-

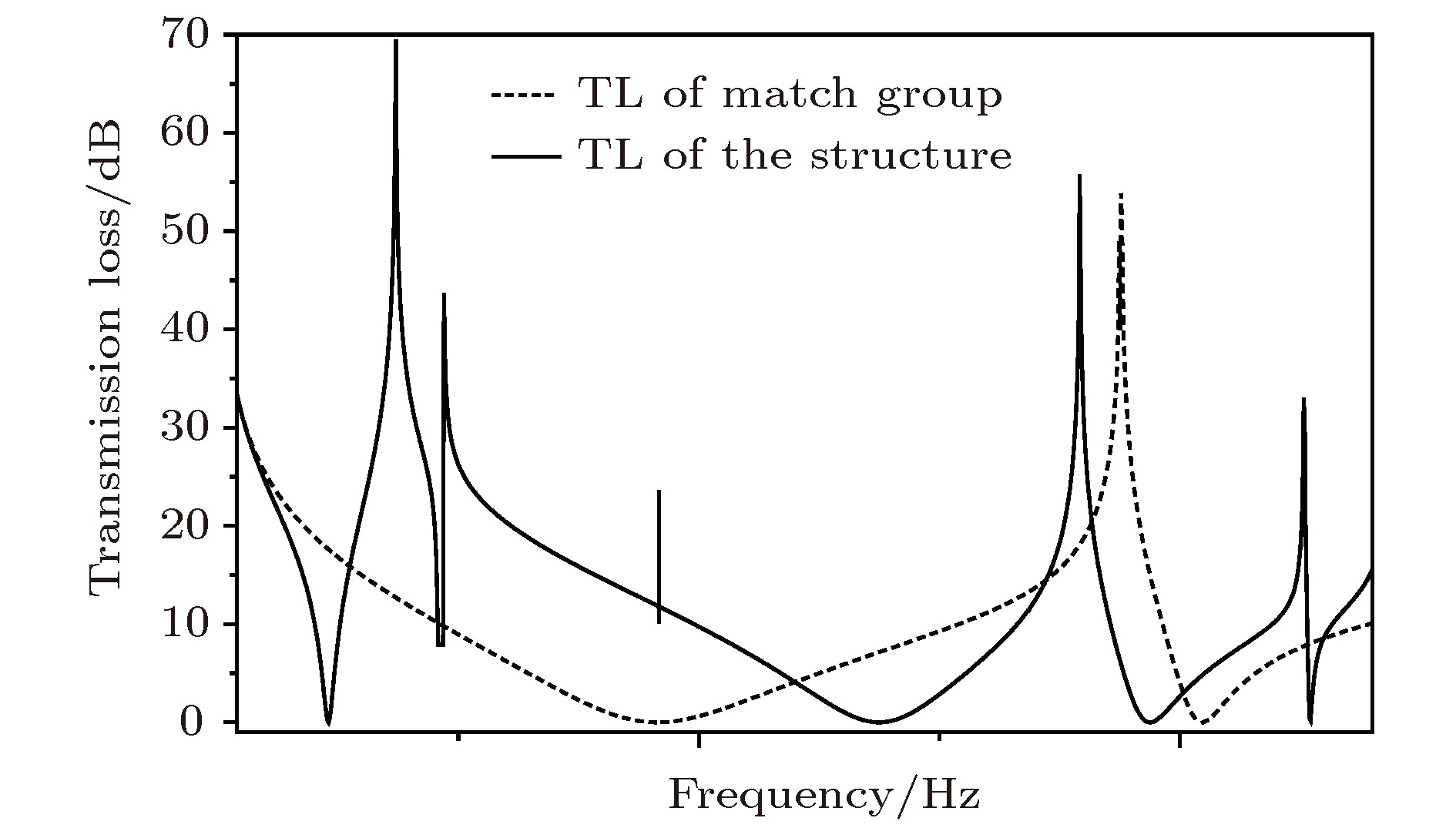

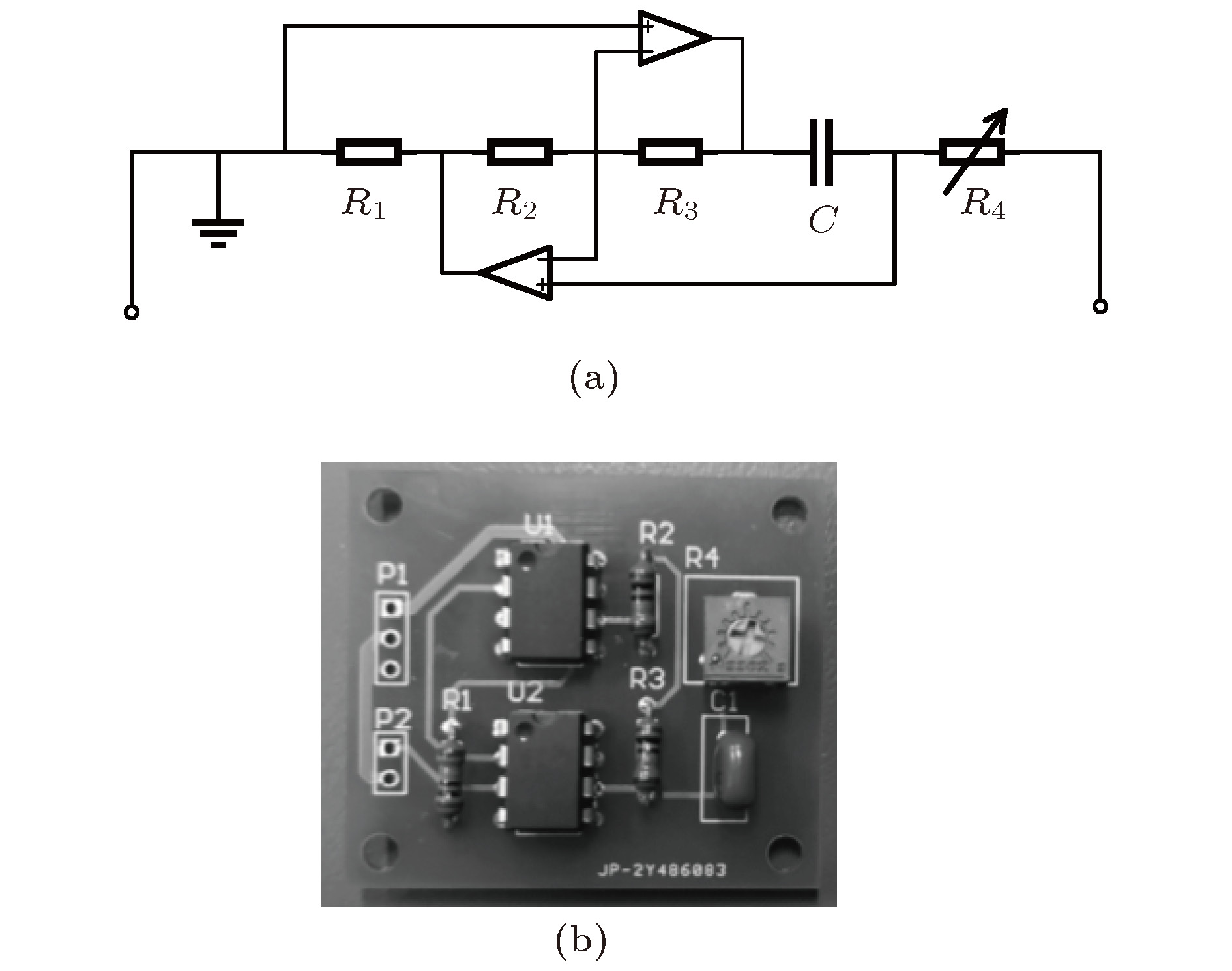

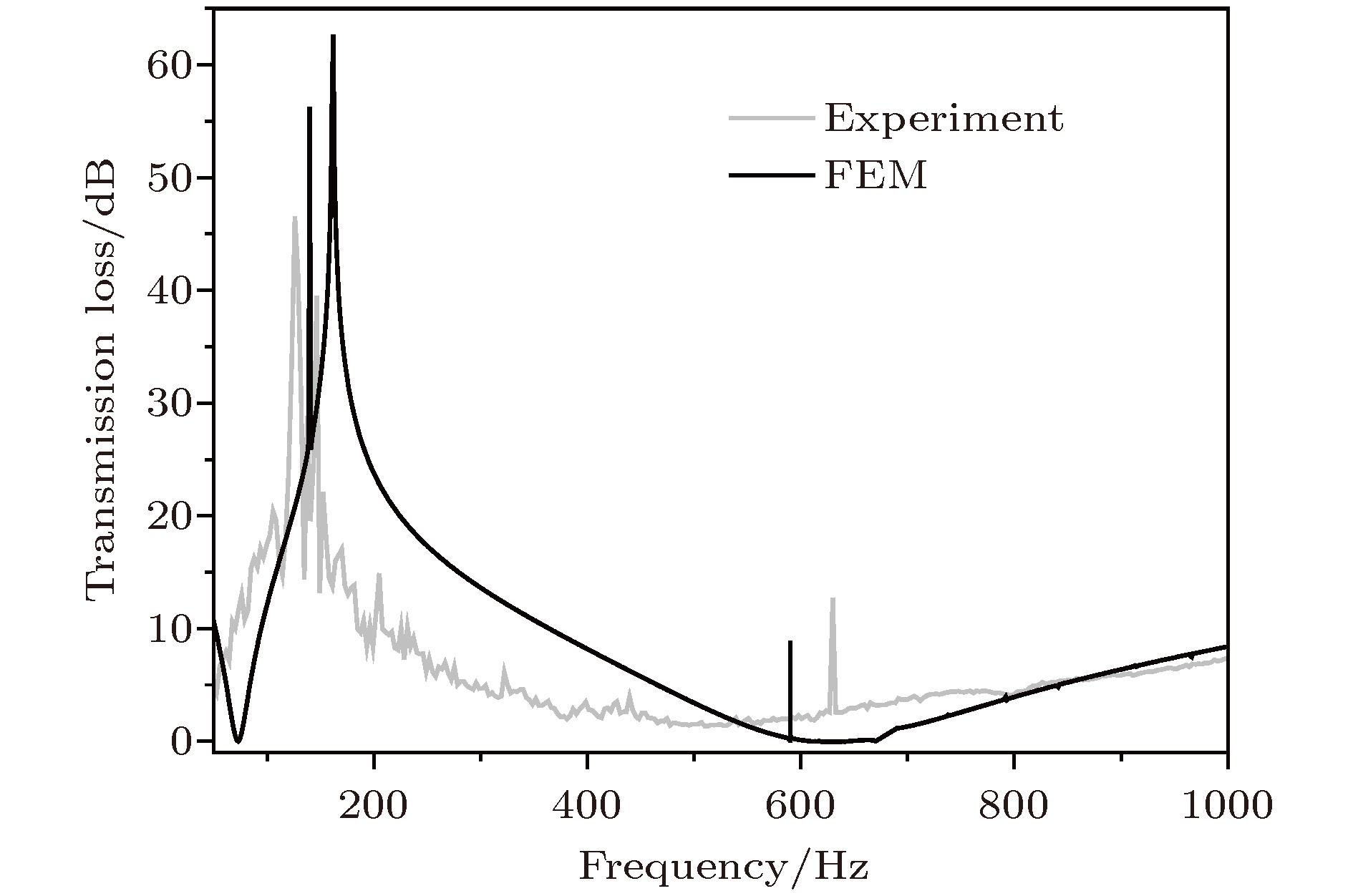

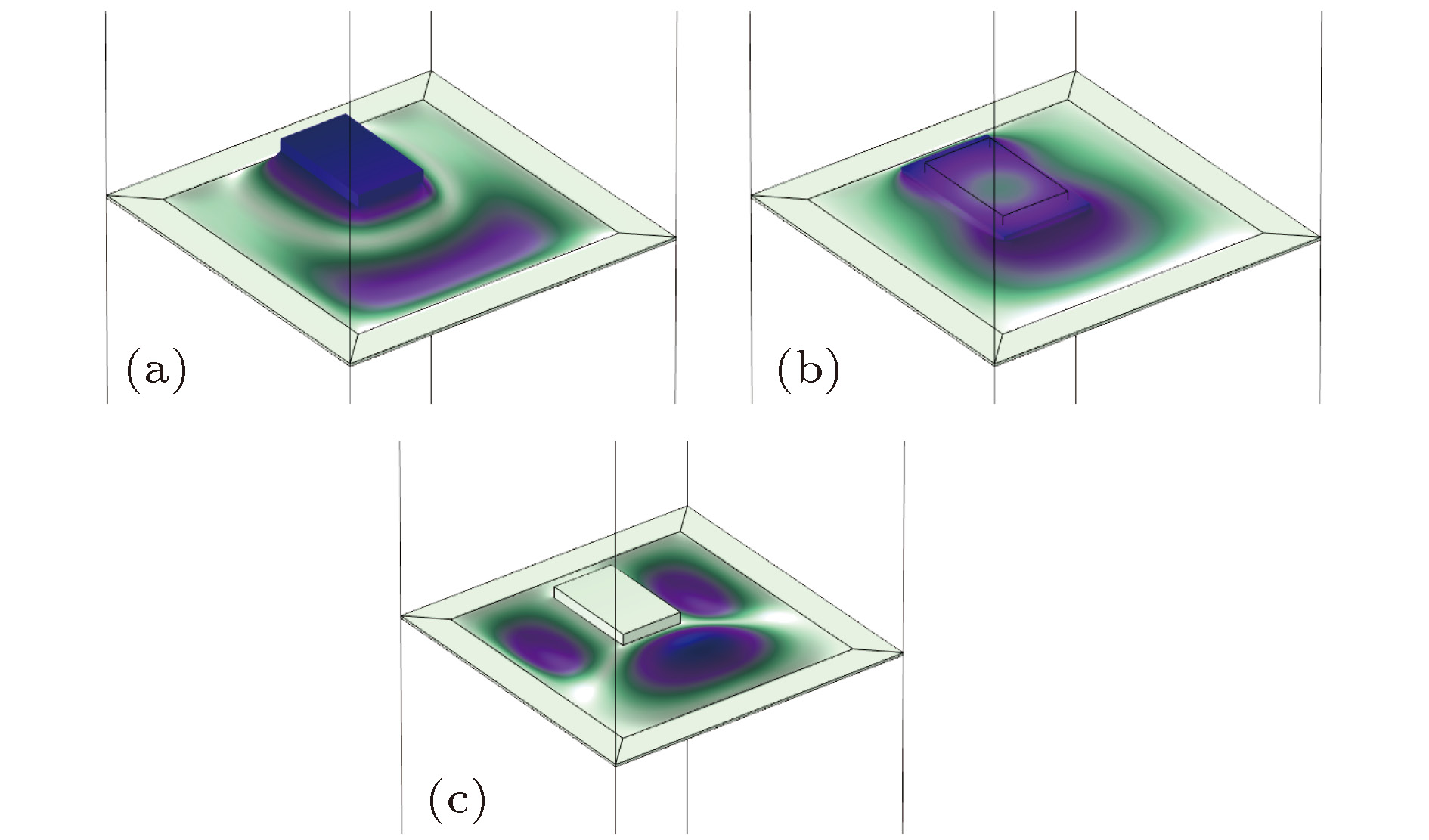

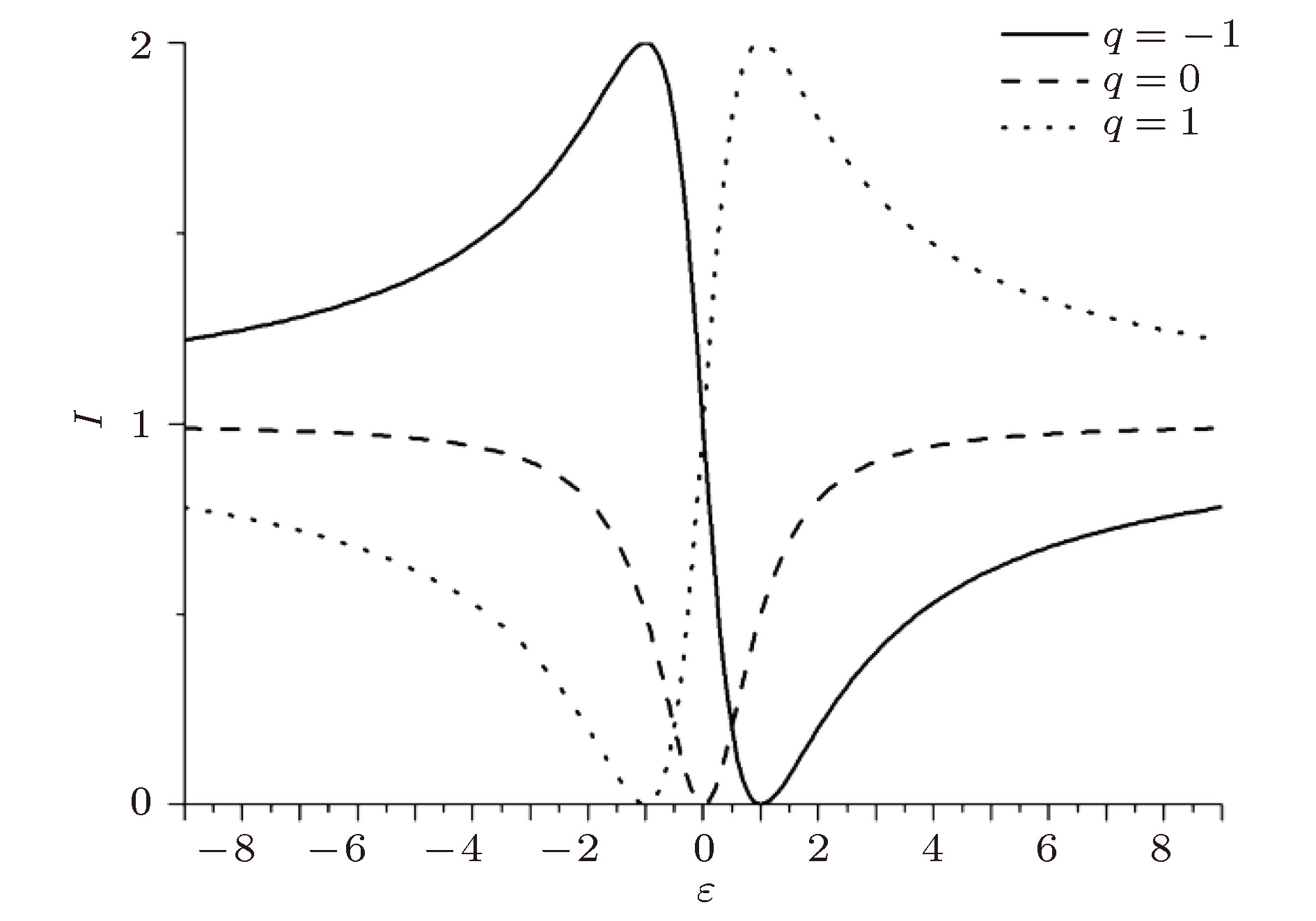

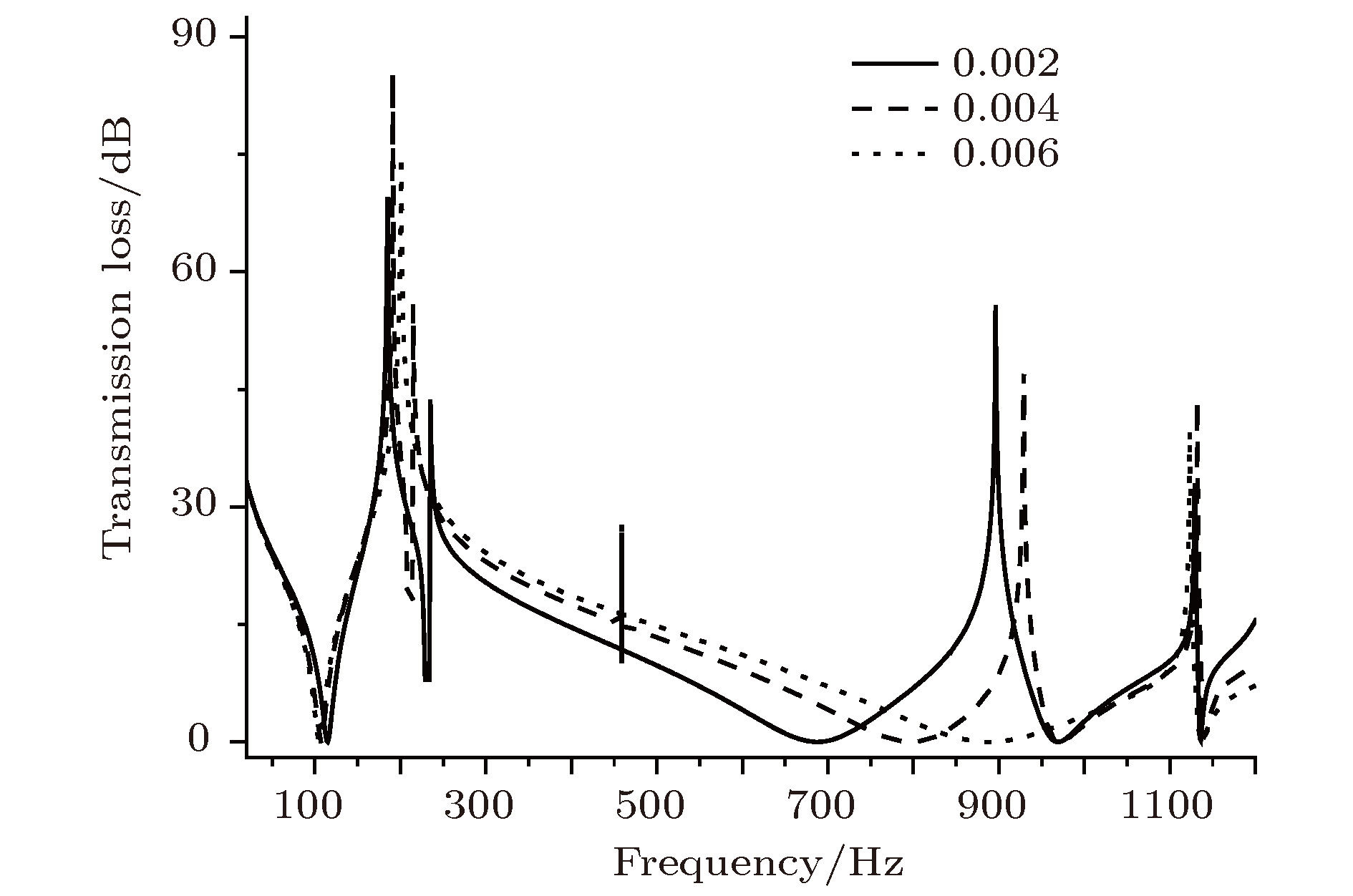

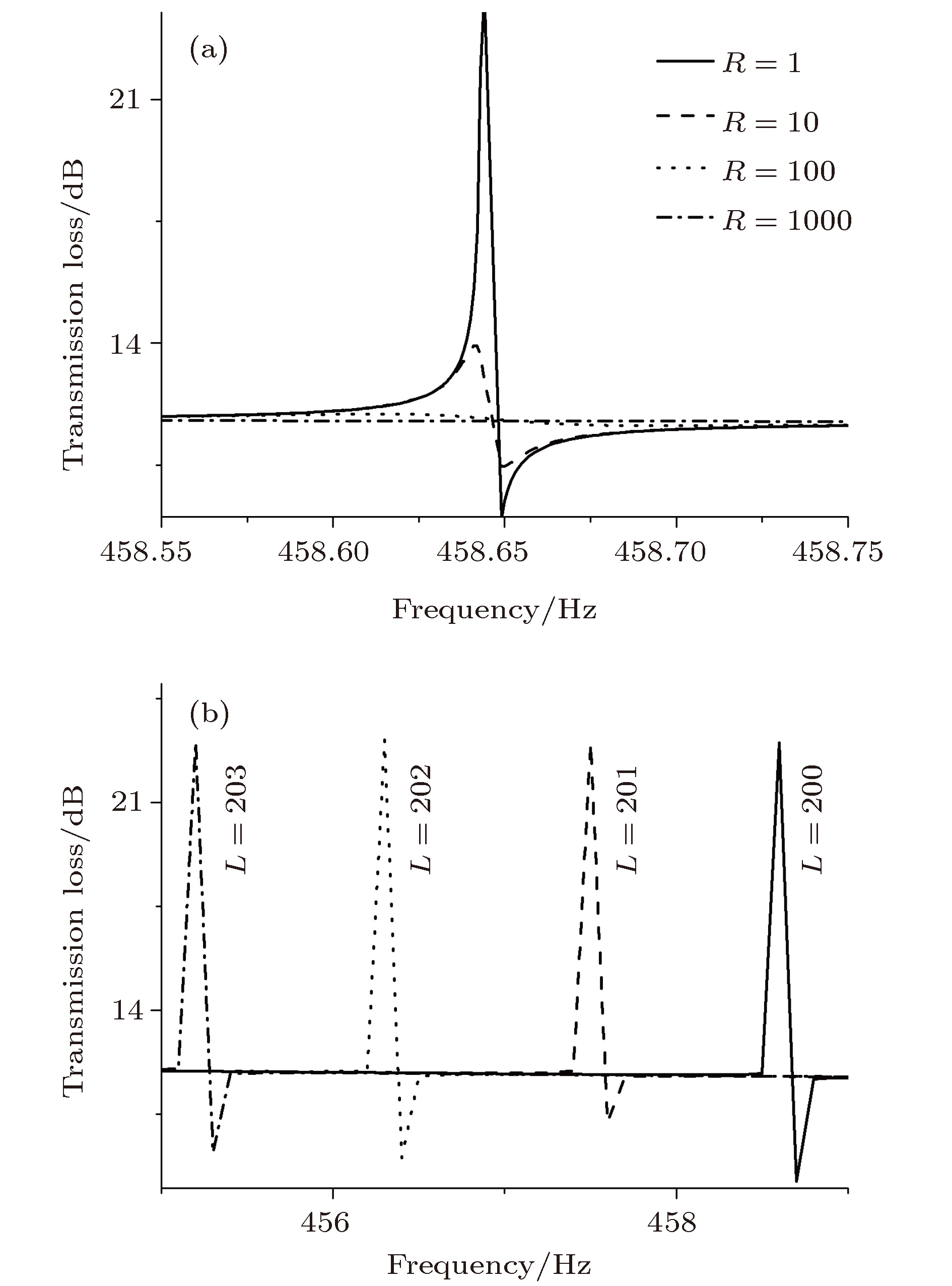

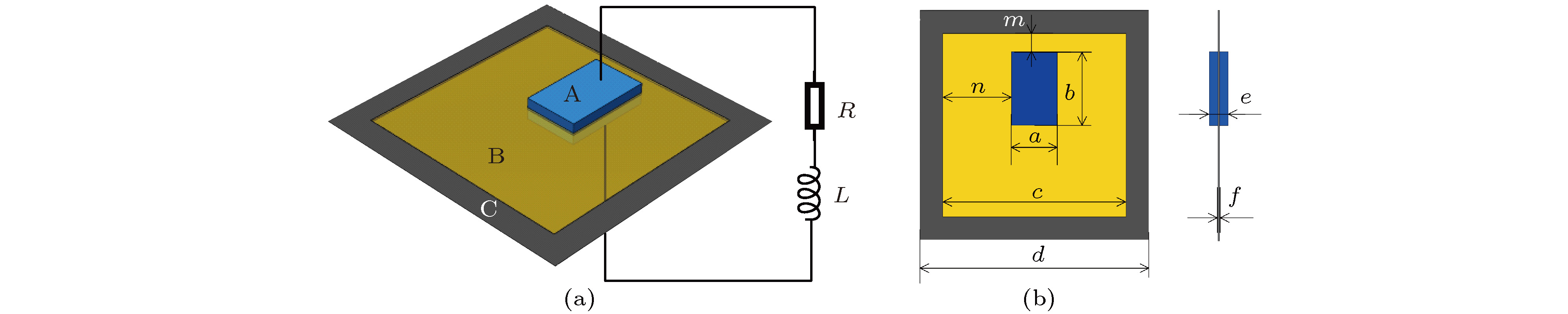

针对低频噪声的隔离问题, 设计了一种基于压电材料的可调控薄膜声学超材料, 该材料由压电质量块嵌入弹性薄膜制成. 建立了材料的有限元分析模型, 并且计算了材料的各阶特征频率与20—1200 Hz频段的传输损失曲线, 并通过实验验证了有限元计算的真实性. 计算结果表明: 此声学超材料在20—1200 Hz频段内隔声性能良好, 存在两个50 dB以上的隔声峰与一个可调式的隔声峰. 通过分析简单结构的首阶共振模态并构建其等效模型, 从理论上探究了结构参数对薄膜声学超材料隔声性能的影响, 并通过有限元计算验证了其等效模型的正确性; 综合分析材料的特征频率与传输损失曲线, 进一步讨论了结构的隔声机理, 分析结果表明, 在特征频率处, 薄膜的“拍动”会导致声波在其后的传播过程中干涉相消, 实现声波的衰减; 通过Fano共振理论, 探究了各共振点处传输损失曲线特征不同的原因; 压电质量块与外接电路组成LC振荡电路, 在电路的共振频率处, 压电材料的振动可以吸收声波的能量从而造成一个隔声峰, 同时可以改变外接电路的参数来调整电路的共振频率, 从而实现对隔声性能的调控. 最后, 探究了压电质量块偏心量对材料性能的影响, 并通过有限元计算验证了材料隔声性能的可调性. 研究结果为可调式薄膜声学超材料的设计提供了理论参考.Aiming at the isolation of low-frequency sound, a kind of thin-film acoustic metamaterialis designed and obtained by implanting PZT into thin film. The finite element method (FEM) of the structure is built, and 1st–14th order eigenfrequencies and transmission loss between 20–1200 Hz are calculated. The reliability of finite element calculation is verified experimentally and the existence of adjustable sound insulation peak is monitored in the experiment. The results show that the acoustic metamaterial has good sound insulation performance in a frequency range between 20 and 1200 Hz, and has two sound insulation peaks of more than 50 dB, and there is a sound insulation peak which can be changed by adjusting the parameters of the outer circuit. By analyzing the first resonance mode of simple structure and building its equivalent model, the effect of structural parameter on the sound insulation performance of thin film acoustic metamaterial is investigated theoretically, and the rationality of the equivalent model is verified by the finite element calculation. The sound insulation mechanism of the structure is further illustrated by taking into consideration the eigenfrequencies, transmission loss curve and vibration mode diagrams at various frequencies. It is found that at the resonance frequency, the flapping motion of the film will cause the sound wave in the subsequent propagation to cancell the interference, therefore realizing the attenuation of the sound wave. Based on Fano resonance theory, the reasons for the different characteristics of transmission loss curves at different resonance points are investigated. The PZT and outer circuit can form a LC oscillator. At the resonant frequency of the oscillator, the vibration of the piezoelectric material can absorb the energy of sound wave to cause a sound insolation peak. The resonant frequency of the circuit can be adjusted by changing the parameters of the outer circuit, thereby realizing the adjustability of the sound insulation performance. The influence of eccentricity of piezoelectric mass block on sound insulation performance of material is explored, proving that the sound insulation performance can be further optimized by improving structure. And through the finite element calculation, it is proved that the sound insulation performance of material is adjustable by changing the parameters of the outer circuit. The results provide a theoretical reference for designing the thin film acoustic metamaterials.

[1] 邓吉宏, 王柯, 陈国平 2008 航空学报 29 1581

Google Scholar

Google Scholar

Deng J H, Wang K, Chen G P 2008 Acta Aeronaut. Astronaut. Sin. 29 1581

Google Scholar

Google Scholar

[2] Bolton J S, Shiau N M, Kang Y 1996 JSV 191 317

Google Scholar

Google Scholar

[3] Liu Z, Zhang X X, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[4] 张思文, 吴九汇 2013 62 134302

Google Scholar

Google Scholar

Zhang S W, Wu J H 2013 Acta Phys. Sin. 62 134302

Google Scholar

Google Scholar

[5] 张帅, 郭书祥, 姚宏, 赵静波, 蒋娟娜, 贺子厚 2018 压电与声光 40 754

Google Scholar

Google Scholar

Zhang S, Guo S X, Yao H, Zhao J B, Jiang J N, He Z H 2018 Piezoelectr. Acoustoopt. 40 754

Google Scholar

Google Scholar

[6] 赵甜甜, 林书玉, 段祎林 2018 67 224207

Google Scholar

Google Scholar

Zhao T T, Lin S Y, Duan W L 2018 Acta Phys. Sin. 67 224207

Google Scholar

Google Scholar

[7] 王莎, 林书玉 2019 68 024303

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 024303

[8] 张振方, 郁殿龙, 刘江伟, 温激鸿 2018 67 074301

Google Scholar

Google Scholar

Zhang Z F, Yu D L, Liu J W, Wen J H 2018 Acta Phys. Sin. 67 074301

Google Scholar

Google Scholar

[9] 杜春阳, 郁殿龙, 刘江伟, 温激鸿 2017 66 140701

Google Scholar

Google Scholar

Du C Y, Yu D L, Liu J W, Wen J H 2017 Acta Phys. Sin. 66 140701

Google Scholar

Google Scholar

[10] Mei J, Yang M, Yang Z Y, Chan N H, Shen P 2018 Phys. Rev. Lett. 101 204301

[11] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Shen P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[12] 梅军, 马冠聪, 杨旻 2012 物理 41 425

Google Scholar

Google Scholar

Mei J, Ma G C, Yang M 2012 Physics 41 425

Google Scholar

Google Scholar

[13] Chen Y, Huang G, Zhou X, Hu G, Sun C 2014 J. Acoust. Soc. Am. 136 969

Google Scholar

Google Scholar

[14] Langfeldt F, Gleine W, von Estorff O 2015 JSV 349 315

Google Scholar

Google Scholar

[15] 张佳龙, 姚宏, 杜军, 赵静波, 董亚科, 祁鹏山 2016 人工晶体学报 45 2549

Google Scholar

Google Scholar

Zhang J L, Yao H, Du J, Zhao J B, Dong Y K, Qi P S 2016 J. Synth. Cryst. 45 2549

Google Scholar

Google Scholar

[16] 叶超, 苏继龙 2017 噪声与振动控制 37 163

Google Scholar

Google Scholar

Ye C, Su J L 2017 Noise Vibr. Control 37 163

Google Scholar

Google Scholar

[17] 周榕, 吴卫国, 闻轶凡 2017 声学技术 36 297

Zhou Y, Wu W G, Wen Y F 2017 Tech. Acoust. 36 297

[18] 邢拓, 李贤徽, 盖晓玲, 张斌, 谢鹏 2016 声学技术 35 2

Xing T, Li X H, Gai X L, Zhang B, Xie P 2016 Tech. Acoust. 35 2

[19] Zhang Y, Wen J 2012 JASA 131 3372

[20] Preumont A 2011 Vibration Control of Active Structures (Berlin: Springer) pp21–59

[21] Chen S B, Wen J H, Yu D L, Wang G, Wen X 2011 Chin. Phys. B 20 014301

Google Scholar

Google Scholar

[22] Zhang H, Wen J, Xiao Y, Wang G, Wen X 2015 JSV 343 104

Google Scholar

Google Scholar

[23] 董亚科, 姚宏, 杜军, 赵静波, 姜久龙 2018 压电与声光 40 860

Google Scholar

Google Scholar

Dong Y K, Yao H, Du J, Zhao J B, Jiang J L 2018 Piezoelectr. Acoustoopt. 40 860

Google Scholar

Google Scholar

[24] 廖涛, 孙小伟, 宋婷, 田俊红, 康太凤, 孙伟彬 2018 67 214208

Google Scholar

Google Scholar

Liao T, Sun X W, Song T, Tian J H, Kang T F, Sun W B 2018 Acta Phys. Sin. 67 214208

Google Scholar

Google Scholar

[25] 孙炜海, 张超群, 鞠桂玲, 潘晶雯 2018 67 194303

Google Scholar

Google Scholar

Sun W H, Zhang C Q, Jü G L, Pan J W 2018 Acta Phys. Sin. 67 194303

Google Scholar

Google Scholar

[26] Yubao S, Leping F, Jihong W, Dianlong Y, Xisen W 2015 Phys. Lett. A 379 1449

Google Scholar

Google Scholar

[27] 陈圣兵 2014 博士学位论文(长沙: 国防科技大学)

Chen S B 2014 Ph. D. Dissertation (Changsha: National University of Defense Technology)(in Chinese)

[28] 汪承灏, 赵哲英 1981 声学学报 4 263

Wang C H, Zhao Z Y 1981 Acta Acust. 4 263

[29] 贺子厚, 赵静波, 姚宏, 蒋娟娜, 张帅 2019 压电与声光 41 40

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Jiang J N, Zhang S 2019 Piezoelectr. Acoustoopt. 41 40

Google Scholar

Google Scholar

[30] Fano U 1961 Phys. Rev. 124 1866

Google Scholar

Google Scholar

[31] 潘庭婷, 曹文, 邓彩松, 王鸣, 夏巍, 郝辉 2018 67 157301

Google Scholar

Google Scholar

Pan T T, Cao W, Deng C S, Wang M, Xia W, Hao H 2018 Acta Phys. Sin. 67 157301

Google Scholar

Google Scholar

[32] Mikhail F, Mikhail V, Alexander N, Yuri S 2017 Nat. Photon. 11 543

Google Scholar

Google Scholar

-

表 1 压电材料参数

Table 1. Piezoelectric material parameters.

ρ/kg·m–3 $s_{11}^{\rm{E}}/{{\rm{m}}^3} \cdot {{\rm{N}}^{ - 1}}$ d31/C·m–2 $\varepsilon _{33}^{\rm{T}}/{\rm{F}} \cdot {{\rm{m}}^{ - 1}}$ 7500 1.65 × 10–11 –2.74 × 10–10 3.01 × 10–8 表 2 材料参数

Table 2. Material parameters.

Material ρ/kg·m–3 E/1010 Pa Possion rate Silastic 1300 1.175 × 10–5 0.469 Steel 7780 21.06 0.3 表 3 模态图

Table 3. Modal diagram.

阶数 频率/Hz 模态图 阶数 频率/Hz 模态图 1 111.77

8 689.74

2 135.84

9 793.01

3 147.67

10 835.10

4 185.63

11 842.97

5 201.65

12 945.92

6 231.21

13 981.43

7 458.62

14 1148.40

-

[1] 邓吉宏, 王柯, 陈国平 2008 航空学报 29 1581

Google Scholar

Google Scholar

Deng J H, Wang K, Chen G P 2008 Acta Aeronaut. Astronaut. Sin. 29 1581

Google Scholar

Google Scholar

[2] Bolton J S, Shiau N M, Kang Y 1996 JSV 191 317

Google Scholar

Google Scholar

[3] Liu Z, Zhang X X, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[4] 张思文, 吴九汇 2013 62 134302

Google Scholar

Google Scholar

Zhang S W, Wu J H 2013 Acta Phys. Sin. 62 134302

Google Scholar

Google Scholar

[5] 张帅, 郭书祥, 姚宏, 赵静波, 蒋娟娜, 贺子厚 2018 压电与声光 40 754

Google Scholar

Google Scholar

Zhang S, Guo S X, Yao H, Zhao J B, Jiang J N, He Z H 2018 Piezoelectr. Acoustoopt. 40 754

Google Scholar

Google Scholar

[6] 赵甜甜, 林书玉, 段祎林 2018 67 224207

Google Scholar

Google Scholar

Zhao T T, Lin S Y, Duan W L 2018 Acta Phys. Sin. 67 224207

Google Scholar

Google Scholar

[7] 王莎, 林书玉 2019 68 024303

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 024303

[8] 张振方, 郁殿龙, 刘江伟, 温激鸿 2018 67 074301

Google Scholar

Google Scholar

Zhang Z F, Yu D L, Liu J W, Wen J H 2018 Acta Phys. Sin. 67 074301

Google Scholar

Google Scholar

[9] 杜春阳, 郁殿龙, 刘江伟, 温激鸿 2017 66 140701

Google Scholar

Google Scholar

Du C Y, Yu D L, Liu J W, Wen J H 2017 Acta Phys. Sin. 66 140701

Google Scholar

Google Scholar

[10] Mei J, Yang M, Yang Z Y, Chan N H, Shen P 2018 Phys. Rev. Lett. 101 204301

[11] Mei J, Ma G C, Yang M, Yang Z Y, Wen W J, Shen P 2012 Nat. Commun. 3 756

Google Scholar

Google Scholar

[12] 梅军, 马冠聪, 杨旻 2012 物理 41 425

Google Scholar

Google Scholar

Mei J, Ma G C, Yang M 2012 Physics 41 425

Google Scholar

Google Scholar

[13] Chen Y, Huang G, Zhou X, Hu G, Sun C 2014 J. Acoust. Soc. Am. 136 969

Google Scholar

Google Scholar

[14] Langfeldt F, Gleine W, von Estorff O 2015 JSV 349 315

Google Scholar

Google Scholar

[15] 张佳龙, 姚宏, 杜军, 赵静波, 董亚科, 祁鹏山 2016 人工晶体学报 45 2549

Google Scholar

Google Scholar

Zhang J L, Yao H, Du J, Zhao J B, Dong Y K, Qi P S 2016 J. Synth. Cryst. 45 2549

Google Scholar

Google Scholar

[16] 叶超, 苏继龙 2017 噪声与振动控制 37 163

Google Scholar

Google Scholar

Ye C, Su J L 2017 Noise Vibr. Control 37 163

Google Scholar

Google Scholar

[17] 周榕, 吴卫国, 闻轶凡 2017 声学技术 36 297

Zhou Y, Wu W G, Wen Y F 2017 Tech. Acoust. 36 297

[18] 邢拓, 李贤徽, 盖晓玲, 张斌, 谢鹏 2016 声学技术 35 2

Xing T, Li X H, Gai X L, Zhang B, Xie P 2016 Tech. Acoust. 35 2

[19] Zhang Y, Wen J 2012 JASA 131 3372

[20] Preumont A 2011 Vibration Control of Active Structures (Berlin: Springer) pp21–59

[21] Chen S B, Wen J H, Yu D L, Wang G, Wen X 2011 Chin. Phys. B 20 014301

Google Scholar

Google Scholar

[22] Zhang H, Wen J, Xiao Y, Wang G, Wen X 2015 JSV 343 104

Google Scholar

Google Scholar

[23] 董亚科, 姚宏, 杜军, 赵静波, 姜久龙 2018 压电与声光 40 860

Google Scholar

Google Scholar

Dong Y K, Yao H, Du J, Zhao J B, Jiang J L 2018 Piezoelectr. Acoustoopt. 40 860

Google Scholar

Google Scholar

[24] 廖涛, 孙小伟, 宋婷, 田俊红, 康太凤, 孙伟彬 2018 67 214208

Google Scholar

Google Scholar

Liao T, Sun X W, Song T, Tian J H, Kang T F, Sun W B 2018 Acta Phys. Sin. 67 214208

Google Scholar

Google Scholar

[25] 孙炜海, 张超群, 鞠桂玲, 潘晶雯 2018 67 194303

Google Scholar

Google Scholar

Sun W H, Zhang C Q, Jü G L, Pan J W 2018 Acta Phys. Sin. 67 194303

Google Scholar

Google Scholar

[26] Yubao S, Leping F, Jihong W, Dianlong Y, Xisen W 2015 Phys. Lett. A 379 1449

Google Scholar

Google Scholar

[27] 陈圣兵 2014 博士学位论文(长沙: 国防科技大学)

Chen S B 2014 Ph. D. Dissertation (Changsha: National University of Defense Technology)(in Chinese)

[28] 汪承灏, 赵哲英 1981 声学学报 4 263

Wang C H, Zhao Z Y 1981 Acta Acust. 4 263

[29] 贺子厚, 赵静波, 姚宏, 蒋娟娜, 张帅 2019 压电与声光 41 40

Google Scholar

Google Scholar

He Z H, Zhao J B, Yao H, Jiang J N, Zhang S 2019 Piezoelectr. Acoustoopt. 41 40

Google Scholar

Google Scholar

[30] Fano U 1961 Phys. Rev. 124 1866

Google Scholar

Google Scholar

[31] 潘庭婷, 曹文, 邓彩松, 王鸣, 夏巍, 郝辉 2018 67 157301

Google Scholar

Google Scholar

Pan T T, Cao W, Deng C S, Wang M, Xia W, Hao H 2018 Acta Phys. Sin. 67 157301

Google Scholar

Google Scholar

[32] Mikhail F, Mikhail V, Alexander N, Yuri S 2017 Nat. Photon. 11 543

Google Scholar

Google Scholar

计量

- 文章访问数: 15399

- PDF下载量: 358

- 被引次数: 0

下载:

下载: