-

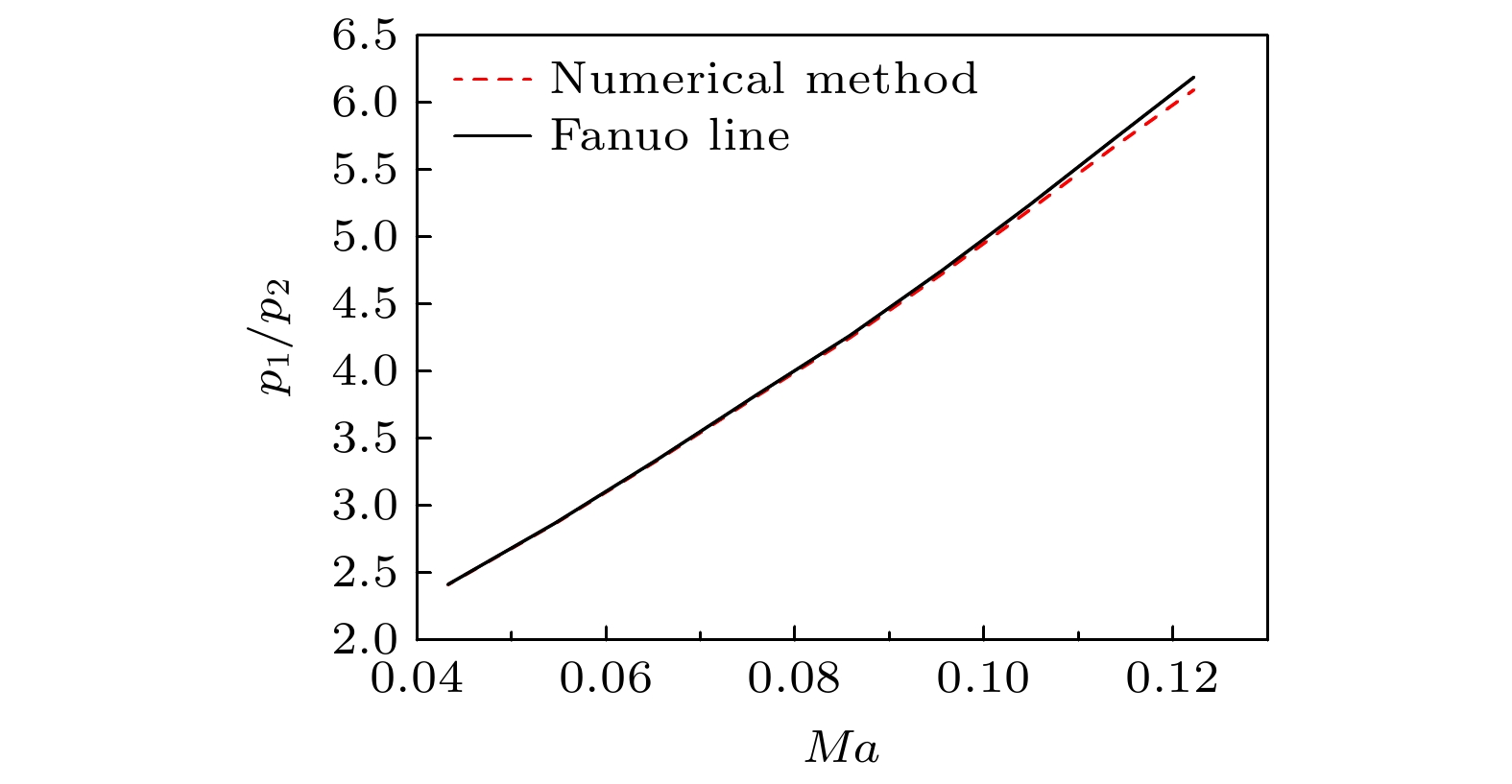

微通道传热传质相关基础问题在新材料、微电子、航空航天等工程领域具有重要的科研需求. 本文针对微圆管内质量运输特性预测问题开展了数值方法研究及实验测量验证. 采用一维近似处理方法简化可压缩流动方程组, 建立了适用于微圆管质量运输特性预测的数值计算方法, 结合范诺线方程及实验方法对数值计算方法的正确性和物理计算模型的有效性进行检验, 并详细分析预测误差来源. 结果表明, 依据范诺线参数比理论结果与数值计算结果证明了数值计算方法的正确性. 对比典型驱动压差条件下微圆管出口工况的计算与纹影结果, 证明了数值方法关于流动壅塞预测的合理性. 在质量流量预测方面, 全层流阶段质量流量预测误差在3%以内, 全湍流状态下的预测误差在8%以内, 而当微圆管内流动包含层流至湍流的过渡过程时, 预测误差则提高至29%, 这是由于给定的转捩雷诺数以及摩擦系数计算公式的误差引入而造成的.

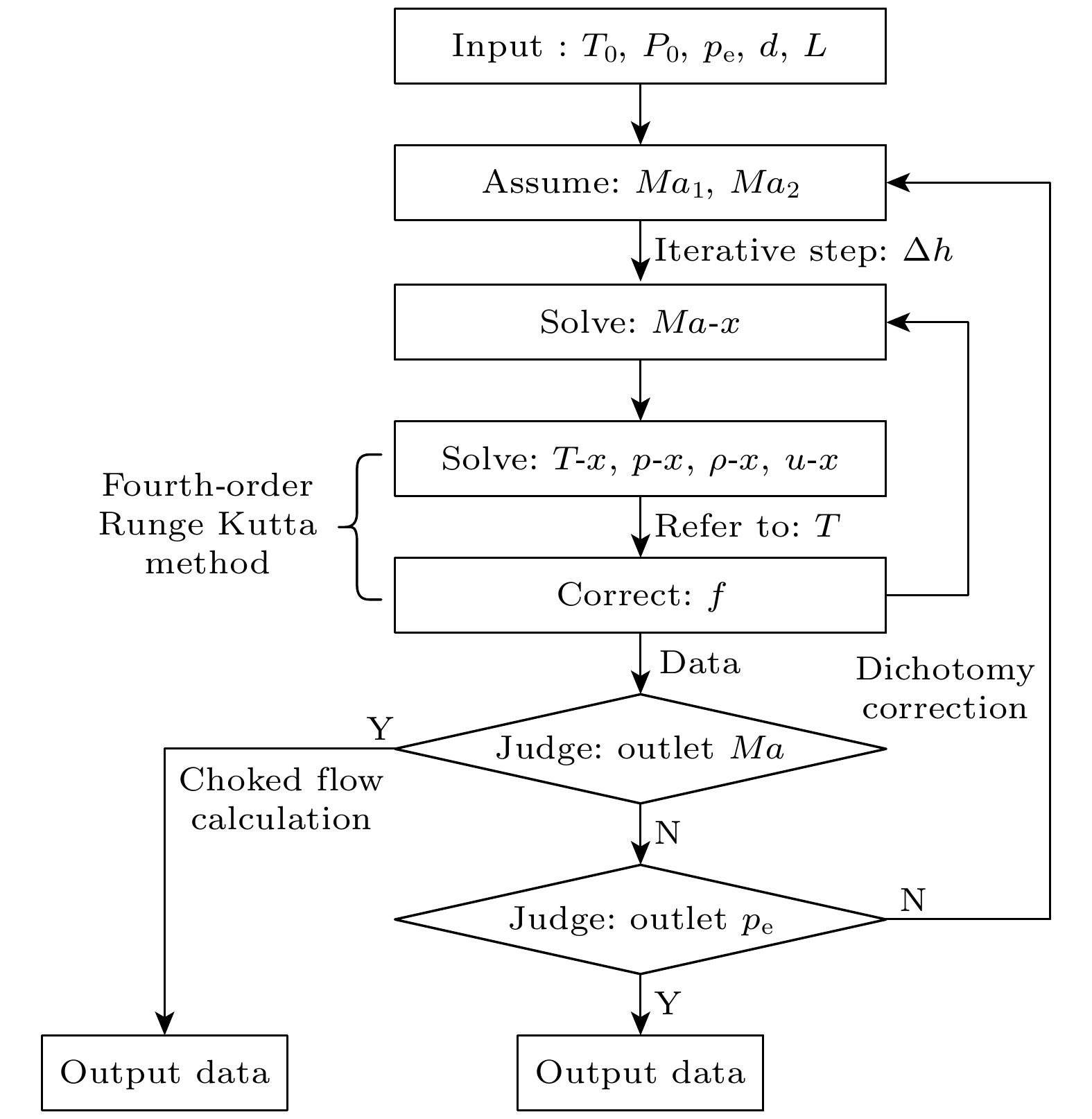

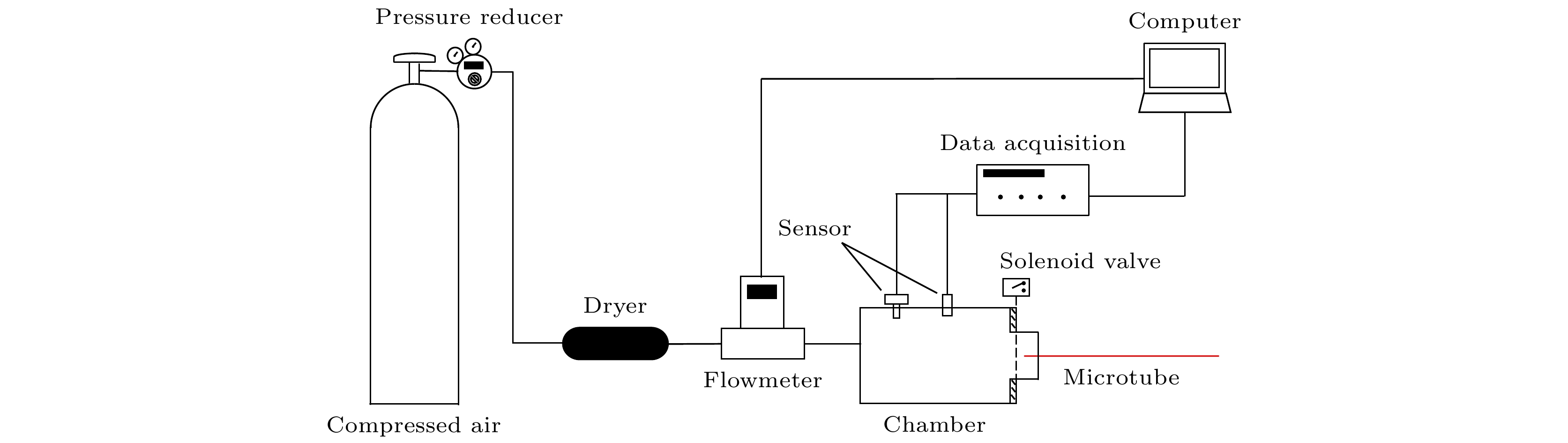

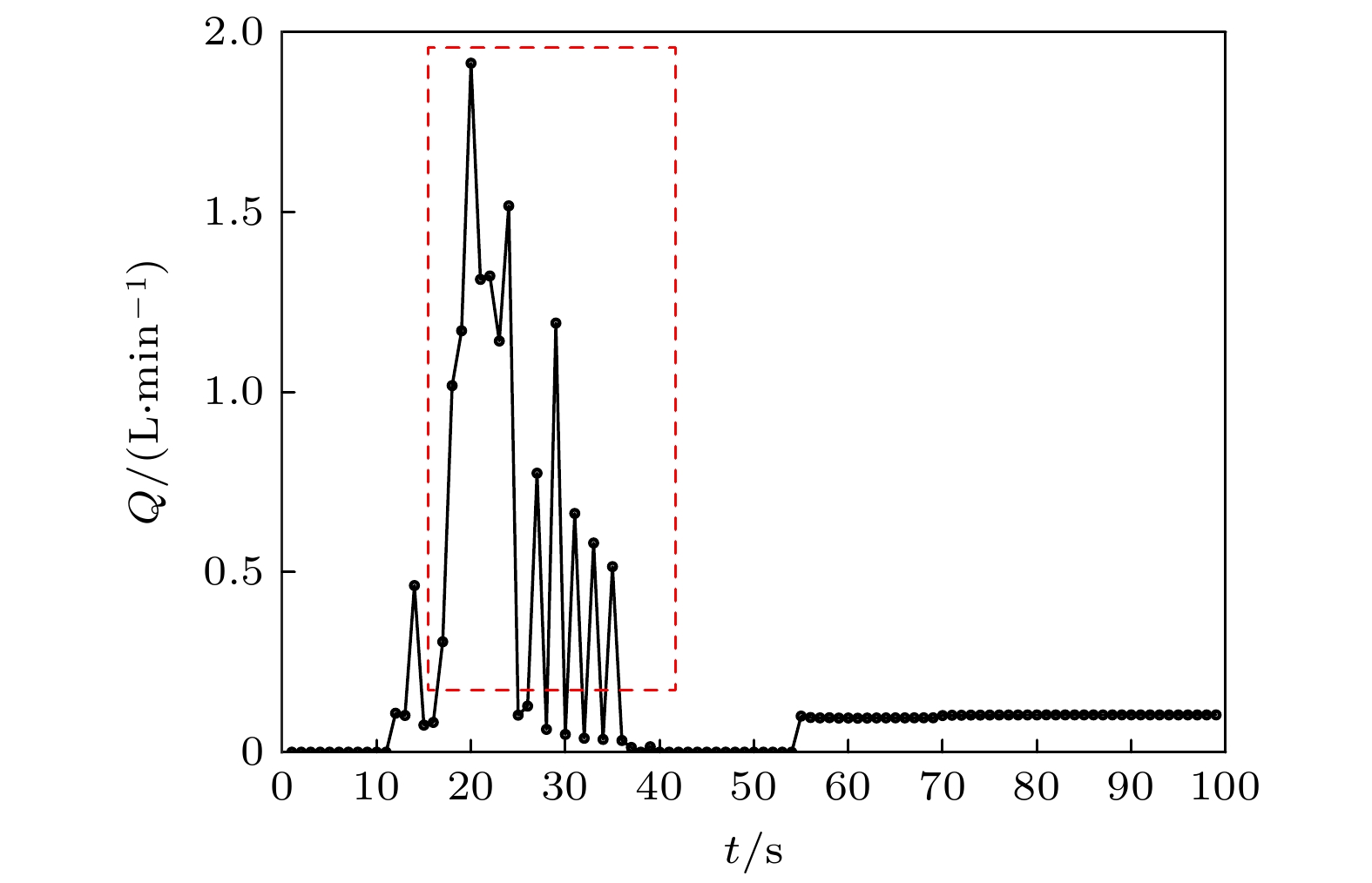

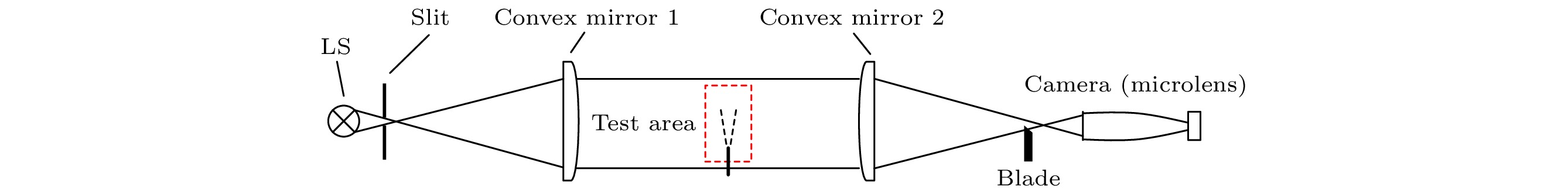

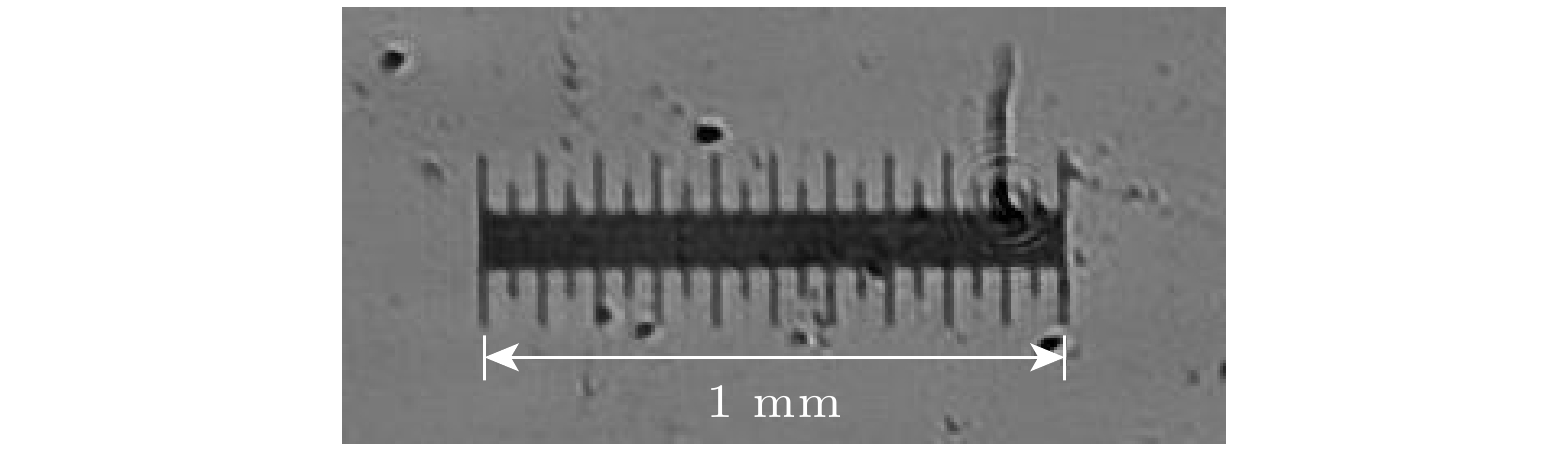

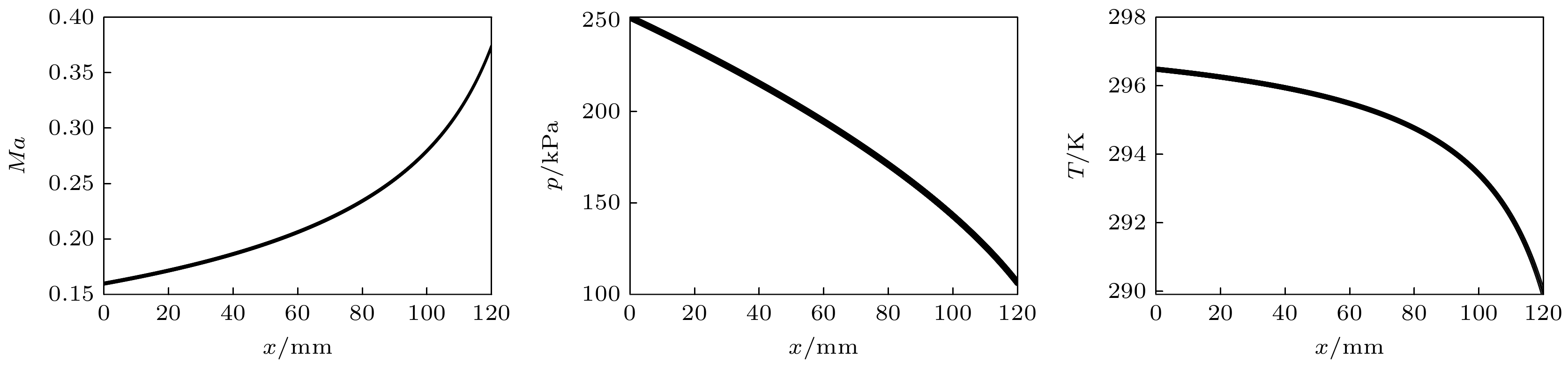

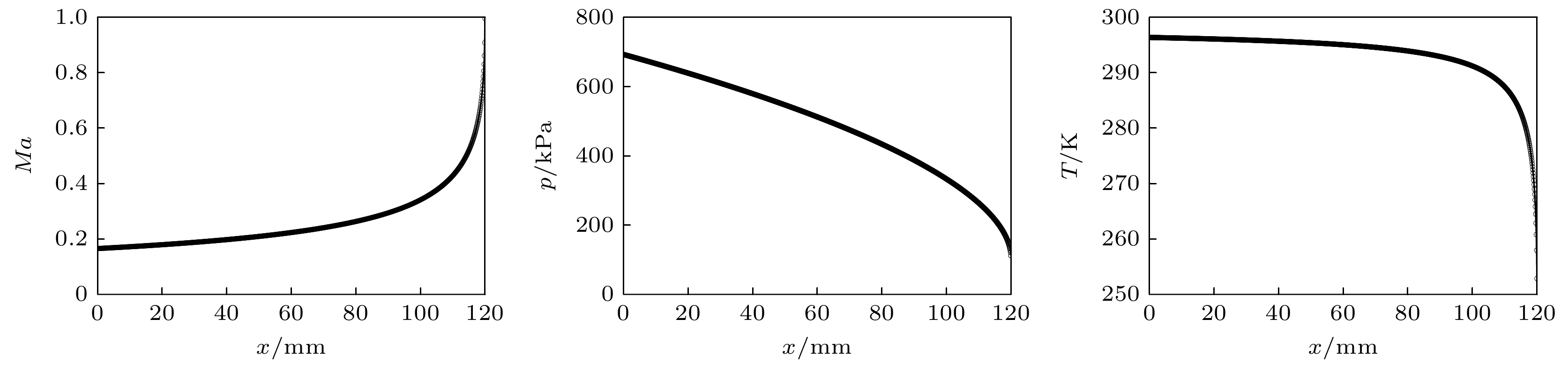

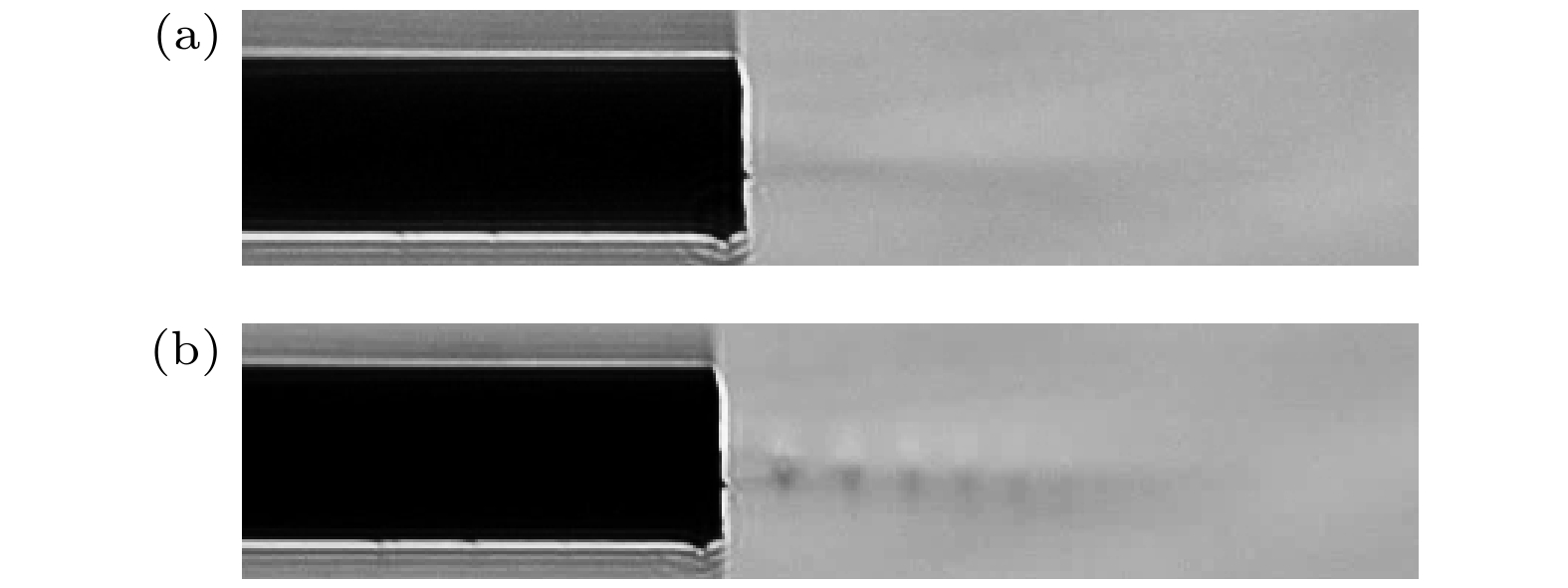

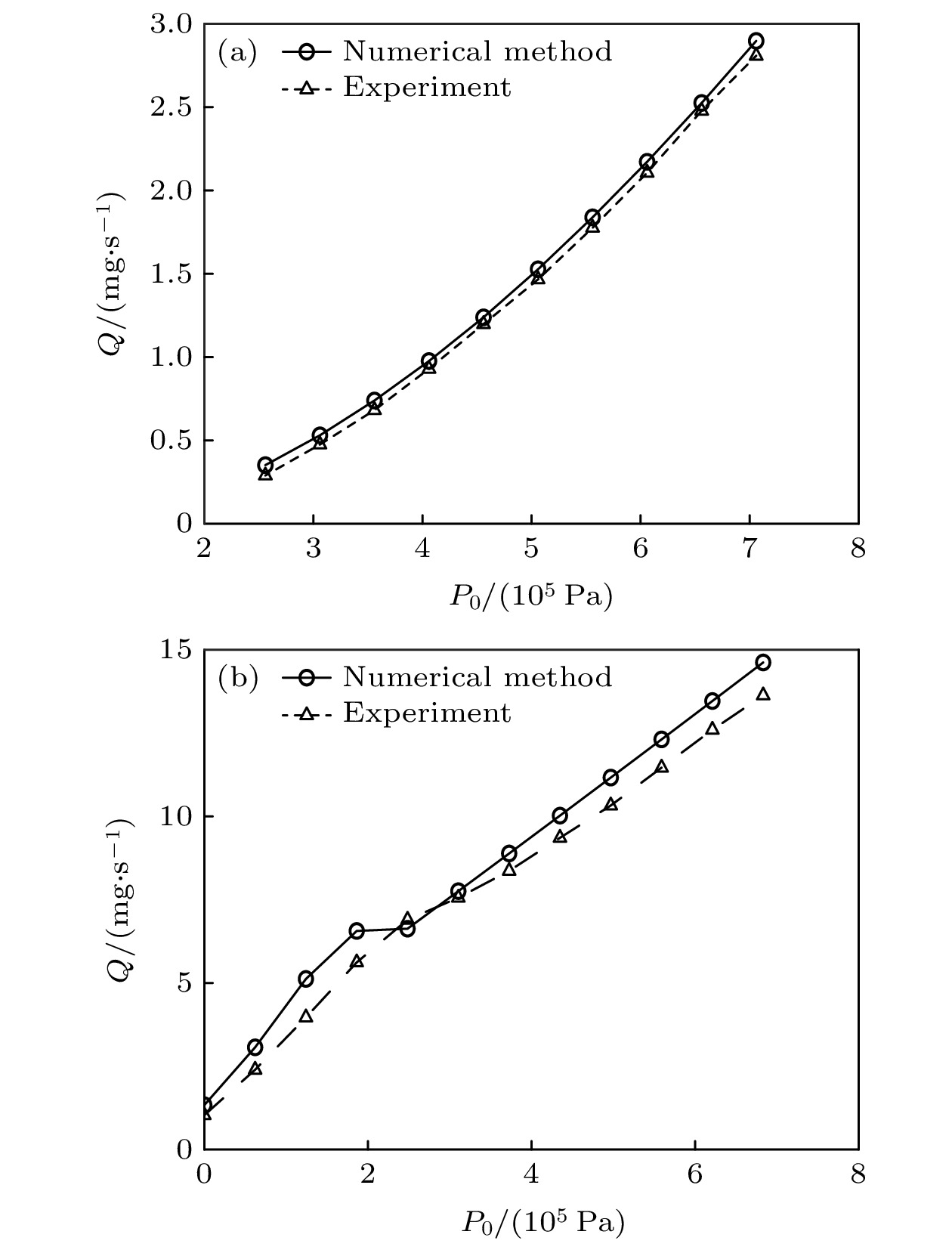

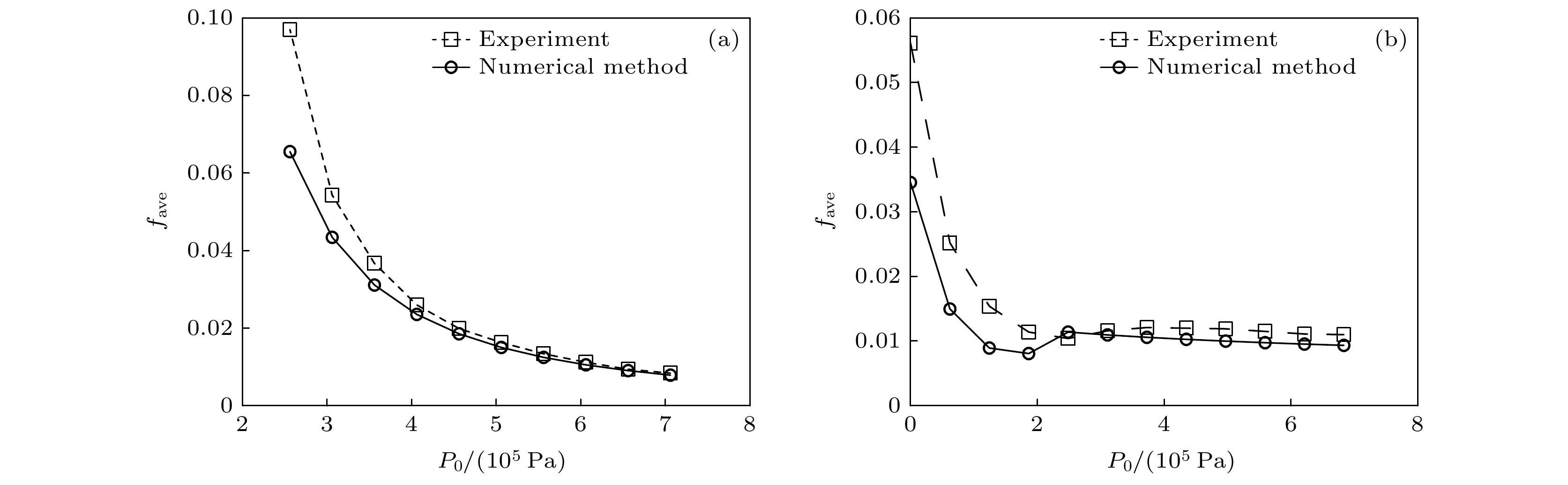

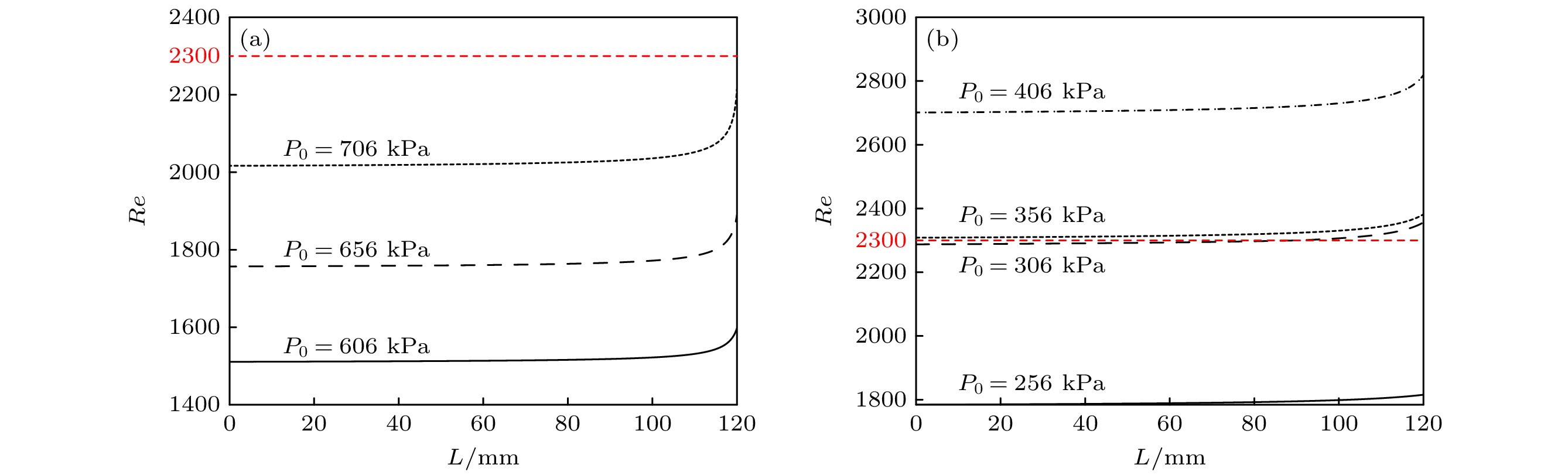

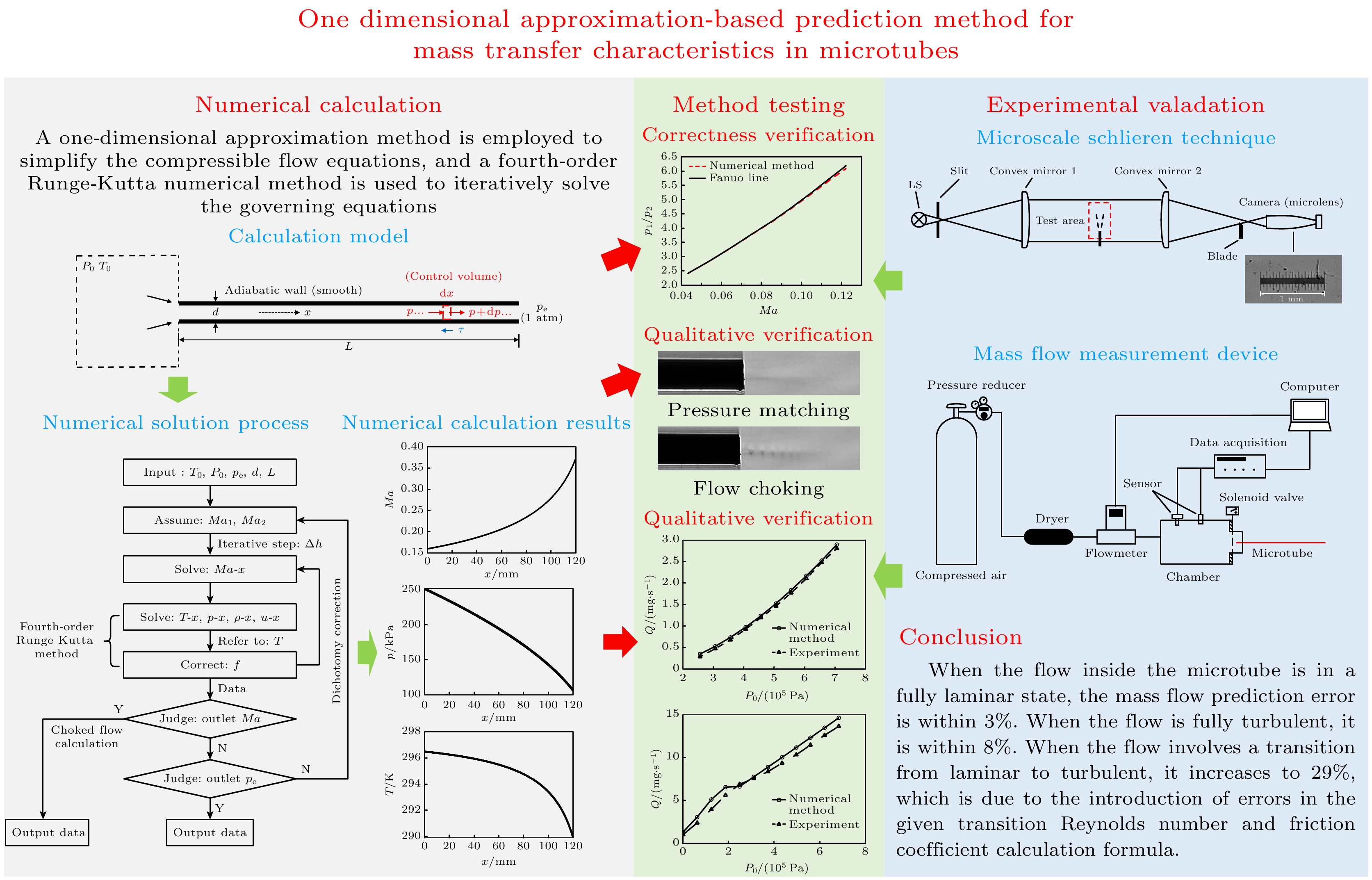

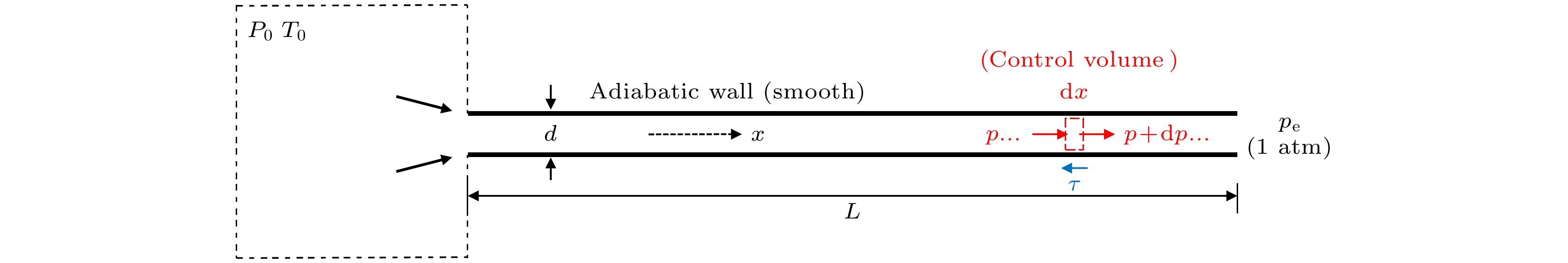

The fundamental issues related to heat and mass transfer in microchannels have significant research needs in various engineering fields, such as new materials, microelectronics, and aerospace. This paper addresses the problem of predicting mass transport characteristics within microtubes by developing numerical methods, conducting experimental measurements for validation, and analyzing prediction errors. A one-dimensional approximation method is employed to simplify the compressible flow equations, and a fourth-order Runge-Kutta numerical method is also used to iteratively solve the governing equations. A theoretical calculation method suitable for predicting mass transport characteristics in microtubes is established. This method can calculate various flow parameters along the length of the microtube and can handle different flow conditions, such as static pressure matching or flow choking at the outlet. Subsequently, by comparing the numerical calculation results with the theoretical results of the Fanuo line parameter ratio, the correctness of the numerical calculation method is verified. Also, Schlieren experiments and a self-designed mass flow measurement device are used to qualitatively and quantitatively verify the effectiveness of physical computing models. Under typical driving pressure differences, the qualitative agreement between the calculated and schlieren results for the outlet conditions of the microtube demonstrate the rationality of the numerical method in terms of static pressure matching and flow choking calculations. Regarding mass flow prediction, comparisons between theoretical calculations and experimental measurements under different driving pressures reveal that when the flow inside the microtube is in a fully laminar state, the mass flow prediction error is within 3%. When the flow is fully turbulent, the prediction error is within 8%. However, when the flow involves a transition from laminar to turbulent, the prediction error increases to 29%. During the numerical calculations, based on existing research results, the formula for transition Reynolds number and the turbulent friction factor are set as input parameters. However, the analyses of the Reynolds numbers along the length of the microtube and the average friction factors under different conditions show that the actual transition Reynolds number in the microtube is lower than the value set in the numerical calculations. Additionally, there is a significant discrepancy between the calculated turbulent friction factor and the actual value. Moreover, during the transition from laminar to turbulent flow, the friction factor should increase continuously with the Reynolds number increasing, but the in the numerical calculations the turbulent friction factor is directly used to represent this process. These factors are the main reasons for the larger mass flow prediction errors when the flow involves transition and turbulence. -

Keywords:

- one-dimensional processing method /

- mass transfer /

- numerical prediction /

- friction coefficient

[1] van den Berg H R, ten Seldam C A, van den Gulik P S 1993 J. Fluid. Mech. 246 1

Google Scholar

Google Scholar

[2] Lorenzini M, Morini G L, Salvigni S 2010 Int. J. Therm. 49 248

Google Scholar

Google Scholar

[3] Fang X, Yue X A, An W Q, Feng X G 2019 Microfluid. Nanofluidics. 23 5

Google Scholar

Google Scholar

[4] Reynolds O 1883 Philos. Trans. 174 935

Google Scholar

Google Scholar

[5] Kawashima D, Yamada T, Hong C, Asako Y 2016 J. Mech. Eng. 230 420

Google Scholar

Google Scholar

[6] American National Standard Institute. ANSI N14.5 2022 Radioactive Materials Leakage Teats on Packages for Shipment

[7] Anderson B L, Carlson R W, Fischer L E 1994 Predicting the Pressure Driven Flow of Gases through Micro-capillaries and Micro-orifices (Washington, DC: Nuclear Regulatory Commission

[8] Chen C S, Kuo W J 2004 Numer. Heat. Transfer. 45 85

Google Scholar

Google Scholar

[9] Asako Y, Nakayama K, Shinozuka T 2005 Int. J. Heat. Mass. Transfer. 48 4985

Google Scholar

Google Scholar

[10] Asako Y, Pi T, Turner S E, Faghri M 2003 Int. J. Heat. Mass. Transfer. 46 3041

Google Scholar

Google Scholar

[11] Murakami S, Toyoda K, Asako Y 2021 J. Fluids. Eng. 134 111301

Google Scholar

Google Scholar

[12] Hong C, Asako Y, Suzuki K, Faghri M 2012 Numer. Heat. Transfer. 61 163

Google Scholar

Google Scholar

[13] Hong C, Tanaka G, Asako Y, Katanoda H 2018 Int. J. Heat. Mass. Transfer. 121 187

Google Scholar

Google Scholar

[14] Lijo V, Kim H D, Setoguchi T 2012 Int. J. Heat. Mass. Transfer. 55 701

Google Scholar

Google Scholar

[15] Wang H, Xing J, Sun Z, Gu H, Sun X, Wang Y 2023 AEST 57 74

Google Scholar

Google Scholar

[16] Agrawal A, Kushwaha H M, Jadhav R S 2020 Microscale Flow and Heat Transfer (New York: Springer

[17] Shome B 2023 Phys. Fluids 35 122004

Google Scholar

Google Scholar

[18] Yovanovich M M, Khan W A 2020 J. Thermophys. Heat. Trans. 34 792

Google Scholar

Google Scholar

[19] Valougeorgis D 2007 Phys. Fluids 19 091702

Google Scholar

Google Scholar

[20] Barber R W, Emerson D R 2006 HTE 27 3

Google Scholar

Google Scholar

[21] Bykov N Y, Zakharov V V 2022 Phys. Fluids. 34 057106

Google Scholar

Google Scholar

[22] Wang X D, Li Y, Gao Y, Gao C G, Fu W C 2023 Aerospace 10 126

Google Scholar

Google Scholar

[23] Xu K, Huang J C 2010 J. Comput. Phys. 229 7747

Google Scholar

Google Scholar

[24] Guo Z L, Xu K, Wang R J 2013 Phys. Rev. E 88 033305

Google Scholar

Google Scholar

[25] Hong C, Yamada T, Asako Y, Faghri M 2012 Int. J. Heat. Mass. Transfer. 55 4397

Google Scholar

Google Scholar

[26] Celata G P, Lorenzini M, Morini G L, Zummo G 2009 Int. J. Heat. Fluid. Flow. 30 814

Google Scholar

Google Scholar

[27] Rehman D, Barattini D, Hong C, Morini G L 2021 Exp. Fluids 62 52

Google Scholar

Google Scholar

[28] Rehman D, Morini G L, Hong C 2019 Micromachines 10 171

Google Scholar

Google Scholar

[29] Hong C, Asako Y, Morini G L, Faghri M 2024 Exp. Therm. Fluid. Sci. 155 111196

Google Scholar

Google Scholar

[30] Brackbill T, Kandlikar S 2007 Proceedings of the International Conference on Nanochannels, Microchannels and Minichannels Puebla, Mexico, June 18−20, 2007 p509

[31] Eckhardt B, Schneider T M, Hof B, Westerweel J 2007 Annu. Rev. Fluid. Mech. 39 468

Google Scholar

Google Scholar

[32] Morini G L, Lorenzini M, Salvigni S 2006 Exp. Therm. Fluid. Sci. 30 733

Google Scholar

Google Scholar

[33] Du D, Li Z, Guo Z 2000 Sci. China. Technol. Sci. 43 171

Google Scholar

Google Scholar

[34] Sonnad J R, Goudar C T 2006 J. Hydraul. Eng 132 863

Google Scholar

Google Scholar

[35] 左克罗, 霍夫曼 著 (王汝涌 译) 气体动力学(上册) (北京: 国防工业出版社)

Zucrow M J, Hoffman J D (translated by Wang R Y) 1984 Gas Dynamics (Vol. 1) (Beijing: National Defense Industry Press

[36] Tang G H, Li Z, He Y L, Tao W Q 2007 Int. J. Heat. Mass. Transfer. 50 2282

Google Scholar

Google Scholar

[37] Moody L F 1944 T. ASME 66 671

Google Scholar

Google Scholar

[38] Avci A, Karagoz I 2019 Eur. J. Mech. B. Fluids 78 182

Google Scholar

Google Scholar

-

表 1 工况条件

Table 1. Operating conditions.

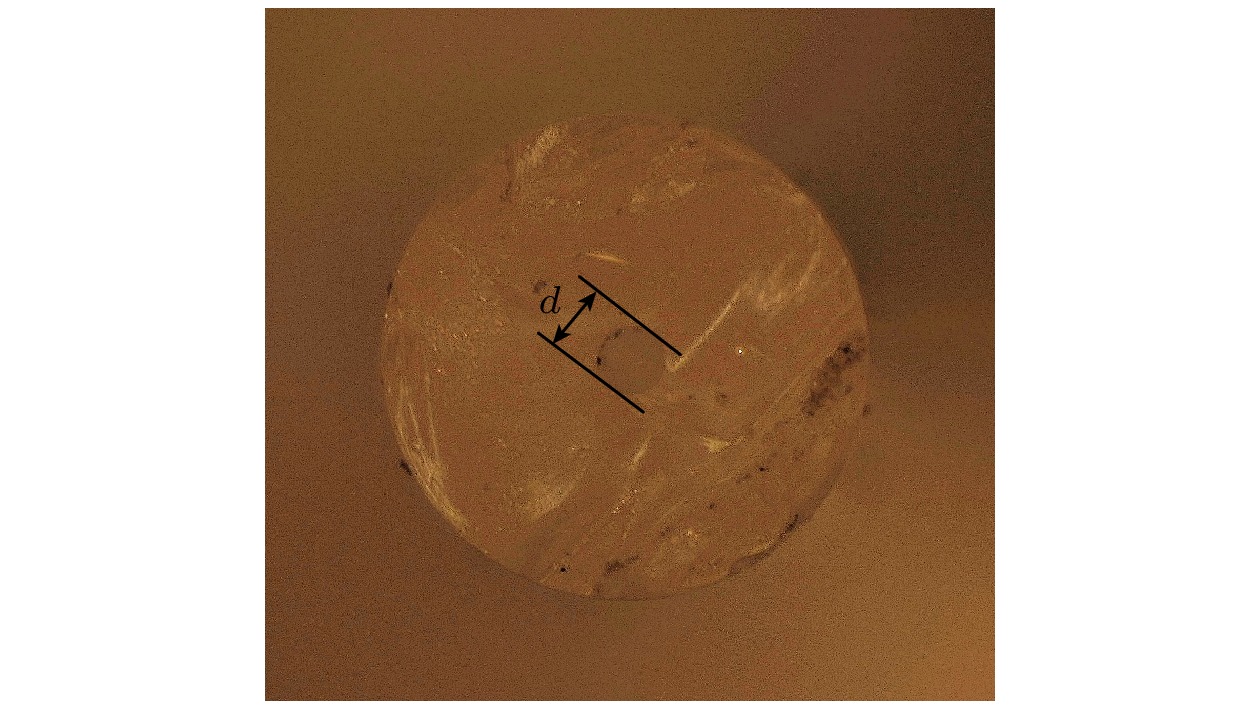

Case P0/kPa T0/K pe/kPa d/μm L/mm 1 256 298 106 200 120 2 706 298 106 200 120 表 2 计算与实验条件

Table 2. Calculation and experimental conditions.

Series P0 /kPa T0 /K pe /kPa d/μm L/mm 1 256—706 298 106 100 120 2 156—706 298 106 200 120 -

[1] van den Berg H R, ten Seldam C A, van den Gulik P S 1993 J. Fluid. Mech. 246 1

Google Scholar

Google Scholar

[2] Lorenzini M, Morini G L, Salvigni S 2010 Int. J. Therm. 49 248

Google Scholar

Google Scholar

[3] Fang X, Yue X A, An W Q, Feng X G 2019 Microfluid. Nanofluidics. 23 5

Google Scholar

Google Scholar

[4] Reynolds O 1883 Philos. Trans. 174 935

Google Scholar

Google Scholar

[5] Kawashima D, Yamada T, Hong C, Asako Y 2016 J. Mech. Eng. 230 420

Google Scholar

Google Scholar

[6] American National Standard Institute. ANSI N14.5 2022 Radioactive Materials Leakage Teats on Packages for Shipment

[7] Anderson B L, Carlson R W, Fischer L E 1994 Predicting the Pressure Driven Flow of Gases through Micro-capillaries and Micro-orifices (Washington, DC: Nuclear Regulatory Commission

[8] Chen C S, Kuo W J 2004 Numer. Heat. Transfer. 45 85

Google Scholar

Google Scholar

[9] Asako Y, Nakayama K, Shinozuka T 2005 Int. J. Heat. Mass. Transfer. 48 4985

Google Scholar

Google Scholar

[10] Asako Y, Pi T, Turner S E, Faghri M 2003 Int. J. Heat. Mass. Transfer. 46 3041

Google Scholar

Google Scholar

[11] Murakami S, Toyoda K, Asako Y 2021 J. Fluids. Eng. 134 111301

Google Scholar

Google Scholar

[12] Hong C, Asako Y, Suzuki K, Faghri M 2012 Numer. Heat. Transfer. 61 163

Google Scholar

Google Scholar

[13] Hong C, Tanaka G, Asako Y, Katanoda H 2018 Int. J. Heat. Mass. Transfer. 121 187

Google Scholar

Google Scholar

[14] Lijo V, Kim H D, Setoguchi T 2012 Int. J. Heat. Mass. Transfer. 55 701

Google Scholar

Google Scholar

[15] Wang H, Xing J, Sun Z, Gu H, Sun X, Wang Y 2023 AEST 57 74

Google Scholar

Google Scholar

[16] Agrawal A, Kushwaha H M, Jadhav R S 2020 Microscale Flow and Heat Transfer (New York: Springer

[17] Shome B 2023 Phys. Fluids 35 122004

Google Scholar

Google Scholar

[18] Yovanovich M M, Khan W A 2020 J. Thermophys. Heat. Trans. 34 792

Google Scholar

Google Scholar

[19] Valougeorgis D 2007 Phys. Fluids 19 091702

Google Scholar

Google Scholar

[20] Barber R W, Emerson D R 2006 HTE 27 3

Google Scholar

Google Scholar

[21] Bykov N Y, Zakharov V V 2022 Phys. Fluids. 34 057106

Google Scholar

Google Scholar

[22] Wang X D, Li Y, Gao Y, Gao C G, Fu W C 2023 Aerospace 10 126

Google Scholar

Google Scholar

[23] Xu K, Huang J C 2010 J. Comput. Phys. 229 7747

Google Scholar

Google Scholar

[24] Guo Z L, Xu K, Wang R J 2013 Phys. Rev. E 88 033305

Google Scholar

Google Scholar

[25] Hong C, Yamada T, Asako Y, Faghri M 2012 Int. J. Heat. Mass. Transfer. 55 4397

Google Scholar

Google Scholar

[26] Celata G P, Lorenzini M, Morini G L, Zummo G 2009 Int. J. Heat. Fluid. Flow. 30 814

Google Scholar

Google Scholar

[27] Rehman D, Barattini D, Hong C, Morini G L 2021 Exp. Fluids 62 52

Google Scholar

Google Scholar

[28] Rehman D, Morini G L, Hong C 2019 Micromachines 10 171

Google Scholar

Google Scholar

[29] Hong C, Asako Y, Morini G L, Faghri M 2024 Exp. Therm. Fluid. Sci. 155 111196

Google Scholar

Google Scholar

[30] Brackbill T, Kandlikar S 2007 Proceedings of the International Conference on Nanochannels, Microchannels and Minichannels Puebla, Mexico, June 18−20, 2007 p509

[31] Eckhardt B, Schneider T M, Hof B, Westerweel J 2007 Annu. Rev. Fluid. Mech. 39 468

Google Scholar

Google Scholar

[32] Morini G L, Lorenzini M, Salvigni S 2006 Exp. Therm. Fluid. Sci. 30 733

Google Scholar

Google Scholar

[33] Du D, Li Z, Guo Z 2000 Sci. China. Technol. Sci. 43 171

Google Scholar

Google Scholar

[34] Sonnad J R, Goudar C T 2006 J. Hydraul. Eng 132 863

Google Scholar

Google Scholar

[35] 左克罗, 霍夫曼 著 (王汝涌 译) 气体动力学(上册) (北京: 国防工业出版社)

Zucrow M J, Hoffman J D (translated by Wang R Y) 1984 Gas Dynamics (Vol. 1) (Beijing: National Defense Industry Press

[36] Tang G H, Li Z, He Y L, Tao W Q 2007 Int. J. Heat. Mass. Transfer. 50 2282

Google Scholar

Google Scholar

[37] Moody L F 1944 T. ASME 66 671

Google Scholar

Google Scholar

[38] Avci A, Karagoz I 2019 Eur. J. Mech. B. Fluids 78 182

Google Scholar

Google Scholar

计量

- 文章访问数: 2294

- PDF下载量: 50

- 被引次数: 0

下载:

下载: