-

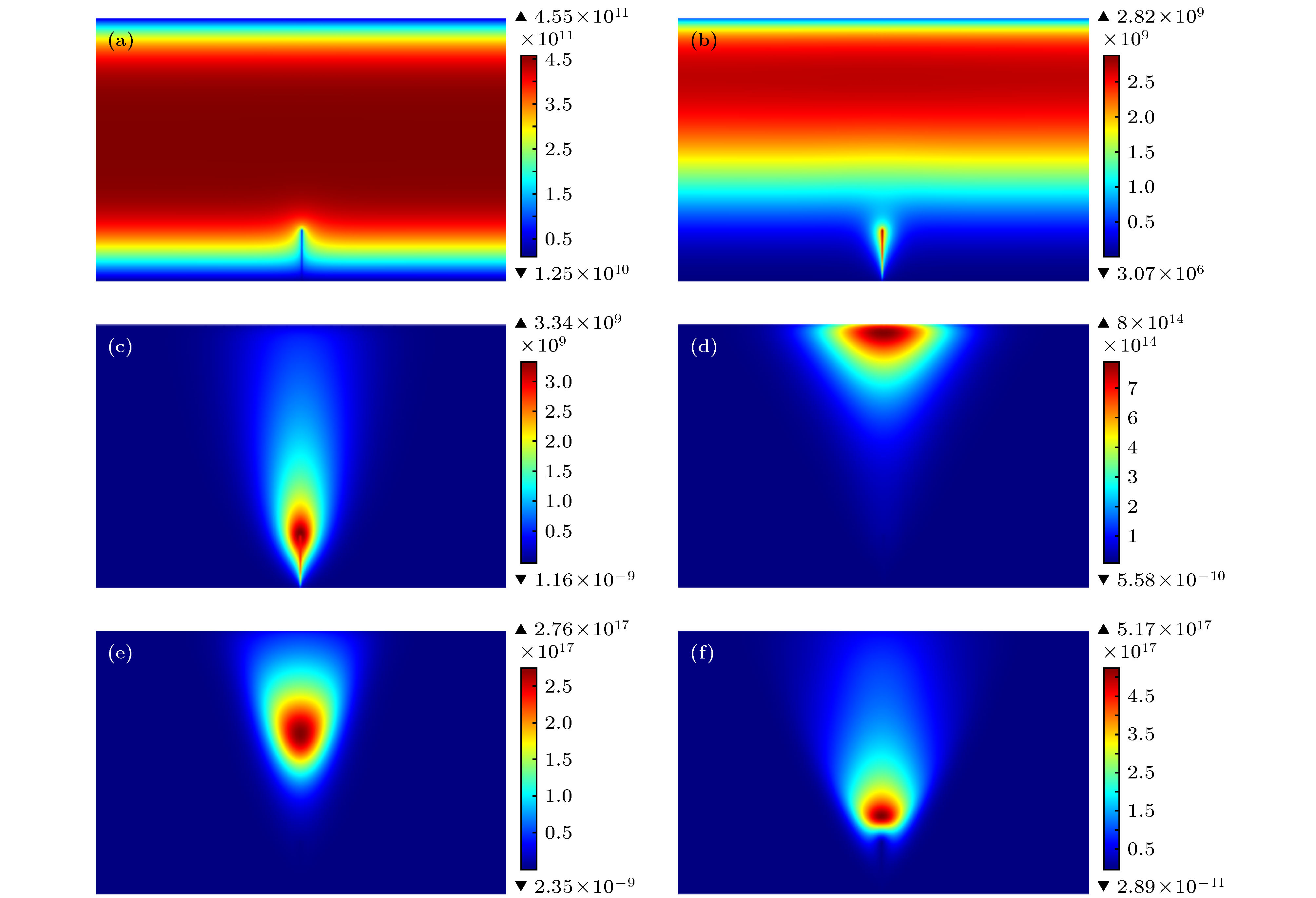

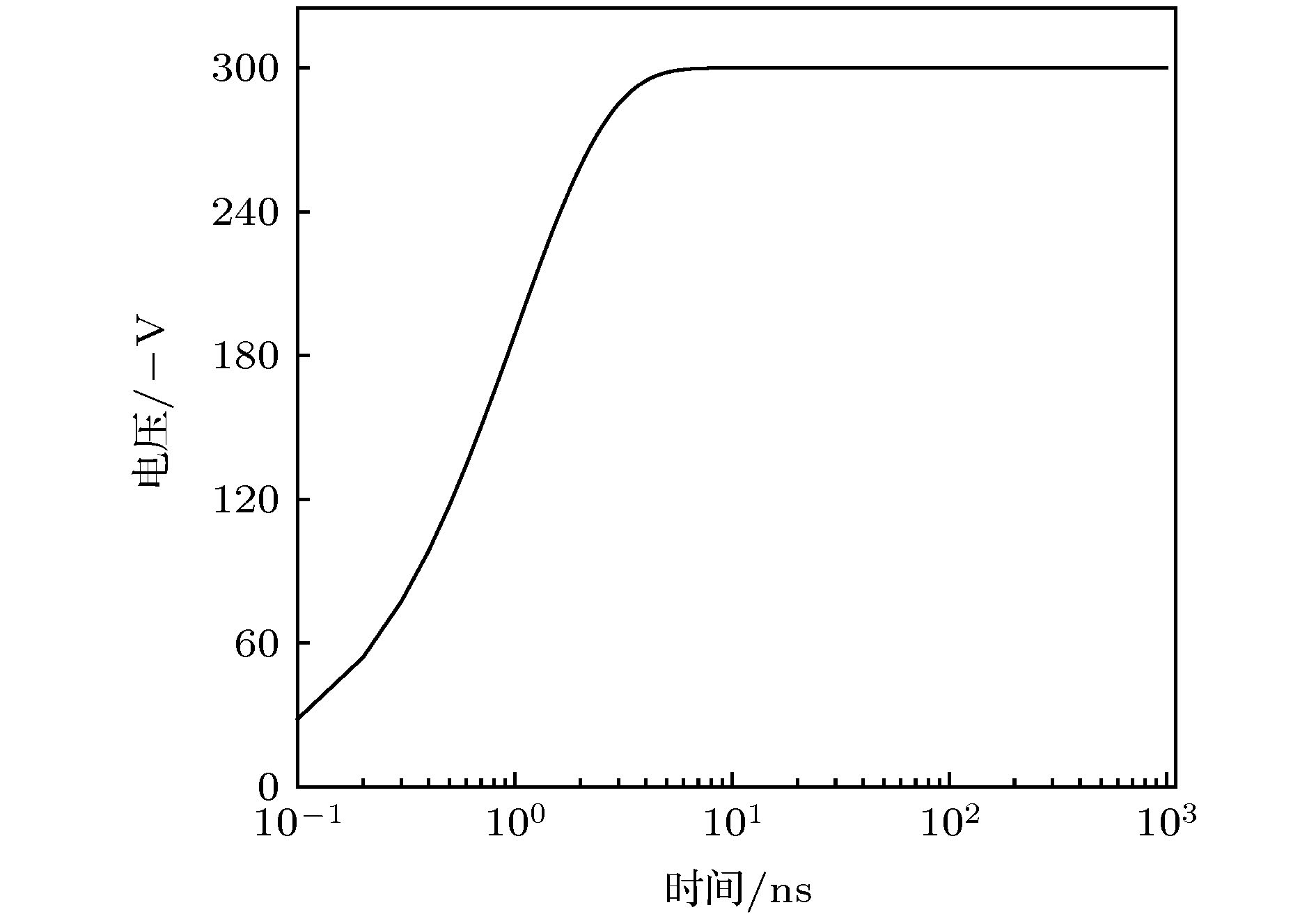

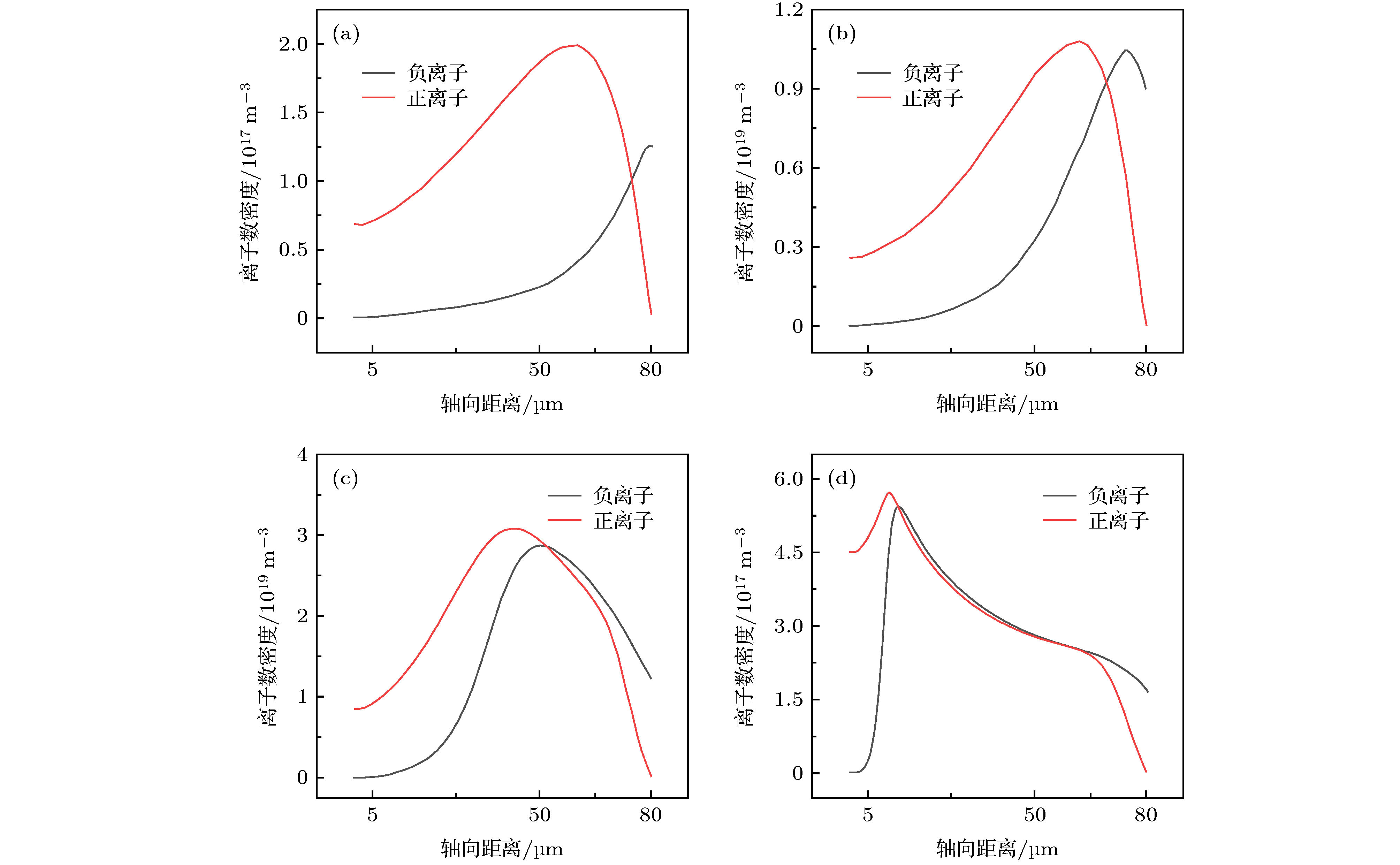

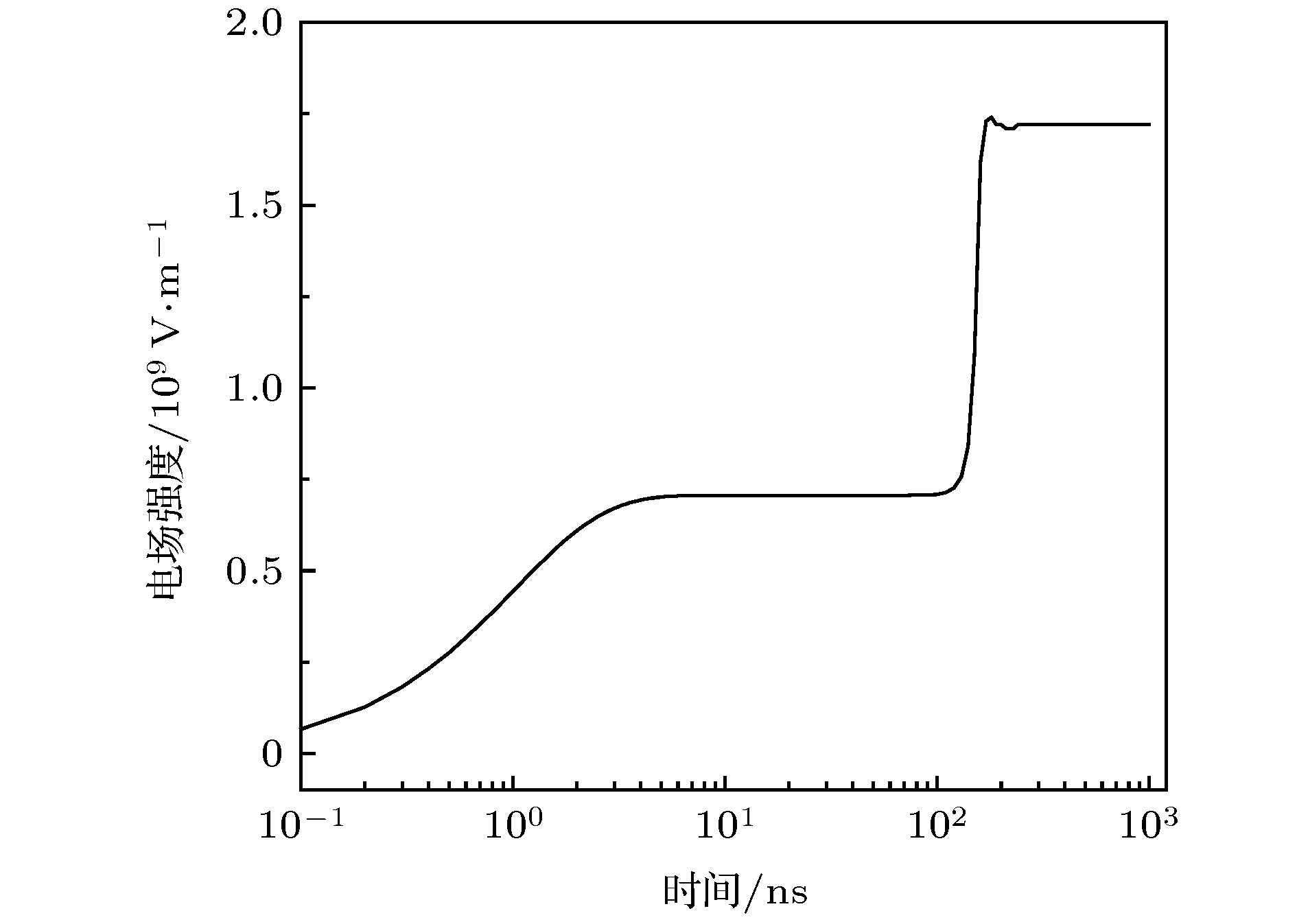

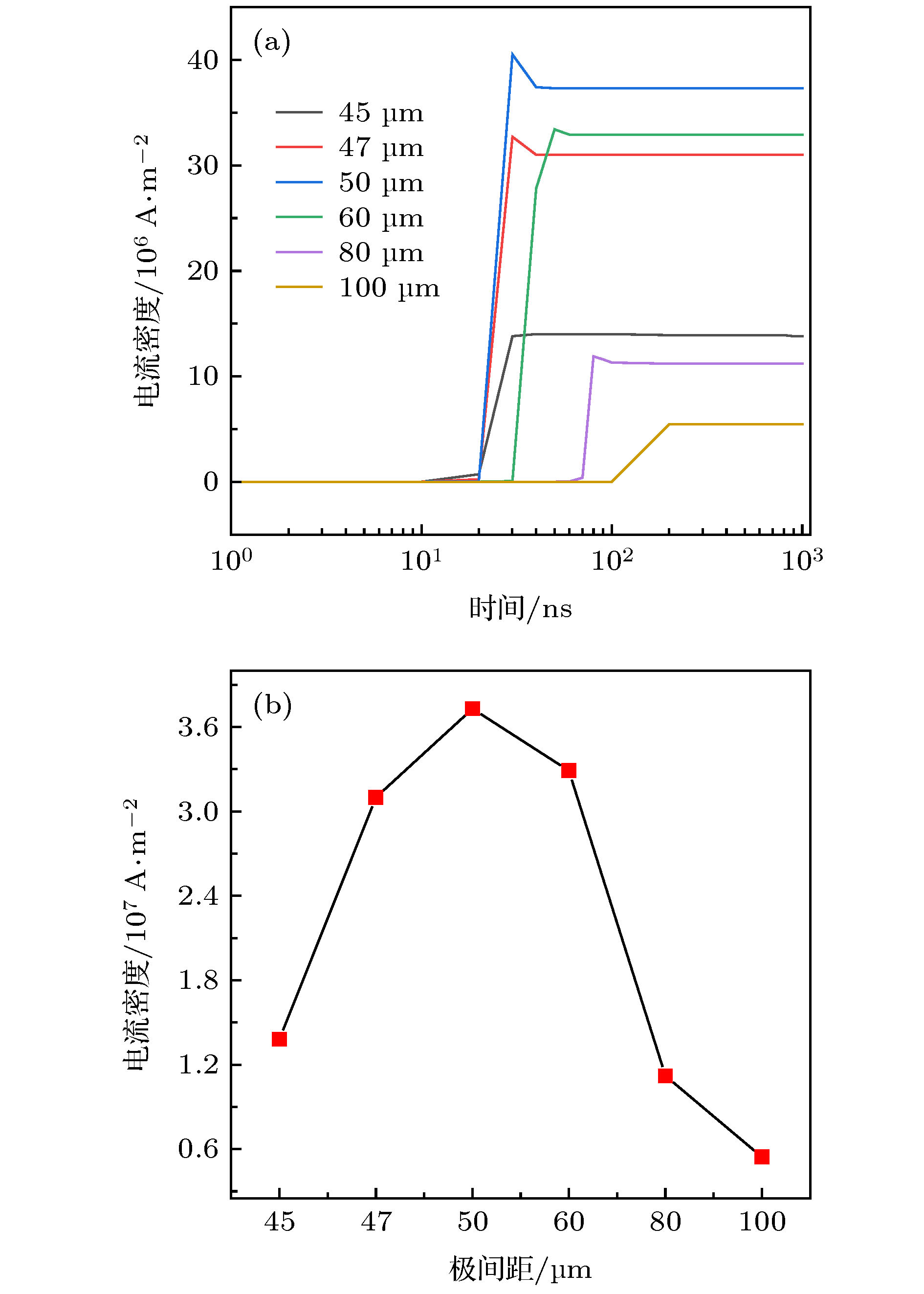

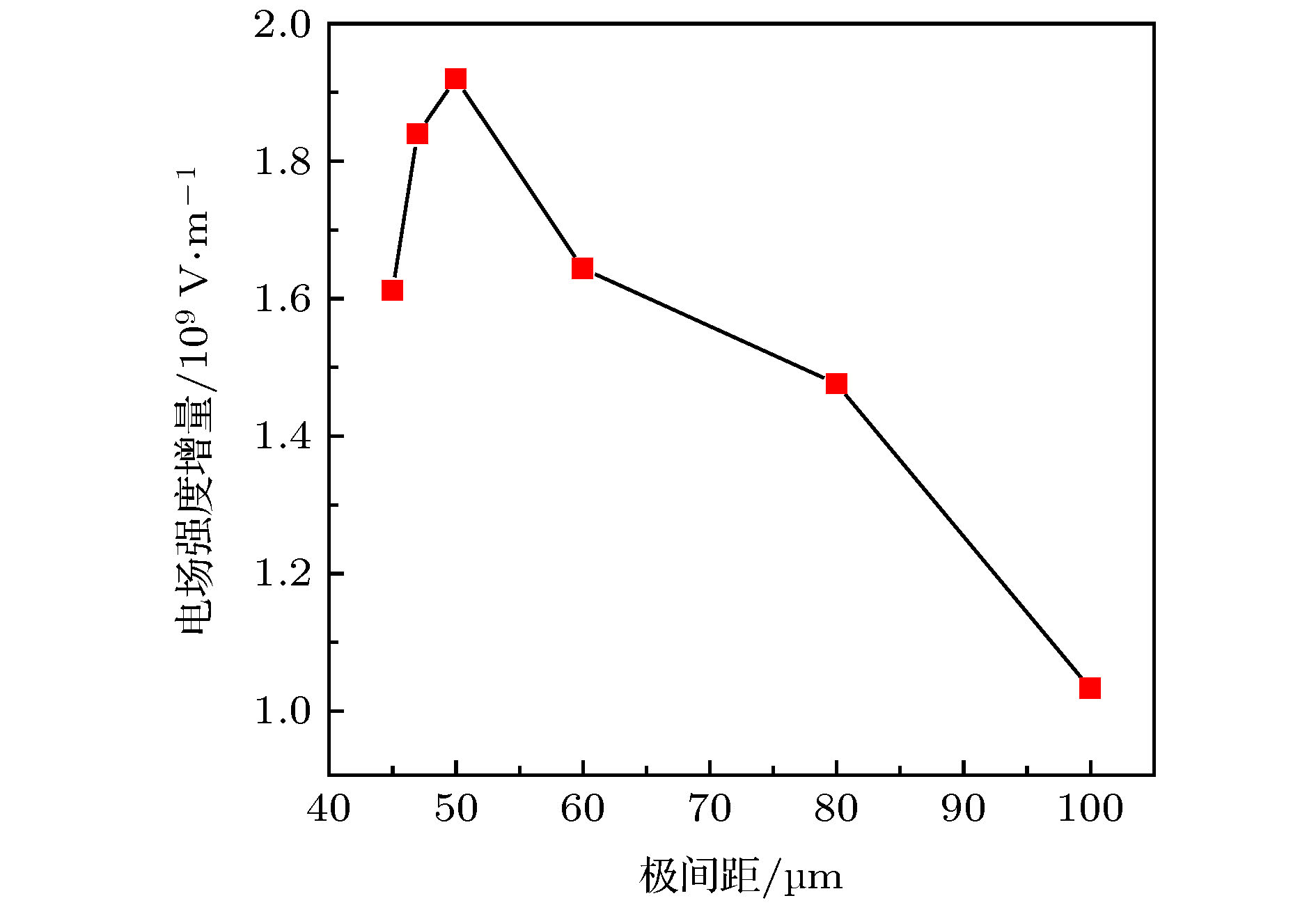

微纳电离式气体传感器基于微尺度放电原理, 具有响应快、精度高、易集成等特点, 有望实现对气体的快速准确检测. 目前缺少对该新型传感器极间放电过程的系统分析. 对此本文采用流体-化学动力学混合方法, 建立了常温常压下大气中N2-O2混合气体在微米间隙-纳米尖端场域的二维空间放电模型, 并通过分析空间电子输运机制、放电电流密度、空间电场强度之间的相互耦合关系, 阐明了该场域下空间放电的动态发展过程, 完善了微纳电离式气体传感器内部放电机理, 且分析了不同极间距对空间放电的影响规律. 结果表明: 该场域下空间电场随正负离子的产生与消耗达到动态平衡而保持恒定, 使空间放电得以维持, 放电电流密度趋于稳定; 且随着极间距的减小放电电流密度呈现出先增大后减小的趋势, 此特性为传感器的优化提供了一定的理论指导.Based on the principle of micro-scale discharge, the micro-nano ionization gas sensor has the characteristics of fast response, high precision and easy integration. It is expected to achieve rapid and accurate detection of gas. At present, there is a lack of systematic analysis of the inter-polar discharge process of the new sensor. This paper uses the fluid-chemical dynamics methodology to create a 2D space discharge model of the N2-O2 mixed gas at the micron gap and the nano-tip field in ambient atmosphere at normal temperature and pressure. Meanwhile, by analyzing the mutual coupling between the space electron transport process, the discharge current density, and the space electric field strength, the paper clarifies the dynamics of space discharge in the field, improves how internal discharges work in such micro-nano structured ionization gas sensors, and analyzes the pattern of influence of different polar distances on space discharges. The results show that the electric field in the space remains constant as the production and consumption of positive and negative ions reaches a dynamic equilibrium in the field. It is reflected in the field strengthening effect of positive ion groups to the cathode plate and of negative ion groups to the anode plate, as well as in the field weakening effect between positive and negative ion groups. The resulting stable and strong electric field of the cathode makes sure that space discharge is maintained, and the discharge current density stabilizes. Initially, as the polar distance decreases gradually, the electric field strength between the poles and plates increases. It plays a leading role in the accumulation of electron energy and in the increase in the number density of electrons, thus leading to the increase of the output current density up to the peak value when the polar distance D = 50 μm. As the polar distance decreases, the field strength between the poles and plates increases. Despite that, when electrons accumulate energy up to such a level that gas molecules can be ionized, the necessary movement distance and the distance required to increase the number density of electrons decreases. As a result, the degree of ionization weakens, and the field strengthening effect of positive ions decreases. In other words, the increment of the field strength caused by positive ions at the tip decreases, and in turn, the discharge current density decreases. This pattern serves as a theoretical support in the optimization of the micro-nano structured ionization gas sensors.

-

Keywords:

- ionization gas sensor /

- discharge process /

- space electric field /

- current density

[1] 谢云龙, 钟国, 杜高辉 2012 化学学报 70 1221

Google Scholar

Google Scholar

Xie Y L, Zhong G, Du G H 2012 Acta Chim. Sinica 70 1221

Google Scholar

Google Scholar

[2] 常进, 张为军, 刘卓峰, 陈兴宇 2016 电子元件与材料 35 15

Google Scholar

Google Scholar

Chang J, Zhang W J, Liu Z F, Chen X Y 2016 Electr. Comp. Mater. 35 15

Google Scholar

Google Scholar

[3] Ashish M, Nikhil K, Eric L, Wei B Q, Pulickel M A 2003 Nature 424 171

Google Scholar

Google Scholar

[4] 刘凯, 邹德福, 廉五州, 马丽铃, 马丽敏, 陈志东 2016 仪表技术与传感器 1 10

Google Scholar

Google Scholar

Liu K, Zou D F, Lian W Z, Ma L L, Ma L M, Chen Z D 2016 Instr. Techn. Sensor 1 10

Google Scholar

Google Scholar

[5] 张一茗, 袁欢, 穆广祺, 宋亚凯, 张文涛, 王小华 2016 高压电器 52 134

Google Scholar

Google Scholar

Zhang Y M, Yuan H, Mu G Q, Song Y K, Zhang W T, Wang X H 2016 High Volt. Appar. 52 134

Google Scholar

Google Scholar

[6] Trichel G W 1938 Phys. Rev. 54 1078

Google Scholar

Google Scholar

[7] 廖瑞金, 刘康淋, 伍飞飞, 杨丽君, 周之 2014 高电压技术 40 965

Google Scholar

Google Scholar

Liao R J, Liu K L, Wu F F, Yang L J, Zhou Z 2014 High Volt. Eng. 40 965

Google Scholar

Google Scholar

[8] 郑殿春, 夏云双, 赵大伟, 陈春天, 王佳 2013 电机与控制学报 17 75

Google Scholar

Google Scholar

Zheng D C, Xia Y S, Zhao D W, Chen C T, Wang J 2013 Electr. Mach. Contrl. 17 75

Google Scholar

Google Scholar

[9] Zhang J Y, Zhang Y, Pan Z G, Yang S, Shi J H, Li S T, Min D M, Li X, Wang X H, Liu D X, Yang A J 2015 Appl. Phys. Lett. 107 093104

Google Scholar

Google Scholar

[10] Zhang Y, Li S T, Zhang J Y, Pan Z G, Min D M, Li Xin, Song X P, Liu J H 2013 Sci. Rep. 3 1267

Google Scholar

Google Scholar

[11] 柴钰, 弓丽萍, 张晶园, 赵永秀 2019 电工技术学报 34 4870

Google Scholar

Google Scholar

Chai Y, Gong L P, Zhang J Y, Zhao Y X 2019 Trans. Chin. Electrotechnical Soc. 34 4870

Google Scholar

Google Scholar

[12] Yang H S, Tan Z M, Liu Y, Ma Z X, Zhang L 2013 IEEE T. Nanotechnol. 12 1037

Google Scholar

Google Scholar

[13] Nebol’sin V A, Spiridonov B A, Dunaev A I, Bogdanovich E V 2016 Inorg. Mater. 53 595

Google Scholar

Google Scholar

[14] 程永红, 孟国栋, 董承业 2017 电工技术学报 32 13

Google Scholar

Google Scholar

Cheng Y H, Meng G D, Dong C Y 2017 Trans. Chin. Electrotechnical Soc. 32 13

Google Scholar

Google Scholar

[15] 孔迪, 李建周, 张昊, 陈昶 2014 电子设计工程 22 127

Google Scholar

Google Scholar

Kong D, Li J Z, Zhang H, Chei C 2014 Int. Electr. Elem. 22 127

Google Scholar

Google Scholar

[16] 廖瑞金, 伍飞飞, 刘兴华, 杨帆, 杨丽君, 周之, 翟蕾 2012 61 245201

Google Scholar

Google Scholar

Liao R J, Wu F F, Liu X H, Yang F, Yang L J, Zhou Z, Zhai L 2012 Acta Phys. Sin. 61 245201

Google Scholar

Google Scholar

[17] 周雪会, 陈登义, 陈则煌 2016 陶瓷避雷器 5 152

Google Scholar

Google Scholar

Zhou X H, Chen D Y, Chen Z H 2016 Insulators and Surge Arresters 5 152

Google Scholar

Google Scholar

[18] 陈硕,张金英,杨天辰,李璐,郑天祥 2017 智能电网 5 812

Google Scholar

Google Scholar

Chen S, Zhang J Y, Yang T C, Li L, Zheng T X 2017 Smart Grid 5 812

Google Scholar

Google Scholar

[19] 李雪辰, 袁宁, 贾鹏英, 常媛媛, 嵇亚飞 2012 60 125204

Li X C, Yuan N, Jia P Y, Chang Y Y, Ji Y F 2012 Acta Phys. Sin. 60 125204

[20] 李维虎, 张锦, 万保权, 何旺龄 2018 高压电器 54 0129

Google Scholar

Google Scholar

Li W H, Zhang J, Wan B Q, He W L 2018 High Volt. Appar. 54 0129

Google Scholar

Google Scholar

[21] Georghiou G E, Papadakis A P, Morroe R, Metaxas A C 2005 Appl. Phys. 38 303

Google Scholar

Google Scholar

[22] Ashish M, Nikhil K, Eric L, Wei B Q, Pulickel M A 2003 Nature 424 172

[23] Akishev Y S, Grushin M E, Karal’nik V B, Trushkin N I 2000 Plasma Phys. Rep. 27 532

[24] Morrow R 1991 IEEE T. Electr. Insul. 26 398

Google Scholar

Google Scholar

[25] Yin H, Zhang B, He J L, Wang W Z 2014 Phys. Plasmas 21 032116

Google Scholar

Google Scholar

[26] 徐学基, 诸定昌 1996 气体放电物理 (上海: 复旦大学出版社) 第243—254页

Xu X J, Zhu D C 1996 Gas Discharge Physics (Shanghai: Fudan University Press) pp243–254

[27] 徐翱,金大志,王亚军,陈 磊,谈效华 2020 高压电技术 46 715

Google Scholar

Google Scholar

Xu A, Jin D Z, Wang Y J, Chen L, Tan X H 2020 High Volt. Eng. 46 715

Google Scholar

Google Scholar

[28] 伍飞飞, 廖瑞金, 杨丽君, 刘兴华, 汪可, 周之 2013 62 115201

Google Scholar

Google Scholar

Wu F F, Liao R J, Yang L J, Liu X H, Wang K, Zhou Z 2013 Acta Phys. Sin. 62 115201

Google Scholar

Google Scholar

[29] Liu X H, He W, Yang F, Wang H Y, Liao R J, Xiao H G 2012 Chin. Phys. B 21 075201

Google Scholar

Google Scholar

[30] 刘学悫 1980 阴极电子学 (北京: 科学出版社) 第244—273

Liu X Q 1980 Cathode electronics (Beijing: Science Press) pp244–273

-

表 1 N2-O2等离子体化学反应

Table 1. N2-O2 plasma chemical reactions.

类型 序号 反应式 反应速率 参考文献 电子碰撞反应 R1 ${\rm{e}} + {{\rm{N}}_{\rm{2}}} \to {\rm{e}} +{\rm{ e}} +{\rm{ N}}_{\rm{2}}^{{ + }} $ f (ε) [29] R2 ${\rm{e}} + {{\rm{O}}_2} \to {\rm{e}} + {\rm{e}} + {\rm{O}}_2^ + $ f (ε) [29] R3 ${\rm{e}} + {\rm{O}}_4^ + \to 2{{\rm{O}}_2}$ 1.4 × 10–42(300/Te)0.5 mol·s–1 [29] R4 ${\rm{e}} + {\rm{O}}_2^ + \to 2{\rm{O}}$ 2.0 × 10–13(300/Te) mol·s–1 [29] R5 ${\rm{e}} + 2{{\rm{O}}_2} \to {{\rm{O}}_2} + {\rm{O}}_2^ - $ 2.0 × 10–41(300/Te) mol·s–1·m–6 [29] 重粒子反应 R6 ${\rm{O}}_{\rm{2}}^{{ + }}{{ + }}{{\rm{O}}_{\rm{2}}}{{ + }}{{\rm{N}}_{\rm{2}}} \to {\rm{O}}_{\rm{4}}^{{ + }}{{ + }}{{\rm{N}}_2}$ 2.4 × 10–42 mol·s–1·m–6 [29] R7 ${{\rm{N}}_{\rm{2}}}{\rm{O}}_{\rm{2}}^{{ + }}{{ + }}{{\rm{O}}_{\rm{2}}} \to {\rm{O}}_{\rm{4}}^{{ + }}{{ + }}{{\rm{N}}_2}$ 1.0 × 10–15 mol·s–1·m–3 [29] R8 ${{\rm{N}}_{\rm{2}}}{\rm{O}}_{\rm{2}}^{{ + }}{{ + }}{{\rm{N}}_{\rm{2}}} \to {\rm{O}}_2^{{ + }}{{ + 2}}{{\rm{N}}_{\rm{2}}}$ 4.3 × 10–10 mol·s–1·m–3 [29] R9 ${\rm{O}}_{\rm{2}}^{{ + }}{{ + 2}}{{\rm{N}}_{\rm{2}}} \to {{\rm{N}}_{\rm{2}}}{\rm{O}}_{\rm{2}}^{{ + }}{{ + }}{{\rm{N}}_{\rm{2}}}$ 9.0 × 10–43 mol·s–1·m–6 [29] R10 ${{\rm{O}}_{\rm{2}}} +{\rm{ N}}_{\rm{2}}^{{ + }} \to {{\rm{N}}_{\rm{2}}} +{\rm{ O}}_{\rm{2}}^{{ + }}$ 6.0 × 10–17 mol·s–1·m–3 [29] R11 ${\rm{N}}_{\rm{2}}^{{ + }}{{ + }}{{\rm{N}}_{\rm{2}}}{{ + }}{{\rm{O}}_{\rm{2}}} \to {{\rm{O}}_{\rm{2}}} + {\rm{N}}_{\rm{4}}^{{ + }}$ 5.0 × 10–41 mol·s–1·m–6 [29] R12 ${{\rm{O}}_{\rm{2}}}+ {\rm{ N}}_{\rm{4}}^{{ + }} \to {\rm{2}}{{\rm{N}}_{\rm{2}}}+ {\rm{ O}}_{\rm{2}}^{{ + }}$ 2.5 × 10–16 mol·s–1·m–3 [29] R13 ${\rm{2}}{{\rm{N}}_{\rm{2}}}+ {\rm{ N}}_{\rm{2}}^{{ + }} \to {{\rm{N}}_{\rm{2}}}+ {\rm{ N}}_{\rm{4}}^{{ + }}$ 5.0 × 10–41 mol·s–1·m–6 [29] R14 ${\rm{O}}_{\rm{2}}^{{ + }}+ {\rm{ 2}}{{\rm{O}}_{\rm{2}}} \to {\rm{O}}_{\rm{4}}^{{ + }}{{ + }}{{\rm{O}}_{\rm{2}}}$ 2.4 × 10–42 mol·s–1·m–6 [29] R15 ${\rm{O}}_{\rm{4}}^{{ + }}+ {\rm{ O}}_{\rm{2}}^ - \to {\rm{3}}{{\rm{O}}_{\rm{2}}}$ 1.0 × 10–13 mol·s–1·m–3 [29] R16 ${\rm{O}}_{\rm{4}}^{{ + }}+ {\rm{ O}}_{\rm{2}}^ - {{ + }}{{\rm{N}}_2} \to {\rm{3}}{{\rm{O}}_{\rm{2}}} + {{\rm{N}}_{\rm{2}}}$ 2.0 × 10–17 mol·s–1·m–6 [29] R17 ${\rm{O}}_{\rm{4}}^{{ + }}+ {\rm{ O}}_{\rm{2}}^ - {{ + }}{{\rm{O}}_{\rm{2}}} \to {\rm{3}}{{\rm{O}}_{\rm{2}}}{{ + }}{{\rm{O}}_{\rm{2}}}$ 2.0 × 10–17 mol·s–1·m–6 [29] R18 ${\rm{O}}_{\rm{2}}^{{ + }}+ {\rm{ O}}_{\rm{2}}^ - {{ + }}{{\rm{O}}_{\rm{2}}} \to {\rm{2}}{{\rm{O}}_{\rm{2}}}{{ + }}{{\rm{O}}_{\rm{2}}}$2 2.0 × 10–17 mol·s–1·m–6 [29] R19 ${\rm{O}}_{\rm{2}}^{{ + }}+ {\rm{ O}}_{\rm{2}}^ - {{ + }}{{\rm{N}}_{\rm{2}}} \to {\rm{2}}{{\rm{O}}_{\rm{2}}}{{ + }}{{\rm{N}}_{\rm{2}}}$ 2.0 × 10–17 mol·s–1·m–6 [29] 表 2 表面反应

Table 2. Surface reactions.

序号 反应式 针电极(阴极) 板电极(阳极) γ εi/eV γ εi/eV R20 ${\rm{e}} + {\rm{N}}_{\rm{2}}^{{ + }} \to {{\rm{N}}_{\rm{2}}}$ 0.05 4 0 0 R21 ${\rm{e }}+{{\rm{N}}_{\rm{2}}}{\rm{O}}_{\rm{2}}^{{ + }} \to {{\rm{N}}_{\rm{2}}}{{ + }}{{\rm{O}}_{\rm{2}}}$ 0.05 4 0 0 R22 ${\rm{e}} + {\rm{N}}_{\rm{4}}^{{ + }} \to {\rm{2}}{{\rm{N}}_{\rm{2}}}$ 0.05 4 0 0 R23 ${\rm{e}} + {\rm{O}}_{\rm{2}}^{{ + }} \to {{\rm{O}}_{\rm{2}}}$ 0.05 4 0 0 R24 ${\rm{e}} +{\rm{ O}}_{\rm{4}}^{{ + }} \to 2{{\rm{O}}_{\rm{2}}}$ 0.05 4 0 0 R25 ${\rm{e}} +{\rm{ O}}_{\rm{2}}^{{ - }} \to {{\rm{O}}_{\rm{2}}}$ 0 0 0 0 -

[1] 谢云龙, 钟国, 杜高辉 2012 化学学报 70 1221

Google Scholar

Google Scholar

Xie Y L, Zhong G, Du G H 2012 Acta Chim. Sinica 70 1221

Google Scholar

Google Scholar

[2] 常进, 张为军, 刘卓峰, 陈兴宇 2016 电子元件与材料 35 15

Google Scholar

Google Scholar

Chang J, Zhang W J, Liu Z F, Chen X Y 2016 Electr. Comp. Mater. 35 15

Google Scholar

Google Scholar

[3] Ashish M, Nikhil K, Eric L, Wei B Q, Pulickel M A 2003 Nature 424 171

Google Scholar

Google Scholar

[4] 刘凯, 邹德福, 廉五州, 马丽铃, 马丽敏, 陈志东 2016 仪表技术与传感器 1 10

Google Scholar

Google Scholar

Liu K, Zou D F, Lian W Z, Ma L L, Ma L M, Chen Z D 2016 Instr. Techn. Sensor 1 10

Google Scholar

Google Scholar

[5] 张一茗, 袁欢, 穆广祺, 宋亚凯, 张文涛, 王小华 2016 高压电器 52 134

Google Scholar

Google Scholar

Zhang Y M, Yuan H, Mu G Q, Song Y K, Zhang W T, Wang X H 2016 High Volt. Appar. 52 134

Google Scholar

Google Scholar

[6] Trichel G W 1938 Phys. Rev. 54 1078

Google Scholar

Google Scholar

[7] 廖瑞金, 刘康淋, 伍飞飞, 杨丽君, 周之 2014 高电压技术 40 965

Google Scholar

Google Scholar

Liao R J, Liu K L, Wu F F, Yang L J, Zhou Z 2014 High Volt. Eng. 40 965

Google Scholar

Google Scholar

[8] 郑殿春, 夏云双, 赵大伟, 陈春天, 王佳 2013 电机与控制学报 17 75

Google Scholar

Google Scholar

Zheng D C, Xia Y S, Zhao D W, Chen C T, Wang J 2013 Electr. Mach. Contrl. 17 75

Google Scholar

Google Scholar

[9] Zhang J Y, Zhang Y, Pan Z G, Yang S, Shi J H, Li S T, Min D M, Li X, Wang X H, Liu D X, Yang A J 2015 Appl. Phys. Lett. 107 093104

Google Scholar

Google Scholar

[10] Zhang Y, Li S T, Zhang J Y, Pan Z G, Min D M, Li Xin, Song X P, Liu J H 2013 Sci. Rep. 3 1267

Google Scholar

Google Scholar

[11] 柴钰, 弓丽萍, 张晶园, 赵永秀 2019 电工技术学报 34 4870

Google Scholar

Google Scholar

Chai Y, Gong L P, Zhang J Y, Zhao Y X 2019 Trans. Chin. Electrotechnical Soc. 34 4870

Google Scholar

Google Scholar

[12] Yang H S, Tan Z M, Liu Y, Ma Z X, Zhang L 2013 IEEE T. Nanotechnol. 12 1037

Google Scholar

Google Scholar

[13] Nebol’sin V A, Spiridonov B A, Dunaev A I, Bogdanovich E V 2016 Inorg. Mater. 53 595

Google Scholar

Google Scholar

[14] 程永红, 孟国栋, 董承业 2017 电工技术学报 32 13

Google Scholar

Google Scholar

Cheng Y H, Meng G D, Dong C Y 2017 Trans. Chin. Electrotechnical Soc. 32 13

Google Scholar

Google Scholar

[15] 孔迪, 李建周, 张昊, 陈昶 2014 电子设计工程 22 127

Google Scholar

Google Scholar

Kong D, Li J Z, Zhang H, Chei C 2014 Int. Electr. Elem. 22 127

Google Scholar

Google Scholar

[16] 廖瑞金, 伍飞飞, 刘兴华, 杨帆, 杨丽君, 周之, 翟蕾 2012 61 245201

Google Scholar

Google Scholar

Liao R J, Wu F F, Liu X H, Yang F, Yang L J, Zhou Z, Zhai L 2012 Acta Phys. Sin. 61 245201

Google Scholar

Google Scholar

[17] 周雪会, 陈登义, 陈则煌 2016 陶瓷避雷器 5 152

Google Scholar

Google Scholar

Zhou X H, Chen D Y, Chen Z H 2016 Insulators and Surge Arresters 5 152

Google Scholar

Google Scholar

[18] 陈硕,张金英,杨天辰,李璐,郑天祥 2017 智能电网 5 812

Google Scholar

Google Scholar

Chen S, Zhang J Y, Yang T C, Li L, Zheng T X 2017 Smart Grid 5 812

Google Scholar

Google Scholar

[19] 李雪辰, 袁宁, 贾鹏英, 常媛媛, 嵇亚飞 2012 60 125204

Li X C, Yuan N, Jia P Y, Chang Y Y, Ji Y F 2012 Acta Phys. Sin. 60 125204

[20] 李维虎, 张锦, 万保权, 何旺龄 2018 高压电器 54 0129

Google Scholar

Google Scholar

Li W H, Zhang J, Wan B Q, He W L 2018 High Volt. Appar. 54 0129

Google Scholar

Google Scholar

[21] Georghiou G E, Papadakis A P, Morroe R, Metaxas A C 2005 Appl. Phys. 38 303

Google Scholar

Google Scholar

[22] Ashish M, Nikhil K, Eric L, Wei B Q, Pulickel M A 2003 Nature 424 172

[23] Akishev Y S, Grushin M E, Karal’nik V B, Trushkin N I 2000 Plasma Phys. Rep. 27 532

[24] Morrow R 1991 IEEE T. Electr. Insul. 26 398

Google Scholar

Google Scholar

[25] Yin H, Zhang B, He J L, Wang W Z 2014 Phys. Plasmas 21 032116

Google Scholar

Google Scholar

[26] 徐学基, 诸定昌 1996 气体放电物理 (上海: 复旦大学出版社) 第243—254页

Xu X J, Zhu D C 1996 Gas Discharge Physics (Shanghai: Fudan University Press) pp243–254

[27] 徐翱,金大志,王亚军,陈 磊,谈效华 2020 高压电技术 46 715

Google Scholar

Google Scholar

Xu A, Jin D Z, Wang Y J, Chen L, Tan X H 2020 High Volt. Eng. 46 715

Google Scholar

Google Scholar

[28] 伍飞飞, 廖瑞金, 杨丽君, 刘兴华, 汪可, 周之 2013 62 115201

Google Scholar

Google Scholar

Wu F F, Liao R J, Yang L J, Liu X H, Wang K, Zhou Z 2013 Acta Phys. Sin. 62 115201

Google Scholar

Google Scholar

[29] Liu X H, He W, Yang F, Wang H Y, Liao R J, Xiao H G 2012 Chin. Phys. B 21 075201

Google Scholar

Google Scholar

[30] 刘学悫 1980 阴极电子学 (北京: 科学出版社) 第244—273

Liu X Q 1980 Cathode electronics (Beijing: Science Press) pp244–273

计量

- 文章访问数: 9146

- PDF下载量: 90

- 被引次数: 0

下载:

下载: