-

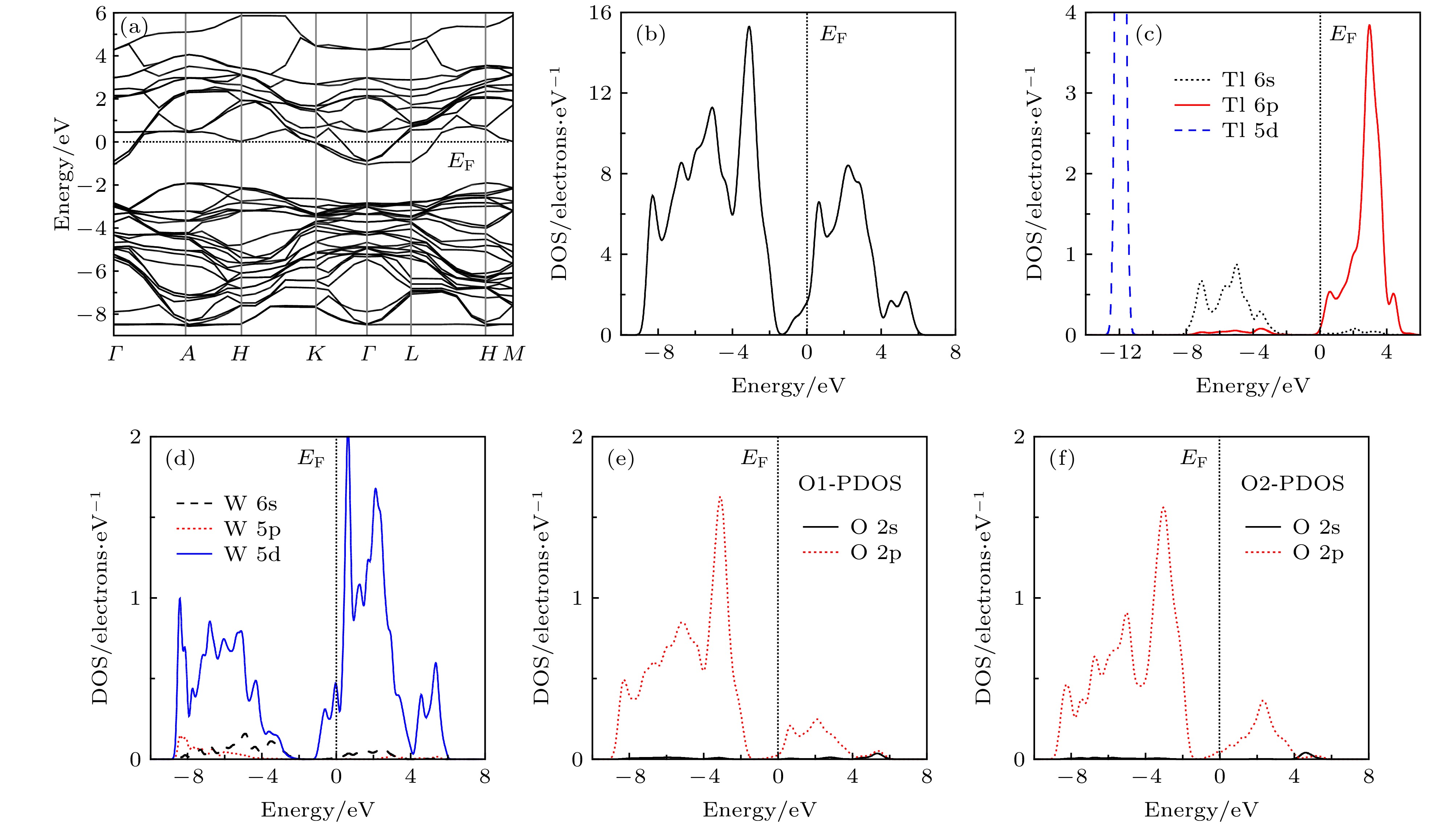

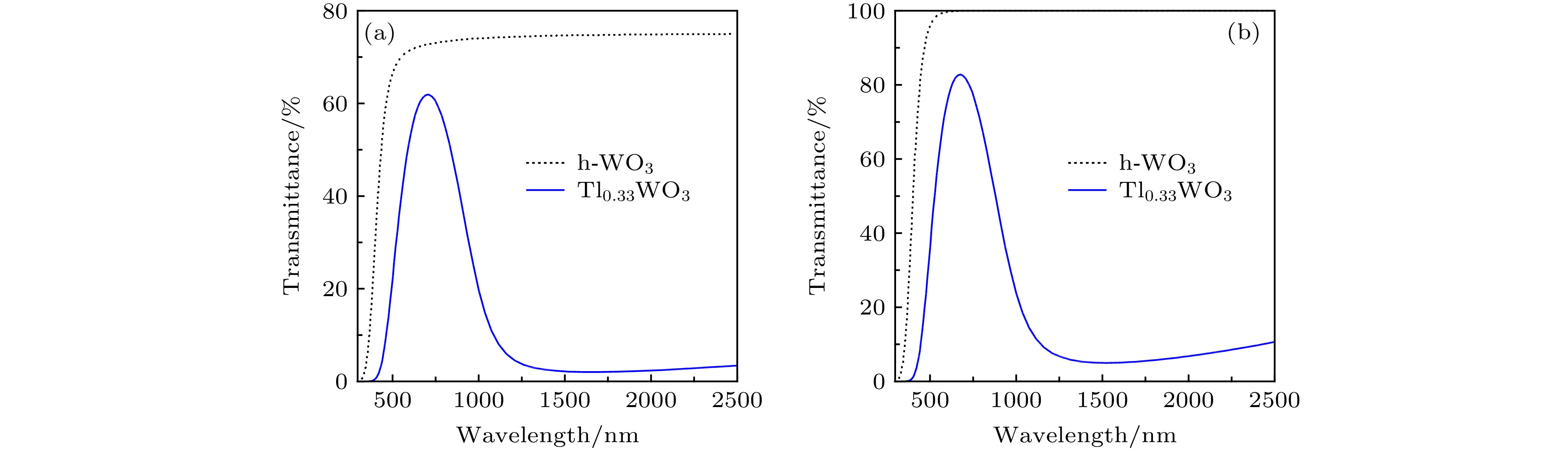

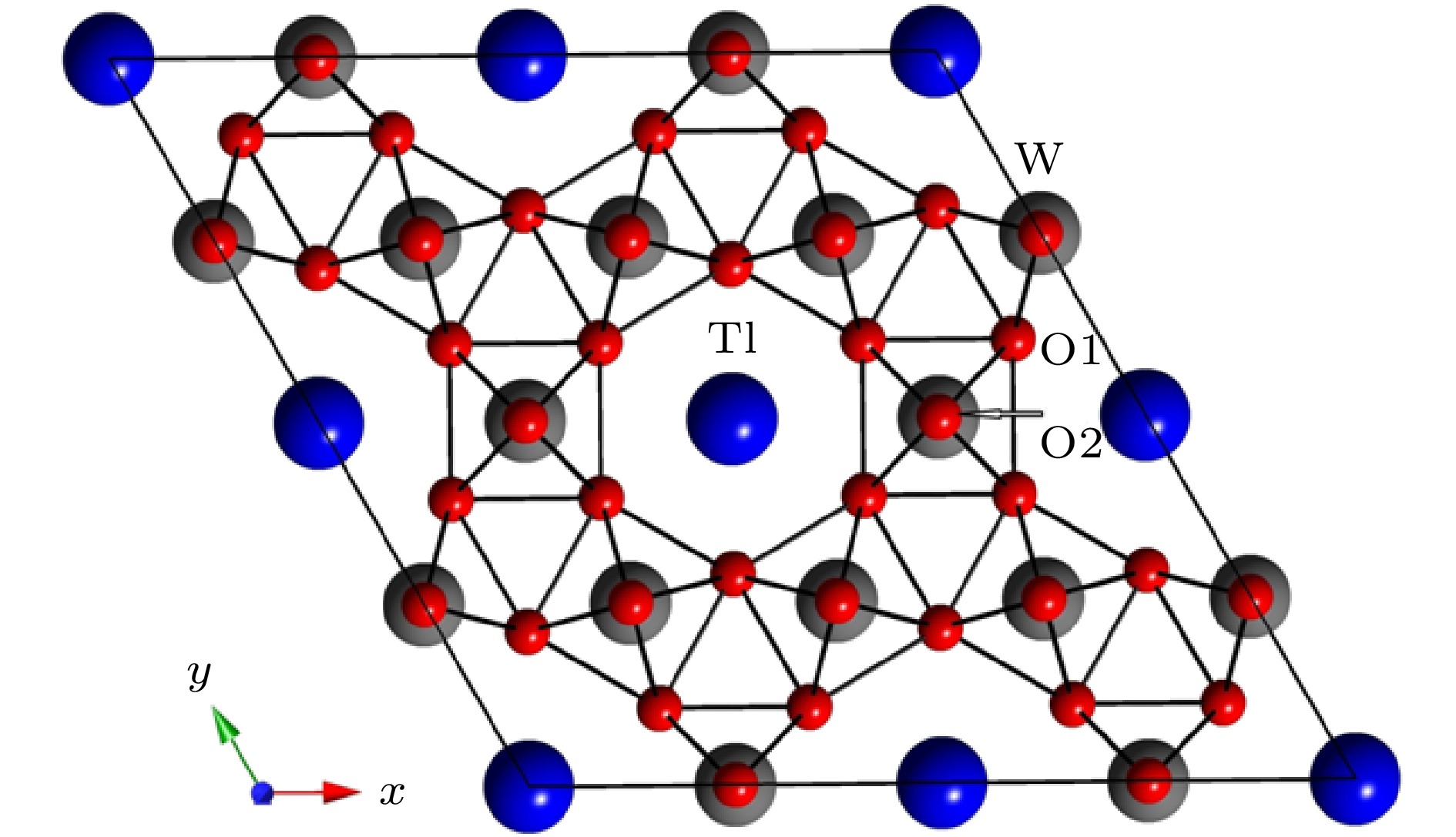

节能减排已成为当今社会发展的主题, 对节约能源、提高太阳能的高效综合利用的新型窗用透明隔热材料的理论设计和研究尤其重要. 本文采用基于密度泛函理论的计算方法, 研究了六方相三氧化钨Tl掺杂前、后的晶格参数、电子能带结构、形成能和光学性质. 研究结果表明, Tl掺杂后晶格体积增大, 系统能量降为负值, 体系具有更好的稳定性; 掺杂后电子能带结构发生很大的变化, 但材料仍保持n型电导率; 随之, 其光学性质也发生改变, 掺杂前h-WO3无近红外吸收性能, 掺杂后的Tl0.33WO3具有很强的近红外吸收性能. 在此基础上研究了Tl掺杂h-WO3前、后的太阳辐射屏蔽性能, 掺杂前无太阳辐射屏蔽性能; 掺杂后的Tl0.33WO3薄膜具有可见光高透明、近红外屏蔽的性能. 计算结果为Tl掺杂h-WO3在窗用透明隔热材料方面的研究提供了理论依据.

With energy-saving and emission-reduction have become the theme of today's social development, the theoretical design and research of novel transparent heat insulation materials for windows, which can save energy and improve the comprehensive utilization efficiency of solar energy, are particularly crucial. In this paper, a calculation method based on DFT(density functional theory) is used to study the lattice parameters (the geometric structure of h-WO3 crystal was optimized by calculation) electronic band structure, formation energy, and optical properties of pure hexagonal phase tungsten trioxide(h-WO3) before and after doping with Tl. The calculated results indicate that the lattice volume increases and the total system energy decreases to a negative value after Tl-doped h-WO3, while the system has better stability; The electron band structure changes greatly after doping, but the material still maintains n-type conductivity. In the meantime, the optical properties of the material also changed, h-WO3 had no near-infrared absorption performance before Tl-doping, and Tl0.33WO3 after Tl-doped had strong near-infrared absorption performance. On this basis, the solar radiation shielding performance of h-WO3 before and after Tl doping has been studied. The results show that pure h-WO3 has no solar radiation shielding performance, while Tl0.33WO3 thin films after Tl-doped h-WO3 have high transparency in visible light region and strong absorption in near infrared radiation. The calculation results provide a theoretical basis for the application of transparent thermal insulating material for windows of Tl-doped h-WO3. -

Keywords:

- first-principles /

- Tl-doped /

- h-WO3 /

- optical properties

[1] Saito M 1997 Convertec 25 7

[2] Muromachi T, Tsujino T, Kamitani K, Maeda K 2006 J. Sol-Gel Sci. Technol. 40 267

Google Scholar

Google Scholar

[3] Xiao L H, Su Y C, Qiu W, Liu Y K, Ran J Y, Wu J M, Lu F H, Shao F, Tang D S, Peng P 2016 Ceram. Int. 42 14278

Google Scholar

Google Scholar

[4] Xiao L H, Su Y C, Ran J Y, Liu Y K, Qiu W, Wu J M, Lu F H, Shao F, Tang D S, Peng P 2016 J. Appl. Phys. 119 164903

Google Scholar

Google Scholar

[5] Xiao L H, Su Y C, Chen H Y, Liu S, Jiang M, Peng P, Liu S 2011 Appl. Phys. Lett. 99 061906

Google Scholar

Google Scholar

[6] Xiao L H, Su Y C, Qiu W, Ran J Y, Liu Y K, Wu J M, Lu F H, Shao F, Peng P 2016 Appl. Phys. Lett. 109 193906

Google Scholar

Google Scholar

[7] Takeda H, Adachi K 2007 J. Am. Ceram. Soc. 90 4059

[8] Yao Y, Zhang L, Chen Z, Cao C, Gao Y, Luo H 2018 Ceram. Int. 44 13469

Google Scholar

Google Scholar

[9] Mattox T M, Bergerud A, Agrawal A, Milliron D. J 2014 Chem. Mater. 26 1779

Google Scholar

Google Scholar

[10] Guo C S, Yin S, Yan M., Sato T 2011 J. Mater. Chem 21 5099

Google Scholar

Google Scholar

[11] Guo C S, Yin S, Sato T 2012 J. Am. Ceram. Soc. 95 1634

Google Scholar

Google Scholar

[12] Guo C S, Yin S, Dong Q 2013 J. Nanosci. Nanotechnol. 13 3236

Google Scholar

Google Scholar

[13] Adachi K, Asahi T 2012 J. Mater. Res. 27 965

Google Scholar

Google Scholar

[14] Yu Z Y, Yao Y J, Yao J N, Zhang L M, Chen Z, Gao Y F, Luo H J 2017 J. Mater. Chem. A 5 6019

Google Scholar

Google Scholar

[15] Lee J S, Liu H C, Peng G D, Tseng Y 2017 J. Cryst. Growth 465 27

Google Scholar

Google Scholar

[16] Yang C X, Chen J F, Zeng X F, Cheng D J, Cao D P 2014 Ind. Eng. Chem. Res. 53 17981

Google Scholar

Google Scholar

[17] Yang C X, Chen J F, Zeng X F, Cheng D J, Huang H F, Cao D P 2016 Nanotechnology 27 075203

Google Scholar

Google Scholar

[18] Lee Y, Lee T, Jang W, Soon A 2016 Chem. Mater. 28 4528

Google Scholar

Google Scholar

[19] Yoshio S, Adachi K 2018 Mater. Res. Express 6 026548

Google Scholar

Google Scholar

[20] Xu Q Y, Xiao L H, Ran J Y, Tursun R, Zhou G D, Deng L L, Tang D S, Shu Q W, Qin J Y, Lu G S, Peng P 2018 J. Appl. Phys. 124 193102

Google Scholar

Google Scholar

[21] McColm I J, Steadman R, Wilson S J 1978 J. Solid State Chem. 23 33

Google Scholar

Google Scholar

[22] Gao T, Jelle B P 2013 J. Phys. Chem. C 117 13753

Google Scholar

Google Scholar

[23] Segall M D, Lindan P J D, Probert M J, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys. Condens. Matter. 14 2717

Google Scholar

Google Scholar

[24] Perdew J P, Chevary J A, Vosko S H, Jackson K A, PedersonM R, Singh D J, Fiolhais C 1992 Phys. Rev. B 46 6671

[25] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[26] He Y, Wu Z, Fu L, Li C, Miao Y, Cao L, Fan H, Zou B 2003 Chem. Mater. 15 4039

Google Scholar

Google Scholar

[27] Bechinger C, Wirth E, Leiderer P 1996 Appl. Phys. Lett. 68 2834

Google Scholar

Google Scholar

[28] Barton D G, Shtein M, Wilson R D, Soled S L, Iglesia E 1999 J. Phys. Chem. B 103 630

Google Scholar

Google Scholar

[29] Gonzalez-Borrero P P, Sato F, Medina A N, Baesso M L, Bento A C, Baldissera G, Persson C, Niklasson G A, Granqvist C G, Ferreira da Silva A 2010 Appl. Phys. Lett. 96 061909

Google Scholar

Google Scholar

[30] Liu J X, Ando Y, Dong X L, Shi F, Yin S, Adachi K, Chonan T, Tanaka A, Sato T, 2010 J. Solid State Chem. 183 2456

Google Scholar

Google Scholar

[31] Dostal A, Kauschka G, Reddy S J, Scholz F 1996 J. Electroanal. Chem. 406 155

Google Scholar

Google Scholar

[32] Gerand B, Novogorocki G, Guenot J, Figlarz M, 1979 J. Solid State Chem. 29 429

Google Scholar

Google Scholar

[33] Migas D B, Shaposhnikov V L, Rodin V N, Borisenko V E 2010 J. Appl. Phys. 108 093713

Google Scholar

Google Scholar

[34] 徐金荣, 王影, 朱兴凤, 李平, 张莉 2012 61 207103

Google Scholar

Google Scholar

Xu J R, Wang Y, Zhu X F, Li P, Zhang L 2012 Acta Phys. Sin. 61 207103

Google Scholar

Google Scholar

[35] 周诗文, 彭平, 陈文钦, 庾名槐, 郭惠, 袁珍 2019 68 037101

Google Scholar

Google Scholar

Zhou S W, Peng P, Chen W Q, Yu M, H, Guo H, Yuan Z 2019 Acta Phys. Sin. 68 037101

Google Scholar

Google Scholar

[36] Granqvist C G 2012 Sol. Energy Mater. Sol. Cells 99 1

Google Scholar

Google Scholar

[37] Kamal H, Akl A A, Abdel-Hady K 2004 Physica B 349 192

Google Scholar

Google Scholar

[38] 沈学础 1992 半导体光学性质 (北京: 科学出版社) 第 24 页

Shen X C 1992 Optical Property of Semiconductor (Beijing: Science Press) p24 (in Chinese)

[39] 褚君浩 2005 窄禁带半导体物理学 (北京: 科学出版社) 第 165 页

Chu J H 2005 Physics of Narrow Gap Semiconductors (Beijing: Science Press) (in Chinese)

[40] Guo C S, Yin S, Huang L J, Yang L, Sato T 2011 Chem. Commun. 47 8853

Google Scholar

Google Scholar

-

表 1 Tl掺杂六方相WO3前、后的晶格参数、带隙与形成能

Table 1. Lattice parameters, band gap and formation energy of pure h-WO3 before and after Tl-doped

-

[1] Saito M 1997 Convertec 25 7

[2] Muromachi T, Tsujino T, Kamitani K, Maeda K 2006 J. Sol-Gel Sci. Technol. 40 267

Google Scholar

Google Scholar

[3] Xiao L H, Su Y C, Qiu W, Liu Y K, Ran J Y, Wu J M, Lu F H, Shao F, Tang D S, Peng P 2016 Ceram. Int. 42 14278

Google Scholar

Google Scholar

[4] Xiao L H, Su Y C, Ran J Y, Liu Y K, Qiu W, Wu J M, Lu F H, Shao F, Tang D S, Peng P 2016 J. Appl. Phys. 119 164903

Google Scholar

Google Scholar

[5] Xiao L H, Su Y C, Chen H Y, Liu S, Jiang M, Peng P, Liu S 2011 Appl. Phys. Lett. 99 061906

Google Scholar

Google Scholar

[6] Xiao L H, Su Y C, Qiu W, Ran J Y, Liu Y K, Wu J M, Lu F H, Shao F, Peng P 2016 Appl. Phys. Lett. 109 193906

Google Scholar

Google Scholar

[7] Takeda H, Adachi K 2007 J. Am. Ceram. Soc. 90 4059

[8] Yao Y, Zhang L, Chen Z, Cao C, Gao Y, Luo H 2018 Ceram. Int. 44 13469

Google Scholar

Google Scholar

[9] Mattox T M, Bergerud A, Agrawal A, Milliron D. J 2014 Chem. Mater. 26 1779

Google Scholar

Google Scholar

[10] Guo C S, Yin S, Yan M., Sato T 2011 J. Mater. Chem 21 5099

Google Scholar

Google Scholar

[11] Guo C S, Yin S, Sato T 2012 J. Am. Ceram. Soc. 95 1634

Google Scholar

Google Scholar

[12] Guo C S, Yin S, Dong Q 2013 J. Nanosci. Nanotechnol. 13 3236

Google Scholar

Google Scholar

[13] Adachi K, Asahi T 2012 J. Mater. Res. 27 965

Google Scholar

Google Scholar

[14] Yu Z Y, Yao Y J, Yao J N, Zhang L M, Chen Z, Gao Y F, Luo H J 2017 J. Mater. Chem. A 5 6019

Google Scholar

Google Scholar

[15] Lee J S, Liu H C, Peng G D, Tseng Y 2017 J. Cryst. Growth 465 27

Google Scholar

Google Scholar

[16] Yang C X, Chen J F, Zeng X F, Cheng D J, Cao D P 2014 Ind. Eng. Chem. Res. 53 17981

Google Scholar

Google Scholar

[17] Yang C X, Chen J F, Zeng X F, Cheng D J, Huang H F, Cao D P 2016 Nanotechnology 27 075203

Google Scholar

Google Scholar

[18] Lee Y, Lee T, Jang W, Soon A 2016 Chem. Mater. 28 4528

Google Scholar

Google Scholar

[19] Yoshio S, Adachi K 2018 Mater. Res. Express 6 026548

Google Scholar

Google Scholar

[20] Xu Q Y, Xiao L H, Ran J Y, Tursun R, Zhou G D, Deng L L, Tang D S, Shu Q W, Qin J Y, Lu G S, Peng P 2018 J. Appl. Phys. 124 193102

Google Scholar

Google Scholar

[21] McColm I J, Steadman R, Wilson S J 1978 J. Solid State Chem. 23 33

Google Scholar

Google Scholar

[22] Gao T, Jelle B P 2013 J. Phys. Chem. C 117 13753

Google Scholar

Google Scholar

[23] Segall M D, Lindan P J D, Probert M J, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys. Condens. Matter. 14 2717

Google Scholar

Google Scholar

[24] Perdew J P, Chevary J A, Vosko S H, Jackson K A, PedersonM R, Singh D J, Fiolhais C 1992 Phys. Rev. B 46 6671

[25] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[26] He Y, Wu Z, Fu L, Li C, Miao Y, Cao L, Fan H, Zou B 2003 Chem. Mater. 15 4039

Google Scholar

Google Scholar

[27] Bechinger C, Wirth E, Leiderer P 1996 Appl. Phys. Lett. 68 2834

Google Scholar

Google Scholar

[28] Barton D G, Shtein M, Wilson R D, Soled S L, Iglesia E 1999 J. Phys. Chem. B 103 630

Google Scholar

Google Scholar

[29] Gonzalez-Borrero P P, Sato F, Medina A N, Baesso M L, Bento A C, Baldissera G, Persson C, Niklasson G A, Granqvist C G, Ferreira da Silva A 2010 Appl. Phys. Lett. 96 061909

Google Scholar

Google Scholar

[30] Liu J X, Ando Y, Dong X L, Shi F, Yin S, Adachi K, Chonan T, Tanaka A, Sato T, 2010 J. Solid State Chem. 183 2456

Google Scholar

Google Scholar

[31] Dostal A, Kauschka G, Reddy S J, Scholz F 1996 J. Electroanal. Chem. 406 155

Google Scholar

Google Scholar

[32] Gerand B, Novogorocki G, Guenot J, Figlarz M, 1979 J. Solid State Chem. 29 429

Google Scholar

Google Scholar

[33] Migas D B, Shaposhnikov V L, Rodin V N, Borisenko V E 2010 J. Appl. Phys. 108 093713

Google Scholar

Google Scholar

[34] 徐金荣, 王影, 朱兴凤, 李平, 张莉 2012 61 207103

Google Scholar

Google Scholar

Xu J R, Wang Y, Zhu X F, Li P, Zhang L 2012 Acta Phys. Sin. 61 207103

Google Scholar

Google Scholar

[35] 周诗文, 彭平, 陈文钦, 庾名槐, 郭惠, 袁珍 2019 68 037101

Google Scholar

Google Scholar

Zhou S W, Peng P, Chen W Q, Yu M, H, Guo H, Yuan Z 2019 Acta Phys. Sin. 68 037101

Google Scholar

Google Scholar

[36] Granqvist C G 2012 Sol. Energy Mater. Sol. Cells 99 1

Google Scholar

Google Scholar

[37] Kamal H, Akl A A, Abdel-Hady K 2004 Physica B 349 192

Google Scholar

Google Scholar

[38] 沈学础 1992 半导体光学性质 (北京: 科学出版社) 第 24 页

Shen X C 1992 Optical Property of Semiconductor (Beijing: Science Press) p24 (in Chinese)

[39] 褚君浩 2005 窄禁带半导体物理学 (北京: 科学出版社) 第 165 页

Chu J H 2005 Physics of Narrow Gap Semiconductors (Beijing: Science Press) (in Chinese)

[40] Guo C S, Yin S, Huang L J, Yang L, Sato T 2011 Chem. Commun. 47 8853

Google Scholar

Google Scholar

计量

- 文章访问数: 12368

- PDF下载量: 179

- 被引次数: 0

下载:

下载: