-

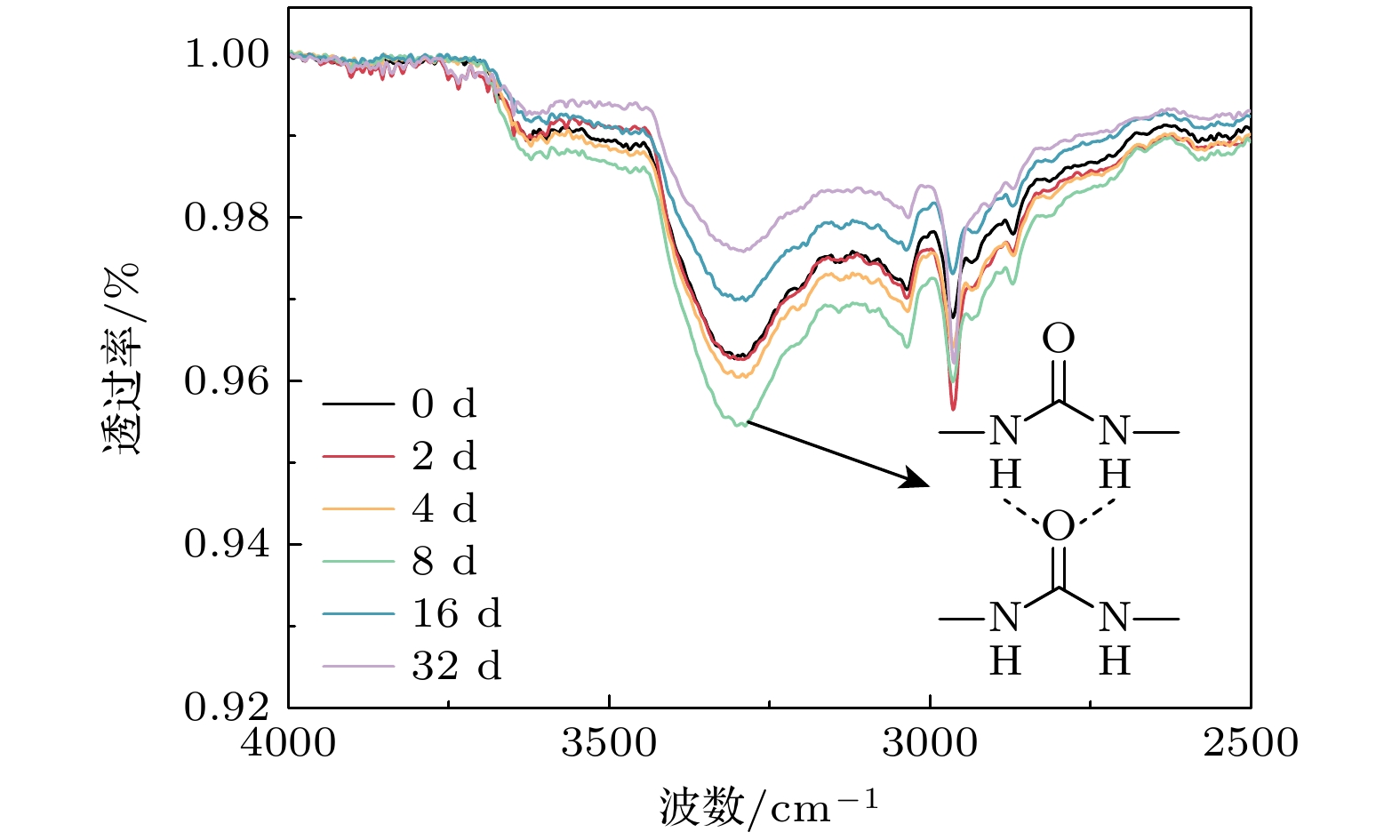

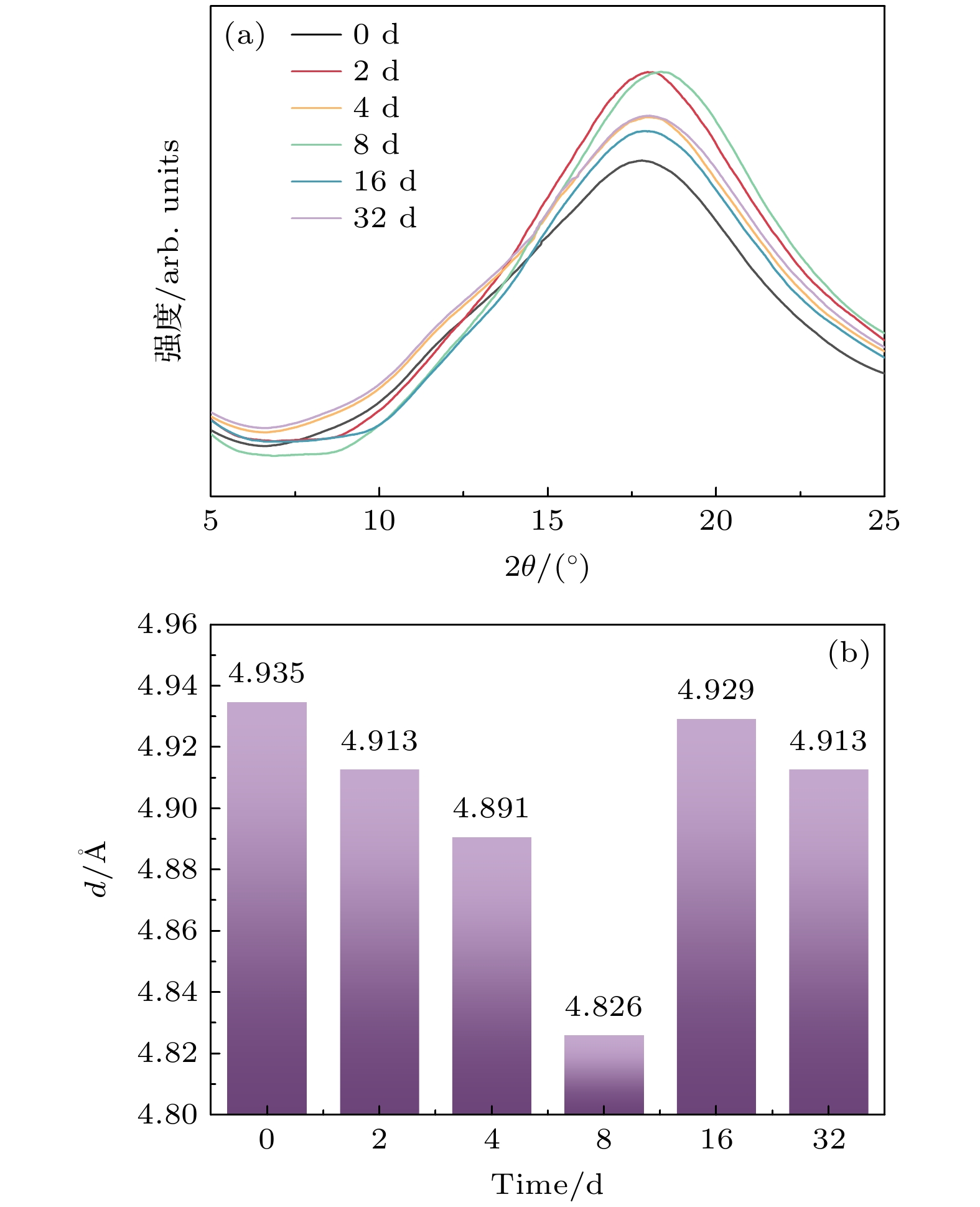

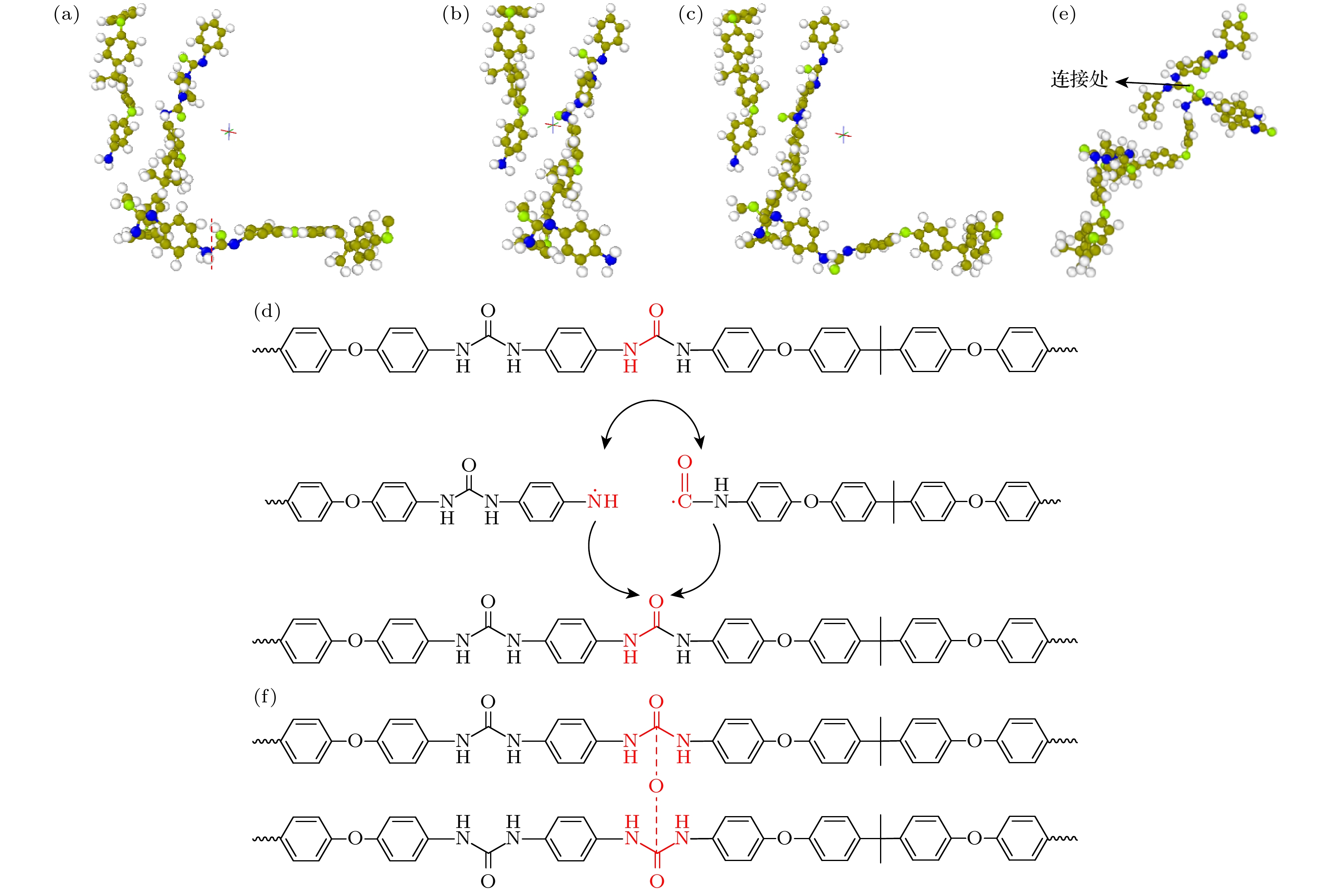

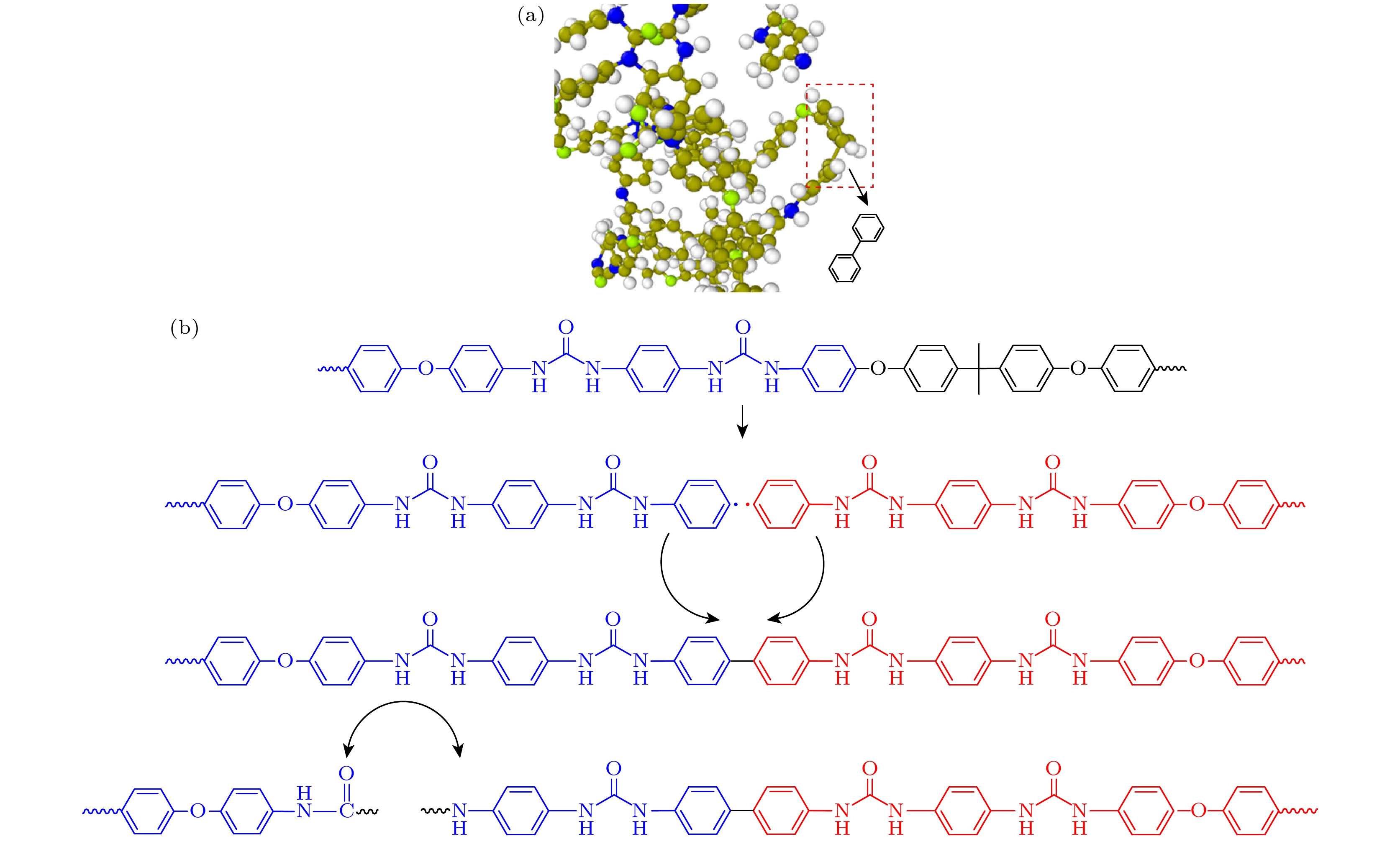

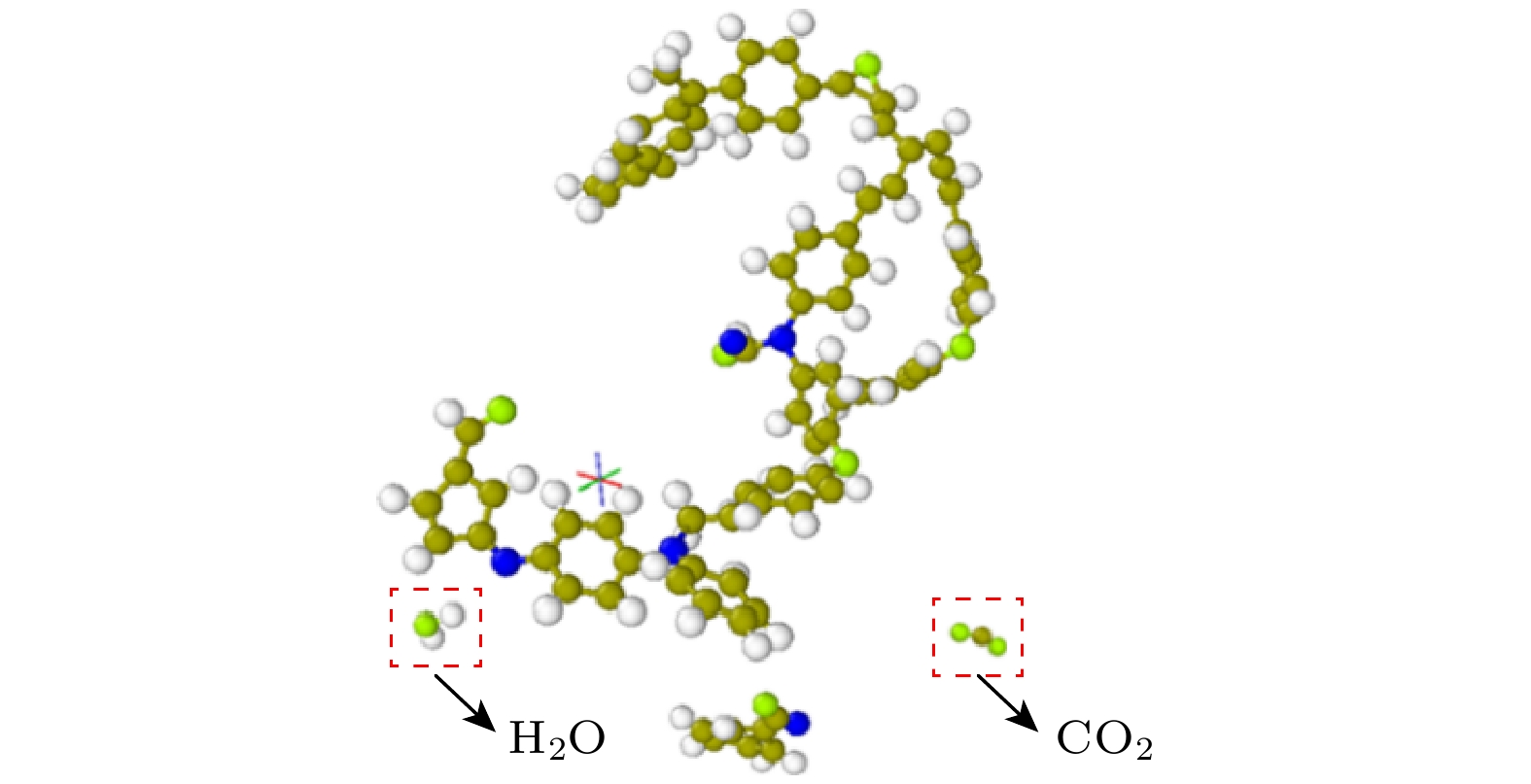

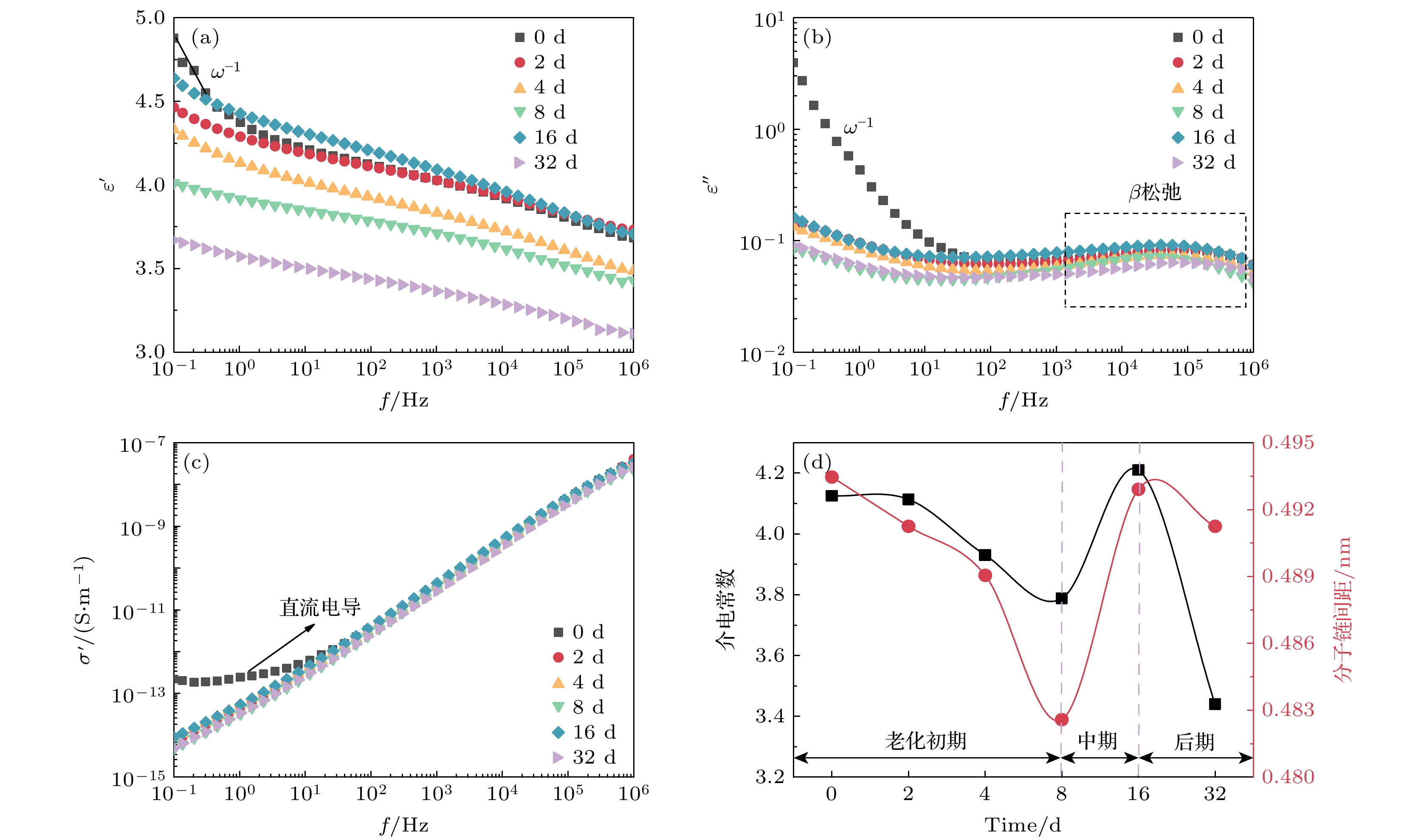

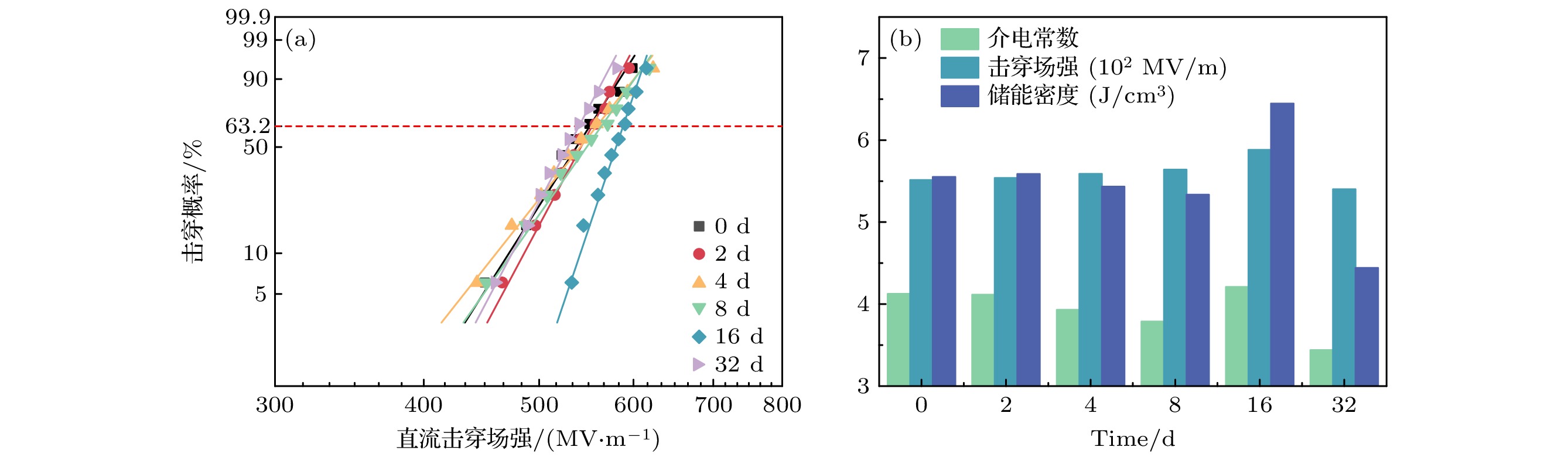

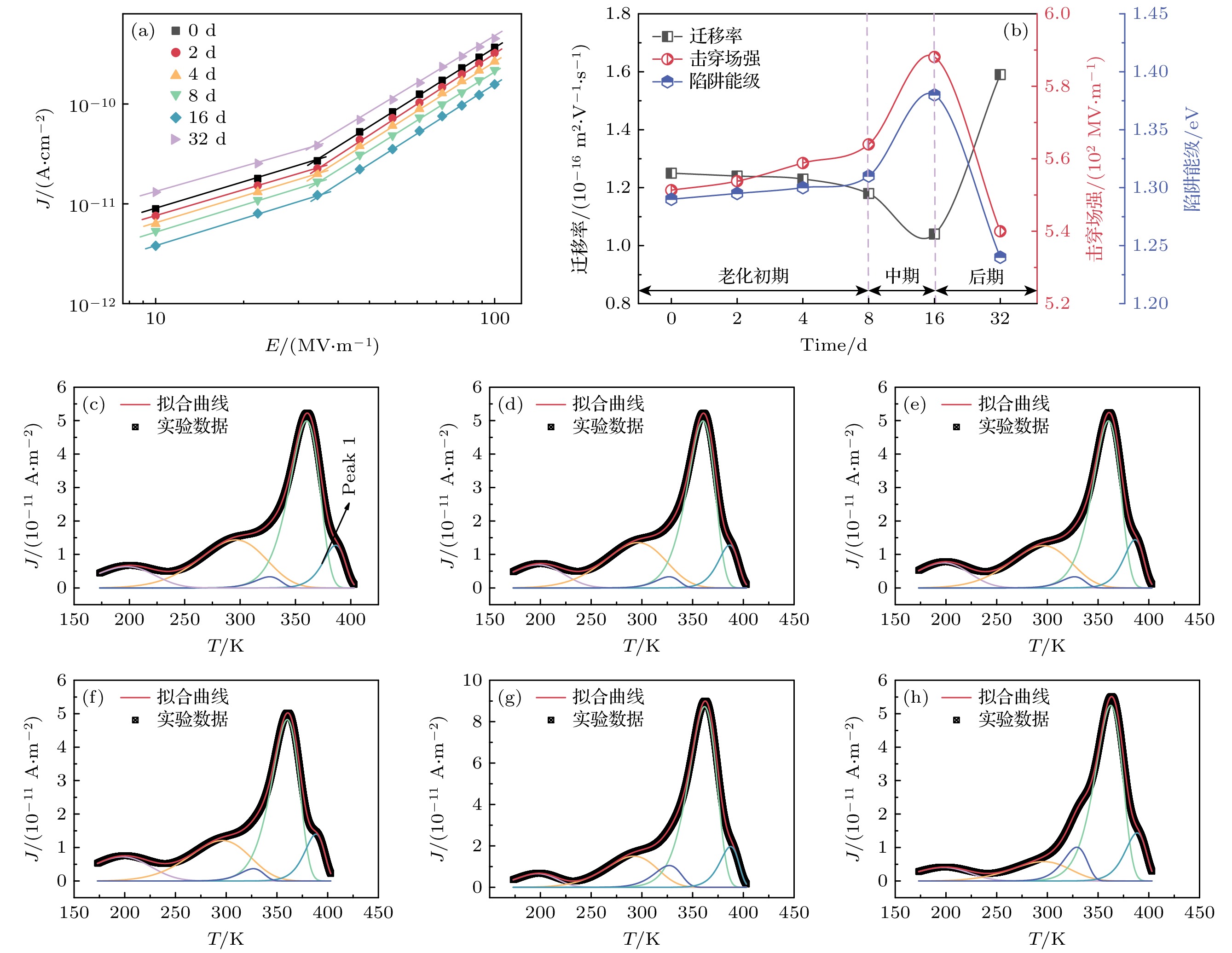

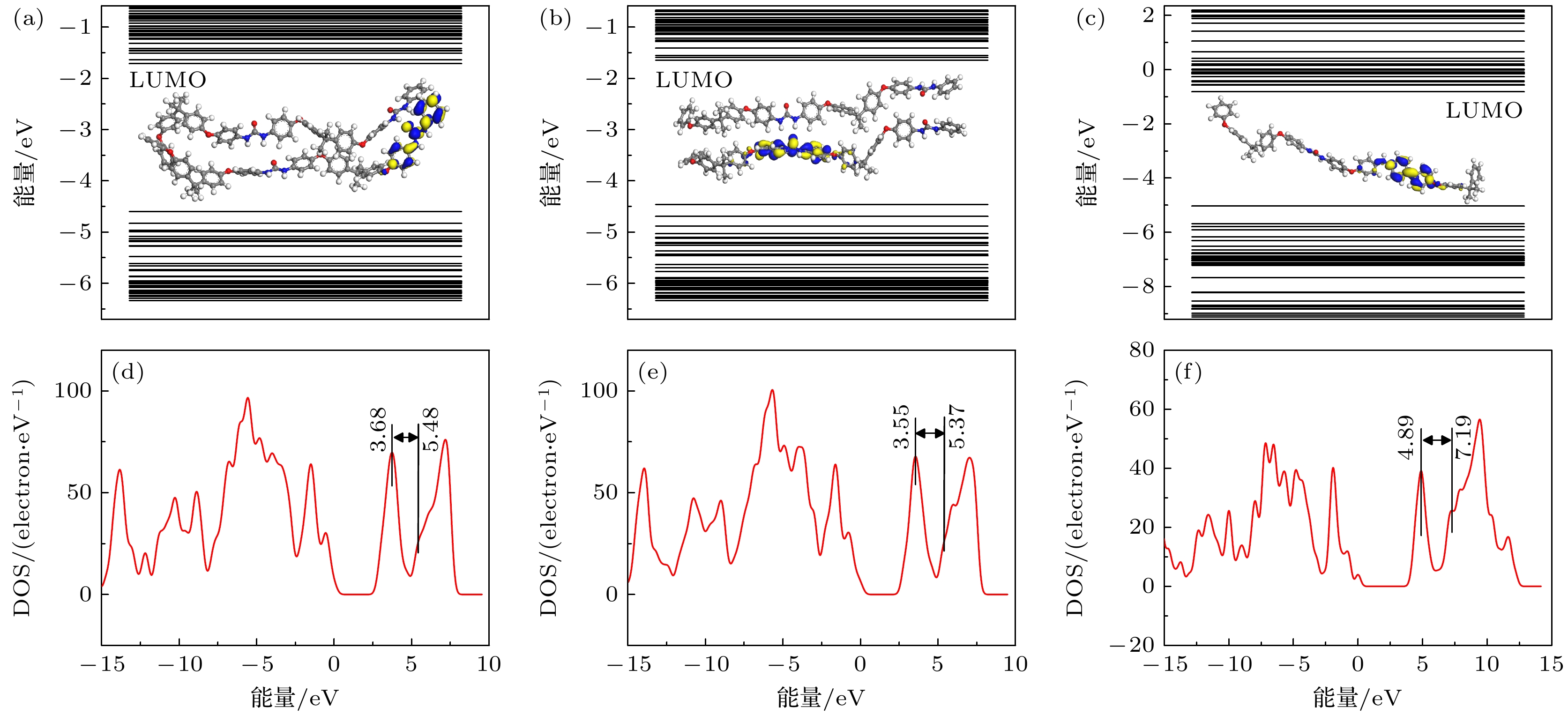

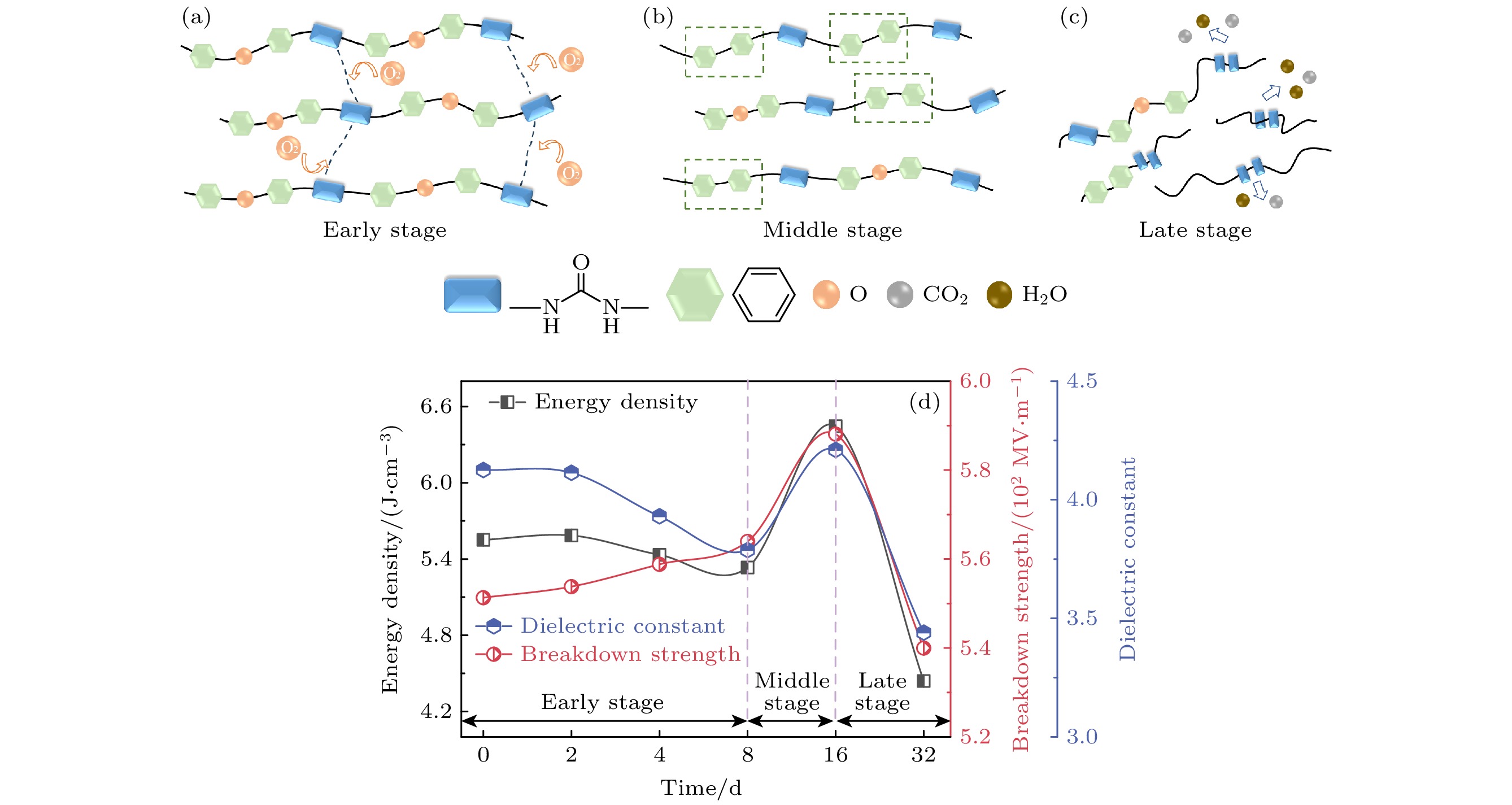

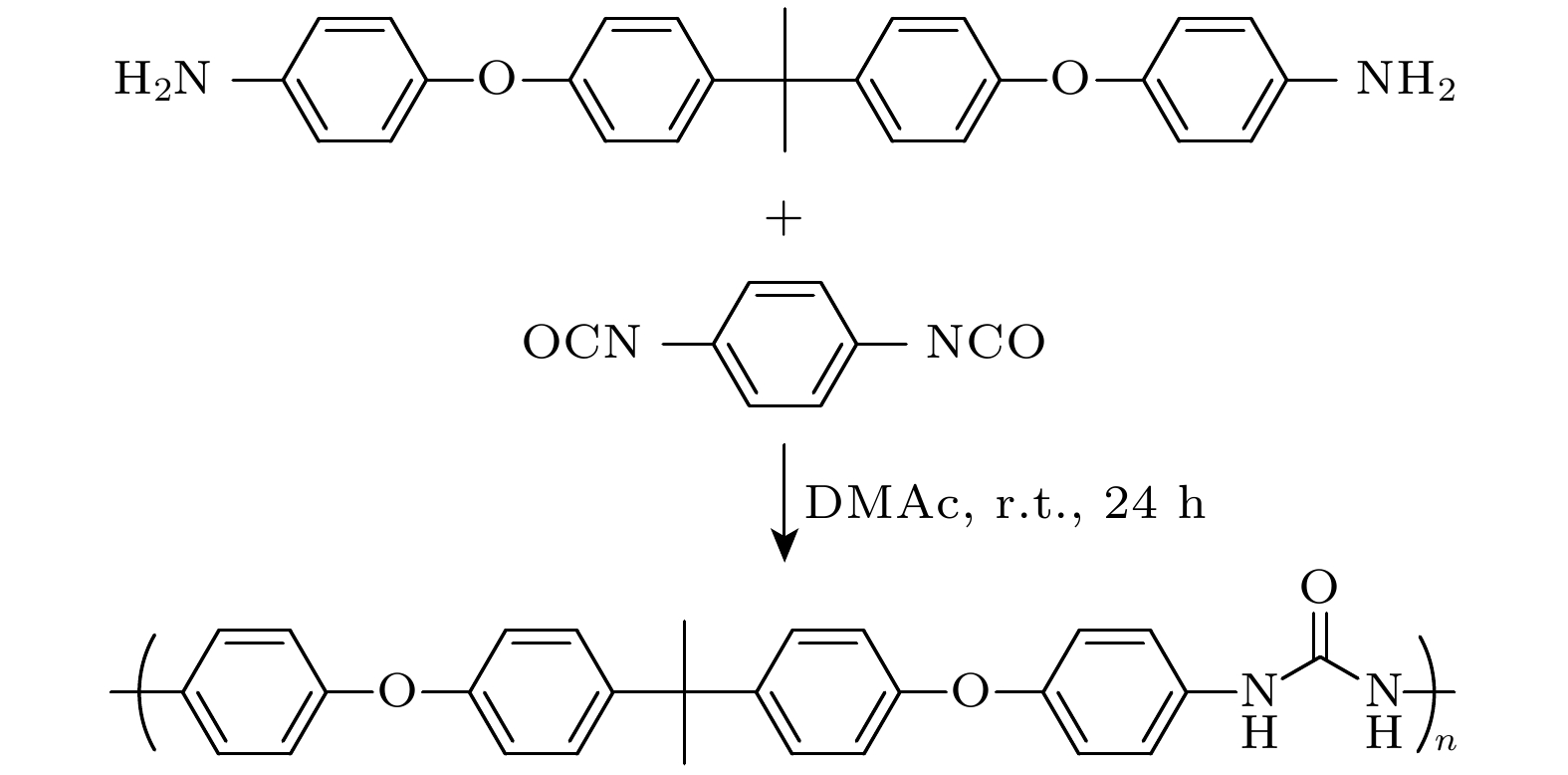

采用热氧老化方式模拟聚脲(polyurea, PU)薄膜在高温工况下的老化行为, 根据PU薄膜介电储能特性的变化规律将其老化过程划分为3个阶段. 结果表明: 老化初期, 氧气的桥接作用促使分子链规整排列, 相邻脲基团之间的氢键作用稍有增强, 分子链间距减小, 介电常数减小, 而击穿场强变化较小; 老化中期, 醚键断裂并诱导形成联苯结构, 体系无定形程度加剧, 介电常数增大, 但联苯结构加深了陷阱深度, 导致载流子迁移率降低, 这提高了薄膜的击穿场强; 老化后期, 氧气促使脲基分解, 造成贡献深陷阱能级的基团数量减少, 同时主链发生裂解, 并释放CO2与H2O等小分子物质, 这些因素共同导致了PU的击穿场强显著降低. 热氧老化过程中PU的储能密度表现出与击穿场强相同的时间依赖性, 证明了计及陷阱演变的PU储能性能退化机理: 氧气对醚键和脲基的分解作用分别诱发了联苯结构的形成和主链的裂解, 这改变了陷阱深度, 其中陷阱深度越浅, PU性能退化越显著.Dielectric capacitors are essential energy storage devices with high power density. The dielectric films of capacitors will age at working temperatures, a leading their performance to degrade. Polyurea (PU) is a potential working dielectric for capacitors with high energy density and low dielectric loss. However, the aging characteristics and underlying mechanism of PU have not been discussed. Considering the operating temperature of commercial dielectric capacitors, the aging characteristics of PU are investigate by being exposed to 80 °C for different durations. Compared with dielectric constant, breakdown strength changes significantly with aging time which can be used as a characteristic parameter to evaluate the aging degree of PU. Combining experimental method and simulation method, the correlation between molecular structure, trap properties and breakdown strength during thermo-oxidative aging is studied and established. The results show that the thermal-oxidative aging of PU can be divided into three stages. In the early stage of aging, the bridging effect of oxygen promotes the order arrangement of molecular chains. In this stage, the molecular chain spacing decreases, but the H-bonding interaction between adjacent urea groups is enhanced slightly as shown in Fig. (a). As a result, the dielectric constant decreases, while the breakdown strength is almost unchanged. In the middle stage of aging, ether bonds break and inducing the formation of biphenyl structures and resulting in a disordered structure as illustrated in Fig. (b). The enhanced mobility effect increases the dielectric constant. Meanwhile, the biphenyl structures deepen the trap depth, resulting in the decrease of carrier mobility and the increase of the breakdown strength. In the late stage of aging, oxygen promotes the decomposition of urea groups, thereby reducing the number of urea groups that form deep traps. At the same time, the main chain undergoes breakage, releasing small molecules such as CO2 and H2O, which is shown in Fig. (c). These factors collectively lead to a significant reduction in the breakdown strength of PU. In addition, the variations of dielectric constant, breakdown strength and energy density in the three stages are summarized in Fig. (d).

-

Keywords:

- polyurea /

- energy storage characteristics /

- thermal-oxidative aging /

- degradation mechanism

[1] Zhang H, Wei T, Zhang Q, Ma W, Fan P, Salamon D, Zhang S T, Nan B, Tan H, Ye Z G 2020 J. Mater. Chem. C 8 16648

Google Scholar

Google Scholar

[2] Palneedi H, Peddigari M, Hwang G T, Jeong D Y, Ryu J 2018 Adv. Funct. Mater. 28 1803665

Google Scholar

Google Scholar

[3] Ren W B, Pan J Y, Dan Z K, Zhang T, Jiang J Y, Fan M Z, Hu P H, Li M, Lin Y H, Nan C W, Shen Y 2021 Chem. Eng. J. 420 127614

Google Scholar

Google Scholar

[4] 李吉超, 王春雷, 钟维烈, 薛旭艳, 王渊旭 2002 51 776

Google Scholar

Google Scholar

Li J C, Wang C L, Zhong W L, Xue X Y, Wang Y X 2002 Acta Phys. Sin. 51 776

Google Scholar

Google Scholar

[5] 董久锋, 邓星磊, 牛玉娟, 潘子钊, 汪宏 2020 69 217701

Google Scholar

Google Scholar

Dong J F, Deng X L, Niu Y J, Pan Z Z, Wang H 2020 Acta Phys. Sin. 69 217701

Google Scholar

Google Scholar

[6] Wang Q, Wu C, Gao Y F, Liu S M, Liu S Q, Zuo Z, Liang X D 2022 High Voltage 7 1123

Google Scholar

Google Scholar

[7] 叶润峰, 裴家耀, 郑明胜, 党智敏 2020 电工技术学报 35 3529

Google Scholar

Google Scholar

Ye R F, Pei J Y, Zheng M S, Dang Z M 2020 Trans. Chin. Electrotech. Soc. 35 3529

Google Scholar

Google Scholar

[8] Jiang X W, Wang S H, Wang W H, Han R 2021 J. Electron. Mater. 50 2400

Google Scholar

Google Scholar

[9] 李奕萱 2021 硕士学位论文 (成都: 西南交通大学)

Li Y X 2021 M. S. Thesis (Chengdu: Southwest Jiaotong University

[10] Wang Y, Zhou X, Lin M R, Lu S G, Lin J H, Furman E, Zhang Q M 2010 IEEE Trans. Dielectr. Electr. Insul. 17 28

Google Scholar

Google Scholar

[11] Wang Y, Zhou X, Lin M R, Zhang Q M 2009 Appl. Phys. Lett. 94 202905

Google Scholar

Google Scholar

[12] Feng Y, Jiang L H, Yang A Q, Liu X, Yang L Q, Lu G H, Li S T 2022 Macromol. Rapid Commun. 43 2100700

Google Scholar

Google Scholar

[13] Wu S, Lin MR, Burlingame Q, Zhang Q M 2014 Appl. Phys. Lett. 104 072903

Google Scholar

Google Scholar

[14] Zhao Z H, Zhang S, Li M R, Feng Y, Yang L Q, Li S T 2024 J. Appl. Phys. 135 194103

Google Scholar

Google Scholar

[15] Hattori T, Takahashi Y, Iijima M, Fukada E 1996 9th International Symposium on Electrets (ISE 9) Shanghai, China, September 25–30, 1996 p819

[16] Zhao Z H, Feng Y, Yang L Q, Zhang S, Liu X, Zhang Y, Li M R, Li S T 2023 Appl. Phys. Lett. 123 232901

Google Scholar

Google Scholar

[17] Wu Y J, Zhao H, Zhang N, Wang H Q, Zhang C Y, Yin L, Bai J B 2024 J. Mater. Chem. C 12 2993

Google Scholar

Google Scholar

[18] Zhu X D, Chen W X, Pan M, Zhou X, Zhang Y, Dong L J 2024 ACS Appl. Polym. Mater. 6 4808

Google Scholar

Google Scholar

[19] Feng Y, Yang L Q, Qu G H, Suga T, Nishide H, Chen G G, Li S T 2020 Macromol. Rapid Commun. 41 2000167

Google Scholar

Google Scholar

[20] Zhou Y, Yuan C, Wang S J, Zhu Y J, Cheng S, Yang X, Yang Y, Hu J, He J L, Li Q 2020 Energy Storage Mater. 28 255

Google Scholar

Google Scholar

[21] Hu J, Zhao X C, Xie J H, Liu Y, Sun S L 2022 J. Polym. Res. 29 182

Google Scholar

Google Scholar

[22] 张家阳,苏安双,徐丽丽,吴志琴,李兆宇,郑健 2021 水利科学与寒区工程 4 1

Zhang J Y, Su A S, Xu L L, Wu Z Q, Li Z Y, Zheng J 2021 Hydro Science and Cold Zone Engineering 4 1

[23] 沙光荣, 来冰冰, 赵启龙, 孙一平, 王晓波, 娄文静, 刘晓玲 2024 摩擦学学报 44 1074

Google Scholar

Google Scholar

Sha G R, Lai B B, Zhao Q L, Sun Y P, Wang X B, Lou W J, Liu X L 2024 Tribology 44 1074

Google Scholar

Google Scholar

[24] 鲁旭, 韩帅, 李庆民, 黄旭炜, 王学磊, 王高勇 2016 电工技术学报 31 14

Google Scholar

Google Scholar

Lu X, Han S, Li Q M, Huang X W, Wang X L, Wang G Y 2016 Trans. Chin. Electrotech Soc. 31 14

Google Scholar

Google Scholar

[25] Xiong J, Fan X, Long D J, Zhu B F, Zhang X, Lu J Y, Xie Y C, Zhang Z C 2022 J. Mater. Chem. A 10 24611

Google Scholar

Google Scholar

[26] 张传升, 章程, 任成燕, 黄邦斗, 邢照亮, 邵涛 2024 电工技术学报 39 2193

Google Scholar

Google Scholar

Zhang C S, Zhang C, Ren C Y, Huang B D, Xing Z L, Shao T 2024 Trans. Chin. Electrotech. Soc. 39 2193

Google Scholar

Google Scholar

[27] Li J L, Wang S J, Zhu Y J, Luo Z, Zhang Y R, Shao Q, Quan H, Wang M T, Hu S X, Yang M C, Fu J, Wang R Hu J, Yuan H, He J L, Li Q 2023 J. Mater. Chem. A 11 10659

Google Scholar

Google Scholar

[28] Yanagisawa Y, Nan Y, Okuro K, Aida T 2018 Science 359 72

Google Scholar

Google Scholar

[29] Sebastian N, Contal C, Sanchez-Ferrer A Pieruccini M 2018 Soft. Matter. 14 7839

Google Scholar

Google Scholar

[30] Dong R, Ranjan V, Nardelli M B Bernholc J 2015 Phys. Rev. B 92 024203

Google Scholar

Google Scholar

[31] 冯阳, 渠广昊, 李盛涛 2024 高电压技术 50 2363

Google Scholar

Google Scholar

Feng Y, Qu G H, Li S T 2024 High Voltage Eng. 50 2363

Google Scholar

Google Scholar

[32] Jiang L H, Liu X, Hu S C, Li M R, Yang L Q, Feng Y, Li S T 2024 Macromol. Rapid. Commun. 45 2300501

Google Scholar

Google Scholar

[33] 冯阳, 渠广昊, 李盛涛 2024 中国电机工程学报 44 3360

Google Scholar

Google Scholar

Feng Y, Qu G H, Li S T 2024 Proc. CSEE 44 3360

Google Scholar

Google Scholar

-

图 5 脲基中C—N键 (a)断裂前; (b)断裂时; (c)断裂后重新连接; (d)动态变化示意图; (e)氧气桥接作用; (f)示意图(OVITO可视化图像中的原子: 氢原子、氧原子、碳原子和氮原子分别用白色、绿色、金色和蓝色球体表示)

Fig. 5. C—N bonds in the urea group: (a) Before breakage; (b) during breakage; (c) reconnection after breakage; (d) schematic representation of the dynamics; (e) oxygen bridging; (f) schematic diagrams (atoms in the OVITO visualization image: hydrogen, oxygen, carbon and nitrogen atoms are represented by white, green, gold and blue spheres, respectively).

图 10 (a)高场电导; (b)载流子迁移率、击穿强度和深陷阱能级的关系图; TSDC曲线(其中图(c), (d), (e), (f), (g), (h)分别对应0, 2, 4, 8, 16, 32 d)

Fig. 10. (a) High-field conductance; (b) plot of carrier mobility, breakdown strength and deep trap energy levels; TSDC curves (where (c), (d), (e), (f), (g), and (h) correspond to 0, 2, 4, 8, 16, and 32 days, respectively).

-

[1] Zhang H, Wei T, Zhang Q, Ma W, Fan P, Salamon D, Zhang S T, Nan B, Tan H, Ye Z G 2020 J. Mater. Chem. C 8 16648

Google Scholar

Google Scholar

[2] Palneedi H, Peddigari M, Hwang G T, Jeong D Y, Ryu J 2018 Adv. Funct. Mater. 28 1803665

Google Scholar

Google Scholar

[3] Ren W B, Pan J Y, Dan Z K, Zhang T, Jiang J Y, Fan M Z, Hu P H, Li M, Lin Y H, Nan C W, Shen Y 2021 Chem. Eng. J. 420 127614

Google Scholar

Google Scholar

[4] 李吉超, 王春雷, 钟维烈, 薛旭艳, 王渊旭 2002 51 776

Google Scholar

Google Scholar

Li J C, Wang C L, Zhong W L, Xue X Y, Wang Y X 2002 Acta Phys. Sin. 51 776

Google Scholar

Google Scholar

[5] 董久锋, 邓星磊, 牛玉娟, 潘子钊, 汪宏 2020 69 217701

Google Scholar

Google Scholar

Dong J F, Deng X L, Niu Y J, Pan Z Z, Wang H 2020 Acta Phys. Sin. 69 217701

Google Scholar

Google Scholar

[6] Wang Q, Wu C, Gao Y F, Liu S M, Liu S Q, Zuo Z, Liang X D 2022 High Voltage 7 1123

Google Scholar

Google Scholar

[7] 叶润峰, 裴家耀, 郑明胜, 党智敏 2020 电工技术学报 35 3529

Google Scholar

Google Scholar

Ye R F, Pei J Y, Zheng M S, Dang Z M 2020 Trans. Chin. Electrotech. Soc. 35 3529

Google Scholar

Google Scholar

[8] Jiang X W, Wang S H, Wang W H, Han R 2021 J. Electron. Mater. 50 2400

Google Scholar

Google Scholar

[9] 李奕萱 2021 硕士学位论文 (成都: 西南交通大学)

Li Y X 2021 M. S. Thesis (Chengdu: Southwest Jiaotong University

[10] Wang Y, Zhou X, Lin M R, Lu S G, Lin J H, Furman E, Zhang Q M 2010 IEEE Trans. Dielectr. Electr. Insul. 17 28

Google Scholar

Google Scholar

[11] Wang Y, Zhou X, Lin M R, Zhang Q M 2009 Appl. Phys. Lett. 94 202905

Google Scholar

Google Scholar

[12] Feng Y, Jiang L H, Yang A Q, Liu X, Yang L Q, Lu G H, Li S T 2022 Macromol. Rapid Commun. 43 2100700

Google Scholar

Google Scholar

[13] Wu S, Lin MR, Burlingame Q, Zhang Q M 2014 Appl. Phys. Lett. 104 072903

Google Scholar

Google Scholar

[14] Zhao Z H, Zhang S, Li M R, Feng Y, Yang L Q, Li S T 2024 J. Appl. Phys. 135 194103

Google Scholar

Google Scholar

[15] Hattori T, Takahashi Y, Iijima M, Fukada E 1996 9th International Symposium on Electrets (ISE 9) Shanghai, China, September 25–30, 1996 p819

[16] Zhao Z H, Feng Y, Yang L Q, Zhang S, Liu X, Zhang Y, Li M R, Li S T 2023 Appl. Phys. Lett. 123 232901

Google Scholar

Google Scholar

[17] Wu Y J, Zhao H, Zhang N, Wang H Q, Zhang C Y, Yin L, Bai J B 2024 J. Mater. Chem. C 12 2993

Google Scholar

Google Scholar

[18] Zhu X D, Chen W X, Pan M, Zhou X, Zhang Y, Dong L J 2024 ACS Appl. Polym. Mater. 6 4808

Google Scholar

Google Scholar

[19] Feng Y, Yang L Q, Qu G H, Suga T, Nishide H, Chen G G, Li S T 2020 Macromol. Rapid Commun. 41 2000167

Google Scholar

Google Scholar

[20] Zhou Y, Yuan C, Wang S J, Zhu Y J, Cheng S, Yang X, Yang Y, Hu J, He J L, Li Q 2020 Energy Storage Mater. 28 255

Google Scholar

Google Scholar

[21] Hu J, Zhao X C, Xie J H, Liu Y, Sun S L 2022 J. Polym. Res. 29 182

Google Scholar

Google Scholar

[22] 张家阳,苏安双,徐丽丽,吴志琴,李兆宇,郑健 2021 水利科学与寒区工程 4 1

Zhang J Y, Su A S, Xu L L, Wu Z Q, Li Z Y, Zheng J 2021 Hydro Science and Cold Zone Engineering 4 1

[23] 沙光荣, 来冰冰, 赵启龙, 孙一平, 王晓波, 娄文静, 刘晓玲 2024 摩擦学学报 44 1074

Google Scholar

Google Scholar

Sha G R, Lai B B, Zhao Q L, Sun Y P, Wang X B, Lou W J, Liu X L 2024 Tribology 44 1074

Google Scholar

Google Scholar

[24] 鲁旭, 韩帅, 李庆民, 黄旭炜, 王学磊, 王高勇 2016 电工技术学报 31 14

Google Scholar

Google Scholar

Lu X, Han S, Li Q M, Huang X W, Wang X L, Wang G Y 2016 Trans. Chin. Electrotech Soc. 31 14

Google Scholar

Google Scholar

[25] Xiong J, Fan X, Long D J, Zhu B F, Zhang X, Lu J Y, Xie Y C, Zhang Z C 2022 J. Mater. Chem. A 10 24611

Google Scholar

Google Scholar

[26] 张传升, 章程, 任成燕, 黄邦斗, 邢照亮, 邵涛 2024 电工技术学报 39 2193

Google Scholar

Google Scholar

Zhang C S, Zhang C, Ren C Y, Huang B D, Xing Z L, Shao T 2024 Trans. Chin. Electrotech. Soc. 39 2193

Google Scholar

Google Scholar

[27] Li J L, Wang S J, Zhu Y J, Luo Z, Zhang Y R, Shao Q, Quan H, Wang M T, Hu S X, Yang M C, Fu J, Wang R Hu J, Yuan H, He J L, Li Q 2023 J. Mater. Chem. A 11 10659

Google Scholar

Google Scholar

[28] Yanagisawa Y, Nan Y, Okuro K, Aida T 2018 Science 359 72

Google Scholar

Google Scholar

[29] Sebastian N, Contal C, Sanchez-Ferrer A Pieruccini M 2018 Soft. Matter. 14 7839

Google Scholar

Google Scholar

[30] Dong R, Ranjan V, Nardelli M B Bernholc J 2015 Phys. Rev. B 92 024203

Google Scholar

Google Scholar

[31] 冯阳, 渠广昊, 李盛涛 2024 高电压技术 50 2363

Google Scholar

Google Scholar

Feng Y, Qu G H, Li S T 2024 High Voltage Eng. 50 2363

Google Scholar

Google Scholar

[32] Jiang L H, Liu X, Hu S C, Li M R, Yang L Q, Feng Y, Li S T 2024 Macromol. Rapid. Commun. 45 2300501

Google Scholar

Google Scholar

[33] 冯阳, 渠广昊, 李盛涛 2024 中国电机工程学报 44 3360

Google Scholar

Google Scholar

Feng Y, Qu G H, Li S T 2024 Proc. CSEE 44 3360

Google Scholar

Google Scholar

计量

- 文章访问数: 2721

- PDF下载量: 40

- 被引次数: 0

下载:

下载: