计量

- 文章访问数: 14796

- PDF下载量: 174

- 被引次数: 0

下载:

下载: